Ignition FIAT MAREA 2001 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2001, Model line: MAREA, Model: FIAT MAREA 2001 1.GPages: 330

Page 7 of 330

marea-marea vvvttnviiu miruuuCuuu ciilu iwnniCai data

2000 range © Index

00.

page

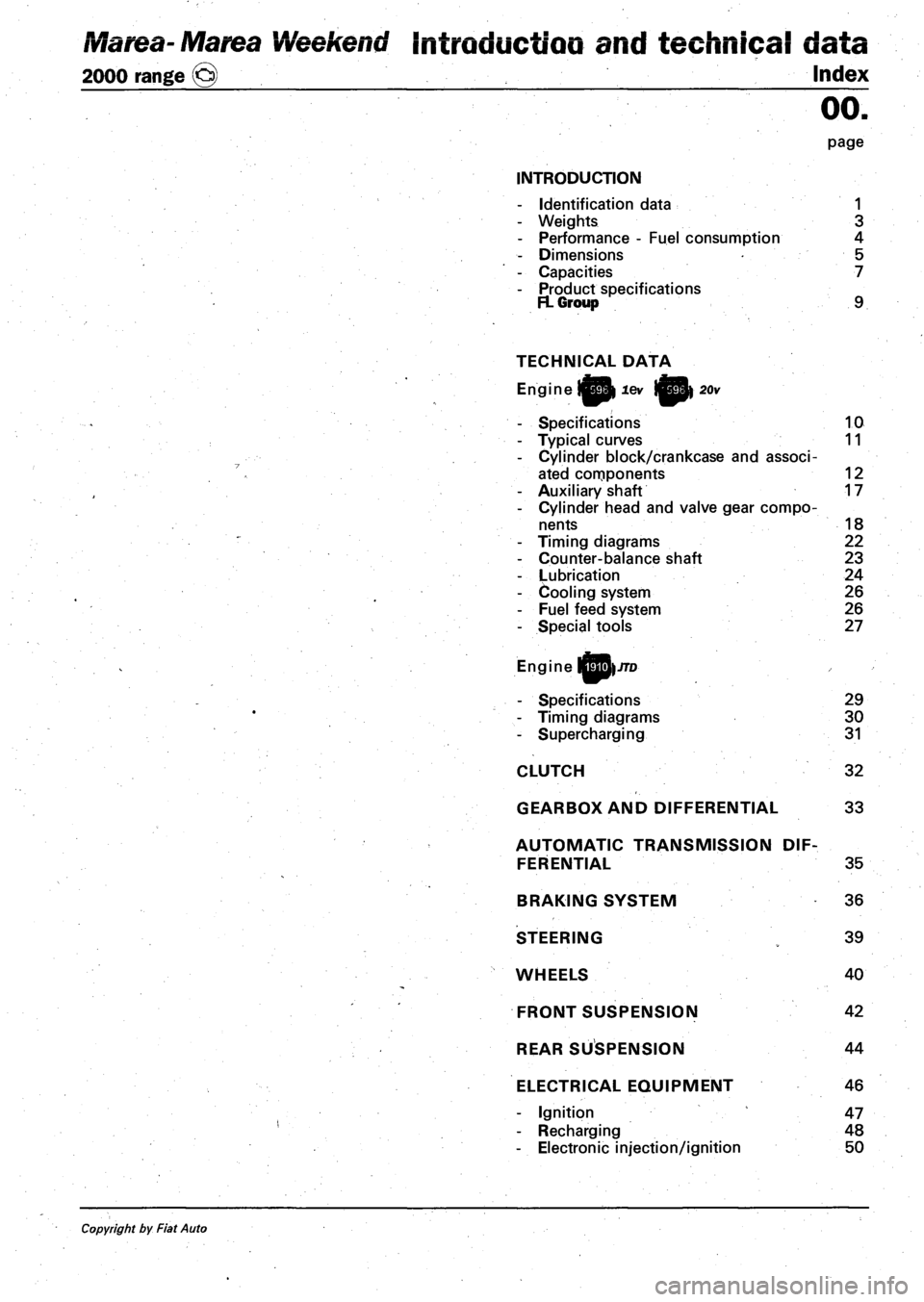

INTRODUCTION

- Identification data 1

- Weights 3

- Performance - Fuel consumption 4

- Dimensions 5

- Capacities 7

- Product specifications

FL Group 9

TECHNICAL DATA

Engine l^^) lev |^^) 20v

- Specifications 10

- Typical curves 11

- Cylinder block/crankcase and associ

ated components 12

- Auxiliary shaft 17

- Cylinder head and valve gear compo

nents 18

- Timing diagrams 22

- Counter-balance shaft 23

- Lubrication 24

- Cooling system 26

- Fuel feed system 26

- Special tools 27

Engine I^^JJTD

- Specifications 29

- Timing diagrams 30

- Supercharging 31

CLUTCH 32

GEARBOX AND DIFFERENTIAL 33

AUTOMATIC TRANSMISSION DIF

FERENTIAL 35

BRAKING SYSTEM 36

STEERING 39

WHEELS 40

FRONT SUSPENSION 42

REAR SUSPENSION 44

ELECTRICAL EQUIPMENT 46

- Ignition 47

1 - Recharging 48

- Electronic injection/ignition 50

Copyright by Fiat Auto

Page 17 of 330

Technical Data

Engine

Marea-Marea Weekend

2000 range @

OO.io

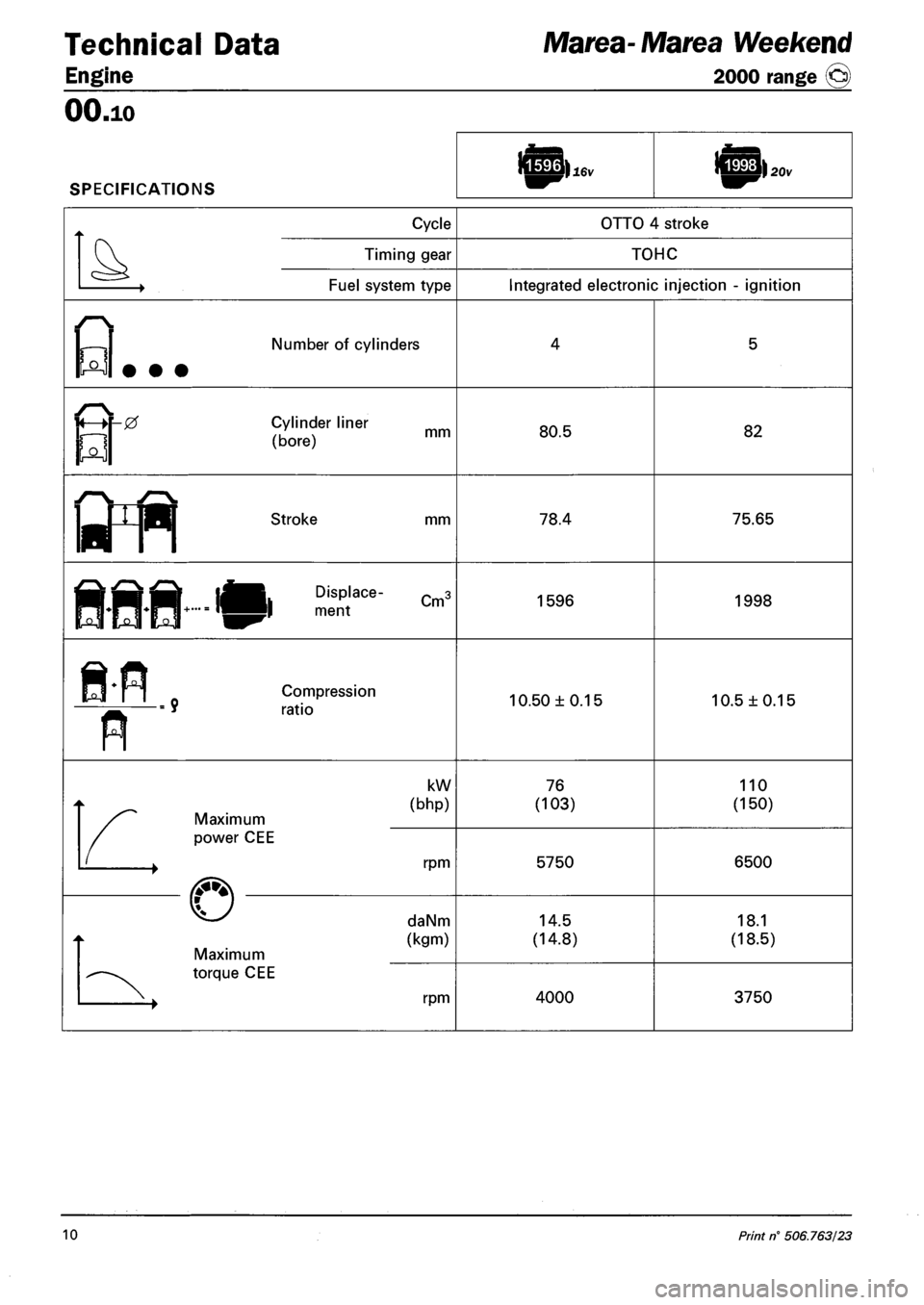

SPECIFICATIONS

Cycle OTTO 4 stroke

^Q\^ Timing gear TOHC

1 Fuel system type Integrated electronic injection - ignition

L—,1 Number of cylinders

Ml • • •

4 5

Vt—•F-jZf Cylinder liner

Is—A \ mm

W (bore)

80.5 82

j^J |q| Stroke mm 78.4 75.65

fifi-9 0> °-ace" cm3

1596 1998

^|*^^ Compression

= 9 ratio

ft

10.50 ±0.15 10.5 ±0.15

kW

r _ (bhp) X Maximum

76

(103)

110

(150)

/ power CEE

/ .. ... • rpm 5750 6500

daNm

(kgm)

Maximum

14.5

(14.8)

18.1

(18.5)

, torque CEE

... \ > rpm 4000 3750

10 Print n° 506.763/23

Page 33 of 330

Technical Data Marea-Marea Weekend

Engine: cooling system • fuel system 2000 range (§)

OO.io

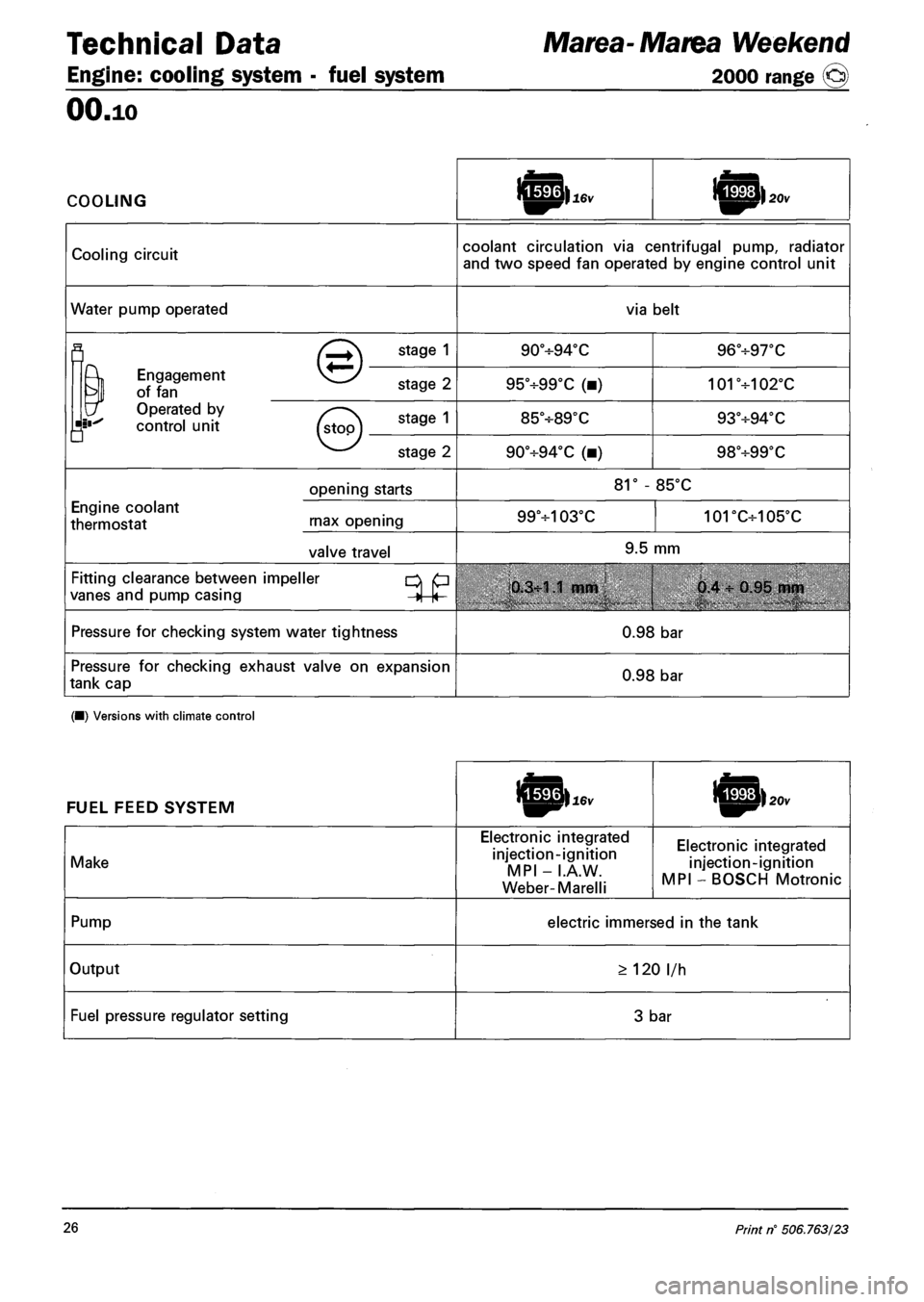

COOLING

Cooling circuit coolant circulation via centrifugal pump, radiator

and two speed fan operated by engine control unit

Water pump operated via belt

fl (^+\ STA9E 1 90°H-94°C 96°+97T

^ Engagement vj^/ ?

of fan stage Z 95°+99°C (•) 101+102°C

\f Operated by v .

control unit (s\oo\ 9 85V89X 93°-H94T

• v y

v—' stage 2 90°+94°C (•) 98+99T

opening starts 81° - 85°C

Engine coolant

thermostat rnax opening 99+103°C 101DC+105'C

valve travel 9.5 mm

Fitting clearance between impeller p

vanes and pump casing j |< 0.3:1.1 mm 0.4 : 0.95 mm

Pressure for checking system water tightness 0.98 bar

Pressure for checking exhaust valve on expansion

tank cap 0.98 bar

(•) Versions with climate control

FUEL FEED SYSTEM

Make

Electronic integrated

injection-ignition

MPI - I.A.W.

Weber-Marelli

Electronic integrated

injection-ignition

MPI - BOSCH Motronic

Pump electric immersed in the tank

Output > 120 l/h

Fuel pressure regulator setting 3 bar

26 Print n° 506.763/23

Page 34 of 330

Marea-Marea Weekend Technical Data

2000 range (j§) Engine: fuel system - special tools

OO.io

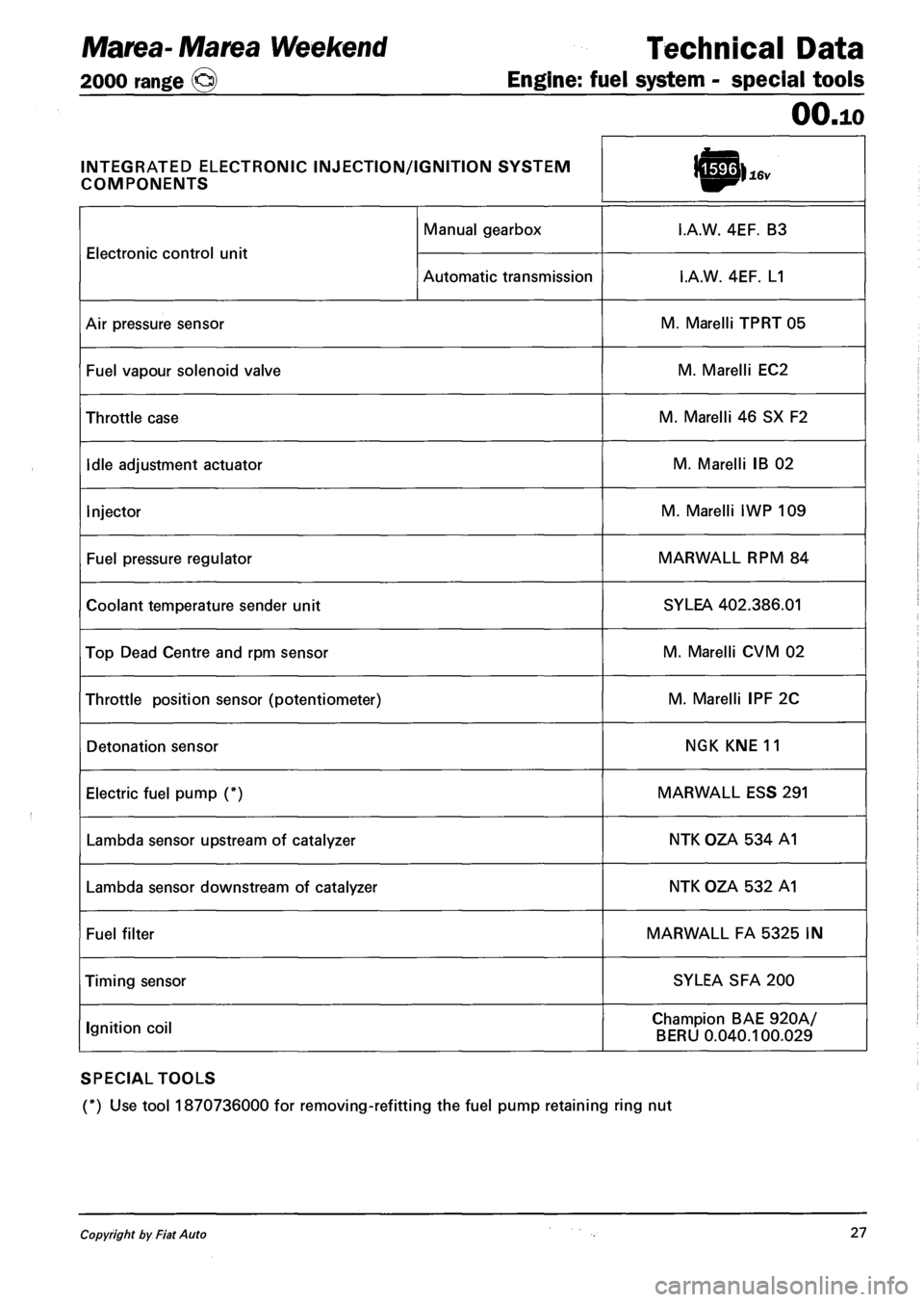

INTEGRATED ELECTRONIC INJECTION/IGNITION SYSTEM

COMPONENTS

Electronic control unit

Manual gearbox I.A.W. 4EF. B3

Electronic control unit

Automatic transmission I.A.W. 4EF. L1

Air pressure sensor M. Marelli TPRT 05

Fuel vapour solenoid valve M. Marelli EC2

Throttle case M. Marelli 46 SX F2

Idle adjustment actuator M. Marelli IB 02

Injector M. Marelli IWP 109

Fuel pressure regulator MARWALL RPM 84

Coolant temperature sender unit SYLEA 402.386.01

Top Dead Centre and rpm sensor M. Marelli CVM 02

Throttle position sensor (potentiometer) M. Marelli IPF 2C

Detonation sensor NGK KNE 11

Electric fuel pump (*) MARWALL ESS 291

Lambda sensor upstream of catalyzer NTK OZA 534 A1

Lambda sensor downstream of catalyzer NTK OZA 532 A1

Fuel filter MARWALL FA 5325 IN

Timing sensor SYLEA SFA 200

Ignition coil Champion BAE 920A/

BERU 0.040.100.029

SPECIAL TOOLS

(*) Use tool 1870736000 for removing-refitting the fuel pump retaining ring nut

Copyright by Fiat Auto 27

Page 35 of 330

Technical Data Marea- Marea Weekend

Engine: fuel system - special tools 2000 arnge ©)

OO.io

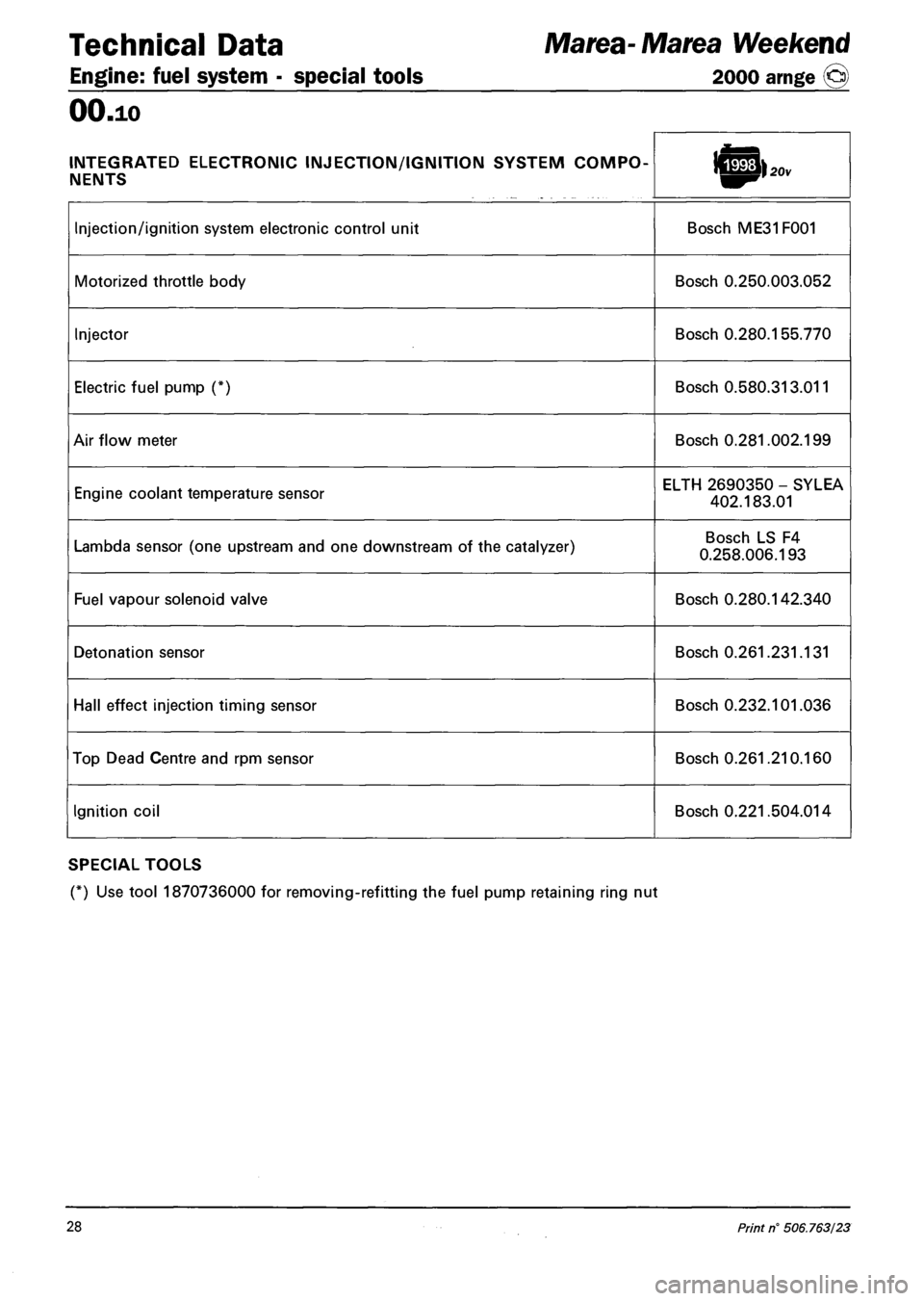

INTEGRATED ELECTRONIC INJECTION/IGNITION SYSTEM COMPO

NENTS

Injection/ignition system electronic control unit Bosch ME31F001

Motorized throttle body Bosch 0.250.003.052

Injector Bosch 0.280.155.770

Electric fuel pump (*) Bosch 0.580.313.011

Air flow meter Bosch 0.281.002.199

Engine coolant temperature sensor ELTH 2690350 - SYLEA

402.183.01

Lambda sensor (one upstream and one downstream of the catalyzer) Bosch LS F4

0.258.006.193

Fuel vapour solenoid valve Bosch 0.280.142.340

Detonation sensor Bosch 0.261.231.131

Hall effect injection timing sensor Bosch 0.232.101.036

Top Dead Centre and rpm sensor Bosch 0.261.210.160

Ignition coil Bosch 0.221.504.014

SPECIAL TOOLS

(*) Use tool 1870736000 for removing-refitting the fuel pump retaining ring nut

28 Print n° 506.763/23

Page 53 of 330

Technical Data Marea- Marea Weekend

Electrical system 2000 range (§)

00.55

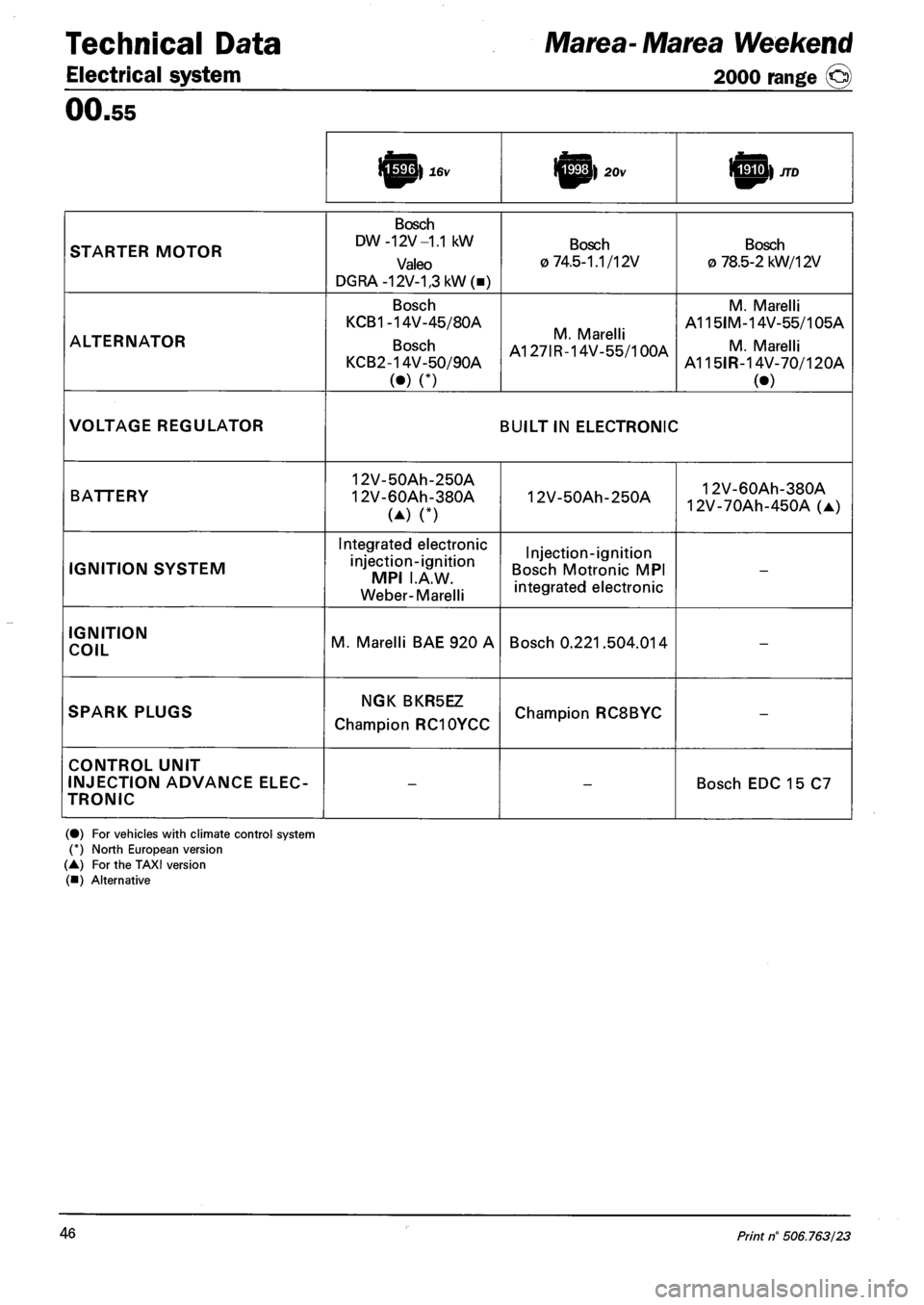

i^p} 16v J^M) 20v

STARTER MOTOR

Bosch

DW -12V -1.1 kW

Valeo

DGRA-12V-1,3kW(B)

Bosch

0 74.5-1.1/12V

Bosch

O 78.5-2 kW/12V

ALTERNATOR

Bosch

KCB1-14V-45/80A

Bosch

KCB2-14V-50/90A

(•) n

M. Marelli

A127IR-14V-55/100A

M. Marelli

A115IM-14V-55/105A

M. Marelli

A115IR-14V-70/120A

(•)

VOLTAGE REGULATOR BUILT IN ELECTRONIC

BATTERY

12V-50Ah-250A

12V-60Ah-380A

(A) n

12V-50Ah-250A 12V-60Ah-380A

12V-70Ah-450A (A)

IGNITION SYSTEM

Integrated electronic

injection-ignition

MPI I.A.W.

Weber-Marelli

Injection-ignition

Bosch Motronic MPI

integrated electronic

-

IGNITION

COIL M. Marelli BAE 920 A Bosch 0.221.504.014 -

SPARK PLUGS NGK BKR5EZ

Champion RC10YCC Champion RC8BYC -

CONTROL UNIT

INJECTION ADVANCE ELEC

TRONIC

--Bosch EDC 15 C7

(•) For vehicles with climate control system (*) North European version (A) For the TAXI version

(•) Alternative

46 Print n° 506.763/23

Page 57 of 330

Technical Data Marea-Marea Weekend

Electrical equipment: electronic injection- ignition 2000 range ©)

00.55

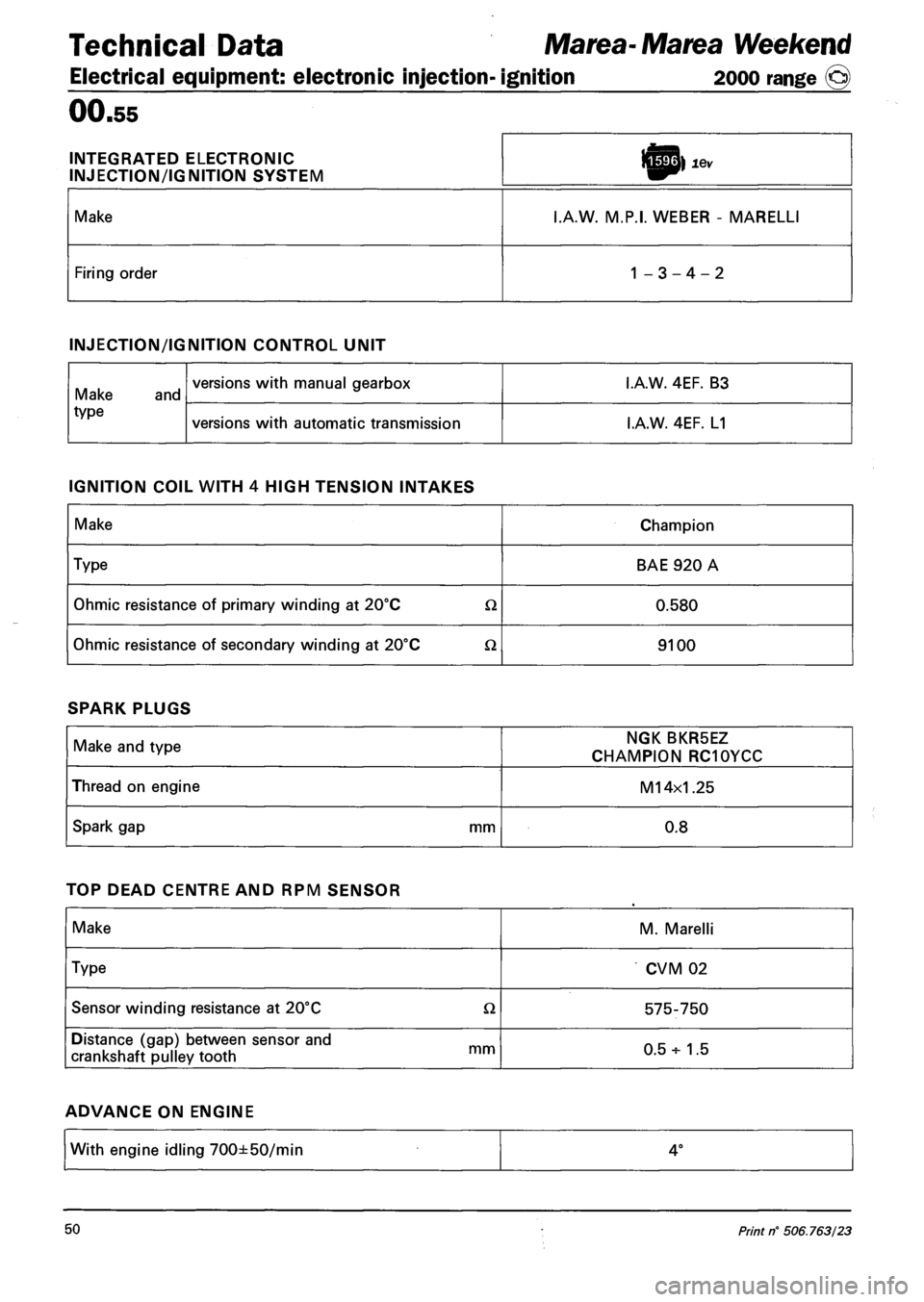

INTEGRATED ELECTRONIC

INJECTION/IGNITION SYSTEM r^p) lev

Make I.A.W. M.P.I. WEBER - MARELLI

Firing order 1-3-4-2

INJECTION/IGNITION CONTROL UNIT

Make and versions with manual gearbox I.A.W. 4EF. B3

type versions with automatic transmission I.A.W. 4EF. L1

IGNITION COIL WITH 4 HIGH TENSION INTAKES

Make Champion

Type BAE 920 A

Ohmic resistance of primary winding at 20°C Q 0.580

Ohmic resistance of secondary winding at 20°C Q 9100

SPARK PLUGS

Make and type NGK BKR5EZ

CHAMPION RC10YCC

Thread on engine M14x1.25

Spark gap mm 0.8

TOP DEAD CENTRE AND RPM SENSOR

Make M. Marelli

Type CVM 02

Sensor winding resistance at 20°C Q 575-750

Distance (gap) between sensor and

crankshaft pulley tooth 0.5 + 1.5

ADVANCE ON ENGINE

With engine idling 700±50/min 4°

50 Print n° 506.763/23

Page 58 of 330

Marea- Marea Weekend Technical Data

2000 range © Electrical equipment: electronic injection- ignition

00.55

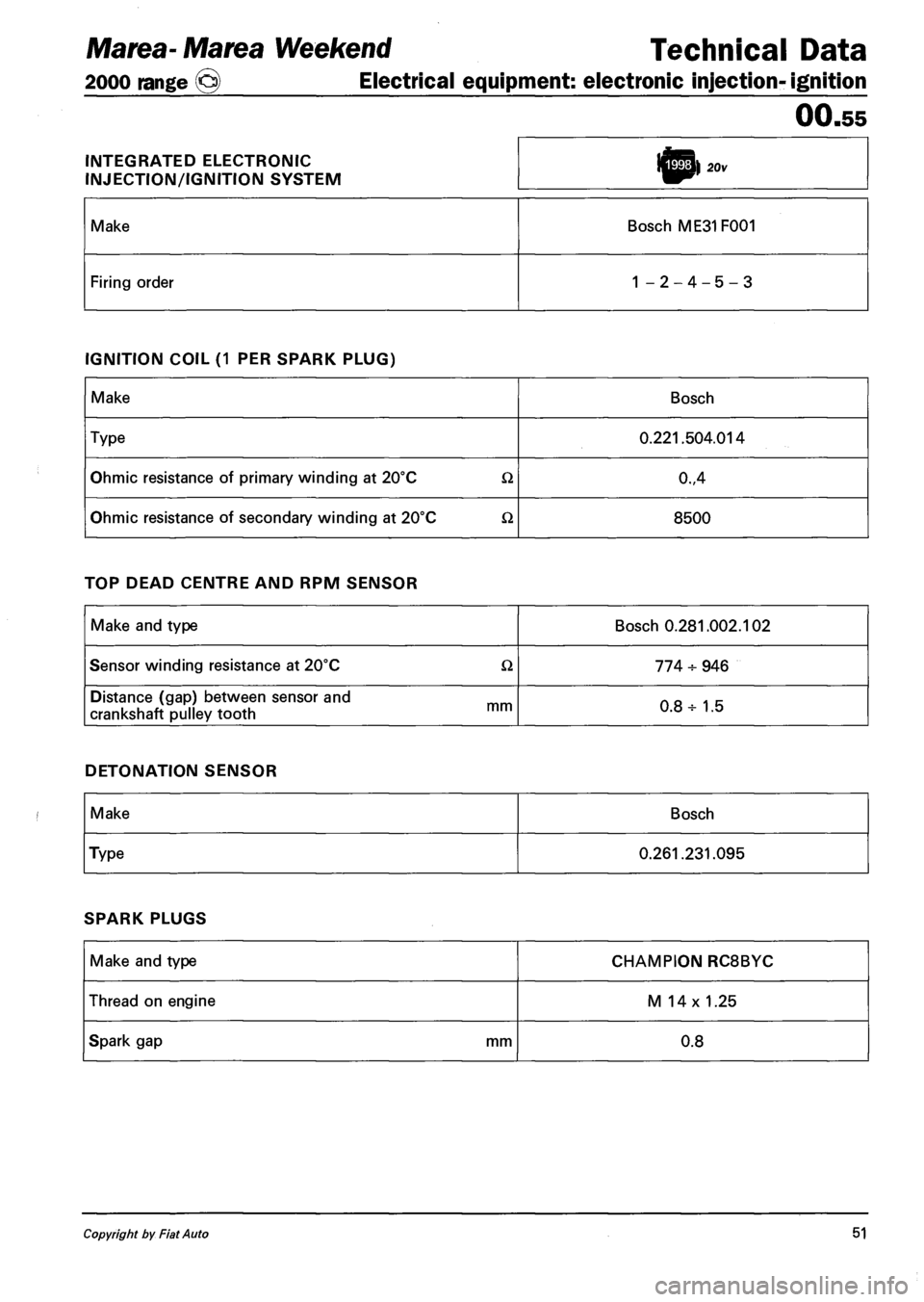

INTEGRATED ELECTRONIC

INJECTION/IGNITION SYSTEM I^P) 20v

Make Bosch ME31F001

Firing order 1-2-4-5-3

IGNITION COIL (1 PER SPARK PLUG)

Make Bosch

Type 0.221.504.014

Ohmic resistance of primary winding at 20°C Q 0.,4

Ohmic resistance of secondary winding at 20°C Q 8500

TOP DEAD CENTRE AND RPM SENSOR

Make and type Bosch 0.281.002.102

Sensor winding resistance at 20°C Q 774 + 946

Distance (gap) between sensor and

crankshaft pulley tooth 0.8 H- 1.5

DETONATION SENSOR

Make Bosch

Type 0.261.231.095

SPARK PLUGS

Make and type CHAMPION RC8BYC

Thread on engine M 14x 1.25

Spark gap mm 0.8

Copyright by Fiat Auto 51

Page 68 of 330

Marea- Marea Weekend • *» Engine

2000 range (§) Fuel feed system

10.

Pages

FUEL FEED SYSTEM

- Engine management system 1

- Diagram showing engine exhaust assem

bly 1

- Fuel anti-evaporation system ~2

- Location of diagnostic socket 2

- Location of injection/ignition system

components in the engine compartment 3

- Front Lambda sensor . 4

- Rear Lambda sensor 4

- Catalytic converter heat shield 5

- Catalytic converter 5

- Exhaust manifold 6

- Electric fuel pump with level sender unit 7

Copyright by Fiat Auto

Page 69 of 330

Marea- Marea Weekend • ^ Engine

2000 range (Q) Fuel feed system

10.

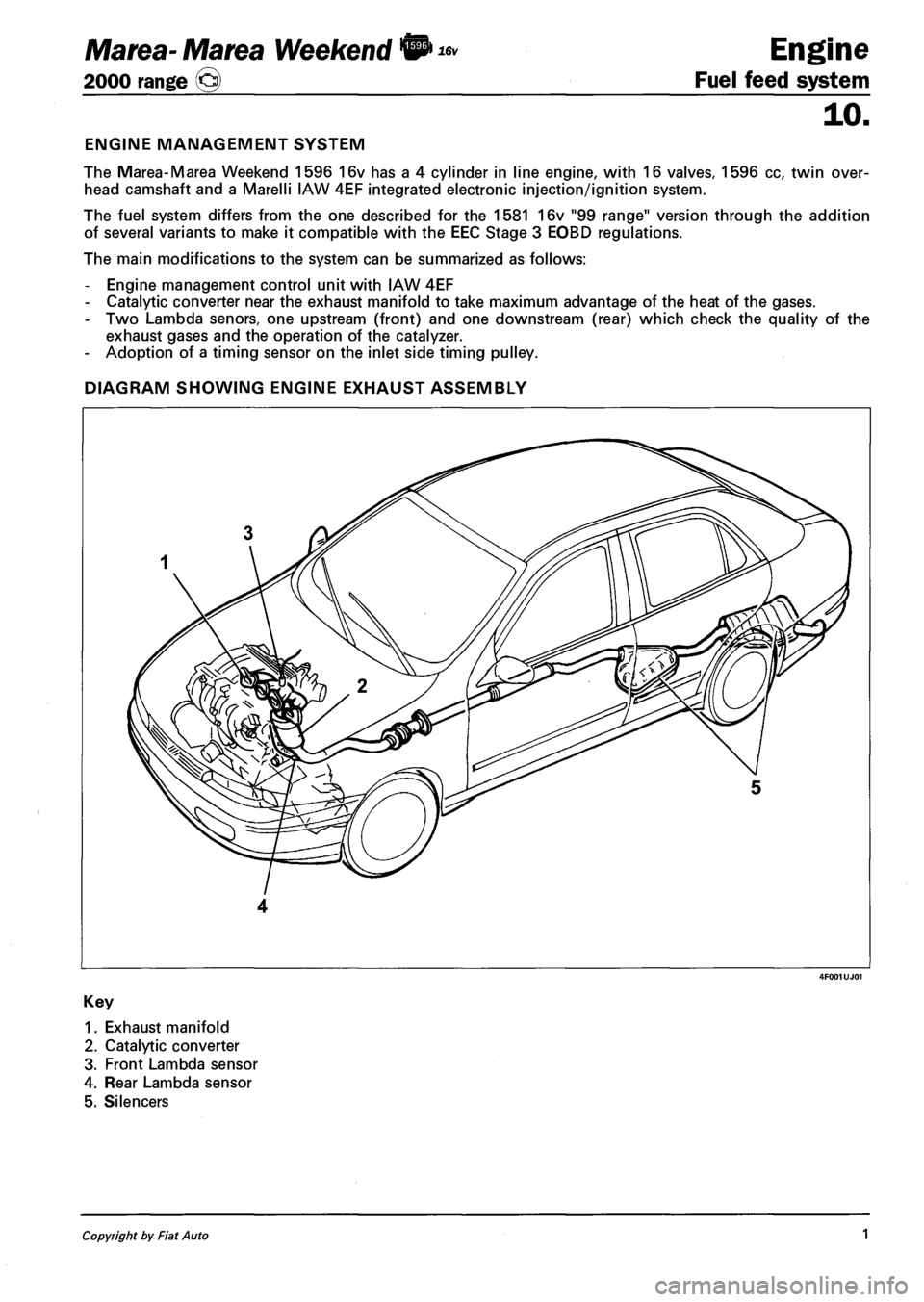

ENGINE MANAGEMENT SYSTEM

The Marea-Marea Weekend 1596 16v has a 4 cylinder in line engine, with 16 valves, 1596 cc, twin over

head camshaft and a Marelli IAW 4EF integrated electronic injection/ignition system.

The fuel system differs from the one described for the 1581 16v "99 range" version through the addition

of several variants to make it compatible with the EEC Stage 3 EOBD regulations.

The main modifications to the system can be summarized as follows:

- Engine management control unit with IAW 4EF

- Catalytic converter near the exhaust manifold to take maximum advantage of the heat of the gases.

- Two Lambda senors, one upstream (front) and one downstream (rear) which check the quality of the

exhaust gases and the operation of the catalyzer.

- Adoption of a timing sensor on the inlet side timing pulley.

DIAGRAM SHOWING ENGINE EXHAUST ASSEMBLY

1. Exhaust manifold

2. Catalytic converter

3. Front Lambda sensor

4. Rear Lambda sensor

5. Silencers

Copyright by Fiat Auto 1