start engine FIAT MAREA 2000 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 11 of 330

Introduction

Performance - Fuel consumption

Marea-Marea Weekend

2000 range ©

OO.o

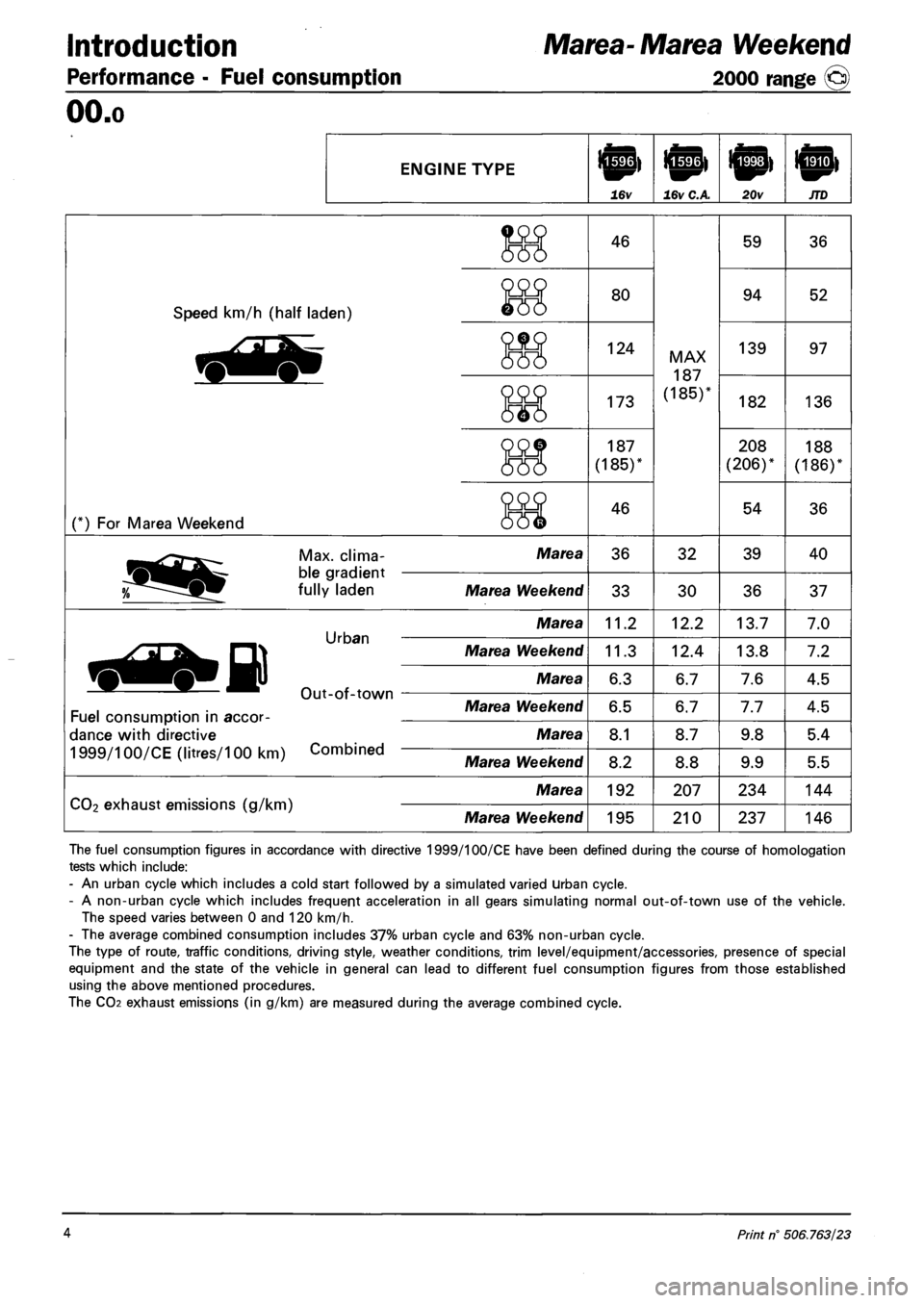

ENGINE TYPE

16v 16v C.A 20v JTD

Speed km/h (half laden)

(*) For Marea Weekend

46

80

124

173

187

(185)'

46

MAX

187

(185)*

59

94

139

182

208

(206)*

54

Max. clima-

ble gradient

fully laden

Marea 36 32 39

Marea Weekend 33 30 36

Urban

Out-of-town

Marea 11.2 12.2 13.7

Marea Weekend 11.3 12.4 13.8

Marea 6.3 6.7 7.6

Fuel consumption in accor

dance with directive

1999/100/CE (litres/100 km) Combined

Marea Weekend 6.5 6.7 7.7

Marea 8.1 8.7 9.8

Marea Weekend 8.2 8.8 9.9

CO2 exhaust emissions (g/km)

Marea 192 207 234

Marea Weekend 195 210 237

The fuel consumption figures in accordance with directive 1999/100/CE have been defined during the course of homologation

tests which include:

- An urban cycle which includes a cold start followed by a simulated varied urban cycle.

- A non-urban cycle which includes frequent acceleration in all gears simulating normal out-of-town use of the vehicle.

The speed varies between 0 and 120 km/h.

- The average combined consumption includes 37% urban cycle and 63% non-urban cycle.

The type of route, traffic conditions, driving style, weather conditions, trim level/equipment/accessories, presence of special

equipment and the state of the vehicle in general can lead to different fuel consumption figures from those established

using the above mentioned procedures.

The CO2 exhaust emissions (in g/km) are measured during the average combined cycle.

4 Print n° 506.763/23

Page 33 of 330

Technical Data Marea-Marea Weekend

Engine: cooling system • fuel system 2000 range (§)

OO.io

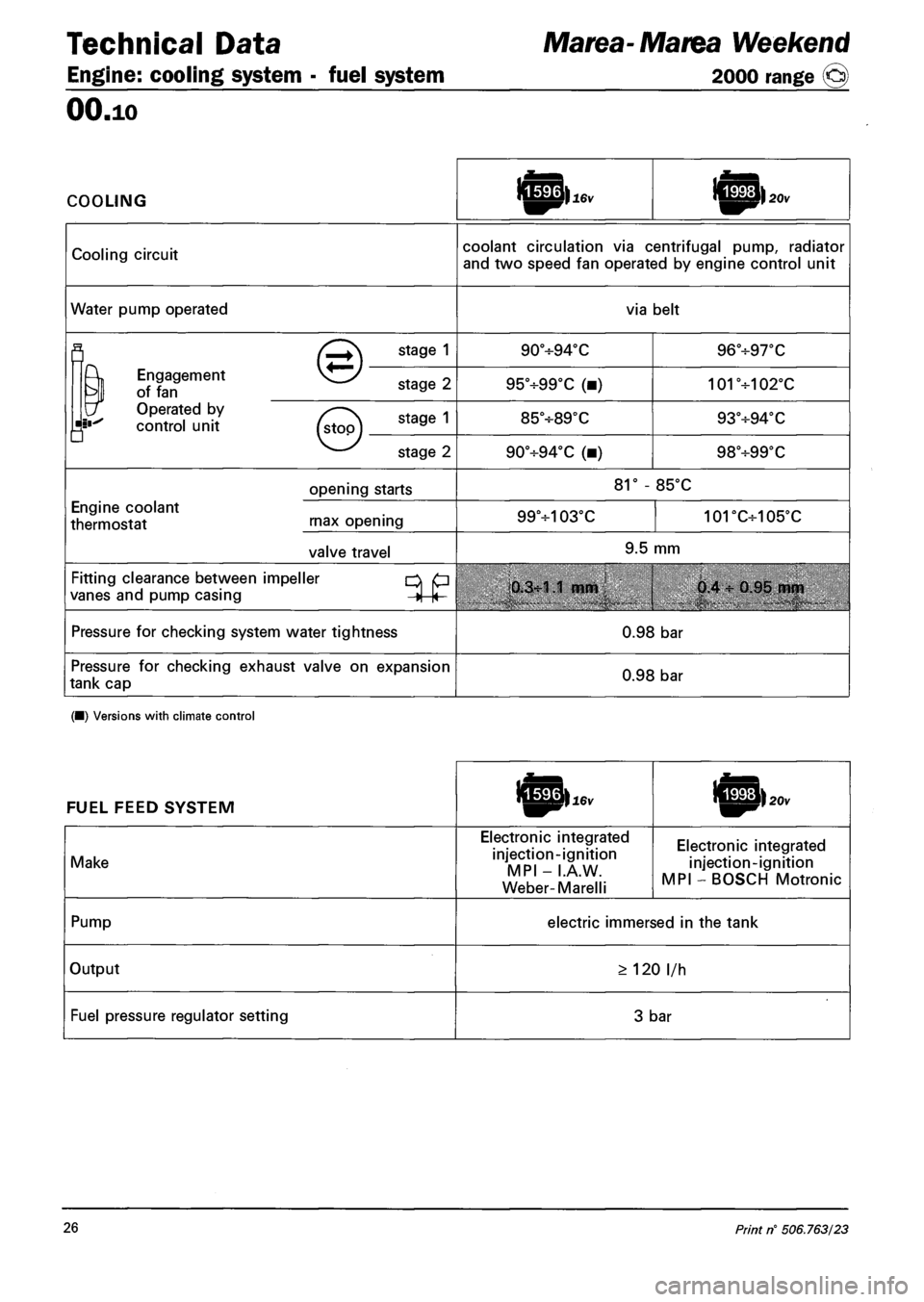

COOLING

Cooling circuit coolant circulation via centrifugal pump, radiator

and two speed fan operated by engine control unit

Water pump operated via belt

fl (^+\ STA9E 1 90°H-94°C 96°+97T

^ Engagement vj^/ ?

of fan stage Z 95°+99°C (•) 101+102°C

\f Operated by v .

control unit (s\oo\ 9 85V89X 93°-H94T

• v y

v—' stage 2 90°+94°C (•) 98+99T

opening starts 81° - 85°C

Engine coolant

thermostat rnax opening 99+103°C 101DC+105'C

valve travel 9.5 mm

Fitting clearance between impeller p

vanes and pump casing j |< 0.3:1.1 mm 0.4 : 0.95 mm

Pressure for checking system water tightness 0.98 bar

Pressure for checking exhaust valve on expansion

tank cap 0.98 bar

(•) Versions with climate control

FUEL FEED SYSTEM

Make

Electronic integrated

injection-ignition

MPI - I.A.W.

Weber-Marelli

Electronic integrated

injection-ignition

MPI - BOSCH Motronic

Pump electric immersed in the tank

Output > 120 l/h

Fuel pressure regulator setting 3 bar

26 Print n° 506.763/23

Page 50 of 330

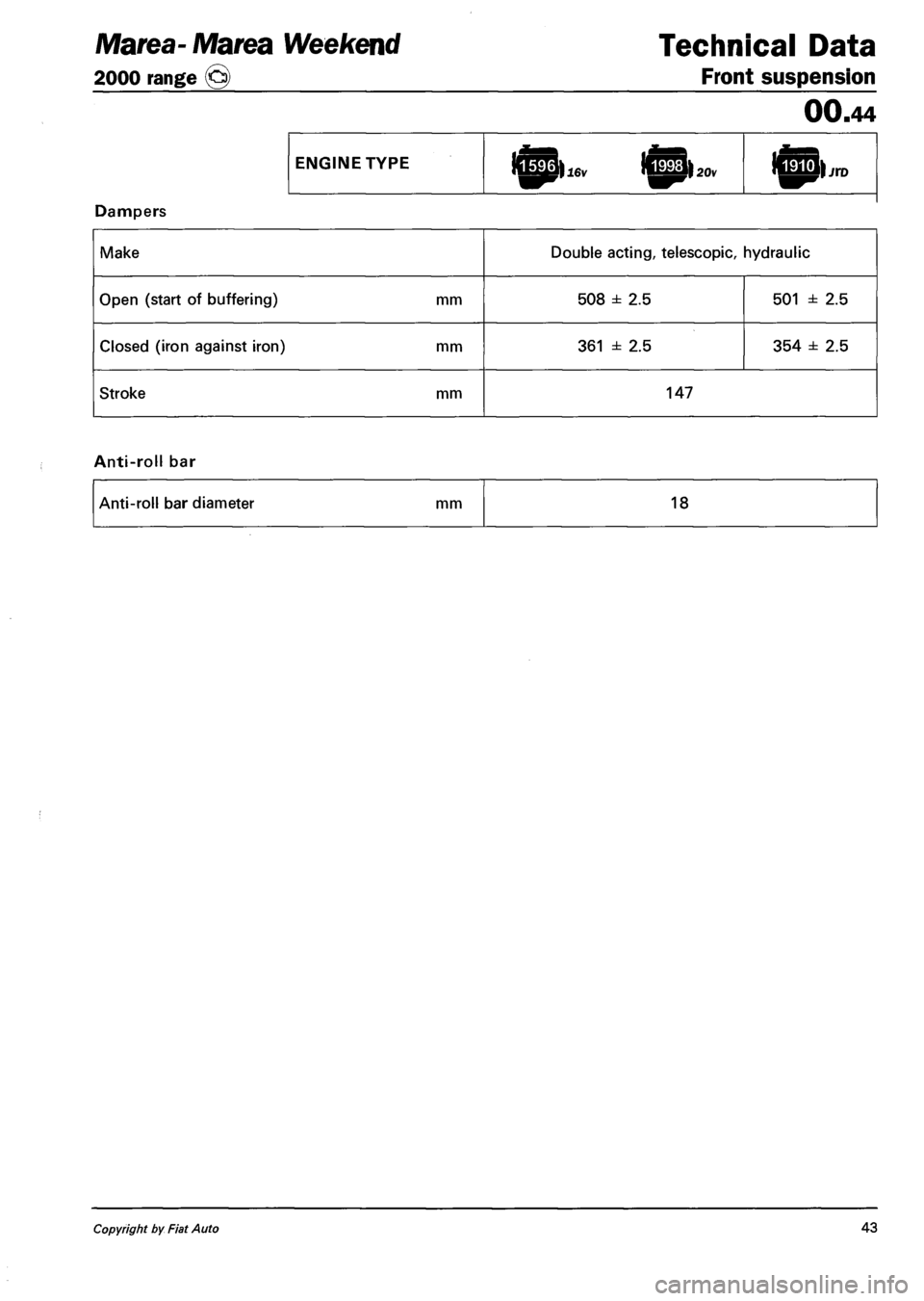

Technical Data

Front suspension

00.44

ENGINE TYPE h|p>jrD

Dampers

Make Double acting, telescopic, hydraulic

Open (start of buffering) mm 508 ± 2.5 501 ± 2.5

Closed (iron against iron) mm 361 ± 2.5 354 ± 2.5

Stroke mm 147

Anti-roll bar

Anti-roll bar diameter mm 18

Marea- Marea Weekend

2000 range ©

Copyright by Fiat Auto 43

Page 51 of 330

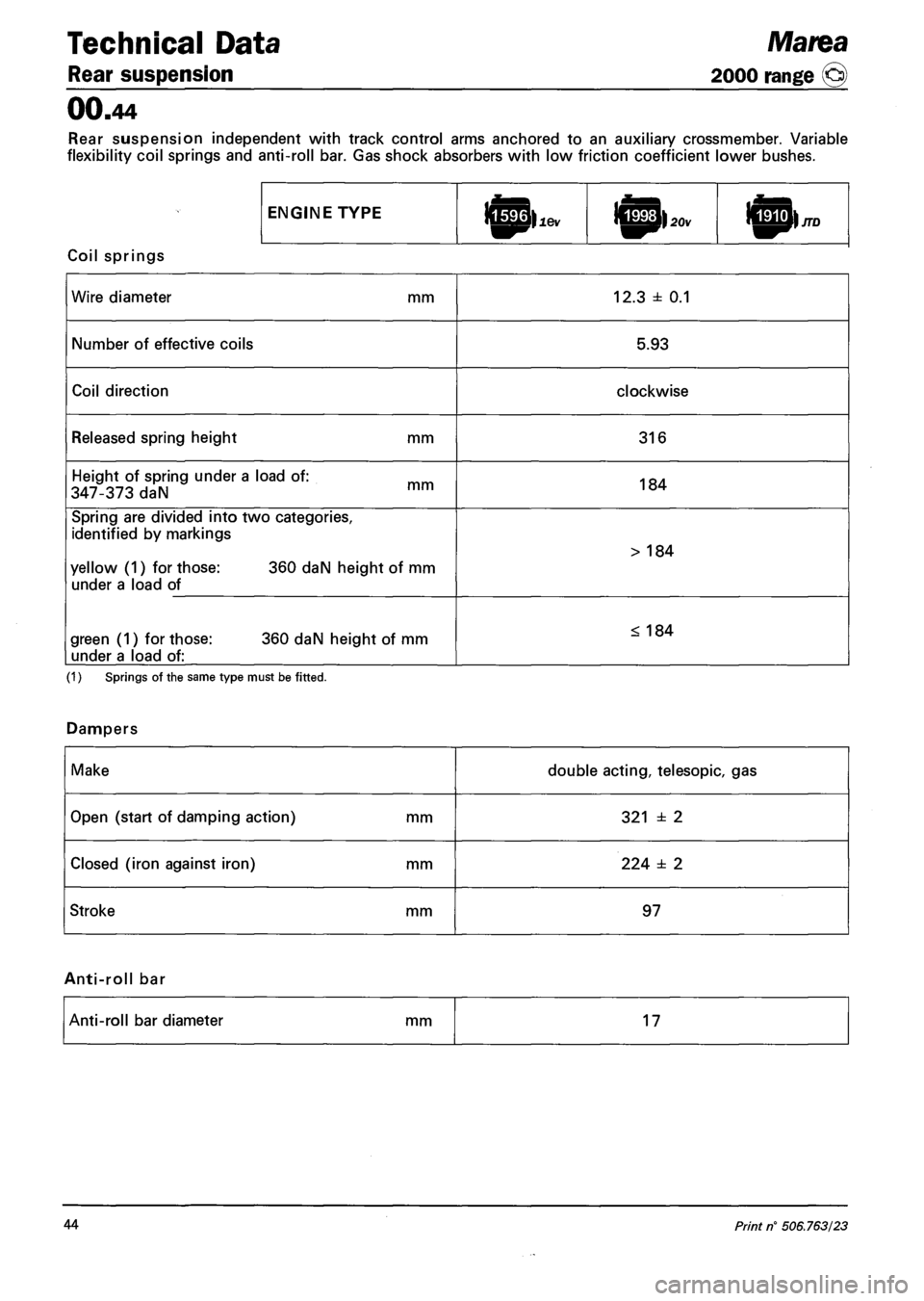

Technical Data Marea

Rear suspension 2000 range (§)

00.44

Rear suspension independent with track control arms anchored to an auxiliary crossmember. Variable

flexibility coil springs and anti-roll bar. Gas shock absorbers with low friction coefficient lower bushes.

ENGINE TYPE lopi lev ICphov

Coil springs

Wire diameter mm 12.3 ± 0.1

Number of effective coils 5.93

Coil direction clockwise

Released spring height mm 316

Height of spring under a load of:

347-373 daN mm 184

Spring are divided into two categories,

identified by markings

yellow (1) for those: 360 daN height of mm

under a load of

> 184

green (1) for those: 360 daN height of mm

under a load of:

< 184

(1) Springs of the same type must be fitted.

Dampers

Make double acting, telesopic, gas

Open (start of damping action) mm 321 ± 2

Closed (iron against iron) mm 224 ± 2

Stroke mm 97

Anti-roll bar

Anti-roll bar diameter mm 17

44 Print n° 506.763/23

Page 52 of 330

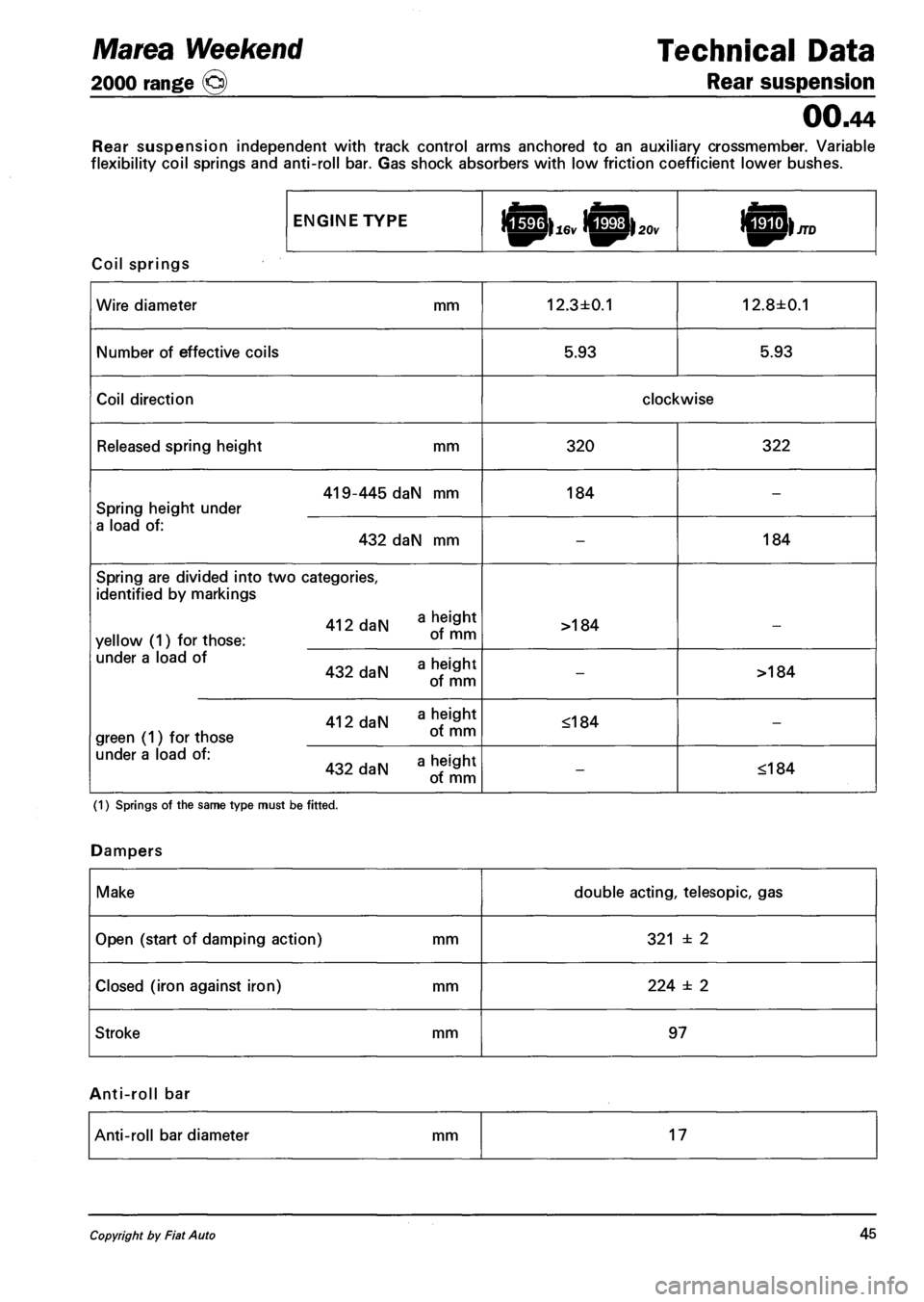

Marea Weekend Technical Data

2000 range o Rear suspension

00.44

Rear suspension independent with track control arms anchored to an auxiliary crossmember. Variable

flexibility coil springs and anti-roll bar. Gas shock absorbers with low friction coefficient lower bushes.

ENGINE TYPE

Coil springs

Wire diameter mm 12.3±0.1 12.8±0.1

Number of effective coils 5.93 5.93

Coil direction clockwise

Released spring height mm 320 322

419-445 daN mm

Spring height under

184 -

a load of:

432 daN mm -184

Spring are divided into two categories,

identified by markings

412 daN

yellow (1) for those: oT mm

>184 _

under a load of hpinht

432 daN a

of mm

->184

412 daN aJS* green (1) for those ot mm

<184 -

under a load of: _ hpiflht 432 daN a "eif£J ot mm -<184

(1) Springs of the same type must be fitted.

Dampers

Make double acting, telesopic, gas

Open (start of damping action) mm 321 ± 2

Closed (iron against iron) mm 224 ± 2

Stroke mm 97

Anti-roll bar

Anti-roll bar diameter mm 17

Copyright by Fiat A uto 45

Page 63 of 330

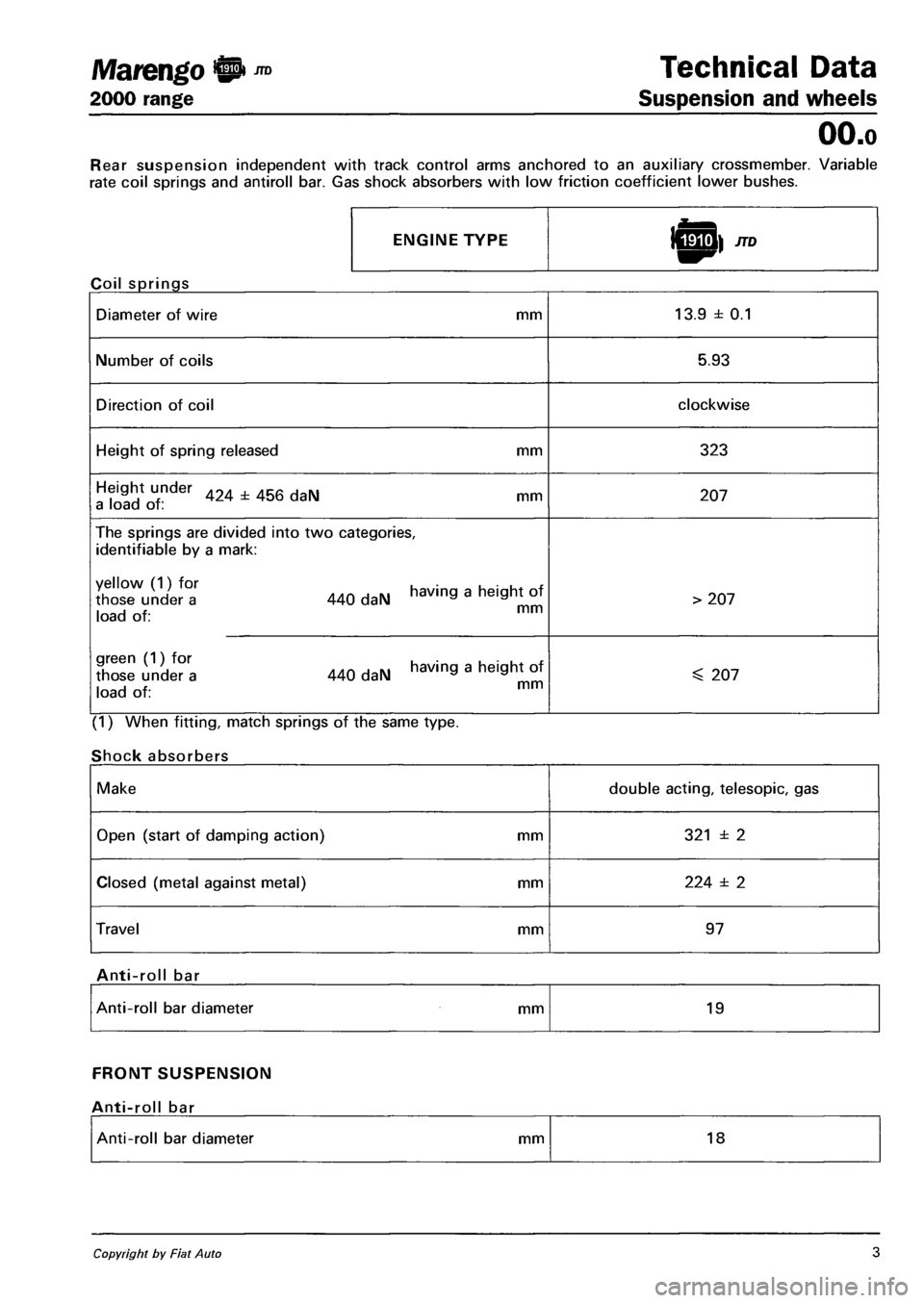

Marengo 0 ™ Technical Data

2000 range Suspension and wheels

OO.o

Rear suspension independent with track control arms anchored to an auxiliary crossmember. Variable

rate coil springs and antiroll bar. Gas shock absorbers with low friction coefficient lower bushes.

ENGINE TYPE

Coil springs

Diameter of wire mm 13.9 ± 0.1

Number of coils 5.93

Direction of coil clockwise

Height of spring released mm 323

Height under 424 ± 456 daN mm a load of : 207

The springs are divided into two categories,

identifiable by a mark:

XX°l 440 daN having a heigh, of i -i x mm load of:

> 207

green (1) for having a height of those under a 440 daN a a i J x. mm load of:

^ 207

(1) When fitting, match springs of the same type.

Shock absorbers

Make double acting, telesopic, gas

Open (start of damping action) mm 321 ± 2

Closed (metal against metal) mm 224 ± 2

Travel mm 97

Anti-roll bar

Anti-roll bar diameter mm 19

FRONT SUSPENSION

Anti-roll bar

Anti-roll bar diameter mm 18

Copyright by Fiat Auto 3

Page 66 of 330

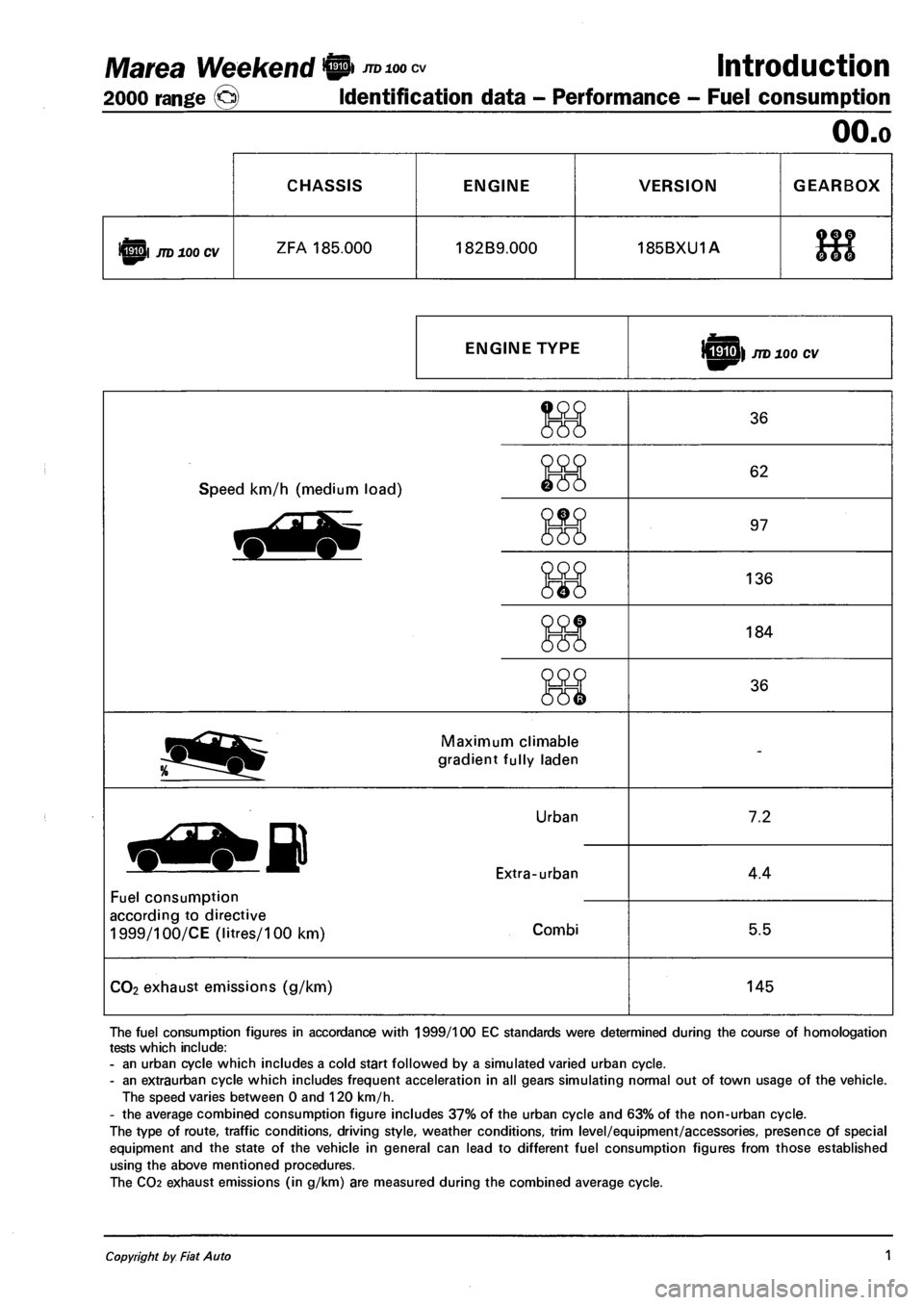

Marea Weekend 9 mnoocv Introduction

2000 range @> Identification data - Performance - Fuel consumption

OO.o

CHASSIS ENGINE VERSION GEARBOX

iQpl JTD 100 CV ZFA 185.000 182B9.000 185BXU1A 9f ?

666

ENGINE TYPE sHU) JTD 100 CV

Speed km/h (medium load)

36

62

97

136

184

36

Maximum climable

gradient fully laden

Fuel consumption

according to directive

1999/100/CE (litres/100 km)

Urban

Extra-urban

Combi

7.2

4.4

5.5

CO2 exhaust emissions (g/km) 145

The fuel consumption figures in accordance with 1999/100 EC standards were determined during the course of homologation

tests which include:

- an urban cycle which includes a cold start followed by a simulated varied urban cycle.

- an extraurban cycle which includes frequent acceleration in all gears simulating normal out of town usage of the vehicle.

The speed varies between 0 and 120 km/h.

- the average combined consumption figure includes 37% of the urban cycle and 63% of the non-urban cycle.

The type of route, traffic conditions, driving style, weather conditions, trim level/equipment/accessories, presence of special

equipment and the state of the vehicle in general can lead to different fuel consumption figures from those established

using the above mentioned procedures.

The CO2 exhaust emissions (in g/km) are measured during the combined average cycle.

Copyright by Fiat Auto 1

Page 89 of 330

Ma tea- Marea Weekend 9 ™

2000 range (Q) Fuel feed system

Engine

10.

Control of injected fuel quantity

The control unit controls the fuel pressure regulator and injectors on the basis of output signals from the

accelerator pedal potentiometer, flow meter and rpm sensor.

The timing and thus the injection sequence are determined when the engine is started up using signals

from the rpm and timing sensor (synchronisation stage); injection timing is then implemented using the

rpm sensor signal alone and considering a injection sequence of 1 -3-4-2.

The control unit inhibits injection in the following cases:

- fuel pressure level greater than 1500 bars;

- fuel pressure level lower than 120 bars;

- engine speed higher than 6000 rpm.

When the engine has warmed up, maximum injection duration (injector opening time) is 1500 ns, but it

can reach 3000 ns during the start-up stage.

Control of injection advance

The electronic control unit determines injection advance mainly on the basis of the quantity of fuel to be

injected.

The injection advance is then corrected on the basis of coolant temperature and speed in order to com

pensate for ignition delays due to low temperatures in the combustion chamber during warm-up.

The optimum injection point is also processed to ensure driving comfort and emission limits laid down by

Euro 3 legislation.

Control of injection pressure

This control is of particular importance because injection pressure influences the following parameters:

- amount of fuel taken into the cylinders for the same injection time duration;

- injected fuel nebulation;

- spray penetration;

- lag between electrical control to injection and actual injection start and end times.

The above parameters engine behaviour significantly, particularly in terms of power output, exhaust emis

sions, noise levels and handling.

The injection control unit controls the pressure governor on the basis of engine load to obtain an optimal

line pressure at all times.

When the engine is cold, injection pressure is corrected on the basis of engine speed and engine coolant

temperature to meet engine needs at different operating temperatures.

Control of auxiliary fuel pump

The auxiliary fuel pump submerged in the tank is supplied by the injection control unit by means of a relay

when the ignition key is turned on.

Fuel supply to the pump is inhibited when one of the following condition occurs:

- when the ignition has been turned on for a certain length of time without the engine running;

- if the inertia switch cuts in.

Control of injection during over-run (cut-off)

The fuel cut-off strategy is implemented when the injection control unit receives information that the ac

celerator pedal has been released from the potentiometer.

Under these conditions, the control unit cuts off the fuel supply to the injectors and restores it before idle

speed is reached.

Copyright by Fiat Auto 3

Page 90 of 330

Fuel feed system

Engine Marea- Marea Weekend 9 ™

2000 range (Q)

10.

Control of idle speed

On the basis of signals from the rpm sensor and engine coolant temperature sensor, the injection control

unit controls the pressure governor and alters the injector control times to maintain idle speed stable at all

times.

Under certain conditions, the idle speed control unit also considers battery voltage.

Control of maximum speed limitation

According to rpm level, the injection control unit limits maximum speed by means of two types of inter

vention:

- as maximum speed approaches, it reduces the amount of fuel injected to reduce line pressure;

- when maximum speed is exceeded, it inhibits operation of the auxiliary pump and injectors.

Control of maximum torque limitation

On the basis of rpm level, the injection control unit computes limit torque and maximum permitted fume

index parameters on the basis of predefined, stored maps.

It then corrects the above parameters using engine coolant temperature and car speed data. The resulting

values are then used to modulate the amount of fuel to be injected by adjusting the pressure regulator and

injectors.

Control of fuel temperature

The injection control uint is kept constantly informed of fuel temperature by a sensor on the return mani

fold.

If fuel temperature exceeds a set value (about 110 °C), the control unit reduces line pressure by adjusting

the pressure governor, leaving injection times unaltered.

Control of coolant temperature

The injection control unit is constantly informed of coolant temperature by a sensor on the thermostat.

If engine coolant temperature or air conditioning fluid pressure exceeds certain levels, the control unit

performs the following actions:

- It reduces the amount of fuel injected by adjusting the pressure governor and injectors (power reduc

tion);

- it controls the engine radiator cooling fan.

Control of glow plugs

The injection control unit controls operation of the glow plug preheating control unit to bring the tem

perature in the combution chambers up to levels that promote fuel self-ignition and thus make start-up

easier.

The control unit controls the operation of the glow plug control unit for a certain time both before (pre

heating) and after (postheating) engine start-up and also controls activation of the warning light on the

control panel.

Preheating, postheating and glow plug warning light activation times vary according to engine coolant

temperature.

4 Publication no. 506.763/24

Page 92 of 330

Fuel feed system

Engine Marea- Marea Weekend © ™

2000 range @

10.

The control unit autodiagnostic system checks the signals coming from the sensors and compares them

with the figures allowed:

- signalling faults during starting

- warning light on for 4 seconds indicates test stage

- warning light off after 4 seconds indicates no fault with components that could alter the pollution con

trol standard figures

- warning light on after 4 seconds indicates fault.

- signalling faults during operation

- warning light on indicates fault

- warning light off indicates no fault with components that could alter the pollution control standard fig

ures.

- recovery

- from time to time, the control unit defines the type of recovery according to the components which are

faulty

- the recovery parameters are managed by components which are not faulty.

Control of cylinder balancing during idling

According to the signals coming from the sensors, the injection control unit controls the idle speed torque,

altering the injector operating times.

Control of irregular operation

Depending on the signals coming from the sensors, the injection control unit corrects the amount of fuel

to be injected in order to improve driveability and reduce jerking whilst driving.

The correction is achieved through the fuel pressure regulator and by varying the injector operating times.

Control of electrical balance

According to the battery voltage, the injection control unit alters the idle speed, to guarantee a sufficient

current supply from the alternator in situations where the consumers are absorbing a great deal of power.

The variation in the idle speed is achived by regulating the fuel pressure and altering the injector operat

ing times.

VGT variable geometry turbocharger control (1910 JTD 110 CV)

The injection control unit processes the signal coming from the supercharging sensor, at the various en

gine operating speeds, and determines the quantity of fuel to be injected, acting on the fuel pressure

regulator and the injector opening times.

In addition, through the solenoid valve, the control unit regulates the geometry of the turbine in order to

ensure optimum performance in all operating conditions.

Turbocharger waste gate valve control (1910 JTD 100 CV)

At the various engine operating speeds, the injection control unit processes the signal coming from the

supercharging sensor and determines the amount of fuel to inject, acting on the fuel pressure regulator

and the injector opening times.

In addition, the control unit controls the opening of the turbocharger waste gate valve, via the solenoid

valve, in order to ensure excellent performance in all operating conditions.

Control of throttle closing when engine is switched off

When the engine is switched off (ignition key in OFF position) the injection control unit closes the throt

tle valve located on the air intake duct via the special solenoid valve.

This action makes it possible to limit the tiresome shuddering of the engine whilst it is switching off.

6 .i. V!-01-.Cancelftand replaces Print n° 506.763/25