warning light FIAT MAREA 2000 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 88 of 330

Engine

Fuel feed system

Marea- Marea Weekend © ™

2000 range ©

10.

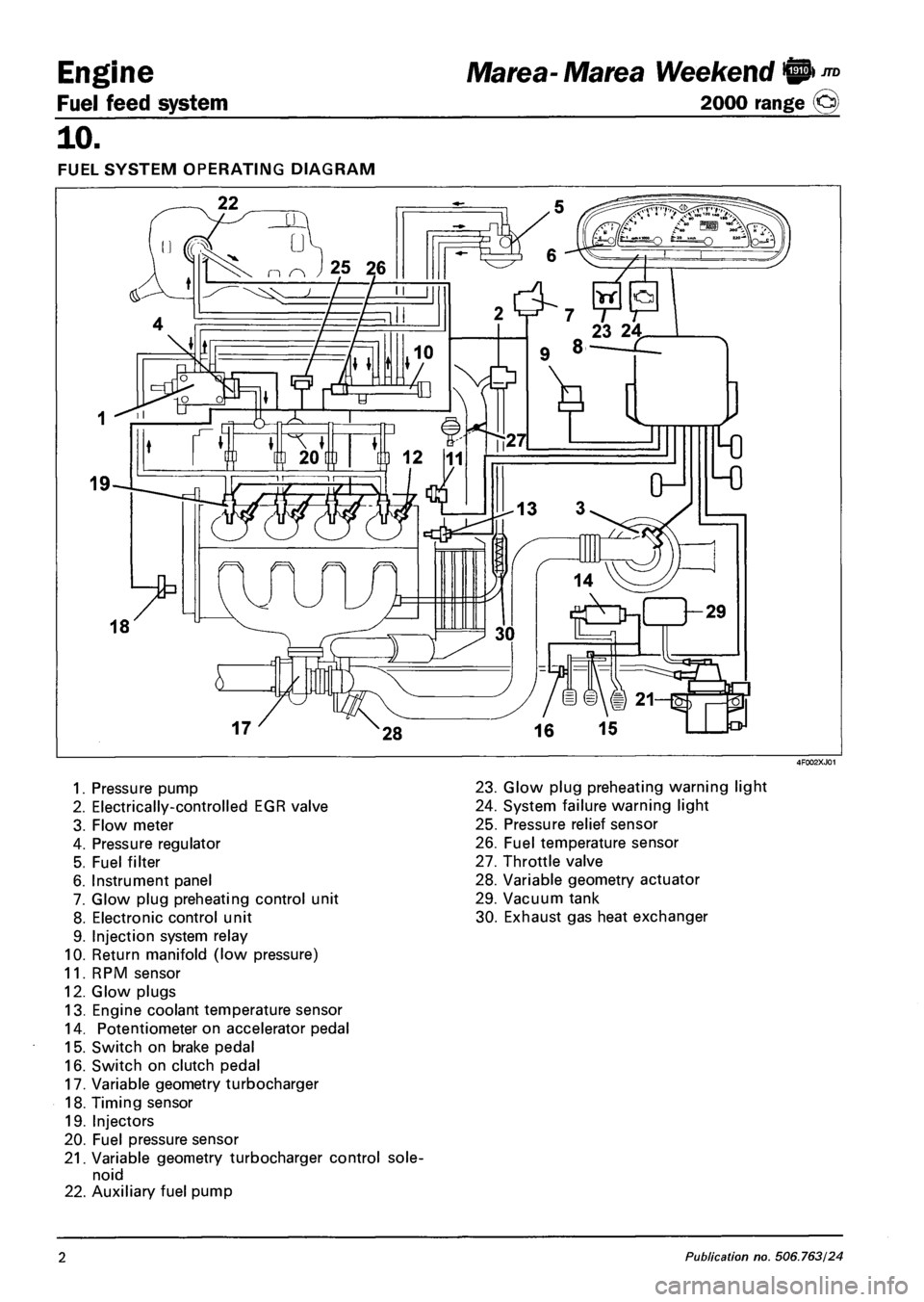

FUEL SYSTEM OPERATING DIAGRAM

1. Pressure pump

2. Electrically-controlled EGR valve

3. Flow meter

4. Pressure regulator

5. Fuel filter

6. Instrument panel

7. Glow plug preheating control unit

8. Electronic control unit

9. Injection system relay

10. Return manifold (low pressure)

11. RPM sensor

12. Glow plugs

13. Engine coolant temperature sensor

14. Potentiometer on accelerator pedal

15. Switch on brake pedal

16. Switch on clutch pedal

17. Variable geometry turbocharger

18. Timing sensor

19. Injectors

20. Fuel pressure sensor

21. Variable geometry turbocharger control sole

noid

22. Auxiliary fuel pump

23. Glow plug preheating warning light

24. System failure warning light

25. Pressure relief sensor

26. Fuel temperature sensor

27. Throttle valve

28. Variable geometry actuator

29. Vacuum tank

30. Exhaust gas heat exchanger

2 Publication no. 506.763/24

Page 90 of 330

Fuel feed system

Engine Marea- Marea Weekend 9 ™

2000 range (Q)

10.

Control of idle speed

On the basis of signals from the rpm sensor and engine coolant temperature sensor, the injection control

unit controls the pressure governor and alters the injector control times to maintain idle speed stable at all

times.

Under certain conditions, the idle speed control unit also considers battery voltage.

Control of maximum speed limitation

According to rpm level, the injection control unit limits maximum speed by means of two types of inter

vention:

- as maximum speed approaches, it reduces the amount of fuel injected to reduce line pressure;

- when maximum speed is exceeded, it inhibits operation of the auxiliary pump and injectors.

Control of maximum torque limitation

On the basis of rpm level, the injection control unit computes limit torque and maximum permitted fume

index parameters on the basis of predefined, stored maps.

It then corrects the above parameters using engine coolant temperature and car speed data. The resulting

values are then used to modulate the amount of fuel to be injected by adjusting the pressure regulator and

injectors.

Control of fuel temperature

The injection control uint is kept constantly informed of fuel temperature by a sensor on the return mani

fold.

If fuel temperature exceeds a set value (about 110 °C), the control unit reduces line pressure by adjusting

the pressure governor, leaving injection times unaltered.

Control of coolant temperature

The injection control unit is constantly informed of coolant temperature by a sensor on the thermostat.

If engine coolant temperature or air conditioning fluid pressure exceeds certain levels, the control unit

performs the following actions:

- It reduces the amount of fuel injected by adjusting the pressure governor and injectors (power reduc

tion);

- it controls the engine radiator cooling fan.

Control of glow plugs

The injection control unit controls operation of the glow plug preheating control unit to bring the tem

perature in the combution chambers up to levels that promote fuel self-ignition and thus make start-up

easier.

The control unit controls the operation of the glow plug control unit for a certain time both before (pre

heating) and after (postheating) engine start-up and also controls activation of the warning light on the

control panel.

Preheating, postheating and glow plug warning light activation times vary according to engine coolant

temperature.

4 Publication no. 506.763/24

Page 92 of 330

Fuel feed system

Engine Marea- Marea Weekend © ™

2000 range @

10.

The control unit autodiagnostic system checks the signals coming from the sensors and compares them

with the figures allowed:

- signalling faults during starting

- warning light on for 4 seconds indicates test stage

- warning light off after 4 seconds indicates no fault with components that could alter the pollution con

trol standard figures

- warning light on after 4 seconds indicates fault.

- signalling faults during operation

- warning light on indicates fault

- warning light off indicates no fault with components that could alter the pollution control standard fig

ures.

- recovery

- from time to time, the control unit defines the type of recovery according to the components which are

faulty

- the recovery parameters are managed by components which are not faulty.

Control of cylinder balancing during idling

According to the signals coming from the sensors, the injection control unit controls the idle speed torque,

altering the injector operating times.

Control of irregular operation

Depending on the signals coming from the sensors, the injection control unit corrects the amount of fuel

to be injected in order to improve driveability and reduce jerking whilst driving.

The correction is achieved through the fuel pressure regulator and by varying the injector operating times.

Control of electrical balance

According to the battery voltage, the injection control unit alters the idle speed, to guarantee a sufficient

current supply from the alternator in situations where the consumers are absorbing a great deal of power.

The variation in the idle speed is achived by regulating the fuel pressure and altering the injector operat

ing times.

VGT variable geometry turbocharger control (1910 JTD 110 CV)

The injection control unit processes the signal coming from the supercharging sensor, at the various en

gine operating speeds, and determines the quantity of fuel to be injected, acting on the fuel pressure

regulator and the injector opening times.

In addition, through the solenoid valve, the control unit regulates the geometry of the turbine in order to

ensure optimum performance in all operating conditions.

Turbocharger waste gate valve control (1910 JTD 100 CV)

At the various engine operating speeds, the injection control unit processes the signal coming from the

supercharging sensor and determines the amount of fuel to inject, acting on the fuel pressure regulator

and the injector opening times.

In addition, the control unit controls the opening of the turbocharger waste gate valve, via the solenoid

valve, in order to ensure excellent performance in all operating conditions.

Control of throttle closing when engine is switched off

When the engine is switched off (ignition key in OFF position) the injection control unit closes the throt

tle valve located on the air intake duct via the special solenoid valve.

This action makes it possible to limit the tiresome shuddering of the engine whilst it is switching off.

6 .i. V!-01-.Cancelftand replaces Print n° 506.763/25

Page 93 of 330

Marea- Marea Weekend 9 ™

2000 range ©

Engine

Fuel feed system

10.

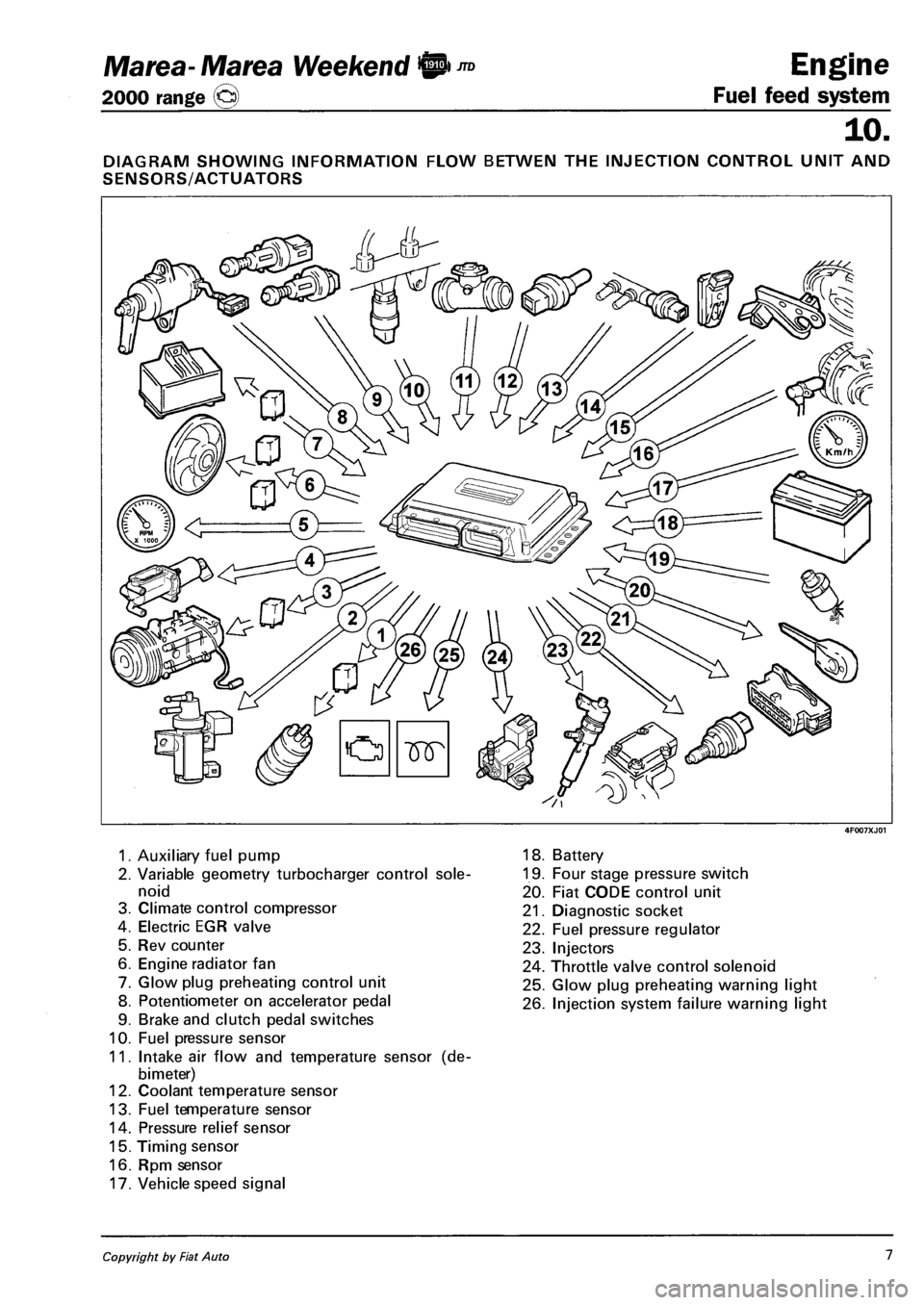

DIAGRAM SHOWING INFORMATION FLOW BETWEN THE INJECTION CONTROL UNIT AND

SENSORS/ACTUATORS

1. Auxiliary fuel pump

2. Variable geometry turbocharger control sole

noid

3. Climate control compressor

4. Electric EGR valve

5. Rev counter

6. Engine radiator fan

7. Glow plug preheating control unit

8. Potentiometer on accelerator pedal

9. Brake and clutch pedal switches

10. Fuel pressure sensor

11. Intake air flow and temperature sensor (de-

bimeter)

12. Coolant temperature sensor

13. Fuel temperature sensor

14. Pressure relief sensor

15. Timing sensor

16. Rpm sensor

17. Vehicle speed signal

18. Battery

19. Four stage pressure switch

20. Fiat CODE control unit

21. Diagnostic socket

22. Fuel pressure regulator

23. Injectors

24. Throttle valve control solenoid

25. Glow plug preheating warning light

26. Injection system failure warning light

Copyright by Fiat Auto 1

Page 95 of 330

Marea- Marea Weekend 9 ™

2000 range ©) Fuel feed system

Engine

10.

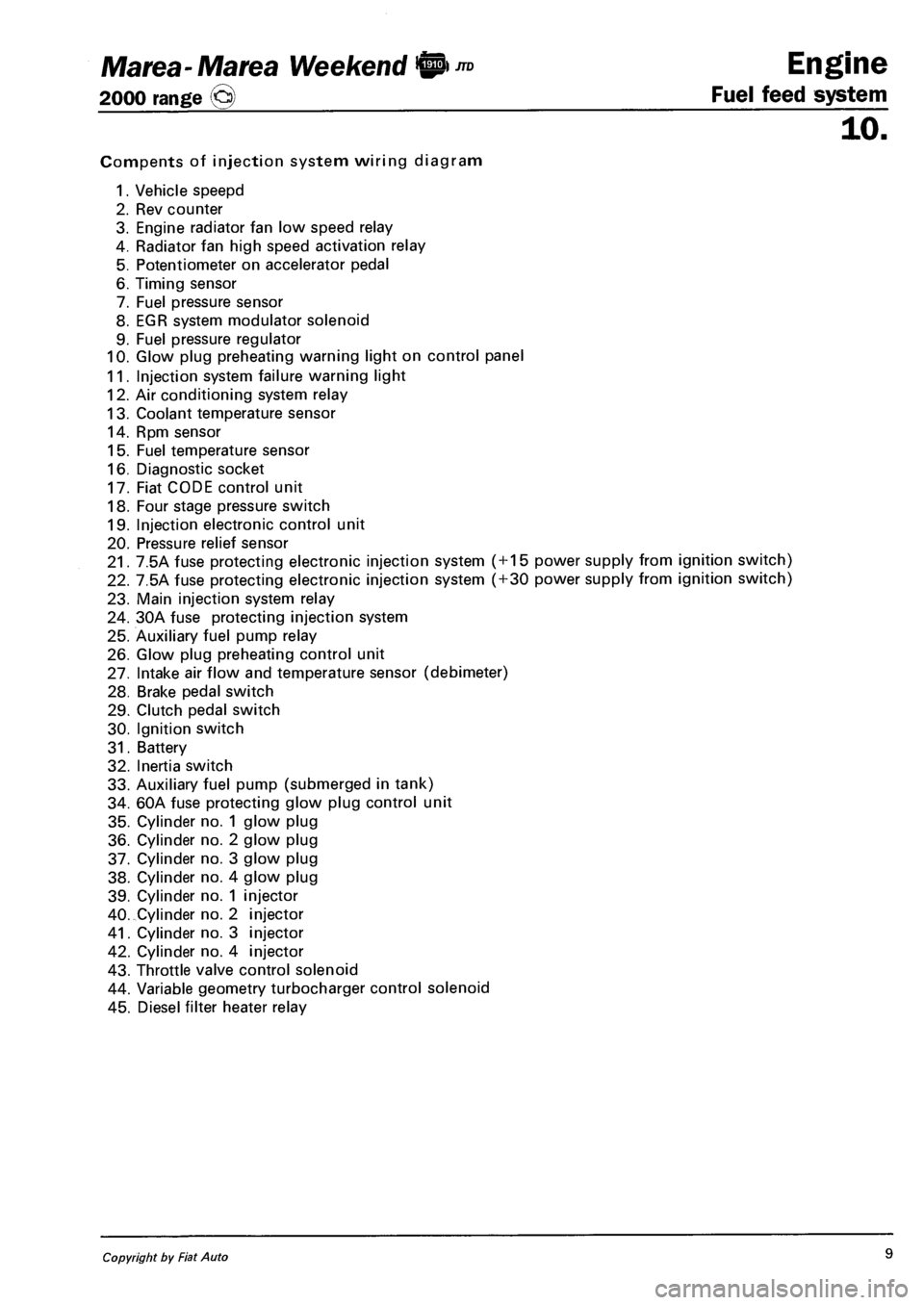

Compents of injection system wiring diagram

1. Vehicle speepd

2. Rev counter

3. Engine radiator fan low speed relay

4. Radiator fan high speed activation relay

5. Potentiometer on accelerator pedal

6. Timing sensor

7. Fuel pressure sensor

8. EGR system modulator solenoid

9. Fuel pressure regulator

10. Glow plug preheating warning light on control panel

11. Injection system failure warning light

12. Air conditioning system relay

13. Coolant temperature sensor

14. Rpm sensor

15. Fuel temperature sensor

16. Diagnostic socket

17. Fiat CODE control unit

18. Four stage pressure switch

19. Injection electronic control unit

20. Pressure relief sensor

21. 7.5A fuse protecting electronic injection system ( + 15 power supply from ignition switch)

22. 7.5A fuse protecting electronic injection system ( + 30 power supply from ignition switch)

23. Main injection system relay

24. 30A fuse protecting injection system

25. Auxiliary fuel pump relay

26. Glow plug preheating control unit

27. Intake air flow and temperature sensor (debimeter)

28. Brake pedal switch

29. Clutch pedal switch

30. Ignition switch

31. Battery

32. Inertia switch

33. Auxiliary fuel pump (submerged in tank)

34. 60A fuse protecting glow plug control unit

35. Cylinder no. 1 glow plug

36. Cylinder no. 2 glow plug

37. Cylinder no. 3 glow plug

38. Cylinder no. 4 glow plug

39. Cylinder no. 1 injector

40. Cylinder no. 2 injector

41. Cylinder no. 3 injector

42. Cylinder no. 4 injector

43. Throttle valve control solenoid

44. Variable geometry turbocharger control solenoid

45. Diesel filter heater relay

Copyright by Fiat Auto 9

Page 96 of 330

Engine Marea- Marea Weekend 9 ™

Fuel feed system 2000 range @

10.

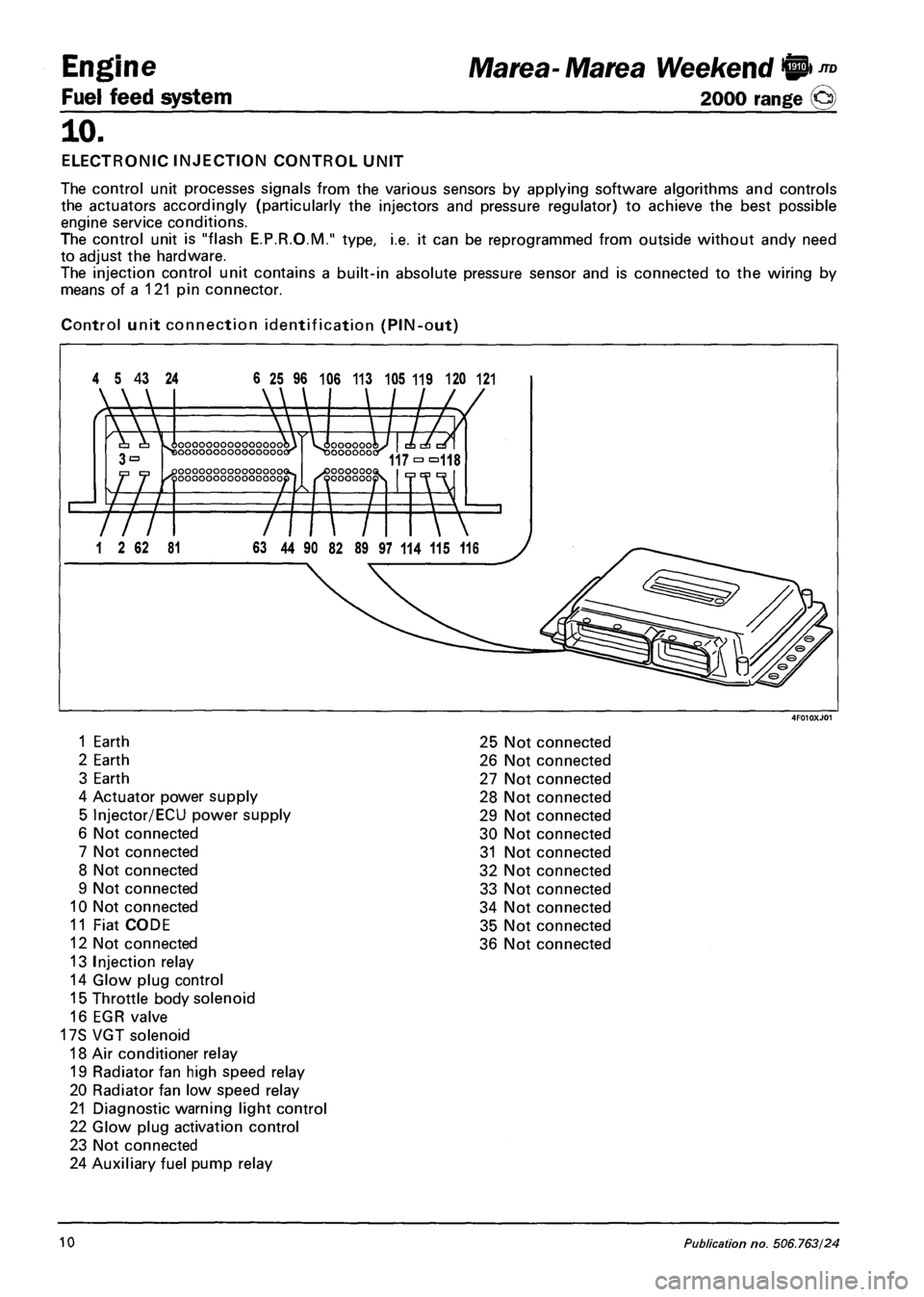

ELECTRONIC INJECTION CONTROL UNIT

The control unit processes signals from the various sensors by applying software algorithms and controls

the actuators accordingly (particularly the injectors and pressure regulator) to achieve the best possible

engine service conditions.

The control unit is "flash E.P.R.O.M." type, i.e. it can be reprogrammed from outside without andy need

to adjust the hardware.

The injection control unit contains a built-in absolute pressure sensor and is connected to the wiring by

means of a 121 pin connector.

Control unit connection identification (PIN-out)

4 5 43 24 6 25 96 106 113 105 119 120 121

1 Earth 25 Not connected

2 Earth 26 Not connected

3 Earth 27 Not connected

4 Actuator power supply 28 Not connected

5 Injector/ECU power supply 29 Not connected

6 Not connected 30 Not connected

7 Not connected 31 Not connected

8 Not connected 32 Not connected

9 Not connected 33 Not connected

10 Not connected 34 Not connected

11 Fiat CODE 35 Not connected

12 Not connected 36 Not connected

13 Injection relay

14 Glow plug control

15 Throttle body solenoid

16 EGR valve

17S VGT solenoid

18 Air conditioner relay

19 Radiator fan high speed relay

20 Radiator fan low speed relay

21 Diagnostic warning light control

22 Glow plug activation control

23 Not connected

24 Auxiliary fuel pump relay

10 Publication no. 506.763/24

Page 105 of 330

Marea- Marea Weekend 9 ™

2000 range (Q)

4F019XJ01

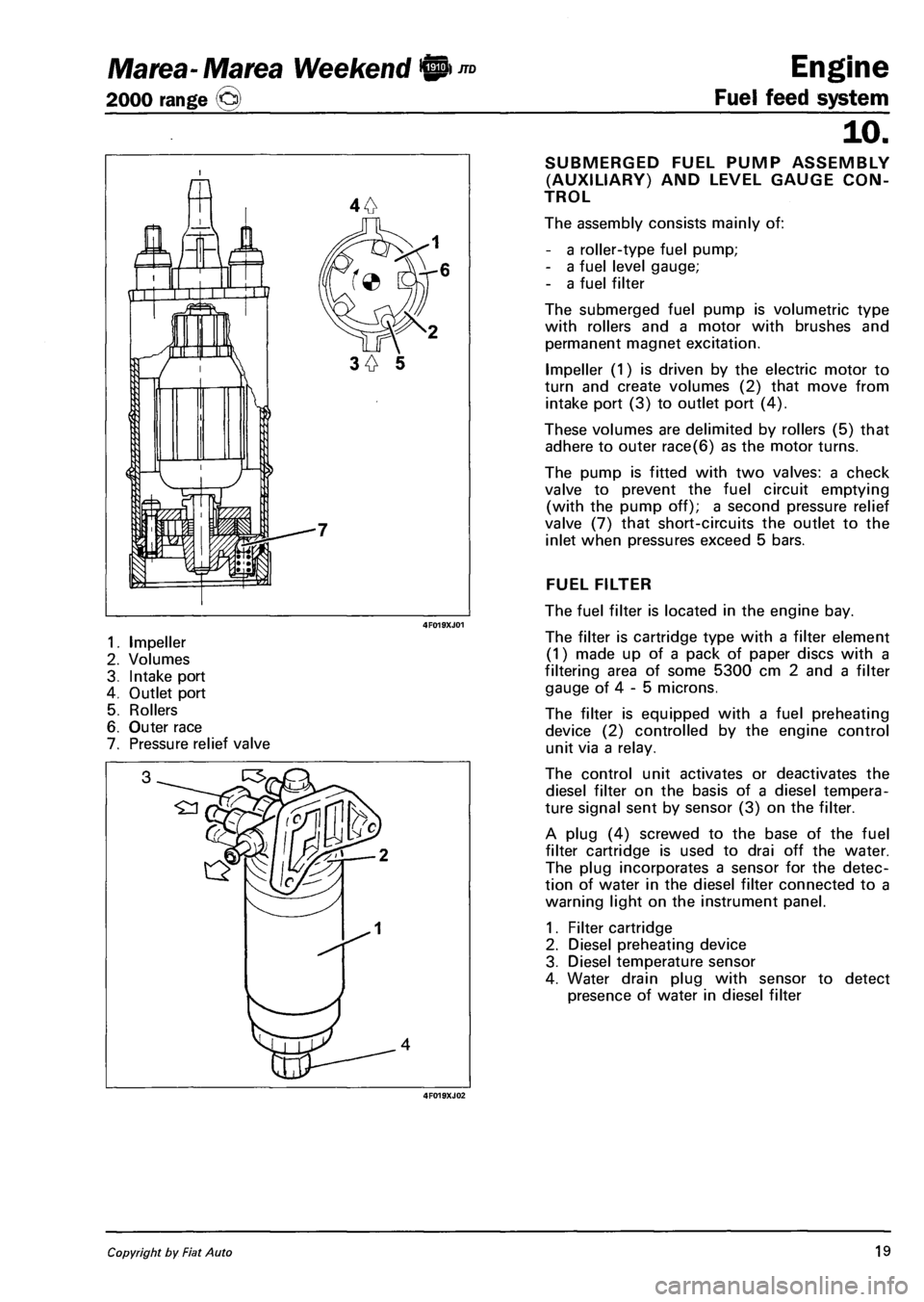

1. Impeller

2. Volumes

3. Intake port

4. Outlet port

5. Rollers

6. Outer race

7. Pressure relief valve

4F019XJ02

Engine

Fuel feed system

10.

SUBMERGED FUEL PUMP ASSEMBLY

(AUXILIARY) AND LEVEL GAUGE CON

TROL

The assembly consists mainly of:

- a roller-type fuel pump;

- a fuel level gauge;

- a fuel filter

The submerged fuel pump is volumetric type

with rollers and a motor with brushes and

permanent magnet excitation.

Impeller (1) is driven by the electric motor to

turn and create volumes (2) that move from

intake port (3) to outlet port (4).

These volumes are delimited by rollers (5) that

adhere to outer race(6) as the motor turns.

The pump is fitted with two valves: a check

valve to prevent the fuel circuit emptying

(with the pump off); a second pressure relief

valve (7) that short-circuits the outlet to the

inlet when pressures exceed 5 bars.

FUEL FILTER

The fuel filter is located in the engine bay.

The filter is cartridge type with a filter element

(1) made up of a pack of paper discs with a

filtering area of some 5300 cm 2 and a filter

gauge of 4 - 5 microns.

The filter is equipped with a fuel preheating

device (2) controlled by the engine control

unit via a relay.

The control unit activates or deactivates the

diesel filter on the basis of a diesel tempera

ture signal sent by sensor (3) on the filter.

A plug (4) screwed to the base of the fuel

filter cartridge is used to drai off the water.

The plug incorporates a sensor for the detec

tion of water in the diesel filter connected to a

warning light on the instrument panel.

1. Filter cartridge

2. Diesel preheating device

3. Diesel temperature sensor

4. Water drain plug with sensor to detect

presence of water in diesel filter

Copyright by Fiat Auto 19

Page 136 of 330

Electrical system

Junction unit

Marea- Marea Weekend

2000 range ©

55. 55.

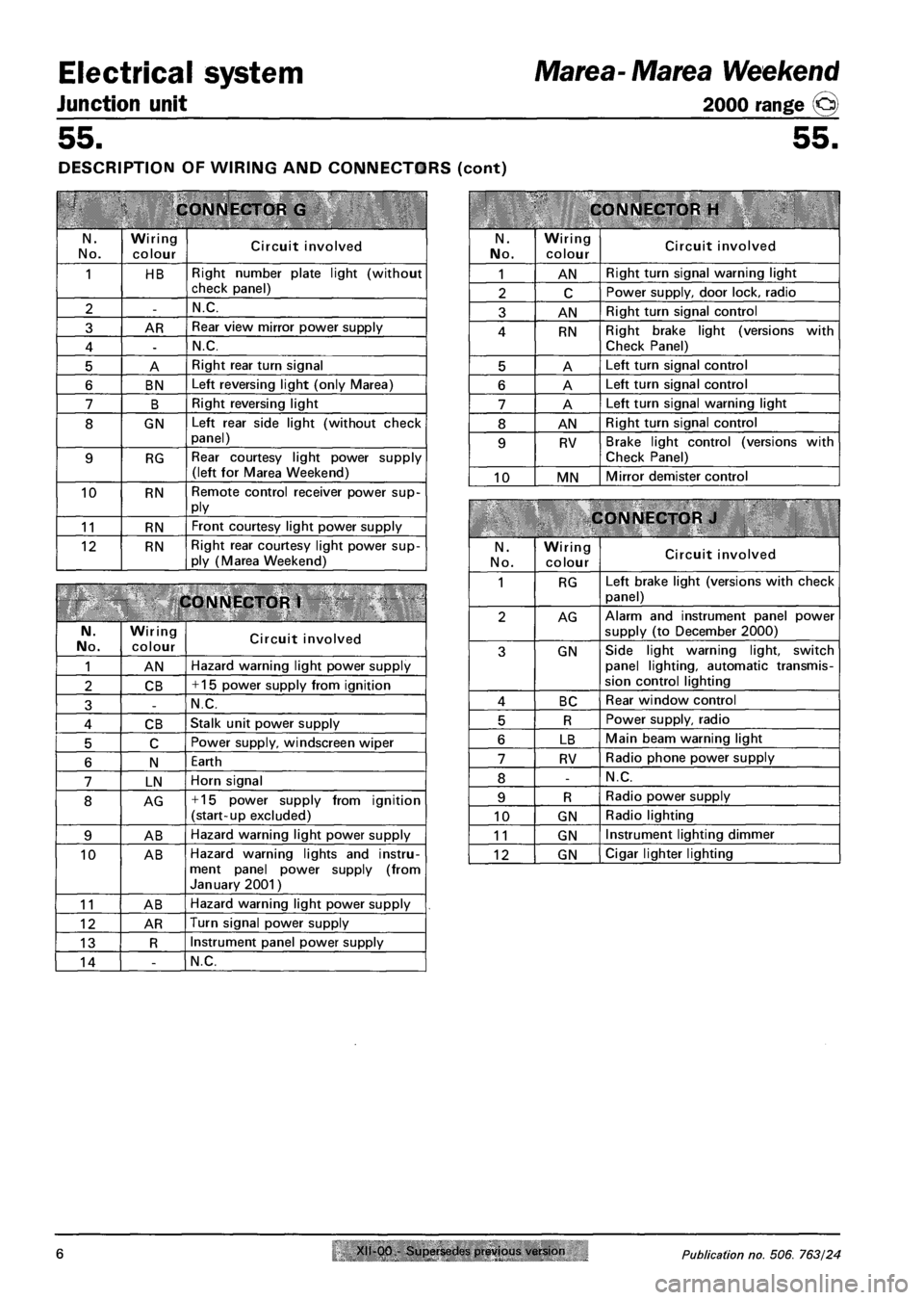

DESCRIPTION OF WIRING AND CONNECTORS (cont)

CONNECTOR G

N.

No.

Wiring

colour Circuit involved

1 HB Right number plate light (without check panel)

2 -N.C.

3 AR Rear view mirror power supply

4 -N.C.

5 A Right rear turn signal

6 BN Left reversing light (only Marea)

7 B Right reversing light

8 GN Left rear side light (without check panel)

9 RG Rear courtesy light power supply (left for Marea Weekend)

10 RN Remote control receiver power supply

11 RN Front courtesy light power supply

12 RN Right rear courtesy light power supply (Marea Weekend)

CONNECTOR 1

N. No. Wiring

colour Circuit involved

1 AN Hazard warning light power supply

2 CB + 15 power supply from ignition

3 -N.C.

4 CB Stalk unit power supply

5 C Power supply, windscreen wiper

6 N Earth

7 LN Horn signal

8 AG + 15 power supply from ignition (start-up excluded)

9 AB Hazard warning light power supply

10 AB Hazard warning lights and instrument panel power supply (from January 2001)

11 AB Hazard warning light power supply

12 AR Turn signal power supply

13 R Instrument panel power supply

14 -N.C.

CONNECTOR H

N.

No.

Wiring

colour Circuit involved

1 AN Right turn signal warning light

2 C Power supply, door lock, radio

3 AN Right turn signal control

4 RN Right brake light (versions with Check Panel)

5 A Left turn signal control

6 A Left turn signal control

7 A Left turn signal warning light

8 AN Right turn signal control

9 RV Brake light control (versions with

Check Panel)

10 MN Mirror demister control

CONNECTOR J

N.

No.

Wiring colour Circuit involved

1 RG Left brake light (versions with check

panel)

2 AG Alarm and instrument panel power

supply (to December 2000)

3 GN Side light warning light, switch panel lighting, automatic transmission control lighting

4 BC Rear window control

5 R Power supply, radio

6 LB Main beam warning light

7 RV Radio phone power supply

8 -N.C.

9 R Radio power supply

10 GN Radio lighting

11 GN Instrument lighting dimmer

12 GN Cigar lighter lighting

6 Publication no. 506. 763/24

Page 137 of 330

Marea-Marea Weekend Electrical system

2000 range @ Junction unit

55.

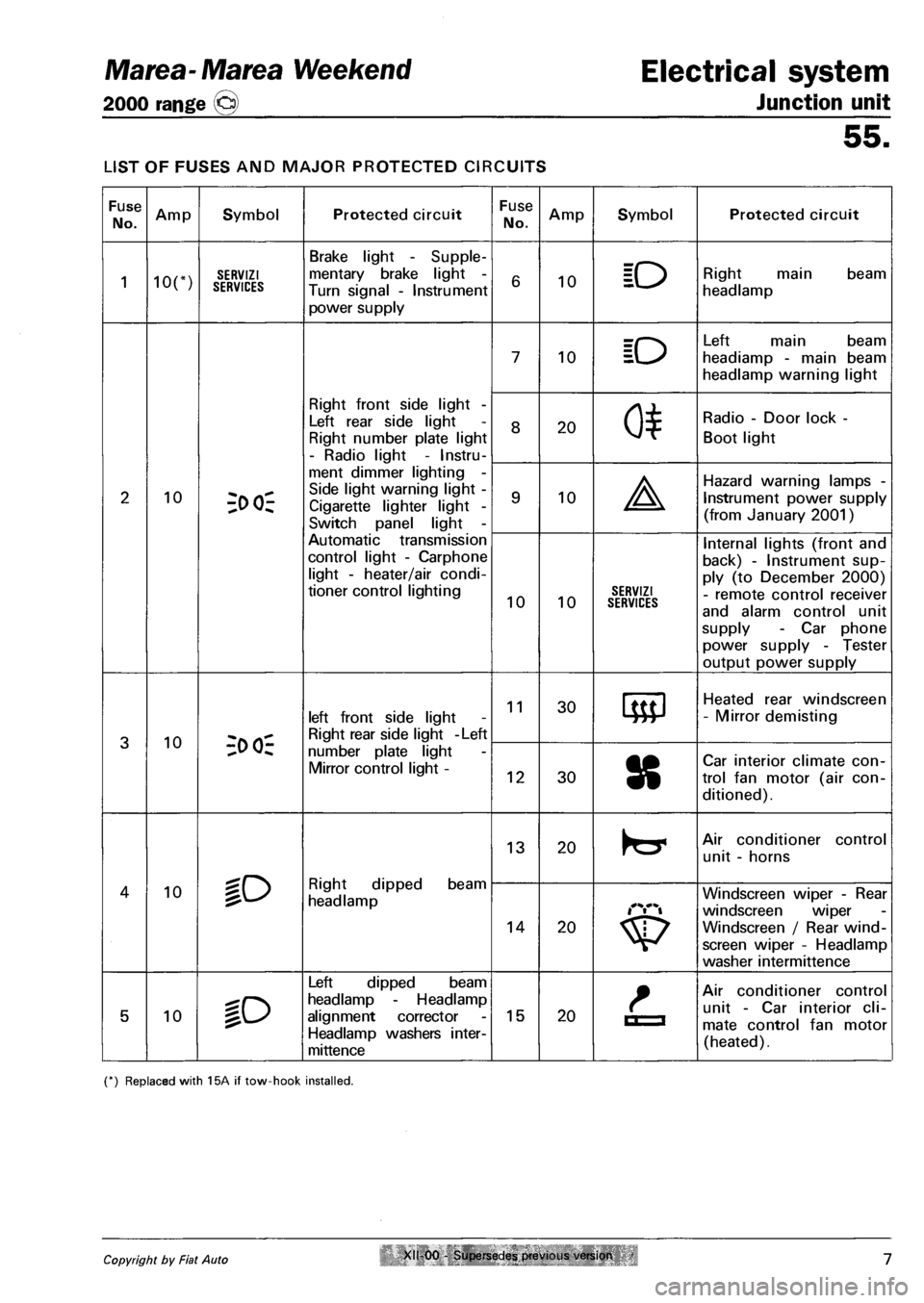

LIST OF FUSES AND MAJOR PROTECTED CIRCUITS

Fuse

No. Amp Symbol Protected circuit Fuse

No. Amp Symbol Protected circuit

1 ion SERVIZI SERVICES

Brake light - Supple

mentary brake light -

Turn signal - Instrument

power supply

6 10 ID Right main beam

headlamp

7 10 ID

Left main beam

headiamp - main beam

headlamp warning light

Right front side light -

Left rear side light

Right number plate light

- Radio light - Instru

8 20 0*

Radio - Door lock -

Boot light

2 10 3>

Side light warning light -

Cigarette lighter light -

Switch panel light -

9 10 A

Hazard warning lamps -

Instrument power supply

(from January 2001)

Automatic transmission

control light - Carphone

light - heater/air condi

tioner control lighting 10 10 SERVIZI SERVICES

Internal lights (front and

back) - Instrument sup

ply (to December 2000)

- remote control receiver

and alarm control unit

supply - Car phone

power supply - Tester

output power supply

3 10 -;o oi-

left front side light

Right rear side light -Left

11 30 Heated rear windscreen

- Mirror demisting

3 10 -;o oi-number plate light

Mirror control light -12 30 8

Car interior climate con

trol fan motor (air con

ditioned).

lO Right dipped beam

headlamp

13 20 Air conditioner control

unit - horns

4 10 lO Right dipped beam

headlamp

14 20

Windscreen wiper - Rear

windscreen wiper

Windscreen / Rear wind

screen wiper - Headlamp

washer intermittence

5 10 %o

Left dipped beam

headlamp - Headlamp

alignment corrector

Headlamp washers inter-

mittence

15 20 La

Air conditioner control

unit - Car interior cli

mate control fan motor

(heated).

(*) Replaced with 15A if tow-hook installed.

Copyright by Fiat Auto XII 00 - Supersedes previous version 7

Page 141 of 330

Marea-Marea Weekend Electrical equipment

2000 range (§) Location of components on the car

55.

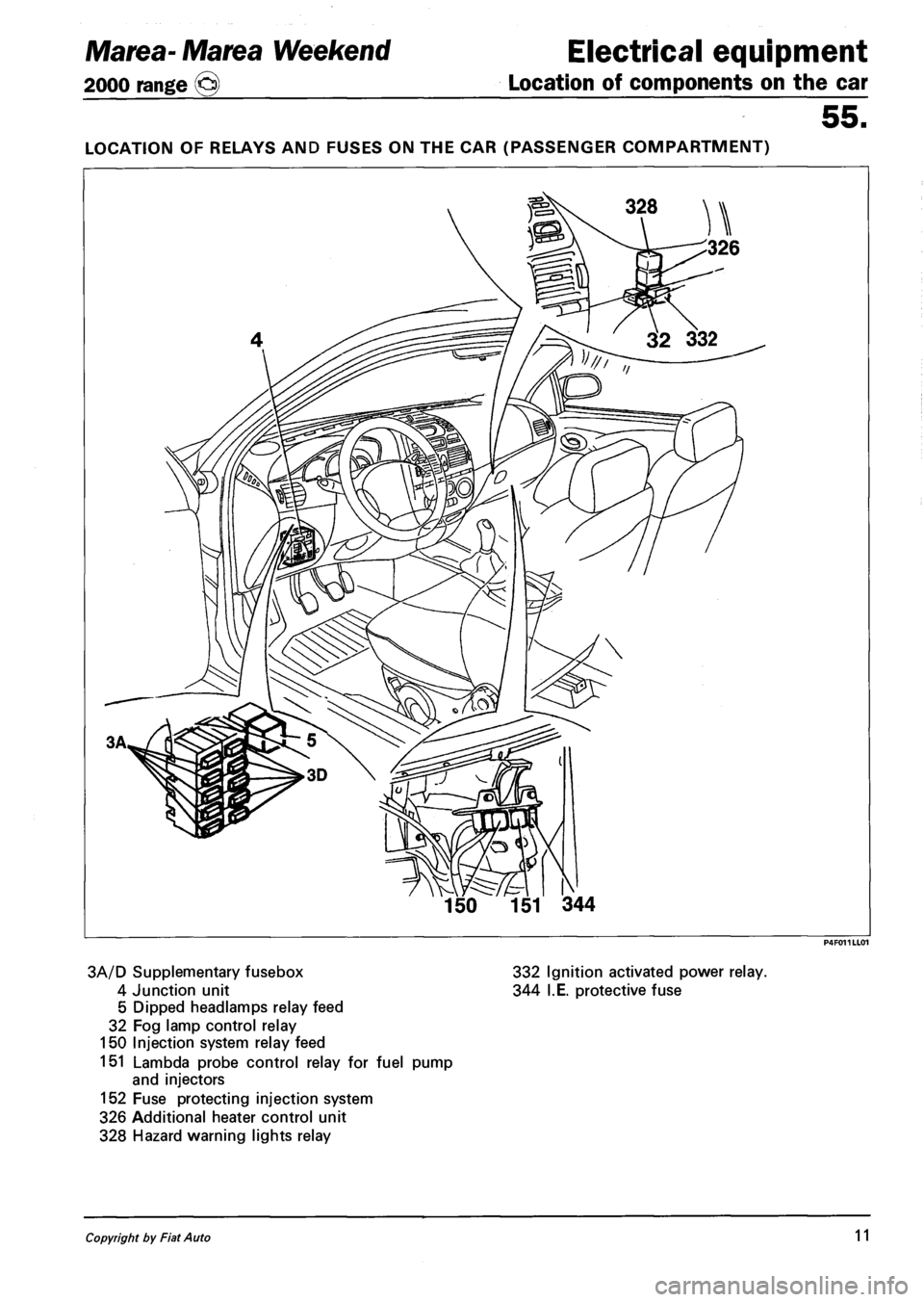

LOCATION OF RELAYS AND FUSES ON THE CAR (PASSENGER COMPARTMENT)

3A/D Supplementary fusebox 332 Ignition activated power relay.

4 Junction unit 344 I.E. protective fuse

5 Dipped headlamps relay feed

32 Fog lamp control relay

150 Injection system relay feed

151 Lambda probe control relay for fuel pump

and injectors

152 Fuse protecting injection system

326 Additional heater control unit

328 Hazard warning lights relay

Copyright by Fiat Auto 11