Lamp FIAT PUNTO 1995 176 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1995, Model line: PUNTO, Model: FIAT PUNTO 1995 176 / 1.GPages: 225, PDF Size: 18.54 MB

Page 191 of 225

Suspension and steering 10*3

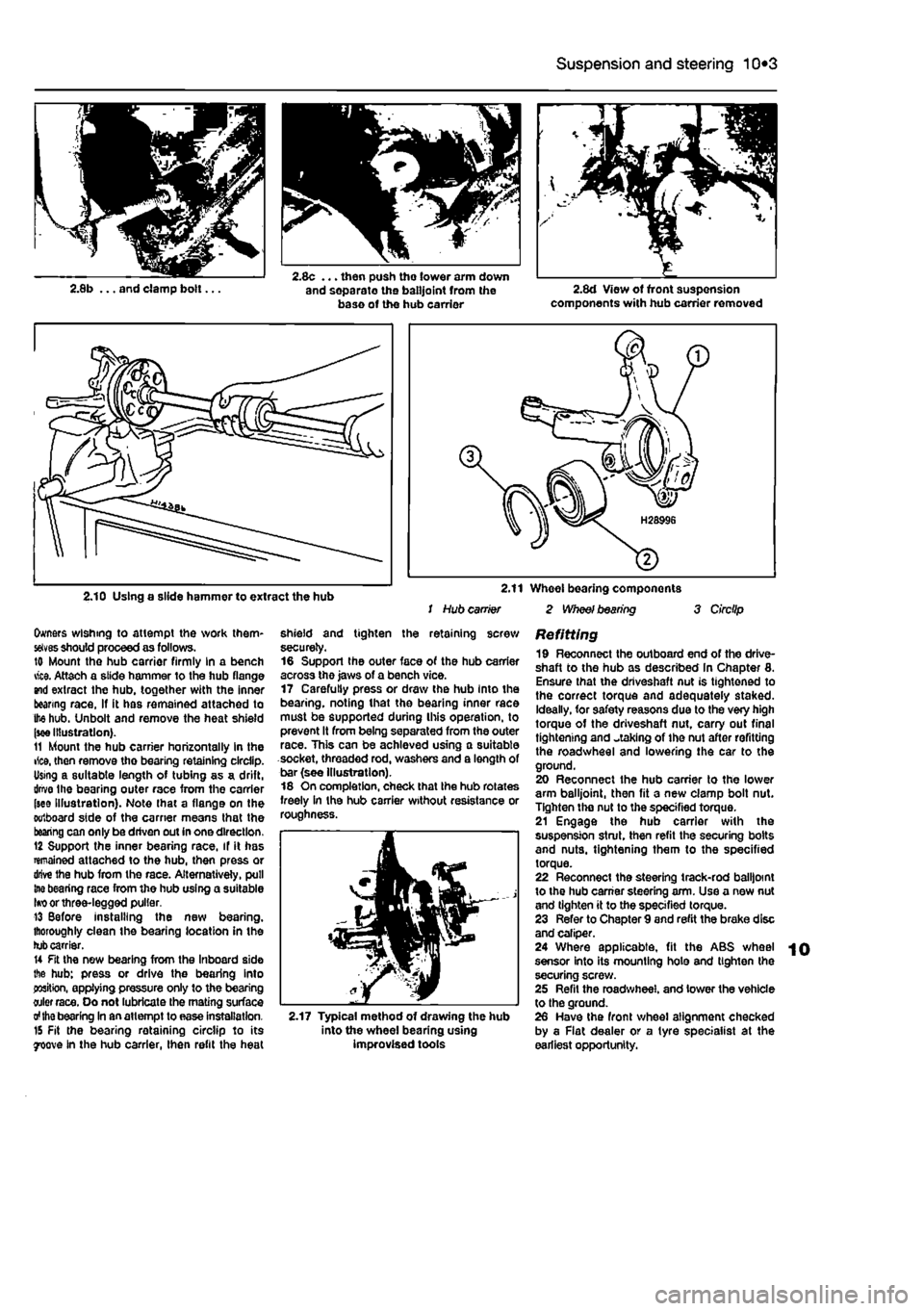

2.10 Using a slide hammer to extract the hub 2.11 Wheel bearing components / Hub carrier 2 Wheel bearing 3 Circlip

Owners wishing to attempt the work them-

selves

should proceed as follows. 10 Mount tho hub carrier firmly In a bench vice. Attach a slide hammer to the hub flange and extract the hub. together with the inner bearing race, If it has remained attached to the hub. Unbolt and remove the heat shield

(see

Illustration). 11 Mount the hub carrier horizontally in the rice, then remove tho bearing retaining circlip. Using a suitable length of tubing as a drift, drive Ihe bearing outer race from the carrier (see Illustration). Note that a flange on the outboard side of the carrier means that the bearing can only be driven out in one direction. 12 Support the inner bearing race, if it has remained attached to the hub, then press or drive the hub from the race. Alternatively, pull trie bearing race from the hub using a suitable Iw or three-legged puller. 13 Before Installing the new bearing, thoroughly clean the bearing location in the tub carrier. U Fit the new bearing from the Inboard side the hub: press or drive the bearing into position, applying pressure only to the bearing oiler race. Oo not lubricate the mating surface

ol the

bearing In an attempt to ease installation. 15 Fit the bearing retaining circlip to its 700ve in the hub carrier, then refit the heat

shield and tighten the retaining screw securely. 16 Support the outer face of the hub carrier across the jaws of a bench vice. 17 Carefully press or draw the hub into the bearing, noting that the bearing inner race must be supported during Ihis operation, to prevent It from being separated from the outer race. This can be achieved using a suitable socket, threaded rod, washers and a length of bar (see Illustration). 18 On completion, check that the hub rotates freely in the hub carrier without resistance or roughness.

2.17 Typical method of drawing the hub into the wheel bearing using improvised tools

Refitting 19 Reconnect the outboard end of the drive-shaft to the hub as described In Chapter 8. Ensure that the driveshaft nut is tightened to the correct torque and adequately staked. Ideally, for safety reasons due to the very high torque of the driveshaft nut, carry out final tightening and staking of the nut after refitting the roadwheel and lowering the car to the ground. 20 Reconnect the hub carrier to the lower arm balljoint, then fit a new clamp bolt nut. Tighten tho nut to the specified torque. 21 Engage the hub carrier with the suspension strut, then refit the securing bolts and nuts, tightening them to the specified torque. 22 Reconnect the steering track-rod balljoint to the hub carrier steering arm. Use a new nut and tighten it to the specified torque. 23 Refer to Chapter 9 and refit the brake disc and caliper. 24 Where applicable, fit the ABS wheel sensor into its mounting hole and tighten the securing screw. 25 Refit the roadwheel, and tower the vehicle to the ground. 26 Have the front wheel alignment checked by a Fiat dealer or a tyre specialist at the earliest opportunity.

Page 192 of 225

Suspension and steering 10*4

3.2 Release the brake fluid line (and where applicable, the pad wear/ABS sensor wiring) from the strut

3 Front suspension strut -removal, overhaul and refitting *

A

Warning: If renewing the Strut damper during overhaul both the left and right hand dampers should be renewed as a pair, to preserve the handling characteristics of the vehicle.

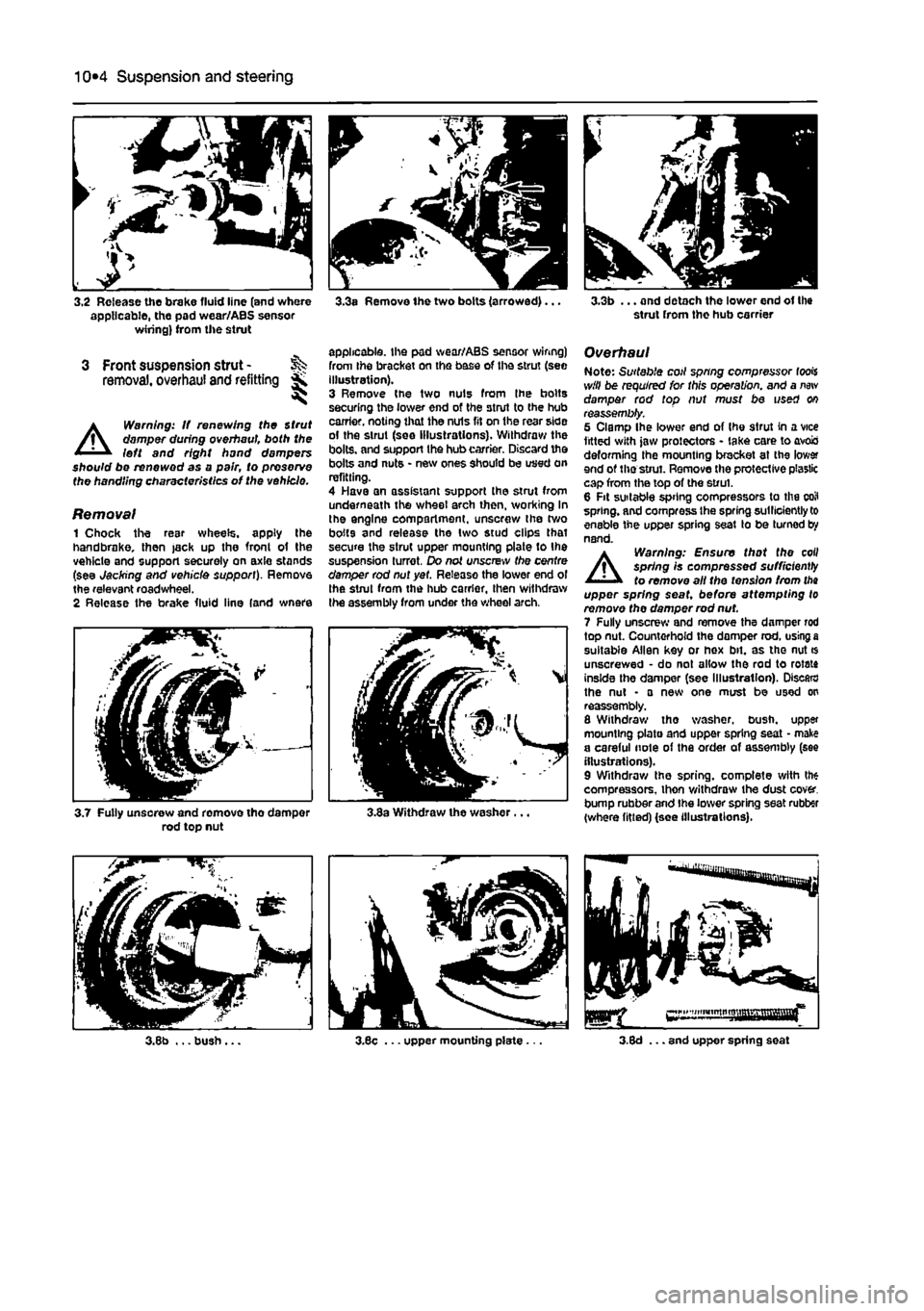

Removal 1 Chock the resr wheels, apply the handbrake, then jack up the fronl of the vehicle and support securely on axle stands (see Jacking and vehicle support). Remove the relevant roadwheel. 2 Release the brake fluid line (and wnere

3.3a Remove the two bolts (arrowed)...

applicable, the pad wear/ABS sensor wiring) from Ihe bracket on the base of the strut (see illustration). 3 Remove the two nuts from Ihe bolts securing the lower end of the strut to the hub carrier, noting that the nuls fit on the rear side of the strut (see illustrations). Withdraw the bolts, and support the hub carrier. Discard the bolts and nuts • new ones should be used on refitting. 4 Have an assistant support the strut from underneath the wheel arch then, working In the engine compartment, unscrew the two bolts and release the two stud clips that secure the strut upper mounting plate to the suspension turret. Do not unscrew the centre damper rod nut yet. Release the lower end ol the strut from the hub carrier, then withdraw the assembly from under the wheel arch.

3.7 Fully unsorew and remove tho damper rod top nut 3.3a Withdraw the washer.

3.3b ... and detach the lower end of the strut from the hub carrier

Overhaul Note: Suitable coil spring compressor fools will be required for this operation, and a

new

damper rod top nut must be used on reassembly. 5 Clamp Ihe lower end of Ihe strut in a vice fitted with jaw protectors - take care to avois deforming the mounting bracket at the lower end of the strut. Remove the protective plastic cap from the top of the strut. 6 Fit suitable spring compressors to the coil spring, and compress Ihe spring sutllciently to enable the upper spring seat to be turned by nand.

A

Warning: Ensure that the coil spring Is compressed sufficiently to remove all the tension from

tha

upper spring seat, before attempting to remove the damper rod nut. 7 Fully unscrew and remove the damper rod top nut. Countorhofd the domper rod. using

a

suitable Allen key or hex bit. as tho nut * unscrewed • do not allow the rod to rotate inside the damper (see Illustration). Discard the nut • a new one must be used on reassembly. 8 Withdraw tho washer, bush, upper mounting plate and upper spring seat • make a careful note of the order of assembly (see illustrations). 9 Withdraw the spring, complete with the compressors, thon v/ithdraw the dust cover, bump rubber and Ihe lower spring seat rubber (where fitted) (see illustrations).

Page 193 of 225

Suspension and steering 10*5

3,9s Withdraw the coll spring, complete with the compressors ... 3.9b ... then withdraw the dust cover and bump rubber 3.9c Fully dismantled strut

10 With the strut assembly now dismantled, examine all the components tor wear, damage or deformation. Check the rubber com-ponents for deterioration. Renew any of the components as necessary. 11 Examine tho damper for signs of fluid teakage. Check the damper rod for signs of pitting along its entire length, and check the stjul body for signs of damage. White holding fc

in an

upright position, test the operation of

Ihe

stmt by moving Ihe damper rod through a fut stroke, and then through short strokes of

SO

to 100 mm. In both cases, the resistance Id should be smooth and continuous. If the resistance is jerky, or uneven, or if there is any wsible sign of wear or damage to the strut, renewal is necessary. Note that the damper cannot be renewed independently, and if leakage, damage or corrosion Is evident, the complete strut/damper assembly must be renewed {in which case, the spring, upper mounting components, bushes, and associated components can be transferred to

Ihe

new strut). 12 If any doubt exists about the condition of

Ihe

coil spring, carefully remove the spring compressors, and check the spring for distortion and signs of cracking. Renew the spring if it is damaged or distorted, or if there isany doubt about its condition. a Warning: Coil springs are /j\ classified by their height when '

11

• undor load • this Is indicatod by a

coloured

paint marking on the side of the

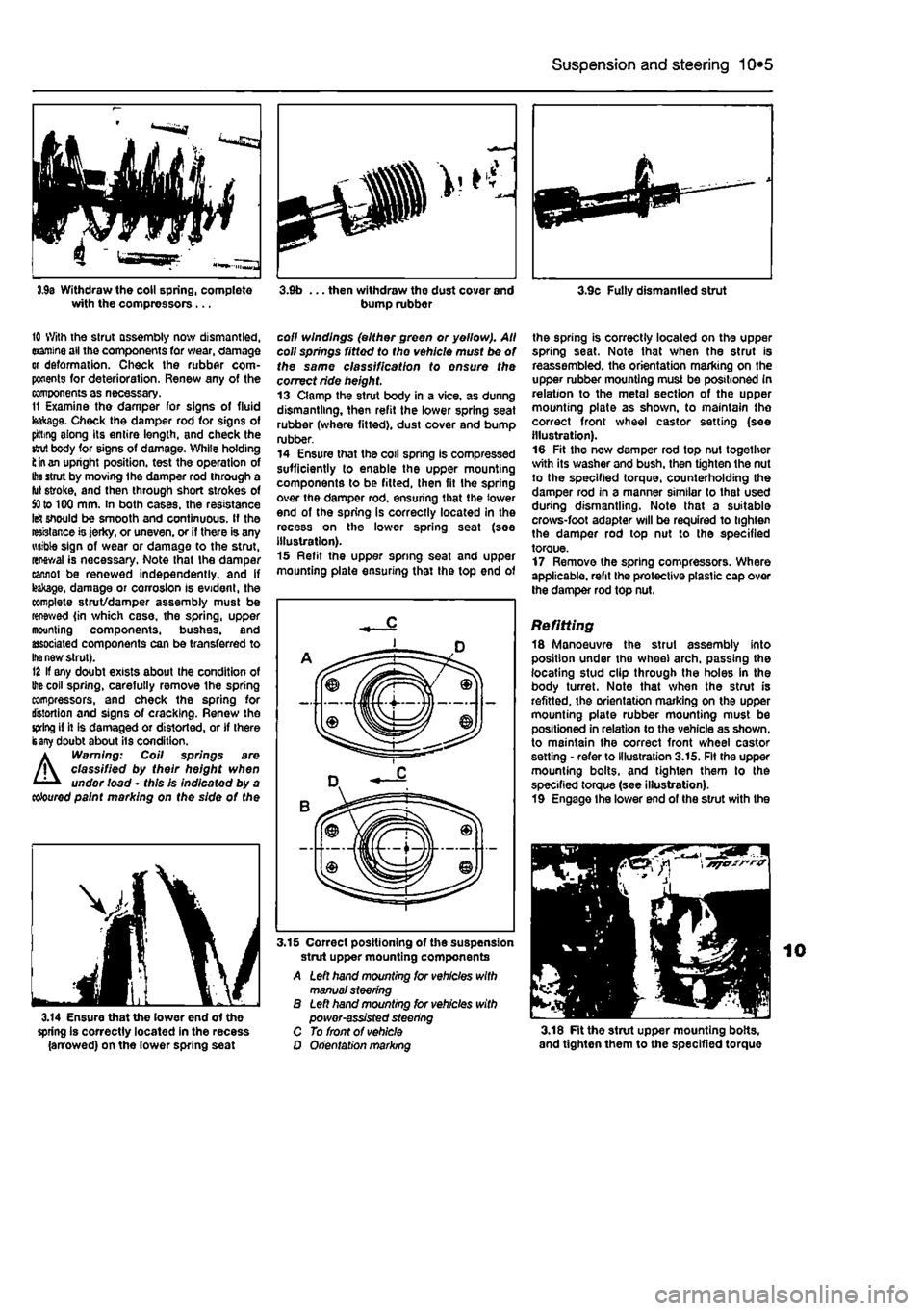

coll windings (either green or yellow). All coll springs fitted to tho vehicle must be of the same classification to ensure the correct ride height. 13 Clamp the strut body in a vice, as dunng dismantling, then refit the lower spring seat rubber (where fitted), dust cover and bump rubber. 14 Ensure that the coil spring is compressed sufficiently to enable the upper mounting components to be fitted, then fit the spring over the damper rod. ensuring that the lower end of the spring is correctly located In the recess on the lower spring seat (soe illustration). 15 Refit the upper spring seat and upper mounting plate ensuring that the top end of

the spring is correctly located on the upper spring seat. Note that when the strut is reassembled, the orientation marking on the upper rubber mounting must be positioned in relation to the metal section of the upper mounting plate as shown, to maintain the correct front wheel castor setting (see illustration). 10 Fit the new damper rod top nut together with its washer and bush, then tighten the nut to the specified torque, counterholding the damper rod in a manner similar to that used during dismantling. Note that a suitable crows-foot adapter will be required to tighten the damper rod top nut to the specified torque. 17 Remove the spring compressors. Where applicable, refit the protective plastic cap over the damper rod top nut.

Refitting 18 Manoeuvre the strut assembly into position under the wheel arch, passing the locating stud clip through the holes in the body turret. Note that when the strut is refitted, the orientation marking on the upper mounting plate rubber mounting must be positioned in relation to the vehicle as shown, to maintain the correct front wheel castor setting • refer to illustration 3.15. Fit the upper mounting bolts, and tighten them to the specified torque (see illustration). 19 Engage Ihe lower end of the strut with the

3.14 Ensure that the lower end of the spring is correctly located in the recess (arrowed) on the lower spring seat

3.15 Correct positioning of the suspension strut upper mounting components A Left hand mounting for vehicles with manual steering B Left hand mounting tor vehicles with power-assisted steering C To front of vehicle O Orientation marking 3.18 Fit the strut upper mounting bolts, and tighten them to the specified torque

Page 194 of 225

Suspension and steering 10*6

hub earner, then fit the securing bolts and nuts, noting that the nuts fit on the rear side of the strut, and tighten to the specified torque (see illustrations). 20 Refit the brake fluid line to the bracket on Ihe base of the strut. 21 Where applicable, press the ABS wheel sensor winng into its retaining bracket. 22 Refit the roadwheel. and lower the vehicle to the ground.

4 Front suspension lower arm - removal and refitting 3.19a Fit the securing bolts, noting that the nuts fit on the rear side of the strut...

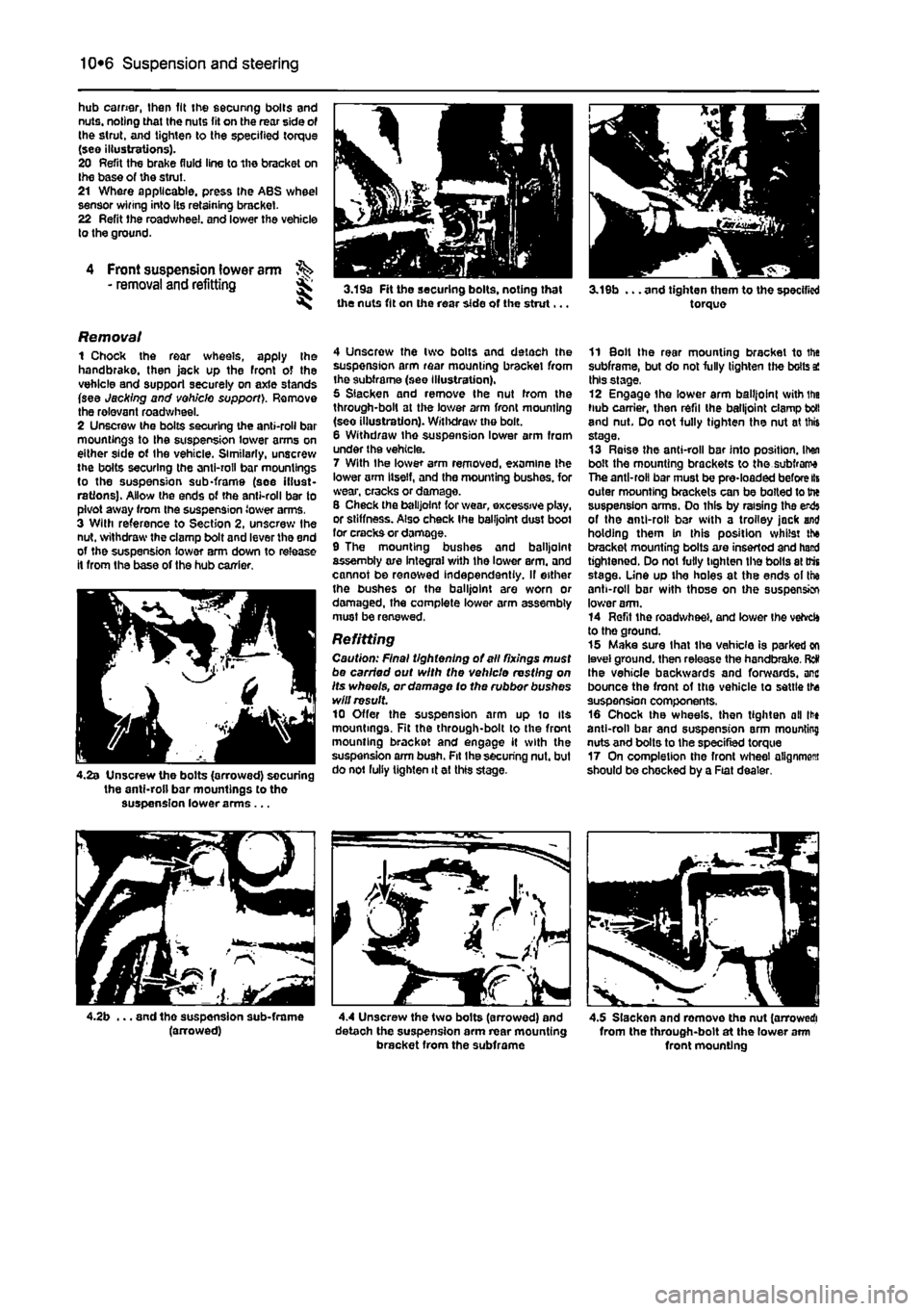

Removal 1 Chock the rear wheels, apply the handbrake, then jack up the front of the vehicle and support securely on axle stands (see Jacking and vehicle support). Remove the relevant roadwheel. 2 Unscrew the bolts securing the anti-roll bar mountings to the suspension lower arms on either side ot Ihe vehicle. Similarly, unscrew the bolts securing the anti-roll bar mountings to the suspension sub-frame (see illust-rations). Allow the ends of the anti-roll bar to pivot away from the suspension lower arms. 3 With reference to Section 2, unscrew Ihe nut. withdraw the clamp bolt and lever the end of the suspension lower arm down to release it from the base of the hub carrier.

4.2s Unscrew the bolts (arrowed) securing the anti-roll bar mountings to tho suspension lower arms...

4 Unscrow the two bolts and detach the suspension arm rear mounting bracket from the subframe (see Illustration). 5 Slacken and remove the nut from the through-bolt at the lower arm front mounting (seo illustration). Withdraw the bolt. 6 Withdraw Ihe suspension lower arm from under the vehicle. 7 With the lower arm removed, examine the lower arm Itself, and the mounting bushes, for wear, cracks or damage. S Check the balljoint for wear, excessive play, or stiffness. Also check Ihe balljoint dust boot for cracks or damage. 9 The mounting bushes and balljoint assembly are integral with the lower arm. and cannot be renewed independently. If either the bushes or the balljoint are worn or damaged, the complete lower arm assembly must be renewed.

Refitting Caution: Final tightening of all fixings must be carried out with the vehicle resting on Its wheels, or damage to the rubbor bushes will result 10 Offer the suspension arm up lo Its mountings. Fit the through-bolt to the front mounting bracket and engage it with the suspension arm bush. Fit Ihe securing nut. but do not fully tighten it at this stage.

. and tho suspension sub-frame (arrowed) 4.4 Unscrew the two bolts (arrowed) and detaoh the suspension arm rear mounting bracket from the subframe

3.19b ... and tighten them to the specified torque

11 Bolt Ihe rear mounting bracket to the subframe, but do not fully tighten the bolts a! this stage, 12 Engage the lower arm balljoint svith ifia hub carrier, then refii the balljoint clamp boll and nut. Do not fully tighten the nut at this stage. 13 Raise the anti-roll bar into position. Itan bolt the mounting brackets to the subfrarra The anti-roll bar must be pre-loaded before lis outer mounting brackets can be bolted to the suspension arms. Do this by raising tha erds of the anti-roll bar with a trolley jack and holding them in this position whilst the bracket mounting bolts are inserted and hand tightened. Do not fully tighten the bolls at trts stage, line up the holes at the ends of the anti-roll bar with those on the suspension lower arm. 14 Refit the roadwheel, and lower the vehrcfe to the ground. 15 Make sure that the vehicle is parked on level ground, then release the handbrake. Red the vehicle backwards and forwards, arc bounce the front of the vehicle to settle the suspension components. 16 Chock the wheels, then tighten all lit* anti-roll bar and suspension arm mounting nuts and bolts to the specified torque 17 On completion the front wheel alignment should be chocked by a Fiat dealer.

4.5 Slacken and romove tho nut (arrowed! from the through-bolt at the lower arm front mounting

Page 197 of 225

Suspension and steering 10*9

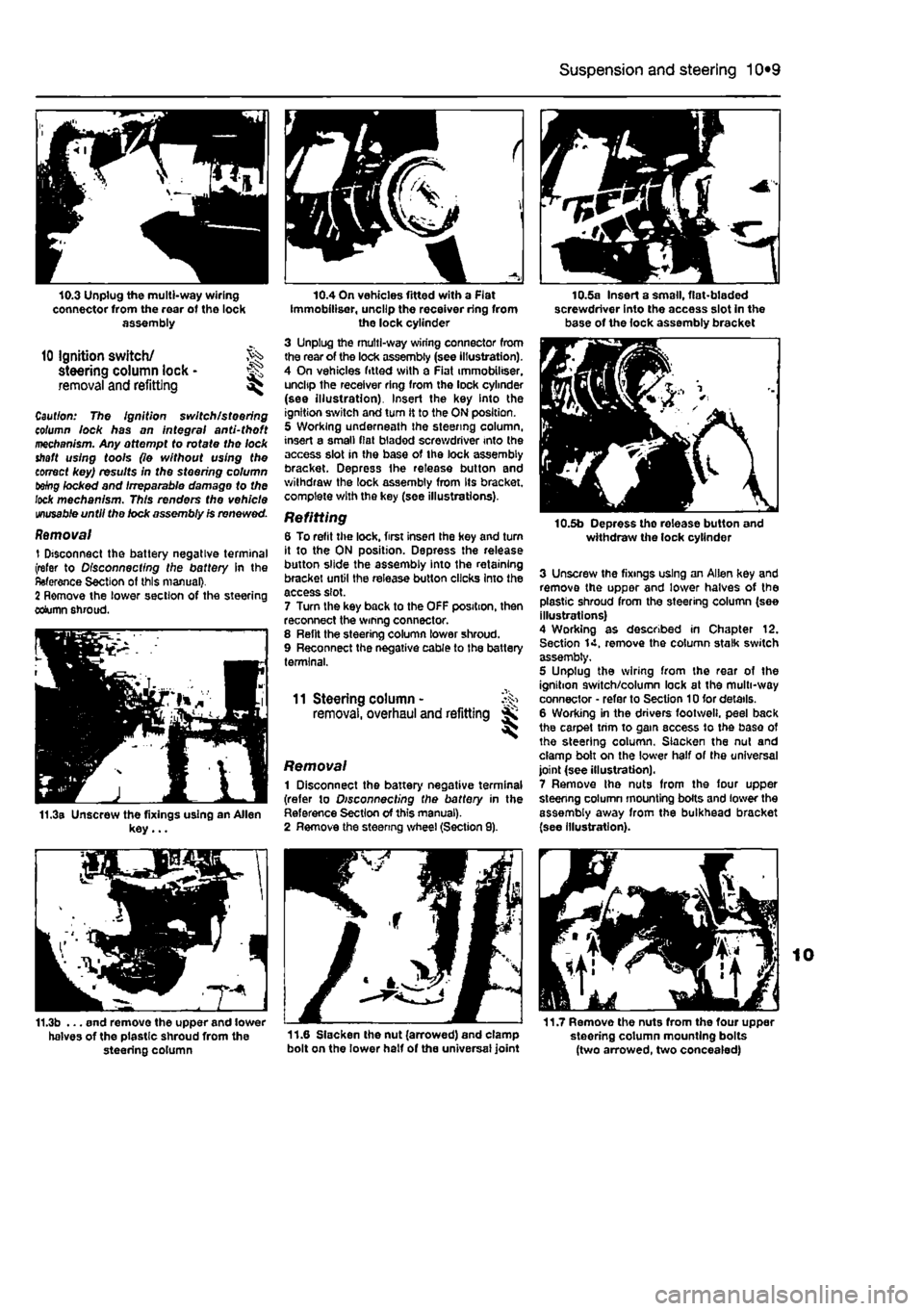

10.3 Unplug the multi-way wiring connector from the rear of tho lock assembly

10 Ignition switch/ steering column lock • ^ removal and refitting ^

Caul/on: The Ignition switch/steering column lock has on integral and-tho ft mechanism. Any attempt to rofafe tho lock shaft using tools (lo without using the correct key) results in the steering column tebg locked and Irreparable damage to the lock mechanism. This renders the vehicle

unusable

until tho lock assembly Is renewed.

Removal 1 Disconnect the battery negative terminal (refer to Disconnecting the battery In the Reference Section of this manual}. 2 Remove the lower section of the steering column shroud.

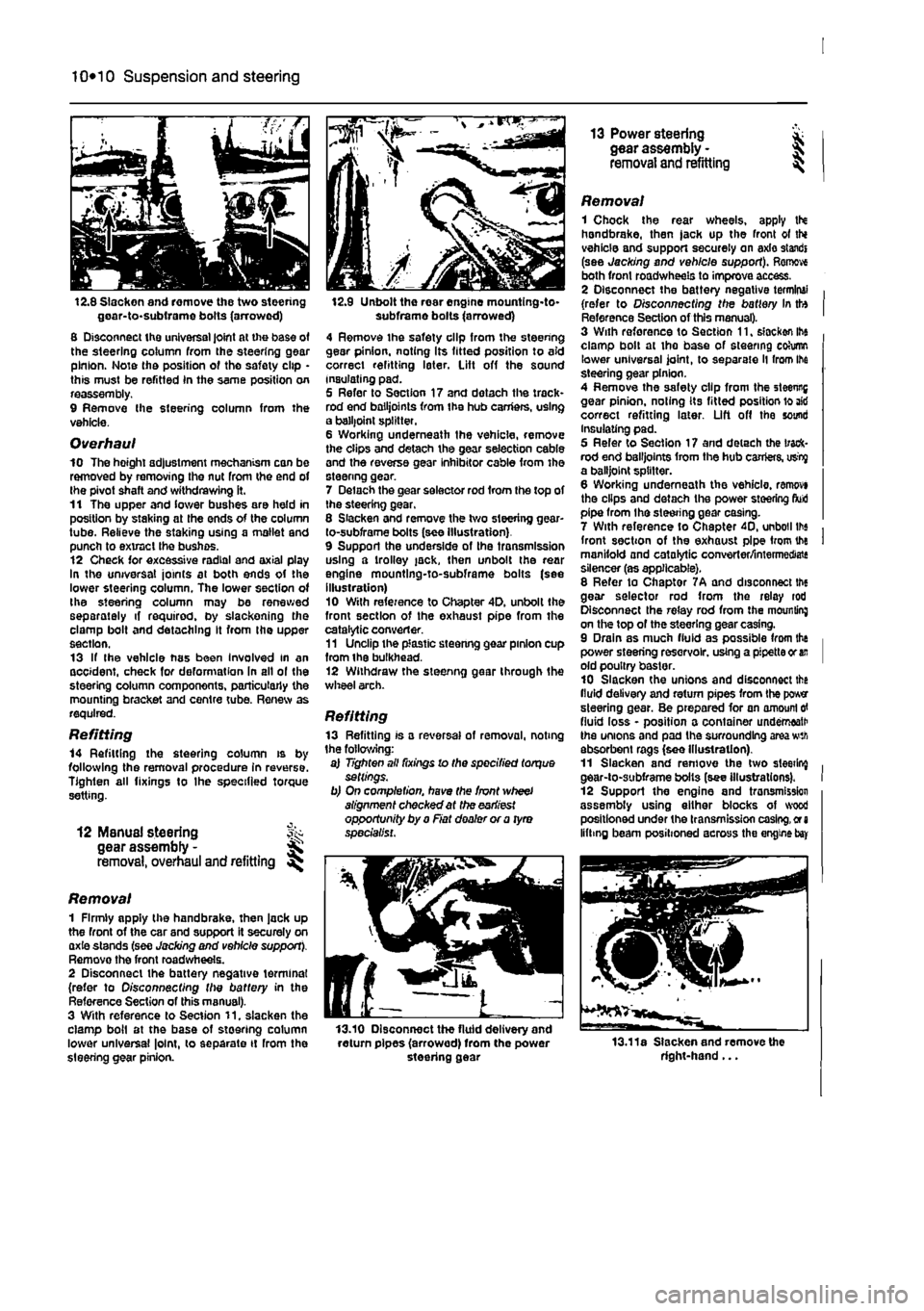

11.3a Unscrew the fixings using an Allen key...

f

10.4 On vehicles fitted with a Flat Immobiliser, uncllp the receiver ring from the lock cylinder 3 Unplug the multi-way wiring connector from the rear of the lock assembly (see illustration). 4 On vehicles fitted with a Fiat immobiliser. uncltp the receiver ring from the lock cylinder (see illustration). Insert the key Into the ignition switch and turn it to the ON position. 5 Working underneath the steering column, insert a small fiat bladed screwdriver into the access slot in the base of the lock assembly bracket. Depress Ihe release button and withdraw the lock assembly from Its bracket, complete with the key (see illustrations).

Refitting 6 To refit the lock, first inserl the hey and turn it to the ON position. Depress the release button slide the assembly into the retaining bracket until the release button clicks Into the access slot. 7 Turn the key back to the OFF position, then reconnect the wmng connector. 8 Relit the steering column lower shroud. 9 Reconnect the negative cable to the battery terminal.

11 Steering column - ^ removal, overhaul and refitting jK

Removal 1 Disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual). 2 Remove the steenng wheel (Section 9).

10.5a Insert a small, flat-bladed screwdriver into the access slot in the base of the lock assembly bracket

10.5b Depress tho release button and withdraw the lock cylinder

3 Unscrew the fixings using an Allen key and remove the upper and lower halves of the plastic shroud from the steering column (see illustrations) 4 Working as described in Chapter 12. Section 14. remove the column stalk switch assembly, 5 Unplug the wiring from the rear of the ignition switch/column lock at the multi-way connector • refer to Section 10 for details. 6 Working in the drivers footweli. peel back the carpet trim to gam access to the base of the steering column. Slacken the nut and clamp bolt on the lower half of the universal joint (see illustration). 7 Remove Ihe nuts from the four upper steenng column mounting bolts and lower the assembly away from the bulkhead bracket (see illustration).

11.7 Remove the nuts from the four upper steering column mounting bolts (two arrowed, two concealed)

11.3b ... end remove the upper and lower halves of the plastic shroud from the 11-6 Slacken the nut (arrowed) and clamp steering column bolt on the lower half of the universal joint

Page 198 of 225

10*10 Suspension and steering

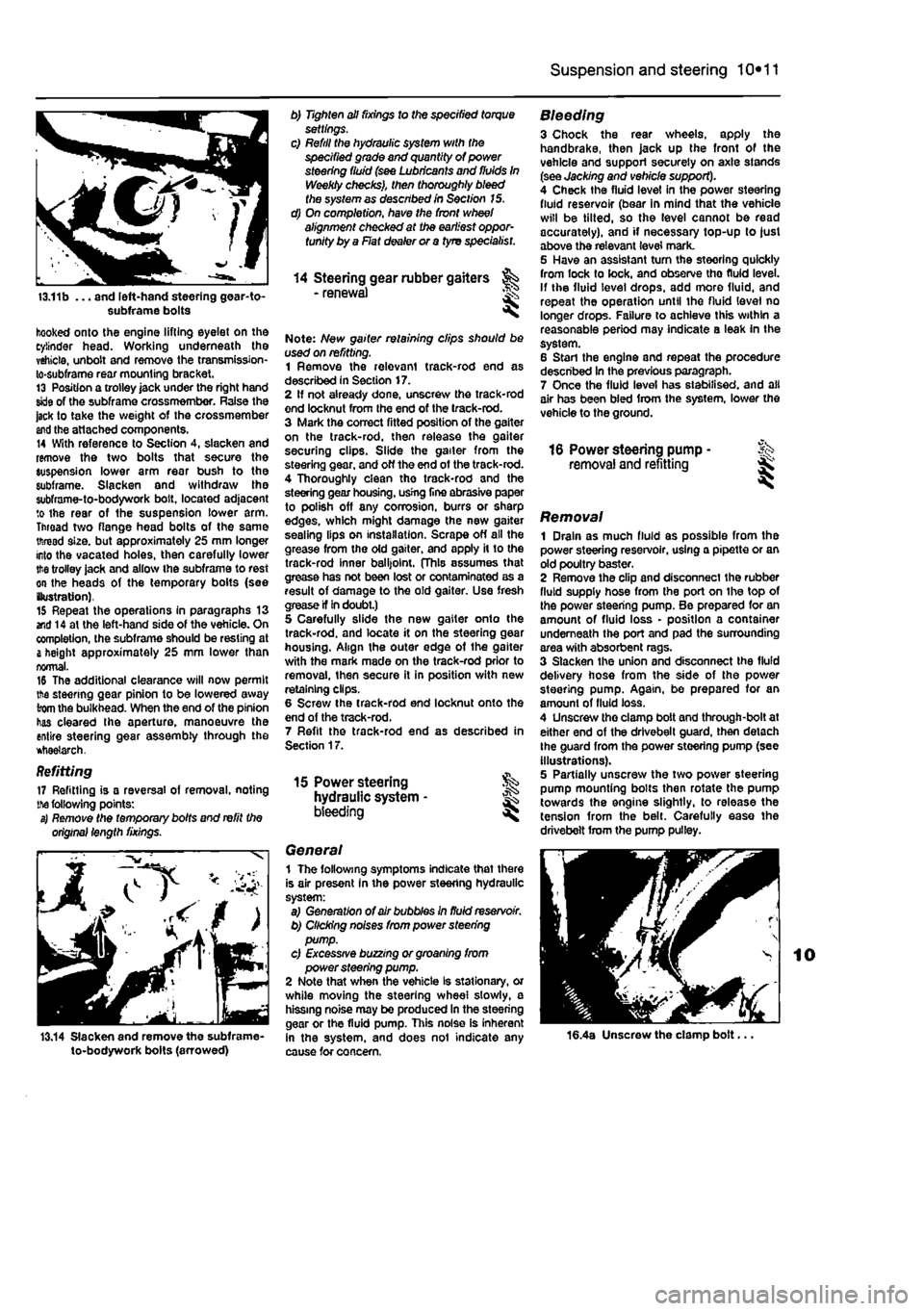

12.8 Slacken and remove the two steering goar-to-subirame bolts (arrowed) 8 Disconnect the universal joint at the base of the steering column from the steering gear pinion. Note the position of tho safety clip • this must be refitted In the same position on reassembly. 9 Remove Ihe steering column from the vehicle.

Overhaul 10 The hoight adjustment mechanism can be removed by removing the nut from the end of the pivot shaft and withdrawing it. 11 The upper and lower bushes are held in position by staking at the ends of the column tube. Relieve the staking using a mallet and punch to extract the bushes. 12 Check for excessive radial and axial play In the universal joints at both ends of the lower steering column. The lower section of the steering column may be renewed separately if required, by slackening the clamp bolt and detaching It from the upper section. 13 If the vehicle has been Involved in an accident, check for deformation In all ol the steering column components, particularly the mounting bracket and centre tube. Renew as required.

Refitting 14 Refitting the steering column is by following the removal procedure in reverse. Tighten all fixings to Ihe specified torque setting.

12 ManuaJ steering fk gear assembly -removal, overhaul and refitting

Removal 1 Firmly apply the handbrake, then jack up the front of the car and support it securely on axie stands (see Jacking and vehicle support). Remove the front road wheels. 2 Disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual). 3 With reference to Section 11. slacken the clamp boil at the base of steering column lower universal |o!nt, to separate it rrom the steering gear pinion.

12.9 Unbolt the rear engine mountlng-to-subframe bolts (arrowed) 4 Remove the safety clip from the steering gear pinion, noting Its fitted position to aid correct refitting later. Lift off the sound insulating pad. 5 Refer to Section 17 and dotach the track* rod end bailjoints from the hub carriers, using a balljoint splitter. 6 Working underneath the vehicle, remove the clips and detach the gear selection cable and the reverse gear inhibitor cable from the steenng gear. 7 Delach the gear selector rod from the top of the steering gear, 8 Slacken and remove the two steering gear-to-subframe bolts (see Illustration) 9 Support the underside of the transmission using a trolley jack, then unbolt the rear engine mountlng-to-subframe bolts (see illustration) 10 With reference to Chapter 4D. unbolt the front section of the exhaust pipe from the catalytic converter. 11 Unclip the plastic steenng gear pinion cup from ihe bulkhead. 12 Withdraw the steenng gear through the wheel arch.

Refitting 13 Refitting is a reversal of removal, noting the following: a) Tighten all fixings lo the specified torque settings. b) On completion, have the front wheel alignment checked at the earliest opportunity by a Fiat dealer or a tyro specialist.

13.10 Disconnect the fluid delivery and return pipes (arrowed) from the power steering gear

13 Power steering * gear assembly - J removal and refitting ^

Removal 1 Chock the rear wheels, apply tN handbrake, then jack up the front ot thi vehicle and support securely on axle standi (see Jacking and vehicle support). Remove both front roadwheels to improve access. 2 Disconnect the battery negative terminal (refer to Disconnecting the battery In tto Reference Section of this manual). 3 With reforence to Section 11, slacken ihe clamp bolt at the base of steering cohimn lower universal joint, to separate ll from Ihe steering gear pinion. 4 Remove the safety clip from the steenng gear pinion, noting its fitted position lo aid correct refitting later. Lift off the sound Insulating pad. 5 Refer to Section 17 and detach the track-rod end bailjoints from the hub carriers, usty a balljoint splitter. 6 Working underneath the vehicle, ranwvi the clips and detach the power steering fluid pipe from the steering gear casing. 7 With reference to Chapter 40, unboil lbs front section of the exhaust pipe from the manifold and catalytic converter/intermediate silencer (as applicable). 8 Refer to Chaptor 7A and disconnect the gear selector rod from the relay rod Disconnect the relay rod from the mounting on the top of the steering gear casing. 9 Drain as much fluid as possible from the power steering reservoir, using a pipette or

an

old poultry baster. 10 Slacken the unions and disconnect the fluid delivery and return pipes from the power steering gear. Be prepared for an amount

erf

fluid loss - position a container underneath the unions and pad the surrounding area wth absorbent rags (see Illustration). 11 Slacken and remove the two sleeting gear-to-subframe bolts (see illustrations). 12 Support the engine and tronsmission assembly using either blocks of wood positioned under the transmission casing,

or a

lifting beam positioned across the engine

bay

13.11a Slacken and remove the right-hand...

Page 199 of 225

Suspension and steering 10*11

13.11b ... and left-hand steering gear-to-subframe bolts

hooked onto the engine lifting eyelet on the cylinder head. Working underneath the vehicle, unbolt and remove the transmission-lo-subframe rear mounting bracket. 13 Position a trolley jack under the right hand skle of the subframe crossmember. Raise the jack to take the weight of the crossmember

and

the attached components. 14 With reference to Section 4, slacken and remove the two bolts that secure the suspension lower arm rear bush to the subframe. Slacken and withdraw the subframe-to-bodywork bolt, located adjacent to the rear of the suspension lower arm. Throad two flange head bolts of the same thread size, but approximately 25 mm longer into the vacated holes, then carefully lower

the

trolley jack and allow ihe subframe to rest on the heads of the temporary bolts (see (lustration), 15 Repeat the operations in paragraphs 13 end 14 at the left-hand side of the vehicle. On completion, the subframe should be resting at

&

height approximately 25 mm lower than normal. 16 The additional clearance will now permit the steering gear pinion to be lowered away from the bulkhead. When the end of the pinion has cleared Ihe aperture, manoeuvre the entire steering gear assembly through the *tiae?arch.

Refitting 17 Refitting is a reversal of removal, noting

the

following points: s) Remote the temporary bolts and refit the original length fixings.

13.14 Slacken and remove the subframe-to-bodywork bolts (arrowed)

b) Tighten all fixings to the specified torque settings. c) Refill the hydraulic system with the specified grade and quantity of power steering fluid (see Lubricants and fluids In Weekly checks), then thoroughly bleed the system as described in Section 15. d) On completion, have the front wheel alignment checked at the earliest oppor-tunity by a Flat dealer or a tyre specialist.

14 Steering gear rubber gaiters - renewal <

Note: New gaiter retaining clips should be used on refitting. 1 Remove the relevant track-rod end as described in Section 17. 2 If not already done, unscresv the track-rod end locknut from Ihe end of the track-rod. 3 Mark the correct fitted position of the gaiter on the track-rod, then release the gaiter securing clips. Slide the gailer from the steering gear, and off the end of the track-rod. 4 Thoroughly clean tho track-rod and the steering gear housing, usrng fine abrasive paper to polish off any corrosion, burrs or sharp edges, which might damage the new gaiter sealing lips on installation. Scrape off all the grease from the old gaiter, and apply it to the track-rod inner balljoint. (This assumes that grease has not been lost or contaminated as a result of damage to the old gaiter. Use fresh crease if In doubt.) 5 Carefully slide the new gaiter onto the track-rod. and locate it on the steering gear housing. Align the outer edge of the gaiter with the mark made on the track-rod prior to removal, then secure it in position with new retaining clips. 6 Screw the track-rod end locknut onto the end of the track-rod. 7 Refit the track-rod end as described in Section 17.

15 Power steering hydraulic system • bleeding ^

General 1 The following symptoms indicate that there is air present In the power steering hydraulic system: a) Generation of air bubbles in fluid reservoir. b) Clicking noises from power steering pump. c) Excessive buzzing or groaning from power steering pump. 2 Note that when the vehicle Is stationary, or while moving the steering wheel slowly, a hissing noise may be produced In the steering gear or the fluid pump. This noise is inherent in the system, and does not indicate any cause for concern.

Bleeding 3 Chock the rear wheels, apply the handbrake, then jack up the front of the vehicle and support securely on axle stands (see Jacking and vehicle support). 4 Check the fluid level in the power steering fluid reservoir (bear in mind that the vehicle will be tilted, so the level cannot be read accurately), and if necessary top-up to just above the relevant level mark. 5 Have an assistant tum the steering quickly from lock to lock, and observe tho fluid level, if the fluid level drops, add more fluid, and repeat the operation until the fluid level no longer drops. Failure to achieve this within a reasonable period may indicate a leak in the system. 6 Stan the engine and repeat the procedure described In the previous paragraph. 7 Once the fluid level has stabilised, and all air has been bled from the system, lower the vehicle to the ground.

16 Power steering pump - Sk removal and refitting ^

Removal 1 Drain as much fluid as possible from the power steering reservoir, using a pipette or an old poultry baster. 2 Remove the clip and disconnect the rubber fluid supply hose from the port on the top of the power steering pump. Be prepared for an amount of fluid loss • position a container underneath the port and pad the surrounding area with absorbent rags. 3 Slacken the union and disconnect the fluid delivery hose from the side of the power steering pump. Again, be prepared for an amount of fluid loss. 4 Unscrew tho clamp bolt and through-bolt at either end of the drivebelt guard, then detach Ihe guard from the power steering pump (see illustrations). 5 Partially unscresv the two power steering pump mounting bolts then rotate the pump towards the engine slightly, to release the tension from the belt. Carefully ease the drivebelt from the pump pulley.

16.4a Unscrew the clamp bolt...

Page 208 of 225

Bodywork and fittings

11

*7

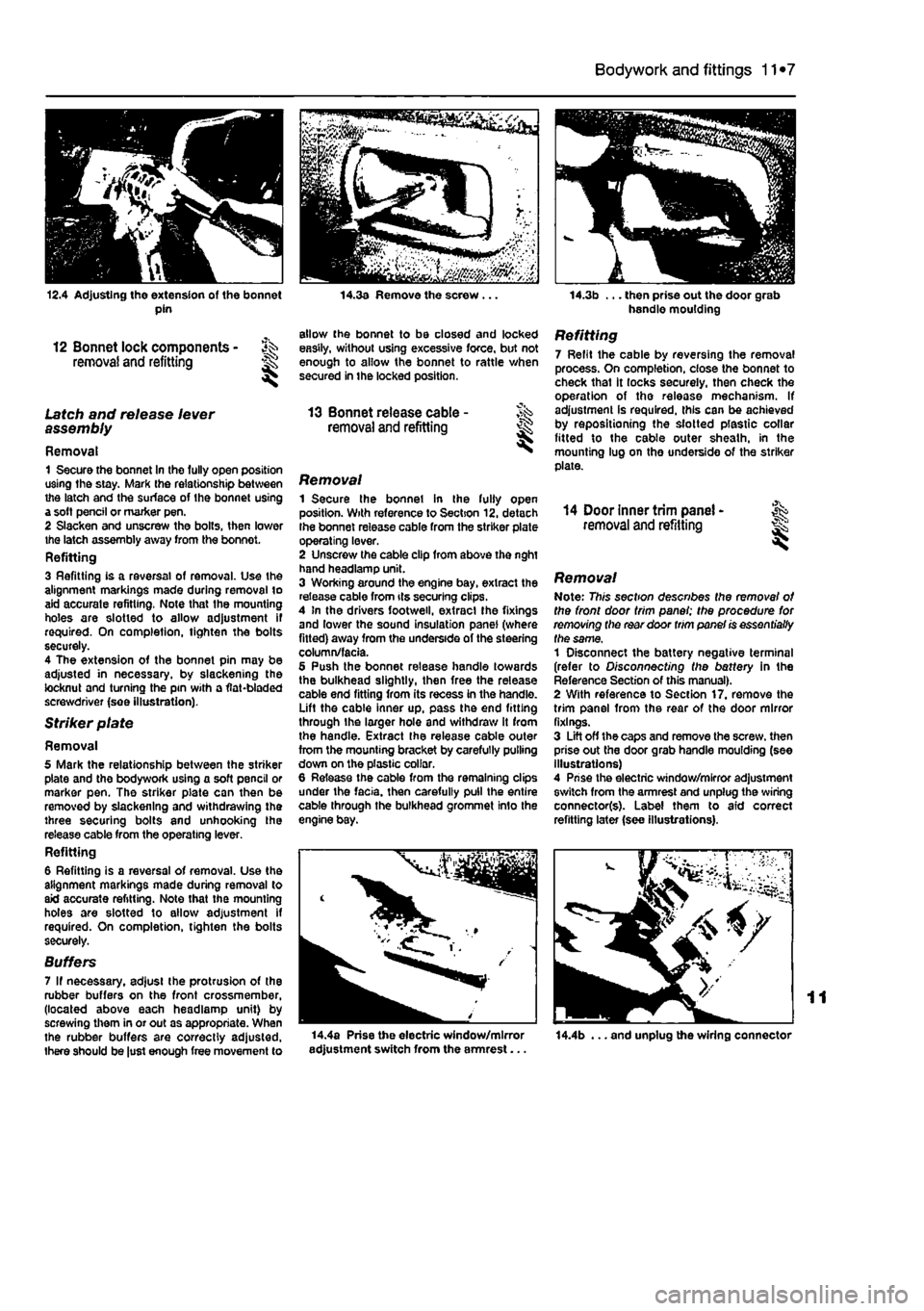

12.4 Adjusting the extension of the bonnet pin

12 Bonnet lock components - ^ removal and refitting H

Latch and release lever assembly

Removal 1 Secure the bonnet In the fully open position using the stay. Mark the relationship between the latch and the surface of the bonnet using a soft pencil or marker pen. 2 Slacken and unscrew the bolts, then lower the latch assembly away from the bonnot. Refitting 3 Refitting is a reversal of removal. Use the alignment markings made during removal to aid accurate refitting. Note that the mounting holes are slotted to allow adjustment if required. On completion, tighten the bolts securely. 4 The extension of the bonnet pin may be adjusted in necessary, by slackening the locknut and turning the pin with a flat-bladed screwdriver (see illustration).

Striker plate

Removal 5 Mark the relationship between the striker plate and the bodywork using a soft pencil or marker pen. The striker plate can then be removed by slackening and withdrawing the three securing bolts and unhooking the release cable from the operating lever. Refitting 6 Refitting is a reversal of removal. Use the alignment markings made during removal to aid accurate refitting. Note that the mounting holes are slotted to allow adjustment if required. On completion, tighten the bolts securely.

Suffers 7 If necessary, adjust the protrusion of the rubber buffers on the front crossmember, (located above each headlamp unit) by screwing them in or out as appropriate. When the rubber buffers are correctly adjusted, there should be just enough free movement to

14.3a Remove the screw .

allow the bonnet to be closed and locked easily, without using excessive force, but not enough to allow the bonnet to rattle when secured in the locked position.

13 Bonnet release cable -removal and refitting I

Removal 1 Secure the bonnet in the fully open position. With reference to Section 12, detach Ihe bonnet release cable from the striker plate operating lever. 2 Unscrew the cable clip from above the nght hand headlamp unit. 3 Working around the engine bay, extract the release cable from its securing clips. 4 In the drivers footweil, extracl Ihe fixings and lower the sound insulation panel (where fitted) away from the underside of the steering column/facia. 5 Push the bonnet release handle towards the bulkhead slightly, then free the release cable end fitting from its recess in the handle. Lift the cable inner up, pass the end fitting through the larger hole and withdraw it from the handle. Extract the release cable outer from the mounting bracket by carefully pulling down on the plastic collar. 6 Release the cable from the remaining clips under the facia, then carefully pull the entire cable through the bulkhead grommet Info the engine bay.

14.3b ... then prise out the door grab handle moulding

Refitting 7 Refit the cable by reversing the removal process. On completion, close the bonnet to check that it locks securely, then check the operation of tho release mechanism. If adjustment is required, this can be achieved by repositioning the slotted plastic collar fitted to the cable outer sheath, in the mounting lug on the underside of the striker plate.

14 Door inner trim panel -removal and refitting I

Removal Note: This section describes the removal of the front door trim panel; the procedure for removing the rear door trim panel is essentially the same, 1 Disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual). 2 With reference to Section 17. remove the trim panel from the rear of the door mirror fixings. 3 Lift off the caps and remove the screw, then prise out the door grab handle moulding (see Illustrations) 4 Prise the electric window/mirror adjustment switch from the armrest and unplug the wiring connector(s). Label them to aid correct refitting later (see illustrations).

14.4a Prise the electric window/mirror adjustment switch from the armrest... 14.4b ... and unplug the wiring connector

Page 213 of 225

11 *12 Bodywork and fittings

switch panel, then remove the panel from the facia (see illustration). Label tho wiring connector to aid refitting, then unplug It. 0 Work along the lower edge of Ihe facia and remove all the securing screws; there are three on the drivers side and three on the passenger side - one is concealed inside the glove compartment, behind a plastic cap. 10 Wilh reference to Chapter 12, remove the cover and open the main fuse box. Where applicable, unscrew the fixings that secure the electronic control unit to Its mounting bracket. Remove the facia mounting bolts located adjacent to the mounting bracket (see illustration). 11 Refer to Chapter 10 and unbolt the steering column from Its support bracket, allowing the column to rest in the footwell. There is no need to slacken the clamp bolt at Ihe base of the steering column to separate it from the steering gear. 12 With reference to Chapter 12, remove front right and left speaker grilles. Remove the two facis upper mounting screws ihat are now exposed. Similarly, prise open the plastic cover from centre of upper edge of the fada and remove the mounting screw behind. 13 Carefully pull whole facia moulding forward away from tho bulkhead slightly. Label all wiring connectors to aid correct refitting later, then unplug Ihem. Check that nothing remains connected between the facia and bulkhead then draw the facia moulding away and remove It from the vehicle.

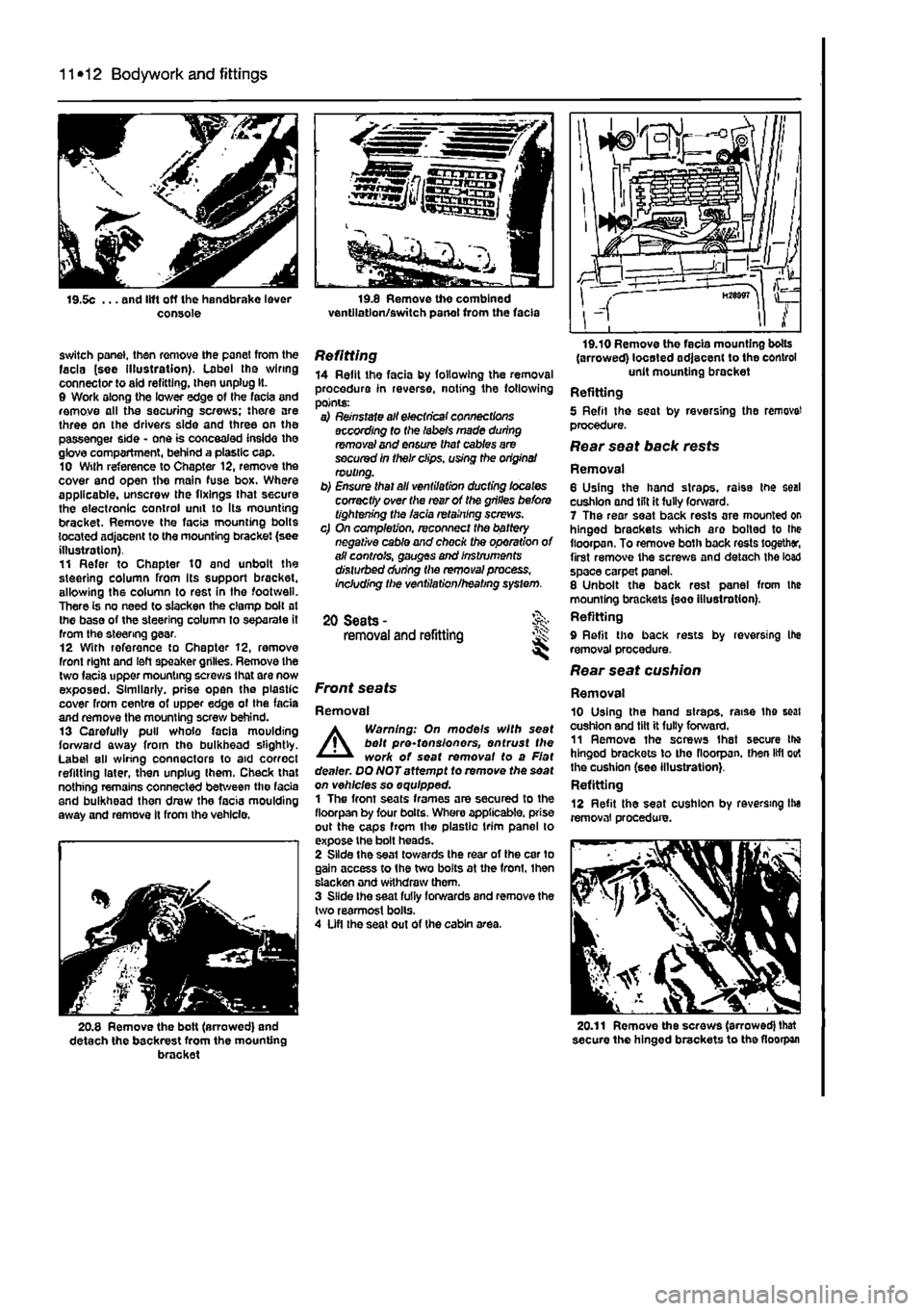

20.8 Remove the bolt (arrowed) and detach the backrest from the mounting bracket

Refitting 14 Refit the facia by following the removal procedure in reverse, noting the following points: a) Reinstate all electrical connections according to (he labels made during removal and ensure that cables are secured in their clips, using the origins/ routing. b) Ensure thai all ventilation ducting locates correctly over the rear of the grilles before tightening the facia retaining screws. c) On completion, reconnect the battery negative cable and chock the operation of all controls, gauges and Instruments disturbed during the removal process, Including the ventilation/heating system.

20 Seats -removal and refitting JS:

Front seats

Removal

A

Warning: On models with seat belt pre-tonsionors, entrust the work of seat removal to a Flat dealer. DQNOTattempt to remove the seat on vehicles so equipped. 1 The front seats frames are secured to the fioorpan by four bolts. Whero applicable, prise out the caps from the plastic trim panel lo expose the bolt heads. 2 Slide the seat towards the rear of the car to gain access to the two bolts at the front, Ihen slacken and withdraw them. 3 Slide Ihe seat fully forwards and remove the two rearmost bolls. 4 Ufl the seat out of the cabin area.

(arrowed) located adjacent to the control unit mounting bracket Refitting 5 Refil the seat by reversing the remove! procedure. Rear seat back rests

Removal 6 Using the hand straps, raise the seal cushion and lilt it fully forward. 7 The rear seat back rests are mounted or hinged brackets which aro boiled to Ihe fioorpan. To remove both back rests together, first remove the screws and detach the load space carpet panel. 8 Unbolt the back rest panel from the mounting brackets (see illustration). Refitting 9 Refit tho back rests by reversing Ihe removal procedure. Rear seat cushion

Removal 10 Using the hand straps, raise the seat cushion and tilt it fully forward. 11 Remove ihe screws Ihat secure Ihe hinged brackets to tho fioorpan. then lift out the cushion (see illustration}. Refitting 12 Refit the seat cushion by reversing Ihe removal procedure.

20.11 Remove the screws (arrowed) that secure the hinged brackets to the fioorpan

Page 221 of 225

12*8 Body electrical systems

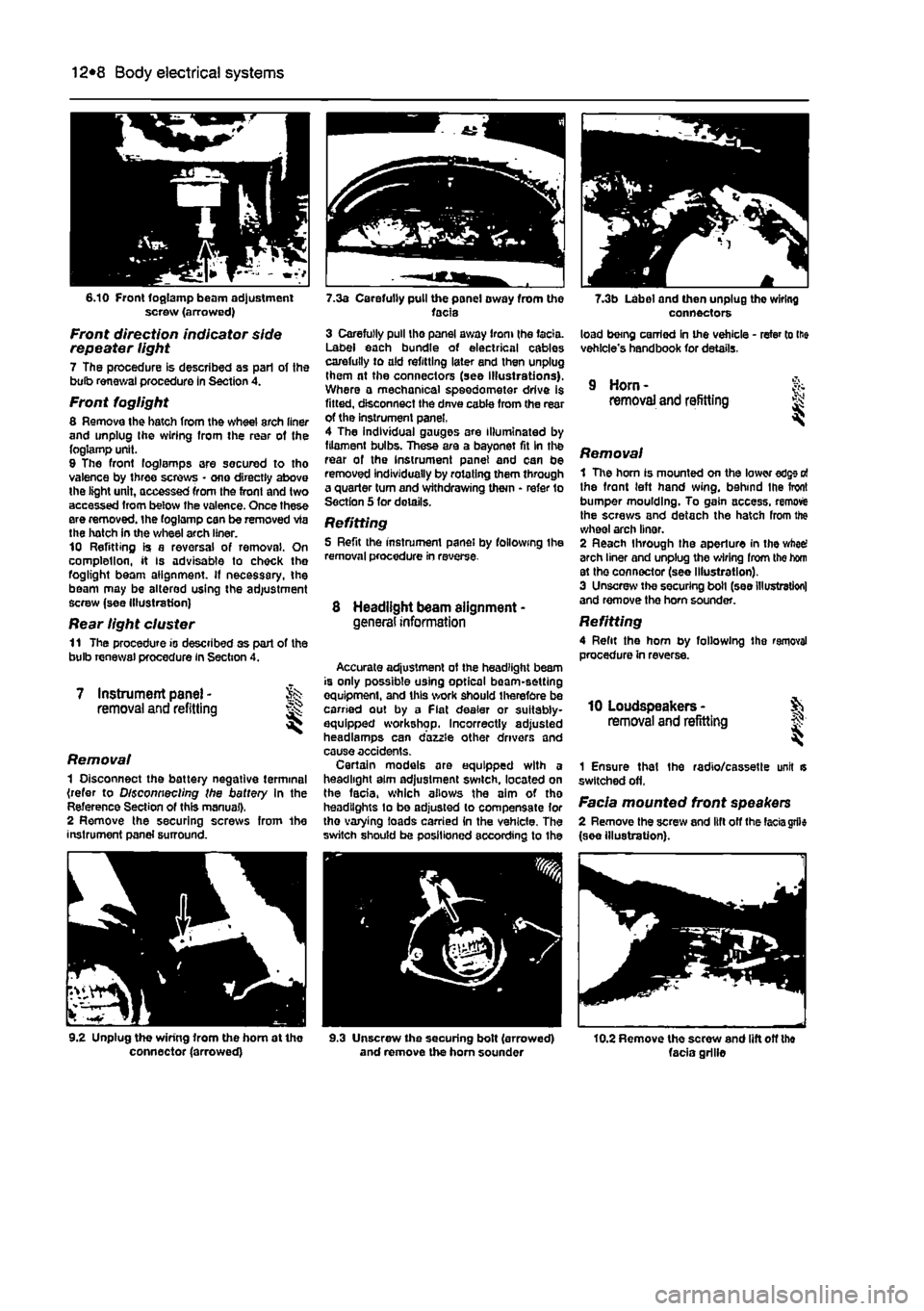

6.10 Front foglamp beam adjustment screw (arrowed)

Front direction indicator side repeater light 7 The procedure is described as pari of the bulb renewal procedure In Section 4.

Front foglight 8 Remove the hatch from the wheel arch liner and unplug Ihe wiring Irom the rear of the foglamp unit. 9 The front foglamps are secured to tho valence by three screws • one directly above the light unit, accessed from the front and two accessed Irom below the valence. Once these ere removed, the foglamp can be removed via the hatch in the wheel arch liner. 10 Refitting is a reversal of removal. On complellon, it Is advisable to check the foglight beam alignment. If necessary, the beam may be altered using the adjustment screw (see Illustration)

Rear light cluster 11 The procedure is described as part of the bulb renewal procedure in Section 4.

7 Instrument panel -removal and refitting

Removal 1 Disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual). 2 Remove the securing screws from 1he instrument panel surround.

9.2 Unplug the wiring from the hom at tho connector (arrowed)

7.3a Carefully pull the panel oway from the facia 3 Carefully pull tho panel away from (he facia. Label each bundle of electrical cables carefully to old refitting later end then unplug them nt the connectors (see illustrations). Where a mechanical speedometer drive is fitted, disconnect the dnve coble from the rear of the instrument panel, 4 The individual gauges are Illuminated by filament bulbs. These are a bayonet fit In the rear of the Instrument panel and can be removed individually by rotating them through a quarter turn and withdrawing them • refer to Section 5 for details.

Refitting 5 Refit the instrument panel by following the removal procedure in reverse

8 Headlight beam alignment -general information

Accurate adjustment ot the headlight beam is only possible using optical beam-setting equipment, and this work should therefore be carried out by a Fiat dealer or suitably-equipped workshop. Incorrectly adjusted headlamps can dazzle other drivers and cause accidents. Certain models are equipped with a headlight aim adjustment switch, located on the facia, which allows the aim of tho headlights lo be adjusted to compensate lor tho varying loads carried in the vehicle. The switch should be positioned according to Ihe

9.3 Unscrew the securing bolt (arrowed) and remove the horn sounder

7.3b Label and then unplug the wiring connectors load being carried in the vehicle - refer to lie vehicle's handbook for details.

9 Horn -removal and refitting

Removal 1 The horn is mounted on the lower edge o! the front left hand wing, behind Ihe front bumper moulding. To gain access, remove the screws and detach the hatch from the wheel arch linor. 2 Reach through the aperture in the wheel arch liner and unplug the wiring Irom the hom st the connector (see Illustration). 3 Unscrew the securing boll (see Illustration) and remove the horn sounder.

Refitting 4 Refit the hom by following the removal procedure in reverse.

10 Loudspeakers -removal and refitting §;

1 Ensure that the radio/cassette unit is switched off.

Facia mounted front speakers 2 Remove the screw and lift off the

facia

grfle (see illustration).

10.2 Remove tho screw and lift off the facia grille