intake FIAT MAREA 2000 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 117 of 330

Marea- Marea Weekend 9 *°

2000 range @)

Engine

Fuel feed system

10.

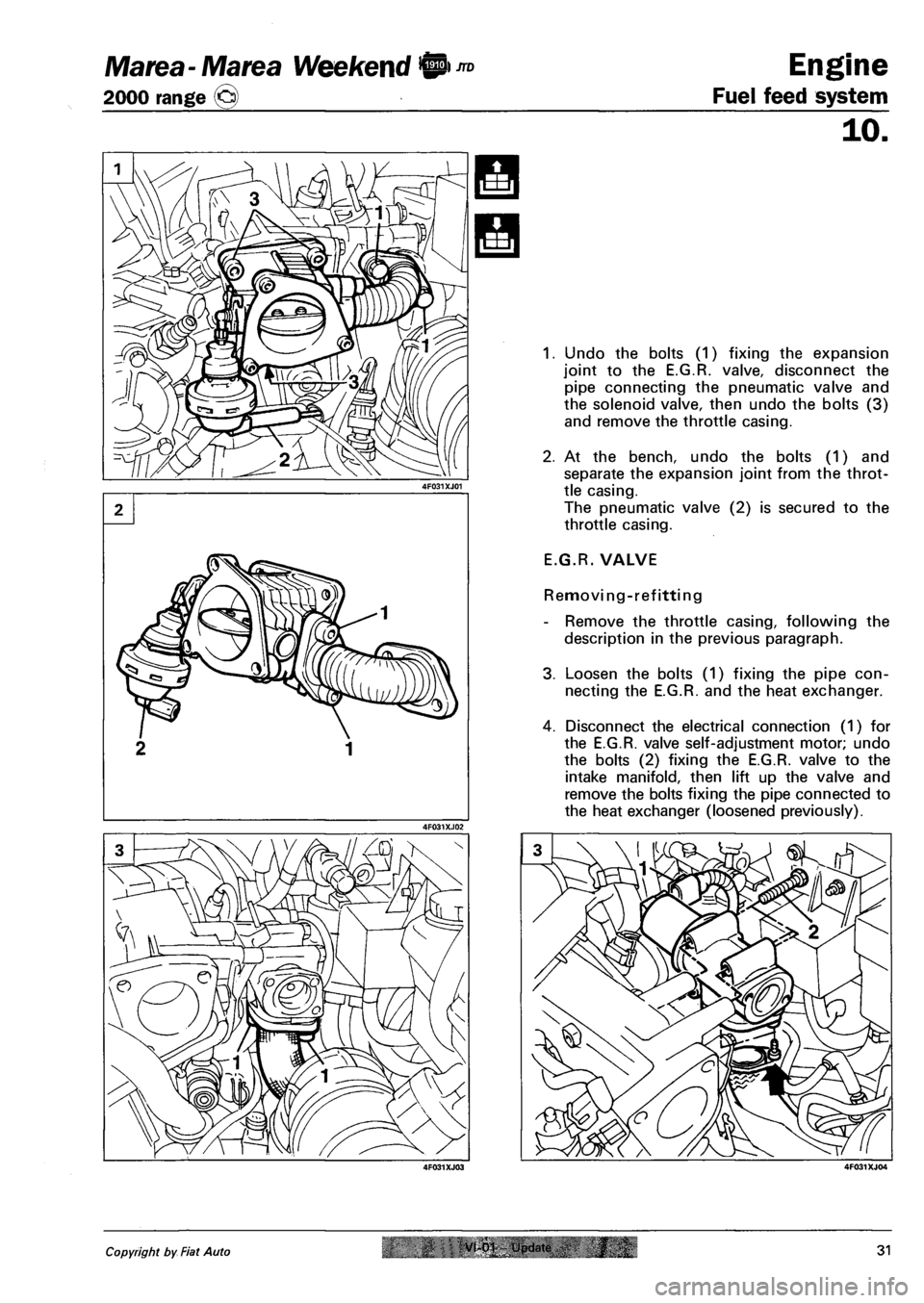

1. Undo the bolts (1) fixing the expansion

joint to the E.G.R. valve, disconnect the

pipe connecting the pneumatic valve and

the solenoid valve, then undo the bolts (3)

and remove the throttle casing.

2. At the bench, undo the bolts (1) and

separate the expansion joint from the throt

tle casing.

The pneumatic valve (2) is secured to the

throttle casing.

E.G.R. VALVE

Removing-refitting

- Remove the throttle casing, following the

description in the previous paragraph.

3. Loosen the bolts (1) fixing the pipe con

necting the E.G.R. and the heat exchanger.

4. Disconnect the electrical connection (1) for

the E.G.R. valve self-adjustment motor; undo

the bolts (2) fixing the E.G.R. valve to the

intake manifold, then lift up the valve and

remove the bolts fixing the pipe connected to

the heat exchanger (loosened previously).

Copyright by Fiat Auto VI 01 i ndate 31

Page 120 of 330

Engine

Fuel feed system

Marea- Marea Weekend 9 ™

2000 range ©

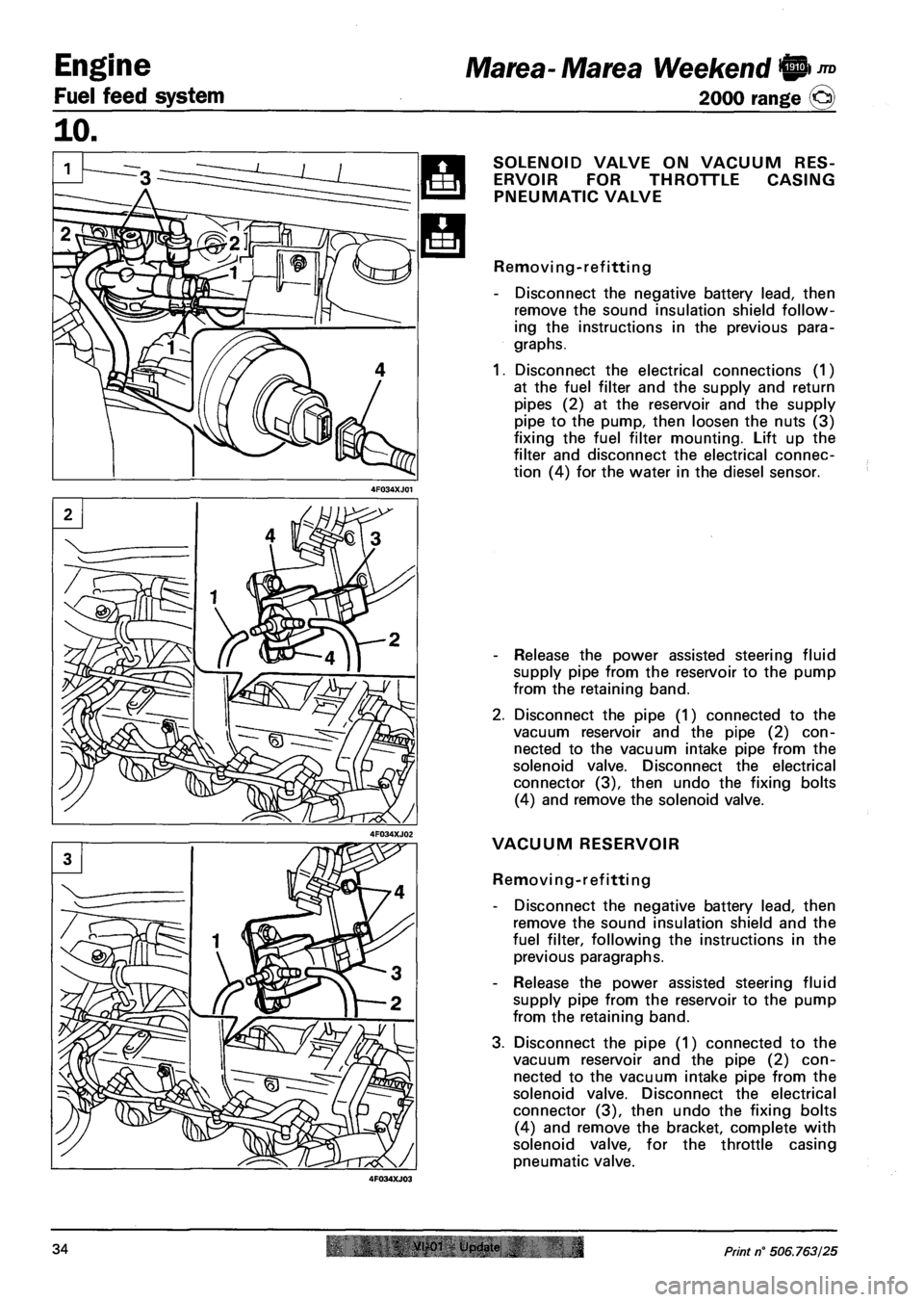

SOLENOID VALVE ON VACUUM RES

ERVOIR FOR THROTTLE CASING

PNEUMATIC VALVE

Removing-refitting

- Disconnect the negative battery lead, then

remove the sound insulation shield follow

ing the instructions in the previous para

graphs.

1. Disconnect the electrical connections (1)

at the fuel filter and the supply and return

pipes (2) at the reservoir and the supply

pipe to the pump, then loosen the nuts (3)

fixing the fuel filter mounting. Lift up the

filter and disconnect the electrical connec

tion (4) for the water in the diesel sensor.

- Release the power assisted steering fluid

supply pipe from the reservoir to the pump

from the retaining band.

2. Disconnect the pipe (1) connected to the

vacuum reservoir and the pipe (2) con

nected to the vacuum intake pipe from the

solenoid valve. Disconnect the electrical

connector (3), then undo the fixing bolts

(4) and remove the solenoid valve.

VACUUM RESERVOIR

Removing-refitting

- Disconnect the negative battery lead, then

remove the sound insulation shield and the

fuel filter, following the instructions in the

previous paragraphs.

- Release the power assisted steering fluid

supply pipe from the reservoir to the pump

from the retaining band.

3. Disconnect the pipe (1) connected to the

vacuum reservoir and the pipe (2) con

nected to the vacuum intake pipe from the

solenoid valve. Disconnect the electrical

connector (3), then undo the fixing bolts

(4) and remove the bracket, complete with

solenoid valve, for the throttle casing

pneumatic valve.

34 VI-01 Update IN Print n° 506.763/25

Page 122 of 330

Engine

Fuel feed system

Marea- Marea Weekend @ ™

2000 range ©

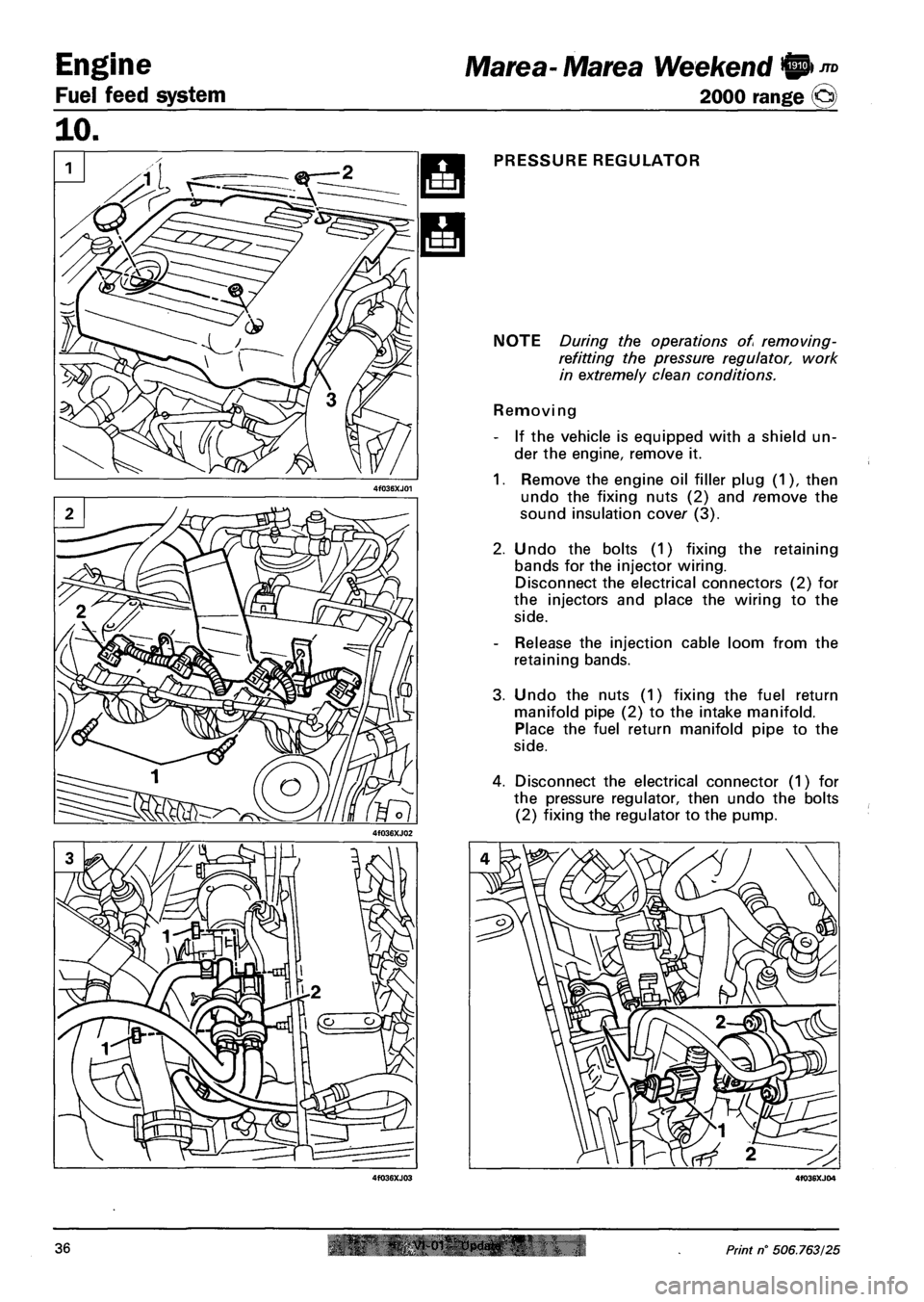

PRESSURE REGULATOR

NOTE During the operations of removing-

refitting the pressure regulator, work

in extremely clean conditions.

Removing

- If the vehicle is equipped with a shield un

der the engine, remove it.

1. Remove the engine oil filler plug (1), then

undo the fixing nuts (2) and remove the

sound insulation cover (3).

2. Undo the bolts (1) fixing the retaining

bands for the injector wiring.

Disconnect the electrical connectors (2) for

the injectors and place the wiring to the

side.

- Release the injection cable loom from the

retaining bands.

3. Undo the nuts (1) fixing the fuel return

manifold pipe (2) to the intake manifold.

Place the fuel return manifold pipe to the

side.

4. Disconnect the electrical connector (1) for

the pressure regulator, then undo the bolts

(2) fixing the regulator to the pump.

36 Print n° 506.763/25

Page 126 of 330

Marea- Marea Weekend

2000 range ©

Auxiliary Units

Climate control

50

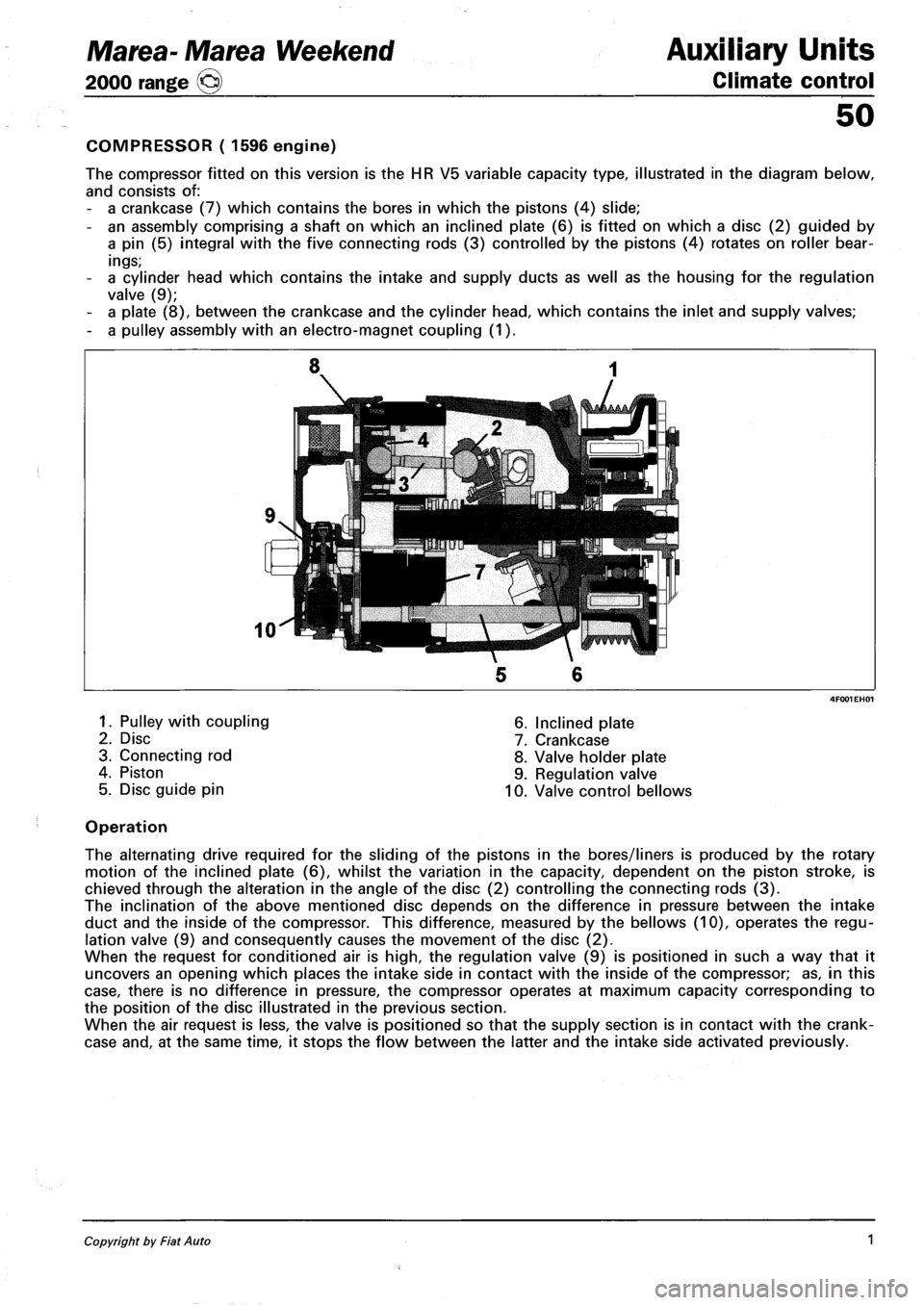

COMPRESSOR ( 1596 engine)

The compressor fitted on this version is the HR V5 variable capacity type, illustrated in the diagram below,

and consists of:

- a crankcase (7) which contains the bores in which the pistons (4) slide;

- an assembly comprising a shaft on which an inclined plate (6) is fitted on which a disc (2) guided by

a pin (5) integral with the five connecting rods (3) controlled by the pistons (4) rotates on roller bear

ings;

- a cylinder head which contains the intake and supply ducts as well as the housing for the regulation

valve (9);

- a plate (8), between the crankcase and the cylinder head, which contains the inlet and supply valves;

- a pulley assembly with an electro-magnet coupling (1).

1. Pulley with coupling

2. Disc

3. Connecting rod

4. Piston

5. Disc guide pin

6. Inclined plate

7. Crankcase

8. Valve holder plate

9. Regulation valve

10. Valve control bellows

Operation

The alternating drive required for the sliding of the pistons in the bores/liners is produced by the rotary

motion of the inclined plate (6), whilst the variation in the capacity, dependent on the piston stroke, is

chieved through the alteration in the angle of the disc (2) controlling the connecting rods (3).

The inclination of the above mentioned disc depends on the difference in pressure between the intake

duct and the inside of the compressor. This difference, measured by the bellows (10), operates the regu

lation valve (9) and consequently causes the movement of the disc (2).

When the request for conditioned air is high, the regulation valve (9) is positioned in such a way that it

uncovers an opening which places the intake side in contact with the inside of the compressor; as, in this

case, there is no difference in pressure, the compressor operates at maximum capacity corresponding to

the position of the disc illustrated in the previous section.

When the air request is less, the valve is positioned so that the supply section is in contact with the crank

case and, at the same time, it stops the flow between the latter and the intake side activated previously.

Copyright by Fiat Auto 1

Page 127 of 330

Auxiliary Units

Climate control

Marea-Marea Weekend

2000 range O

50

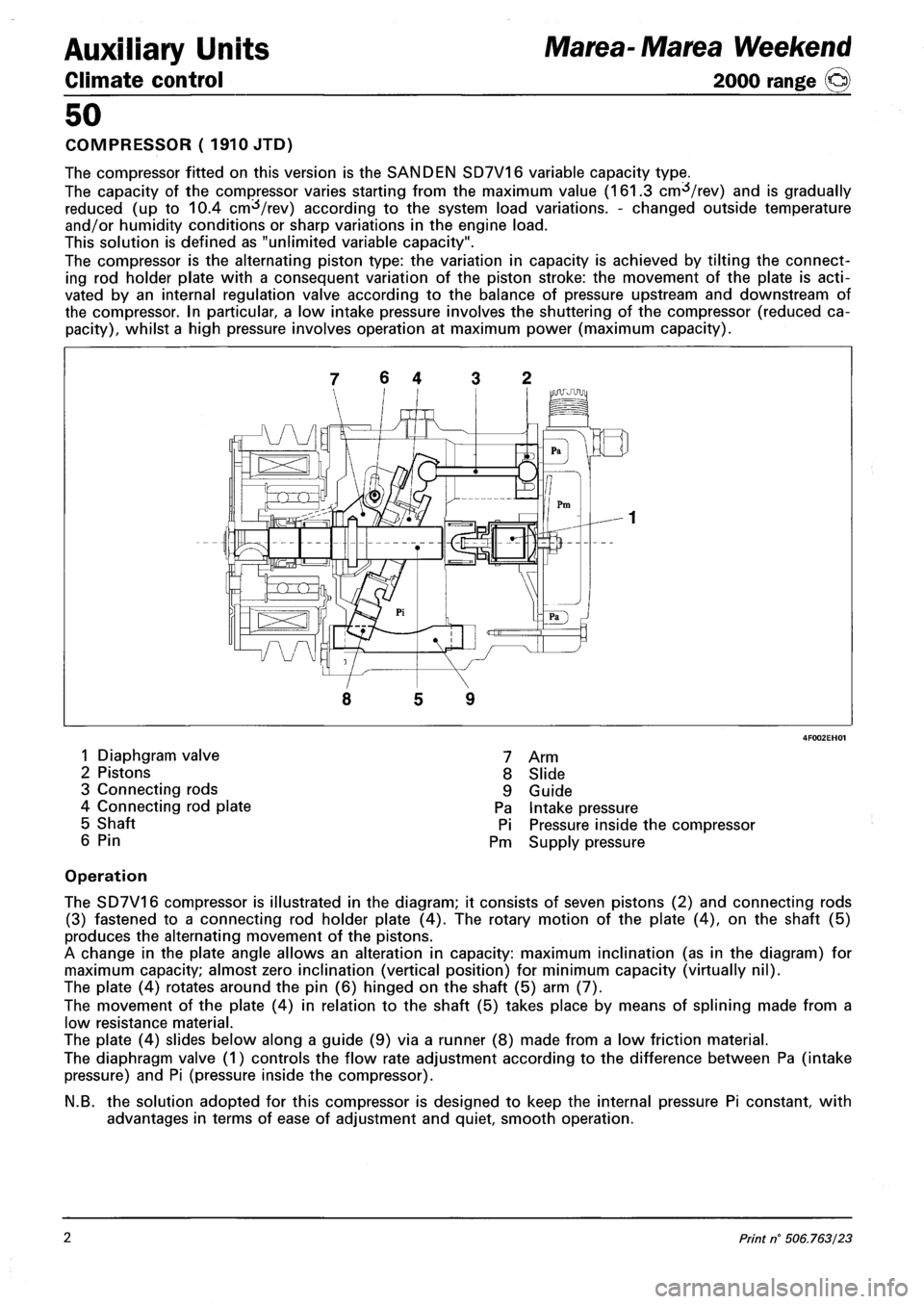

COMPRESSOR (1910 JTD)

The compressor fitted on this version is the SANDEN SD7V16 variable capacity type.

The capacity of the compressor varies starting from the maximum value (161.3 cm^/rev) and is gradually

reduced (up to 10.4 cm^/rev) according to the system load variations. - changed outside temperature

and/or humidity conditions or sharp variations in the engine load.

This solution is defined as "unlimited variable capacity".

The compressor is the alternating piston type: the variation in capacity is achieved by tilting the connect

ing rod holder plate with a consequent variation of the piston stroke: the movement of the plate is acti

vated by an internal regulation valve according to the balance of pressure upstream and downstream of

the compressor. In particular, a low intake pressure involves the shuttering of the compressor (reduced ca

pacity), whilst a high pressure involves operation at maximum power (maximum capacity).

7 6 4 3 2

5 9

1 Diaphgram valve

2 Pistons

3 Connecting rods

4 Connecting rod plate

5 Shaft

6 Pin

7 Arm

8 Slide

9 Guide

Pa Intake pressure

Pi Pressure inside the compressor

Pm Supply pressure

Operation

The SD7V16 compressor is illustrated in the diagram; it consists of seven pistons (2) and connecting rods

(3) fastened to a connecting rod holder plate (4). The rotary motion of the plate (4), on the shaft (5)

produces the alternating movement of the pistons.

A change in the plate angle allows an alteration in capacity: maximum inclination (as in the diagram) for

maximum capacity; almost zero inclination (vertical position) for minimum capacity (virtually nil).

The plate (4) rotates around the pin (6) hinged on the shaft (5) arm (7).

The movement of the plate (4) in relation to the shaft (5) takes place by means of splining made from a

low resistance material.

The plate (4) slides below along a guide (9) via a runner (8) made from a low friction material.

The diaphragm valve (1) controls the flow rate adjustment according to the difference between Pa (intake

pressure) and Pi (pressure inside the compressor).

N.B. the solution adopted for this compressor is designed to keep the internal pressure Pi constant, with

advantages in terms of ease of adjustment and quiet, smooth operation.

2 Print n° 506.763/23

Page 128 of 330

Marea-Marea Weekend

2000 range ©)

Auxiliary Units

Climate control

50

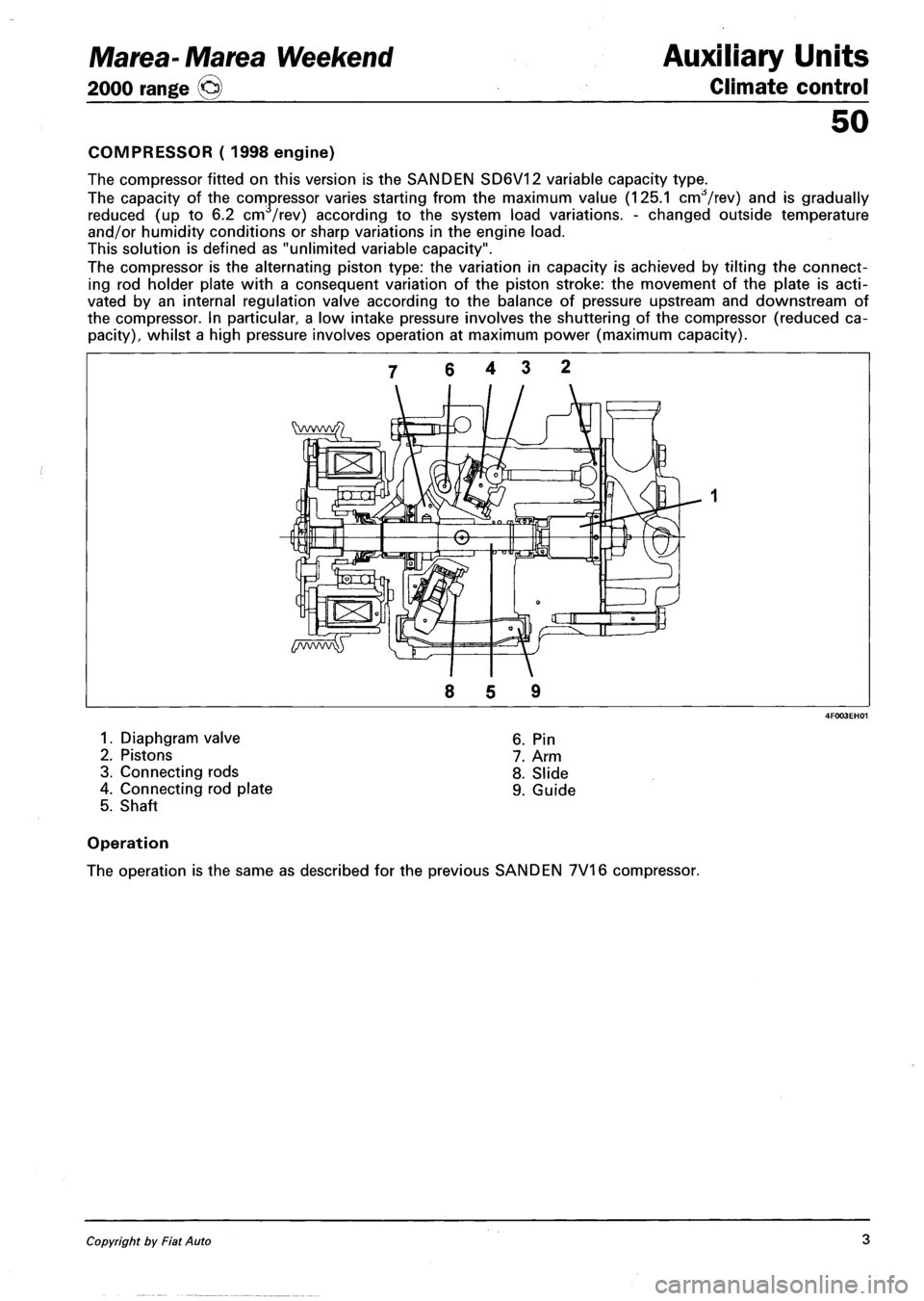

COMPRESSOR ( 1998 engine)

The compressor fitted on this version is the SANDEN SD6V12 variable capacity type.

The capacity of the compressor varies starting from the maximum value (125.1 cnrfVrev) and is gradually

reduced (up to 6.2 cm /rev) according to the system load variations. - changed outside temperature

and/or humidity conditions or sharp variations in the engine load.

This solution is defined as "unlimited variable capacity".

The compressor is the alternating piston type: the variation in capacity is achieved by tilting the connect

ing rod holder plate with a consequent variation of the piston stroke: the movement of the plate is acti

vated by an internal regulation valve according to the balance of pressure upstream and downstream of

the compressor. In particular a low intake pressure involves the shuttering of the compressor (reduced ca

pacity), whilst a high pressure involves operation at maximum power (maximum capacity).

1. Diaphgram valve

2. Pistons

3. Connecting rods

4. Connecting rod plate

5. Shaft

6. Pin

7. Arm

8. Slide

9. Guide

Operation

The operation is the same as described for the previous SANDEN 7V16 compressor.

Copyright by Fiat Auto 3

Page 238 of 330

Electrical equipment

Component location

Marea- Marea Weekend

2000 range ®

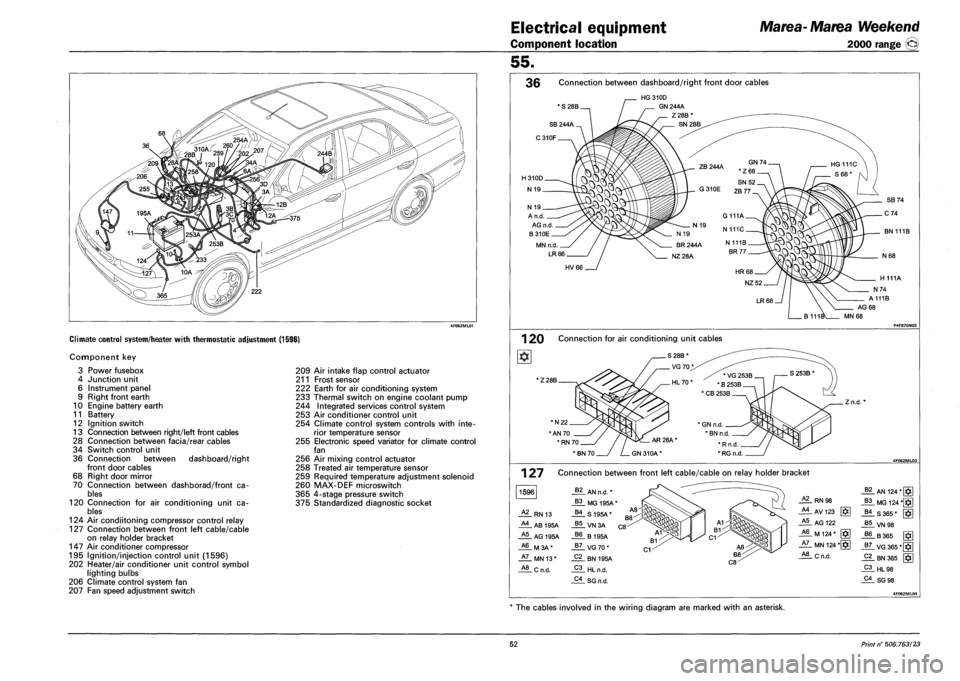

Climate control system/heater with thermostatic adjustment (1596)

Component key

3 Power fusebox

4 Junction unit

6 Instrument panel

9 Right front earth

10 Engine battery earth

11 Battery

12 Ignition switch

13 Connection between right/left front cables

28 Connection between facia/rear cables

34 Switch control unit

36 Connection between dashboard/right

front door cables

68 Right door mirror

70 Connection between dashborad/front ca

bles

120 Connection for air conditioning unit ca

bles

124 Air condiitoning compressor control relay

127 Connection between front left cable/cable

on relay holder bracket

147 Air conditioner compressor

195 Ignition/injection control unit (1596)

202 Heater/air conditioner unit control symbol

lighting bulbs

206 Climate control system fan

207 Fan speed adjustment switch

209 Air intake flap control actuator

211 Frost sensor

222 Earth for air conditioning system

233 Thermal switch on engine coolant pump

244 Integrated services control system

253 Air conditioner control unit

254 Climate control system controls with inte

rior temperature sensor

255 Electronic speed variator for climate control

fan

256 Air mixing control actuator

258 Treated air temperature sensor

259 Required temperature adjustment solenoid

260 MAX-DEF microswitch

365 4-stage pressure switch

375 Standardized diagnostic socket

55.

36 Connection between dashboard/right front door cables

* S 28B.

HG310D

GN 244A

Z28B

N 19 _

A n.d.

AG n.d

B310E

MN n.d.

LR66

BN 111B

HV66

AG 68

MN 68

1 20 Connection for air conditioning unit cables

1Z 28B.

*N22.

"AN 70

' RN 70.

. Z n.d.

127

1596

Connection between front left cable/cable on relay holder bracket

62 AN n.d. *

B3 MG 195A*

A2 RN 13 B4 S195A*

A4 AB 195A B5 VN3A

A5 AG 195A B6 B195A

A6 M3A* B7 VG70*

A7 MN 13* C2 BN 195A

A8 Cn.d. C3 HL n.d.

C4 SG n.d.

RN 98

_AlAV123 g*]

A5 AG 122

_A6_ M 124 * [§]

JiL MN 124 *[§]

_*!L C n.d.

_§?_ AN 124*[§]

_B3_MG 124 *§]

-US 365* [$]

J*!LVN98

J?6. B 365 [ffi

_g7_ VG 365*[

_Pi_ HL98

_?i_SG 98

The cables involved in the wiring diagram are marked with an asterisk.

52 Print n° 506.763/23

Page 240 of 330

Electrical equipment

Component location

Marea- Marea Weekend

2000 range ®

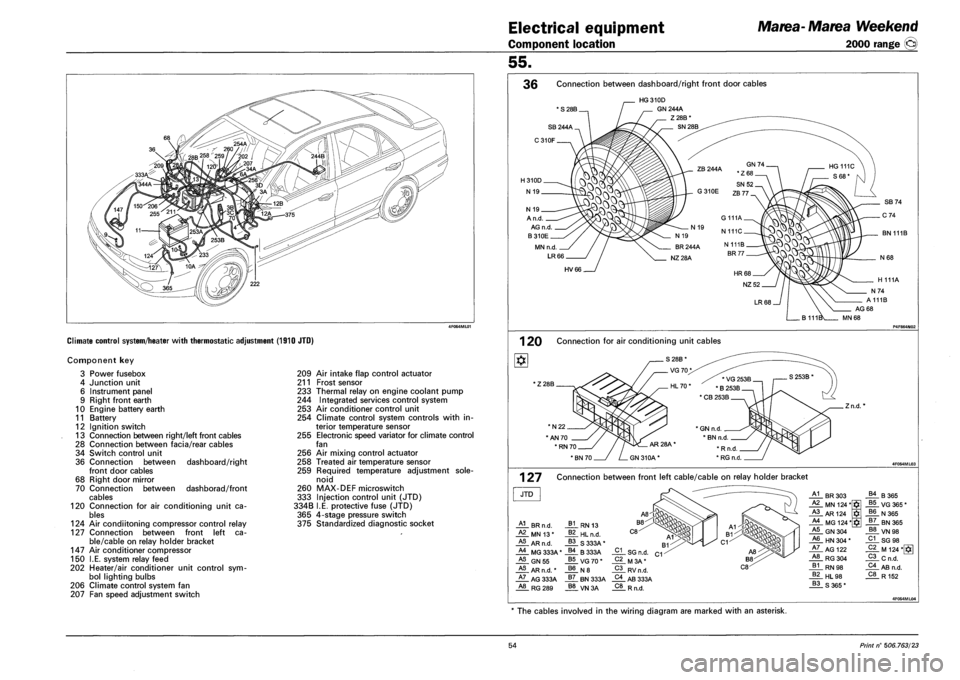

Climate control system/heater with thermostatic adjustment (1910 JTO)

Component key

Power fusebox

Junction unit

Instrument panel

Right front earth

Engine battery earth

Battery

Ignition switch

Connection between right/left front cables

Connection between facia/rear cables

Switch control unit

Connection between

front door cables

Right door mirror

Connection between

cables

Connection for air conditioning unit ca

bles

124 Air condiitoning compressor control relay

127 Connection between front left ca

ble/cable on relay holder bracket

Air conditioner compressor

I.E. system relay feed

Heater/air conditioner unit control sym

bol lighting bulbs

Climate control system fan

Fan speed adjustment switch

3

4

6

9

10

11

12

13

28

34

36

68

70

120

147

150

202

206

207

dashboard/right

dashborad/front

209 Air intake flap control actuator

211 Frost sensor

233 Thermal relay on engine coolant pump

244 Integrated services control system

253 Air conditioner control unit

254 Climate control system controls with in

terior temperature sensor

255 Electronic speed variator for climate control

fan

256 Air mixing control actuator

258 Treated air temperature sensor

259 Required temperature adjustment sole

noid

260 MAX-DEF microswitch

333 Injection control unit (JTD)

334B I.E. protective fuse (JTD)

365 4-stage pressure switch

375 Standardized diagnostic socket

55.

36 Connection between dashboard/right front door cables

' S 28B.

HG310D

GN 244A

Z28B*

SN 28B

A n.d.

AG n.d.

B310E

MN n.d

LR66

BN 111B

HV66

1 20 Connection for air conditioning unit cables

' Z 28B

*N22.

"AN 70

.Zn.d.

1 27 Connection between front left cable/cable on relay holder bracket

JTD

HL BR n.d.

_ALMNI3*

HL AR n.d.

HL MG 333A'

HL GN55

HL AR n.d. *

HL AG 333A A8 RG289

_A1_ BR 303 B4 B365 A2 MN 124* $ B5 VG 365 * A3 AR124 B6 N365 A4 MG 124* $ B7 BN 365 A5 GN 304 B8 VN 98 A6 HN 304 * C1 SG 98 A7 AG 122 C2 M 124*[*g A8 RG304 C3 Cn.d. B1 RN 98 C4 AB n.d. B2 HL 98 C8 R152 B3 S365*

The cables involved in the wiring diagram are marked with an asterisk.

54 Print n° 506.763/23

Page 242 of 330

![FIAT MAREA 2000 1.G Owners Manual Electrical equipment

Component location

Marea- Marea Weekend

2000 range ©

Climate control unit/heater with thermostatic control (1998)

Component key

] 3 Power fusebox

4 Junction unit

6 Instru FIAT MAREA 2000 1.G Owners Manual Electrical equipment

Component location

Marea- Marea Weekend

2000 range ©

Climate control unit/heater with thermostatic control (1998)

Component key

] 3 Power fusebox

4 Junction unit

6 Instru](/img/10/4653/w960_4653-241.png)

Electrical equipment

Component location

Marea- Marea Weekend

2000 range ©

Climate control unit/heater with thermostatic control (1998)

Component key

] 3 Power fusebox

4 Junction unit

6 Instrument panel

10 Engine battery earth

11 Battery

12 Ignition switch

28 Connection between facia/rear cables

34 Switch control unit

36 Connection between dashboard/right

front door cables

55 Connection between front/engine cables

68 Right door mirror

70 Connection between dashborad/front ca

bles

120 Connection for air conditioning unit ca

bles

124 Air condiitoning compressor control relay

127 Connection between front left cable/cable

on relay holder bracket

147 Air conditioner compressor

190 Injection/ignition electronic control unit

(1998)

202 Heater/air conditioner unit control symbol

lighting bulbs

206 Climate control system fan

207 Fan speed adjustment selector

209 Air intake flap control actuator

211 Frost sensor

222 Earth for air conditioning system

244 Integrated services control system

253 Air conditioner control unit

254 Climate control system controls with inte

rior temperature sensor

255 Electronic speed variator for climate control

fan

256 Air mixing control actuator

258 Treated air temperature sensor

259 Required temperature adjustment solenoid

260 MAX-DEF microswitch

365 4-stage pressure switch

375 Standardized diagnostic socket

55.

36 Connection between dashboard/right front door cables

* S 28B.

HG 310D

GN 244A

Z28B

N 19.

A n.d.

AG n.d.

B310E.

MN n.d

LR66

BN 111B

HV66

1 20 Connection for air conditioning unit cables

* Z 28B.

*N22.

'AN 70 _

*RN70

'BN 70

AR28A

GN310A*

. Zn.d.

1 27 Connection between front left cable/cable on relay holder bracket

1998

A1 Rn.d. B1 MB 4C A2 RN 13 B2 AN n.d. * A3 BG 190A B3 MG 190A* A4 AB 190A B4 S190A* A5 AG 190A B5 VN3A A6 M3A* B6 B 190A A7 MN 55* B7 VG70* A8 Cn.d. B8 Rn.d.

C2

C3

C4

C5

C6

C7

BN190A B1

HLn.d. C1

SG n.d.

HRn.d.

AR n.d.

G 190A

A1 Rn.d. B4 S365* 0 A2 RN 98 B5 VN 98 A3 BV151 B6 B365 A4 AB123 @ VG 365' A5 AG 122 @ B8 R 150 A6 M 124* C2 BN 365 A7 MN 124* C3 HL98 A8 Cn.d. C4 SG98 B1 MB 151 C5 HR 152A B2 AN 124 * C6 AR152B B3 MG 124* C7 G 150

The cables involved in the wiring diagram are marked with an asterisk.

56 Print n° 506.763/23

Page 306 of 330

Electrical equipment

Connector blocks

Marea-Marea Weekend

__ 2000 range ©

55.

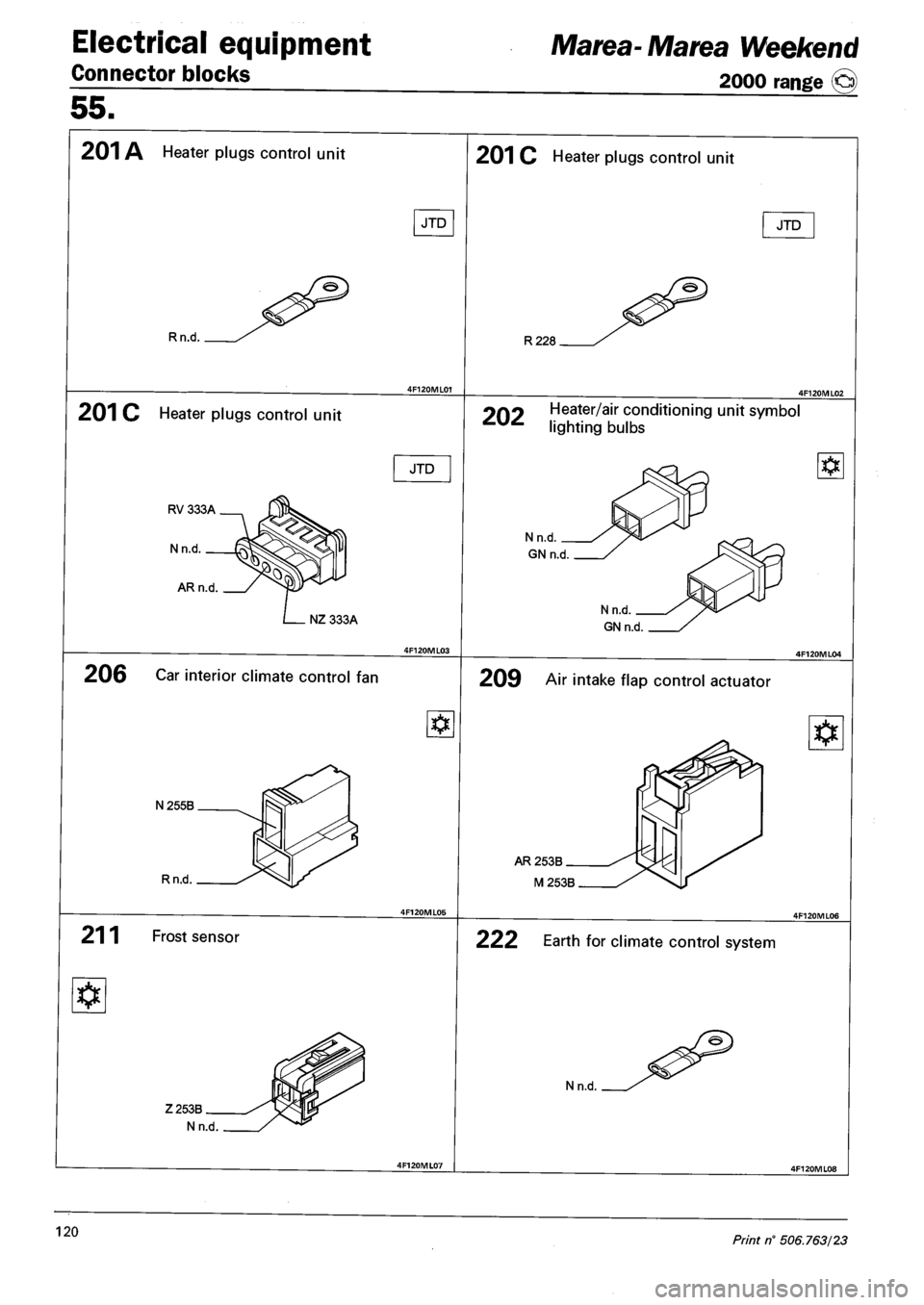

201 A Heater plugs control unit

JTD

&

Rn.d..

201 C Heater plugs control unit

JTD

RV 333A

Nn.d.

AR n.d

NZ 333A

206 Car interior climate control fan

2>

N255B

Rn.d.

211 Frost sensor

Z253B

Nn.d.

201 C Heater plugs control unit

JTD

&

R228.

OflO Heater/air conditioning unit symbol

AUA lighting bulbs

N n.d.

GN n.d

GN n.d

209 Air intake flap control actuator

AR 253B

M253B

222 Earth for climate control system

Nn.d.

120 Print n° 506.763/23