Injection FIAT MAREA 2001 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2001, Model line: MAREA, Model: FIAT MAREA 2001 1.GPages: 330

Page 90 of 330

Fuel feed system

Engine Marea- Marea Weekend 9 ™

2000 range (Q)

10.

Control of idle speed

On the basis of signals from the rpm sensor and engine coolant temperature sensor, the injection control

unit controls the pressure governor and alters the injector control times to maintain idle speed stable at all

times.

Under certain conditions, the idle speed control unit also considers battery voltage.

Control of maximum speed limitation

According to rpm level, the injection control unit limits maximum speed by means of two types of inter

vention:

- as maximum speed approaches, it reduces the amount of fuel injected to reduce line pressure;

- when maximum speed is exceeded, it inhibits operation of the auxiliary pump and injectors.

Control of maximum torque limitation

On the basis of rpm level, the injection control unit computes limit torque and maximum permitted fume

index parameters on the basis of predefined, stored maps.

It then corrects the above parameters using engine coolant temperature and car speed data. The resulting

values are then used to modulate the amount of fuel to be injected by adjusting the pressure regulator and

injectors.

Control of fuel temperature

The injection control uint is kept constantly informed of fuel temperature by a sensor on the return mani

fold.

If fuel temperature exceeds a set value (about 110 °C), the control unit reduces line pressure by adjusting

the pressure governor, leaving injection times unaltered.

Control of coolant temperature

The injection control unit is constantly informed of coolant temperature by a sensor on the thermostat.

If engine coolant temperature or air conditioning fluid pressure exceeds certain levels, the control unit

performs the following actions:

- It reduces the amount of fuel injected by adjusting the pressure governor and injectors (power reduc

tion);

- it controls the engine radiator cooling fan.

Control of glow plugs

The injection control unit controls operation of the glow plug preheating control unit to bring the tem

perature in the combution chambers up to levels that promote fuel self-ignition and thus make start-up

easier.

The control unit controls the operation of the glow plug control unit for a certain time both before (pre

heating) and after (postheating) engine start-up and also controls activation of the warning light on the

control panel.

Preheating, postheating and glow plug warning light activation times vary according to engine coolant

temperature.

4 Publication no. 506.763/24

Page 91 of 330

![FIAT MAREA 2001 1.G Owners Manual Marea-Marea Weekend 9]

2000 range (j§)

I) JTD

Fuel feed system

Engine

10.

Exhaust fumes control

Through this function the injection control unit limits any exhaust fumes that could be produce FIAT MAREA 2001 1.G Owners Manual Marea-Marea Weekend 9]

2000 range (j§)

I) JTD

Fuel feed system

Engine

10.

Exhaust fumes control

Through this function the injection control unit limits any exhaust fumes that could be produce](/img/10/4653/w960_4653-90.png)

Marea-Marea Weekend 9]

2000 range (j§)

I) JTD

Fuel feed system

Engine

10.

Exhaust fumes control

Through this function the injection control unit limits any exhaust fumes that could be produced during

transition speeds.

To satisy these requirements the control unit processes the signals supplied by the accelerator pedal po

tentiometer, the rpm sensor and the air flow meter and controls the fuel pressure regulator and the injec

tors to meter the correct amount of fuel to inject.

Exhaust gas recirculation control

On the basis of the signals supplied by the rpm sensor, intake air quantity sensor, engine coolant tempe

rature sensor and accelerator pedal position sensor, the control unit calculates the operating times for the

EGR valve so that the exhaust gases are partly recirculated in certain engine operating conditions in line

with Euro 3 pollution control standards.

Air conditioning system engagement control

The injection control unit manages the operation of the air conditioning system compressor electro

magnet coupling following a logic aimed at preventing operating conditions that would adversely affect

engine performance.

- When the compressor is switched on the injection control unit increases the quantity of fuel during

idling to allow the engine to adjust to the increased power requirements and momentarily interrupts the

supply to the compressor in high engine power requirement conditions (strong acceleration).

Engine immobilizer function control

The system is equipped with an engine immobilizer function. This function is achieved through the pre

sence of a specific control unit (Fiat CODE), capable of conversing with the injection control unit and an

electronic key with a special transmitter for sending a recognition code.

Each time the key is turned to the OFF position, the Fiat CODE system completely deactivates the injecti

on control unit.

When the key is turned to the ON position the following operations take place, in order:

1. the injection control unit (whose memory contains a secret code) sends the Fiat CODE control unit a

request to send the secret code to deactivate the immobilizer functions;

2. the Fiat CODE control unit responds by only sending the secret code after, in turn, having received the

recognition code transmitted by the ignition key;

3. the recognition of the secret code allows the deactivation of the injection control unit immobilizer func

tion and its normal operation.

Autodiagnosis

The complete electronic fault diagnosis of the injection system is carried out by connecting the special

equipment (EXAMINER or EXAMINER PLUS) to the standardized diagnostic socket (EOBD).

The system is also equipped with a self-diagnostic function which recognizes, memorizes and signals any

faults.

If a fault is detected in the sensors or actuators, the recovery strategy is immediately activated in order to

ensure that the engine functions at an acceptable level. The vehicle can be driven to a service centre for

the appropriate repairs to be carried out.

Copyright by Fiat Auto 5

Page 92 of 330

Fuel feed system

Engine Marea- Marea Weekend © ™

2000 range @

10.

The control unit autodiagnostic system checks the signals coming from the sensors and compares them

with the figures allowed:

- signalling faults during starting

- warning light on for 4 seconds indicates test stage

- warning light off after 4 seconds indicates no fault with components that could alter the pollution con

trol standard figures

- warning light on after 4 seconds indicates fault.

- signalling faults during operation

- warning light on indicates fault

- warning light off indicates no fault with components that could alter the pollution control standard fig

ures.

- recovery

- from time to time, the control unit defines the type of recovery according to the components which are

faulty

- the recovery parameters are managed by components which are not faulty.

Control of cylinder balancing during idling

According to the signals coming from the sensors, the injection control unit controls the idle speed torque,

altering the injector operating times.

Control of irregular operation

Depending on the signals coming from the sensors, the injection control unit corrects the amount of fuel

to be injected in order to improve driveability and reduce jerking whilst driving.

The correction is achieved through the fuel pressure regulator and by varying the injector operating times.

Control of electrical balance

According to the battery voltage, the injection control unit alters the idle speed, to guarantee a sufficient

current supply from the alternator in situations where the consumers are absorbing a great deal of power.

The variation in the idle speed is achived by regulating the fuel pressure and altering the injector operat

ing times.

VGT variable geometry turbocharger control (1910 JTD 110 CV)

The injection control unit processes the signal coming from the supercharging sensor, at the various en

gine operating speeds, and determines the quantity of fuel to be injected, acting on the fuel pressure

regulator and the injector opening times.

In addition, through the solenoid valve, the control unit regulates the geometry of the turbine in order to

ensure optimum performance in all operating conditions.

Turbocharger waste gate valve control (1910 JTD 100 CV)

At the various engine operating speeds, the injection control unit processes the signal coming from the

supercharging sensor and determines the amount of fuel to inject, acting on the fuel pressure regulator

and the injector opening times.

In addition, the control unit controls the opening of the turbocharger waste gate valve, via the solenoid

valve, in order to ensure excellent performance in all operating conditions.

Control of throttle closing when engine is switched off

When the engine is switched off (ignition key in OFF position) the injection control unit closes the throt

tle valve located on the air intake duct via the special solenoid valve.

This action makes it possible to limit the tiresome shuddering of the engine whilst it is switching off.

6 .i. V!-01-.Cancelftand replaces Print n° 506.763/25

Page 93 of 330

Marea- Marea Weekend 9 ™

2000 range ©

Engine

Fuel feed system

10.

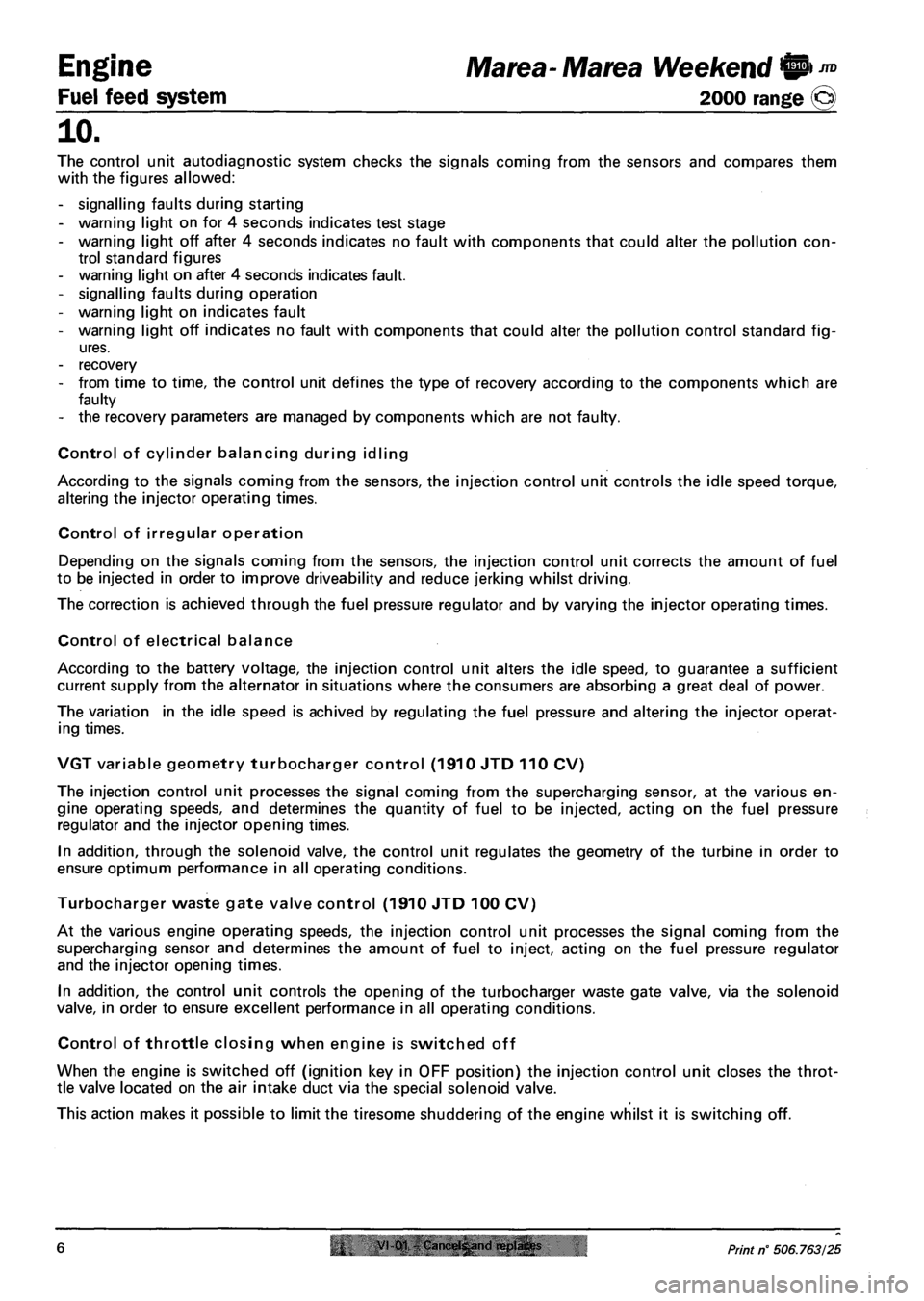

DIAGRAM SHOWING INFORMATION FLOW BETWEN THE INJECTION CONTROL UNIT AND

SENSORS/ACTUATORS

1. Auxiliary fuel pump

2. Variable geometry turbocharger control sole

noid

3. Climate control compressor

4. Electric EGR valve

5. Rev counter

6. Engine radiator fan

7. Glow plug preheating control unit

8. Potentiometer on accelerator pedal

9. Brake and clutch pedal switches

10. Fuel pressure sensor

11. Intake air flow and temperature sensor (de-

bimeter)

12. Coolant temperature sensor

13. Fuel temperature sensor

14. Pressure relief sensor

15. Timing sensor

16. Rpm sensor

17. Vehicle speed signal

18. Battery

19. Four stage pressure switch

20. Fiat CODE control unit

21. Diagnostic socket

22. Fuel pressure regulator

23. Injectors

24. Throttle valve control solenoid

25. Glow plug preheating warning light

26. Injection system failure warning light

Copyright by Fiat Auto 1

Page 94 of 330

Engine

Fuel feed system

Marea- Marea Weekend 9 ™

2000 range O

10.

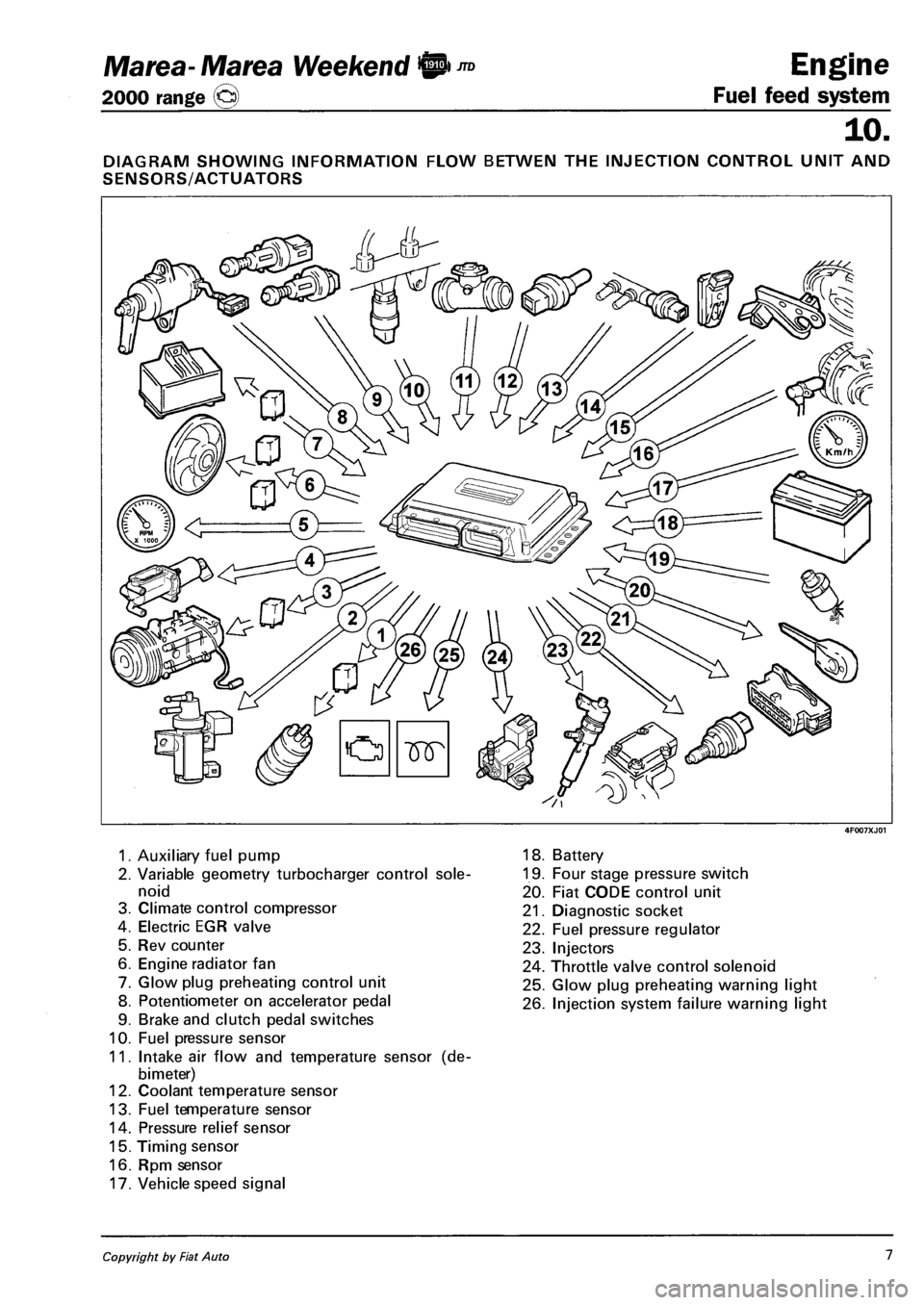

INJECTION SYSTEM WIRING DIAGRAM

4F008XJ01

8 Publication no. 506.763/24

Page 95 of 330

Marea- Marea Weekend 9 ™

2000 range ©) Fuel feed system

Engine

10.

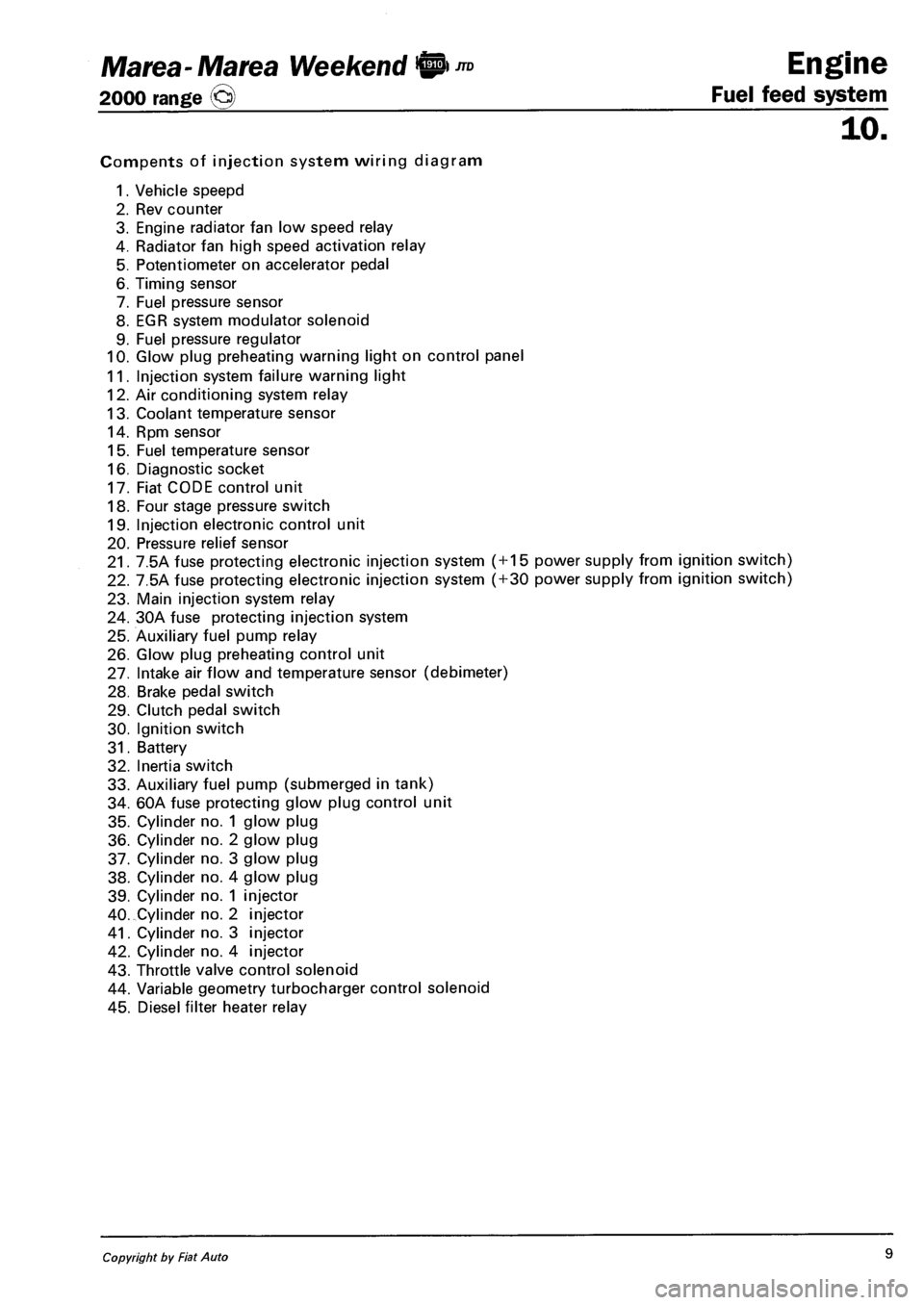

Compents of injection system wiring diagram

1. Vehicle speepd

2. Rev counter

3. Engine radiator fan low speed relay

4. Radiator fan high speed activation relay

5. Potentiometer on accelerator pedal

6. Timing sensor

7. Fuel pressure sensor

8. EGR system modulator solenoid

9. Fuel pressure regulator

10. Glow plug preheating warning light on control panel

11. Injection system failure warning light

12. Air conditioning system relay

13. Coolant temperature sensor

14. Rpm sensor

15. Fuel temperature sensor

16. Diagnostic socket

17. Fiat CODE control unit

18. Four stage pressure switch

19. Injection electronic control unit

20. Pressure relief sensor

21. 7.5A fuse protecting electronic injection system ( + 15 power supply from ignition switch)

22. 7.5A fuse protecting electronic injection system ( + 30 power supply from ignition switch)

23. Main injection system relay

24. 30A fuse protecting injection system

25. Auxiliary fuel pump relay

26. Glow plug preheating control unit

27. Intake air flow and temperature sensor (debimeter)

28. Brake pedal switch

29. Clutch pedal switch

30. Ignition switch

31. Battery

32. Inertia switch

33. Auxiliary fuel pump (submerged in tank)

34. 60A fuse protecting glow plug control unit

35. Cylinder no. 1 glow plug

36. Cylinder no. 2 glow plug

37. Cylinder no. 3 glow plug

38. Cylinder no. 4 glow plug

39. Cylinder no. 1 injector

40. Cylinder no. 2 injector

41. Cylinder no. 3 injector

42. Cylinder no. 4 injector

43. Throttle valve control solenoid

44. Variable geometry turbocharger control solenoid

45. Diesel filter heater relay

Copyright by Fiat Auto 9

Page 96 of 330

Engine Marea- Marea Weekend 9 ™

Fuel feed system 2000 range @

10.

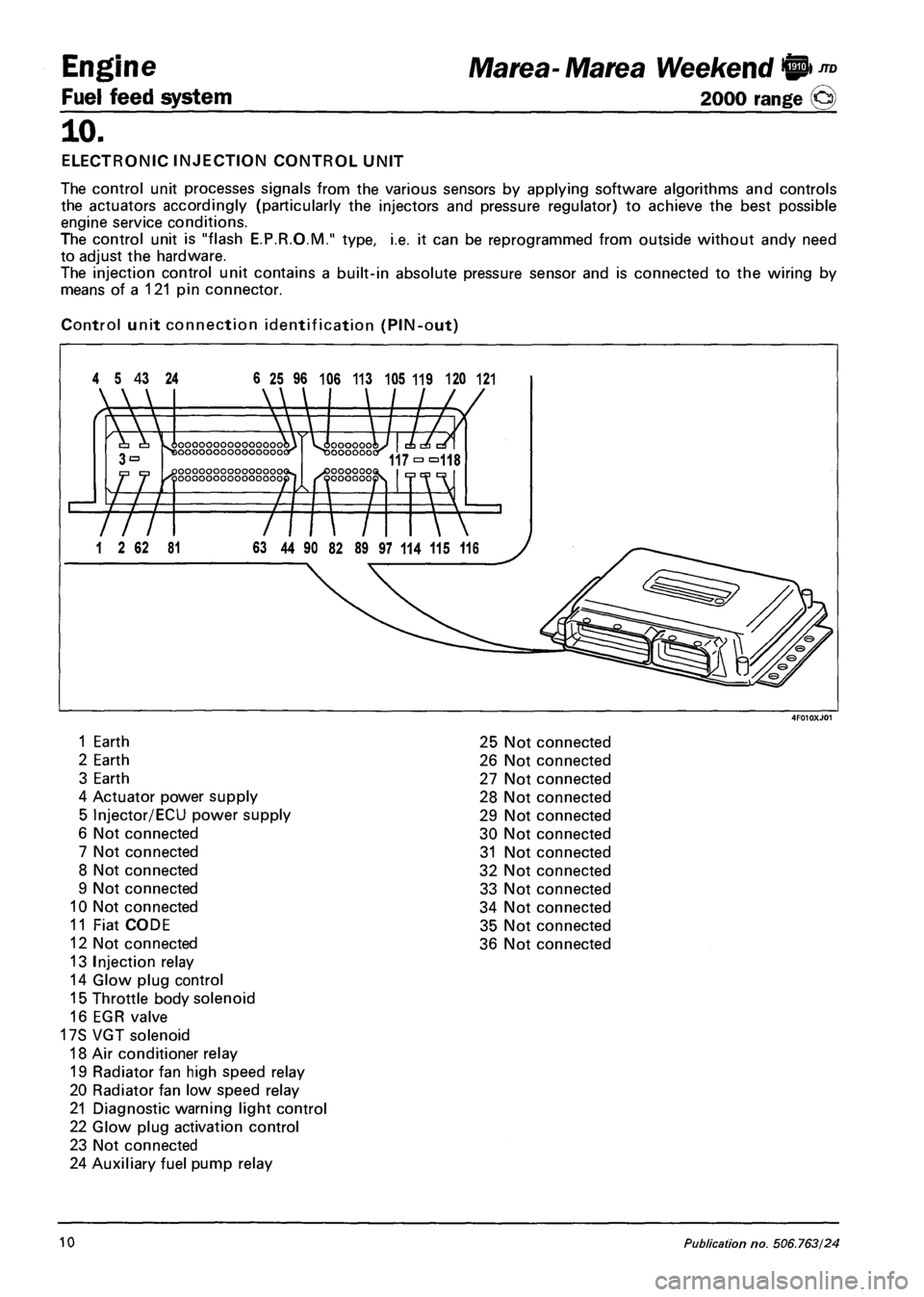

ELECTRONIC INJECTION CONTROL UNIT

The control unit processes signals from the various sensors by applying software algorithms and controls

the actuators accordingly (particularly the injectors and pressure regulator) to achieve the best possible

engine service conditions.

The control unit is "flash E.P.R.O.M." type, i.e. it can be reprogrammed from outside without andy need

to adjust the hardware.

The injection control unit contains a built-in absolute pressure sensor and is connected to the wiring by

means of a 121 pin connector.

Control unit connection identification (PIN-out)

4 5 43 24 6 25 96 106 113 105 119 120 121

1 Earth 25 Not connected

2 Earth 26 Not connected

3 Earth 27 Not connected

4 Actuator power supply 28 Not connected

5 Injector/ECU power supply 29 Not connected

6 Not connected 30 Not connected

7 Not connected 31 Not connected

8 Not connected 32 Not connected

9 Not connected 33 Not connected

10 Not connected 34 Not connected

11 Fiat CODE 35 Not connected

12 Not connected 36 Not connected

13 Injection relay

14 Glow plug control

15 Throttle body solenoid

16 EGR valve

17S VGT solenoid

18 Air conditioner relay

19 Radiator fan high speed relay

20 Radiator fan low speed relay

21 Diagnostic warning light control

22 Glow plug activation control

23 Not connected

24 Auxiliary fuel pump relay

10 Publication no. 506.763/24

Page 98 of 330

Engine

Fuel feed system

10.

4F012XJ03

Marea- Matea Weekend 9 ™

2000 range (Q)

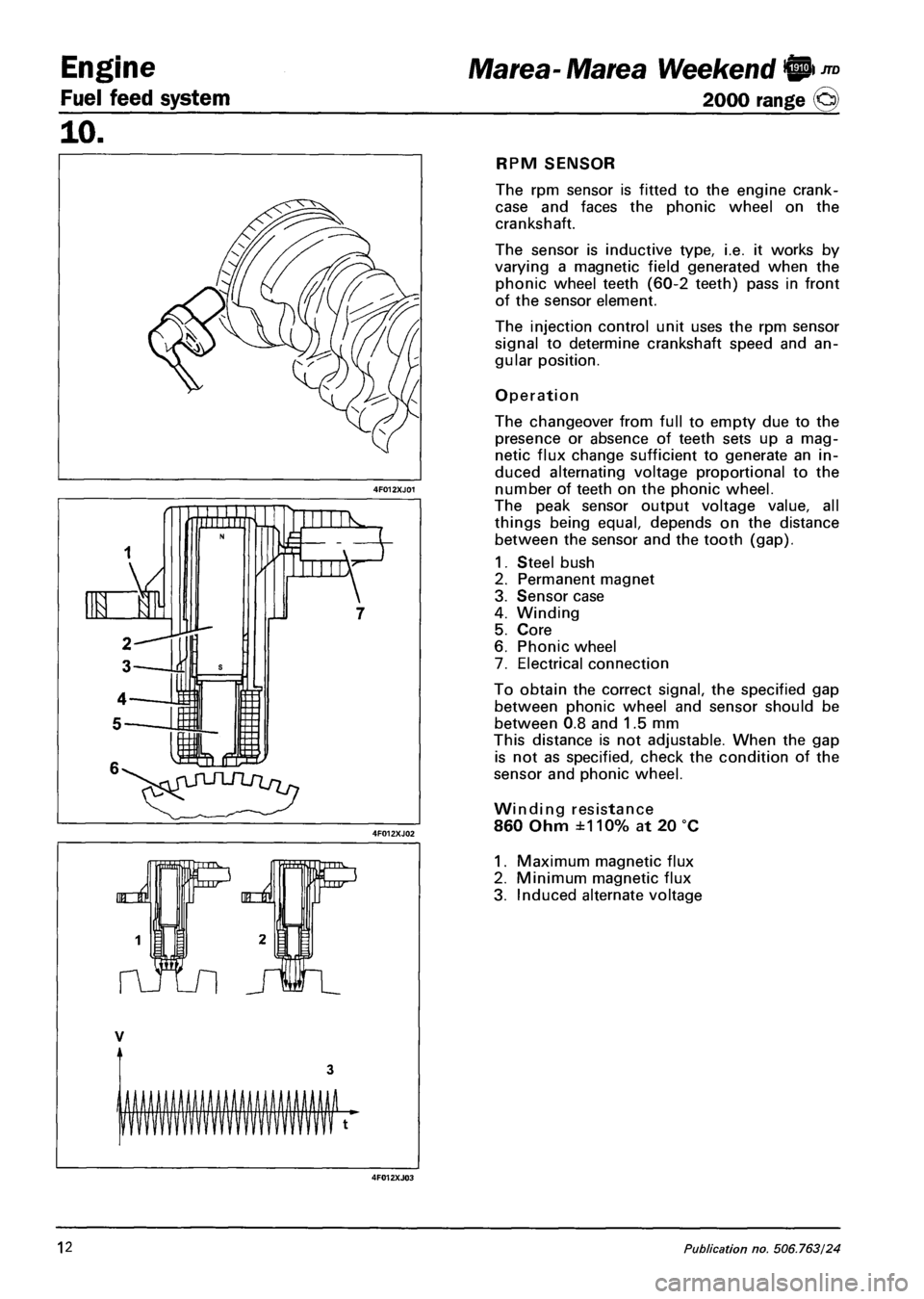

RPM SENSOR

The rpm sensor is fitted to the engine crank-

case and faces the phonic wheel on the

crankshaft.

The sensor is inductive type, i.e. it works by

varying a magnetic field generated when the

phonic wheel teeth (60-2 teeth) pass in front

of the sensor element.

The injection control unit uses the rpm sensor

signal to determine crankshaft speed and an

gular position.

Operation

The changeover from full to empty due to the

presence or absence of teeth sets up a mag

netic flux change sufficient to generate an in

duced alternating voltage proportional to the

number of teeth on the phonic wheel.

The peak sensor output voltage value, all

things being equal, depends on the distance

between the sensor and the tooth (gap).

1. Steel bush

2. Permanent magnet

3. Sensor case

4. Winding

5. Core

6. Phonic wheel

7. Electrical connection

To obtain the correct signal, the specified gap

between phonic wheel and sensor should be

between 0.8 and 1.5 mm

This distance is not adjustable. When the gap

is not as specified, check the condition of the

sensor and phonic wheel.

Winding resistance

860 Ohm ±110% at 20 °C

1. Maximum magnetic flux

2. Minimum magnetic flux

3. Induced alternate voltage

12 Publication no, 506.763/24

Page 99 of 330

Marea- Marea Weekend 9"°

2000 range ©

Engine

Fuel feed system

10.

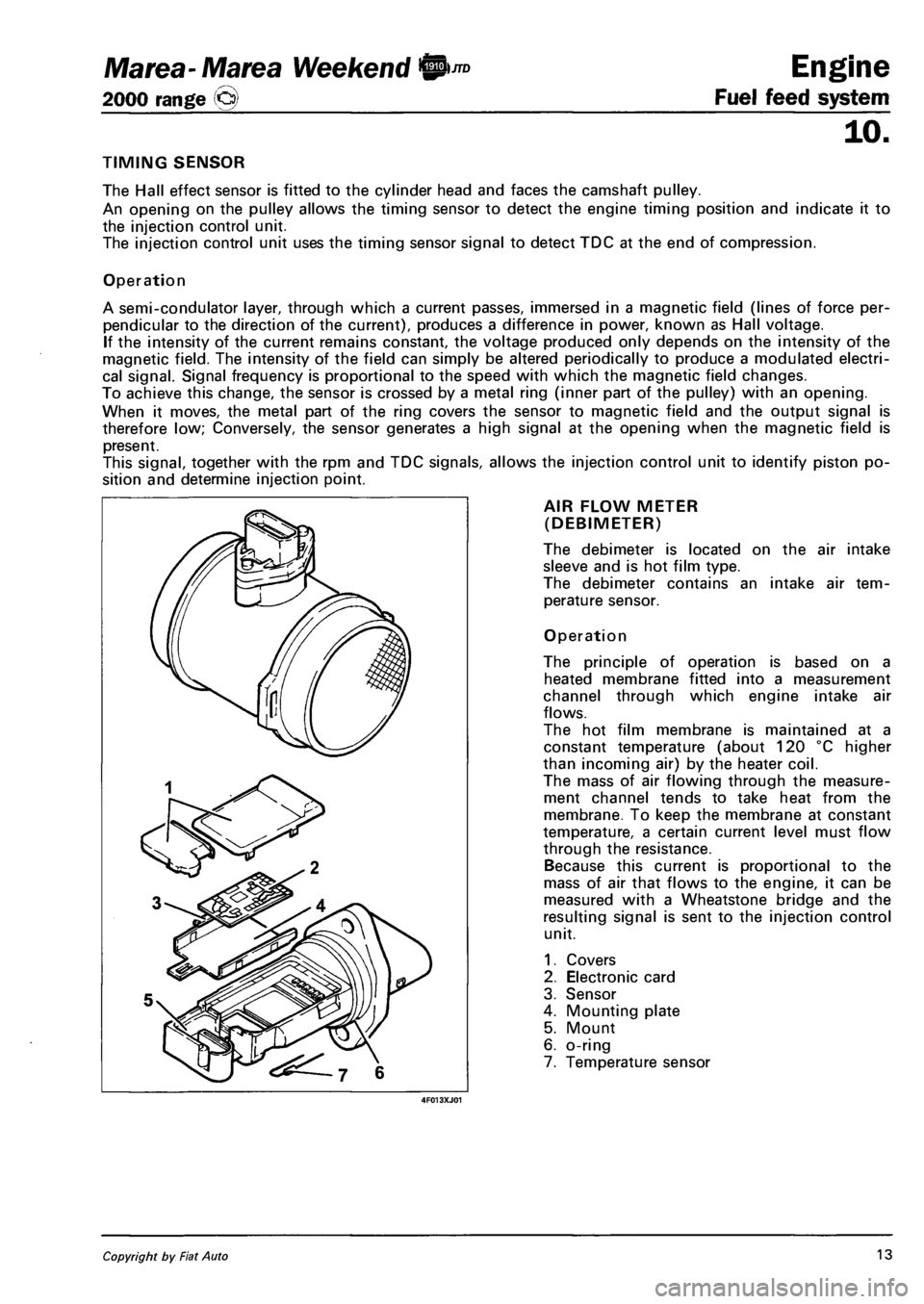

TIMING SENSOR

The Hall effect sensor is fitted to the cylinder head and faces the camshaft pulley.

An opening on the pulley allows the timing sensor to detect the engine timing position and indicate it to

the injection control unit.

The injection control unit uses the timing sensor signal to detect TDC at the end of compression.

Operation

A semi-condulator layer, through which a current passes, immersed in a magnetic field (lines of force per

pendicular to the direction of the current), produces a difference in power, known as Hall voltage.

If the intensity of the current remains constant, the voltage produced only depends on the intensity of the

magnetic field. The intensity of the field can simply be altered periodically to produce a modulated electri

cal signal. Signal frequency is proportional to the speed with which the magnetic field changes.

To achieve this change, the sensor is crossed by a metal ring (inner part of the pulley) with an opening.

When it moves, the metal part of the ring covers the sensor to magnetic field and the output signal is

therefore low; Conversely, the sensor generates a high signal at the opening when the magnetic field is

present.

This signal, together with the rpm and TDC signals, allows the injection control unit to identify piston po

sition and determine injection point.

AIR FLOW METER

(DEBIMETER)

The debimeter is located on the air intake

sleeve and is hot film type.

The debimeter contains an intake air tem

perature sensor.

Operation

The principle of operation is based on a

heated membrane fitted into a measurement

channel through which engine intake air

flows.

The hot film membrane is maintained at a

constant temperature (about 120 °C higher

than incoming air) by the heater coil.

The mass of air flowing through the measure

ment channel tends to take heat from the

membrane. To keep the membrane at constant

temperature, a certain current level must flow

through the resistance.

Because this current is proportional to the

mass of air that flows to the engine, it can be

measured with a Wheatstone bridge and the

resulting signal is sent to the injection control

unit.

1. Covers

2. Electronic card

3. Sensor

4. Mounting plate

5. Mount

6. o-ring

7. Temperature sensor

Copyright by Fiat Auto 13

Page 100 of 330

Engine

Fuel feed system

10.

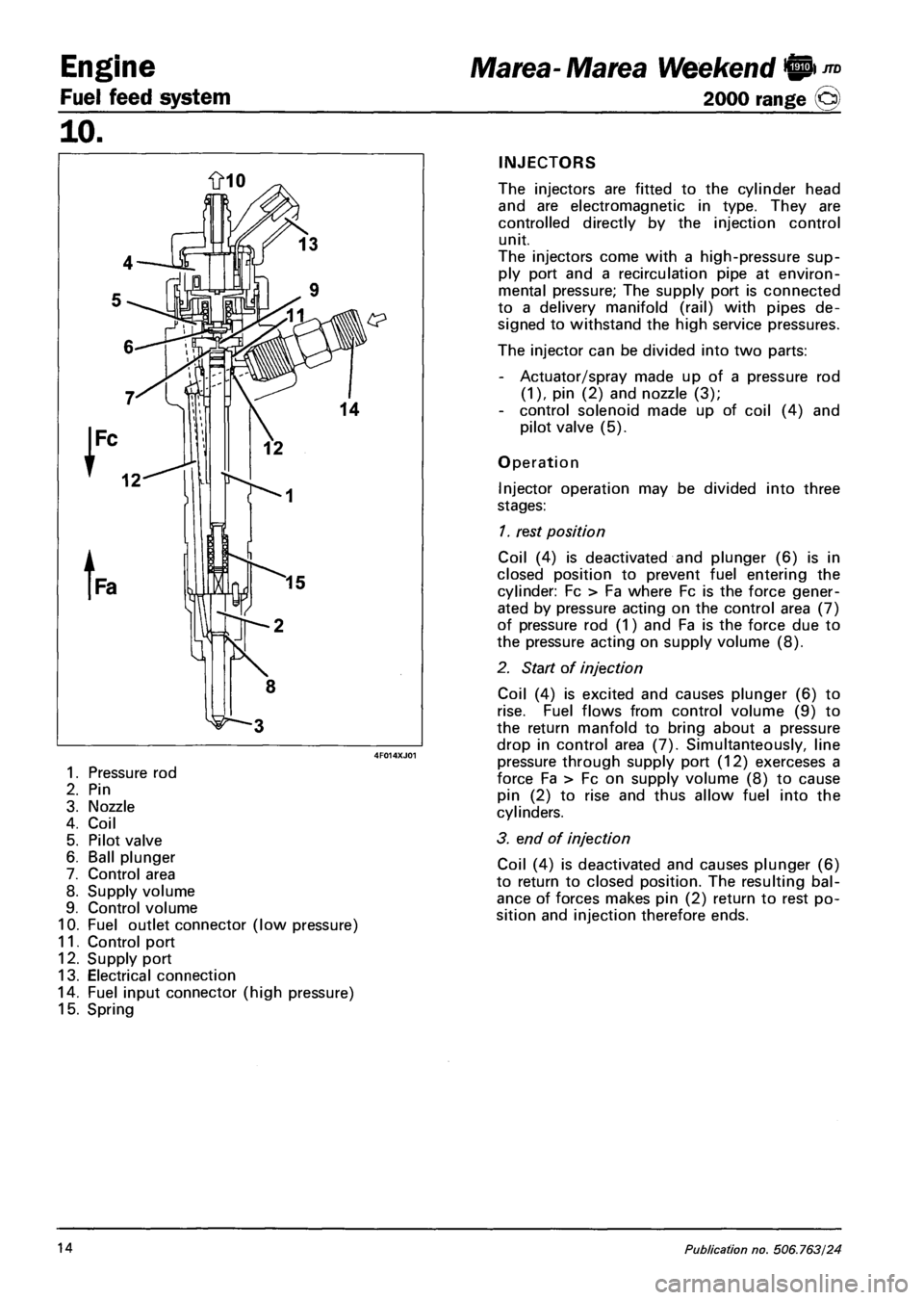

1. Pressure rod

2. Pin

3. Nozzle

4. Coil

5. Pilot valve

6. Ball plunger

7. Control area

8. Supply volume

9. Control volume

10. Fuel outlet connector (low pressure)

11. Control port

12. Supply port

13. Electrical connection

14. Fuel input connector (high pressure)

15. Spring

Marea- Marea Weekend 9 ™

2000 range (Q)

INJECTORS

The injectors are fitted to the cylinder head

and are electromagnetic in type. They are

controlled directly by the injection control

unit.

The injectors come with a high-pressure sup

ply port and a recirculation pipe at environ

mental pressure; The supply port is connected

to a delivery manifold (rail) with pipes de

signed to withstand the high service pressures.

The injector can be divided into two parts:

- Actuator/spray made up of a pressure rod

(1), pin (2) and nozzle (3);

- control solenoid made up of coil (4) and

pilot valve (5).

Operation

Injector operation may be divided into three

stages:

1. rest position

Coil (4) is deactivated and plunger (6) is in

closed position to prevent fuel entering the

cylinder: Fc > Fa where Fc is the force gener

ated by pressure acting on the control area (7)

of pressure rod (1) and Fa is the force due to

the pressure acting on supply volume (8).

2. Start of injection

Coil (4) is excited and causes plunger (6) to

rise. Fuel flows from control volume (9) to

the return manfold to bring about a pressure

drop in control area (7). Simultanteously, line

pressure through supply port (12) exerceses a

force Fa > Fc on supply volume (8) to cause

pin (2) to rise and thus allow fuel into the

cylinders.

3. end of injection

Coil (4) is deactivated and causes plunger (6)

to return to closed position. The resulting bal

ance of forces makes pin (2) return to rest po

sition and injection therefore ends.

14 Publication no. 506.763/24