light FIAT PANDA 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2018, Model line: PANDA, Model: FIAT PANDA 2018Pages: 228, PDF Size: 17.05 MB

Page 112 of 228

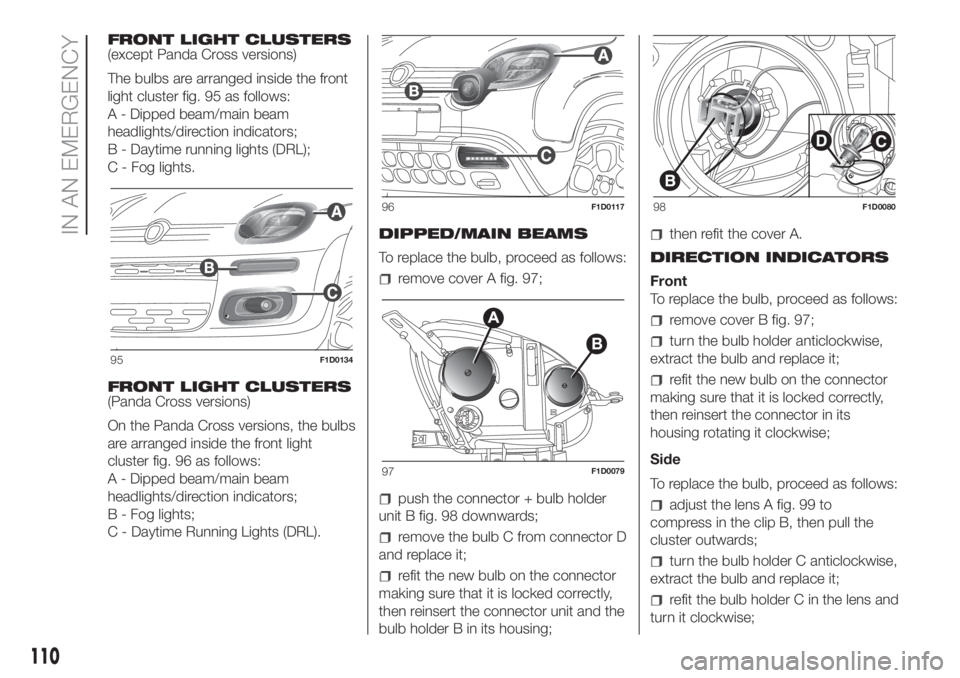

FRONT LIGHT CLUSTERS

(except Panda Cross versions)

The bulbs are arranged inside the front

light cluster fig. 95 as follows:

A - Dipped beam/main beam

headlights/direction indicators;

B - Daytime running lights (DRL);

C - Fog lights.

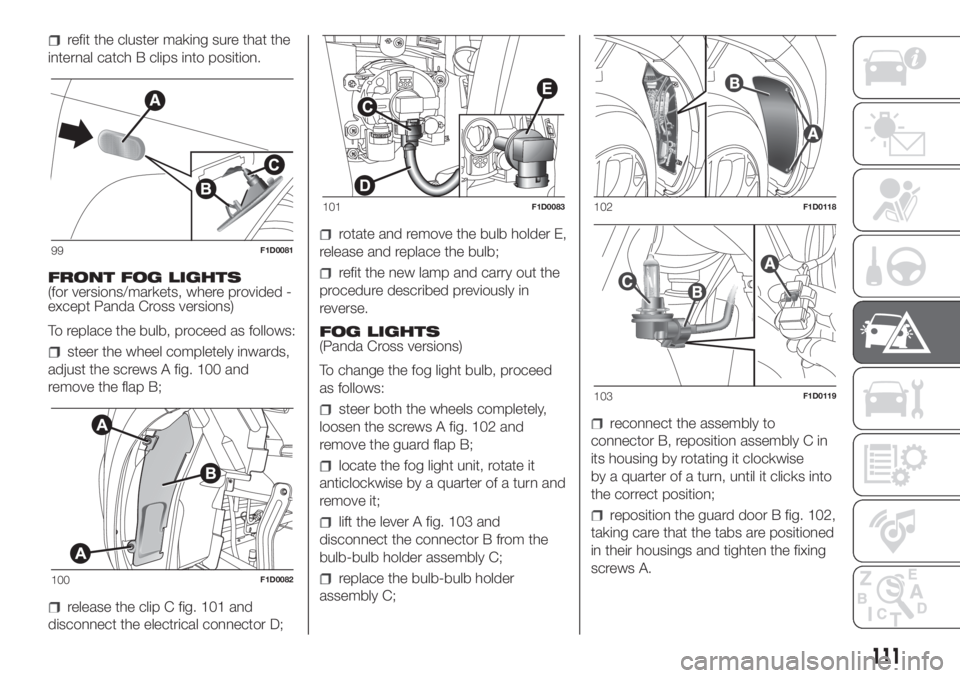

FRONT LIGHT CLUSTERS

(Panda Cross versions)

On the Panda Cross versions, the bulbs

are arranged inside the front light

cluster fig. 96 as follows:

A - Dipped beam/main beam

headlights/direction indicators;

B - Fog lights;

C - Daytime Running Lights (DRL).DIPPED/MAIN BEAMS

To replace the bulb, proceed as follows:

remove cover A fig. 97;

push the connector + bulb holder

unit B fig. 98 downwards;

remove the bulb C from connector D

and replace it;

refit the new bulb on the connector

making sure that it is locked correctly,

then reinsert the connector unit and the

bulb holder B in its housing;

then refit the cover A.

DIRECTION INDICATORS

Front

To replace the bulb, proceed as follows:

remove cover B fig. 97;

turn the bulb holder anticlockwise,

extract the bulb and replace it;

refit the new bulb on the connector

making sure that it is locked correctly,

then reinsert the connector in its

housing rotating it clockwise;

Side

To replace the bulb, proceed as follows:

adjust the lens A fig. 99 to

compress in the clip B, then pull the

cluster outwards;

turn the bulb holder C anticlockwise,

extract the bulb and replace it;

refit the bulb holder C in the lens and

turn it clockwise;

95F1D0134

96F1D0117

97F1D0079

98F1D0080

110

IN AN EMERGENCY

Page 113 of 228

refit the cluster making sure that the

internal catch B clips into position.

FRONT FOG LIGHTS

(for versions/markets, where provided -

except Panda Cross versions)

To replace the bulb, proceed as follows:

steer the wheel completely inwards,

adjust the screws A fig. 100 and

remove the flap B;

release the clip C fig. 101 and

disconnect the electrical connector D;

rotate and remove the bulb holder E,

release and replace the bulb;

refit the new lamp and carry out the

procedure described previously in

reverse.

FOG LIGHTS

(Panda Cross versions)

To change the fog light bulb, proceed

as follows:

steer both the wheels completely,

loosen the screws A fig. 102 and

remove the guard flap B;

locate the fog light unit, rotate it

anticlockwise by a quarter of a turn and

remove it;

lift the lever A fig. 103 and

disconnect the connector B from the

bulb-bulb holder assembly C;

replace the bulb-bulb holder

assembly C;

reconnect the assembly to

connector B, reposition assembly C in

its housing by rotating it clockwise

by a quarter of a turn, until it clicks into

the correct position;

reposition the guard door B fig. 102,

taking care that the tabs are positioned

in their housings and tighten the fixing

screws A.

99F1D0081

100F1D0082

101F1D0083102F1D0118

103F1D0119

111

Page 114 of 228

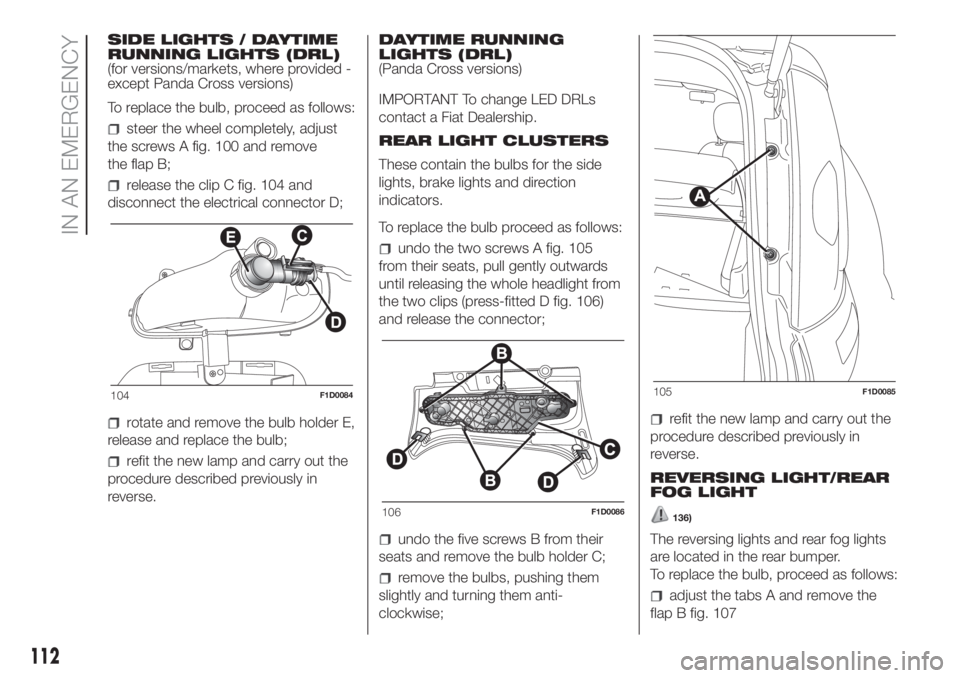

SIDE LIGHTS / DAYTIME

RUNNING LIGHTS (DRL)

(for versions/markets, where provided -

except Panda Cross versions)

To replace the bulb, proceed as follows:

steer the wheel completely, adjust

the screws A fig. 100 and remove

the flap B;

release the clip C fig. 104 and

disconnect the electrical connector D;

rotate and remove the bulb holder E,

release and replace the bulb;

refit the new lamp and carry out the

procedure described previously in

reverse.DAYTIME RUNNING

LIGHTS (DRL)

(Panda Cross versions)

IMPORTANT To change LED DRLs

contact a Fiat Dealership.

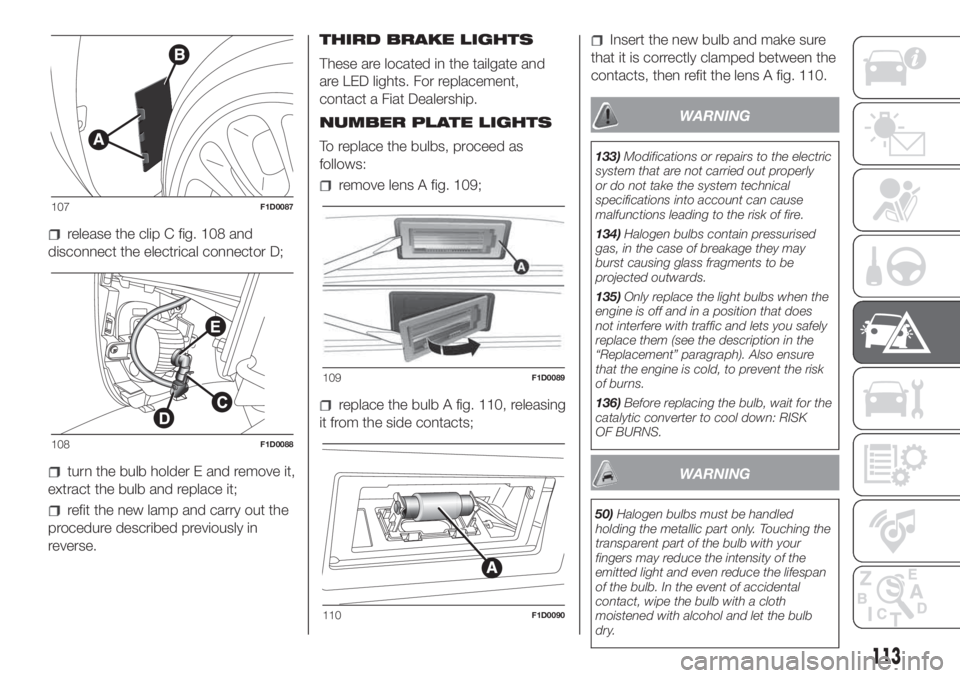

REAR LIGHT CLUSTERS

These contain the bulbs for the side

lights, brake lights and direction

indicators.

To replace the bulb proceed as follows:

undo the two screws A fig. 105

from their seats, pull gently outwards

until releasing the whole headlight from

the two clips (press-fitted D fig. 106)

and release the connector;

undo the five screws B from their

seats and remove the bulb holder C;

remove the bulbs, pushing them

slightly and turning them anti-

clockwise;

refit the new lamp and carry out the

procedure described previously in

reverse.

REVERSING LIGHT/REAR

FOG LIGHT

136)

The reversing lights and rear fog lights

are located in the rear bumper.

To replace the bulb, proceed as follows:

adjust the tabs A and remove the

flap B fig. 107

104F1D0084

106F1D0086

105F1D0085

112

IN AN EMERGENCY

Page 115 of 228

release the clip C fig. 108 and

disconnect the electrical connector D;

turn the bulb holder E and remove it,

extract the bulb and replace it;

refit the new lamp and carry out the

procedure described previously in

reverse.THIRD BRAKE LIGHTS

These are located in the tailgate and

are LED lights. For replacement,

contact a Fiat Dealership.

NUMBER PLATE LIGHTS

To replace the bulbs, proceed as

follows:

remove lens A fig. 109;

replace the bulb A fig. 110, releasing

it from the side contacts;

Insert the new bulb and make sure

that it is correctly clamped between the

contacts, then refit the lens A fig. 110.

WARNING

133)Modifications or repairs to the electric

system that are not carried out properly

or do not take the system technical

specifications into account can cause

malfunctions leading to the risk of fire.

134)Halogen bulbs contain pressurised

gas, in the case of breakage they may

burst causing glass fragments to be

projected outwards.

135)Only replace the light bulbs when the

engine is off and in a position that does

not interfere with traffic and lets you safely

replace them (see the description in the

“Replacement” paragraph). Also ensure

that the engine is cold, to prevent the risk

of burns.

136)Before replacing the bulb, wait for the

catalytic converter to cool down: RISK

OF BURNS.

WARNING

50)Halogen bulbs must be handled

holding the metallic part only. Touching the

transparent part of the bulb with your

fingers may reduce the intensity of the

emitted light and even reduce the lifespan

of the bulb. In the event of accidental

contact, wipe the bulb with a cloth

moistened with alcohol and let the bulb

dry.

107F1D0087

108F1D0088

109F1D0089

110F1D0090

113

Page 116 of 228

51)Where possible, it is advisable to have

bulbs changed at a Fiat Dealership. The

correct operation and direction of the

external lights are absolutely essential for

the safety of the car and of compliance

with the law.REPLACING FUSES

137) 138) 139) 140) 141) 142)

52)

GENERAL INFORMATION

To facilitate fuse replacement, use the

pliers hooked inside the fuse box lid on

the dashboard left-hand side.

ENGINE COMPARTMENT

FUSEBOX

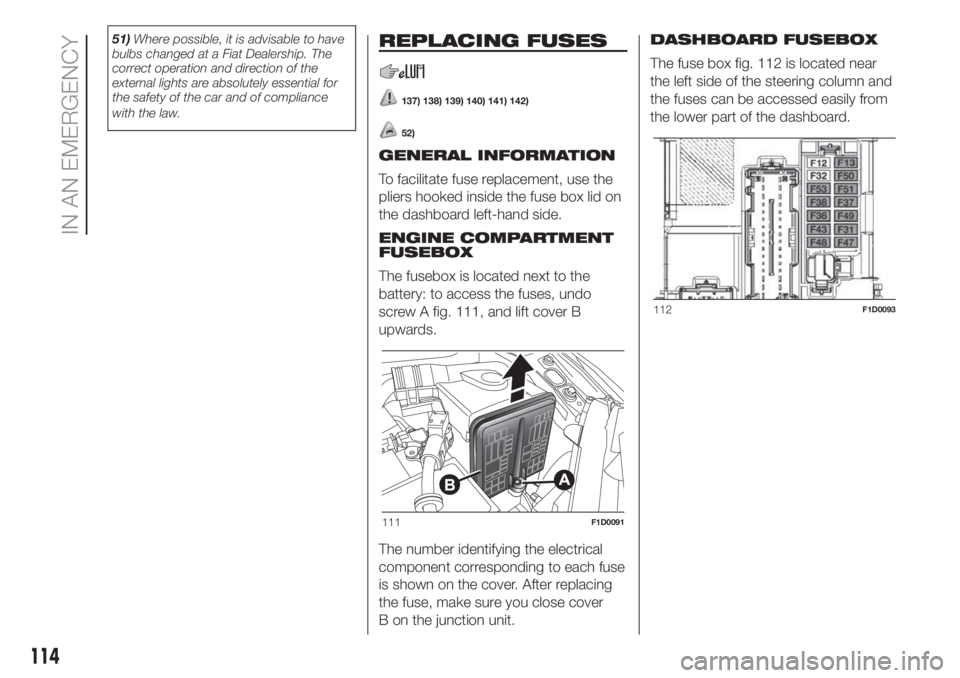

The fusebox is located next to the

battery: to access the fuses, undo

screw A fig. 111, and lift cover B

upwards.

The number identifying the electrical

component corresponding to each fuse

is shown on the cover. After replacing

the fuse, make sure you close cover

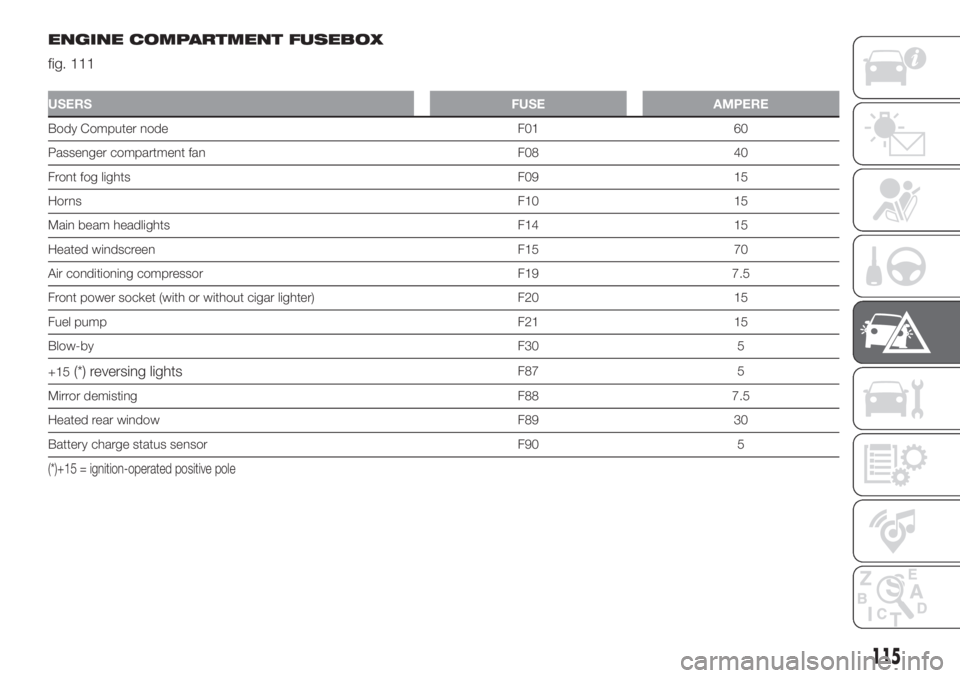

B on the junction unit.DASHBOARD FUSEBOX

The fuse box fig. 112 is located near

the left side of the steering column and

the fuses can be accessed easily from

the lower part of the dashboard.

111F1D0091

112F1D0093

114

IN AN EMERGENCY

Page 117 of 228

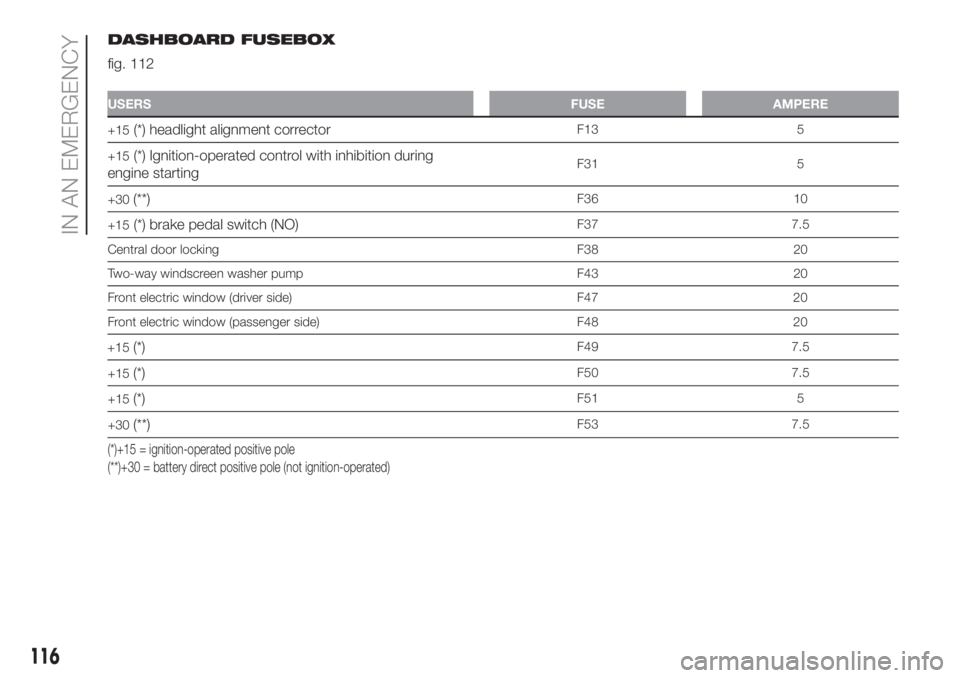

ENGINE COMPARTMENT FUSEBOX

fig. 111

USERSFUSE AMPERE

Body Computer node F01 60

Passenger compartment fan F08 40

Front fog lights F09 15

HornsF10 15

Main beam headlights F14 15

Heated windscreen F15 70

Air conditioning compressor F19 7.5

Front power socket (with or without cigar lighter) F20 15

Fuel pump F21 15

Blow-byF30 5

+15

(*) reversing lightsF87 5

Mirror demisting F88 7.5

Heated rear window F89 30

Battery charge status sensor F90 5

(*)+15 = ignition-operated positive pole

115

Page 118 of 228

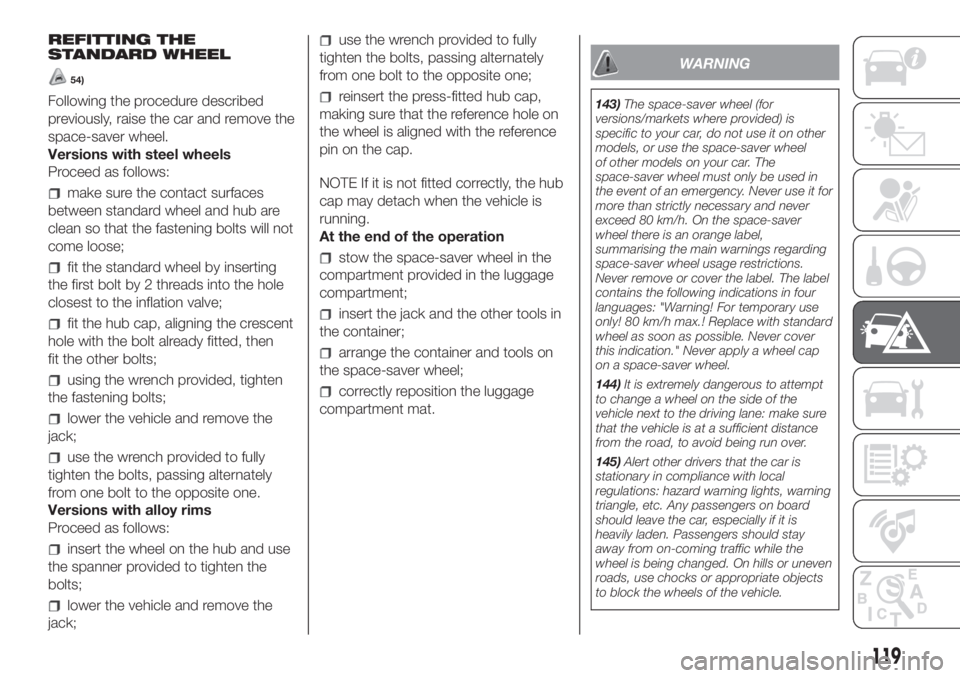

DASHBOARD FUSEBOX

fig. 112

USERSFUSE AMPERE

+15(*) headlight alignment correctorF13 5

+15

(*) Ignition-operated control with inhibition during

engine startingF31 5

+30

(**)F36 10

+15

(*) brake pedal switch (NO)F37 7.5

Central door locking F38 20

Two-way windscreen washer pump F43 20

Front electric window (driver side) F47 20

Front electric window (passenger side) F48 20

+15

(*)F49 7.5

+15

(*)F50 7.5

+15

(*)F51 5

+30

(**)F53 7.5

(*)+15 = ignition-operated positive pole

(**)+30 = battery direct positive pole (not ignition-operated)

116

IN AN EMERGENCY

Page 121 of 228

REFITTING THE

STANDARD WHEEL

54)

Following the procedure described

previously, raise the car and remove the

space-saver wheel.

Versions with steel wheels

Proceed as follows:

make sure the contact surfaces

between standard wheel and hub are

clean so that the fastening bolts will not

come loose;

fit the standard wheel by inserting

the first bolt by 2 threads into the hole

closest to the inflation valve;

fit the hub cap, aligning the crescent

hole with the bolt already fitted, then

fit the other bolts;

using the wrench provided, tighten

the fastening bolts;

lower the vehicle and remove the

jack;

use the wrench provided to fully

tighten the bolts, passing alternately

from one bolt to the opposite one.

Versions with alloy rims

Proceed as follows:

insert the wheel on the hub and use

the spanner provided to tighten the

bolts;

lower the vehicle and remove the

jack;

use the wrench provided to fully

tighten the bolts, passing alternately

from one bolt to the opposite one;

reinsert the press-fitted hub cap,

making sure that the reference hole on

the wheel is aligned with the reference

pin on the cap.

NOTE If it is not fitted correctly, the hub

cap may detach when the vehicle is

running.

At the end of the operation

stow the space-saver wheel in the

compartment provided in the luggage

compartment;

insert the jack and the other tools in

the container;

arrange the container and tools on

the space-saver wheel;

correctly reposition the luggage

compartment mat.

WARNING

143)The space-saver wheel (for

versions/markets where provided) is

specific to your car, do not use it on other

models, or use the space-saver wheel

of other models on your car. The

space-saver wheel must only be used in

the event of an emergency. Never use it for

more than strictly necessary and never

exceed 80 km/h. On the space-saver

wheel there is an orange label,

summarising the main warnings regarding

space-saver wheel usage restrictions.

Never remove or cover the label. The label

contains the following indications in four

languages: "Warning! For temporary use

only! 80 km/h max.! Replace with standard

wheel as soon as possible. Never cover

this indication." Never apply a wheel cap

on a space-saver wheel.

144)It is extremely dangerous to attempt

to change a wheel on the side of the

vehicle next to the driving lane: make sure

that the vehicle is at a sufficient distance

from the road, to avoid being run over.

145)Alert other drivers that the car is

stationary in compliance with local

regulations: hazard warning lights, warning

triangle, etc. Any passengers on board

should leave the car, especially if it is

heavily laden. Passengers should stay

away from on-coming traffic while the

wheel is being changed. On hills or uneven

roads, use chocks or appropriate objects

to block the wheels of the vehicle.

119

Page 123 of 228

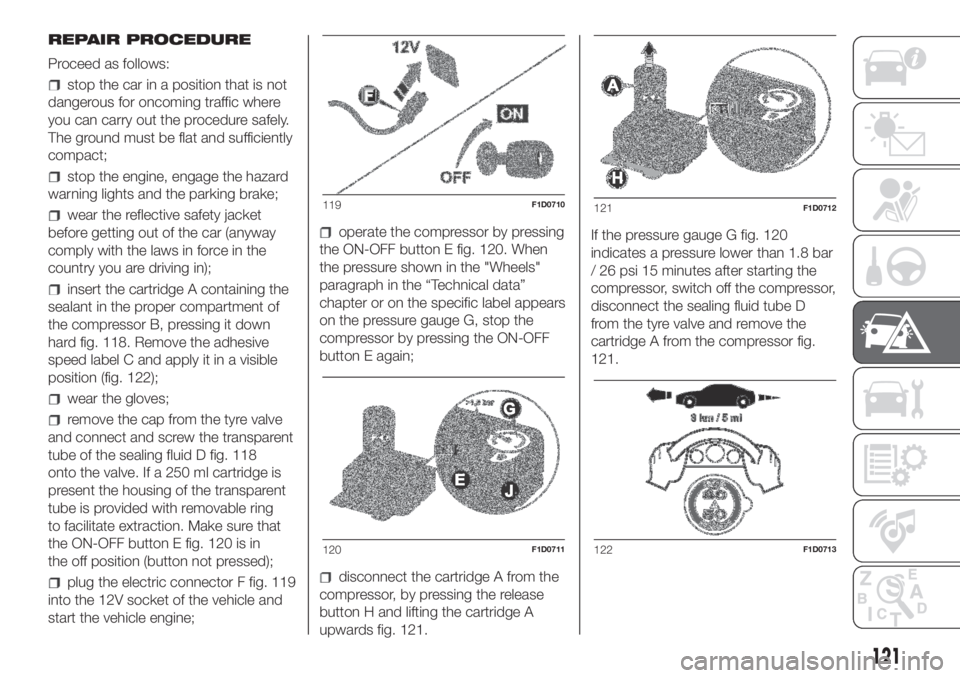

REPAIR PROCEDURE

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can carry out the procedure safely.

The ground must be flat and sufficiently

compact;

stop the engine, engage the hazard

warning lights and the parking brake;

wear the reflective safety jacket

before getting out of the car (anyway

comply with the laws in force in the

country you are driving in);

insert the cartridge A containing the

sealant in the proper compartment of

the compressor B, pressing it down

hard fig. 118. Remove the adhesive

speed label C and apply it in a visible

position (fig. 122);

wear the gloves;

remove the cap from the tyre valve

and connect and screw the transparent

tube of the sealing fluid D fig. 118

onto the valve. If a 250 ml cartridge is

present the housing of the transparent

tube is provided with removable ring

to facilitate extraction. Make sure that

the ON-OFF button E fig. 120 is in

the off position (button not pressed);

plug the electric connector F fig. 119

into the 12V socket of the vehicle and

start the vehicle engine;

operate the compressor by pressing

the ON-OFF button E fig. 120. When

the pressure shown in the "Wheels"

paragraph in the “Technical data”

chapter or on the specific label appears

on the pressure gauge G, stop the

compressor by pressing the ON-OFF

button E again;

disconnect the cartridge A from the

compressor, by pressing the release

button H and lifting the cartridge A

upwards fig. 121.If the pressure gauge G fig. 120

indicates a pressure lower than 1.8 bar

/ 26 psi 15 minutes after starting the

compressor, switch off the compressor,

disconnect the sealing fluid tube D

from the tyre valve and remove the

cartridge A from the compressor fig.

121.

119F1D0710

120F1D0711

121F1D0712

122F1D0713

121

Page 125 of 228

JUMP STARTING

If the battery is flat, a jump starting can

be performed using the battery and

the cables of another vehicle, or using a

booster battery.

If the warning light

remains on

continuously on the instrument panel,

contact the Fiat Dealership immediately.

IMPORTANT NOTES

When a booster battery is used, comply

with the utilisation and precaution

instructions specified by the producer.

Do not use the booster battery or

any other source of external supply with

a voltage above 12 V: the battery, the

starter, the alternator and the electrical

system of the vehicle could be

damaged.

Do not attempt jump starting if the

battery is frozen. The battery could

break and explode!PREPARATION TO JUMP

STARTING

151) 152)

56) 57)

IMPORTANT The positive terminal (+) of

the battery is shielded by a protective

cover. Lift the cover to access the

positive terminal.

Proceed as follows:

engage the handbrake, move the

Dualogic gear lever to P (Park) or,

for versions with manual gearbox, to

neutral and bring the ignition key to

STOP;

switch off all the other electrical

devices in the car;

if another vehicle is ready for jump

starting, park the vehicle within the

reach of the cables to be used for

starting, operate the handbrake and

make sure that the ignition is

deactivated.

IMPORTANT Avoid contact between

the two vehicles since this could cause

a connection to earth and may result

in serious injury to any people nearby.PROCEDURE FOR JUMP

STARTING

IMPORTANT If the procedure below is

carried out incorrectly, it can cause

severe injury to people or damage the

recharging system of one or both

vehicles. Carefully follow the

instructions given below.

Cable connection

Proceed as follows to carry out a jump

starting:

connect one end of the cable used

for positive (+) to the positive terminal

(+) of the car with flat battery;

connect the other end of the cable

used for positive (+) to the positive

terminal (+) of the auxiliary battery;

connect one end of the cable used

for negative (–) to the negative terminal

(–) of the auxiliary battery;

connect the other end of the cable

used for negative (–) to an engine earth

(the visible metal part of the car engine

with flat battery) far from the battery

and the fuel injection system;

start the vehicle engine with the

auxiliary battery, let it run for a few

minutes at idling. Start the engine of the

car with flat battery.

123