FIAT PALIO 2003 178 / 1.G India Version Owners Manual

Manufacturer: FIAT, Model Year: 2003, Model line: PALIO, Model: FIAT PALIO 2003 178 / 1.GPages: 156, PDF Size: 6.27 MB

Page 131 of 156

130

ENGINES CODE -

BODYWORK VERSIONS

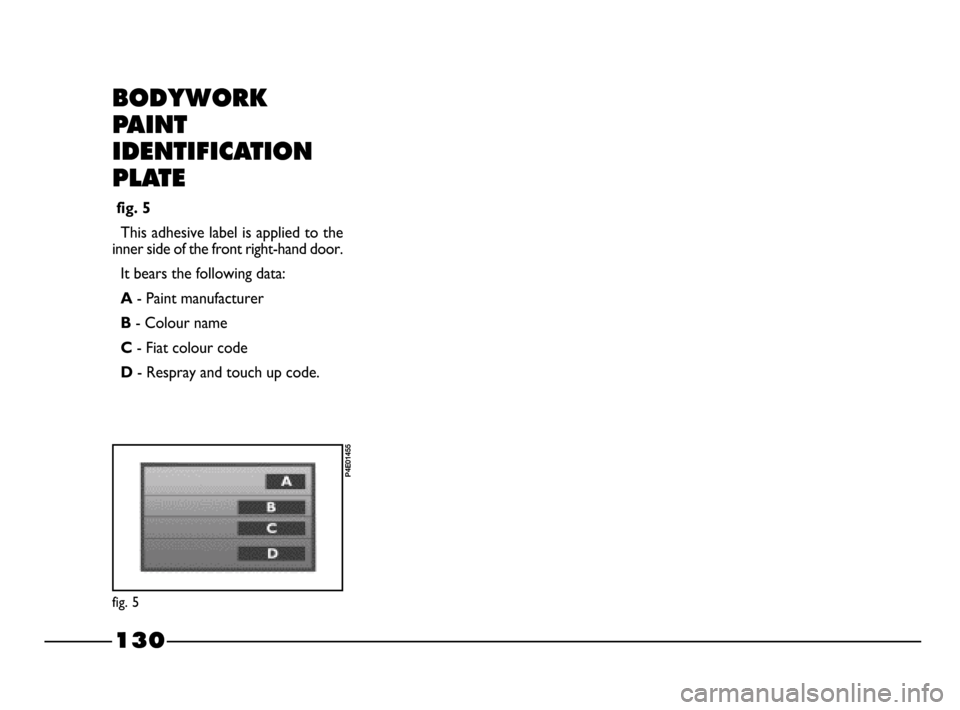

fig. 5

P4E01455

BODYWORK

PAINT

IDENTIFICATION

PLATE

fig. 5

This adhesive label is applied to the

inner side of the front right-hand door.

It bears the following data:

A - Paint manufacturer

B - Colour name

C - Fiat colour code

D- Respray and touch up code.

128-143 03/03/2003 07:39 PM Page 130

Page 132 of 156

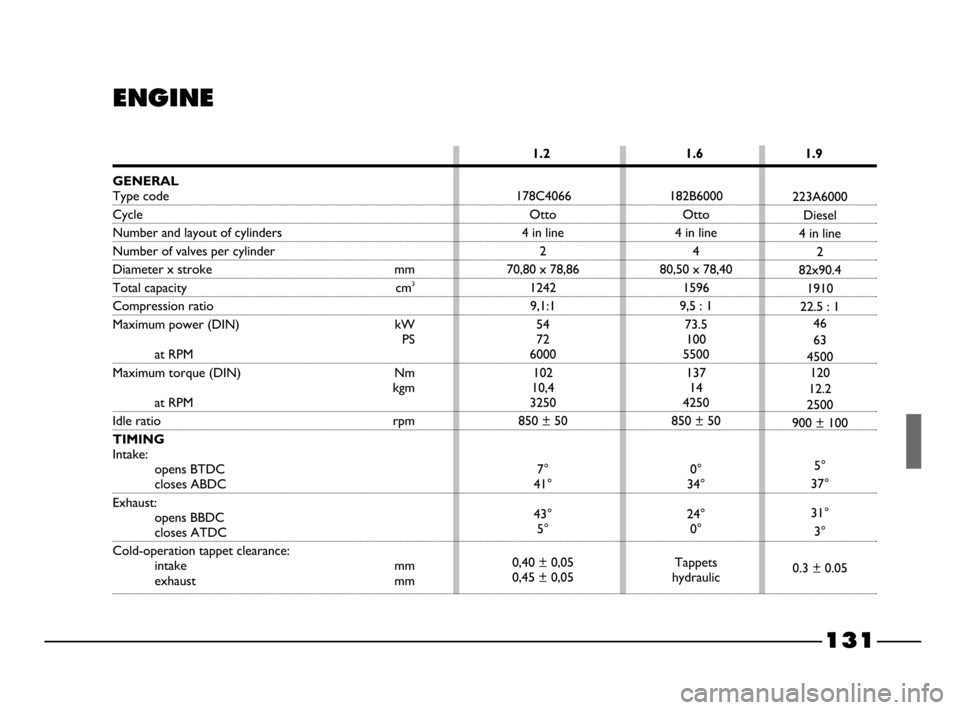

178C4066 182B6000

Otto Otto

4 in line 4 in line

24

70,80 x 78,86 80,50 x 78,40

1242 1596

9,1:1 9,5 : 1

54 73.5

72 100

6000 5500

102 137

10,4 14

3250 4250

850 ± 50 850 ± 50

7° 0°

41° 34°

43° 24°

5° 0°

0,40 ± 0,05 Tappets

0,45 ± 0,05 hydraulic

131

1.2 1.6 1.9

ENGINE

223A6000

Diesel

4 in line

2

82x90.4

1910

22.5 : 1

46

63

4500

120

12.2

2500

900 ± 100

5°

37°

31°

3°

0.3 ± 0.05

GENERAL

Type code

Cycle

Number and layout of cylinders

Number of valves per cylinder

Diameter x stroke mm

Total capacity cm3

Compression ratio

Maximum power (DIN) kW

PS

at RPM

Maximum torque (DIN) Nm

kgm

at RPM

Idle ratio rpm

TIMING

Intake:

opens BTDC

closes ABDC

Exhaust:

opens BBDC

closes ATDC

Cold-operation tappet clearance:

intake mm

exhaust mm

128-143 03/03/2003 07:39 PM Page 131

Page 133 of 156

132

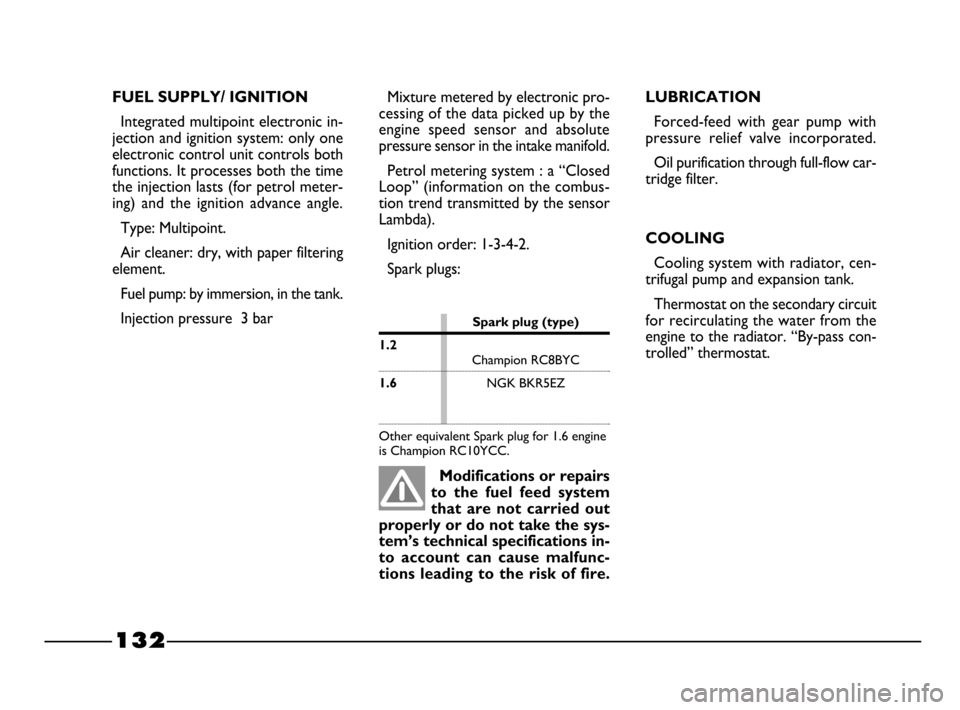

FUEL SUPPLY/ IGNITION

Integrated multipoint electronic in-

jection and ignition system: only one

electronic control unit controls both

functions. It processes both the time

the injection lasts (for petrol meter-

ing) and the ignition advance angle.

Type: Multipoint.

Air cleaner: dry, with paper filtering

element.

Fuel pump: by immersion, in the tank.

Injection pressure 3 barMixture metered by electronic pro-

cessing of the data picked up by the

engine speed sensor and absolute

pressure sensor in the intake manifold.

Petrol metering system : a “Closed

Loop” (information on the combus-

tion trend transmitted by the sensor

Lambda).

Ignition order: 1-3-4-2.

Spark plugs:

Modifications or repairs

to the fuel feed system

that are not carried out

properly or do not take the sys-

tem’s technical specifications in-

to account can cause malfunc-

tions leading to the risk of fire.

LUBRICATION

Forced-feed with gear pump with

pressure relief valve incorporated.

Oil purification through full-flow car-

tridge filter.

COOLING

Cooling system with radiator, cen-

trifugal pump and expansion tank.

Thermostat on the secondary circuit

for recirculating the water from the

engine to the radiator. “By-pass con-

trolled” thermostat.

Electrical fan for cooling the radiator

with connection/disconnection, con-

trolled by a thermostatic switch lo-

cated on the radiator.

Spark plug (type)

1.2

Champion RC7BMCChampion RC8BYC

1.6NGK BKR5EZ

Champion RC10YCC

Bosch FR8DE

Other equivalent Spark plug for 1.6 engine

is Champion RC10YCC.

128-143 03/03/2003 07:39 PM Page 132

Page 134 of 156

133

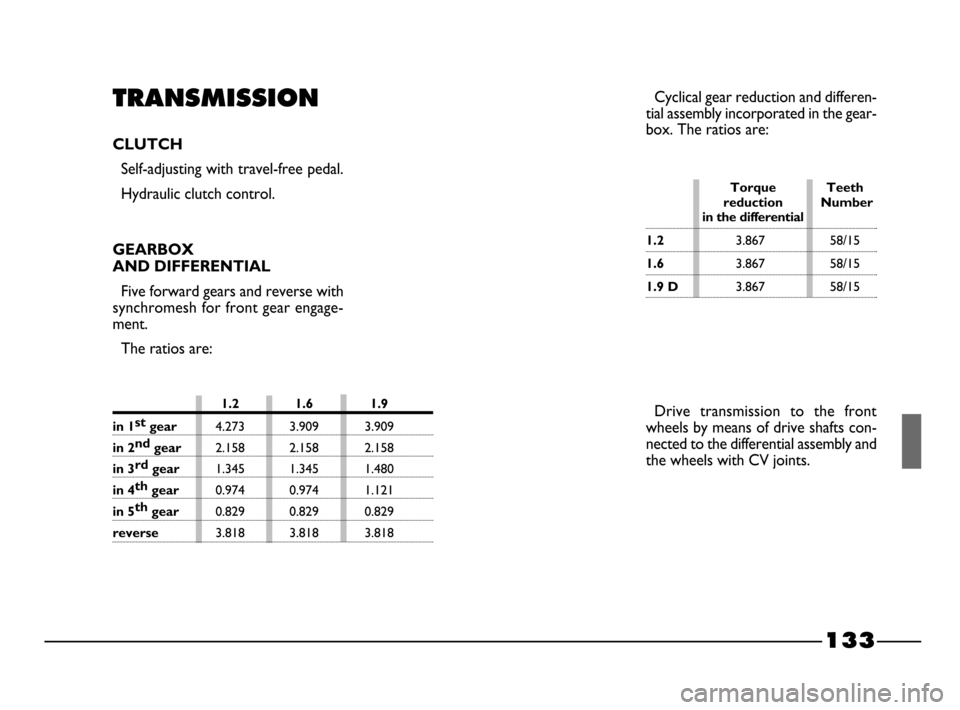

TRANSMISSION

CLUTCH

Self-adjusting with travel-free pedal.

Hydraulic clutch control.Cyclical gear reduction and differen-

tial assembly incorporated in the gear-

box. The ratios are:

Drive transmission to the front

wheels by means of drive shafts con-

nected to the differential assembly and

the wheels with CV joints.

GEARBOX

AND DIFFERENTIAL

Five forward gears and reverse with

synchromesh for front gear engage-

ment.

The ratios are:

1.2 1.6 1.9

in 1st

gear4.273 3.909 3.909

in 2nd

gear 2.158 2.158 2.158

in 3rd

gear 1.345 1.345 1.480

in 4th

gear0.974 0.974 1.121

in 5th

gear 0.829 0.829 0.829

reverse3.818 3.818 3.818

Torque Teeth

reduction Number

in the differential

1.23.867 58/15

1.63.867 58/15

1.9 D3.867 58/15

128-143 03/03/2003 07:39 PM Page 133

Page 135 of 156

134

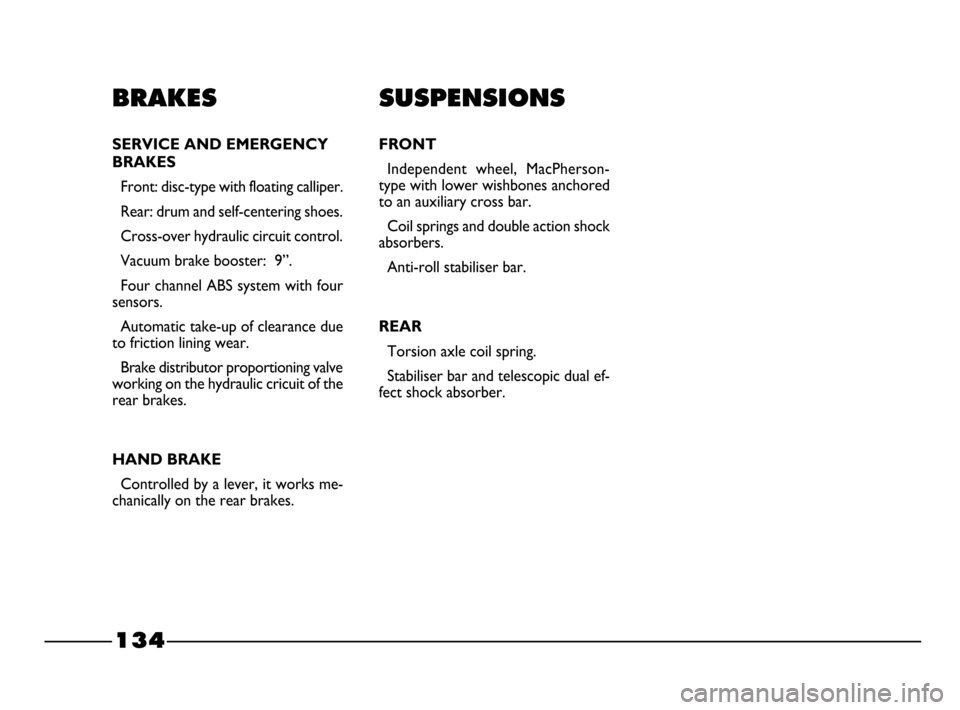

SUSPENSIONS

FRONT

Independent wheel, MacPherson-

type with lower wishbones anchored

to an auxiliary cross bar.

Coil springs and double action shock

absorbers.

Anti-roll stabiliser bar.

REAR

Torsion axle coil spring.

Stabiliser bar and telescopic dual ef-

fect shock absorber.

BRAKES

SERVICE AND EMERGENCY

BRAKES

Front: disc-type with floating calliper.

Rear: drum and self-centering shoes.

Cross-over hydraulic circuit control.

Vacuum brake booster: 9”.

Four channel ABS system with four

sensors.

Automatic take-up of clearance due

to friction lining wear.

Brake distributor proportioning valve

working on the hydraulic cricuit of the

rear brakes.

HAND BRAKE

Controlled by a lever, it works me-

chanically on the rear brakes.

128-143 03/03/2003 07:39 PM Page 134

Page 136 of 156

135

STEERING

Energy absorbing steering wheel (air

bag, if provided).

Rake adjustable, jointed energy ab-

sorbing steering column.

Mechanical or hydraulic rack and pin-

ion command with permanent lubri-

cation.

Hydraulic power steering (as pro-

vided).

Permanent lubrication joints.

Minimum turning diameter:

10.2 metres.

Number of steering wheel turns lock

to lock:

3.69 turns for mechanical steering;

2.66 turns for hydraulic steering.

Do not push the power

steering to its limit while

the engine is running for

more than 15 seconds: this will

make a noise and could damage

the system.

128-143 03/03/2003 07:39 PM Page 135

Page 137 of 156

136

Max speed index

Q

= up to 160 km/h.

R= up to 170 km/h.

S= up to 180 km/h.

T= up to 190 km/h.

U= up to 200 km/h.

H= up to 210 km/h.

V= up to 240 km/h.

W= up to 270 km/h.

Y= up to 300 km/h.

Load index (capacity)

60

= 250 kg

61 = 257 kg

62= 265 kg

63= 272 kg

64= 280 kg

65= 290 kg

66= 300 kg

67= 307 kg

68= 315 kg

69= 325 kg

70 = 335 kg

71= 345 kg

72= 355 kg

73= 365 kg

74= 375 kg

75= 387 kg

76= 400 kg

77= 412 kg

78= 425 kg

79= 437 kg

80= 450 kg

81= 462 kg

82= 475 kg

83= 487 kg

84= 500 kg

85= 515 kg

86= 530 kg

87= 545 kg

88= 560 kg

89= 580 kg

90= 600 kg

91= 615 kg

92= 630 kg

93= 650 kg

94= 670 kg

95= 690 kg

96 = 710 kg

97= 730 kg

98= 750 kg

99= 775 kg

100= 800 kg

101= 825 kg

102= 850 kg

103= 875 kg

104= 900 kg

1CORRECT READING

OF THE RIM fig. 6

The indications, necessary to know

the meaning of the identification ini-

tials printed on the rim, are listed be-

low.

CORRECT READING

OF THE TYRE fig. 6

The indications, necessary to know

the meaning of the identification ini-

tials printed on the tyre, are listed be-

low.

175= Nominal (S, distance in mm

between the sides).

65= height/width ratio (H/S) in per-

centage.

R= Radial tyre.

14= Diameter of the rim in inches

(Ø).

82= Load index (capacity).

T= Max speed index. Example

175/65 R 14 82 S

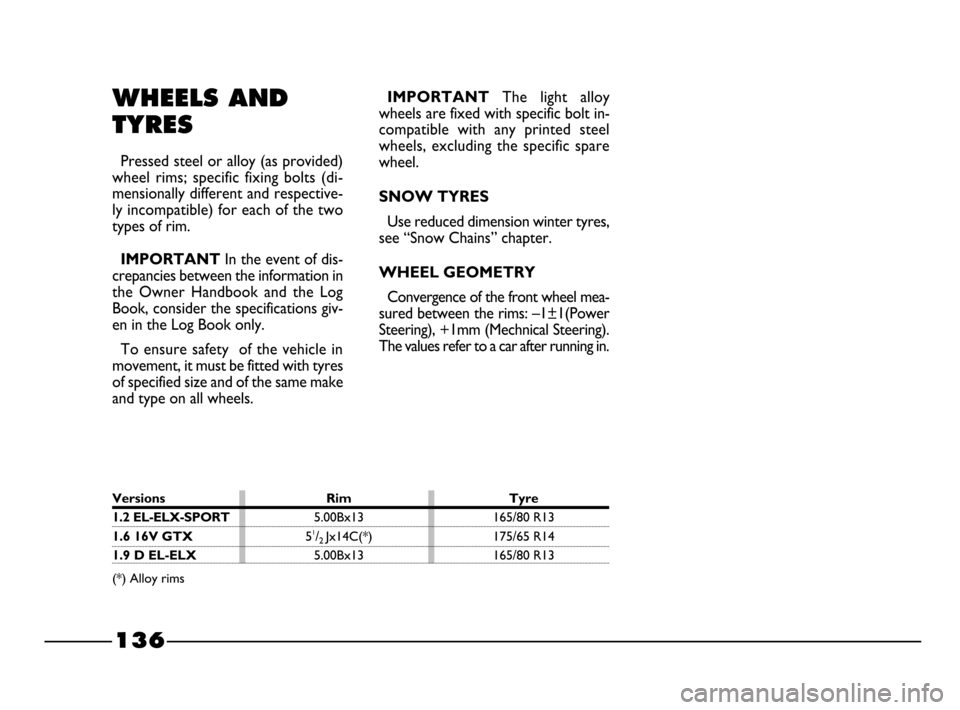

IMPORTANTThe light alloy

wheels are fixed with specific bolt in-

compatible with any printed steel

wheels, excluding the specific spare

wheel.

SNOW TYRES

Use reduced dimension winter tyres,

see “Snow Chains” chapter.

WHEEL GEOMETRY

Convergence of the front wheel mea-

sured between the rims: –1±1(Power

Steering), +1mm (Mechnical Steering).

The values refer to a car after running in.

WHEELS AND

TYRES

Pressed steel or alloy (as provided)

wheel rims; specific fixing bolts (di-

mensionally different and respective-

ly incompatible) for each of the two

types of rim.

IMPORTANTIn the event of dis-

crepancies between the information in

the Owner Handbook and the Log

Book, consider the specifications giv-

en in the Log Book only.

To ensure safety of the vehicle in

movement, it must be fitted with tyres

of specified size and of the same make

and type on all wheels.

Versions Rim Tyre

1.2 EL-ELX-SPORT5.00Bx13 165/80 R13

1.6 16V GTX51/2 Jx14C(*) 175/65 R14

1.9 D EL-ELX5.00Bx13 165/80 R13

(*) Alloy rims

128-143 03/03/2003 07:39 PM Page 136

Page 138 of 156

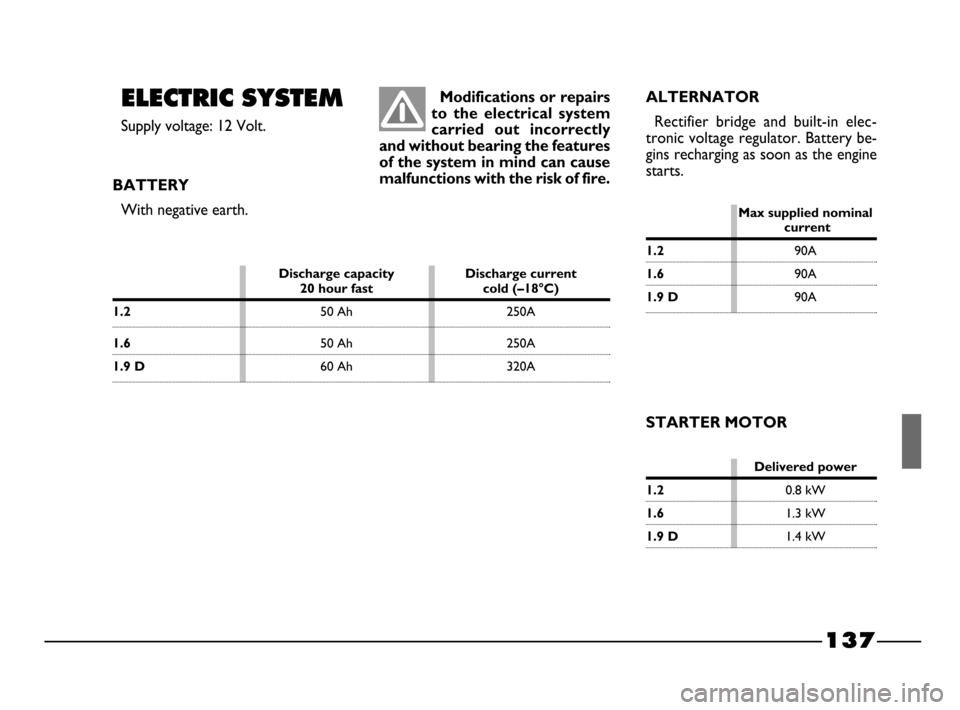

Delivered power

1.20.8 kW

1.61.3 kW

1.9 D1.4 kW

137

ALTERNATOR

Rectifier bridge and built-in elec-

tronic voltage regulator. Battery be-

gins recharging as soon as the engine

starts.

STARTER MOTOR Modifications or repairs

to the electrical system

carried out incorrectly

and without bearing the features

of the system in mind can cause

malfunctions with the risk of fire.

ELECTRIC SYSTEM

Supply voltage: 12 Volt.

BATTERY

With negative earth.

Discharge capacity Discharge current 20 hour fast cold (–18°C)

1.250 Ah 250A

1.650 Ah 250A

1.9 D60 Ah 320A

Max supplied nominalcurrent

1.290A

1.690A

1.9 D90A

128-143 03/03/2003 07:39 PM Page 137

Page 139 of 156

1015 1085

375 375

800 850

800 800

50 50

138

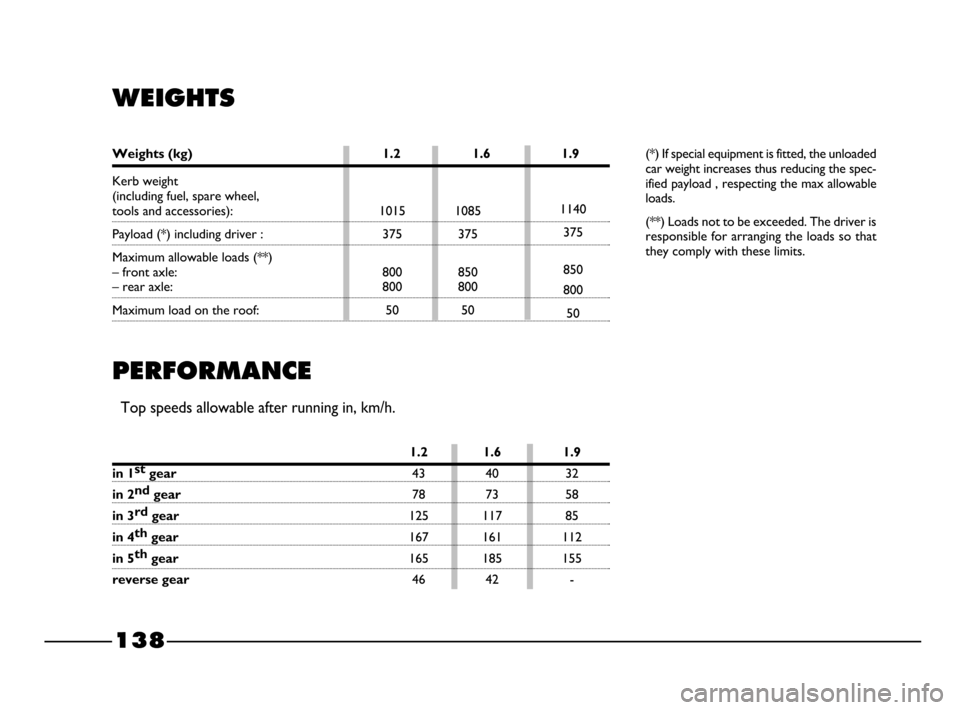

WEIGHTS

(*) If special equipment is fitted, the unloaded

car weight increases thus reducing the spec-

ified payload , respecting the max allowable

loads.

(**) Loads not to be exceeded. The driver is

responsible for arranging the loads so that

they comply with these limits.

PERFORMANCE

Top speeds allowable after running in, km/h.

1140

375

850

800

50 Kerb weight

(including fuel, spare wheel, tools and accessories):

Payload (*) including driver :

Maximum allowable loads (**)

– front axle:

– rear axle:

Maximum load on the roof:

Weights (kg) 1.2 1.6 1.9

1.2 1.6 1.9

in 1st

gear43 40 32

in 2nd

gear78 73 58

in 3rd

gear125 117 85

in 4th

gear167 161 112

in 5th

gear165 185 155

reverse gear46 42 -

128-143 03/03/2003 07:39 PM Page 138

Page 140 of 156

139

P4E02266

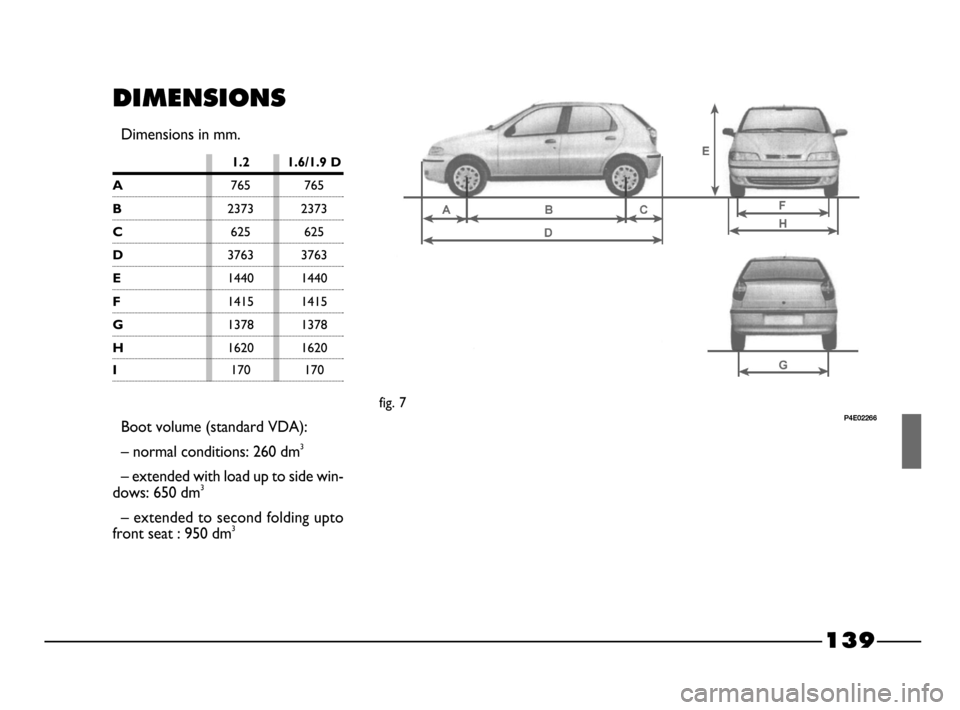

DIMENSIONS

Dimensions in mm.

1.2 1.6/1.9 D

A765 765

B2373 2373

C625 625

D3763 3763

E1440 1440

F1415 1415

G1378 1378

H1620 1620

Boot volume (standard VDA):

– normal conditions: 260 dm

3

– extended with load up to side win-

dows: 650 dm3

– extended to second folding upto

front seat : 950 dm3

fig. 7

I170 170

128-143 03/03/2003 07:39 PM Page 139