engine coolant FIAT PUNTO 1994 176 / 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1994, Model line: PUNTO, Model: FIAT PUNTO 1994 176 / 1.GPages: 225, PDF Size: 18.54 MB

Page 34 of 225

Maintenance procedures - petrol models 1A.15

Every 40 000 miles (60 000 km) or 4 years

29 Rear brake shoe check

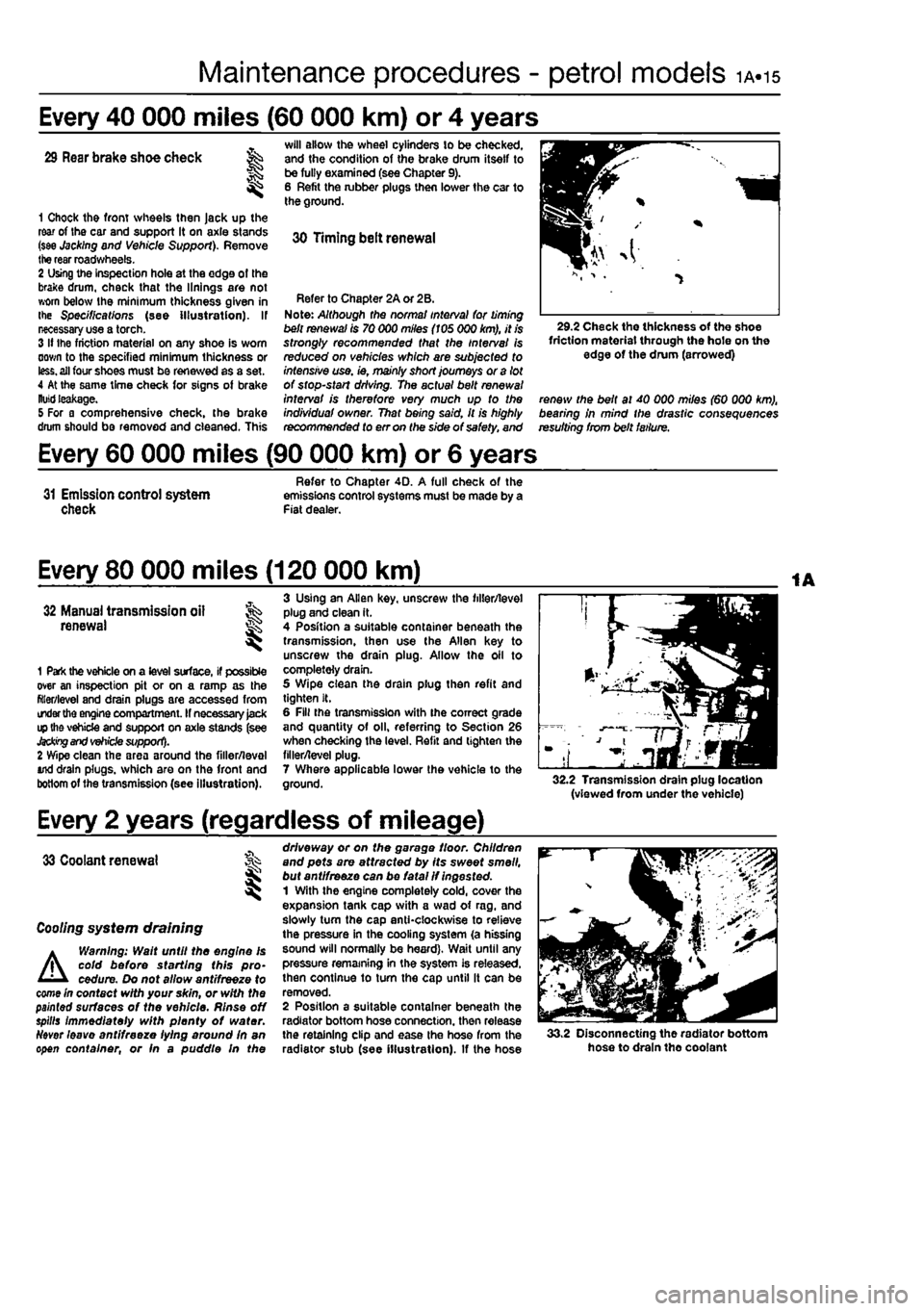

1 Chock the front wheels then Jack up the rear of Ihe car and support it on axle stands (see Jacking and Vehicle Support). Remove the rear roadwheels. 2 Using the inspection hole at the edge of the brake drum, check that the linings are not worn below Ihe minimum thickness given in the Specifications (see illustration). If necessary use a torch. 3 If the friction material on any shoe is worn down to the specified minimum thickness or

less,

all four shoes must be renewed as a set. 4 At the same time check for signs of brake

Kutti

leakage. 5 For a comprehensive check, the brake drum should be removed and cleaned. This

will allow the wheel cylinders to be checked, and the condition of the brake drum itself to be fully examined (see Chapter 9). 6 Refit the lubber plugs then lower the car to the ground.

30 Timing belt renewal

Refer to Chapter 2A or 2B. Note: Although the norma/ interval for timing belt renewal is 70 000 miles (105 000 km), it is strongly recommended that the interval Is reduced on vehicles which are subjected to intensive use. ie, mainly short journeys or a lot of stop-start driving. The actual belt renewal interval is therefore very much up to the individuaf owner. That being said, it is highly recommended to err on the side of safety, and

29.2 Check the thickness of the shoe friction material through the hole on the edge of the drum (arrowed)

renew the belt at 40 000 miles (60 000 km), bearing in mind the drastic consequences resulting from belt failure.

Every 60 000 miles (90 000 km) or 6 years

31 Emission control system check

Refer to Chapter 4D. A full check of the emissions control systems must be made by a Fiat dealer.

Every 80 000 miles (120 000 km)

32 Manual transmission all renewal S

1 Park the vehicle on a level surface, if possible over an inspection pit or on a ramp as the filler/level and drain plugs are accessed from order

the

engine compartment. If necessary

Jack

ip the vehicle and support on axle stands (see

Jacking and vehicle

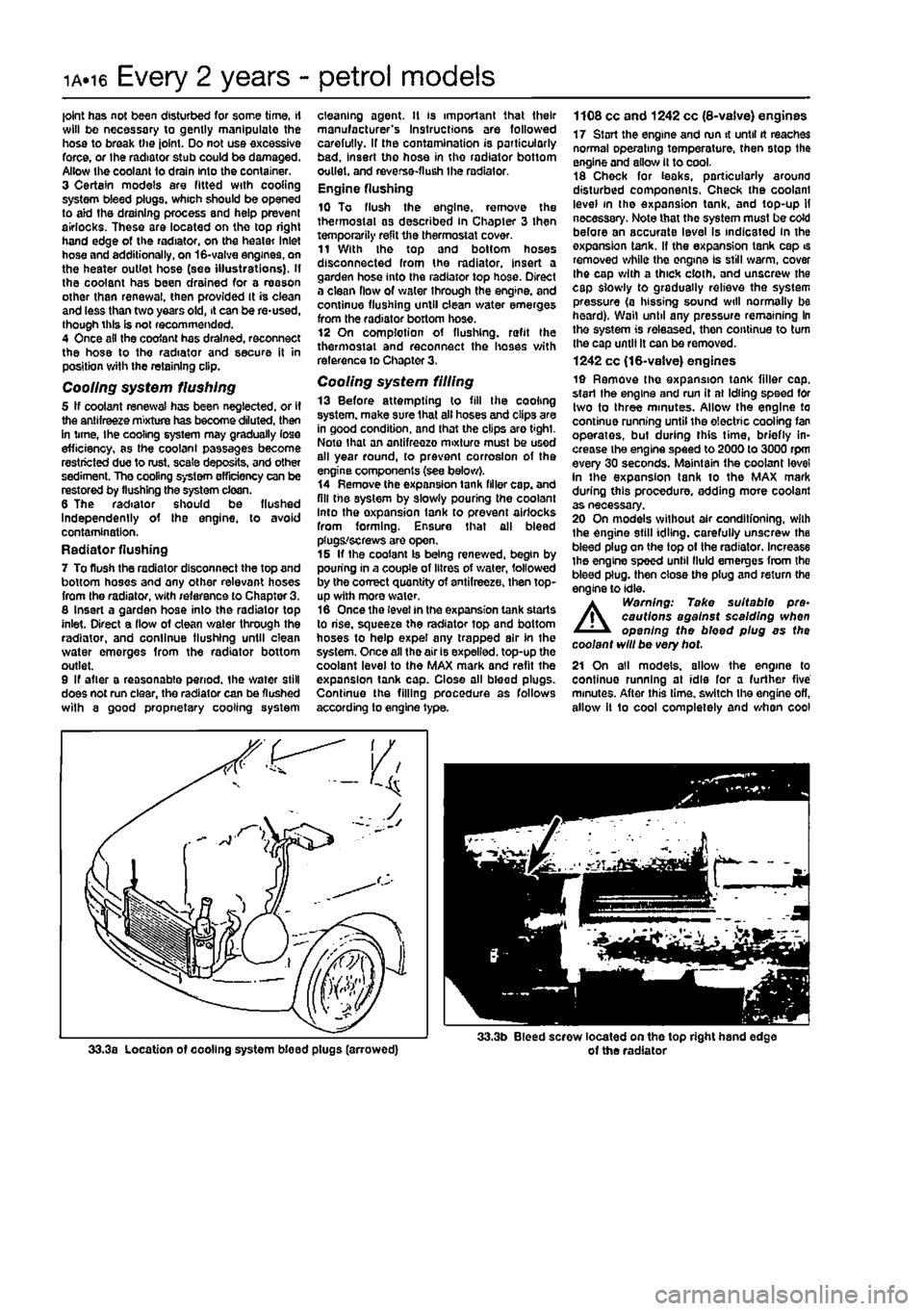

support). 2 Wipe clean the area around the filler/leval And drain plugs, which are on the front and bottom of the transmission (see illustration).

3 Using an Allen key. unscrew the filler/level plug and clean it. 4 Position a suitable container beneath the transmission, then use the Allen key to unscrew the drain plug. Allow the oil to completely drain. 5 Wipe clean the drain plug then refit and tighten It. 6 Fill the transmission with ihe correct grade and quantity of oil, referring to Section 26 when checking the level. Refit and lighten the filler/level plug. 7 Where applicable lower the vehicle to the ground. 32.2 Transmission drain plug location (viewed from under the vehicle)

Every 2 years (regardless of mileage)

33 Coolant renewal

I

Cooling system draining

A

Warning: Walt until the engine Is cold before starting this pro-cedure. Do not allow antifreeze to come In contact with your skin, or with the painted surfaces of the vehicle. Rinse off spills immediately with plenty of water.

Ndver

leave antifreeze lying around In an open container, or fn a puddle In the

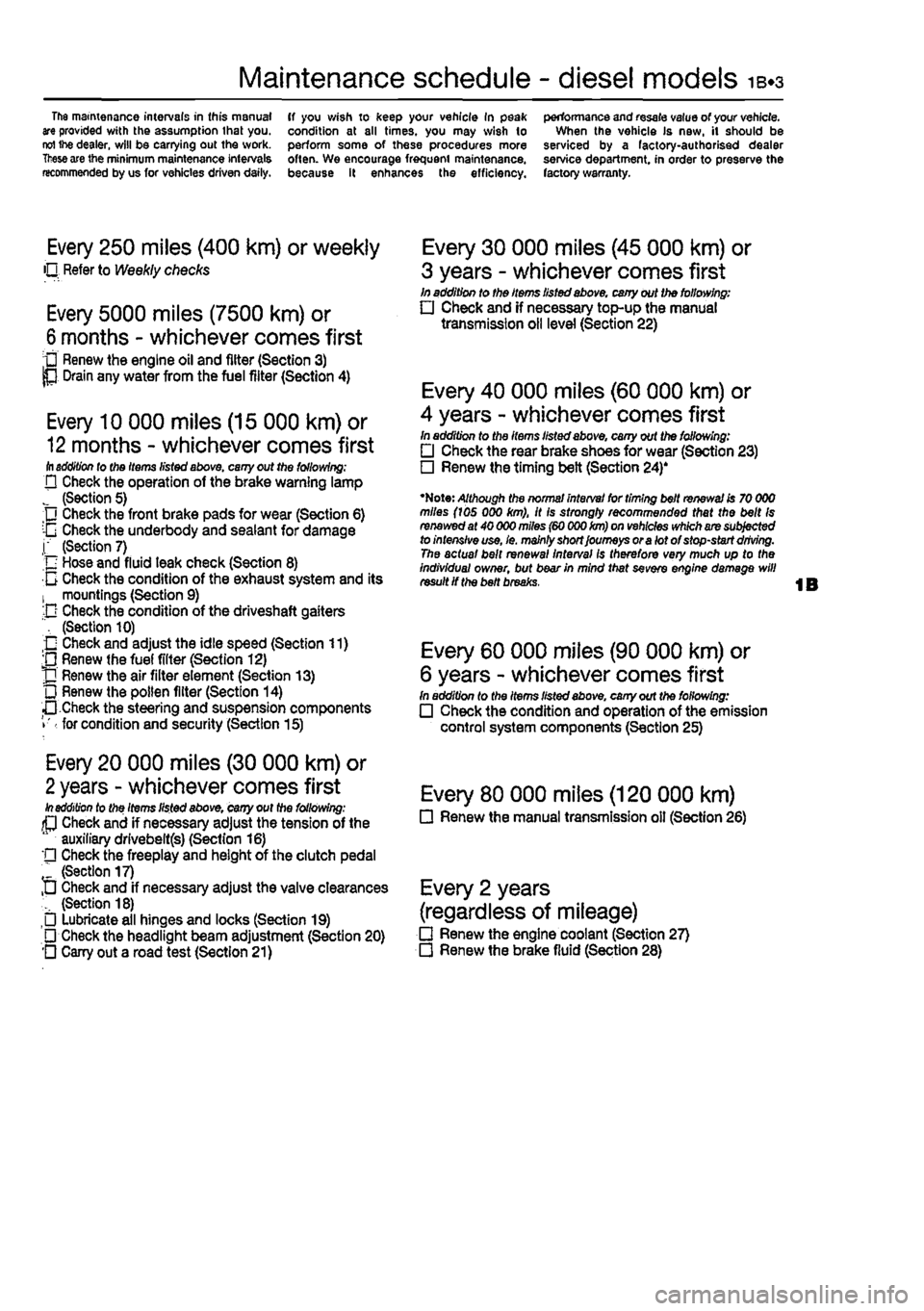

driveway or on the garage floor. Children and pets are attracted by its sweet smell, but ant/freeze can be fatal if ingested. 1 With the engine completely cold, cover the expansion tank cap with a wad of rag. and slowly turn the cap anticlockwise to relieve the pressure in the cooling system (a hissing sound will normally be heard). Wait until any pressure remaining in the system is released, then continue to tum the cap until it can be removed. 2 Position a suitable container beneath the radiator bottom hose connection, then release the retaining clip and ease the hose from the radiator stub (see illustration). If the hose 33.2 Disconnecting the radiator bottom hose to drain tho coolant

Page 35 of 225

ia.16 Every 2 years - petrol models

joint has not been disturbed for some time, if will bo necessary to gently manipulate the hose to break the joint. Do not use excessive force, or the radiator stub could be damaged. Allow the coolant to drain Into the container. 3 Certain models are fitted with cooling system bleed plugs, which should be opened to aid the draining process and help prevent airlocks. These are located on the top right hand edge of the radiator, on the heater Inlet hose and additionally, on 16-valve engines, on the heater outlet hose (see illustrations). If the coolant has been drained for a reason other than renewal, then provided It is ciean and less than two years old, it can be re-used, though this is not recommended. 4 Once ail the coofant has drained, reconnect the hose to the radiator and secure it in position with the retaining clip.

Cooling system flushing 5 If coolant renewal has been neglected, or If the antifreeze mixture has become diluted, then in time, Ihe cooling system may gradually lose efficiency, as the coolant passages become restricted due to rust, scale deposits, and other sediment. The cooling system efficiency can be restored by flushing the system clean. 6 The radiator should be flushed Independently of the engine, to avoid contamination. Radiator flushing 7 To flush the radiator disconnect the top and bottom hoses and any other relevant hoses from the radiator, with reference to Chapter 3. 8 Insert a garden hose into the radiator top inlet. Direct a flow of clean v/ater through the radiator, and continue flushing until clean water emerges from the radiator bottom outlet. 9 If after a reasonable period, the water still does not run clear, the radiator can be flushed wilh a good propnetary cooling system

cleaning agent. It is important that their manufacturer's Instructions are followed carefully. If the contamination is particularly bad, insert the hose in the radiator bottom outlet, and reverse-flush the radiator. Engine flushing 10 To flush the engine, remove the thermostat as described In Chapter 3 then temporarily refit the thermostat cover. 11 With the top and bottom hoses disconnected from the radiator, insert a garden hose into the radiator top hose. Direct a clean flow of water through the engine, and continue flushing until clean water emerges from the radiator bottom hose. 12 On complotion of flushing, refit the thermostat and reconnect the hoses with reference to Chapter 3,

Cooling system filling 13 Before attempting to fill the cooling system, make sure that all hoses and clips are in good condition, and that the clips are tight. Note that an antifreezo mixture must be used all year round, to prevent corrosion of the engine components (see below). 14 Remove the expansion tank filler cap. and fill the system by slowly pouring the coolant Into the oxpansion lank to prevent airlocks from forming. Ensure that all bleed plugs/screws are open. 15 If the coolant Is being renewed, begin by pouring in a couple of litres of v/ater, followed by the correct quantity of antifreeze, then top-up with more water. 16 Once the level in the expansion tank starts to rise, squeeze the radiator top and bottom hoses to help expel any trapped air In the system. Once all the air is expelled, top-up the coolant level to the MAX mark and refit the expansion tank cap. Close all bleed plugs. Continue the filling procedure as follows according to engine type.

1108 cc and 1242 cc (8-vaive) engines 17 Start the engine and run it until tt reaches normal operating temperature, then stop the engine and allow it to cool. 18 Chock for teaks, particularly around disturbed components. Check the coolant level in the expansion tank, and top-up H necessary. Note that the system must be coW before an accurate level Is indicated in the oxpansion tank. If the expansion tank cap is removed while the engine Is still warm, cover Ihe cap with a thick cloth, and unscrew the cap slowly to gradually relieve the system pressure (a hissing sound will normally be heard). Wall until any pressure remaining In the system is released, then continue to turn the cap until It can be removed. 1242 cc (16-valve) engines 19 Remove the expansion tank filler cap. start the engine and run it at Idling speed for two to three minutes. Allow the engine to continue running until the electric cooling fan operates, but during this time, briefly in-crease the engine speed to 2000 to 3000 rpm every 30 seconds. Maintain the coolant level in the expansion tank to the MAX mark during tliis procedure, adding more coolant as necessary. 20 On models without air conditfoning, wilh the engine still idling, carefully unscrew the bleed plug on the top of the radiator. Increase the engine speed until fluid emerges from the bleed plug, then close the plug and return the engine to idle.

A

Warning: Take suitable pre-cautions against scalding when opening the bleed plug as the coolant will be very hot. 21 On all models, allow the engine to continue running at idle for a further five minutes. After this time, switch the engine ofl, allow it 1o cool completely and when cool

Page 39 of 225

Maintenance schedule - diesel models 1B.3

The mamtenance intervals in this manual are provided with the assumption that you. reI ihe dealer, will be carrying out the work.

These

are the minimum maintenance intervals recommended by us for vehicles driven daily.

ff you wish to keep your vehicle In peak condition at all times, you may wish to perform some of these procedures more often. We encourage frequent maintenance, because it enhances the efficiency.

performance and resale value of your vehicle. When the vehicle Is new, it should be serviced by a factory-authorised dealer service department, in order to preserve the factory warranty.

Every 250 miles (400 km) or weekly O Refer to Weekly checks

Every 5000 miles (7500 km) or

6

months - whichever comes first • Renew the engine oil and filter (Section 3) P Drain any water from the fuel filter (Section 4)

Every 10 000 miles (15 000 km) or

12

months - whichever comes first ill addition lo tho Items listed above, cany out the following; D Check the operation of the brake warning lamp J (Section 5) Check the front brake pads for wear (Section 6) :-G Check the underbody and sealant for damage j" (Section 7) n Hose and fluid leak check (Section 8) 0 Check the condition of the exhaust system and its 1 mountings (Section 9) -D Check the condition of the driveshaft gaiters ", (Section 10) O Check and adjust the idle speed (Section 11) ;0 Renew (he fuel filter (Section 12) J] Renew the air filter element (Section 13) L) Renew the pollen filter (Section 14) •• Check the steering and suspension components • for condition and security (Section 15)

Every 20 000 miles (30 000 km) or

2

years - whichever comes first In addition to the Items listed above, cany out the following: (P Check and if necessary adjust the tension of the auxiliary drlvebeltfs) (Section 16) '• Check the freeplay and height of the clutch pedal " (Section 17) D Check and if necessary adjust the valve clearances (Section 18) Lubricate all hinges and locks (Section 19) • Check the headlight beam adjustment (Section 20) O Cany out a road test (Section 21)

Every 30 000 miles (45 000 km) or

3 years - whichever comes first In addition to the Items listed above, cany out the following: • Check and if necessary top-up the manual transmission oil level (Section 22)

Every 40 000 miles (60 000 km) or

4 years - whichever comes first In addition to the items listed above, cany out the following: • Check the rear brake shoes for wear (Section 23) • Renew the timing belt (Section 24)'

•Note: Although the normal interval for timing belt renewal is 70 000 miles (ids 000 km), it is strongly recommended that the belt Is renewed at 40 000 miles (60 000 km) on vehicles which are subjected to intensive use, le. mainly short Journeys or a lot of stop-start driving. The actual bait renewal interval Is therefore very much up to the Individual owner, but bear in mind that sevefe engine damage will result if the belt breaks.

Every 60 000 miles (90 000 km) or

6 years - whichever comes first In addition to the Items listed above, cany out the following: • Check the condition and operation of the emission control system components (Section 25)

Every 80 000 miles (120 000 km) • Renew the manual transmission oil (Section 26)

Every 2 years

(regardless of mileage) • Renew the engine coolant (Section 27) • Renew the brake fluid (Section 28)

Page 40 of 225

ib-4 Component location - diesel models

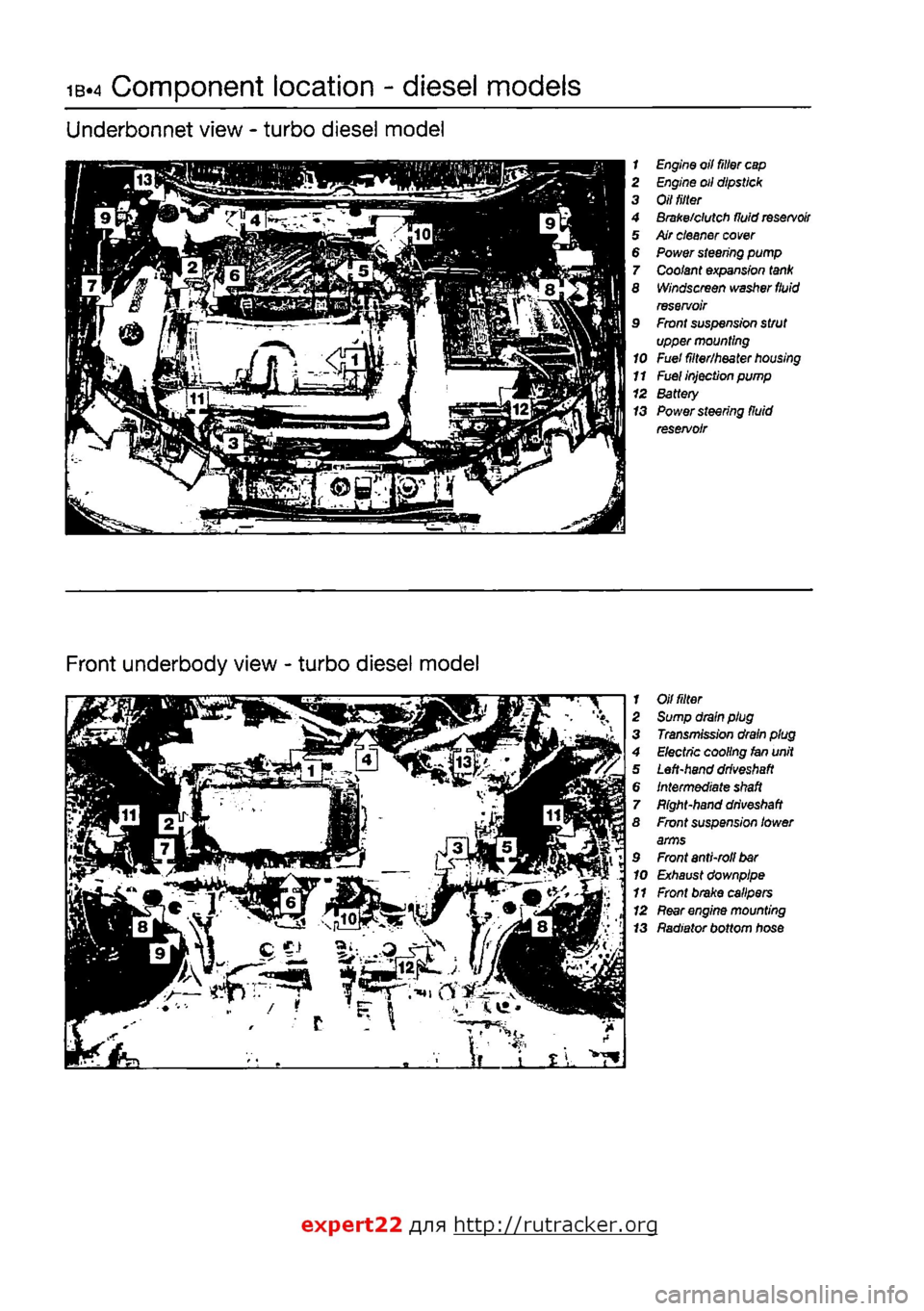

Underbonnet view - turbo diesel model

1 Engine oil filter

cap

2 Engine oil dipstick 3 Oil

tilter

4 Brake/clutch fluid

reservoir

5 Air cleaner

cover

6 Power steering pump 7 Coolant expansion

tank

8 Windscreen washer

fluid

reservoir 9 Front suspension strut upper mounting 10 Fuel filter/heater

housing

11

Fuel

injection pump 12 Battery 13 Power steering fluid reservoir

Front underbody view - turbo diesel model

1 Oil

fitter

2 Sump drain plug 3 Transmission drain plug 4 Electric cooling fan unit 5 Left-hand

driveshaft

6 Intermediate

shaft

7 Bight-hand

driveshaft

8 Front suspension lower arms 9 Front anti-roll

bar

10 Exhaust downpipe 11 Front brake calipers 12

Rear

engine mounting 13 Radiator bottom hose

expert22 fl/ia http://rutracker.org

Page 49 of 225

Maintenance procedures - diesel models 1B.13

Every 60 000 miles (90 000 km) or 6 years

Refer to Chapter 40. A full chock of the 26 Emissions control systems emissions control systems must be made by a check Fiat dealer.

Every 80 000 miles (120 000 km)

26 Manual transmission ,v->> oil renewal K

1 Pak the vehicle on a level surface, if possible over an inspection pit or on a ramp as the filer/level and drain plugs are accessed from

under the

engine compartment, ff necessary tack up Ihe vehicle and support on axle stands (see Jacking and

vehicle

support). 2

Wipe

clean the area around the filler/! a vol and vain plugs, which are situated on the front and bottom of the transmission (see Illustration}.

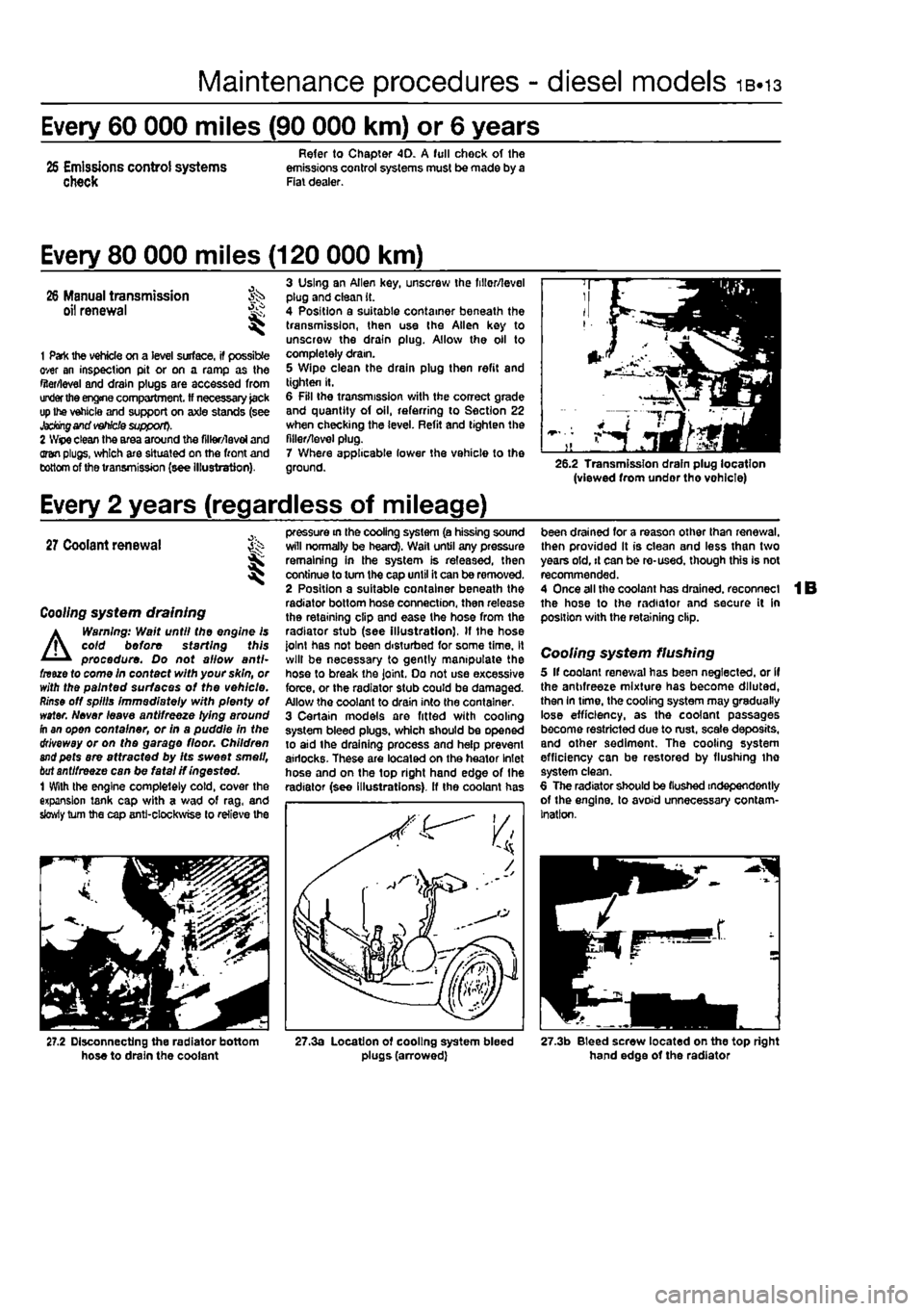

3 Using an Allen key, unscrew the fillor/level plug and clean it. 4 Position a suitable container beneath the transmission, then use the Allen key to unscrew the drain plug. Allow the oil to completely dram. 5 Wipe clean the drain plug then refit and tighten It. 6 Fill the transmission with the correct grade and quantity of oil, referring to Section 22 when checking the level. Refit and tighten the filler/level plug. 7 Where applicable lower the vehicle to the ground. 26.2 Transmission drain plug location (viewed from undor tho vohlcle)

Every 2 years (regardless of mileage)

27

Coolant renewal St I

Coo//ng system draining

A

Warning: Wait until the engine is coid before starting this procedure. Do not allow anti-fnue to come in contact with your skin, or with the painted surfaces of the vehicle.

Rinse

off spills immediately with plenty of water. Never leave antifreeze lying around fh an open container, or in a puddle in the driveway or on the garage floor. Children

and

pets are attracted by Its sweet smell,

bat

antifreeze can be fatal if ingested. 1 With the engine completely cold, cover the expansion tank cap with a wad of rag, and slowly turn the cap anti-clockwise to relieve the

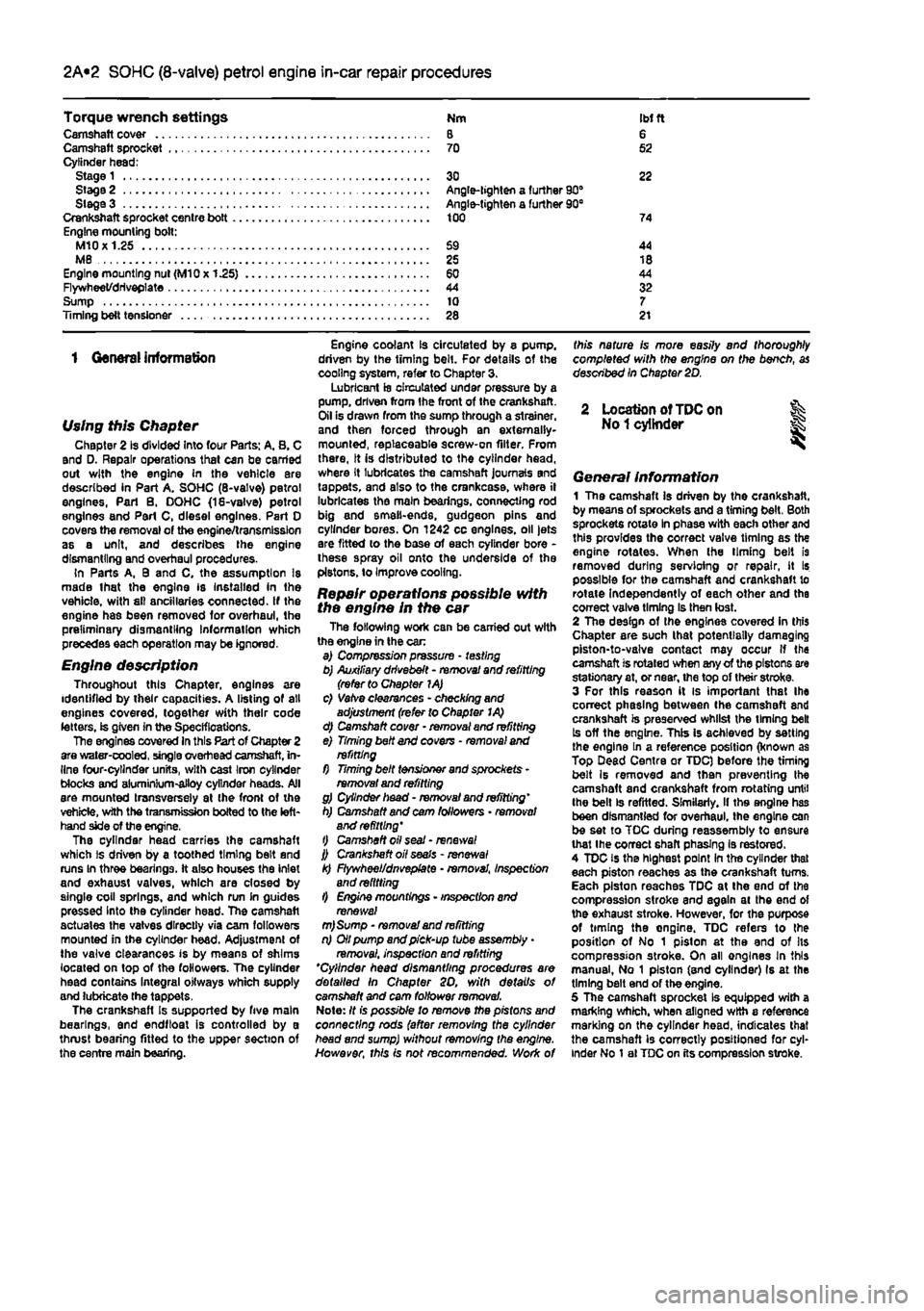

pressure in the cooling system (a hissing sound will normally be heard). Wail until any pressure remaining in the system is released, then continue to turn the cap until it can be removed. 2 Position a suitable container beneath the radiator bottom hose connection, then release the retaining clip and ease the hose from the radiator stub (see Illustration), If the hose joint has not been disturbed for some time, it will be necessary to gently manipulate the hose to break the joint. Do not use excessive force, or the radiator stub could be damaged. Allow the coolant to drain into the container. 3 Certain models are fitted with cooling system bleed plugs, which should be opened to aid the draining process and help prevent airlocks. These are located on the heator Inlet hose and on the top right hand edge of the radiator (see Illustrations), ff the coolant has

been drained for a reason other than renewal, then provided It is clean and less than two years old, it can be re-used, though this is not recommended. 4 Once all the coolant has drained, reconnect the hose to the radiator and secure it in position with the retaining clip.

Cooling system flushing 5 If coolant renewal has been neglected, or if the antifreeze mixture has become diluted, then In time, the cooling system may gradually lose efficiency, as the coolant passages become restricted due to rust, scale deposits, and other sediment. The cooling system efficiency can be restored by flushing tho system clean. 6 The radiator should be (lushed independently of the engine, to avoid unnecessary contam-ination.

27.2 Disconnecting the radiator bottom hose to drain the coolant 27.3a Location of cooling system bleed plugs (arrowed) 27.3b Bleed screw located on the top right hand edge of the radiator

Page 50 of 225

ib.14 Every 2 years - diesel models

Radiator flushing 7 To flush the radiator disconnect the top and bottom hoses and any other relevant hoses from the radiator, with reference to Chapter 3. 8 Insert a garden hose into the radiator top inlet. Direct a flow of dean water through the radiator, and continue Hushing until clean water emerges from the radiator bottom outlet. 9 II after a reasonable period, the water still does not run clear, the radiator can be flushed with a good proprietary cooling system cleaning agent. It is important that their manufacturer's instructions are followed carefully. If Ihe contamination is particularly bad, insert the hose in the radiator bottom outlet, and reverse-flush the radiator.

Engine flushing 10 To flush tho engine, remove the thermostat as described in Chapter 3. 11 With the bottom hose disconnected, direct a clean flow of water through the engine, and continue Hushing until clean water emerges from the radiator bottom hose. 12 On completion of flushing, refit the thermostat and reconnect the hose with reference to Chapter 3.

Cooling system filling 13 Before attempting to fill the cooling system, make sure that all hoses and clips are in good condition, and that the clips are tight. Note that an antifreeze mixture must be used all year round, to prevent corrosion of the engine components (see following sub* Section). 14 Remove the expansion tank filler cap. and fill the system by slowly pouring the coolant Into Ihe expansion tank to prevent airlocks from forming. Ensure that all bleed plugs/screws are open. 15 If the coolant is being renewed, begin by pouring in a couple of litres of water, followed by the correct quantity of antifreeze, then top* up with more water. 18 Once ihe level in the expansion tank starts to rise, squeeze the radiator top and bottom hoses to help expel any trapped air in

the system. Once all the air is expelled, top-up the coolant level to the MAX mark and refit the expansion tank cap. Close all bleed plugs. 17 Start Ihe engine and run il until it reaches normal operating temperature, then stop the engine and allow It to cool. 18 Check for leaks, particularly around disturbed components. Check the coolant level In the expansion tank, and top-up if necessary. Note that the system must be cold before an accurate level Is indicated In the expansion tank. If the expansion tank cap Is removed while the engine is still warm, cover the cap with a thick cloth, and unscrew the cap slowly to gradually relieve the system pressure (a hissing sound will normally be heard). Wait until any pressure remaining in the system Is released, then continue to turn the cap untH it can be removed.

Antifreeze mixture 19 The antifreeze should always be renewed at the specified intervals. This is necessary not only to maintain the antifreeze properties, but also to prevent corrosion which would otherwise occur as the corrosion Inhibitors become progressively less effective. 20 Always use an ethylene-glycol based antifreeze which is suitable for use in mixed-metal cooling systems. The quantity of antifreeze and levels of protection are indicated in the Specifications. 21 Before adding antifreeze, the cooling system should be complelely drained, preferably flushed, and all hoses checked for condition and security. 22 After filling with antifreeze, a label should be attached to the expansion tank, stating the type and concentration of antifreeze used, and the dale installed. Any subsequent topping-up should bs made with the same type and concentration of antifreeze. 23 Do not use engine antifreeze In the windscreen/tailgate washer system, as it will cause damage to the vehicle paintwork. A screenwash additive should be added to the washer system in the quantities stated on the bottle.

28 Brake fluid renewal

A

Warning: Brake hydraulic fluid can harm your eyas and damage painted surfaces, so use extreme caution when handling and pouring It. Do not use fluid that has been standing open for some time, as It absorbs moisture from the air. Excess moisture can causa a dangerous loss of braking effectiveness. 1 The procedure is similar to that for the bleeding of the hydraulic system as described In Chapter 9. except that the brake fluid reservoir should be emptied by siphoning, using a clean poultry baster or similar before starting, and allowance should be made for the old fluid to be expelled when bleeding a section of the circuit. 2 Working as described in Chapter 9, open Ihe first bleed screw in the sequence, and pump the brake pedal gently until nearly all the old fluid has been emptied from the master cylinder reservoir.

ffffTOgf Old hydraulic fluid Is

lifcjllitt*

Invariably much darker In [HINT] colour than the new, making /{easy to distinguish the two.

3 Top-up to the MAX level with new fluid, and continue pumping until only the new fluid remains in the reservoir, and new fluid can be seen emerging from (he bleed screw. Tighten the screw, and top the reservoir level up to Ihe MAX level line. 4 Work through all the remaining bleed screws In the sequence until new fluid can be seen al all of them. Be careful to keep the master cylinder reservoir topped-up 10 above the MIN level al all limes, or air may enter the system and greatly increase the length of the task. 5 When the operation is complete, check thai all bleed screws are securely tightened, and that their dust caps are refitted. Wash off ail traces of split fluid, and recheck the master cylinder reservoir fluid level. 6 Check the operation of the brakes before taking the car on the road,

Page 52 of 225

2A*10 SOHC (8-valve) petrol engine in-car repair procedures

Torque wrench settings Nm

IM

ft Camshaft cover 8 6 Camshaft sprocket 70 52 Cylinder head; Stage 1 30 22 Stage 2 Angle-lighten a further 90° Siege 3 Angle-tighten a further 90B Crankshaft sprocket centre bott 100 74 Engine mounting bolt: M10X1.25 69 44 MB 25 18 Engine mounting nut (M10x 1.25) 60 44 Flywheet/driveplate 44 32 Sump 10 7 Timing belt tensJoner 28 21

1 General information

Using this Chapter Chapter 2 is divided Into four Parts: A. 8. C and D. Repair operations that can be carried out with the engine in the vehicle are described in Part A. SOHC (8-valve) petrol engines, Part B. DOHC (18-valve) petrol engines and Part C, diesel engines. Part 0 covers the removal of the engine/transmission as a unit, and describes the engine dismantling and overhaul procedures. In Parts A, 9 and C, the assumption Is made lhat the engine is Installed in the vehicle, with sll ancillaries connected. If the engine has been removed for overhaul, the preliminary dismantling Information which precedes each operation may be ignored.

Engine description Throughout this Chapter, engines are identified by their capacities. A listing of all engines covered, together with their code letters, is given in the Specifications. The engines covered In this Part of Chapter 2 are water-cooled, single overhead camshaft, in-line four-cylinder units, with cast Iron cylinder Mocks and aluminium-alloy cylinder heads. All are mounted transversely at the front ot the vehicle, with the transmission bolted to the left-hand side of the engine, The cylinder head carries the camshaft which is driven by a toothed timing belt and runs In three bearings. It also houses the inlet and exhaust valves, which are closed by single coil springs, and which run in guides pressed Into the cylinder head. The camshaft actuates the vatves directly via cam followers mounted in the cylinder head. Adjustment of the valve clearances is by means of shims located on top of the followers. The cylinder head contains Integral oitways which supply and lubricate the tappets. The crankshafl Is supported by five main bearings, and endftoat is controlled by a thrust bearing fitted to the upper section of the centre main bearing.

Engine coolant is circulated by 8 pump, driven by the timing belt. For details of the cooling system, refer to Chapter 3. Lubricant is circulated under pressure by a pump, driven from ihe front of the crankshaft. Oil Is drawn from the sump through a strainer, and then forced through an externally-mounted, replaceable screw-on filter. From there, It is distributed to the cylinder head, where It lubricates the camshaft journals and tappets, and also to the crankcase, where il lubricates the main bearings, connecting rod big and smell-ends, gudgeon pins and cylinder bores. On 1242 cc engines, oil jets are fitted lo the base of each cylinder bore -these spray oil onto the underside of the pistons, to Improve cooling.

Repair operations possible with the engine in the car The following work can be carried out with the engine in the car a) Compression pressure - testing b) Auxiliary drivebelt - removal and refitting (refer to Chapter 1A) c) Vatve clearances - checking and adjustment (refer to Chapter I A) d) Camshaft cover - removal and refitting e) Timing belt and covens - removal and refitting f) Timing belt tensioner and sprockets -removal and refitting g) Cylinder head - removal and refitting' h) Camshaft and cam followers • removal and refitting' t) Camshaft oil seal - renews/ j) Crankshaft oil seals - renewal k) Flywheel/dnvepfate • removal, inspection and refitting l) Engine mountings - inspection and renewal m)Sump - removal and refitting n) Oil pump and pick-up tube assembly

•

removai. inspection and refitting *Cylinder head dismantling procedures are detailed In Chapter SO, with details of camshaft and cam follower removal. Note: It is possible to remove the pistons and connecting rods (after removing the cylinder head and sump) without removing the engine. However, this is not recommended. Work of

this nature is more easily and thoroughly completed with the engine on the bench, as described In Chapter 2D.

2 Location of

TDC

on % No

1

cylinder

General Information 1 The camshaft Is driven by the crankshaft, by means of sprockets and a timing belt. Both sprockets rotate In phase with each other and this provides the correct valve timing as the engine rotates. When (he liming belt is removed during servioing or repair, it Is possible for the camshaft and crankshaft to rotate Independently of each other and the correct valve timing Is then lost. 2 The design of the engines covered In this Chapter are such lhat potentially damaging piston-to-valve contact may occur if the camshaft is rotated when any of the pistons are stationary at, or near, the top of their stroke. 3 For this reason it is important lhat Ihe correct phasing between the camshaft and crankshaft is preserved whilst the timing belt Is off the engine. This is achieved by setting the engine In a reference position (known as Top Dead Centre or TDC) before the timing belt Is removed and then preventing the camshaft and crankshaft from rotating until the belt is refitted. Similarly, if ths engine has been dismantled for overhaul, the engine can be set to TOC during reassembly to ensure that Ihe correct shaft phasing is restored. 4 TDC is the highest point In the cylinder that each piston reaches as the crankshaft turns. Each piston reaches TDC at Ihe end of the compression stroke and again at the end of the exhaust stroke. However, for the purpose of timing the ongine. TDC refers to the position of No 1 piston at the end of Its compression stroke. On ail engines In this manual, No 1 piston (and cylinder) Is at the timing belt end of the engine. 5 The camshaft sprocket Is equipped with a marking which, when aligned with a reference marking on the cylinder head, indicates that the camshaft is correctly positioned for cyl-inder No 1 al TDC on its compression stroke.

Page 53 of 225

2A*10 SOHC (8-valve) petrol engine in-car repair procedures

2.11 Unscrewing the crankshaft pulley bolts

6 Itae crankshaft sprocket Is also equipped •nth a timing mark - when this is aligned with 3relarence marking on the oil pump cover.

Hie

engine is set with cylinders No 1 and 4 at

TDC.

Note that it is the camshaft positioning that determines whether a cylinder is on its comcression or exhaust stroke.

Location

of TDC on cylinder No 1 7 Remove the air cleaner and ducting as descnbed in Chapter 4A or 4B. Remove the

spark

plug from No 1 cylinder as described in Chapter 1A. 8 Firmly apply the handbrake, then |ack up

the

front of the car and support it securely on iiia stands (see Jacking end vehicle support). 9 Remove the auxiliary drivebelt(s) as described in Chapter 1A. 10 Unbolt and remove the timing belt cover. Mole the bolt located at the bottom of the

coven

this can be easily overlooked. 11 Undo the three bolts and remove the crankshaft pulley from the sprocket (see {lustration). 12 Turn Ihe engine in its normal direction of rotation (using a socket or spanner on Ihe crankshaft sprocket centre bolt) until pressure an be felt at No

1

cylinder spark plug hole.

1 flfliyflg^ Remove all four spark plugs; "••"•1 this will make the engine HlNTl easier to turn; refer to Chapter 1A for details.

13 Continue turning the engine until the crahaft sprocket TDC timing mark is aligned with the mark on the cylinder head and the crankshaft sprocket timing mark is aligned with the mark on the oil pump cover (see ilustrations). 14 The engine is now set at TDC for No 1 cylinder on compression.

3 Cylinder compression test t ^

1 When engine performance Is down, or if misfiring occurs which cannot be attributed to tne ignition or fuei systems, a compression isst can provide diagnostic clues as to the

2.13a Camshaft sprocket and cylinder head TDC timing marks (arrowed) aligned -shown with timing belt removed engine's condition. II the test is performed regularly, it can give warning of trouble any other symptoms become apparent. 2 The engine must be fully warmed-up to normal operating temperature, the battery must be fufly charged, and all the spark plugs must be removed (Chapter 1A). The aid of an assistant will also be required. 3 Disable the ignition system by dis-connecting the LT wiring plug to the ignition coils. 4 Fit a compression tester to the No 1 cyl-inder spark plug hole - the type of tester which screws into the plug thread is to be preferred, 5 Have the assistant hold the throttle wide open, and crank the engine on the starter motor; after one or two revolutions, the compression pressure should build up to a maximum figure, and then stabilise. Record the highest reading obtained. 6 Repeat the lest on the remaining cylinders, recording the pressure in each. 7 All cylinders should produce very similar pressures; any excessive difference indicates the existence of a fault. Note that the compression should build up quickly in a healthy engine; low compression on the first stroke, followed by gradually increasing pressure on successive strokes, indicates worn piston rings. A low compression reading on the first stroke, which does not build up during successive strokes, indicates leaking valves or a blown head gasket (a cracked head could also be the cause). 8 If the pressure in any cylinder is very low. carry out the following test to isolate the cause. Introduce a teaspoonful of clean oil into that cylinder through its spark plug hole and repeat the test. 9 If the addition of oil temporarily improves the compression pressure, this indicates that bore or piston wear Is responsible for the pressure loss. No improvement suggests that leaking or burnt valves, or a biown head gasket, may be to blame. 10 A low reading from two adjacent cylinders is almost certainly due to the head gasket having blown between them; the presence of coolant in the engine oil will confirm this. 11 If one cylinder is about 20 percent lower

2.13b Crankshaft sprocket and oil pump cover TDC timing marks (arrowed) aligned

than the others and Ihe engine has a slightly rough idle, a worn camshaft lobe could be the cause. 12 On completion of the test, refit the spark plugs and reconnect the ignition LT wiring plug.

4 Timing belt and covers -removal and refitting ^

Note: Fiat specify the use of a special timing belt fens/on measuring toot to correctly set tho timing belt tension. If access to this equipment cannot be obtained, an approximate setting can be achieved using the method described below. It the method described is used, the tension must be checked using the special tool at the earliest possible opportunity. Do not drive the vehicle over large distances, or use high engine speeds, until the belt tension is known fo be correct. Refer to a Fiat dealer foradvSce.

General information 1 The function of the timing belt is to drive Ihe camshaft and coolant pump. Should the belt slip or break In service, the valve timing will be disturbed and piston-to-valvo contact will occur, resulting in serious engine damage, 2 The timing belt should be renewed ai the specified intervals (see Chapter 1A), or earlier if it is contaminated with oil. or if it is at all noisy in operation (a scraping noise due to uneven wear). 3 If the timing belt is being removed, it Is a wise precaution to check the condition of the coolant pump at the same time (check for signs of coolant leakage). This may avoid the need to remove the timing belt again at a later stage, should the coolant pump fall.

Removal 4 Firmly apply the handbrake, then jack up the front of the car and support it securely on axle stands (see Jacking and vehicle support). Remove the right-hand front road wheel. 5 Remove the air cleaner and air ducting as described in Chapter 4A or 46. 6 Remove the auxiliary drivebelt(s) and the spark plugs as described in Chapter 1A.

2A

Page 54 of 225

2A*10 SOHC (8-valve) petrol engine in-car repair procedures

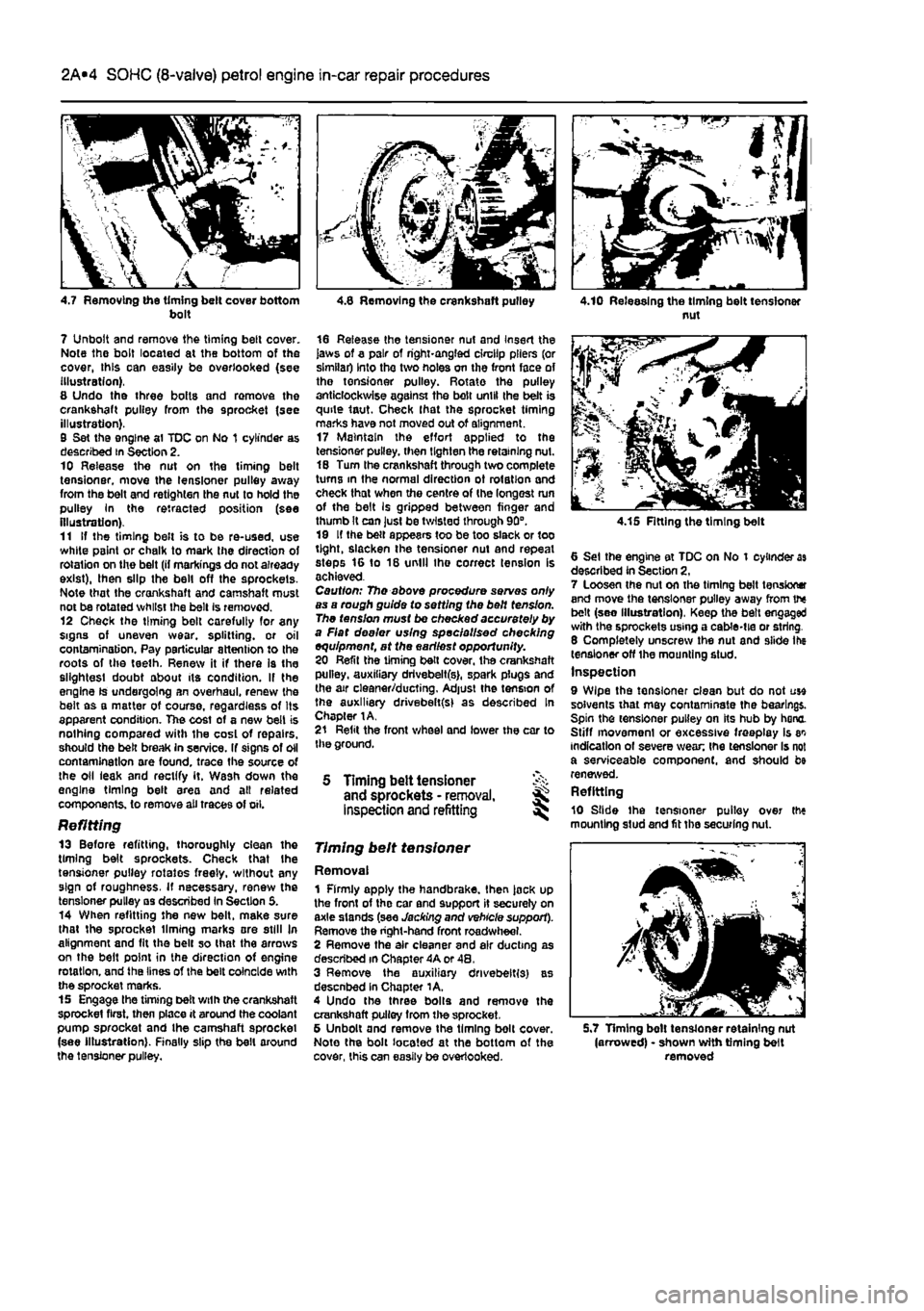

4.7 Removing the timing belt cover bottom bolt

7 Unbolt and remove the timing belt cover. Note the bolt located at the bottom of the cover, this can easily be overlooked (see illustration), 8 Undo the three bolts and remove the crankshaft pulley from the sprocket (see illustration). 9 Set the engine al TDC on No 1 cylinder as described in Section 2. 10 Release the nut on the timing belt tensioner, move the lensloner pulley away from the belt and retighten the nut to hold the pulley In the retracted position (see illustration). 11 If the timing belt is to be re-used, use white paint or chalk to mark the direction of rotation on the belt (if markings do not already exist), then slip the bell off the sprockets-Note that the crankshaft and camshaft must not be rotated whilst the belt Is removed. 12 Check the timing belt carefully for any signs of uneven wear, splitting, or oil contamination. Pay particular attention to the roots of the teeth. Renew it if there is the slightest doubt about its condition. If the engine ts undergoing an overhaul, renew the belt as a matter of course, regardless of Its apparent condition. The cost of a new belt is nothing compared with the cost of repairs, should the belt break in sen/ice. If signs of oil contamination are found, trace the source of the oil leak and rectify it. Wash down the engine timing belt area and alt related components, to remove all traces of oil.

Refitting 13 Before refitting, thoroughly clean the timing belt sprockets. Check that Ihe tensioner pulley rotates freely, without any sign of roughness. If necessary, renew the tensioner pulley as described In Section 5. 14 When refitting the new belt, make sure that the sprocket liming marks ore still In alignment and fit the belt so that the arrows on the belt point in the direction of engine rotation, and the lines of the belt coincide with the sprocket marks. 15 Engage the timing belt wilh the crankshaft sprocket first, then place it around the coolant pump sprocket and the camshaft sprocket (see illustration). Finally slip the bell around the tensioner pulley.

II

4.8 Removing the crankshaft pulley

16 Refease the tensioner nut and Insert the laws of a pair of right-angled clmilp pliers (or similar Into the two holes on the front face of the tensioner pulley. Rotate the pulley anticlockwise against the belt until the belt is quite taut. Check lhat the sprocket timing marks have not moved out of alignment. 17 Maintain the effort apptied to the tensioner pulley, then tighten the retaining nut. 18 Turn the crankshaft through two complete turns in the normal direction ot rotation and check that when the centre of (he longest run of the belt Is gripped between finger and thumb It can Just be twisted through 90°. 19 If the belt appears too be too slack or too fight, slacken the tensioner nut and repeat steps 16 to 18 until the correct tension is achieved. Caution: The above procedure serves only as a rough guide to setting the belt tension. The tension must be checked accurately by a Flat dealer using specialised checking equipment, at the earliest opportunity. 20 Refit the timing belt cover, the crankshaft pulley, auxiliary drivebelt(s>, spark plugs and the air cleaner/ducting. Adjust the tension of the auxiliary drivebelt(sl as described In Chapter 1A. 21 Refit the front wheel and lower the car to the ground.

5 Timing belt tensioner % and sprockets - removal, ^ Inspection and refitting ^

Timing beit tensioner

Removal 1 Firmly apply the handbrake, then jock up the front of the car and support it securely on axle stands (see Jacking and vehicle support). Remove the right-hand front roadwheel. 2 Remove the air cleaner and air ducting as described m Chapter 4A or 48, 3 Remove the auxiliary drivebeltfs) as descnbed In Chapter 1A. 4 Undo the three bolts and remove the crankshaft pulley from the sprocket, 5 Unbolt and remove the timing bolt cover. Note the bolt located at the bottom ot the cover, this can easily be overlooked.

4.10 Releasing the timing belt tensioner nut

4.15 Fitting the timing belt

6 Set the engine at TDC on No 1 cylinder as described In Section 2, 7 Loosen the nut on the timing belt tension* and move the tensioner pulley away from the belt (see Illustration), Keep the belt engaged with the sprockets using a cable-tie or string. 8 Completely unscrew the nut and slide Ihe tensioner off Ihe mounting stud. Inspection 9 Wipe the tensioner clean but do not use solvents that may contaminate the bearings. Spin the tensioner pulley on Its hub by hono. Stiff movement or excessive freeplay is w indication of severe wean the tensioner Is not a serviceable component, and should be renewed. Refitting 10 Slide the tensioner pulley over the mounting stud and fit the securing nut.

S.7 Timing bell tensioner retaining nut (arrowed) - shown with timing belt removed

Page 56 of 225

2A*10 SOHC (8-valve) petrol engine in-car repair procedures

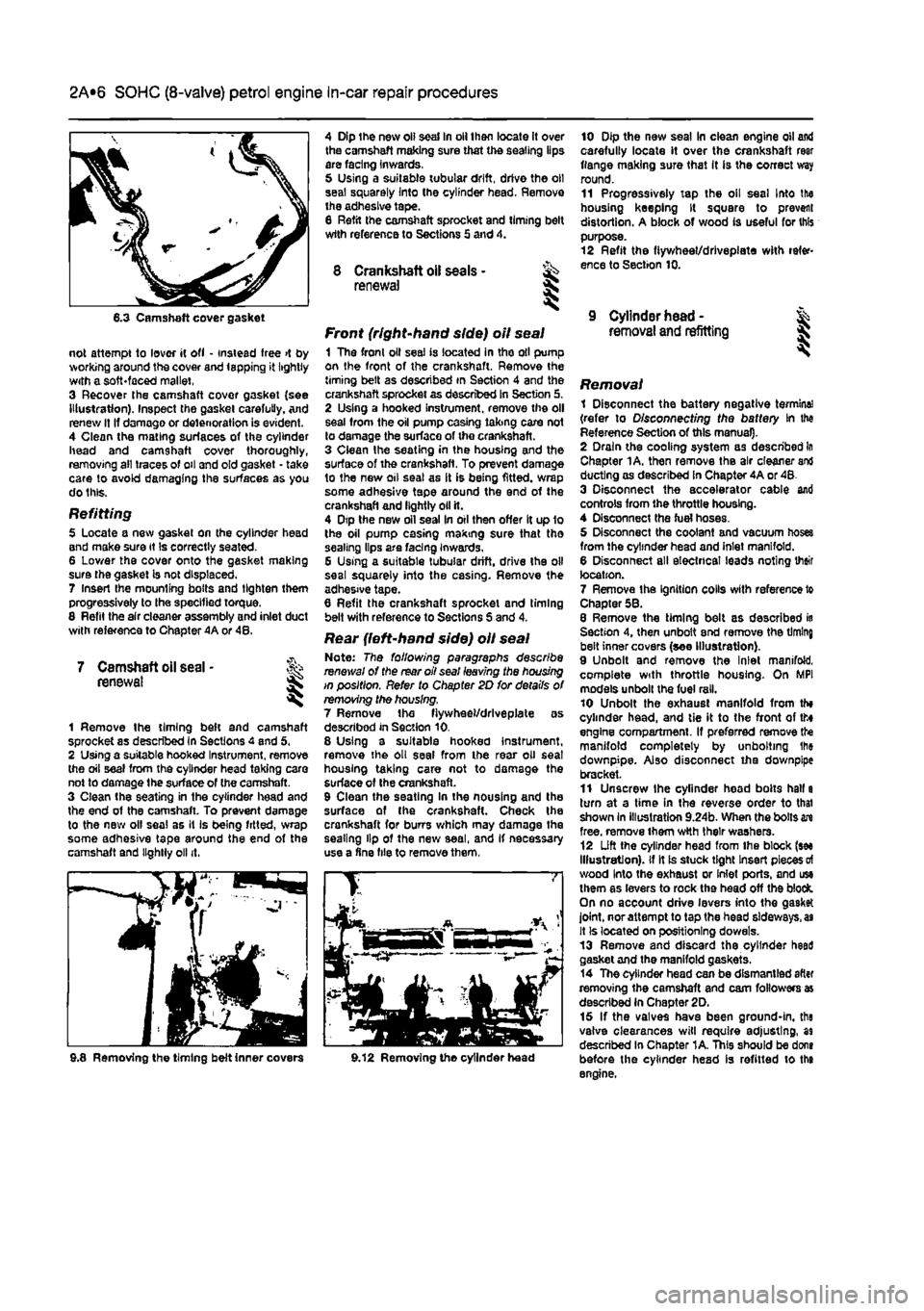

6.3 Camshaft cover gasket

not attempt to lover it ofl • instead free >t by working around the cover and lapping it lightly with a soft-faced mallet, 3 Recover the camshaft covor gasket {see Illustration). Inspect the gasket carefully. And renew It If damage or deterioration is evident. 4 Clean the mating surfaces of the cylinder head and camshaft cover thoroughly, removing all traces of oil and old gasket - take care to avoid damaging the surfaces as you do this.

Refitting 5 Locate a new gasket on the cylinder head and make sure it Is correctly seated. 6 Lower the cover onto the gasket making sure the gasket is not displaced. 7 Insert Ihe mounting bolts and tighten them progressively to the specified torque. 8 Refit the air cleaner assembly and inlet duct with reference to Chapter 4A or 48.

7 Camshaft oil seal • renewal I

1 Remove the timing beft and camshaft sprocket as described in Sections 4 and 5, 2 Using a suitable hooked Instrument, remove the oil seal from the cylinder head taking care not to damage the surface of (he camshaft. 3 Clean the seating in the cylinder head and the end of the camshaft. To prevent damage to the new olf seal as it is being fitted, wrap some adhesive tape around the end of the camshaft and lightly oil it.

4 Dip the new oil seal In oil then locate it over the camshaft making sure that the sealing lips are facing inwards, 5 Using a suitable tubular drift, drive the oil seal squarely Into the cylinder head. Remove the adhesive tape. 8 Refit the camshaft sprocket and liming belt wtth reference to Sections 5 and 4.

8 Crankshaft oil seals - ^ renewal S

Front (right-hand side) oil seal 1 The fronl oil seal is located in tho oil pump on the front of the crankshaft. Remove the timing belt as described in Section 4 and the crankshaft sprocket as described in Section 5. 2 Using a hooked instrument, remove the oil seal from the oil pump casing taking care not to damage the surface of the crankshaft. 3 Clean Ihe seating in the housing and the surface of the crankshaft. To prevent damage to the new oil seal as it is being fitted, wrap some adhesive tape around the end of the crankshaft and lightly oil it. 4 Dtp the new oil seal In oil then offer It up 1o the oil pump casing making sure that tho sealing lips are facing Inwards. G Using a suitable tubular drift, drive the oil seal squarely into the casing. Remove the adhesive tape. 6 Refit the crankshaft sprocket and timing belt with reference to Sections S and 4.

Rear {left-hand side) oil seal Note: The following paragraphs describe renewal of the rear oil seal leaving the housing in position. Refer to Chapter 2D for details of removing the housing. 7 Remove the fiywheel/drlveplate as described in Section 10. 8 Using a suitable hooked instrument, remove the oil seal from the rear oil seat housing taking care not to damage the surface of Ihe crankshaft. 9 Clean the seating In the nousing and the surface of the crankshaft. Check the crankshaft for burrs which may damage the sealing lip of the new seal, and If necessary use a fine file to remove them,

10 Dip the new seal In clean engine oil and carefully locate it over the crankshaft rear flange making sure that It is the correct way round. 11 Progressively tap the oil seal Into the housing keeping It square to prevent distortion. A block of wood is useful for this purpose. 12 Refit the fiywheet/drlvepiate with refer-ence to Section 10.

9 Cylinder head -removal and refitting I

i Removing the timing belt inner covers 9.12 Removing the cylinder head

Removal 1 Disconnect the battery negative termine! (refer to Disconnecting the battery In the Reference Section of this manual). 2 Drain the cooling system as described In Chapter 1A. then remove the air cleaner and ducting as described in Chapter 4A or 48. 3 Disconnect the accelerator cable and controls from the throttle housing. 4 Disconnect the fuel hoses. 5 Disconnect the coolant and vacuum hoses from the cylinder head and inlet manifold. 6 Disconnect all electrical leads noting their location. 7 Remove the Ignition colls with reference to Chapter 58. 8 Remove the timing belt as described in Section 4, then unbolt end remove the timing belt inner covers (see Illustration). 9 Unbolt and remove the Inlet manifold, complete with throttle housing. On MPI models unbolt the fuel rail. 10 Unbolt the exhaust manifold from th» cylinder head, and tie it to the front of tto engine compartment. If preferred remove the manifold completely by unbolting Ihe downpipe. Also disconnect iha downpipe bracket. 11 Unscrew the cylinder head bolts hall a turn at a time in the reverse order to thai shown In illustration 9.24b. When the bolts in free, remove them wtth their washers. 12 Lift the cylinder head from Ihe block (see Illustration), if It is stuck tight Insert pieces

of

wood Into the exhaust or Inlet ports, and use them as levers to rock the head off the block. On no account drive levers into the gasket joint, nor attempt to tap the head sideways,

as

It Is located on positioning dowels. 13 Remove and discard the cylinder heed gasket and the manifold gaskets. 14 The cylinder head can be dismantled after removing the camshaft and cam followers as described in Chapter 2D. 15 If the valves have been ground-in, the valve clearances will require adjusting, as described In Chapter 1A. This should be dons before the cylinder head is refitted to the engine.