FIAT PANDA 2017 319 / 3.G Owners Manual

Manufacturer: FIAT, Model Year: 2017, Model line: PANDA, Model: FIAT PANDA 2017 319 / 3.GPages: 216, PDF Size: 19.25 MB

Page 101 of 216

STOP/START

SYSTEM

125) 126)46)

The Stop/Start system automatically

stops the engine when the vehicle

is stationary and starts it again when

the driver wants to move off. This

reduces consumption, the emission of

harmful gases and noise pollution.

OPERATING MODE

Engine stopping mode: with the

vehicle stopped, the engine stops with

gearbox in neutral and clutch pedal

released.

NoteThe engine can only be stopped

automatically after exceeding a speed

of about 10 km/h, to prevent the engine

from being repeatedly stopped when

driving at walking pace.

Restarting the engine: press the

clutch pedal to restart the engine.MANUAL SYSTEM

ACTIVATION/

DEACTIVATION

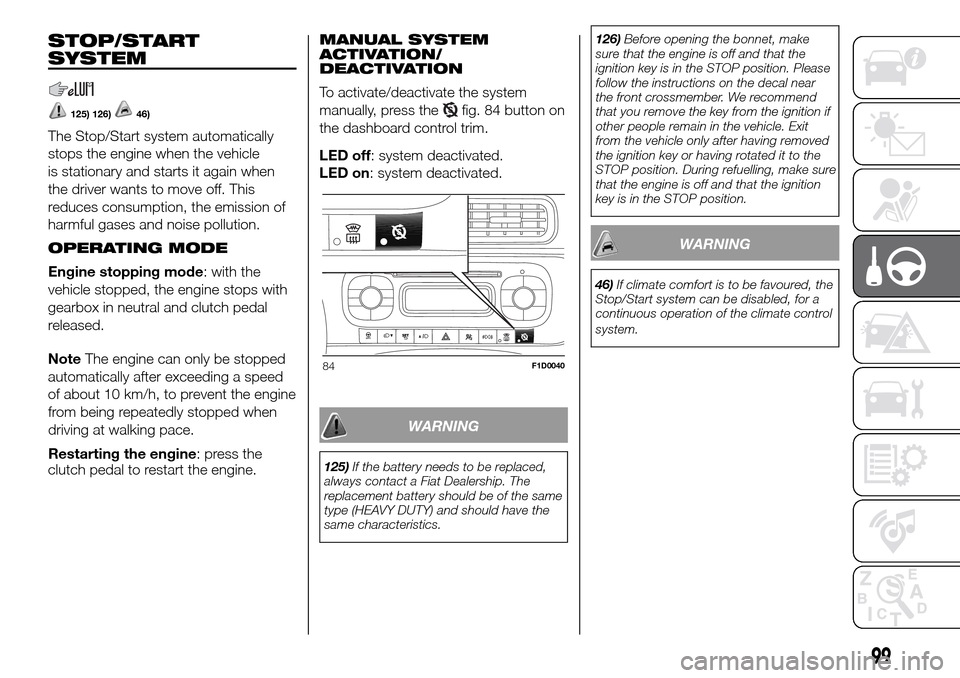

To activate/deactivate the system

manually, press the

fig. 84 button on

the dashboard control trim.

LED off: system deactivated.

LED on: system deactivated.

WARNING

125)If the battery needs to be replaced,

always contact a Fiat Dealership. The

replacement battery should be of the same

type (HEAVY DUTY) and should have the

same characteristics.126)Before opening the bonnet, make

sure that the engine is off and that the

ignition key is in the STOP position. Please

follow the instructions on the decal near

the front crossmember. We recommend

that you remove the key from the ignition if

other people remain in the vehicle. Exit

from the vehicle only after having removed

the ignition key or having rotated it to the

STOP position. During refuelling, make sure

that the engine is off and that the ignition

key is in the STOP position.

WARNING

46)If climate comfort is to be favoured, the

Stop/Start system can be disabled, for a

continuous operation of the climate control

system.

84F1D0040

99

Page 102 of 216

PARKING SENSORS

127)47)

SENSORS

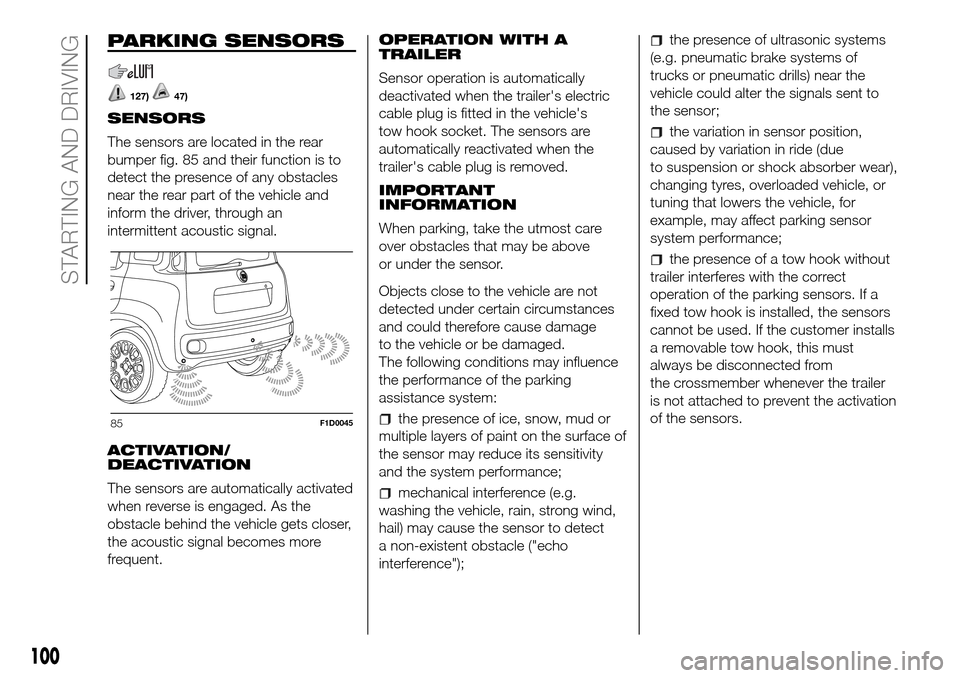

The sensors are located in the rear

bumper fig. 85 and their function is to

detect the presence of any obstacles

near the rear part of the vehicle and

inform the driver, through an

intermittent acoustic signal.

ACTIVATION/

DEACTIVATION

The sensors are automatically activated

when reverse is engaged. As the

obstacle behind the vehicle gets closer,

the acoustic signal becomes more

frequent.OPERATION WITH A

TRAILER

Sensor operation is automatically

deactivated when the trailer's electric

cable plug is fitted in the vehicle's

tow hook socket. The sensors are

automatically reactivated when the

trailer's cable plug is removed.

IMPORTANT

INFORMATION

When parking, take the utmost care

over obstacles that may be above

or under the sensor.

Objects close to the vehicle are not

detected under certain circumstances

and could therefore cause damage

to the vehicle or be damaged.

The following conditions may influence

the performance of the parking

assistance system:

the presence of ice, snow, mud or

multiple layers of paint on the surface of

the sensor may reduce its sensitivity

and the system performance;

mechanical interference (e.g.

washing the vehicle, rain, strong wind,

hail) may cause the sensor to detect

a non-existent obstacle ("echo

interference");

the presence of ultrasonic systems

(e.g. pneumatic brake systems of

trucks or pneumatic drills) near the

vehicle could alter the signals sent to

the sensor;

the variation in sensor position,

caused by variation in ride (due

to suspension or shock absorber wear),

changing tyres, overloaded vehicle, or

tuning that lowers the vehicle, for

example, may affect parking sensor

system performance;

the presence of a tow hook without

trailer interferes with the correct

operation of the parking sensors. If a

fixed tow hook is installed, the sensors

cannot be used. If the customer installs

a removable tow hook, this must

always be disconnected from

the crossmember whenever the trailer

is not attached to prevent the activation

of the sensors.

85F1D0045

100

STARTING AND DRIVING

Page 103 of 216

WARNING

127)The responsibility for parking and

other dangerous manoeuvres always and

in every case lies with the driver. While

carrying out these manoeuvres, always

make sure that no people (especially

children) or animals are in the area

concerned. The parking sensors are used

to assist the driver, who must never allow

his attention to lapse during potentially

dangerous manoeuvres, even those

executed at low speeds.

WARNING

47)The sensors must be clean of mud,

dirt, snow or ice in order for the system to

operate correctly. Be careful not to scratch

or damage the sensors while cleaning

them. Avoid using dry, rough or hard

cloths. The sensors must be washed using

clean water, with the addition of vehicle

shampoo if necessary. When using special

washing equipment such as high pressure

jets or steam cleaning, clean the sensors

very quickly keeping the jet more than

10 cm away.

REFUELLING THE

VEHICLE

128) 129) 130)

Always stop the engine before

refuelling.

PETROL ENGINES

Only use unleaded petrol, with an

octane number (R.O.N.) not lower than

95. In order to prevent damage to the

catalytic converter never introduce even

the smallest amount of leaded petrol,

even in the event of an emergency.

DIESEL ENGINES

Only use Diesel for motor vehicles

(EN590 specification).

When using or parking the car for a

long time in the mountains or cold

areas, it is advisable to refuel using

locally available diesel. In this case, it is

also advisable to keep the tank over

50% full.

REFUELLING

PROCEDURE

48)

Diesel and petrol versions

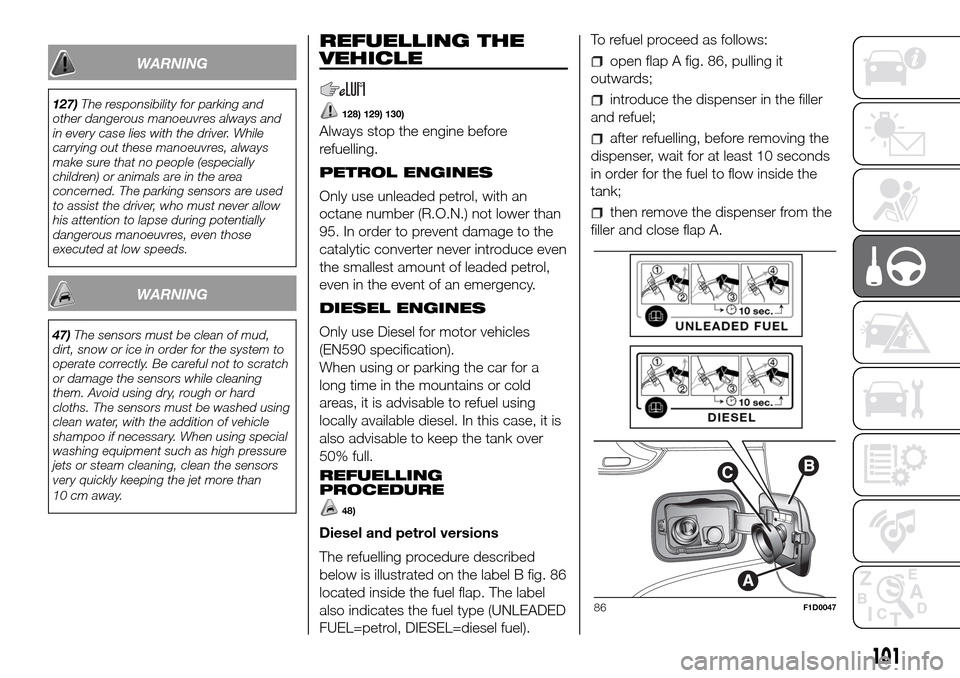

The refuelling procedure described

below is illustrated on the label B fig. 86

located inside the fuel flap. The label

also indicates the fuel type (UNLEADED

FUEL=petrol, DIESEL=diesel fuel).To refuel proceed as follows:

open flap A fig. 86, pulling it

outwards;

introduce the dispenser in the filler

and refuel;

after refuelling, before removing the

dispenser, wait for at least 10 seconds

in order for the fuel to flow inside the

tank;

then remove the dispenser from the

filler and close flap A.

86F1D0047

101

Page 104 of 216

Flap A fig. 86 is provided with a dust

cover gaiter C which prevents deposits

of impurities and dust at the end of

the filler when the flap is closed.

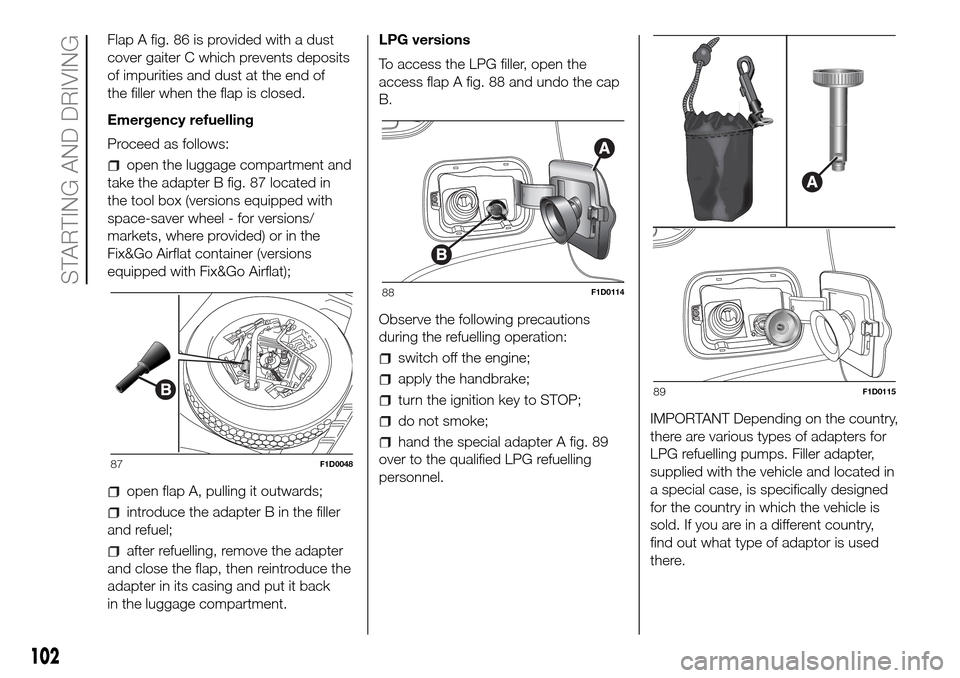

Emergency refuelling

Proceed as follows:

open the luggage compartment and

take the adapter B fig. 87 located in

the tool box (versions equipped with

space-saver wheel - for versions/

markets, where provided) or in the

Fix&Go Airflat container (versions

equipped with Fix&Go Airflat);

open flap A, pulling it outwards;

introduce the adapter B in the filler

and refuel;

after refuelling, remove the adapter

and close the flap, then reintroduce the

adapter in its casing and put it back

in the luggage compartment.LPG versions

To access the LPG filler, open the

access flap A fig. 88 and undo the cap

B.

Observe the following precautions

during the refuelling operation:

switch off the engine;

apply the handbrake;

turn the ignition key to STOP;

do not smoke;

hand the special adapter A fig. 89

over to the qualified LPG refuelling

personnel.IMPORTANT Depending on the country,

there are various types of adapters for

LPG refuelling pumps. Filler adapter,

supplied with the vehicle and located in

a special case, is specifically designed

for the country in which the vehicle is

sold. If you are in a different country,

find out what type of adaptor is used

there.

87F1D0048

88F1D0114

89F1D0115

102

STARTING AND DRIVING

Page 105 of 216

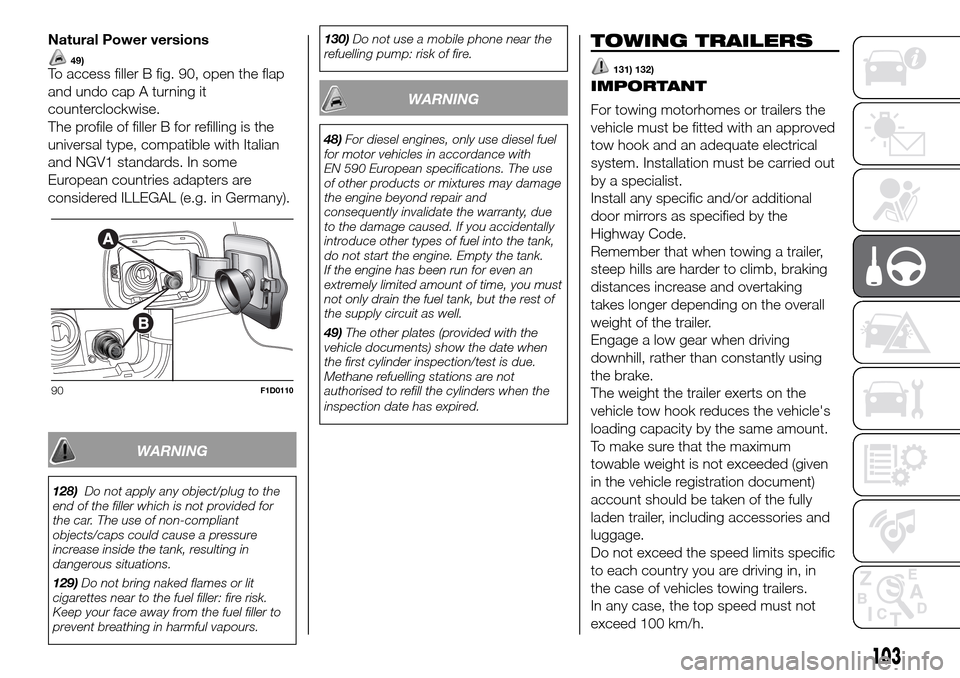

Natural Power versions

49)To access filler B fig. 90, open the flap

and undo cap A turning it

counterclockwise.

The profile of filler B for refilling is the

universal type, compatible with Italian

and NGV1 standards. In some

European countries adapters are

considered ILLEGAL (e.g. in Germany).

WARNING

128)Do not apply any object/plug to the

end of the filler which is not provided for

the car. The use of non-compliant

objects/caps could cause a pressure

increase inside the tank, resulting in

dangerous situations.

129)Do not bring naked flames or lit

cigarettes near to the fuel filler: fire risk.

Keep your face away from the fuel filler to

prevent breathing in harmful vapours.130)Do not use a mobile phone near the

refuelling pump: risk of fire.

WARNING

48)For diesel engines, only use diesel fuel

for motor vehicles in accordance with

EN 590 European specifications. The use

of other products or mixtures may damage

the engine beyond repair and

consequently invalidate the warranty, due

to the damage caused. If you accidentally

introduce other types of fuel into the tank,

do not start the engine. Empty the tank.

If the engine has been run for even an

extremely limited amount of time, you must

not only drain the fuel tank, but the rest of

the supply circuit as well.

49)The other plates (provided with the

vehicle documents) show the date when

the first cylinder inspection/test is due.

Methane refuelling stations are not

authorised to refill the cylinders when the

inspection date has expired.

TOWING TRAILERS

131) 132)

IMPORTANT

For towing motorhomes or trailers the

vehicle must be fitted with an approved

tow hook and an adequate electrical

system. Installation must be carried out

by a specialist.

Install any specific and/or additional

door mirrors as specified by the

Highway Code.

Remember that when towing a trailer,

steep hills are harder to climb, braking

distances increase and overtaking

takes longer depending on the overall

weight of the trailer.

Engage a low gear when driving

downhill, rather than constantly using

the brake.

The weight the trailer exerts on the

vehicle tow hook reduces the vehicle's

loading capacity by the same amount.

To make sure that the maximum

towable weight is not exceeded (given

in the vehicle registration document)

account should be taken of the fully

laden trailer, including accessories and

luggage.

Do not exceed the speed limits specific

to each country you are driving in, in

the case of vehicles towing trailers.

In any case, the top speed must not

exceed 100 km/h.

90F1D0110

103

Page 106 of 216

An electric brake (or electric winch)

should be supplied directly by the

battery through a cable with a cross

section of no less than 2.5 mm

2.

In addition to the electrical branches,

the vehicle electrical system can only

be connected to the supply cable for an

electric brake and to the cable for an

internal light for the trailer, not

exceeding 15 W. For connections, use

the preset control unit with a battery

cable with section not less than 2.5

mm

2.

On Panda Cross and Panda 4x4

versions, in the event of prolonged

vehicle use at maximum tow capacity

on slopes, replacing engine oil more

frequently (every 10,000 km) is

advisable.

IMPORTANT The use of auxiliary loads

other than external lights (electric brake,

winch, etc.) must be used with engine

running.

IMPORTANT To install a tow hook

contact a Fiat Dealership.

WARNING

131)The ABS with which the vehicle is

equipped will not control the braking

system of the trailer. Particular caution is

required on slippery roads.

132)Never modify the braking system of

the vehicle to control the trailer brake.

The trailer braking system must be fully

independent of the vehicle’s hydraulic

system.

104

STARTING AND DRIVING

Page 107 of 216

IN AN EMERGENCY

A punctured tyre or a burnt-out bulb?

At times, a problem may interfere

with our journey.

The pages on emergencies can help

you to deal with critical situations

independently and with calm.

In an emergency we recommend that

you call the freephone number found in

the Warranty Booklet.

It is also possible to call the national or

international universal freephone

number to search for the nearest

Dealership.HAZARD WARNING LIGHTS...........106

REPLACING A BULB ......................106

REPLACING FUSES........................112

CHANGING A WHEEL ....................115

“FIX&GO AIRFLAT” KIT ....................118

JUMP STARTING ............................121

FUEL CUT-OFF SYSTEM ................122

TOWING THE VEHICLE ..................123

105

Page 108 of 216

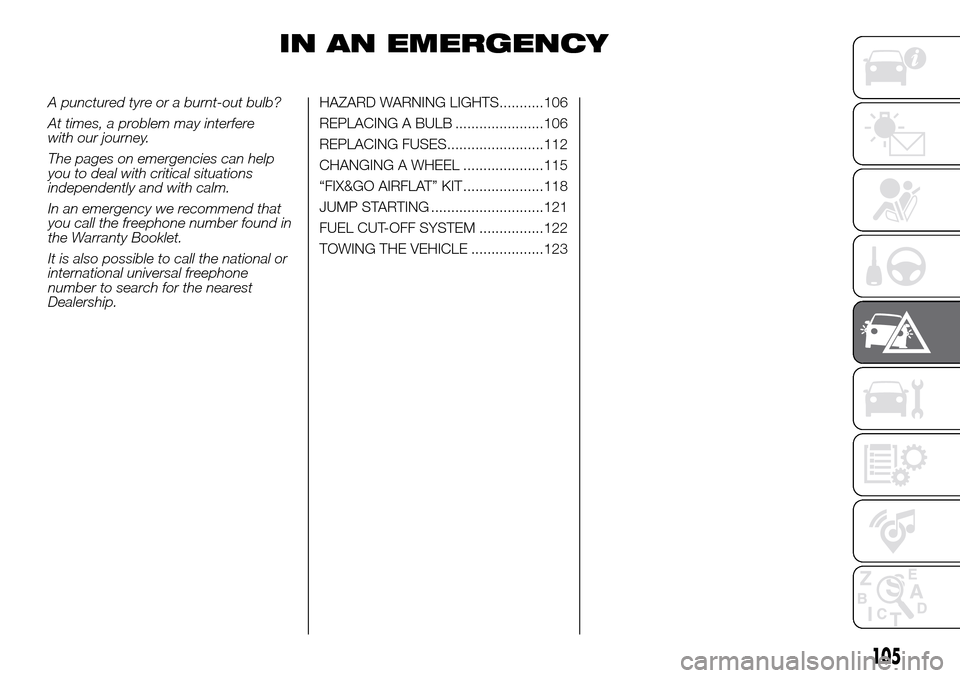

HAZARD WARNING

LIGHTS

Press button A fig. 91 to switch the

lights on/off. Warning lights

andin

the instrument panel are lit up when

the lights are ON.

IMPORTANT The use of hazard warning

lights is governed by the highway

code of the country you are driving in:

comply with legal requirements.

Emergency braking

In the event of emergency braking the

hazard warning lights switch on

automatically as well as the

and

warning lights in the instrument

panel. The lights switch off

automatically when emergency braking

ceases.

REPLACING A BULB

133) 134)50) 51)

GENERAL

INSTRUCTIONS

Before changing a bulb check the

contacts for oxidation;

burnt bulbs must be replaced by

others of the same type and power;

after replacing a headlight bulb,

always check its alignment;

when a light is not working, check

that the corresponding fuse is intact

before changing a bulb. For the location

of fuses, refer to the paragraph “If a

fuse blows” in this section;

IMPORTANT When the weather is cold

or damp or after heavy rain or washing,

the surface of headlights or rear lights,

may steam up and/or form drops of

condensation on the inside. This is

a natural phenomenon due to the

difference in temperature and humidity

between the inside and the outside

of the glass which does not indicate a

fault and does not compromise the

normal operation of lighting devices.

The mist disappears quickly when the

lights are turned on, starting from

the centre of the diffuser, extending

progressively towards the edges.

91F1D0023

106

IN AN EMERGENCY

Page 109 of 216

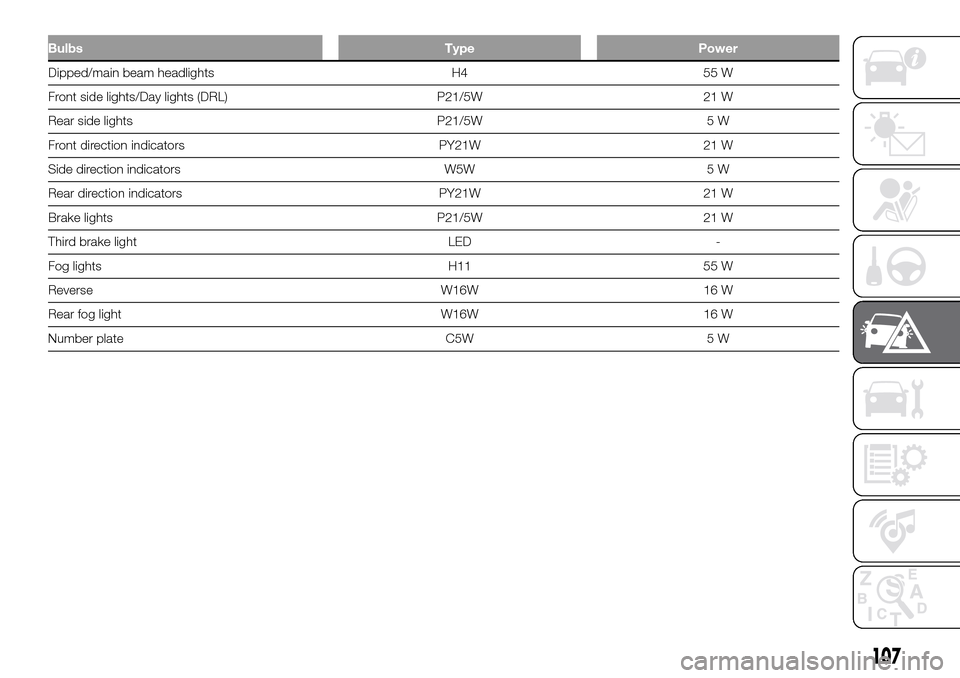

Bulbs Type Power

Dipped/main beam headlights H4 55 W

Front side lights/Day lights (DRL) P21/5W 21 W

Rear side lights P21/5W 5 W

Front direction indicators PY21W 21 W

Side direction indicators W5W 5 W

Rear direction indicators PY21W 21 W

Brake lights P21/5W 21 W

Third brake light LED -

Fog lights H11 55 W

Reverse W16W 16 W

Rear fog light W16W 16 W

Number plate C5W 5 W

107

Page 110 of 216

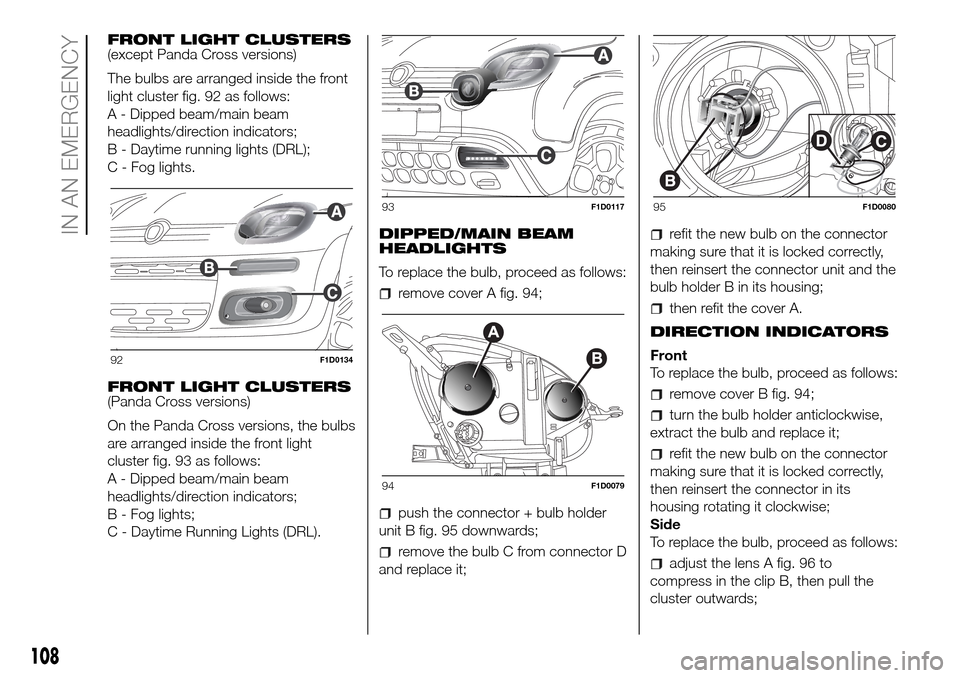

FRONT LIGHT CLUSTERS

(except Panda Cross versions)

The bulbs are arranged inside the front

light cluster fig. 92 as follows:

A - Dipped beam/main beam

headlights/direction indicators;

B - Daytime running lights (DRL);

C - Fog lights.

FRONT LIGHT CLUSTERS

(Panda Cross versions)

On the Panda Cross versions, the bulbs

are arranged inside the front light

cluster fig. 93 as follows:

A - Dipped beam/main beam

headlights/direction indicators;

B - Fog lights;

C - Daytime Running Lights (DRL).DIPPED/MAIN BEAM

HEADLIGHTS

To replace the bulb, proceed as follows:

remove cover A fig. 94;

push the connector + bulb holder

unit B fig. 95 downwards;

remove the bulb C from connector D

and replace it;

refit the new bulb on the connector

making sure that it is locked correctly,

then reinsert the connector unit and the

bulb holder B in its housing;

then refit the cover A.

DIRECTION INDICATORS

Front

To replace the bulb, proceed as follows:

remove cover B fig. 94;

turn the bulb holder anticlockwise,

extract the bulb and replace it;

refit the new bulb on the connector

making sure that it is locked correctly,

then reinsert the connector in its

housing rotating it clockwise;

Side

To replace the bulb, proceed as follows:

adjust the lens A fig. 96 to

compress in the clip B, then pull the

cluster outwards;

92F1D0134

93F1D0117

94F1D0079

95F1D0080

108

IN AN EMERGENCY