alternator FIAT MAREA 2000 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 53 of 330

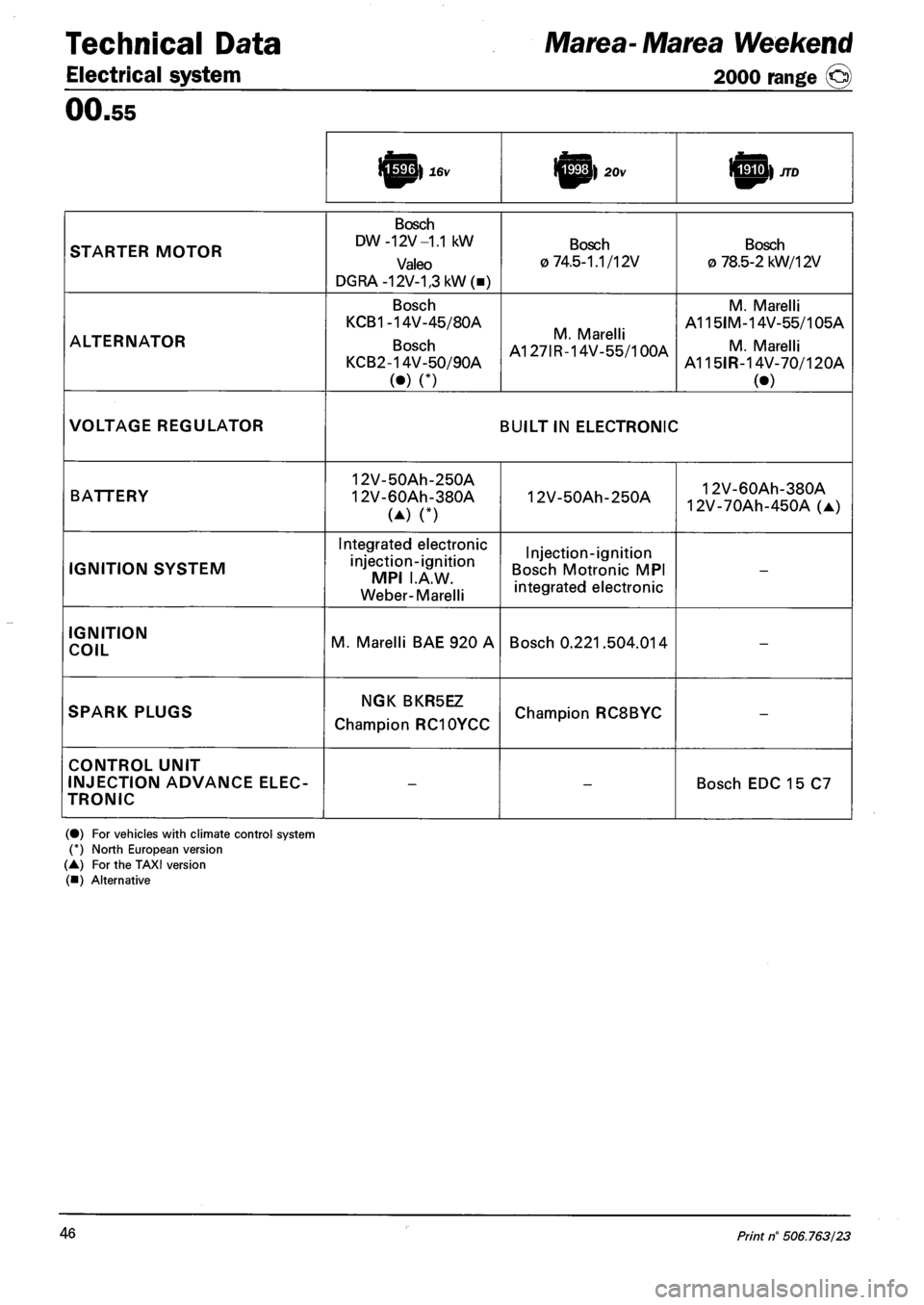

Technical Data Marea- Marea Weekend

Electrical system 2000 range (§)

00.55

i^p} 16v J^M) 20v

STARTER MOTOR

Bosch

DW -12V -1.1 kW

Valeo

DGRA-12V-1,3kW(B)

Bosch

0 74.5-1.1/12V

Bosch

O 78.5-2 kW/12V

ALTERNATOR

Bosch

KCB1-14V-45/80A

Bosch

KCB2-14V-50/90A

(•) n

M. Marelli

A127IR-14V-55/100A

M. Marelli

A115IM-14V-55/105A

M. Marelli

A115IR-14V-70/120A

(•)

VOLTAGE REGULATOR BUILT IN ELECTRONIC

BATTERY

12V-50Ah-250A

12V-60Ah-380A

(A) n

12V-50Ah-250A 12V-60Ah-380A

12V-70Ah-450A (A)

IGNITION SYSTEM

Integrated electronic

injection-ignition

MPI I.A.W.

Weber-Marelli

Injection-ignition

Bosch Motronic MPI

integrated electronic

-

IGNITION

COIL M. Marelli BAE 920 A Bosch 0.221.504.014 -

SPARK PLUGS NGK BKR5EZ

Champion RC10YCC Champion RC8BYC -

CONTROL UNIT

INJECTION ADVANCE ELEC

TRONIC

--Bosch EDC 15 C7

(•) For vehicles with climate control system (*) North European version (A) For the TAXI version

(•) Alternative

46 Print n° 506.763/23

Page 55 of 330

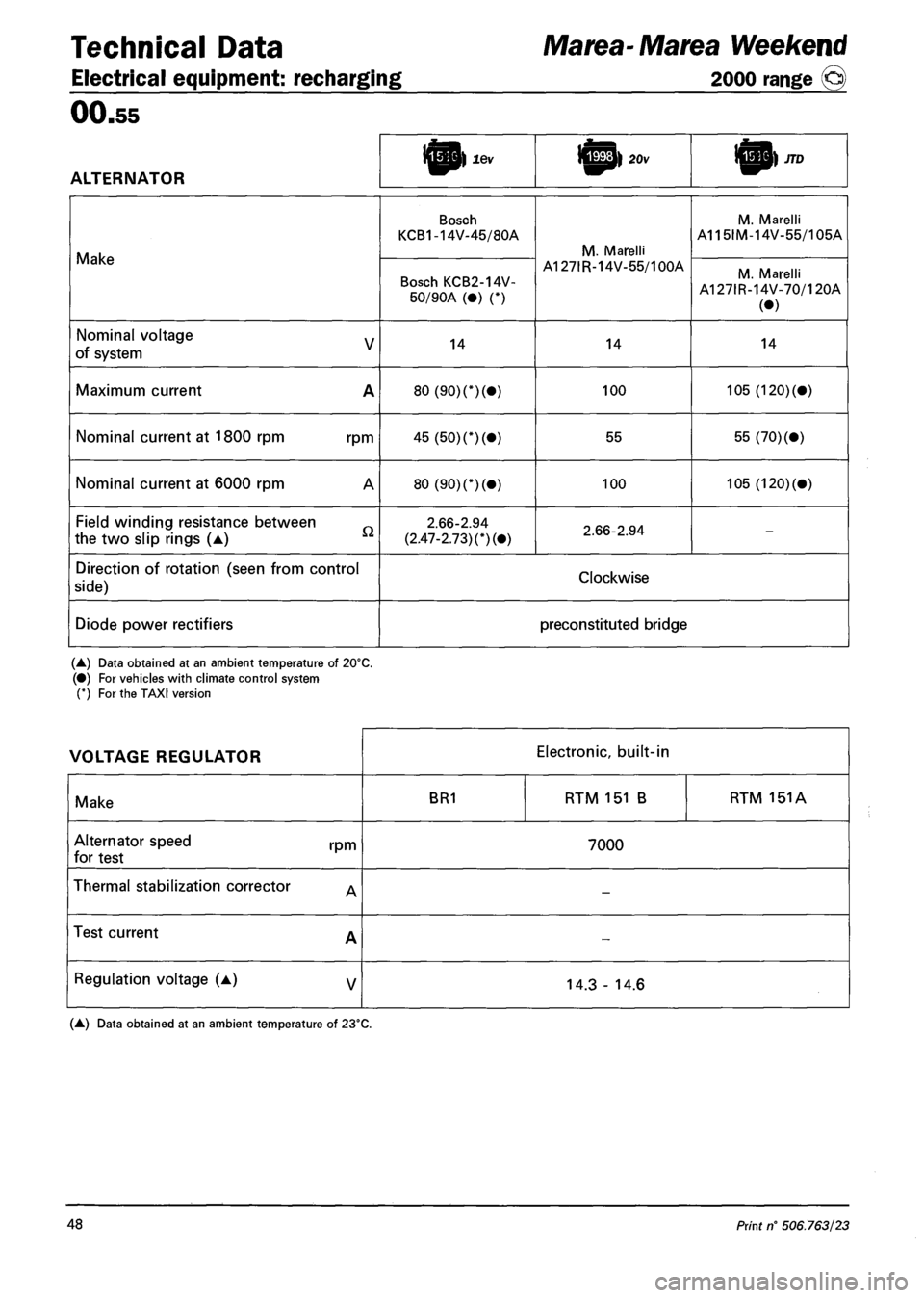

Technical Data Marea-Marea Weekend

Electrical equipment: recharging 2000 range @)

00.55

ALTERNATOR

l^p) lev rgp> JTD

Make

Bosch

KCB1-14V-45/80A

M. Marelli A127IR-14V-55/100A

M. Marelli A115IM-14V-55/105A

Make

Bosch KCB2-14V-

50/90A (•) (*)

M. Marelli A127IR-14V-55/100A M. Marelli

A127IR-14V-70/120A

(•)

Nominal voltage y

of system 14 14 14

Maximum current A 80 (90) (*)(•) 100 105 (120)(«)

Nominal current at 1800 rpm rpm 45 (50) (*)(•) 55 55 (70)(»)

Nominal current at 6000 rpm A 80 (90) (*)(•) 100 105 (120)(«)

Field winding resistance between

the two slip rings (A)

2.66-2.94

(2.47-2.73) (*)(•) 2.66-2.94 -

Direction of rotation (seen from control

side) Clockwise

Diode power rectifiers preconstituted bridge

(A) Data obtained at an ambient temperature of 20°C. (•) For vehicles with climate control system C) For the TAXI version

VOLTAGE REGULATOR Electronic, built-in

Make BR1 RTM 151 B RTM 151A

Alternator speed rpm

for test 7000

Thermal stabilization corrector ^ -

Test current A -

Regulation voltage (A) y 14.3-14.6

(A) Data obtained at an ambient temperature of 23°C.

48 Print n° 506.763/23

Page 56 of 330

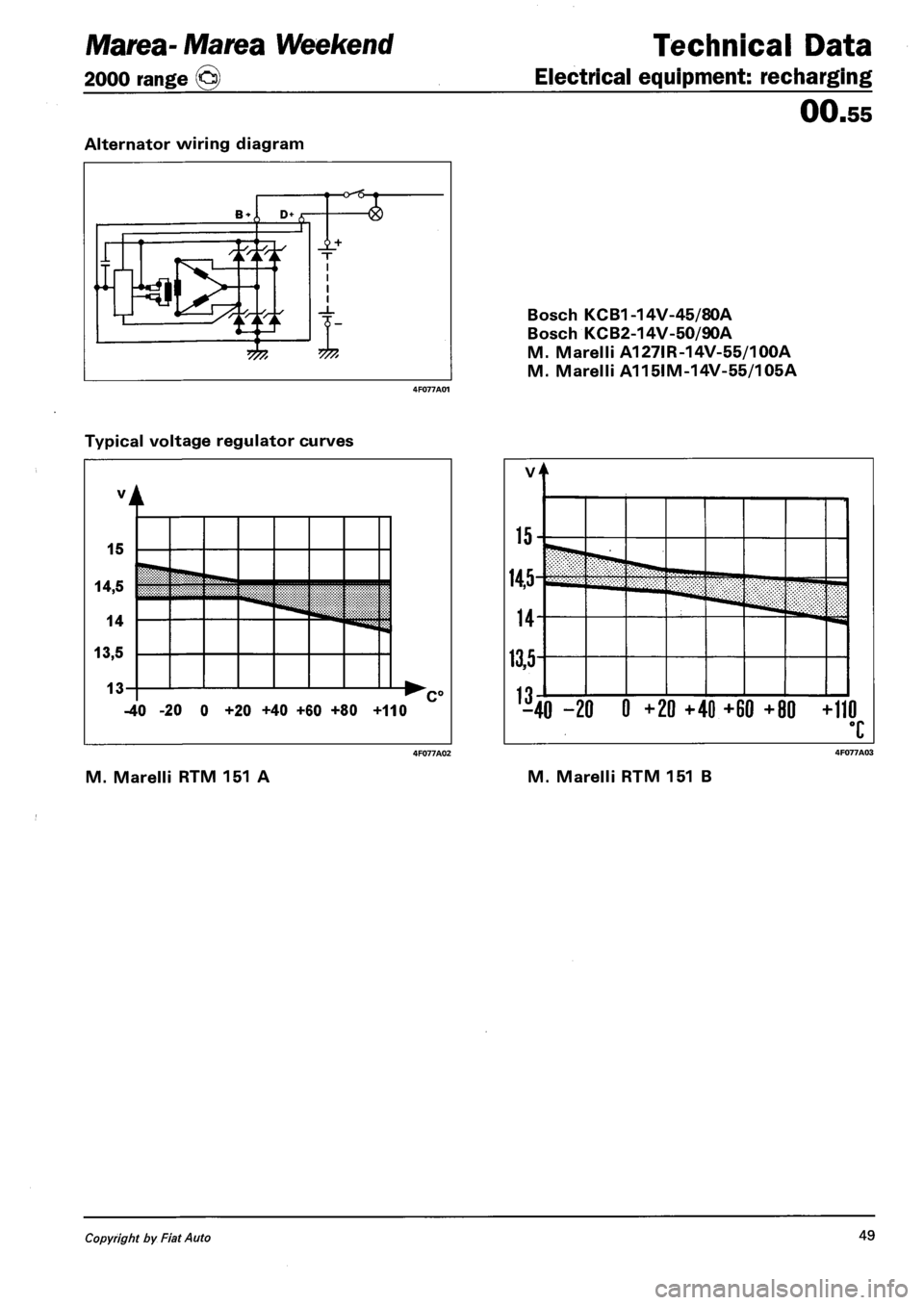

Technical Data

Electrical equipment: recharging

00.55

Bosch KCB1-14V-45/80A

Bosch KCB2-14V-50/90A

M. Marelli A127IR-14V-55/100A

M. Marelli A115IM-14V-55/105A

M. Marelli RTM 151 B

Marea- Marea Weekend

2000 range ©)

Alternator wiring diagram

Typical voltage regulator curves

M. Marelli RTM 151 A

Copyright by Fiat Auto 49

Page 92 of 330

Fuel feed system

Engine Marea- Marea Weekend © ™

2000 range @

10.

The control unit autodiagnostic system checks the signals coming from the sensors and compares them

with the figures allowed:

- signalling faults during starting

- warning light on for 4 seconds indicates test stage

- warning light off after 4 seconds indicates no fault with components that could alter the pollution con

trol standard figures

- warning light on after 4 seconds indicates fault.

- signalling faults during operation

- warning light on indicates fault

- warning light off indicates no fault with components that could alter the pollution control standard fig

ures.

- recovery

- from time to time, the control unit defines the type of recovery according to the components which are

faulty

- the recovery parameters are managed by components which are not faulty.

Control of cylinder balancing during idling

According to the signals coming from the sensors, the injection control unit controls the idle speed torque,

altering the injector operating times.

Control of irregular operation

Depending on the signals coming from the sensors, the injection control unit corrects the amount of fuel

to be injected in order to improve driveability and reduce jerking whilst driving.

The correction is achieved through the fuel pressure regulator and by varying the injector operating times.

Control of electrical balance

According to the battery voltage, the injection control unit alters the idle speed, to guarantee a sufficient

current supply from the alternator in situations where the consumers are absorbing a great deal of power.

The variation in the idle speed is achived by regulating the fuel pressure and altering the injector operat

ing times.

VGT variable geometry turbocharger control (1910 JTD 110 CV)

The injection control unit processes the signal coming from the supercharging sensor, at the various en

gine operating speeds, and determines the quantity of fuel to be injected, acting on the fuel pressure

regulator and the injector opening times.

In addition, through the solenoid valve, the control unit regulates the geometry of the turbine in order to

ensure optimum performance in all operating conditions.

Turbocharger waste gate valve control (1910 JTD 100 CV)

At the various engine operating speeds, the injection control unit processes the signal coming from the

supercharging sensor and determines the amount of fuel to inject, acting on the fuel pressure regulator

and the injector opening times.

In addition, the control unit controls the opening of the turbocharger waste gate valve, via the solenoid

valve, in order to ensure excellent performance in all operating conditions.

Control of throttle closing when engine is switched off

When the engine is switched off (ignition key in OFF position) the injection control unit closes the throt

tle valve located on the air intake duct via the special solenoid valve.

This action makes it possible to limit the tiresome shuddering of the engine whilst it is switching off.

6 .i. V!-01-.Cancelftand replaces Print n° 506.763/25

Page 131 of 330

Marea- Marea Weekend

2000 range ©

Electrical equipment

Protection and security devices

55.

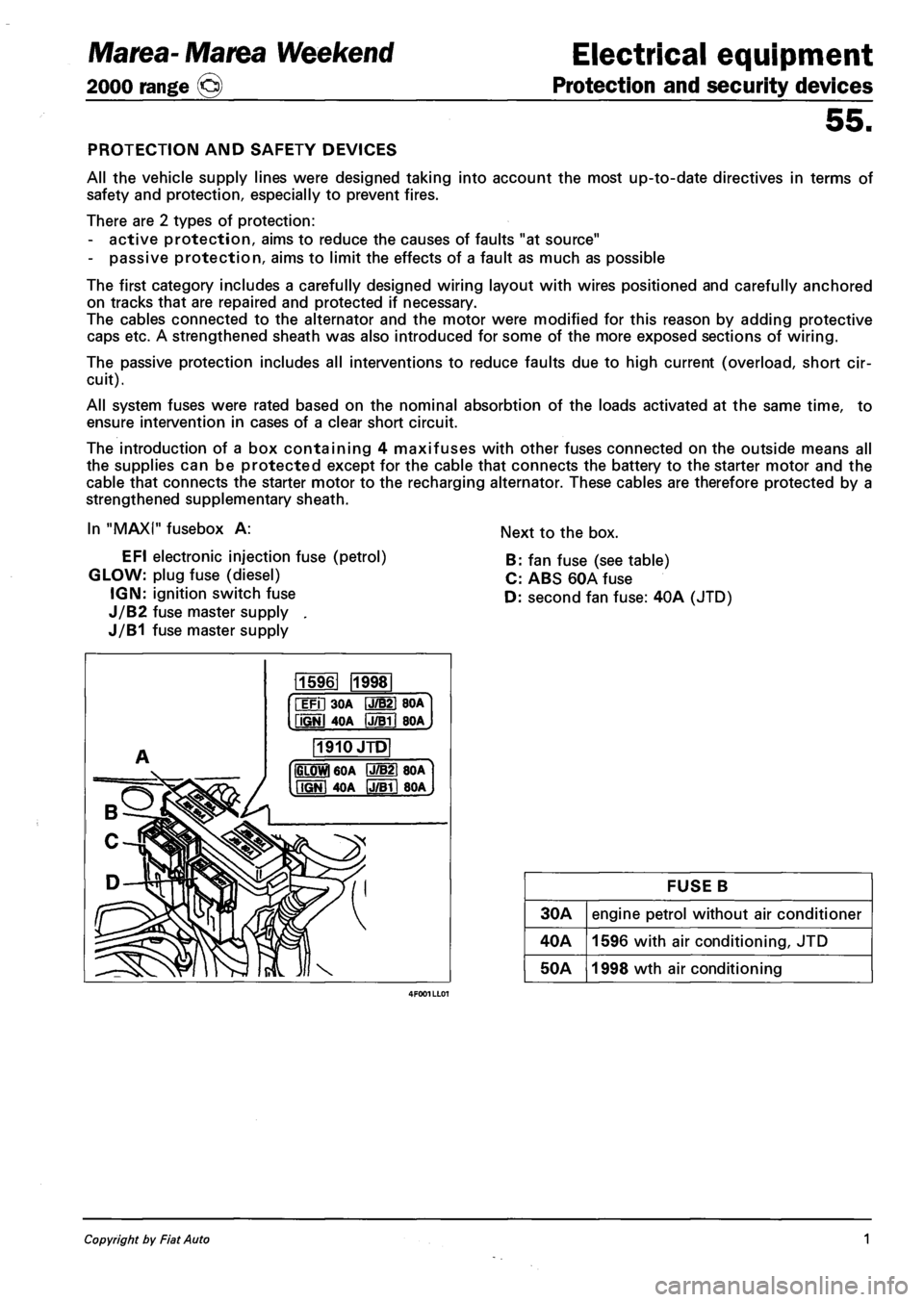

PROTECTION AND SAFETY DEVICES

All the vehicle supply lines were designed taking into account the most up-to-date directives in terms of

safety and protection, especially to prevent fires.

There are 2 types of protection:

- active protection, aims to reduce the causes of faults "at source"

- passive protection, aims to limit the effects of a fault as much as possible

The first category includes a carefully designed wiring layout with wires positioned and carefully anchored

on tracks that are repaired and protected if necessary.

The cables connected to the alternator and the motor were modified for this reason by adding protective

caps etc. A strengthened sheath was also introduced for some of the more exposed sections of wiring.

The passive protection includes all interventions to reduce faults due to high current (overload, short cir

cuit).

All system fuses were rated based on the nominal absorbtion of the loads activated at the same time, to

ensure intervention in cases of a clear short circuit.

The introduction of a box containing 4 maxifuses with other fuses connected on the outside means all

the supplies can be protected except for the cable that connects the battery to the starter motor and the

cable that connects the starter motor to the recharging alternator. These cables are therefore protected by a

strengthened supplementary sheath.

In "MAXI" fusebox A:

EFI electronic injection fuse (petrol)

GLOW: plug fuse (diesel)

IGN: ignition switch fuse

J/B2 fuse master supply .

J/B1 fuse master supply

Next to the box.

B: fan fuse (see table)

C: ABS 60A fuse

D: second fan fuse: 40A (JTD)

115961 1998

iFil 30A IJ/B21 BOA

fiGNl 4OA IJTBTI BOA

1910JTD

IGLOWl 60A P7B21 80A

MGNI 40A IJ/Bll 80A

FUSE B

30A engine petrol without air conditioner

40A 1596 with air conditioning, JTD

50A 1998 wth air conditioning

Copyright by Fiat Auto 1

Page 256 of 330

Electrical equipment

Component location

Marea-Marea Weekend

2000 range ©

55.

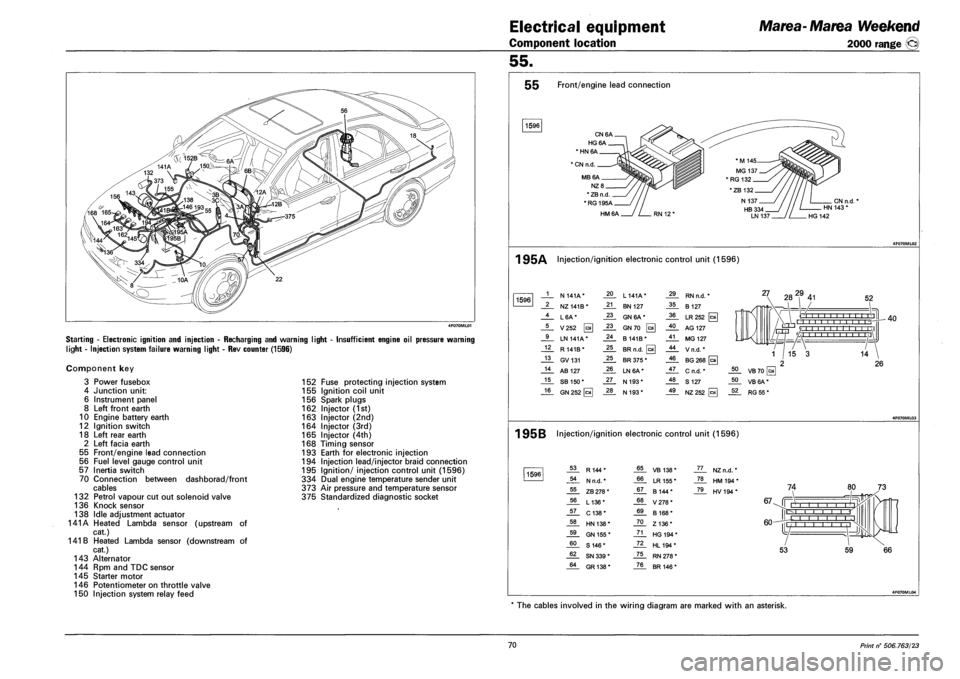

Starting - Electronic ignition and injection - Recharging and warning light

light - Injection system failure warning light - Rev counter (1596)

Insufficient engine oil pressure warning

Component key

3 Power fusebox

4 Junction unit:

6 Instrument panel

8 Left front earth

10 Engine battery earth

12 Ignition switch

18 Left rear earth

2 Left facia earth

55 Front/engine lead connection

56 Fuel level gauge control unit

57 Inertia switch

70 Connection between dashborad/front

cables

132 Petrol vapour cut out solenoid valve

136 Knock sensor

138 Idle adjustment actuator

141A Heated Lambda sensor (upstream of

cat.)

141 B Heated Lambda sensor (downstream of

cat.)

143 Alternator

144 Rpm and TDC sensor

145 Starter motor

146 Potentiometer on throttle valve

150 Injection system relay feed

152 Fuse protecting injection system

155 Ignition coil unit

156 Spark plugs

162 Injector (1st)

163 Injector (2nd)

164 Injector (3rd)

165 Injector (4th)

168 Timing sensor

193 Earth for electronic injection

194 Injection lead/injector braid connection

195 Ignition/ injection control unit (1596)

334 Dual engine temperature sender unit

373 Air pressure and temperature sensor

375 Standardized diagnostic socket

55 Front/engine lead connection

1596

CN6A.

HG6A.

* HN 6A

1 CN n.d.

MB6A.

NZ8_

* ZB n.d

*RG195A_

HM6A

CN n.d. HN 143 *

HG 142

1 95A Injection/ignition electronic control unit (1596)

1596 1 N 141A* 20 L 141A* 29 RN n.d. *

2 NZ141B* 21 BN 127 35 B 127

4 L6A* 23 GN 6A* 36 LR252 [c*

5 V252 0 23 GN70 0 40 AG 127

9 LN 141A* 24 B141B* 41 MG 127

12 R 141B* 25 BR n.d. 0 44 Vn.d.*

13 GV131 25 BR 375 * 46 BG 268 [a

14 AB 127 26 LN6A* 47 C n.d. *

15 SB 150* 27 N 193* 48 S 127

16 GN 252 [cal 28 N 193* 49 NZ252

27 282,9 41 52

O I I I I I I -r-r-r'n , , r'l -r-

rrrri '/ 1 1 1 1 1 1 1 1 1 1 1 \1 L/-HJ 'A i I I i i ,I

40

1 95B Injection/ignition electronic control unit (1596)

1596 53 R144* 65 VB 138* JL. NZn.d. *

54 N n.d. * 66 LR 155 * _ZL HM194*

55 ZB 278 * 67 B 144* _7JL HV194*

56 L136* 68 V278*

57 C138* 69 B 168*

58 HN 138* 70 Z136*

59 GN 155 * 71 HG 194 *

60 S 146* 72 HL194*

62 SN 339 * 75 RN 278 *

64 GR138* 76 BR 146 *

74

67-Jf Mill i i r r-l I I I

60-

IE

L -j |l

53 59

The cables involved in the wiring diagram are marked with an asterisk.

70 Print n° 506.763/23

Page 258 of 330

Electrical equipment

Component location

Marea-Marea Weekend

2000 range ®

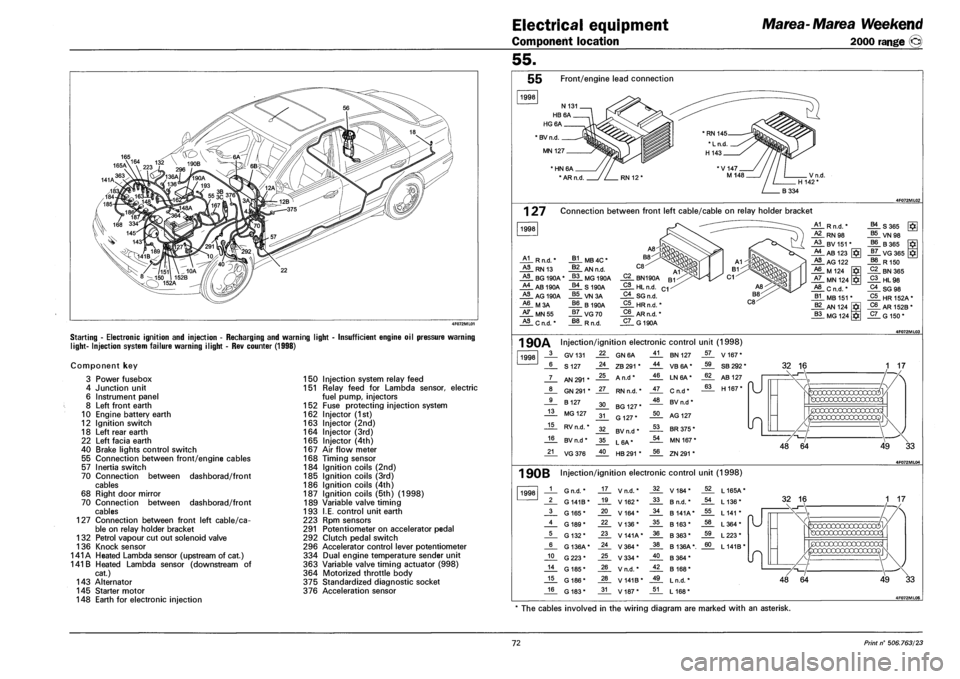

Starting - Electronic ignition and injection - Recharging and warning light

light- Injection system failure warning ilight - Rev counter (1998)

Insufficient engine oil pressure warning

Component key

3 Power fusebox

4 Junction unit

6 Instrument panel

8 Left front earth

10 Engine battery earth

12 Ignition switch

18 Left rear earth

22 Left facia earth

40 Brake lights control switch

55 Connection between front/engine cables

57 Inertia switch

70 Connection between dashborad/front

cables

68 Right door mirror

70 Connection between dashborad/front

cables

127 Connection between front left cable/ca

ble on relay holder bracket

132 Petrol vapour cut out solenoid valve

136 Knock sensor

141A Heated Lambda sensor (upstream of cat.)

141 B Heated Lambda sensor (downstream of

cat.)

143 Alternator

145 Starter motor

148 Earth for electronic injection

150 Injection system relay feed

151 Relay feed for Lambda sensor, electric

fuel pump, injectors

152 Fuse protecting injection system

162 Injector (1st)

163 Injector (2nd)

164 Injector (3rd)

165 Injector (4th)

167 Air flow meter

168 Timing sensor

184 Ignition coils (2nd)

185 Ignition coils (3rd)

186 Ignition coils (4th)

187 Ignition coils (5th) (1998)

189 Variable valve timing

193 I.E. control unit earth

223 Rpm sensors

291 Potentiometer on accelerator pedal

292 Clutch pedal switch

296 Accelerator control lever potentiometer

334 Dual engine temperature sender unit

363 Variable valve timing actuator (998)

364 Motorized throttle body

375 Standardized diagnostic socket

376 Acceleration sensor

55.

55 Front/engine lead connection

1998

* BV n.d

MN 127

' HN 6A

* AR n.d

1 27 Connection between front left cable/cable on relay holder bracket

1998

A1 R n.d.'

HL RN 13

HL BG 190A

A4 AB 190A

HL AG 190A

A6 M3A

HL MN55

HL C n.d. *

J*L MB 4C *

J*L AN n.d.

_§§_ MG 190A

_§£. S 190A

VN3A

66 B190A

_§7_ VG70

R n.d.

C2 BN190A

_2L HL n.d.

C4_ SG n.d.

C5 HRn.fi.'

C6 AR n.d. *

_5L G 190A

A1 R n.d. * B4 S365

HL RN98 B5 VN 98 A3 BV 151 * B6 B365 A4 AB 123 J7_ VG365 J*I

HL AG 122 B8 R 150 A6 M 124 C2 BN365 A7 MN 124 C3 HL98 A8 Cn.d.* C4 SG 98 B1 MB 151 * C5 HR152A* B2 AN 124 C6 AR 152B *

B3 MG 124 C7 G 150*

1 90A Injection/ignition electronic control unit (1998)

1998 3 GV131 22 GN6A 41 BN 127 57 V 167*

6 S 127 24 ZB 291 * 44 VB6A* 59 SB 292 *

7 AN 291 * 25 A n.d* 46 LN6A* 62 AB 127

"U 8 GN 291 * 27 RN n.d. * 47 Cn.d* 63 H 167* "U

9 B 127 30 BG 127 * 48 BV n.d *

13 MG 127 31 G 127* 50 AG 127

15 RV n.d. * 32 BV n.d * 53 BR 375 *

16 BV n.d * 35 L6A* 54 MN 167 *

21 VG376 40 HB 291 * 56 ZN 291 *

32 16

49 33

1 90B Injection/ignition electronic control unit (1998)

1998 1 G n.d. * 17 V n.d. * 32 V184* 52 L165A*

2 G 141B* 19 V162* 33 B n.d. * 54 L 136*

3 G 165* 20 V164* 34 B 141A* 55 L 141 *

4 G 189* 22 V136* 35 B 163* 58 L364*

5 G 132* 23 V141A* 36 B363* 59 L223*

6 G 136A* 24 V364* 38 B 136A*. 60 L141B*

10 G223* 25 V334* 40 B364*

14 G 185* 26 V n.d. * 42 B 168*

15 G 186* 28 V 141B* 49 L n.d. *

16 G 183* 31 V187* 51 L 168*

49 33

* The cables involved in the wiring diagram are marked with an asterisk.

72 Print n° 506.763/23

Page 260 of 330

Electrical equipment

Component location

Marea-Marea Weekend

2000 range ©

55.

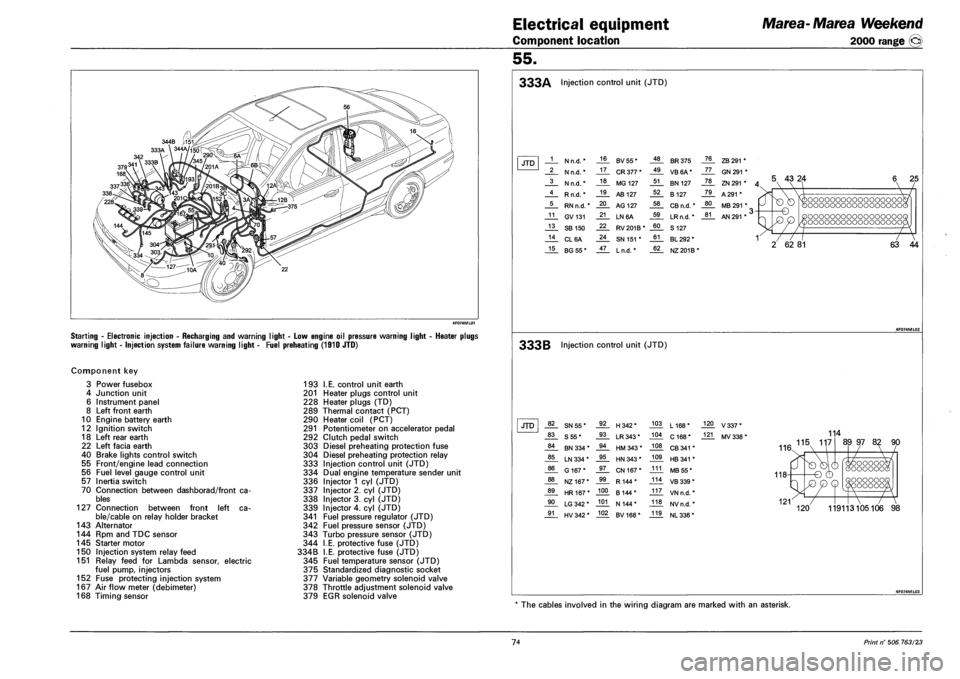

Starting - Electronic injection - Recharging and warning light - Low engine oil pressure warning

warning light - Injection system failure warning light - Fuel preheating (1910 JTD)

ight - Heater plugs

Component key

3 Power fusebox

4 Junction unit

6 Instrument panel

8 Left front earth

10 Engine battery earth

12 Ignition switch

18 Left rear earth

22 Left facia earth

40 Brake lights control switch

55 Front/engine lead connection

56 Fuel level gauge control unit

57 Inertia switch

70 Connection between dashborad/front ca

bles

127 Connection between front left ca

ble/cable on relay holder bracket

143 Alternator

144 Rpm and TDC sensor

145 Starter motor

150 Injection system relay feed

151 Relay feed for Lambda sensor, electric

fuel pump, injectors

152 Fuse protecting injection system

167 Air flow meter (debimeter)

168 Timing sensor

193 I.E. control unit earth

201 Heater plugs control unit

228 Heater plugs (TD)

289 Thermal contact (PCT)

290 Heater coil (PCT)

291 Potentiometer on accelerator pedal

292 Clutch pedal switch

303 Diesel preheating protection fuse

304 Diesel preheating protection relay

333 Injection control unit (JTD)

334 Dual engine temperature sender unit

336 Injector 1 cyl (JTD)

337 Injector 2. cyl (JTD)

338 Injector 3. cyl (JTD)

339 Injector 4. cyl (JTD)

341 Fuel pressure regulator (JTD)

342 Fuel pressure sensor (JTD)

343 Turbo pressure sensor (JTD)

344 I.E. protective fuse (JTD)

334B I.E. protective fuse (JTD)

345 Fuel temperature sensor (JTD)

375 Standardized diagnostic socket

377 Variable geometry solenoid valve

378 Throttle adjustment solenoid valve

379 EGR solenoid valve

333A Injection control unit (JTD)

JTD 1 N n.d. * 16 BV55* 48 BR 375 76 ZB 291 *

2 N n.d. * 17 CR 377 * 49 VB6A* 77 GN 291 *

3 N n.d. * 18 MG 127 51 BN 127 78 ZN 291 * A 4 Rn.d.* 19 AB 127 52 B 127 79 A 291 *

5 RN n.d. * 20 AG 127 58 CB n.d. * 80 MB 291 * ,

11 GV131 21 LN6A 59 LRn.d. * 81 AN 291 * ' >

13 SB 150 22 RV201B* 60 S 127

14 CL6A 24 SN 151 * 61 BL 292 * 1

15 BG55* 47 Ln.d. * 62 NZ 201B*

5 43 24

-o

T7

2 62 81

oooooooooooooooooc oooooooooooooooooc

oooooooooooooooooc oooooooooooooooooc

~7

63 44

333B Injection control unit (JTD)

JTD 82 SN55* 92 H342* 103 L168* 120 V337*

83 S55* 93 LR 343* 104 C 168* 121 MV 338 *

84 BN 334 * 94 HM 343 * 108 CB 341 *

85 LN 334 * 95 HN 343 * 109 HB 341 *

86 G 167* 97 CN 167* 111 MB 55*

88 NZ167* 99 R144* 114 VB 339 *

89 HR167* 100 B 144* 117 VN n.d. *

90 LG 342 * 101 N 144* 118 NVn.d. *

91 HV 342 * 102 BV168* 119 NL 336 *

114

AA 115 117

116.

89 97 82 90

oooooc OOOOOOG OOOOOOO 'OOOOOC

119113105106 98

* The cables involved in the wiring diagram are marked with an asterisk.

74 Print n° 506.763/23

Page 297 of 330

Marea- Marea Weekend

2000 range ©

Electrical equipment

Connector blocks

55.

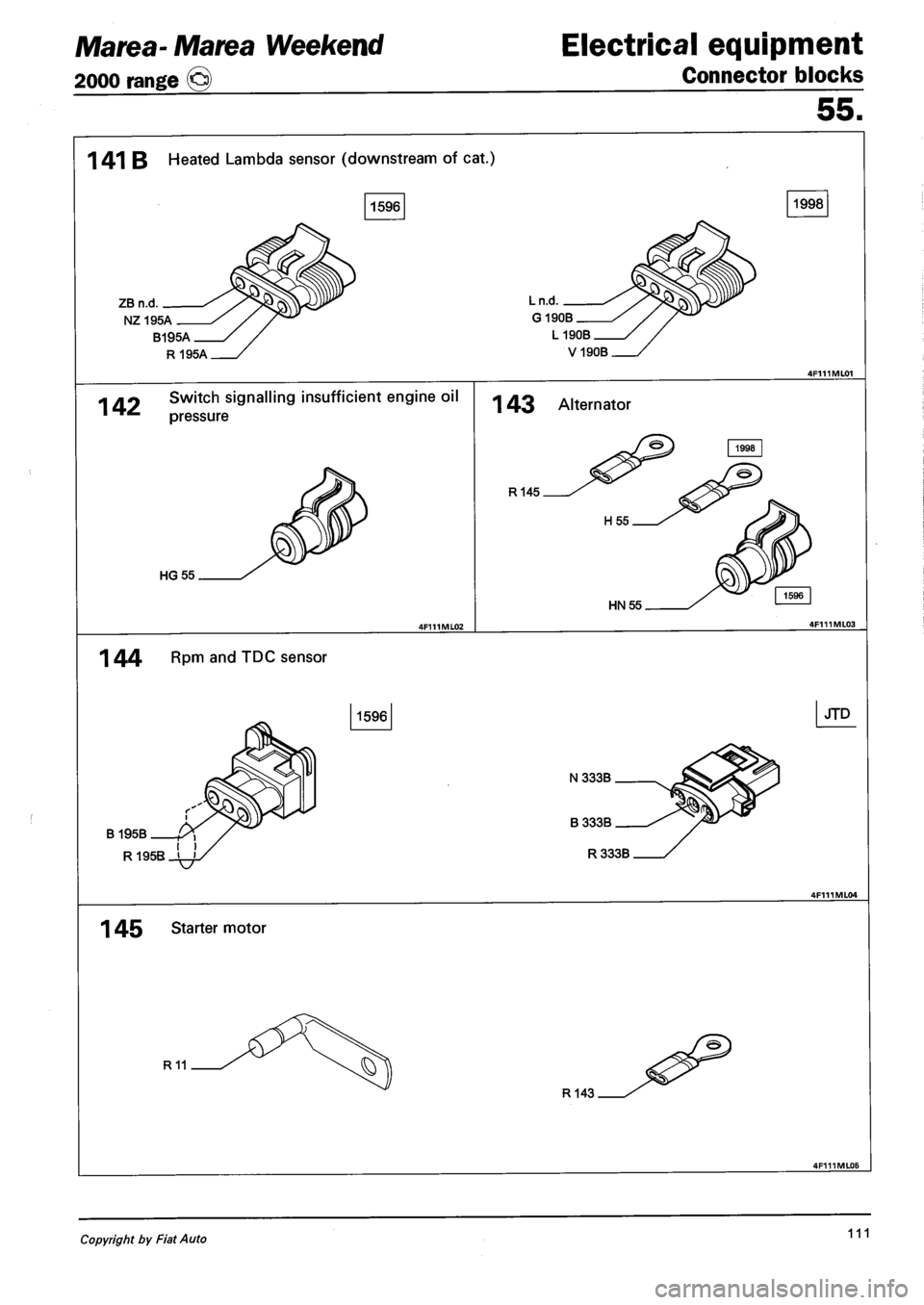

1 41 B Heated Lambda sensor (downstream of cat.)

ZB n.d.

NZ195A

1998

Ln.d.

G190B

B195A

R195A

L 190B

V190B

142 Switch signalling insufficient engine oil

pressure

HG55

143 Alternator

R145

HN55

1 44 RPm and TDC sensor

B195B

1596

N333B

R1QSR ' '

1 45 Starter motor

R11

R143

JTD

Copyright by Fiat Auto 111

Page 329 of 330

A

21

128 Connection between front/radiator cables

129 Engine cooling fan protection power fuse

129A Power fuse protecting engine cooling fan

no.2

131 Fiat-CODE electronic control unit

132 Petrol vapours cut-out solenoid valve

134 Connection between rear/heated driver's

seat cables

135 Connection between rear/heated passenger

seat cables

136 Detonation sensor

136A 2nd Detonation sensor

137 Vehicle speed sensor

138 Idle adjustment actuator

139 Tester socket for injection system

141A Heated Lambda sensor (upstream of cat.)

141B Heated Lambda sensor (downstream of

cat.)

142 Switch signalling insufficient engine oil

pressure

143 Alternator

144 Rev and TDC sensor

145 Starter motor

146 Throttle valve potentiometer

147 Compressor for air conditioning

148 Earth for electronic injection

150 Injection system relay feed

151 Relay feed for Lambda sensor, electric fuel

pump, injectors

152 Fuse protecting injection system

152A Fuse protecting injection system

152B Fuse protecting injection system

154 Engine cooling fan

155 Ignition coil unit

156 Spark plugs

159 Reversing lights control switch

162 Injector (1)

163 Injector (2)

164 Injector (3)

165 Injector (4)

165A Injector (5) (1998)

166 Idle adjustment actuator

167 Air flow meter

168 Timing sensor

170 Resistance for engine cooling fan

174 Power earth for A.B.S.

177 Sensor on left front wheel for A.B.S.

178 Sensor on left rear wheel for A.B.S.

179 Sensor on right front wheel for A.B.S.

180 Sensor on right rear wheel for A.B.S.

181 A.B.S. hydraulic control unit

182A Right brake pad wear sensor cable connec

tion

183 Ignition coil (1°)

184 Ignition coil (2°)

185 Ignition coil (3°)

186 Ignition coil (4°)

187 Ignition coil (5°) (1998)

189 Variable valve timing

190 Injection/ignition electronic control unit

(1998)

193 Earth for electronic injection

194 Injection/injector braid lead connection

195 Injection/ignition electronic control unit

(1596)

199 FIAT CODE aerial

201 Heaer plugs control unit

202 Heater/air conditioning unit symbol lighting

bulbs

206 Car interior climate control fan

209 Intake air flap control actuator

211 Frost sensor

222 Climate control system earth

223 RPM sensor

228 Heater plugs (TD)

231 Clock spring connector

236 Connection betwen rear lead and tail-gate

238 Rear electric windows control unit

239 Connection between Air Bag/left preten

sioner cables

240 Connection between Air Bag/right preten

sioner cables

241 Left pretensioner

242 Right pretensioner

243 Luggage compartment light button

244 Integrated services control system

245 Rear courtesy light

248 Radio controls on steering wheel

252 Connection between automatic transmis

sion/engine cables

253 Air conditioner control unit

254 Climate control system controls with pas

senger compartment temperature sensor

255 Electronic speed governor for climate con

trol fan

256 Air mixture control actuator

257 Fuel pump relay feed

258 Treated air temperature sensor

259 Required temperature adjustment switch

260 MAX-DEF microswitch

261 Tailgate locking/unlocking actuator

262 Seat belts warning light switch

264 Left rear vehicle interior courtesy light

265 Right rear vehicle interior courtesy light

267 Automatic transmission control unit

268 Connection between automatic transmis

sion/front cables

269 Connection between automatic transmis

sion/dashboard cables

270 Connection between automatic transmis

sion/rear cables

271 Kick-down switch

272 Ignition switch solenoid

273 Automatic transmission system protective

fuse

Co