wheel bolts FIAT PALIO 2003 178 / 1.G India Version Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2003, Model line: PALIO, Model: FIAT PALIO 2003 178 / 1.GPages: 156, PDF Size: 6.27 MB

Page 83 of 156

82

BUMP STARTING IF A TYRE IS

PUNCTURED

Follow the instructions on this and

the following pages to use the jack and

spare wheel correctly.

Remember that until

the engine has started the

brake booster and power

steering systems will not work

and a greater effort will therefore

be required to depress the brake

pedal or turn the steering wheel.

An incorrectly posi-

tioned jack may cause the

car to fall.

Do not use the jack to lift loads

exceeding that indicated on the

label attached to the jack itself.

The jack should only be used to

change a wheel on the car for

which it is designed. It should not

be put to other uses or employed

to raise other models of cars. Un-

der no circumstances should it be

used when carrying out repairs

under the car.

Do not lubricate the bolt

threads before fitting them back:

they could come loose.

Never start the engine,

when the car is raised on

a jack. Never tamper with

the inflation valve. Never place

tools between the rim and tyre.

Check the tyre and spare wheel

pressure regularly. The tyre in-

flation pressure is shown in the

“Technical specifications” chap-

ter.

Never bump start the

engine (by pushing, tow-

ing or coasting downhill).

This could cause fuel to flow in-

to the catalytic exhaust system

and damage it beyond repair.

If the car is fitted with al-

loy rims, a specific spare

wheel is provided. It is dif-

ferent from the one provided for

the cars fitted with steel rims. In

the event of successive purchase

of alloy rims, replacing the steel

rims, we suggest you to keep at

disposal 4 genuine bolts, which

will be used only with the spare

wheel. Danger of damaging the

wheel hubs

80-103 03/03/2003 06:49 PM Page 82

Page 85 of 156

5) Warn anyone nearby that the car

is about to be lifted. They must stay

clear and not touch the car until it is

back on the ground.

6)Fit the operating handle on the

jack and turn it until the wheel to be

changed lifts a few centimetres off the

ground. When turning the jack handle

make sure that it can be used easily

and take care not to scrape your hand

against the ground› . The moving parts

of the jack (screw and joints) may al-

so cause injury if touched. Clean off

any grease.

7)Unscrew the 4 wheel bolts and

remove the wheel.

8) Ensure that the housing for the

wheel bolts on the spare wheel are

clean and free from dirt, which could

cause the wheel bolts to come loose.

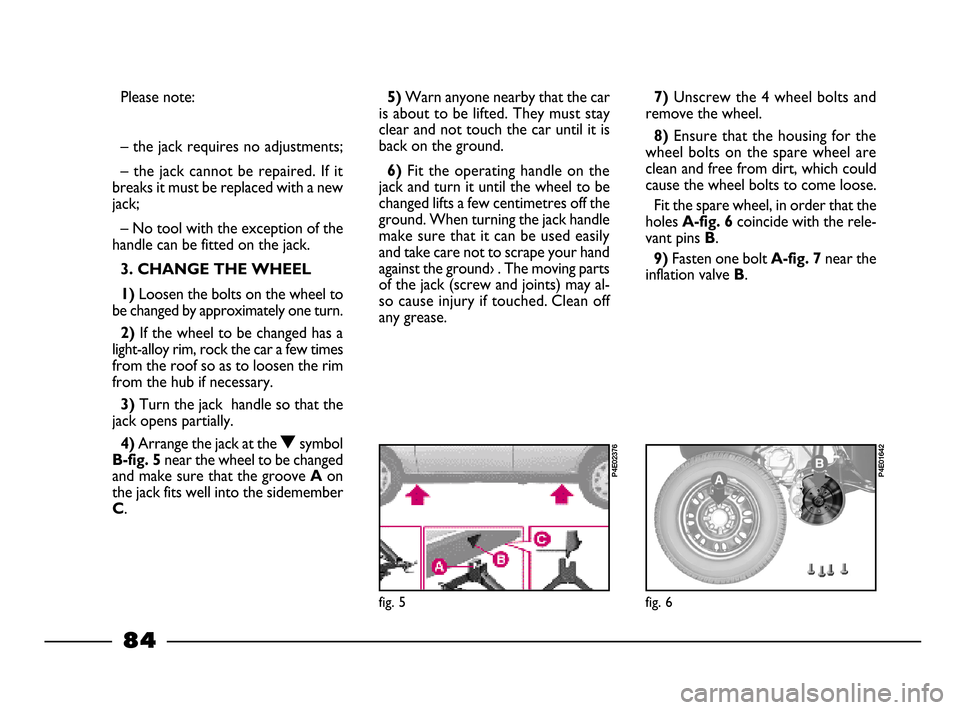

Fit the spare wheel, in order that the

holes

A-fig. 6coincide with the rele-

vant pins

B.

9) Fasten one bolt A-fig. 7near the

inflation valve

B.

fig. 6

P4E01642

fig. 5

P4E02376

84

Please note:

– the jack weighs 2.900 kg;

– the jack requires no adjustments;

– the jack cannot be repaired. If it

breaks it must be replaced with a new

jack;

– No tool with the exception of the

handle can be fitted on the jack.

3. CHANGE THE WHEEL

1)

Loosen the bolts on the wheel to

be changed by approximately one turn.

2) If the wheel to be changed has a

light-alloy rim, rock the car a few times

from the roof so as to loosen the rim

from the hub if necessary.

3) Turn the jack handle so that the

jack opens partially.

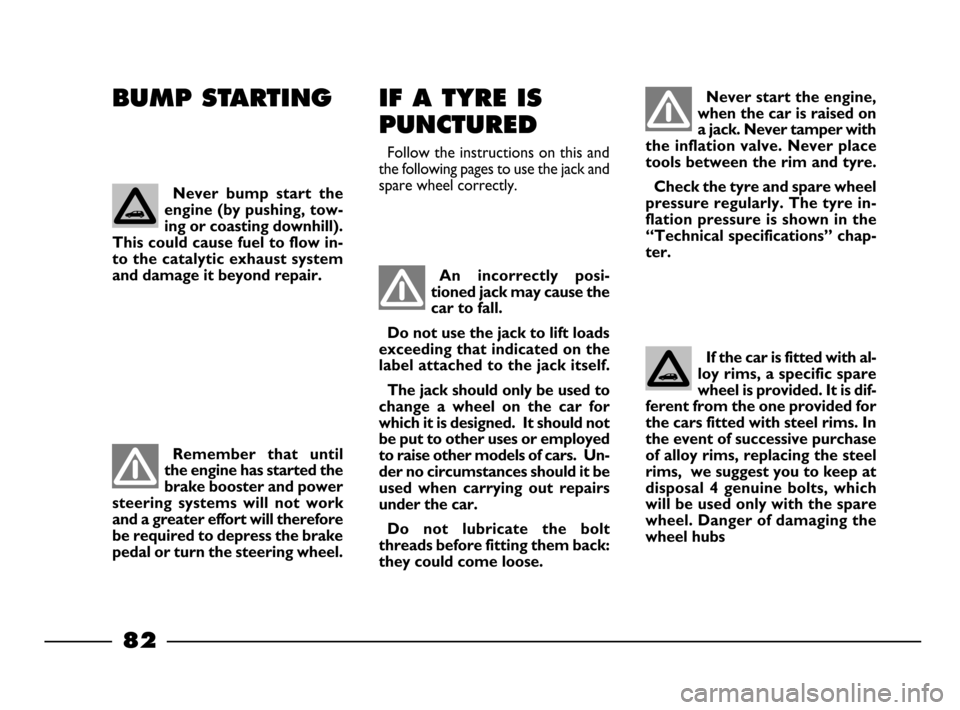

4)Arrange the jack at the Osymbol

B-fig. 5 near the wheel to be changed

and make sure that the groove

Aon

the jack fits well into the sidemember

C.

80-103 03/03/2003 06:49 PM Page 84

Page 86 of 156

85

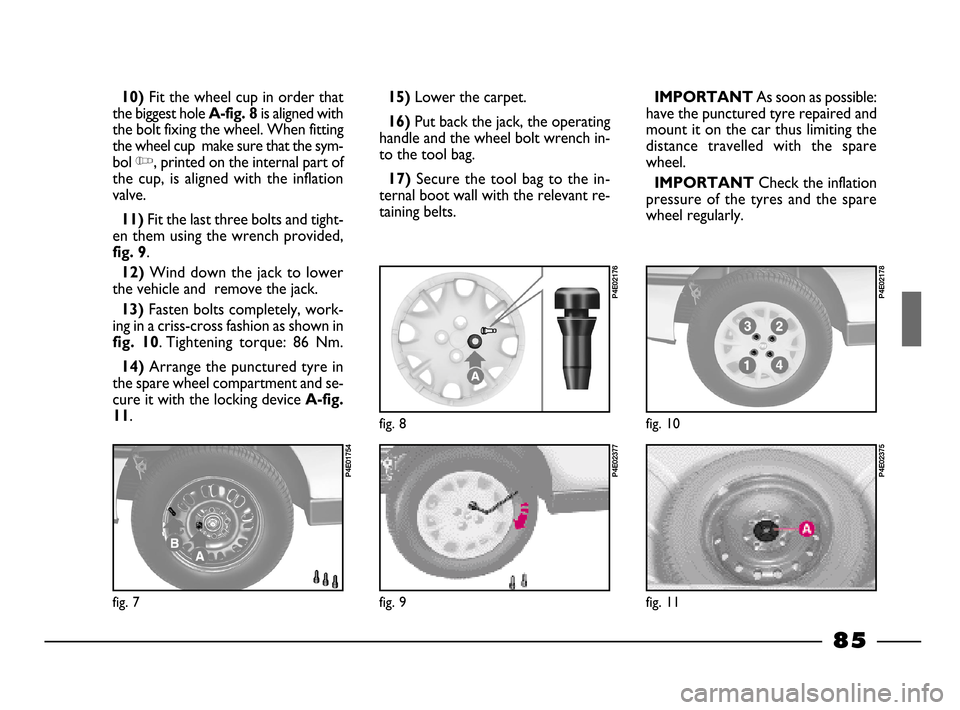

10)Fit the wheel cup in order that

the biggest hole

A-fig. 8is aligned with

the bolt fixing the wheel. When fitting

the wheel cup make sure that the sym-

bol

Y, printed on the internal part of

the cup, is aligned with the inflation

valve.

11)Fit the last three bolts and tight-

en them using the wrench provided,

fig. 9.

12)Wind down the jack to lower

the vehicle and remove the jack.

13)Fasten bolts completely, work-

ing in a criss-cross fashion as shown in

fig. 10. Tightening torque: 86 Nm.

14)Arrange the punctured tyre in

the spare wheel compartment and se-

cure it with the locking device

A-fig.

11

.

fig. 7

P4E01754

15)Lower the carpet.

16)Put back the jack, the operating

handle and the wheel bolt wrench in-

to the tool bag.

17)Secure the tool bag to the in-

ternal boot wall with the relevant re-

taining belts.

fig. 8

P4E02176

fig. 9

P4E02377

IMPORTANT As soon as possible:

have the punctured tyre repaired and

mount it on the car thus limiting the

distance travelled with the spare

wheel.

IMPORTANT Check the inflation

pressure of the tyres and the spare

wheel regularly.

fig. 10

P4E02178

fig. 11

P4E02375

80-103 03/03/2003 06:49 PM Page 85

Page 137 of 156

136

Max speed index

Q

= up to 160 km/h.

R= up to 170 km/h.

S= up to 180 km/h.

T= up to 190 km/h.

U= up to 200 km/h.

H= up to 210 km/h.

V= up to 240 km/h.

W= up to 270 km/h.

Y= up to 300 km/h.

Load index (capacity)

60

= 250 kg

61 = 257 kg

62= 265 kg

63= 272 kg

64= 280 kg

65= 290 kg

66= 300 kg

67= 307 kg

68= 315 kg

69= 325 kg

70 = 335 kg

71= 345 kg

72= 355 kg

73= 365 kg

74= 375 kg

75= 387 kg

76= 400 kg

77= 412 kg

78= 425 kg

79= 437 kg

80= 450 kg

81= 462 kg

82= 475 kg

83= 487 kg

84= 500 kg

85= 515 kg

86= 530 kg

87= 545 kg

88= 560 kg

89= 580 kg

90= 600 kg

91= 615 kg

92= 630 kg

93= 650 kg

94= 670 kg

95= 690 kg

96 = 710 kg

97= 730 kg

98= 750 kg

99= 775 kg

100= 800 kg

101= 825 kg

102= 850 kg

103= 875 kg

104= 900 kg

1CORRECT READING

OF THE RIM fig. 6

The indications, necessary to know

the meaning of the identification ini-

tials printed on the rim, are listed be-

low.

CORRECT READING

OF THE TYRE fig. 6

The indications, necessary to know

the meaning of the identification ini-

tials printed on the tyre, are listed be-

low.

175= Nominal (S, distance in mm

between the sides).

65= height/width ratio (H/S) in per-

centage.

R= Radial tyre.

14= Diameter of the rim in inches

(Ø).

82= Load index (capacity).

T= Max speed index. Example

175/65 R 14 82 S

IMPORTANTThe light alloy

wheels are fixed with specific bolt in-

compatible with any printed steel

wheels, excluding the specific spare

wheel.

SNOW TYRES

Use reduced dimension winter tyres,

see “Snow Chains” chapter.

WHEEL GEOMETRY

Convergence of the front wheel mea-

sured between the rims: –1±1(Power

Steering), +1mm (Mechnical Steering).

The values refer to a car after running in.

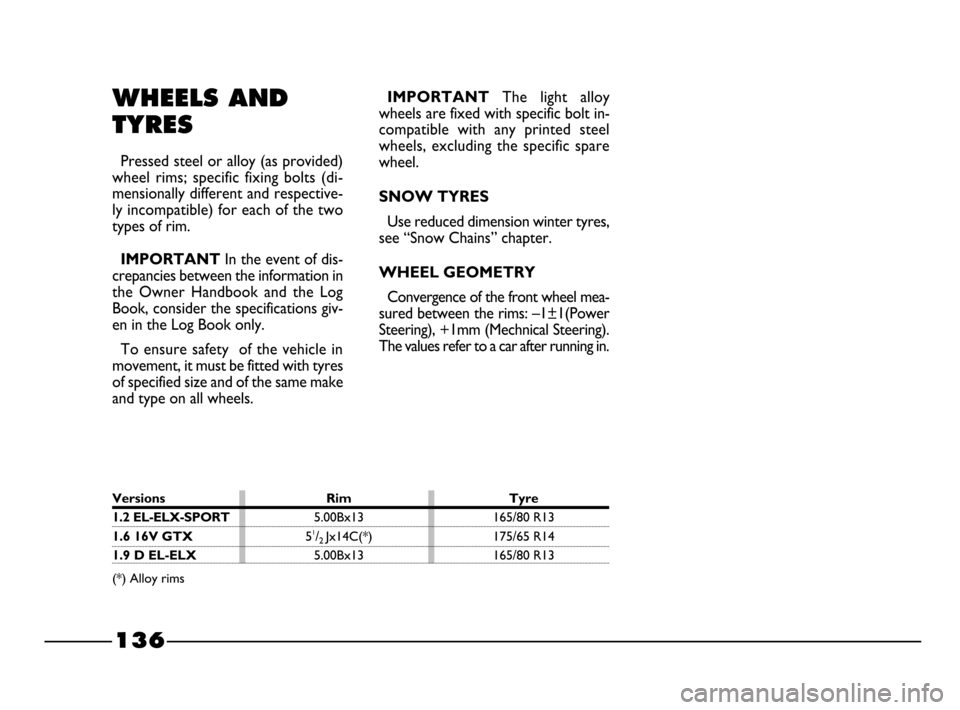

WHEELS AND

TYRES

Pressed steel or alloy (as provided)

wheel rims; specific fixing bolts (di-

mensionally different and respective-

ly incompatible) for each of the two

types of rim.

IMPORTANTIn the event of dis-

crepancies between the information in

the Owner Handbook and the Log

Book, consider the specifications giv-

en in the Log Book only.

To ensure safety of the vehicle in

movement, it must be fitted with tyres

of specified size and of the same make

and type on all wheels.

Versions Rim Tyre

1.2 EL-ELX-SPORT5.00Bx13 165/80 R13

1.6 16V GTX51/2 Jx14C(*) 175/65 R14

1.9 D EL-ELX5.00Bx13 165/80 R13

(*) Alloy rims

128-143 03/03/2003 07:39 PM Page 136