Fuel injection FIAT MAREA 2001 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2001, Model line: MAREA, Model: FIAT MAREA 2001 1.GPages: 330

Page 93 of 330

Marea- Marea Weekend 9 ™

2000 range ©

Engine

Fuel feed system

10.

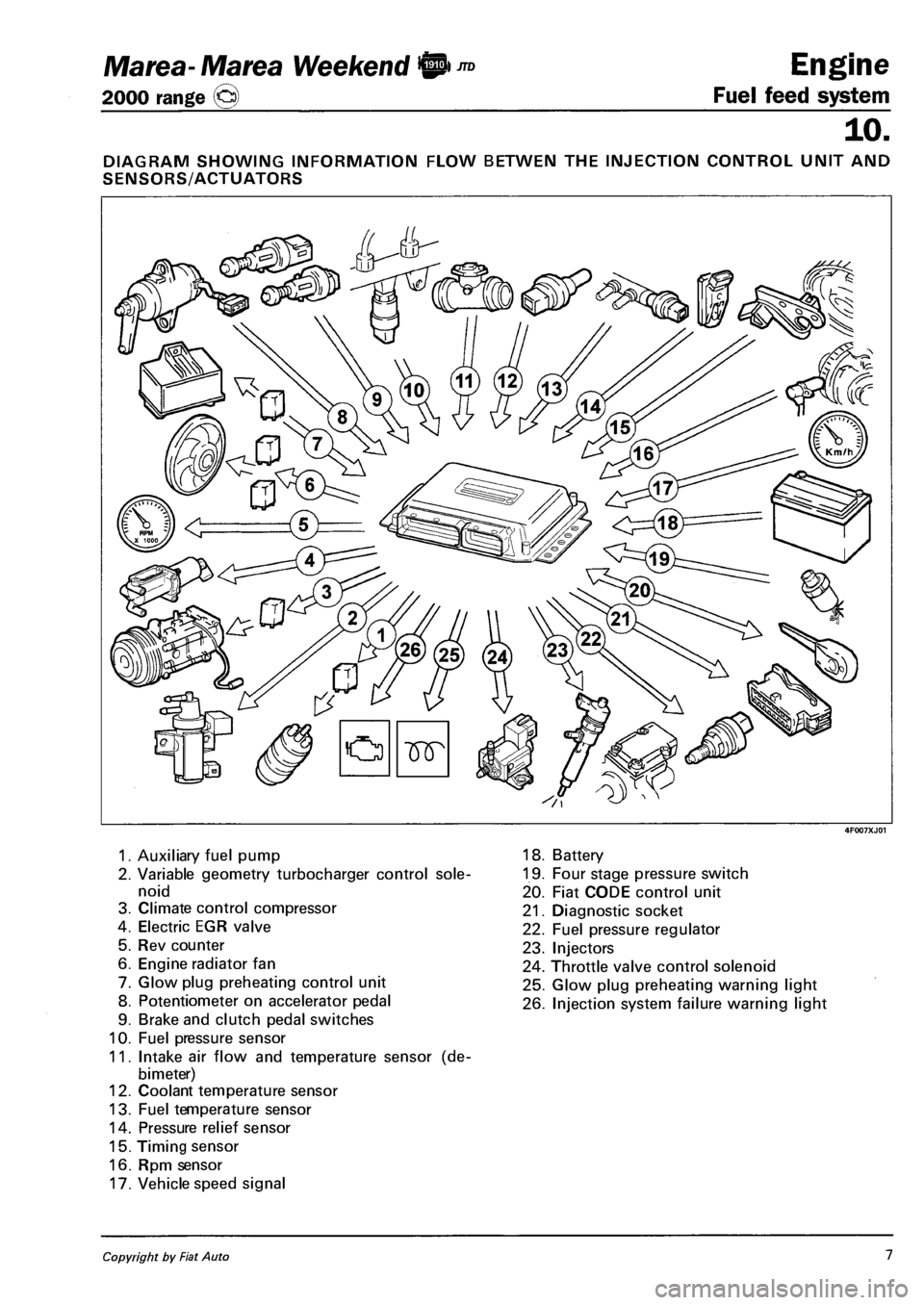

DIAGRAM SHOWING INFORMATION FLOW BETWEN THE INJECTION CONTROL UNIT AND

SENSORS/ACTUATORS

1. Auxiliary fuel pump

2. Variable geometry turbocharger control sole

noid

3. Climate control compressor

4. Electric EGR valve

5. Rev counter

6. Engine radiator fan

7. Glow plug preheating control unit

8. Potentiometer on accelerator pedal

9. Brake and clutch pedal switches

10. Fuel pressure sensor

11. Intake air flow and temperature sensor (de-

bimeter)

12. Coolant temperature sensor

13. Fuel temperature sensor

14. Pressure relief sensor

15. Timing sensor

16. Rpm sensor

17. Vehicle speed signal

18. Battery

19. Four stage pressure switch

20. Fiat CODE control unit

21. Diagnostic socket

22. Fuel pressure regulator

23. Injectors

24. Throttle valve control solenoid

25. Glow plug preheating warning light

26. Injection system failure warning light

Copyright by Fiat Auto 1

Page 94 of 330

Engine

Fuel feed system

Marea- Marea Weekend 9 ™

2000 range O

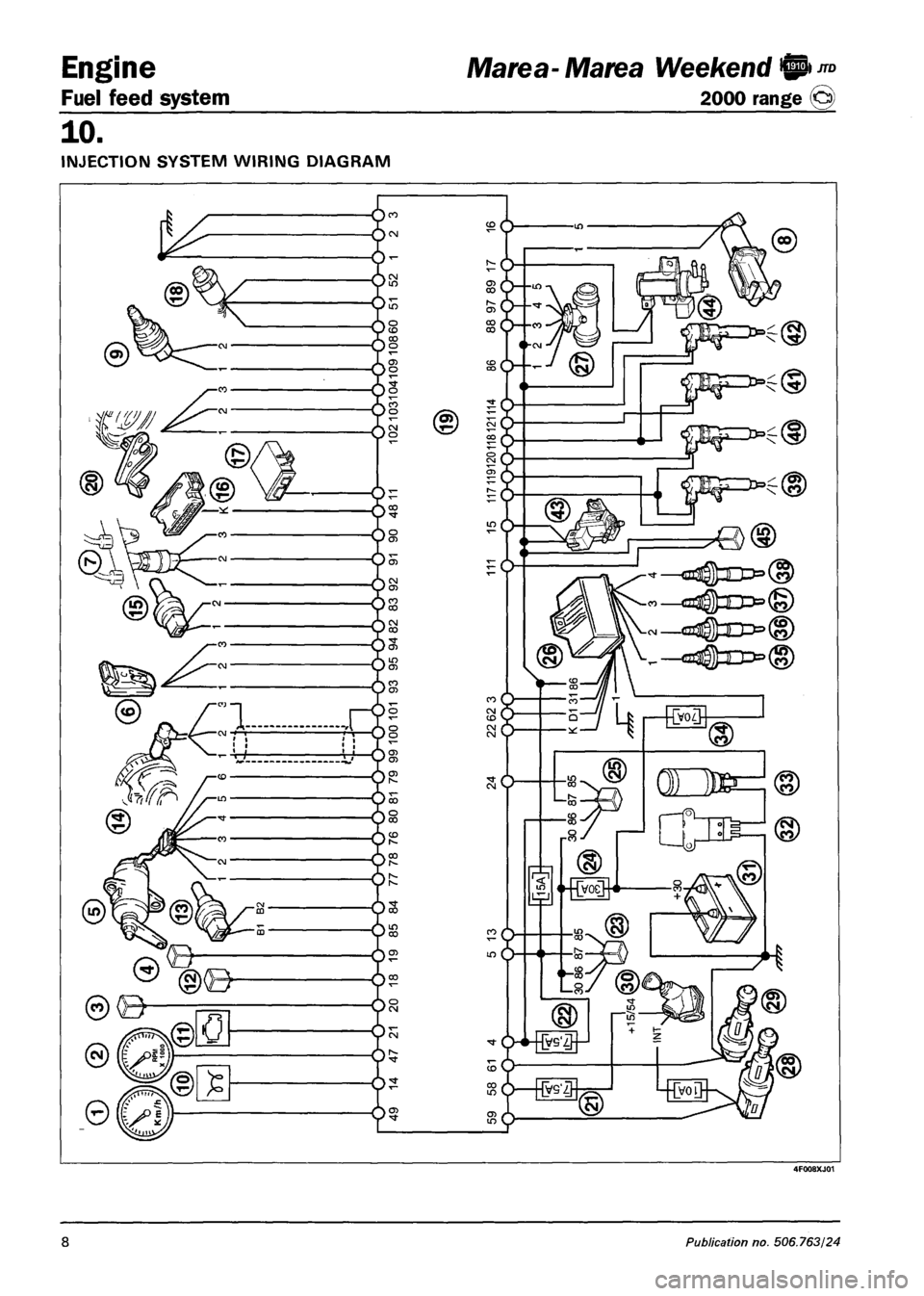

10.

INJECTION SYSTEM WIRING DIAGRAM

4F008XJ01

8 Publication no. 506.763/24

Page 95 of 330

Marea- Marea Weekend 9 ™

2000 range ©) Fuel feed system

Engine

10.

Compents of injection system wiring diagram

1. Vehicle speepd

2. Rev counter

3. Engine radiator fan low speed relay

4. Radiator fan high speed activation relay

5. Potentiometer on accelerator pedal

6. Timing sensor

7. Fuel pressure sensor

8. EGR system modulator solenoid

9. Fuel pressure regulator

10. Glow plug preheating warning light on control panel

11. Injection system failure warning light

12. Air conditioning system relay

13. Coolant temperature sensor

14. Rpm sensor

15. Fuel temperature sensor

16. Diagnostic socket

17. Fiat CODE control unit

18. Four stage pressure switch

19. Injection electronic control unit

20. Pressure relief sensor

21. 7.5A fuse protecting electronic injection system ( + 15 power supply from ignition switch)

22. 7.5A fuse protecting electronic injection system ( + 30 power supply from ignition switch)

23. Main injection system relay

24. 30A fuse protecting injection system

25. Auxiliary fuel pump relay

26. Glow plug preheating control unit

27. Intake air flow and temperature sensor (debimeter)

28. Brake pedal switch

29. Clutch pedal switch

30. Ignition switch

31. Battery

32. Inertia switch

33. Auxiliary fuel pump (submerged in tank)

34. 60A fuse protecting glow plug control unit

35. Cylinder no. 1 glow plug

36. Cylinder no. 2 glow plug

37. Cylinder no. 3 glow plug

38. Cylinder no. 4 glow plug

39. Cylinder no. 1 injector

40. Cylinder no. 2 injector

41. Cylinder no. 3 injector

42. Cylinder no. 4 injector

43. Throttle valve control solenoid

44. Variable geometry turbocharger control solenoid

45. Diesel filter heater relay

Copyright by Fiat Auto 9

Page 96 of 330

Engine Marea- Marea Weekend 9 ™

Fuel feed system 2000 range @

10.

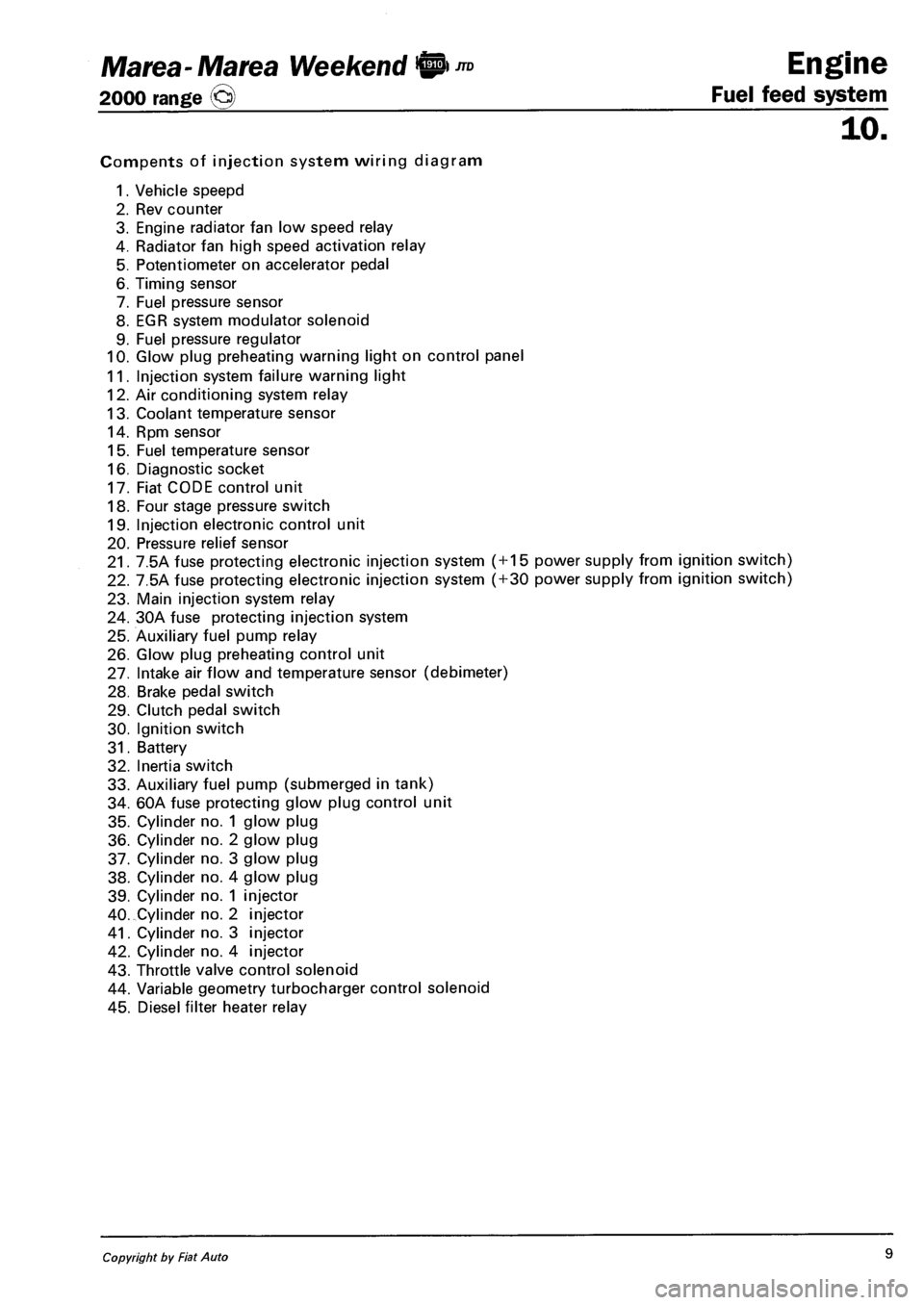

ELECTRONIC INJECTION CONTROL UNIT

The control unit processes signals from the various sensors by applying software algorithms and controls

the actuators accordingly (particularly the injectors and pressure regulator) to achieve the best possible

engine service conditions.

The control unit is "flash E.P.R.O.M." type, i.e. it can be reprogrammed from outside without andy need

to adjust the hardware.

The injection control unit contains a built-in absolute pressure sensor and is connected to the wiring by

means of a 121 pin connector.

Control unit connection identification (PIN-out)

4 5 43 24 6 25 96 106 113 105 119 120 121

1 Earth 25 Not connected

2 Earth 26 Not connected

3 Earth 27 Not connected

4 Actuator power supply 28 Not connected

5 Injector/ECU power supply 29 Not connected

6 Not connected 30 Not connected

7 Not connected 31 Not connected

8 Not connected 32 Not connected

9 Not connected 33 Not connected

10 Not connected 34 Not connected

11 Fiat CODE 35 Not connected

12 Not connected 36 Not connected

13 Injection relay

14 Glow plug control

15 Throttle body solenoid

16 EGR valve

17S VGT solenoid

18 Air conditioner relay

19 Radiator fan high speed relay

20 Radiator fan low speed relay

21 Diagnostic warning light control

22 Glow plug activation control

23 Not connected

24 Auxiliary fuel pump relay

10 Publication no. 506.763/24

Page 98 of 330

Engine

Fuel feed system

10.

4F012XJ03

Marea- Matea Weekend 9 ™

2000 range (Q)

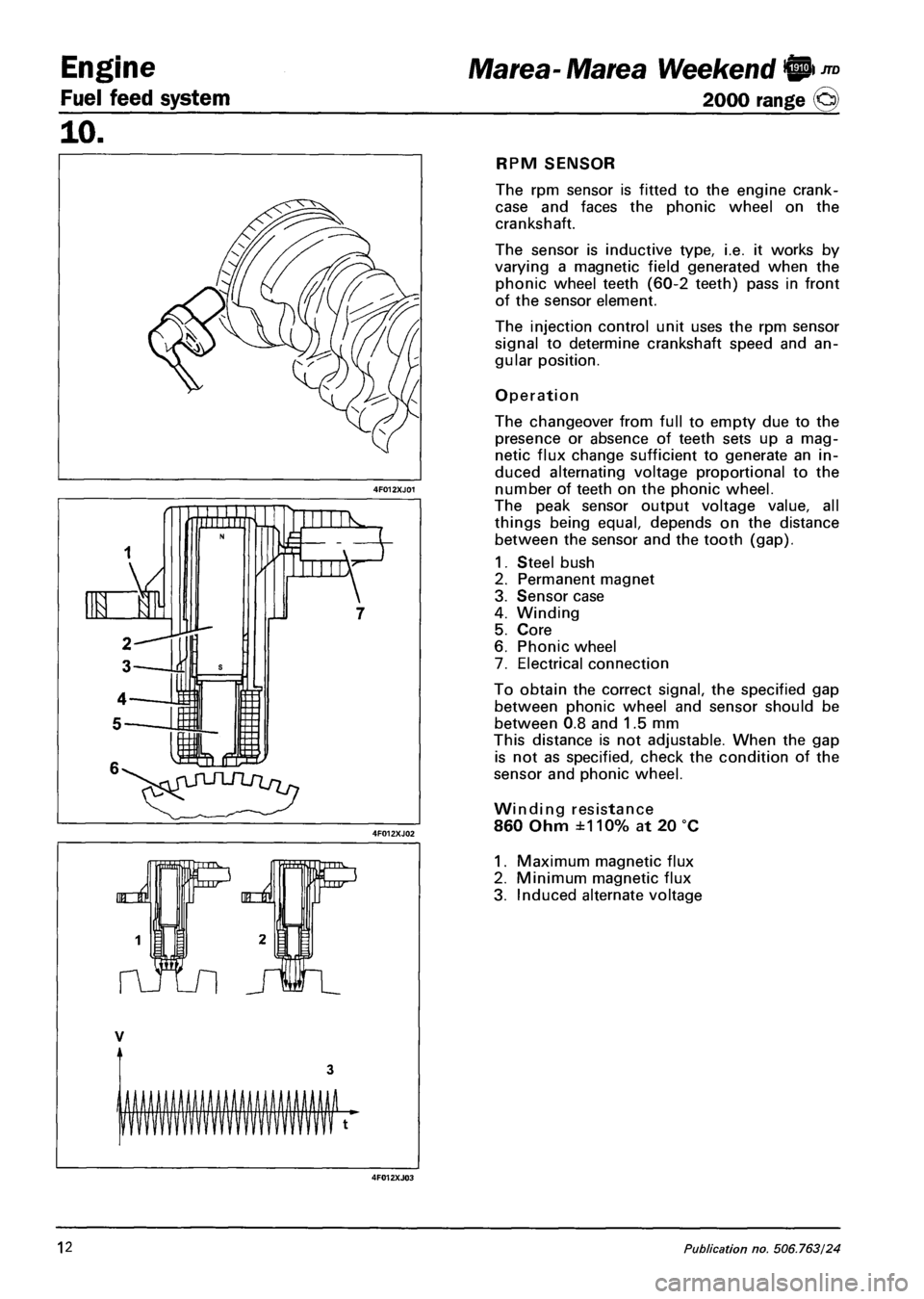

RPM SENSOR

The rpm sensor is fitted to the engine crank-

case and faces the phonic wheel on the

crankshaft.

The sensor is inductive type, i.e. it works by

varying a magnetic field generated when the

phonic wheel teeth (60-2 teeth) pass in front

of the sensor element.

The injection control unit uses the rpm sensor

signal to determine crankshaft speed and an

gular position.

Operation

The changeover from full to empty due to the

presence or absence of teeth sets up a mag

netic flux change sufficient to generate an in

duced alternating voltage proportional to the

number of teeth on the phonic wheel.

The peak sensor output voltage value, all

things being equal, depends on the distance

between the sensor and the tooth (gap).

1. Steel bush

2. Permanent magnet

3. Sensor case

4. Winding

5. Core

6. Phonic wheel

7. Electrical connection

To obtain the correct signal, the specified gap

between phonic wheel and sensor should be

between 0.8 and 1.5 mm

This distance is not adjustable. When the gap

is not as specified, check the condition of the

sensor and phonic wheel.

Winding resistance

860 Ohm ±110% at 20 °C

1. Maximum magnetic flux

2. Minimum magnetic flux

3. Induced alternate voltage

12 Publication no, 506.763/24

Page 99 of 330

Marea- Marea Weekend 9"°

2000 range ©

Engine

Fuel feed system

10.

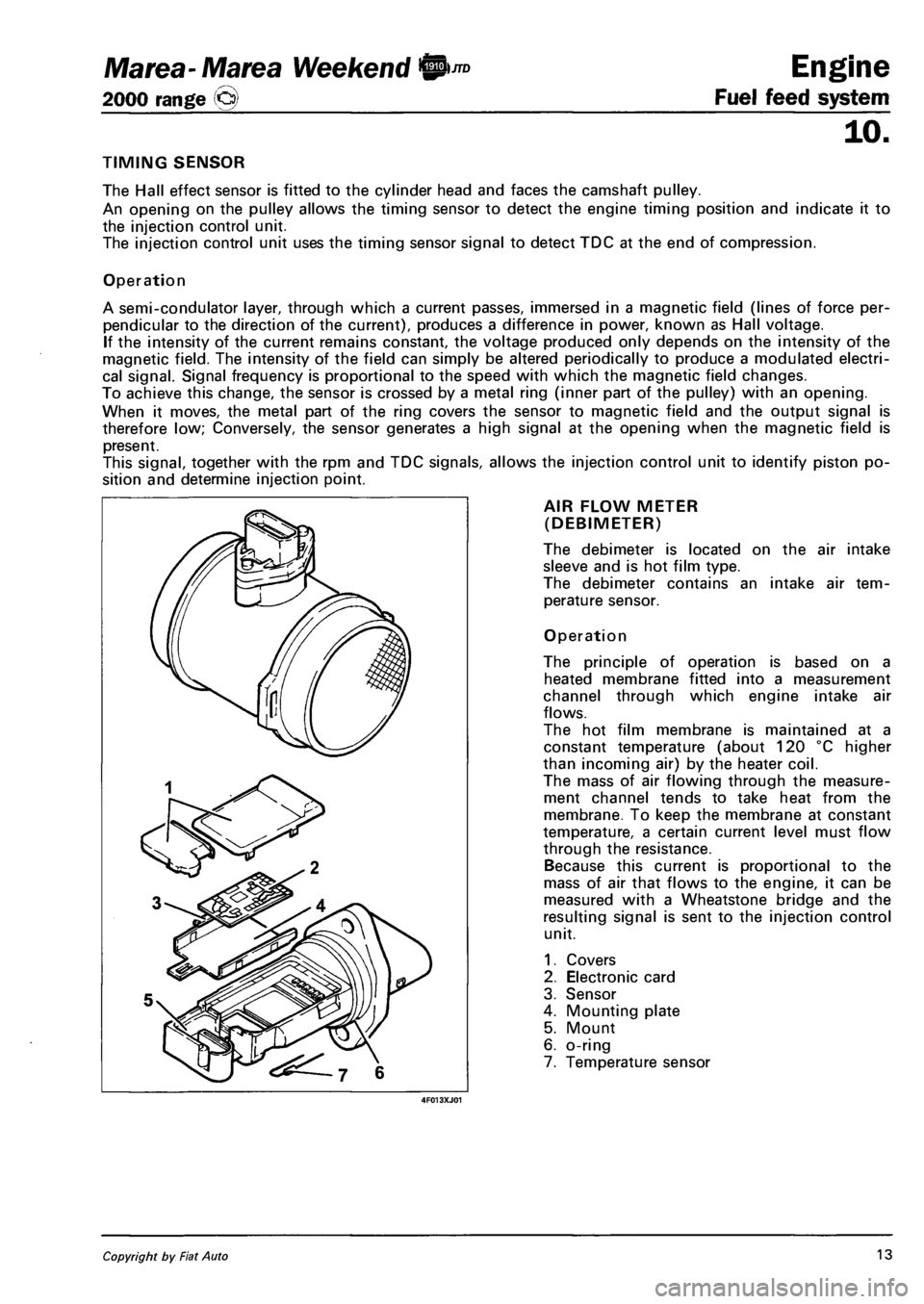

TIMING SENSOR

The Hall effect sensor is fitted to the cylinder head and faces the camshaft pulley.

An opening on the pulley allows the timing sensor to detect the engine timing position and indicate it to

the injection control unit.

The injection control unit uses the timing sensor signal to detect TDC at the end of compression.

Operation

A semi-condulator layer, through which a current passes, immersed in a magnetic field (lines of force per

pendicular to the direction of the current), produces a difference in power, known as Hall voltage.

If the intensity of the current remains constant, the voltage produced only depends on the intensity of the

magnetic field. The intensity of the field can simply be altered periodically to produce a modulated electri

cal signal. Signal frequency is proportional to the speed with which the magnetic field changes.

To achieve this change, the sensor is crossed by a metal ring (inner part of the pulley) with an opening.

When it moves, the metal part of the ring covers the sensor to magnetic field and the output signal is

therefore low; Conversely, the sensor generates a high signal at the opening when the magnetic field is

present.

This signal, together with the rpm and TDC signals, allows the injection control unit to identify piston po

sition and determine injection point.

AIR FLOW METER

(DEBIMETER)

The debimeter is located on the air intake

sleeve and is hot film type.

The debimeter contains an intake air tem

perature sensor.

Operation

The principle of operation is based on a

heated membrane fitted into a measurement

channel through which engine intake air

flows.

The hot film membrane is maintained at a

constant temperature (about 120 °C higher

than incoming air) by the heater coil.

The mass of air flowing through the measure

ment channel tends to take heat from the

membrane. To keep the membrane at constant

temperature, a certain current level must flow

through the resistance.

Because this current is proportional to the

mass of air that flows to the engine, it can be

measured with a Wheatstone bridge and the

resulting signal is sent to the injection control

unit.

1. Covers

2. Electronic card

3. Sensor

4. Mounting plate

5. Mount

6. o-ring

7. Temperature sensor

Copyright by Fiat Auto 13

Page 100 of 330

Engine

Fuel feed system

10.

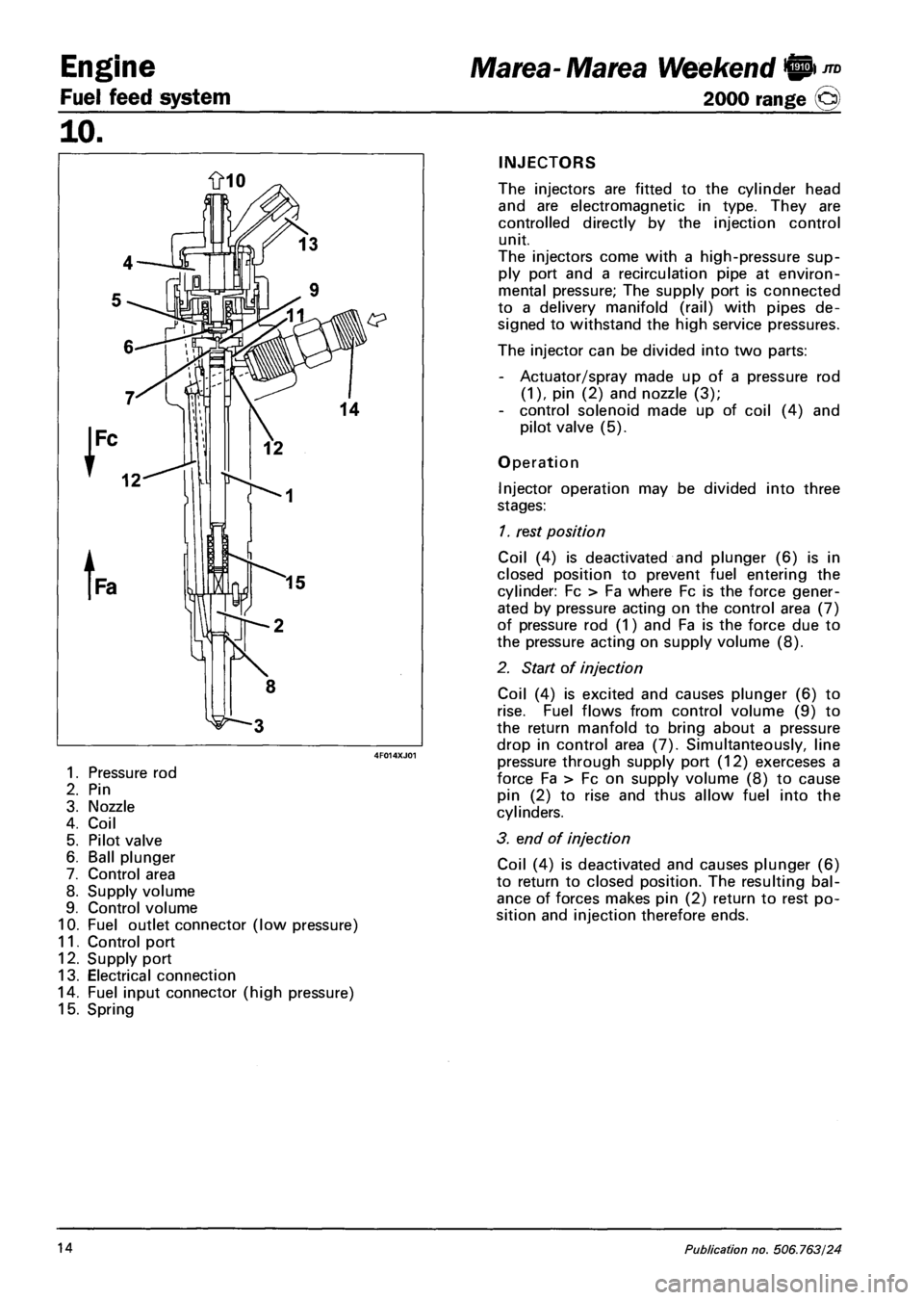

1. Pressure rod

2. Pin

3. Nozzle

4. Coil

5. Pilot valve

6. Ball plunger

7. Control area

8. Supply volume

9. Control volume

10. Fuel outlet connector (low pressure)

11. Control port

12. Supply port

13. Electrical connection

14. Fuel input connector (high pressure)

15. Spring

Marea- Marea Weekend 9 ™

2000 range (Q)

INJECTORS

The injectors are fitted to the cylinder head

and are electromagnetic in type. They are

controlled directly by the injection control

unit.

The injectors come with a high-pressure sup

ply port and a recirculation pipe at environ

mental pressure; The supply port is connected

to a delivery manifold (rail) with pipes de

signed to withstand the high service pressures.

The injector can be divided into two parts:

- Actuator/spray made up of a pressure rod

(1), pin (2) and nozzle (3);

- control solenoid made up of coil (4) and

pilot valve (5).

Operation

Injector operation may be divided into three

stages:

1. rest position

Coil (4) is deactivated and plunger (6) is in

closed position to prevent fuel entering the

cylinder: Fc > Fa where Fc is the force gener

ated by pressure acting on the control area (7)

of pressure rod (1) and Fa is the force due to

the pressure acting on supply volume (8).

2. Start of injection

Coil (4) is excited and causes plunger (6) to

rise. Fuel flows from control volume (9) to

the return manfold to bring about a pressure

drop in control area (7). Simultanteously, line

pressure through supply port (12) exerceses a

force Fa > Fc on supply volume (8) to cause

pin (2) to rise and thus allow fuel into the

cylinders.

3. end of injection

Coil (4) is deactivated and causes plunger (6)

to return to closed position. The resulting bal

ance of forces makes pin (2) return to rest po

sition and injection therefore ends.

14 Publication no. 506.763/24

Page 101 of 330

Marea- Marea Weekend 9™

2000 range (§)

4F015XJ03

Engine

Fuel feed system

ijo.

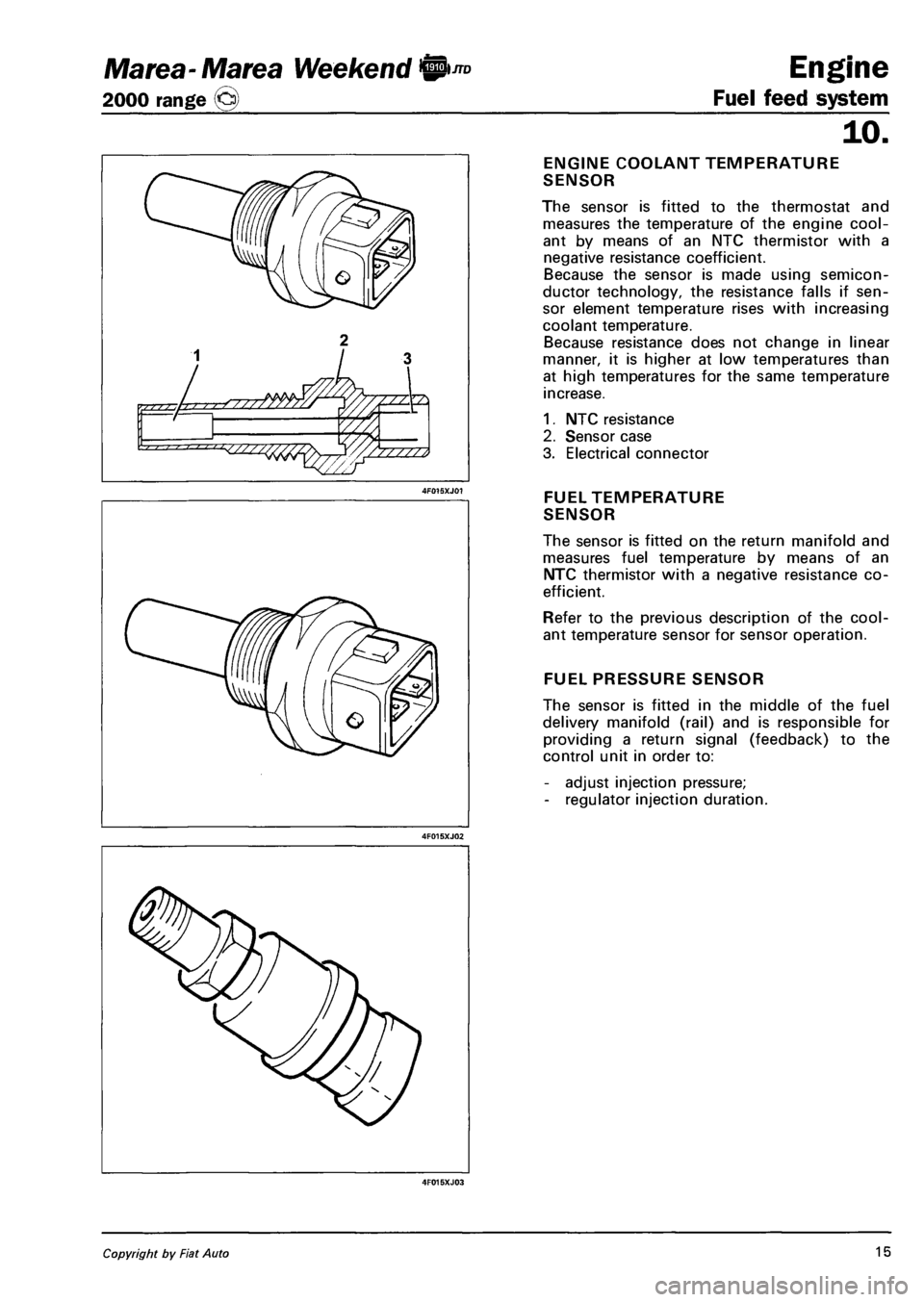

ENGINE COOLANT TEMPERATURE

SENSOR

The sensor is fitted to the thermostat and

measures the temperature of the engine cool

ant by means of an NTC thermistor with a

negative resistance coefficient.

Because the sensor is made using semicon

ductor technology, the resistance falls if sen

sor element temperature rises with increasing

coolant temperature.

Because resistance does not change in linear

manner, it is higher at low temperatures than

at high temperatures for the same temperature

increase.

1. NTC resistance

2. Sensor case

3. Electrical connector

FUEL TEMPERATURE

SENSOR

The sensor is fitted on the return manifold and

measures fuel temperature by means of an

NTC thermistor with a negative resistance co

efficient.

Refer to the previous description of the cool

ant temperature sensor for sensor operation.

FUEL PRESSURE SENSOR

The sensor is fitted in the middle of the fuel

delivery manifold (rail) and is responsible for

providing a return signal (feedback) to the

control unit in order to:

- adjust injection pressure;

- regulator injection duration.

Copyright by Fiat Auto 15

Page 102 of 330

![FIAT MAREA 2001 1.G Owners Manual Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1 <fi=2 1 1 15J

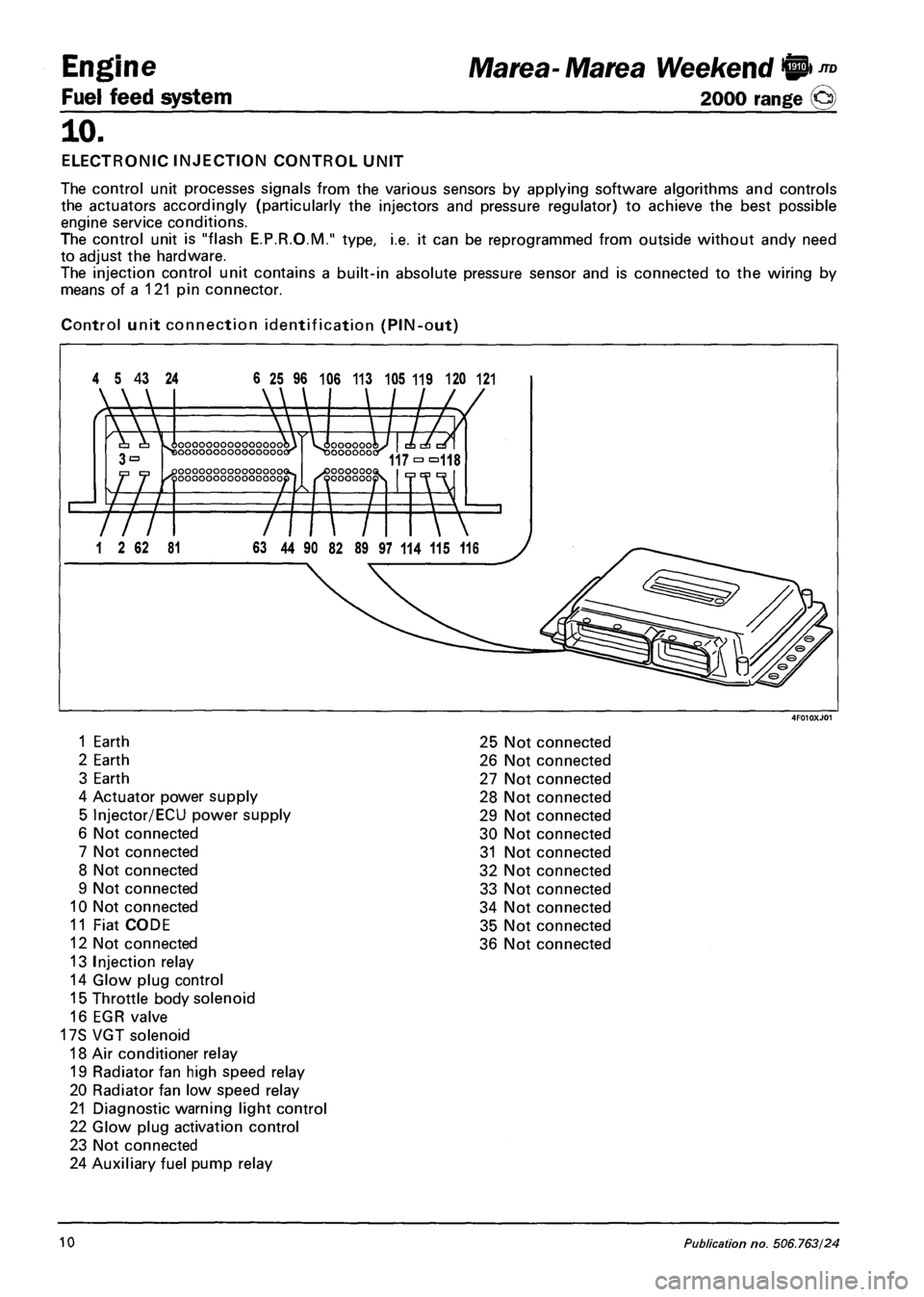

GLOW PLUG PREHEATING CONTROL

UNIT

The glow plugs are controlled by mea FIAT MAREA 2001 1.G Owners Manual Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1 <fi=2 1 1 15J

GLOW PLUG PREHEATING CONTROL

UNIT

The glow plugs are controlled by mea](/img/10/4653/w960_4653-101.png)

Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1

UNIT

The glow plugs are controlled by means of a

preheating control unit under the direct con

trol of the injection control unit.

The preheating control unit contains a smart

relay that sends a return response (feedback)

to the injection control unit, which is thus in

formed of faults in the preheating control unit

or glow plug short-circuits to earth.

The figure shows the connectors on the base

of the preheating control unit and the pin-out

1. Earth

2. Injection control unit (pin 22)

3. Power supply from main injection relay

4. Not connected

5. Injection control unit (pin 62)

8. Positive from battery (+30)

G. Glow plugs (only four outputs are used)

ACCELERATOR

PEDAL POTENTIOMETER

Accelerator pedal position is converted to an

electrical voltage signal and send to the injec

tion control unit by a potentiometer connected

to the accelerator pedal.

Accelerator pedal position is processed to

gether with rpm information to provide injec

tion times and pressure.

The sensor consists of a case (1) secured to

the pedal by a flange, which contains an axi-

ally-positioned shaft (2) connected to two

potentiometers (3): main and safety potenti

ometers.

A coil spring on the shaft ensures the correct

resistance to pressure while a second spring

ensures return upon release.

16 Publication no. 506.763/24

Page 103 of 330

Marea-Marea Weekend 9 -™ Engine

2000 range (j§) Fuel feed system

10.

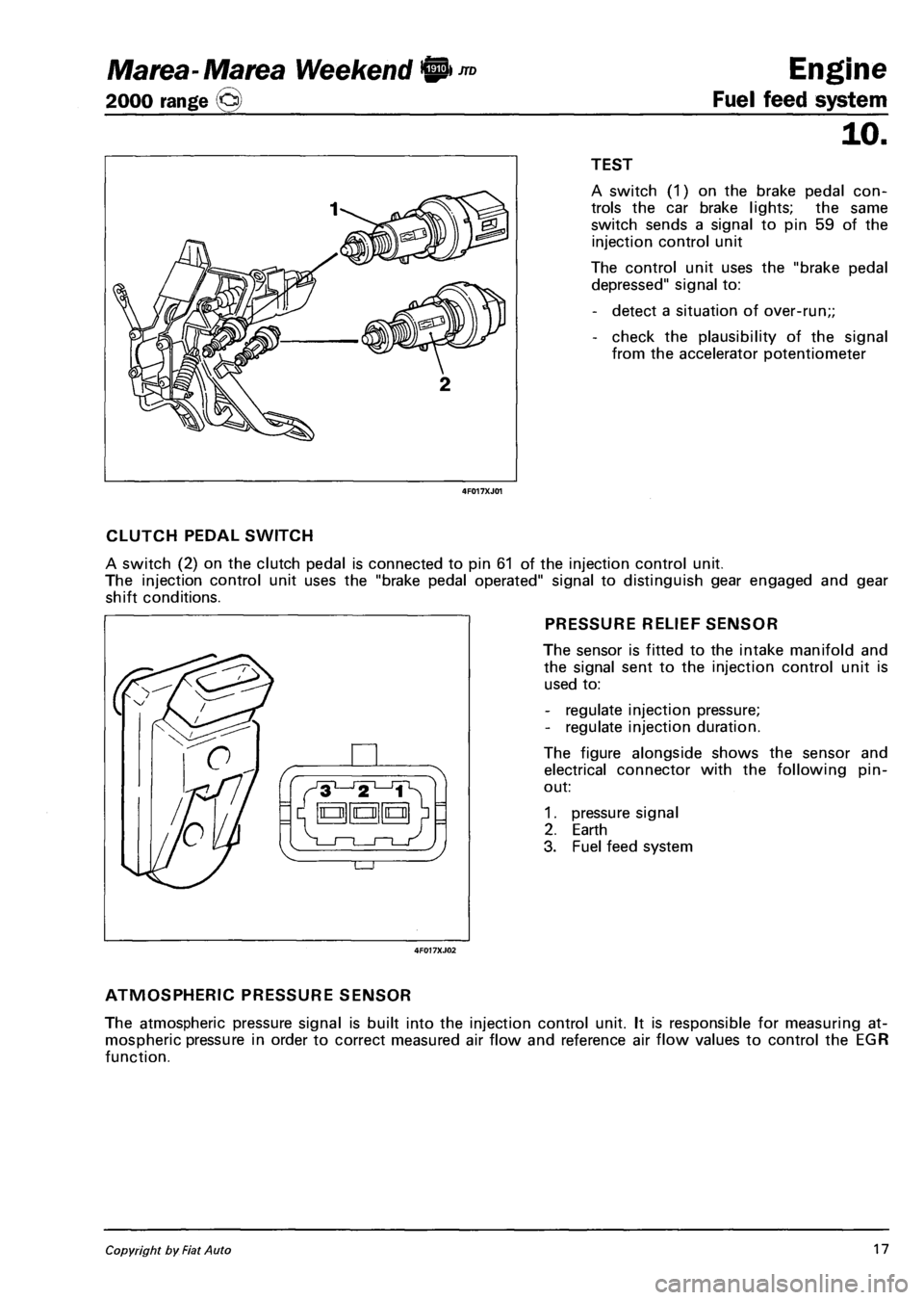

I I TEST

4F017XJ01

A switch (1) on the brake pedal con

trols the car brake lights; the same

switch sends a signal to pin 59 of the

injection control unit

The control unit uses the "brake pedal

depressed" signal to:

- detect a situation of over-run;;

- check the plausibility of the signal

from the accelerator potentiometer

CLUTCH PEDAL SWITCH

A switch (2) on the clutch pedal is connected to pin 61 of the injection control unit.

The injection control unit uses the "brake pedal operated" signal to distinguish gear engaged and gear

shift conditions.

PRESSURE RELIEF SENSOR

The sensor is fitted to the intake manifold and

the signal sent to the injection control unit is

used to:

- regulate injection pressure;

- regulate injection duration.

The figure alongside shows the sensor and

electrical connector with the following pin-

out:

1. pressure signal

2. Earth

3. Fuel feed system

ATMOSPHERIC PRESSURE SENSOR

The atmospheric pressure signal is built into the injection control unit. It is responsible for measuring at

mospheric pressure in order to correct measured air flow and reference air flow values to control the EGR

function.

Copyright by Fiat Auto 17