Speed FIAT PUNTO 1994 176 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1994, Model line: PUNTO, Model: FIAT PUNTO 1994 176 / 1.GPages: 225, PDF Size: 18.54 MB

Page 119 of 225

3*2 Cooling, heating and ventilation systems

Heater matrix Removal 10 Remove the complete heater assembly as described previously in this Section. 11 Slacken and remove the securing screws, then withdraw the heater matrix from the tester assembly casing. Refitting 12 Refitting is a reversal of removal; refit Ihe neater assembly as described previously in

this

Section.

Heater blower motor

Removal 13 Disconnect the battery negative terminal {refer to Disconnecting the battery in the Reference Section of this manual). 14 Unplug the wiring from the blower motor

al the

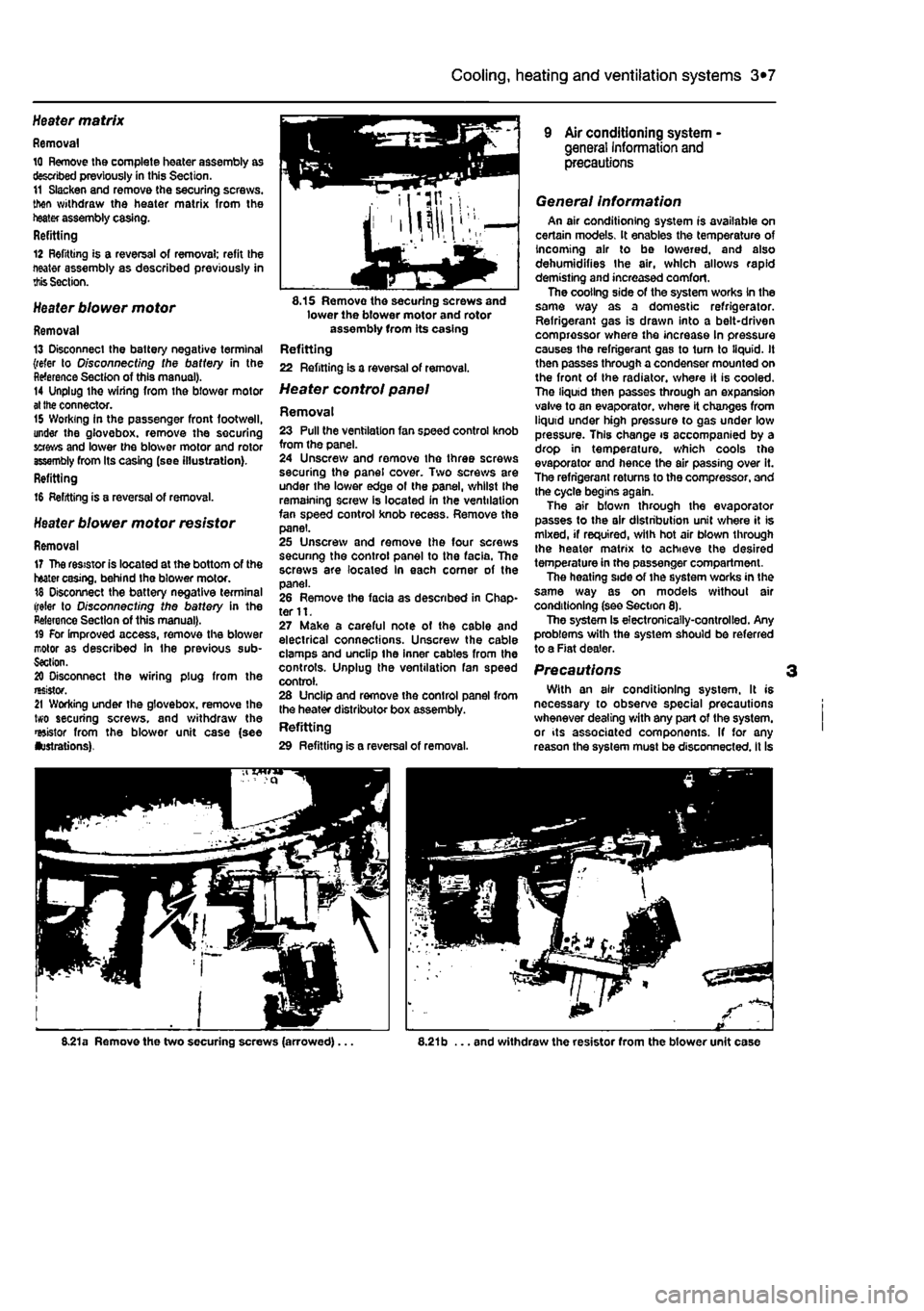

connector. 15 Working in the passenger front footwell, under the glovebox. remove the securing grows and lower the blower motor and rotor assembly from Its casing (see illustration). Refitting

16 Refitting is a reversal of removal.

Heater blower motor resistor

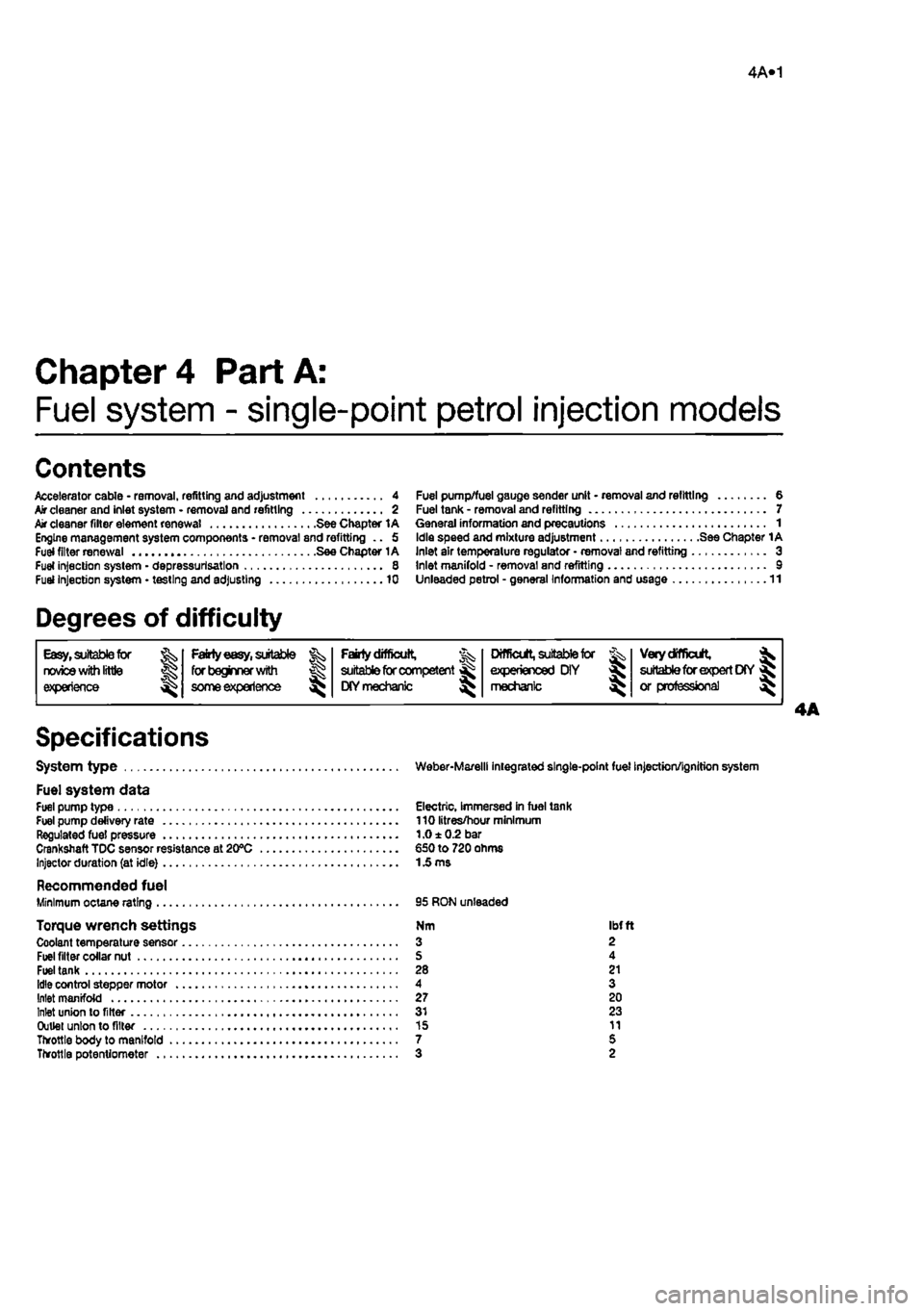

Removal 17 The resistor is located at the bottom of the heater casing, behind the blower motor. 18 Disconnect the battery negative terminal (refer to O/sconnecf/ng the battery in the Reference Section of this manual). 19 For improved access, remove the blower motor as described in the previous sub-Section. 20 Disconnect the wiring plug from the resistor. 21 Working under the glovebox. remove the two securing screws, and withdraw the resistor from the blower unit case (see lustrations).

8.15 Removo the securing screws and lower the blower motor and rotor assembly from its casing Refitting 22 Refining Is a reversal of removal.

Heater control panel

Removal 23 Pull the ventilation fan speed control knob from the panel. 24 Unscrew and remove the three screws securing the panel cover. Two screws are under the lower edge of the panel, whilst Ihe remaining screw is located in the ventilation fan speed control knob recess. Remove the panel. 25 Unscrew and remove the four screws securing the control panel to the facia. The screws are located in each comer of the panel. 26 Remove the facia as described in Chap-ter 11. 27 Make a careful note of the cable and electrical connections. Unscrew the cable clamps and unclip the inner cables from the controls. Unplug the ventilation fan speed control. 28 Unclip and remove the control panel from the heater distributor box assembly. Refitting 29 Refitting is a reversal of removal.

9 Air conditioning system -general Information and precautions

General information An air conditioning system is available on certain models. It enables the temperature of Incoming air to be lowered, and also dehumidifies the air, which allows rapid demisting and increased comfort. The cooling side of the system works In the same way as a domestic refrigerator. Refrigerant gas is drawn into a belt-driven compressor where the increase In pressure causes the refrigerant gas to turn to liquid. It then passes through a condenser mounted on the front of the radiator, where it is cooled. Tho liquid then passes through an expansion vaive to an evaporator, where it changes from liquid under high pressure to gas under low pressure. This change is accompanied by a drop in temperature, which cools the evaporator and hence the air passing over it. The refrigerant returns to the compressor, and the cycle begins again. The air bfown through the evaporator passes to the air distribution unit where it is mixed, if required, with hot air blown through the heater matrix to achieve the desired temperature in the passenger compartment. The heating side of ihe system works in the same way as on models without air conditioning (see Section 8). The system Is electronically-controlled. Any problems with the system should be referred to a Fiat dealer.

Precautions With an air conditioning system. It is necessary to observe special precautions whenever dealing with any part of the system, or its associated components. If for any reason the system must be disconnected, it Is

8.21a Remove the two securing screws (arrowed)... ,21b ... and withdraw the resistor from the blower unit case

Page 121 of 225

4A«1

Chapter 4 Part A:

Fuel system - single-point petrol injection models

Contents

Accelerator cable • removal, refitting and adjustment 4 Air cleaner and inlet system - removal and refitting 2 Air cleaner filter element renewal See Chapter 1A Engine management system components - removal 8nd refitting .. 5 fuel filter renewal See Chapter 1A Fuel injection system - depressurlsatlon 8 Fuel injection system • testing and adjusting 10

Degrees of difficulty

Fuel pump/fuel gauge sender unit - removal and refitting 8 Fuel tank - removal and refitting 7 General information and precautions 1 Idle speed and mixture adjustment See Chapter 1A Inlet air temperature regulator • removal and refitting 3 Inlet manifold - removal and refitting 9 Unleaded petrol - general Information and usage 11

Easy, suitable for Fairty easy, suitable Fairly difficult, Jx suitable for competent ^ OY mechanic ^

DifficUt, suitable tor % Very difficult, ^ novice with Me for begrmer with &

Fairly difficult, Jx suitable for competent ^ OY mechanic ^ experienced DIY > * suitable for expert D(Y JS or professional ^ experience some experience &

Fairly difficult, Jx suitable for competent ^ OY mechanic ^ mechanic > * suitable for expert D(Y JS or professional ^

Specifications

System type Weber-Marelll integrated single-point fuel injection/ignition system

Fuel system data Fuel pump type Electric, Immersed in fuel tank Fuel pump delivery rate 110 litres/hour minimum Regulated fuel pressure 1.0 ± 0.2 bar Crankshaft TDC sensor resistance at 20°C €50 to 720 ohms Injector duration (at idle)

1

£ ms

Recommended fuel Minimum octane rating 95 RON unleaded

Torque wrench settings Nm ibfft Coolant temperature sensor 3 2 Fuel filter collar nut S 4 Fuel tank 28 21 Idle control stepper motor 4 3 Inlet manifold 27 20 Inlet union to filter 31 23 Outlet union to filter 15 11 Throttle body to manifold 7 5 Throttle potentiometer 3 2

Page 122 of 225

4A*2 Fuel system - single-point petrol Injection models

1 General information and precautions

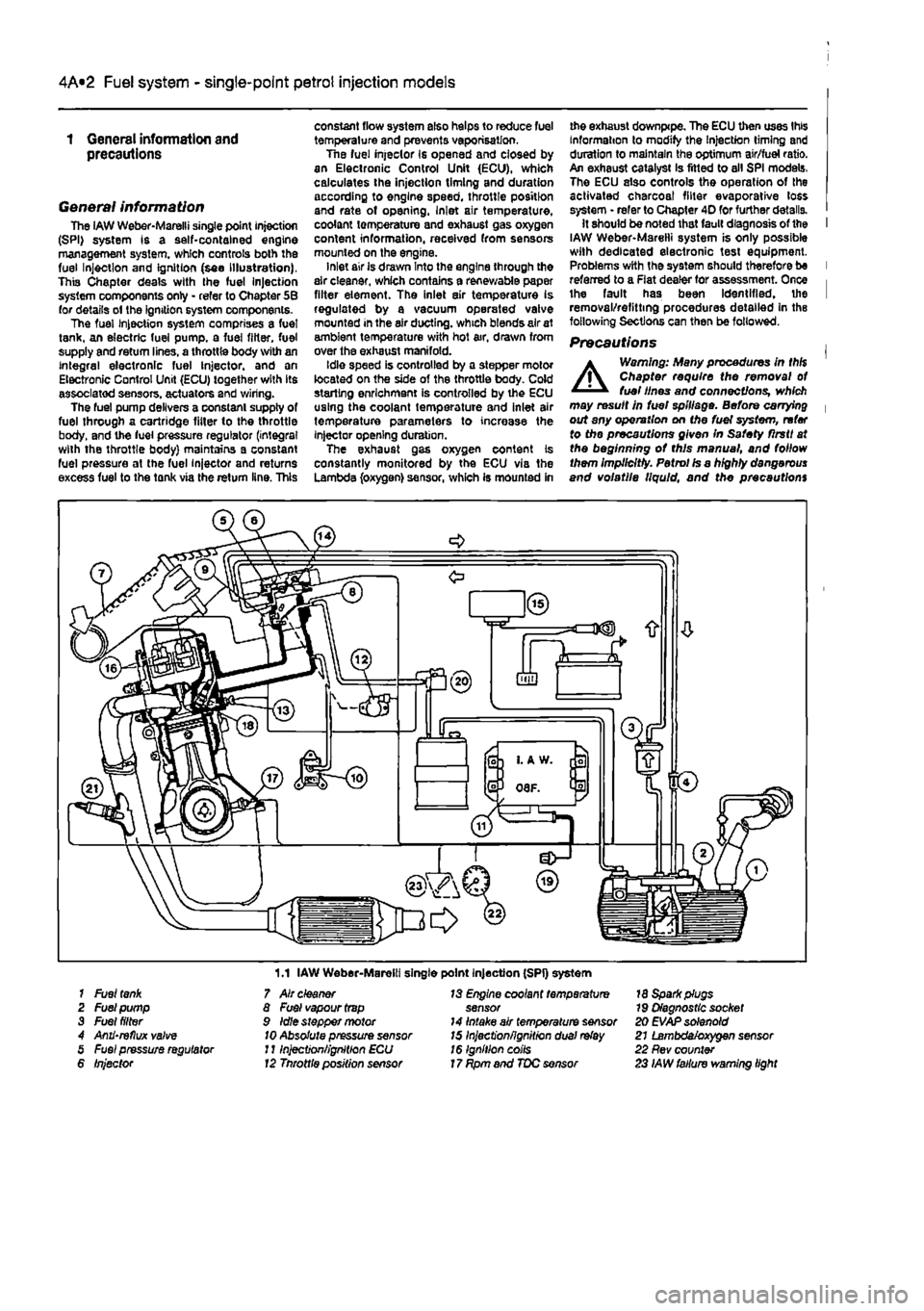

General information The iAW Weber-Marelli single point Injection (SPI) system is a self-contained engine management system, which controls both the fuel Injection and Ignition (see Illustration), This Chapter deals with the fuel Injection system components only - refer to Chapter 5B for details ol the ignition system components. The fuel Injection system comprises a fuel tank, an electric fuel pump, a fuel filter, fuel supply and return lines, a throttle body with an integral electronic fuel Injector, and an Electronic Control Unit (ECU) together with its associated sensors, actuators and wiring. The fuel pump delivers a constant supply of fuel through a cartridge fitter to the throttle body, and the fuel pressure regulator (integral with the throttle body) maintains a constant fuel pressure at the fuel injector and returns excess fuel to the tank via the return line. This

constant flow system also helps to reduce fuel temperature and prevents vaporisation. Tne fuel injeclor Is opened and closed by an Electronic Control Unit (ECU), which calculates the injection timing and duration according to engine speed, throttle position and rate of opening, Inlet air temperature, coolant temperature and exhaust gas oxygen content information, received from sensors mounted on the engine. inlet air is drawn Into the engine through the air cleaner, which contains a renewable paper filter element. The inlet air temperature is regulated by a vacuum operated valve mounted in the air ducting, which blends air at ambient temperature with hot air, drawn from over the exhaust manifold. Idle speed is controlled by a stepper motor located on the side of the throttle body. Cold starling enrichment is controlled by the ECU using the coolant temperature and inlet air temperature parameters to increase the injector opening duration. The exhaust gas oxygen content is constantly monitored by the ECU via the Lambda (oxygen) sensor, which is mounted in

me exhaust downpipe. The ECU then uses this Information to modify the Injection timing and duration to maintain the optimum air/fuel ratio. An exhaust catalyst Is fitted to all SPI models. The ECU also controls the operation of the activated charcoal filter evaporative loss system • refer to Chapter 4D for further details. It should be noted that fault diagnosis of the I IAW Weber-Marelli system is only possible with dedicated electronic test equipment. Problems with the system should therefore be I referred to a Flat dealer for assessment. Once i the fault has been Identified, the I removal/refitting procedures detailed in the following Sections can then be followed.

Precautions |

A

Warning: Many procedures in thH Chapter require the removal ot fuel lines and connections, which may result in fuel spillage. Before carrying | out any operation on Me fuel system, refer to the precautions given In Safety flrstt at the beginning ot this manual, and follow them Implicitly. Petrol Is a highly dangerous and volatile liquid, and the precautions

1.1 IAW Weber-Marelli single point Injection (SPI) system 1 Fuel

tank

2 Fuel pump 3 Fuel filter 4 Anii'reflux valve 5 Fuel pressure regulator 6 Injector

7 Air cleaner 8 Fuel vapour

trap

9 Idle stepper motor

10

Absolute pressure sensor J11njection/ignition ECU 12 Tnrottle position sensor

13 Engine coolant temperature sensor 14 Intake air temperature sensor 15 Inject'onfignitron dual

relay

16 Ignition coils 17 Rpm and TDC sensor

18 Spark plugs 79 Diagnostic socket 20 EVAP solenoid 21 Lambda/oxygen sensor 22 Rev counter 23 IAW failure warning light

Page 126 of 225

4A*2 Fuel system - single-point petrol Injection models

1 The luel system referred to In this Section is defined as the tank-mounted fuel pump, the fuel litter, the throttle body and pressure regulator components, and the metal pipes and flexible hoses of the fuel lines between these components. All ihese contain fuel which will be under pressure while the engine Is running and/or while tha Ignition is switched on. The pressure will remain for some time after tho ignition has been switched off, and must be relieved before any of these components are disturbed (or servicing work. 2 Disconnect the battery negative terminal (refer to D/sconnecf/ngr the battery in the Reference Section of this manual), 3 Place a container beneath the relevant connection/union to be disconnected, and have a large rag ready to soak up any escaping fuel not being caught by the container. 4 Slowly loosen the connection or union nut (as applicable) to avoid a sudden release of pressure, and wrap tho rag around the connection to catch any fuel spray which may be expelled. Once the pressure is released, disconnect the fuel line, and Insert plugs to minimise fuel loss and prevent the entry of dirt Into the fuel system.

9 Inlet manifold -removal and refitting ^

Note: Refer to the warning given In Section 1 before proceeding.

Removal 1 Remove the throttle body assembly as described in Section 5. 2 Drain the cooling system as described in Chapter 1A. 3 Disconnect the winng connector from the coolanl temperature sensor (situated on the left-hand sidB of the manifold). 4 Undo the bolt securing the accelerator cable mounting bracket to the manifold, and position it clear of the manifold. 5 Slacken the retaining clip and disconnect tha coolant hose from the rear of the manifold. 6 Disconnect the brake vacuum hose. 7 Undo the seven manifold retaining nuts and

10.2 The diagnostic connector la located behind the ECU bolts, and remove (he manifold from the engine. Remove the gasket and discard It; a new one should be used on refitting.

Refitting 8 Refitting is a reverse of the removal procedure, noting the following points: a) Ensure that the manifold and cylinder head mating surfaces are clean and dry, and fit a nev/ manifold gasket. Refit the manifold and securely tighten Its retaining nuts. b) Ensure that all relevant hoses are reconnected fo their original positions and are securely held (where necessary) by the retaining clips. c) Refit the throttle body assembly with reference to Section S. d) On completion, refill the cooling system as described In Chapter 1A.

correctly adjusted, and that the engine breather hoses are clear and undamaged. 2 If these checks fall to reveal the cause of the problem, the vehicle should be taken to a suitably-equipped Fiat dealer for testing. A wiring block connector Is Incorporated In the engine management circuit, into which a special electronic diagnostic tester can be plugged; the connector is situated behind the ECU (see Illustration). The tester will locate the fault quickly and simply, alleviating the need to test all the system components Individually, which is a time-consuming operation that carries a high risk of damaging the ECU.

Adjustments 3 As mentioned above, the idle speed and mixture adjustment are all monitored and controlled by the ECU, and are not adjustable Experienced home mechanics with a considerable amount of skill and equipment (including a good-quality tachometer and a good-quality, carefully calibrated exhaust gas analyser) may be able to check the exhaust CO level and ihe idle speed. However, If thes* are found lo be in need of adjustment, the car must be taken to a suitably-equipped Flat dealer for testing using the special test equipment which is plugged into the diagnostic connector.

11 Unleaded petrol -general Information and usage

10 Fuel injection system - & testing and adjustment S

Testing 1 If a fault appears in the fuel injection system, first ensure that all the system winng connectors are securely connected and free of corrosion. Then ensure that the fault Is not due to poor maintenance; ie, check that the air cleanor fitter element is clean, the spark plugs are In good condition and correctly gapped, that tho valve clearances are

Note: The information given in this Chapter

is

correct at the time of writing. If updated Information is thought to be required, check with a Fiat dealer. If travelling abroad, consult one of the motonng organisations (or a similar authority) for advice on the fuel available. 1 All petrol models are fitted with a catalytic converter and must be run on unleaded fuel only - the fuel recommended by Flat is given In the Specifications of this Chapter. Under no circumstances should leaded fuei (UK 4-slar) be used, as this may damage the converter. 2 Super unleaded petrol (98 octane) can also be used in all models if wished, though there is no advantage in doing so.

Page 127 of 225

4B*1

Chapter 4 Part B:

Fuel system - multi-point petrol injection models

Contents

Accelerator cable - removal, refitting and adjustment 4 Air cleaner and Inlet system • removal and refitting 2 Air cleaner filter element renewal See Chapter 1A Engine management system components (1242 cc, 8-valve engines) -removal and refitting 5 Engine management system components (1242 cc, 16-valve engines) - removal and refitting 6 Fuel filter renewal See Chapter 1A Fuel Injection system - depressurisation 9

Degrees of difficulty

Fuel injection system - testing and adjustment 11 Fuel pump and fuel gauge sender unit - removal and refitting 7 Fuel tank - removal and refitting 8 General Information and precautions 1 Idle speed and mixture adjustment See Chapter 1A Inlet air temperature regulator - removal and refitting 3 Inlet manifold - removal and refitting 10 Unleaded petrol • general Information and usage 12

Easy, suitable

for ^

novice with

Ittie experience ^

Fairly

easy,

suitable Jk for beginner

with

® someexperiencs ^

FaMycSffiait, J^ suitable

for

competent ^

DIY mechanic

^

Difficult

suitable

for experienced BY SJ mechanic ^

Very difficult,

^

suitable

for expert

DIY

jR or professional ^

Specifications

System type

Fuel system data Fuel pump type Fuel pump delivery rate: 1242 cc (8-vatve) engine 1242 cc (16-valve) engine Regulated fuel pressure: 1242 cc (8-vaive) engine: Pre-1998 models 1998 models onward 1242 cc (16*valve) engine Crankshaft TDC sensor resistance al 20°C Injector electrical resistance: Pre-1998 models 1998 models onward Injector duration (at Idle)

Recommended fuel Minimum octane rating

Torque wrench settings Coolant temperature sensor

Idle

control stepper motor Inlet manifold brake servo union Inlet manifold upper section-to-lower section (16-valve engines) Inlet manifold-to-cylinder head (16-valve engines) Inlet manlfold-to-cylinder head (8-valve engines) Throttle body to manifold Throttle potentiometer

Weber-Marelli integrated multi-point fuel injection/ignition system

Electric, immersed In fuel tank

120 Hires/hour minimum 110 litres/hour minimum

2.5 bars 3.5 bars 3.0 bars 650 to 720 ohms

16.2 ohms 13.8 to 15.2 ohms 2.0 ms

95 RON unleaded

Nm Ibfft a 2 4 3 35 26 9 7 15 11 27 20 7 5 3 2

Page 128 of 225

4A*2 Fuel system -

single-point

petrol Injection models

1 General information and precautions

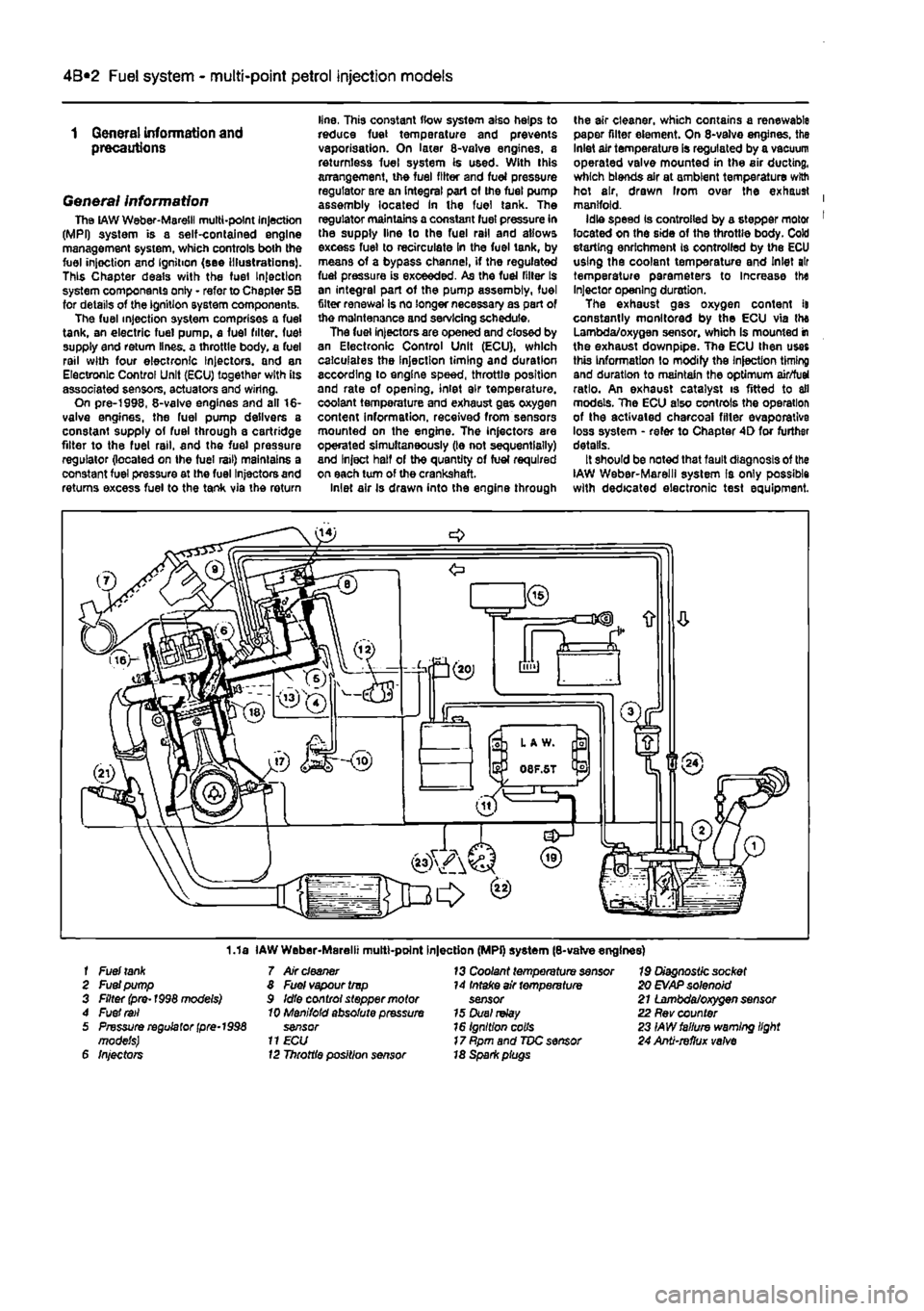

General information The

LAW

Weber-Maretil multi-point Injection (MPI) system is a self-contained engine management system, which controls both the fuel injoction and Ignition (see Illustrations). This Chapter deals with the fuel Injection system components only - refer to Chapter 5B for details of the ignition system components. The fuel injection system comprises a fuel tank, an electric fuel pump, a fuel filter, fuel supply end return lines, a throttle body, a fuel rail with four electronic Injectors, and an Electronic Control Unit (ECU) together with its associated sensors, actuators and wiring. On pre-1998, 8-valve engines and all 16-valve engines, the fuel pump delivers a constant supply of fuel through a cartridge filter to the fuel rail, and the fuel pressure regulator (located on Ihe fuel rail) maintains a constant fuel pressure at the fuel Injectors and returns excess fuel to the tank via the return

line, This constant flow system also helps to reduce fuel temperature and prevents vaporisation. On later 8-valve engines, a returnless fuel system is used. With this arrangement, the fuel filter and fuel pressure regulator are an integral part of the fuel pump assembly located In the fuel tank. The regulator maintains a constant fuel pressure in the supply line lo the fuel rail and allows excess fuel to recirculate in the fuel tank, by means of a bypass channel, if the regulated fuel pressure is exceeded. As the fuel filler Is an integral part of the pump assembly, fuel filter renewal Is no longer necessary as part of the maintenance and servicing schedule. The fuel injectors are opened and closed by an Electronic Control Unit (ECU), which calculates the Injection timing and duration according to engine speed, throttle position and rate of opening, inlet air temperature, coolant temperature and exhaust gas oxygen content information, received from sensors mounted on the engine. The injectors are operated simultaneously (le not sequentially) and Inject half of the quantity of fuel required on each turn of the crankshaft. Inlet air Is drawn into the engine through

the air cleaner, which contains a renewable paper filter element. On 8-valve engines, the Inlet air temperature is regulated by a vacuum operated valve mounted in the air ducting, which blends air at ambient temperature with hot air, drawn Irom over the exhaust | manifold. Idle speed Is controlled by a stepper motor 1 located on the side of the throttle body. Cold storting enrichment is controlled by the ECU using the coolant temperature and Inlet air temperature parameters to Increase the Injector opening duration. The exhaust gas oxygen content it constantly monitored by the ECU via the Lambda/oxygen sensor, whioh Is mounted in the exhaust downpipe. The ECU then uses this Information to modify the Injection timing and duration to maintain the optimum air/fuel ratio. An exhaust catalyst is fitted to all models. The ECU also controls the operation of the activated charcoal filler evaporative loss system - refer to Chapter 4D for further details. It should be noted that fault diagnosis of the IAW Weber-Marelll system Is only possible with dedicated electronic test equipment.

1.1a IAW Weber-Marelii multt-point Injection (MPi) system (8-valve engines) f Fuel

tank

7 Air

cleaner

13 Coolant temperature sensor 19 Diagnostic socket 2 Fuel pump 8 Fuel vapour trvp 14 Intake air temperature 20

EVAP

solenoid 3 Filter (pre-1998 models) 9 Idle control stepper motor sensor 21 Lambda/oxygen sensor 4 Fuel

rail

10 Manifold absolute pressure 15 Duel

relay

22 Rev counter 5 Pressure regulator

(pre-1998

sensor 16 Ignition colls 23 IAW failure warning light models)

11 ECU

17 Rpm and TDC sensor 24 Anti-refhjx

valve

6 Injectors 12 Throttle position sensor 18 Spark piugs

Page 136 of 225

4C»1

Chapter 4 PartC:

Fuel system - diesel models

Contents

Accelerator cable • removal, refitting and adjustment 3 Air cleaner and inlet system • removal and refitting 2

AJr

cleaner filter element - renewal See Chapter IB Fuet filter renewal See Chapter 1B Fuel gauge sender unit • removal and refitting 10 Fuel injection pump • removal and refitting 5 Fuel injectors - testing, removal and refitting 9

Fuel

system • priming and bleeding 4

Fuel

tank - removal and refitting 11 General Information and precautions 1

Idle speed - checking and adjustment See Chapter 1B Injection timing • checking methods 6 injection timing {Bosch fuel Injection pump) • checking and adjustment 7 Injection timing (Lucas fuel Injection pump) - checking and adjustment 8 Inlet manifold - removal and refitting 12 Turbocharger - description and precautions 13 Turbocharger - examination and renovation 15 Turbocharger - removal and refitting 14

Degrees of difficulty

Easy,

suitable for novice

with Ittle

p experience sS^

Fairly easy, suitable (or beginner with some experience

Fairly tfifficuit, suitable

for

competent ^

DIY

mechanic

Difficult, suitable

for ^ experienced DIY jR mechanic ^

Very difficult, ^ sutable for expert

DIY

S or professional ^

Specifications

General System type

Firing order

Injection pump (Bosch VE) Direction of rotation Static timing: Engine position Pump timing measurement Maximum engine speed

Injection pump (Lucas/CAV FT08) Direction of rotation Static timing: Engine position Pump timing measurement Maximum engine speed

injectors Type Opening pressure: Bosch Lucas: New After running in

RPM sensor Sensor-to-flywheel ring gear teeth gap — Winding resistance

Rear-mounted fuel tank, distributor fuel injection pump with integral transfer pump. Indirect Injection, Turbocharger on TDS, TD and TDSX models 1-3-4-2 (No

1

at timing belt end of engine)

Clockwise, viewed from sprocket end

No

1

piston at TDC 0.93 ± 0.05 mm 5200 to 5300 rpm

Clockwise, viewed from sprocket end

No 1 piston at TDC 0° ± 1° TDC (Note: Value shown on pump - see text} 5150150 rpm

Pintle

150 to 158 bar

124 to

131

bar 116lo123 bar

0.25 to 1.3 mm 680* 100 ohms

Page 137 of 225

Fuel system - diesel models 4C*3

Torque wrench settings Nm Ibfft Fuel injection pump roar bracket .. . 29 21 Fuel Injection pump .... 25 18 Fuel Injectors 41 Fuel pipe union nuts .... 30 22 Inlet manifold .... 24 18 Lower oil tiller mounting and injection pump mounting nut ..... .... 71 S2 Turbocnarger to exhaust manifold .... <10 30 Upper Dtl filter mounting end injection pump mounting nut 98 72

1 General information and precautions

General information The fuel system consists of a rear-mounted fust tank, a fuel filter with integral water separator, a fuel injection pump, in|eciors and associated components. A turbocharger is fitted to TDS, TD and TDSX models. Fuel Is drawn from the fuel tank to the fuel Injection pump by a vane-type transfer pump Incorporated in the fuel injection pump. Before reaching tho pump, the fuel passes through a fuel filter, where foreign matter and water aro removed. Excess fuel lubricates the moving components of the pump, and Is then returned to the tank. On turbo models with the Bosch fuel Injection systom, an eiectncally operated heater is incorporated In the fuel filter housing. The fuel injection pump is driven at half-crankshaft speed by the timing belt. The nigh pressure required to inject tho fuel into the compressed air in the swirl chambers Is achlovod by a cam plate acting on a single piston on the Bosch pumo, or by two opposed pistons forced together by rollers running in a cam ring on the Lucas (CAV) pump. Tlie fuel passes through acentral rotor with a single outlet drilling which aligns With ports leading to the Injector pipes. Fuel metering is controlled by a centrifugal governor, which reacts to accelerator pedal

position end engine speed. The governor is linked lo a metering valve, which increases or decreases the amount of fuel delivered at each pumping stroke. On turbocharged models, a separate device also Increases luel delivery with increasing boost pressure. Basic injection timing is determined when the pump is fitted. When the engine is running, it Is varied automatically to suit the prevailing engine speed by a mechanism which turns the cam plate or ring, Tho four fuel injectors proouco a homogeneous spray of fuel Into the swirl chambers located In the cylinder head. The Injectors are calibrated to open end close at critical pressures lo provide efficient and even combustion. Each injector needle is lubricated by fuel, which accumulates In the spring chamber and is channelled to the injection pump return hose by loak-off pipes Bosch or Lucas fuel system components mBy be fitted, depending on the model. Components from the latter manufacturer are marked either CAV. Roto-dlesel or Con-diesel. depending on their date and place of manufacture. With the exception of the fuel filter assembly, replacement components must be of tho same make as those originally fitted. Cold starting is assisted by preheater or glow plugs fitted to each swirl chamber. On the Bosch injection pump, an automatic cold Injection advance device operated through a thermal switch, advances the injection timing by Increasing the fuel pressure. The device operates at coolant temperatures below 55° C,

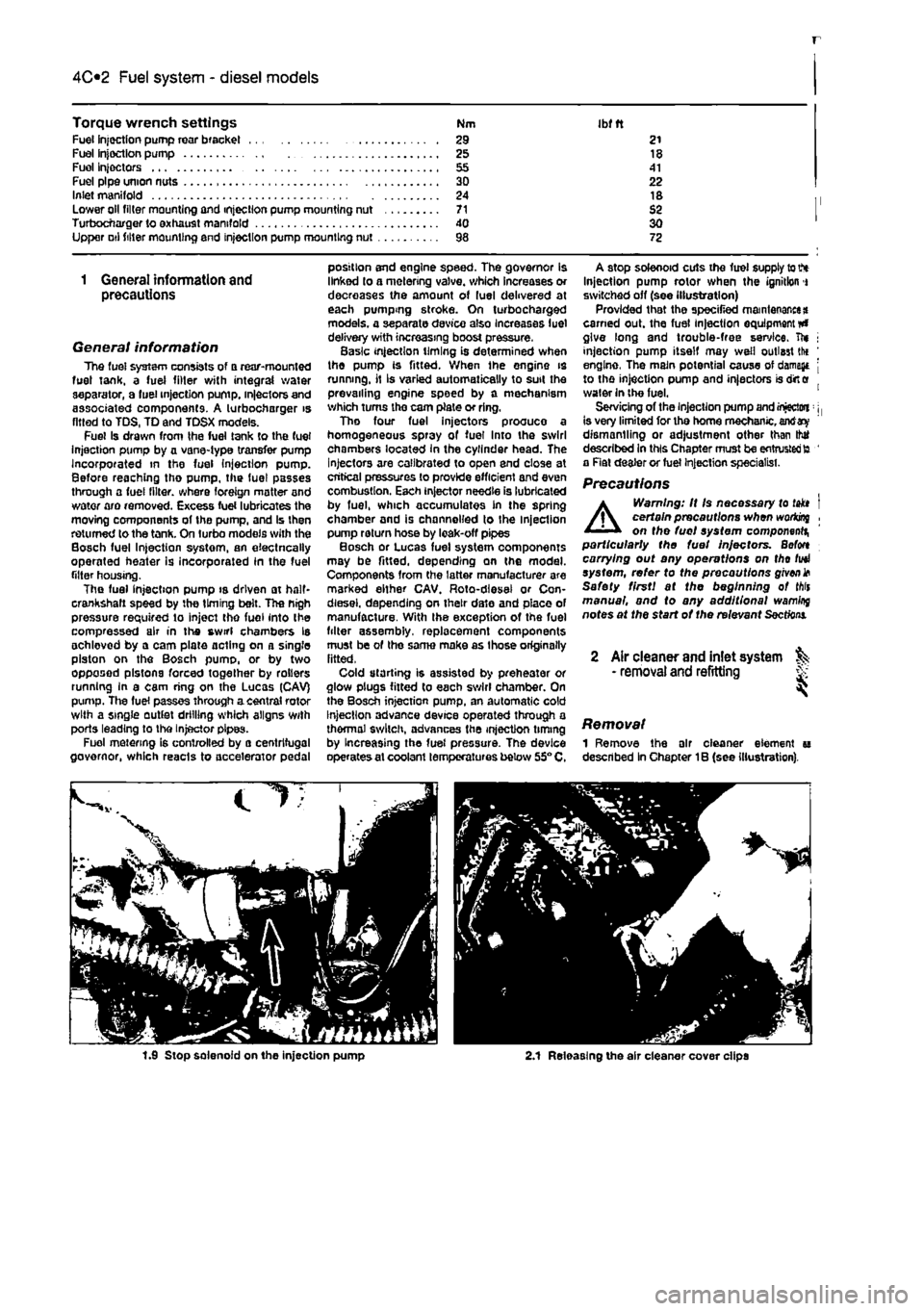

A stop solenoid cuts the fuel supply to V* Injection pump rotor when the ignition i switched off (see illustration) Provided that the specified maintenance* earned out. the fuel injection equipment #» give long and trouble-free service, ft* j injection pump itself may well outlast tlx ' engine, The main potential cause of damage j to the injection pump and injectors is dirt e water in the fuel. 1 Servicing of the injection pump and injectwi: j, is very limited for tho home mechanic, antf dismantling or adjustment other than thtf described In this Chapter must be entrusted to ' a Rat dealer or fuel Injection specialist.

Precautions

A

Warning: It Is necessary to takt I certain precautions when woriong , on the fuel system component^ particularly the fuel Injectors. Befon carrying out any operations on tho fuel system, refer to the precautions given* Safety first! at the beginning of Mis manual, and to any additional wamlrq notes at the start of the relevant

Sections.

2 Air cleaner and inlet system ^ • removal and refitting S

Removal 1 Remove the air cleaner element u described In Chapter 1B (see illustration).

1.9 Stop solenoid on the injection pump 2.1 Releasing the air cleaner cover clips

Page 139 of 225

Fuel system - diesel models 4C*3

bolt (Bosch)

4 Fuel system -priming and bleeding

The Injection pump Is self-priming and no special procedures are necessary to prime the fuel system. However where the luei system has been completely drained it (s helpful to loosen the injector union nuts while turning the engine on the starter motor In order to purge trooped air.

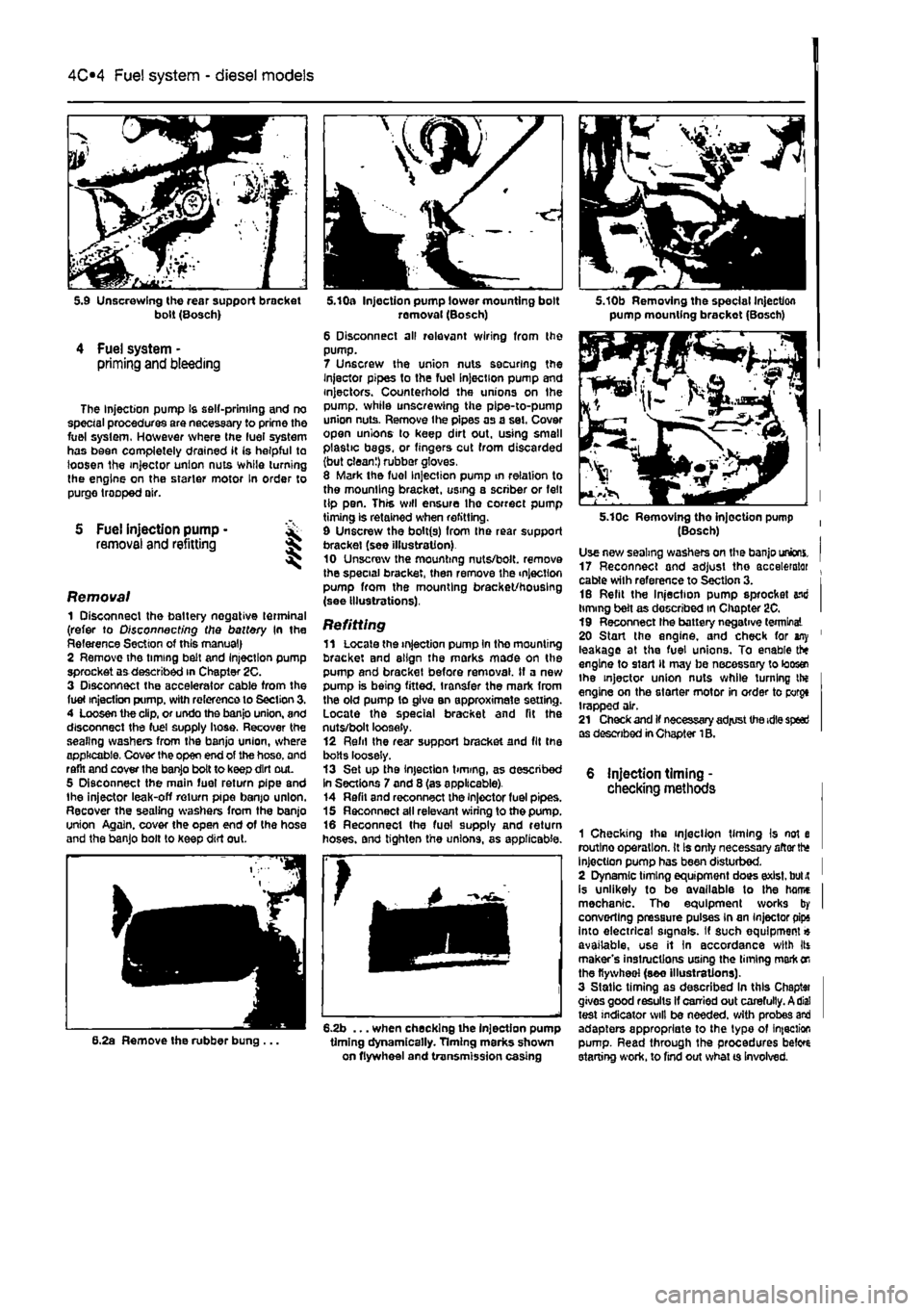

S Fuel injection pump • removal and refitting 5

Removal 1 Disconnect the battery negative terminal (refer to Disconnecting the battery In the Reference Section of this manual) 2 Remove the timing belt and Injection pump sprocket aa described in Chapter 2C. 3 Disconnect the accelerator cable from the fuel injection pump, with reference to Section 3. 4 Loosen the clip, or undo the banjo union, and disconnect the fuel supply hose. Recover the sealing washers from the banjo union, where applicable. Cover the open end of the hose, and raflt and cover the banjo bolt to keep dirt out. 5 Disconnect the main fuel return pipe and the injector leak-off return pipe banjo union. Recover the sealing washers from the banjo union Again, cover the open end of the hose and the banjo bolt to keep dirt out.

6.2a Remove the rubber bung ...

k

5.10a Injection pump lower mounting bolt removal (Bosch) 6 Disconnect all relevant wiring from the pump. 7 Unscrew the union nuts securing the Injector pipes to the fuel Injection pump and injectors. Counterhold the unions on Ihe pump, while unscrewing the pipe-to-pump union nuts. Remove the pipes as a set. Cover open unions lo keep dirt out. using small plastic begs, or fingers cut from discarded (but clean!) rubber gloves. 8 Mark the fuel Injection pump in relation to the mounting bracket, using a scriber or felt tip pen. This will ensure Ihe correct pump timing is retained when refitting. 9 Unscrew the bolt(s) from Ihe rear support bracket (see illustration) 10 Unscrew the mounting nuts/bolt, remove the special bracket, then remove the injection pump from the mounting bracket/housing (see illustrations).

Refitting 11 Locate the injection pump In the mounting bracket and align the marks mode on the pump and bracket before removal. If a new pump is being fitted, transfer the mark from the old pump to give an approximate setting. Locate the special bracket and fit the nuts/bolt loosely. 12 Refil Ihe rear support bracket and fit the bolts loosely. 13 Set up the injection timing, as described In Sections 7 and 8 (as applicable). 14 Refil and reconnect the injector fuel pipes. 15 Reconnect all relevant wiring to the pump. 16 Reconnect the fuel supply and return hoses, and tighten the unions, as applicable.

6.2b ... when checking the injection pump timing dynamically. Timing marks shown on flywheel and transmission casing

5.10b Removing the special Injection pump mounting brackot (Bosch)

5.10c Removing tho injection pump (Bosch) Use new sealing washers on the banjo unions. 17 Reconnect and adjust the accelerator . cable with reference to Section 3. i 16 Refit the Injection pump sprocket end timing belt as described in Chapter 2C. I 19 Reconnect Ihe battery negative terminal 20 Start the engine, and check for any ' leakage at the fuel unions. To enable the engine to start It may be necessary to loos® the injector union nuts while turning the engine on the starter motor in order to porgt trapped air. 21 Check and if necessary adjust the idle speed as described in Chapter 1B.

6 injection timing -checking methods

1 Checking the injection timing Is not e routlno operation. It Is only necessary aftorth* Injection pump has been disturbed. I 2 Dynamic timing equipment does exist, bulit ' is unlikely to be available to the hame I mechanic. Tho equipment works by I converting pressure pulses in an Injector pips into electrical signals. If such equipment« available, use it In accordance with Its maker's instructions using the liming mark

on

the flywheel (see illustrations). 3 Static timing as described In this Chaptai gives good results If carried out carefully. A dial test indicator will be needed, with probes and adapters appropriate to the typo of infection pump. Read through the procedures beto starting work, to find out what ts Involved.

Page 140 of 225

Fuel system - diesel models

4C*3

7.4 Unscrew the access screw from the 7.5 Dial gauge and adapter (Bosch) rear of the Injection pump (Bosch)

7 Injection timing ^ (Bosch fuel injection pump) -checking and adjustment ^

Caution: Some of the Injection pump uttlngs and access plugs may be sealed ty the manufacturers at the factory, using

paint

or locking wire and lead seals. Do not

disturb

the seals If the vehicle is still within the warranty period, otherwise the warranty will be invalidated. Also do not attempt the timing procedure unless

accurate

Instrumentation Is available. Note: To check the injection pump timing a special

timing

probe and mounting bracket is required. Without access to this piece of

tquipment.

injection pump timing should be intrusted to a Fiat dealer or other suitably

eqwpped

specialist. 1

H

the Injection timing is being checked with ffie pump in position on the engine, rather rian as part ot the pump refitting procedure, disconnect the battery negative terminal (refer to

Disconnecting

the battery in the Reference S«ction of this manual), and remove the air rtel ducting from the front of the engine. 2 Unscrew the union nuts and disconnect the injector pipes from the Injection pump and injectors. Counterhold the unions on the pump, while unscrewing the pipe-to-pump irion

nuts.

Remove the pipes as a set. Cover open unions to keep dirt out, using small plastic bags, or fingers cut from discarded

ibut clean!)

rubber gloves. 3 Referring to Chapter 2C, set the engine at

TDC on

cylinder No 1. 4 Unscrew the access screw, situated In the centre of the four injector pipe unions, from the rear of the Injection pump (see illustration). As the screw Is removed, position a suitable container beneath the

pump

to catch any escaping fuel, Mop up any tpilt fuel with a clean cloth. 5 Screw the adapter into the rear of the pump

and

mount the dial gauge in ihe adapter (see •ustration). If access to the special Fiat *Japter cannot be gained, they can be purchased from most good motor factors. Position the dial gauge so that its plunger is at

Ifce

mid-point of its travel and securely tighten Ite adapter locknut. 6 Slowly rotate the crankshaft first back then towards whilst observing the dial gauge, to ctotermlne when the Injection pump piston is

a',

the bottom of Its travel (BDC), When the pston Is correctly positioned, zero the dial

7 Rotate the crankshaft slowly in the correct direction until the TDC timing marks are tfjned on both the crankshaft, camshaft and rjecbon pump sprockets.

6

The reading obtained on the dial gauge should be equal to the specified pump timing measurement given in the Specifications at ew start of this Chapter, If adjustment is necessary, slacken the fronl and rear pump mounting nuts/bolts and slowly rotate the

pump body until the point is found where the specified reading Is obtained. When the pump is correctly posilioned, tighten both its front and rear mounting nuts and bolts securely. 9 Rotate the crankshaft through one and three quarter rotations in the normal direction of rotation. Find the injection pump piston BDC as described in paragraph 6 and zero the dial gauge. 10 Rotate the crankshaft slowly in the correct direction of rotation until the TDC marks are aligned. Recheck the timing measurement. 11 If adjustment is necessary, slacken the pump mounting nuts and bolts and repeat the operations In paragraphs 8 to 10. 12 When the pump timing Is correctly set, unscrew the adapter and remove the dial gauge. 13 Refit the screw and sealing washer to the pump and tighten it securely. 14 If the procedure is being carried out as part of the pump refitting sequence, proceed as described in Section 5, 15 If the procedure is being carried out with the pump fitted to the engine, refit the injector pipes tightening their union nuts to the specified torque setting. Reconnect the battery and refit the air inlet ducting. 16 Start the engine, and check for any leakage at the luel unions. To enable the engine to start it may be necessary to loosen the injector union nuts while turning tho engine on the starter motor in order to purge trapped air. 17 Check and if necessary adjust the idle speed as described in Chapter 1B.

8.4 Removing the injection pump timing inspection plug (Lucas)

8 injection timing ^ (Lucas fuel injection pump) - ^ checking

and

adjustment ^

Caution: Some of the injection pump settings and access plugs may be sealed by the manufacturers at the factory, using paint or locking wire and lead seo/s. Do not disturb the seals if the vehicle Is still within the warranty period, otherwise tho warranty will be Invalidated. Also do not affempf the timing procedure unless accurate instrumentation is available.

Note: To check the Injection pump timing a speciai timing probe and mounting bracket Is required. Without access to this piece of equipment, injection pump timing should be entrusted to a Fiat dealer or other suitably equipped specialist. 1 If the injection timing is being checked with the pump tn position on the engine, rather than as part of the pump refitting procedure, disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual), and remove the air inlet ducting from the front of the engine. 2 Unscrew the union nuts and disconnect the injector pipes from the Injection pump and In-jectors. Counterhold the unions on the pump, while unscrewing the pipe-to-pump union nuts. Remove the pipes as a set. Cover open unions to keep dirt out. using smalt plastic bags, or fingers cut from discarded (but clean!) rubber gloves. 3 Referring to Chapter 2C, set the engine at TDC on cylinder No 1, then turn the crank-shaft backwards (anti-clockwise) approx-imately a quarter of a turn. 4 Unscrew the access plug from the guide on the top of the pump body and recover the sealing washer (soe Illustration). Insert the special liming probe Into the guide, making sure it Ib correctly seated against the guide seating washer surface. Note: The timing probe must be seated against the guide sealing washer surface and not the upper lip of the guide for the measurement to be accurate. 5 Mount the bracket on the pump guide (using adapter tool) and securely mount the dial gauge {dial test indicator) In the bracket

expert22 fl/i* http://rutracker.org