power steering fluid FIAT PUNTO 1998 176 / 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1998, Model line: PUNTO, Model: FIAT PUNTO 1998 176 / 1.GPages: 225, PDF Size: 18.54 MB

Page 38 of 225

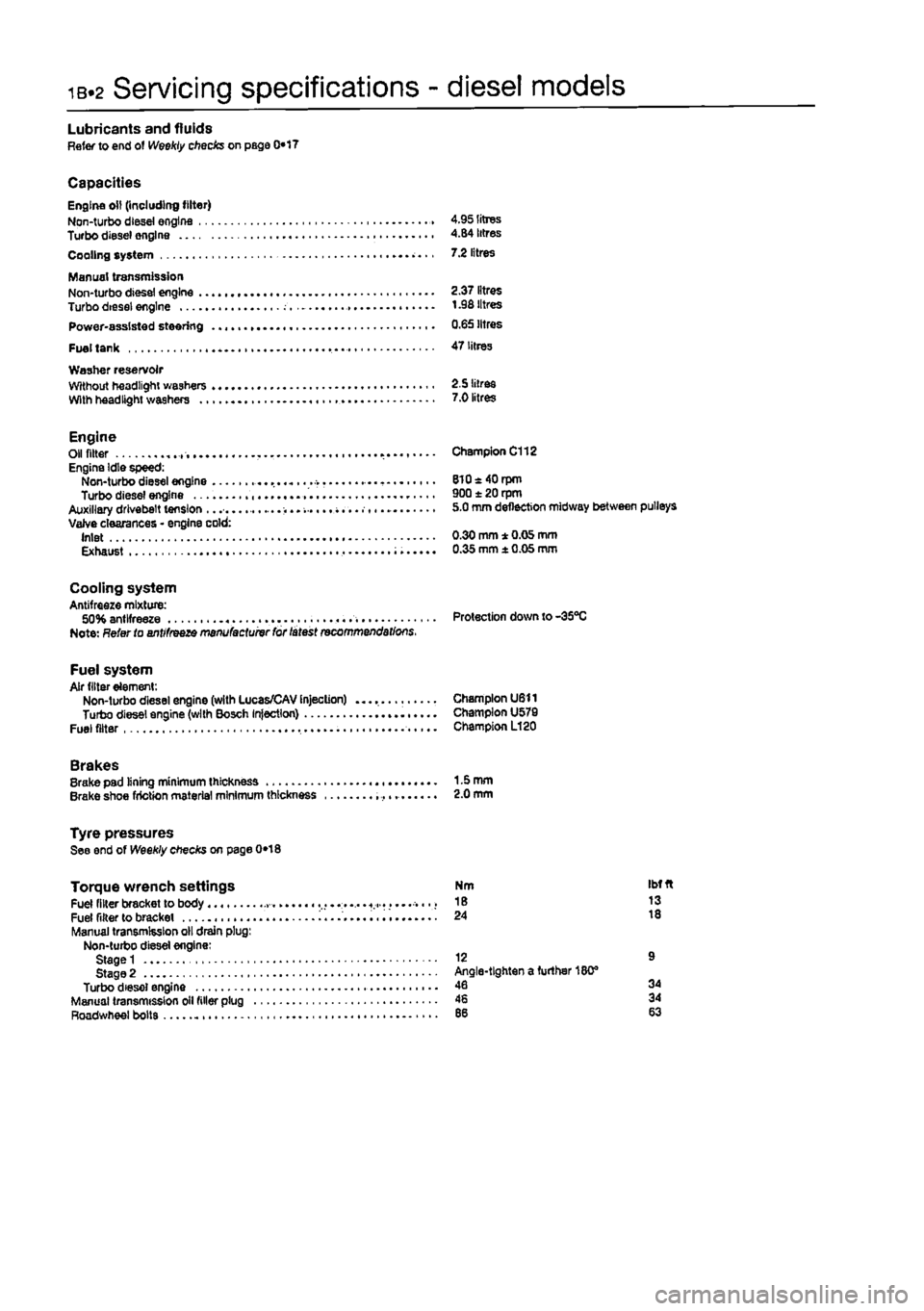

1B.2

Servicing specifications - diesel models

Lubricants and fluids Refer to end of Weekly checks on page 0*17

Capacities Engine oil (including filter) Non-turbo diesei engine 4.95 litres Turbo diesel engine 4.84 litres Cooling system 7.2 litres

Manual transmission Non-turbo diesel engine 2.37 litres Turbo diesei engine t .98 litres Power-assisted steering 0.65 litres

Fuel tank 47 litres Washer reservoir Without headlight washers 2.5 litres With headlight washers 7.0 litres

Engine Oil fitter Engine Idle speed: Non-turbo diesel engine Turbo diesel engine Auxiliary drivebelt tension ...... Valve clearances • engine cold: Inlet Exhaust

Champion C112

8l0«40rpm 900 ± 20 rpm 5.0 mm deflection midway between pulleys

0.30 mm * 0.05 mm 0.35 mm ± 0.05 mm

Cooling system Antifreeze mixture: 50% antifreeze Protection down to-35°C Note: Refer to antifreeze manufactuivr for latest recommendations.

Fuel system Air filter element: Non-turbo diesel engine (with Lucas/CAV Injection) Champion U611 Turbo diesel engine (with Bosch Injection) Champion U579 Fuel filter Champion L120

Brakes Brake pad lining minimum thickness 1-5 mm Brake shoe friction material minimum thickness 2.0 mm

Tyre pressures See end of Weekly checks on page 0*18

Torque wrench settings Fuel filter bracket to body ..... « Fuel filter to bracket i........ Manual transmission oil drain plug: Non-turbo diesel engine: Stage 1 Stage 2 Turbo diesel engine Manual transmission oil filler plug Roadwheel bolts

Nm Ibfft 18 13 24 18

12 9 Angle-tighten a further 180® 46 34 46 34

Page 40 of 225

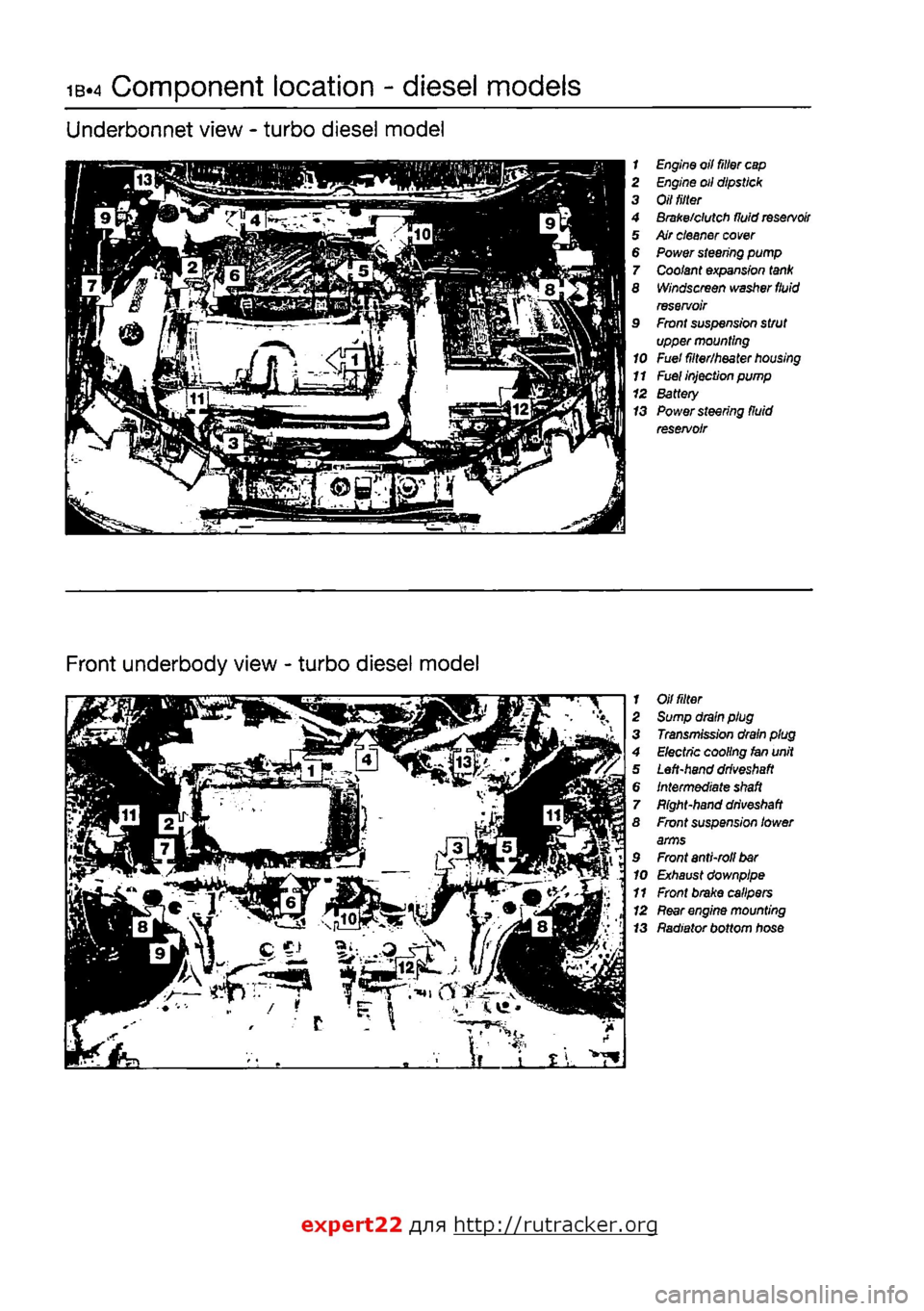

ib-4 Component location - diesel models

Underbonnet view - turbo diesel model

1 Engine oil filter

cap

2 Engine oil dipstick 3 Oil

tilter

4 Brake/clutch fluid

reservoir

5 Air cleaner

cover

6 Power steering pump 7 Coolant expansion

tank

8 Windscreen washer

fluid

reservoir 9 Front suspension strut upper mounting 10 Fuel filter/heater

housing

11

Fuel

injection pump 12 Battery 13 Power steering fluid reservoir

Front underbody view - turbo diesel model

1 Oil

fitter

2 Sump drain plug 3 Transmission drain plug 4 Electric cooling fan unit 5 Left-hand

driveshaft

6 Intermediate

shaft

7 Bight-hand

driveshaft

8 Front suspension lower arms 9 Front anti-roll

bar

10 Exhaust downpipe 11 Front brake calipers 12

Rear

engine mounting 13 Radiator bottom hose

expert22 fl/ia http://rutracker.org

Page 43 of 225

Maintenance procedures - diesel models ib.?

Every 10 000 miles (15 000 km) or 12 months

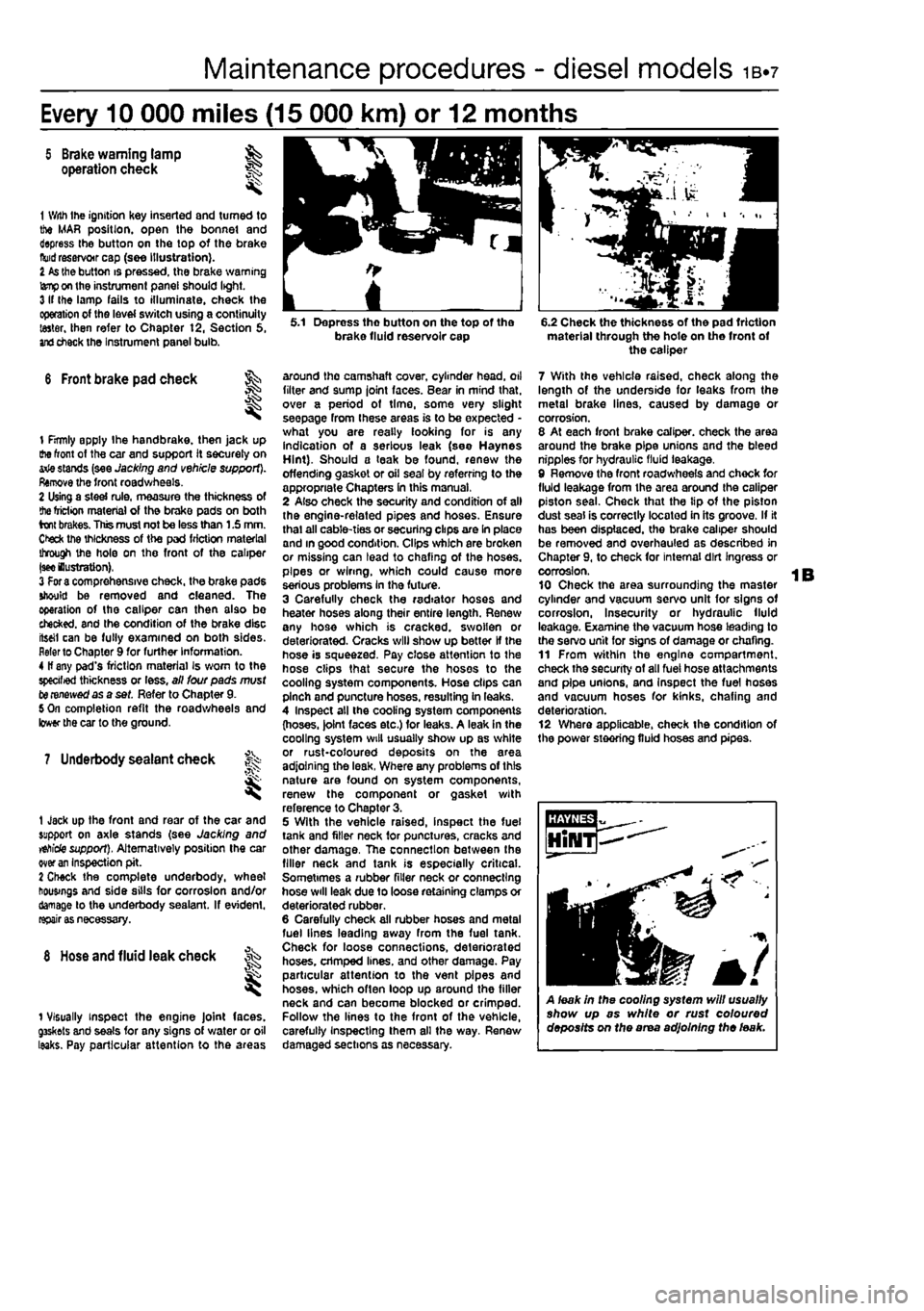

5 Brake warning lamp operation check 1

1 With Ihe ignition Key inserted and turned to the MAR position, open the bonnet and depress the button on the top of the brake

fluid

reservoir cap (see illustration). I

As

the button is pressed, the brake warning

lamp

on the instrument panel should light. 3 If Ihe lamp fails to illuminate, check the operation of the level switch using a continuity taster, then refer to Chapter t2, Section 5,

and

check the Instrument panel bulb.

6 Front brake pad check ^

I

1 firmly apply Ihe handbrake, then jack up the front of the car and support it securely on arie stands (see Jacking and vehicle support). Remove the front roadwheels. 2 Using a steel rule, measure the thickness of

the

friction material of the brake pads on both brakes. This must not be less than 1.5 mm. Ctefc the thickness of the pad friction material through the hole on the front of the caliper

|see

lustration), 3

For a

comprehensive check, the brake pads should be removed and cleaned. The operation of the caliper can then also bo checked, and the condition of the brake disc iteeil can be fully examined on both sides. Refer to Chapter 9 for further Information. 4 If any pad's friction material Is worn to the specified thickness or less, all lour pads must to renewed as a set. Refer to Chapter 9. 5 On completion refit the roadwheels and lower the car to the ground.

7 Underbody sealant check f^

1 Jack up the front and rear of the car and support on axle stands (see Jacking and

vehicle

support). Alternatively position the car over

an

Inspection pit. 2 Check the complete underbody, wheel housings and side sills for corrosion and/or damage to the underbody sealant. If evident,

rapairi

8

Hose

and fluid leak check

1 Visually inspect the engine Joint faces. g3skets and seals for any signs of water or oil leaks. Pay particular attention to the areas

5.1 Depress tho button on the top of the brake fluid reservoir cap

around the camshaft cover, cylinder head, oil filter and sump joint faces. Bear in mind that, over a period of time, some very slight seepage from these areas is to be expected -what you are really looking for is any indication of a serious leak (see Haynes Hint). Should a teak be found, renew the offending gasket or oil seal by referring to the appropriate Chapters In this manual, 2 Also check the security and condition of all the engine-related pipes and hoses. Ensure thai all cable-ties or securing clips are In place and in good condition. Clips which are broken or missing can lead to chafing of the hoses, pipes or wiring, which could cause more serious problems In the future. 3 Carefully check the radiator hoses and heater hoses along their entire length. Renew any hose which is cracked, swollen or deteriorated. Cracks will show up better If the hose is squeezed. Pay close attention to the hose clips that secure the hoses to the cooling system components. Hose clips can pinch and puncture hoses, resulting in leaks. 4 Inspect all the cooling system components (hoses. )olnt faces etc.) for leaks. A leak in the cooling system will usually show up as white or rust-coloured deposits on the area adjoining the leak, Where any problems of this nature are found on system components, renew the component or gasket with reference to Chapter 3. 5 With the vehicle raised, inspect the fuel tank and filler neck for punctures, cracks and other damage, The connection between the filler neck and tank is especially critical. Sometimes a rubber filler neck or connecting hose will leak due to loose retaining clamps or deteriorated rubber. 6 Carefully check all rubber hoses and metal fuel lines leading away from the fuel tank. Check for loose connections, deteriorated hoses, crimped lines, and other damage. Pay particular attention to the vent pipes and hoses, which often loop up around the filler neck and can become blocked or crimped. Follow the lines to the front of the vehicle, carefully Inspecting them all the way. Renew damaged sections as necessary.

6.2 Check the thickness of the pad friction material through the hote on the front of the caliper

7 With the vehicle raised, check along the length of the underside for leaks from the metal brake lines, caused by damage or corrosion. 8 At each front brake caliper, check the area around the brake pipe unions and the bleed nipples for hydraulic fluid leakage, 9 Remove the front roadwheels and chock for fluid leakage from the area around the caliper piston seal. Check that the tip of the piston dust seal is correctly located in its groove. If it has been displaced, the brake caliper should be removed and overhauled as described in Chapter 9, to check for internal dirt Ingress or corrosion. 10 Check the area surrounding the master cylinder and vacuum servo unit for signs of corrosion, Insecurity or hydraulic fluid leakage. Examine the vacuum hose leading to the servo unit for signs of damage or chafing. 11 From within the engine compartment, check the security of all fuel hose attachments and pipe unions, and Inspect the fuel hoses and vacuum hoses for kinks, chafing and deterioration. 12 Where applicable, check the condition of the power steering fluid hoses and pipes.

A leak in the cooling system will usually show up as white or rust coloured deposits on the area adjoining the leak.

Page 45 of 225

Every 10 000 miles - diesel models ib«9

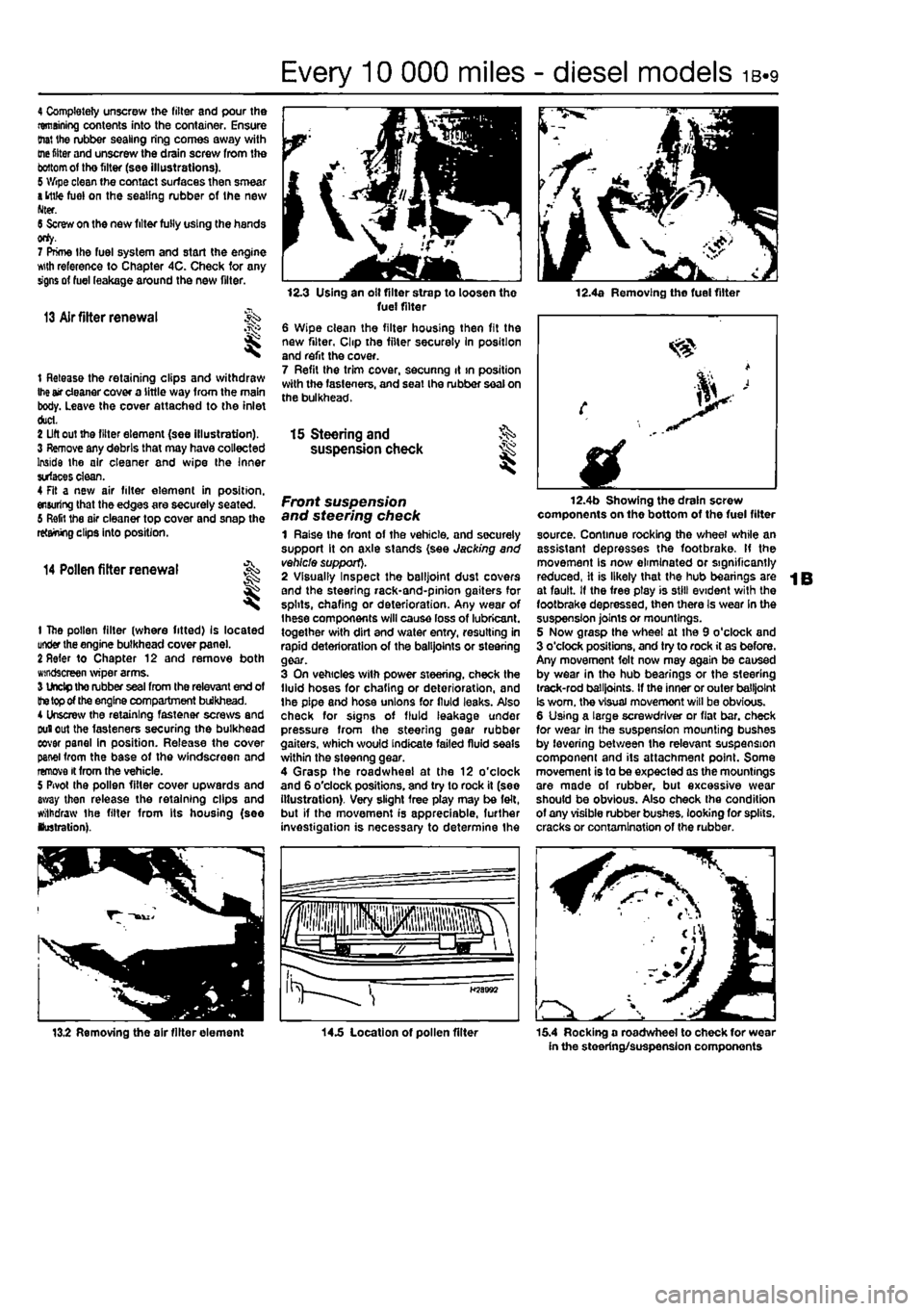

4 Completely unscrew the filter and pour the remaining contents into the container. Ensure (hat the rubber sealing ring comes away with

me

fitter and unscrew the drain screw from the

bottom

of tho filter (see illustrations). 5 Wipe clean the contact surfaces then smear

a

ittfe fuel on the sealing rubber of the new Nter. 6 Screw on the new filter fully using the hands orty. 7 Prime the fuel system and start the engine wth reference to Chapter 4C. Check for any signs of fuel leakage around the new filter.

13 Air fitter renewal

t Release the retaining clips and withdraw

Ihe

air cleaner cover a little way from the main body. Leave the cover attached to the inlet duct. 2 Lift out the filter element (see illustration). 3 Remove any debris that may have collected Inside the air cleaner and wipe the Inner surfaces clean. 4 Fit a new air filter element in position, ensuring that the edges are securely seated. 6 Refit the air cleaner top cover and snap the retaining clips into position.

14 Pollen filter renewal

t

1 The pollen filter (where fitted) Is located under the engine bulkhead cover pane). 2 Refer to Chapter 12 and remove both windscreen wiper arms. 3 Undp tho rubber seal from the relevant end of

the top

of the engine compartment bulkhead. 4 Unscrew the retaining fastener screws and Duiout the fasteners securing the bulkhead eovar panel in position. Release the cover panel from the base of the windscreen and remove it from the vehicle. 5 Pivot the pollen filter cover upwards and away then release the retaining clips and withdraw the filter from Its housing (see lustration).

12.3 Using an olt filter strap to loosen the fuel filter 6 Wipe clean the filter housing then fit the new filter, Clip the filter securely In position and refit the cover. 7 Refit the trim cover, secunng it >n position with the fasteners, and seat Ihe rubber seal on the bulkhead.

12.4a Removing the fuel filter

15 Steering and §S> suspension check ^

Front suspension and steering check 1 Raise the front of the vehicle, and securely support it on axle stands (see Jacking and vehicle support). 2 Visually Inspect the balljoint dust covers and the steering rack-and-pinion gaiters for splits, chafing or deterioration. Any wear of Ihese components will cause loss of lubricant, together with dirt and water entry, resulting in rapid deterioration of the balljoints or steering gear. 3 On vehicles with power steering, check the fluid hoses for chafing or deterioration, and the pipe and hose unions for fluid leaks. Also check for signs of fluid leakage under pressure from the steering gear rubber gaiters, which would indicate failed fluid seals within the steenng gear. 4 Grasp the roadwheel at the 12 o'clock and 6 o'clock positions, and try to rock it (see illustration). Very slight free play may be felt, but if the movement is appreciable, further investigation is necessary to determine the

fplllll iHpjiiisisps fa^aJw a LJgr >

H58B92

12.4b Showing the drain screw components on the bottom of the fuel filter source. Continue rocking the wheel while an assistant depresses the footbrake. If the movement Is now eliminated or significantly reduced, it is likely that the hub bearings are at fault. If the free ptay is still evident with the footbrake depressed, then there Is wear In the suspension joints or mountings. 5 Now grasp the wheel at the 9 o'clock and 3 o'clock positions, and try to rock it as before. Any movement felt now may again be caused by wear in the hub bearings or the steering track-rod balljoints. If the inner or outer balljoint Is worn, the visual movemont will be obvious. 6 Using a large screwdriver or flat bar. check for wear in the suspension mounting bushes by levering between the relevant suspension component and its attachment point. Some movement is to be expected as the mountings are made of rubber, but excessive wear should be obvious. Also check the condition of any visible rubber bushes, looking for splits, cracks or contamination of the rubber.

13.2 Removing the air filter element 14.5 Location of pollen filter 15.4 Rocking a roadwheel to check for wear in the steering/suspension components

Page 46 of 225

ib-io Every 10 000 miles - diesel models

7 With the car standing on Its wheels, have an assistant turn the steering wheel back and forth about an eighth of a turn each way. There should be very hide. If any, lost movement between the steering wheel and roadwheels. If this is not the case, closely observe the joints and mountings previously described, but in addition, check the steering column universal joints for wear, and the rack-and-plnion steering gear itself.

Suspension strut/ shock absorber check 8 Check for any signs of fluid leakage around the suspension strut/shock absorber body, or from the rubber gaiter around the piston rod, Should any fluid be noticed, the suspension strut/shock absorber is defective Internally, and should be renewed. Note: Suspension struts/shock absorbers should always be renewed in pairs on the same axle.

9 The efficiency of the suspension strut/shock] absorber may be checked by bouncing 0*1 vehicle at each comer. Generally speaking. th»| body will return to its normal position and 8top| after being depressed. If It rises and returns cn| a rebound, the suspension strut/shocH absorber is probably suspect. Examine also* the suspension strut/shock absorber uppeij and lower mountings for any signs of wear.

Every 20 000 miles (30 000 km) or 2 years

18 Auxiliary drivebeltfs) % check and renewal

Note: Fiat specify the use of a spec/a/ toot to correctly set the drivebelt fens/on. if access to this equipment cannot be obtained, an approximate setting can be achieved using the method described beiow. If the method described Is used, the tension should be checked using the spec/a/ too! at the earliest possible opportunity. 1 Depending on equipment fitted, one, two or three auxiliary drivebeits may be fitted. The alternator, power steering pump and air conditioning compressor, as applicable, are each driven by an individual drivebelt. Checking 2 Disconnect the battery negative terminal (refer to Disconnecting the battery In the Reference Section of this manual). 3 Firmly apply the handbrake, then Jack up the Iront of the car and support it securely on exie stands (see Jacking and vehicle support). 4 Remove the right-hand wheel. 5 Remove the Inner cover(s) from under the right-hand wheelarch for access to the right-hand side of the engine. 6 Using a socket on the crankshaft sprocket bolt, rotate the crankshaft so that the full length of the auxiliary drivebelt(s) can be examined. Look for cracks, splitting and fraying on the surface of the belt: check also for signs of glazing (shiny patches) and

16.10a Loosening the alternator drivebelt adjustment bolt

separation of the belt plies. If damage or wear Is visible, the bell should be renewed, 7 If the condition of the belt Is satisfactory, check tho drivebelt tension as described below.

Renewal

Alternator drivebelt 8 On models with air conditioning, remove the compressor drivebelt as described below, 9 Unclip and remove the upper timing belt cover, then unbolt end remove the lower timing belt cover. 10 Loosen the pivot bolt and adjustment lockbolt then unscrew the adjustment bolt to move the alternator towards the engine so that the drivebelt may be slipped off the alternator, crankshaft, and, on models with air con-ditioning, the Idler pulley (see Illustrations), 11 When renewing a drivebelt. ensure that the correct type is used. Fit the belt around the pulleys then tighten the adjustment bolt to take up any slsck In the belt. Adjust the tension correctly as described below. Power steering pump drivebelt

12 Remove the alternator drivebelt as described previously. 13 Slacken the bolts securing the power steering pump to the mounting bracket. 14 Slacken the adjusting bolt locknut and turn the adjusting bolt until ail the tension Is removed from the dnvebelt. 15 Undo the bolts and remove the pulley guard from the power steering pump then slip the drivebelt off the pulleys,

16.10b Removing the drivebelt from the alternator pulley

18 Ensuring that the correct type of dnveberti^ used, fit the belt around the pulleys and turn

the

adjusting bolt to just take up the slack in thi j belt. Adjust the tension correctly as described! below. Air conditioning compressor drivebelt 17 Slacken the bolts securing the adjustment j pulley bracket to the engine. 18 Slacken the adjusting bolt locknut and] turn the adjusting bolt until ell the tension is | removed from the drivebelt. then slip the be& | off the pulleys. 19 Ensuring that the correct type of drivebeX; is used, fit ihe belt around the pulleys and turn | the adjusting bolt to just take up the slack

m

] the belt. Adjust the tension correctly as described below.

Tensioning 20 Correct tensioning of the belt will ensure that it has a long life. A belt which is too slack will slip and perhaps squeal. Beware, however, of overiightenlng. as this can cause wear in the alternator, power steering pump or air conditioning compressor bearings. Note: Flat recommend use of their spec's/ tensioning tool however the following procedure will set the tension correctly. 21 The belt(s) should be tensioned so that, under firm thumb pressure, there is approximately 5.0 mm of free movement at the mid-point between the pulleys. To adjust, tighten or loosen the relevant adjustment bolt until the tension is correct. Fully tighten the pivot and adjustment lockbotts. Repeat this procedure for any remaining drivebeits removed for access. 22 Refit the lower timing belt cover end tighten the mounting bolts. 23 Refit the upper timing belt cover and secure with the clips. 24 Refit the inner cover and wheel, lower the vehicle to the ground, then reconnect the battery negative terminal.

17 Clutch adjustment check

Refer lo Chapter 6, Section 2.

Page 92 of 225

2D*10 Engine removal and overhaul procedures

Engine and transmission -removal, separation, connection and refitting

Note: The engine Is lowered from the engine compartment as a complete unit with the transmission; tho two are then separated for overhaul.

Removal 1 Remove the bonnet and disconnect the washer tubing as described in Chapter 11 (see illustrations). 2 Apply the handbrake, then jack up the front of the vehicle and support on axle stands (see Jacking and vehicle support). Remove both front wheels. In order to remove tne engine/transmission assembly in an upright position from under the vehicle, there must be a minimum clearance of 660 mm between the floor and the front crossmember. Additional height Is necessary if the assembly is to be lowered onto a trolley. 3 Where fitted, unbolt and remove the engine compartment lower cover. 4 Remove the auxiliary drivebelt(s) with reference to Chapter 1A or 1B. 5 Dram the engine oil. transmission oil/fluid and coolant with reference to Chapter 1A or 1B. 6 Remove the battery (see Chapter 5A). 7 On manual transmission models with a cable dutch, disconnect the clutch cable from the transmission (refer to Chapter 6). On manual transmission models with a hydraulic clutch unbolt the clutch slave cylinder from the top of the transmission then fit a cable-tie around it to prevent the piston coming out (see Illustration). Position the cylinder to one side. 8 Unscrew the nut and disconnect the earth lead from the transmission (see illustration). Petrol engines 9 Unbolt and remove the battery tray. 10 Disconnect the wiring from the reversing light switch. 11 On manual transmission models disconnect the reverse Inhibition cable from the transmission then disconnect the gear selector rod from the lever on the transmission. 12 Remove the air cleaner and ducting as descnbed In Chapter 4A or 4B. 13 On automatic transmission models disconnect the kickdown cable and gear selector cable as described in Chapter 7B. Also disconnect the wiring for the electro-magnetic clutch. 14 Unbolt and remove the cover from the bulkhead then disconnect the oxygen sensor wiring. 15 Disconnect the remaining wiring at the bulkhead and release the fuse holders at the mounting. 16 Disconnect the vacuum pipe from the inlet manifold, and also disconnect the wiring connector located next to it.

4.1a Unscrewing the bonnet hinge bolts

17 Unscrewthenutsandseparatetheengine wiring harness lead from the battery positive cable terminal. 18 Disconnect the accelerator cable from the engine as described in Chapter 4A or 4B, 19 Loosen the clip and disconnect the radiator top hose from the elbow on the left-hand end of the cylinder head. Similarly disconnect the bottom hose. On 16-valve models, remove the radiator electric cooling fan as described in Chapter 3. 20 Identify the hoses connected to the throttle housing, then disconnect them. 21 Identify the coolant heater hoses on the bulkhead for position, then loosen the clips and disconnect the hoses. 22 Loosen the clip and disconnect the brake servo vacuum hose from the Inlet manifold. Where applicable, disconnect the remaining emission control system vacuum hoses from the Inlet manifold after Identifying their locations to aid refitting. 23 Disconnect tho fuel supply and return hoses from the throttle housing. 24 Release the connector from the ignition/fuel ECU located on the right-hand side of the engine compartment. 25 Unscrew the nut and detach the earth cable from its location near the ECU. 26 Disconnect the diagnostic connector located near the ECU. 27 On models fitted with power steering, refer to Chapter 10 and unbolt the power steering pump from the front of the engine without disconnecting the hydraulic fluid lines then tie It to one side so that it will not obstruct the removal of the engine. On

4.1b Disconnecting the washer tubing

models with air conditioning, similarly unbolt the air conditioning compressor and position it clear of the engine. Do not disconnect the air conditioning refngerant pipes/hoses. 26 On manual transmission models pull out the retaining plate and disconnect the gear selector cable from the lever on the transmission. 29 Unscrew the nuts retaining the track rod ends on the swivel hubs and use a balljoint separator tool to disconnect them. 30 Release the flexible brake fluid hoses and ABS system sensor wrring from the front suspension struts. 31 On manual transmission models, unscrew the nuts from the outer ends of each driveshaft. To prevent the hubs from turning either have an assistant depress the brake pedal, or temporarily Insert two wheel bolts and use a lever to hold the hub. 32 On automatic transmission models use a suitable drift to drive out Ihe roll pins securing 2D the inner ends of the drlveshafts to tho trans-mission output stubs. Turn the driveshalts as necossary to access the roll pins . 33 Unscrew the two bolts securing the right-hand swivel hub assembly to the front suspension strut, then move the hub assembly outwards. On manual transmission models release the outer end of the driveshaft from the hub assembly - on automatic transmission models slide the inner end of the driveshaft off the final drive output stub. Take care not to strain the flexible brake hose while doing this. Move the driveshaft to one side thon temporanly refit the hub assembly to the strut. On manual transmission models, make

^ - / //

4.7 Fit a cable tie around the dutch slave cylinder to prevent the piston coming out 4.8 Disconnecting the earth lead from the transmission

Page 94 of 225

2D*10 Engine removal and overhaul procedures

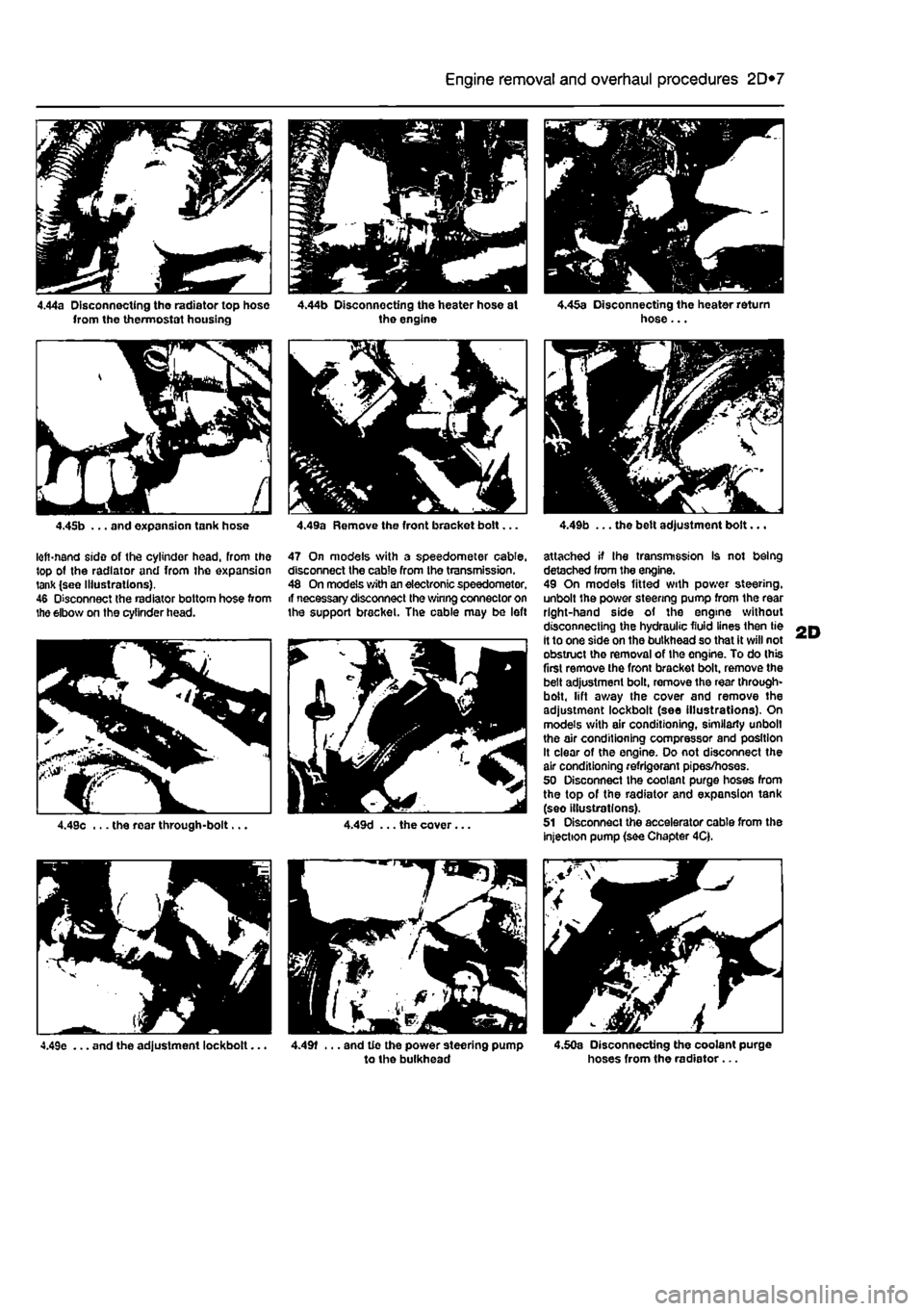

4.44a Disconnecting tho radiator top hose from the thermostat housing

4.45b ... and expansion tank hose

lofi-nand side of the cylinder head, From the top ot the radiator and from the expansion tank (see Illustrations). 46 Disconnect the radiator bottom hose from the elbow on the cylinder head.

4.49e ... and the adjustment lockbolt...

4.44b Disconnecting the heater hose st the engine

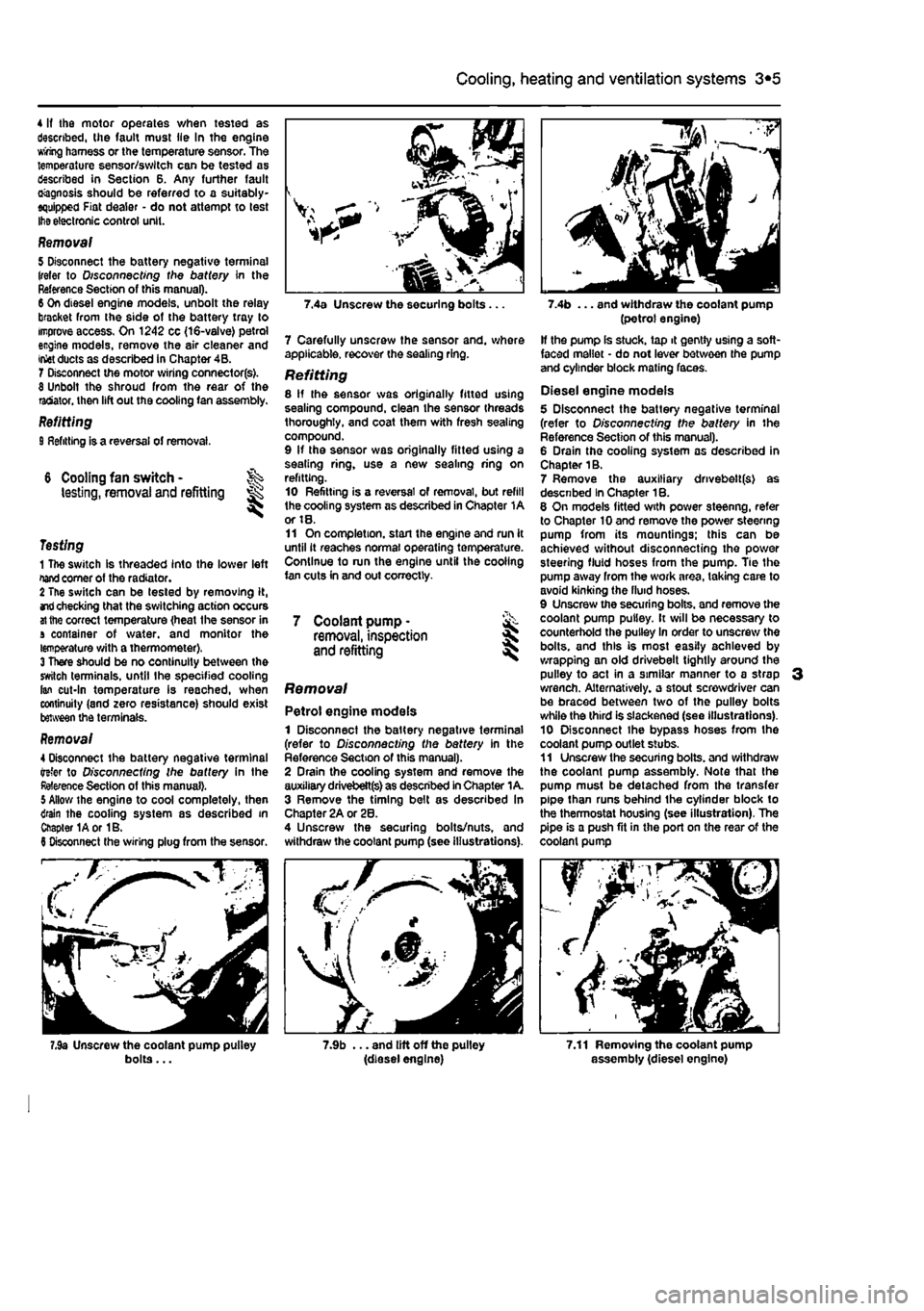

4.49a Remove the front bracket bolt...

47 On models with a speedometer cable, disconnect the cable from the transmission. 48 On models with an electronic speedometer, if necessary disconnect the winng connector on the support bracket. The cable may be left

4.49f ... and tie the power steering pump to the bulkhead

. m " • V;

<4

4.45a Disconnecting the heater return hose...

4.49b ... the belt adjustment bolt...

attached if Ihe transmission Is not being detached from the engine. 49 On models fitted with power steering, unbolt the power steering pump from the rear right-hand side of the engine without disconnecting the hydraulic fluid lines then tie it to one side on the bulkhead so that it will not obstruct the removal of the engine. To do (his first remove the front bracket bolt, remove the belt adjustment bolt, remove the rear through-bolt, lift away the cover and remove the adjustment lockbolt (see illustrations). On models with air conditioning, similarly unbolt the air conditioning compressor and position It clear of the engine. Do not disconnect the air conditioning refrigerant pipes/hoses. 50 Disconnect the coolant purge hoses from the top of the radiator and expansion tank (seo illustrations). 51 Disconnect the accelerator cable from the injection pump (see Chapter 4Q.

4.50a Disconnecting the coolant purge hoses from the radiator...

Page 117 of 225

3*2 Cooling, heating and ventilation systems

4 If the motor operates when tested as described, (he fault must lie In the engine wring harness or the temperature sensor. The temperature sensor/switch can be tested as described in Section 6. Any further fault Diagnosis should be referred to a suitably-equipped Fiat dealer - do not attempt to test

Ihe

electronic control unit.

Removal 5 Disconnect the battery negative terminal (refer to D/scon oecf/ng the battery in the Reference Section of this manual). 6 On diesel engine models, unbolt the relay bracket from the side of the battery tray to improve access. On 1242 cc {16-valve) petrol engine models, remove the air cleaner and

inset

ducts as described in Chapter 4B. 1 Disconnect the motor wiring connectorfs). 8 Unbolt the shroud from the rear of the ratiator. then lift out the cooling fan assembly. Refitting 9 Refitting is a reversal of removal

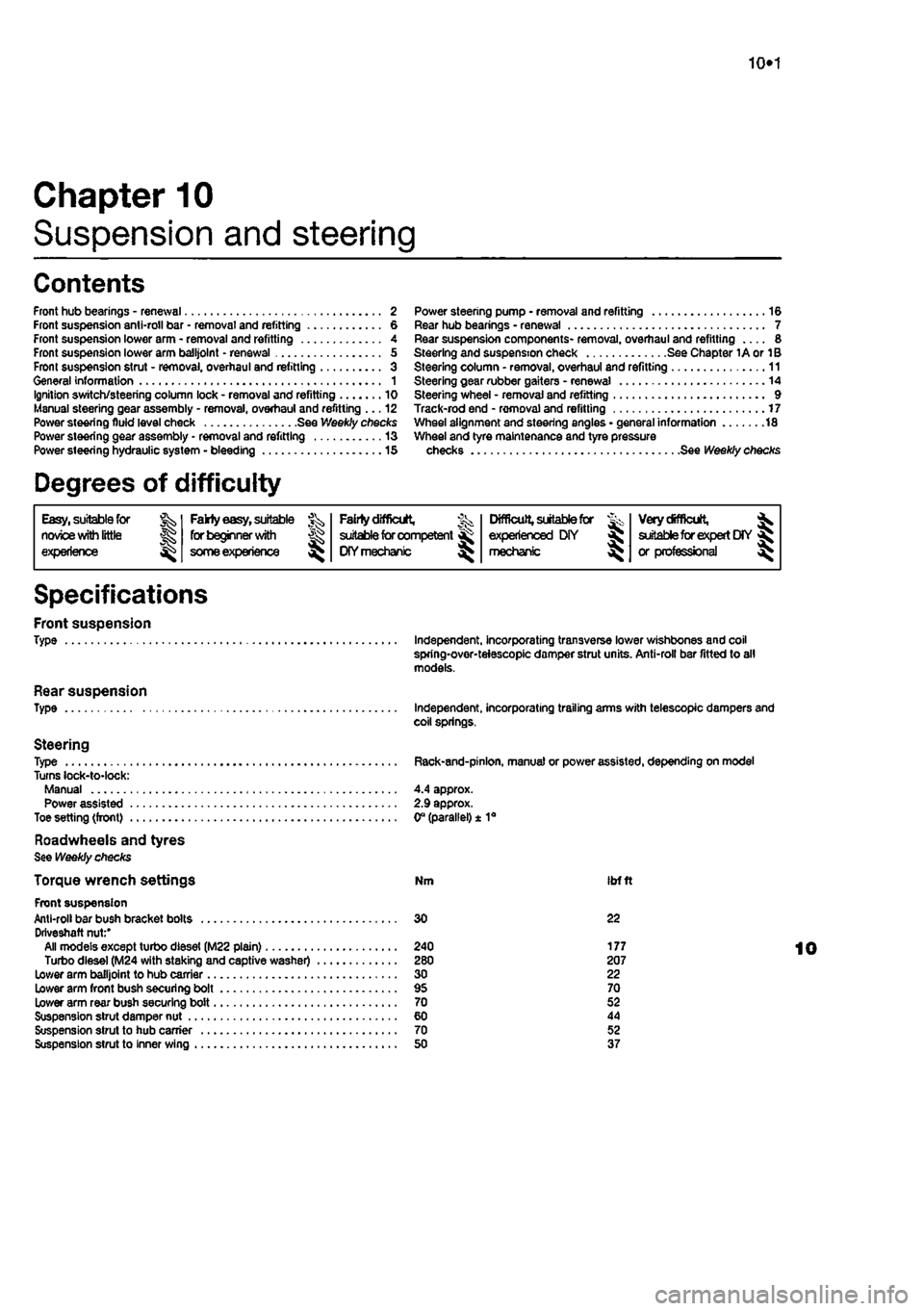

6 Cooling fan switch -testing, removal and refitting ^

Testing 1 The switch is threaded into the lower left

nand

comer of the radiator. 2 The switch can be tested by removing it,

and

checking that the switching action occurs

at

the correct temperature {heat the sensor in a container of water, and monitor the temperature with a thermometer). 3 There should be no continuity between the switch terminals, until Ihe specified cooling fan cut-In temperature Is reached, when continuity (and zero resistance) should exist between the terminals.

Removal 4 Disconnect the battery negative terminal refer to Disconnecting the battery in the Reference Section of this manual). 5 Allow the engine to cool completely, then drain the cooling system as described in Chapter 1Aor 1B. 6 Disconnect the wiring plug from the sensor.

bolts...

7 Carefully unscrew the sensor and. whore applicable, recover the sealing ring. Refitting 8 If the sensor was originally fitted using sealing compound, clean the sensor threads thoroughly, and coat them with fresh sealing compound. 9 If the sensor was originally fitted using a sealing ring, use a new sealing ring on refitting. 10 Refitting is a reversal of removal, but refill the cooling system as described in Chapter 1A or 18. 11 On completion, start the engine and run it until it reaches normal operating temperature. Continue to run the engine until the cooling fan cuts in and out correctly.

7 Coolant pump • & removal, inspection 5 and refitting

Removal

Petrol engine models 1 Disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual). 2 Drain the cooling system and remove the auxiliary drivebett(s) as described In Chapter 1 A. 3 Remove the timing belt as described In Chapter 2A or 28. 4 Unscrew the securing bolts/nuts, and withdraw the coolant pump (see illustrations).

7.9b ... and lift off the pulley (diesel engine)

(petrol engine) If the pump Is stuck, tap it gently using a soft-faced mallet - do not lever between the pump and cylinder block mating faces.

Diesel engine models 5 Disconnect the battery negative terminal (refer to D/s connecting the battery in the Reference Section of this manual). 6 Drain the cooling system as described in Chapter 1B. 7 Remove the auxiliary drivebelt(s) as descnbed In Chapter 1B. 6 On models fitted with power steenng, refer to Chapter 10 and remove the power steering pump from its mountings; this can be achieved without disconnecting the power steering fluid hoses from the pump. Tie the pump away from the work area, taking care to avoid kinking the fluid hoses. 9 Unscrew the securing bolts, and remove the coolant pump pulley. It will be necessary to counterhold the pulley In order to unscrew the bolts, and this is most easily achieved by wrapping an old drivebelt tightly around the pulley to act in a similar manner to a strap 3 wrench. Alternatively, a stout screwdriver can be braced between two of the pulley bolts while the third is slackened (see illustrations). 10 Disconnect ihe bypass hoses from the coolant pump outlet stubs. 11 Unscrew the securing bolts, and withdraw the coolant pump assembly. Note that the pump must be detached from the transfer pipe than runs behind the cylinder block to the thermostat housing (see illustration). The pipe is a push fit in the port on the rear of the coolant pump

7.11 Removing the coolant pump assembly (diesel engine)

Page 189 of 225

10*1

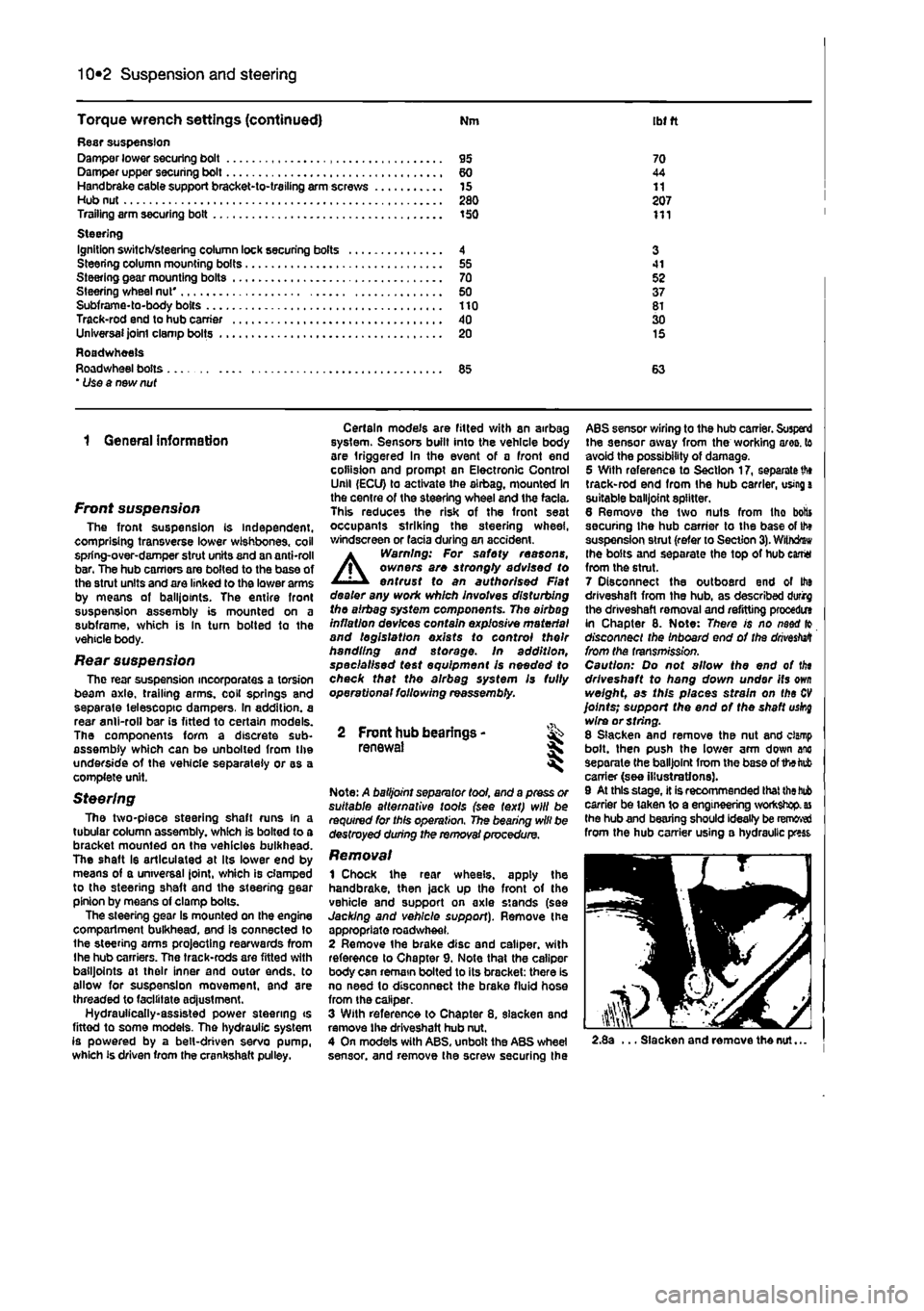

Chapter 10

Suspension and steering

Contents

Front hub bearings - renewal 2 Front suspension anti-roll bar • removal and refitting 6 Front suspension lower arm - removal and refitting 4 Front suspension lower arm balljolnt - renewal 5 From suspension strut - removal, overhaul and refitting 3 General information 1 Ignition switch/steering column lock - removal and refitting 10 Manual steering gear assembly - removal, overhaul and refitting ... 12 Power steering fluid level check See Weekly checks Power steering gear assembly - removal and refitting 13 Power steering hydraulic system - bleeding 15

Degrees of difficulty

Power steering pump • removal and refitting 16 Rear hub bearings - renewal 7 Rear suspension components- removal, overhaul and refitting 8 Steering and suspension check See Chapter 1A or 1B Steering column - removal, overhaul and refitting 11 Steering gear rubber gaiters - renewal 14 Steering wheel - removal and refitting 9 Track-rod end - removal and refitting 17 Wheel alignment and steering angles • general information 18 Wheel and tyre maintenance and tyre pressure checks See Weekly checks

Easy, suitable for nowoe with little

Jg experience ^

Fakty easy,

suitable for beginner

with

J£>

some experience

^

FaMy difficult,

% suitable for competent ^

DIY mechanic

^

Difficult,

suitable for & experienced DIY « mechsmc ^

Very difficult,

^ suitable for expert

DIY

fij or professional ^

Specifications

Front suspension Type

Rear suspension Type

Steering Type Turns lock-to-lock: Manual Power assisted Toe setting (front)

Roadwheeis and tyres See Weekly checks

Torque wrench settings Front suspension Anti-roll bar bush bracket bolts Driveshaft nut:' All models except turbo diesel (M22 plain) Turbo diesel (M24 with staking and captive washer) Lower arm balljoint to hub carrier Lower arm front bush securing bolt Lower arm rear bush securing bolt Suspension strut damper nut Suspension strut to hub carrier Suspension strut to inner wing

Independent, incorporating transverse lower wishbones and coil spring-over-teiescopic damper strut units. Anti-roll bar fitted to all models.

Independent, incorporating trailing arms with telescopic dampers and coil springs.

Rack-and-pinlon, manual or power assisted, depending on model

4.4 approx. 2.9 approx. 0° (parallel) ± 1a

Nm ibfft

30 22

240 177 280 207 30 22 95 70 70 52 60 44 70 52 50 37

Page 190 of 225

Suspension and steering 10*2

Torque wrench settings (continued) Nm ibt ft Rasr suspension Damper lower securing bolt 95 70 Damper upper securing bolt 60 44 Handbrake cable support bracket-to-trailing arm screws 15 11 Hub nut 280 207 Trailing arm securing bolt 150 111 Steering Ignition switch/steering column lock securing bolts 4 3 Steering column mounting bolts 55 41 Steering gear mounting bolts 70 52 Steering wheel nut' 50 37 Subframe-to-body bolts 110 81 Track-rod end to hub carrier 40 30 Unlversaijointclampbolts 20 15 Roadwheels Roadwheel bolts 85 63 * Use a new nut

1 General information

Front suspension The front suspension is independent, comprising transverse lower wishbones, coil spring-over-damper strut units and an anti-roll bar. The hub carriors are bolted to the base of the stmt units and are linked to the lower arms by means ot balliotnts. The entire front suspension assembly is mounted on a subframe, which is In turn botted to the vehicle body.

Rear suspension The rear suspension incorporates a torsion beam axle, trailing arms, coil springs and separate telescopic dampers. In addition, a rear anil-roll bar is fitted to certain models. The components form a discrete sub-assembly which can be unboiled from the underside of the vehicle separately or as a complete unit.

Steering The two-piece steering shaft runs in a tubular column assembly, which is bolted to a bracket mounted on the vehicles bulkhead. The shaft Is articulated at its lower end by means of a universal Joint, which is clamped to the steering shaft and the steering gear pinion by moans of clamp bolts. The steering gear is mounted on the engine compartment bulkhead, and is connected to the steering arms projecting rearwards from Ihe hub carriers. The track-rods are fitted with balljoints at their inner and outer ends, to allow for suspension movement, and are threaded to facilitate ad|ustment. Hydrauiically-assisted power steering ts fittod to some models. The hydraulic system is powered by a belt-driven servo pump, which is driven from the crankshaft pulley.

Certain models are fitted with an airbag system. Sensors built into the vehicle body are triggered in the event of a front end collision and prompt an Electronic Control Unll (ECU) to activate the airbag, mounted In the centre of the steering wheel and the facia. This reduces the risk of the front seat occupants striking the steering wheel, windscreen or facia during an accident.

A

Warning: For safety reasons, owners are strongty advised to entrust to an authorised Flat dealer any work which involves disturbing the airbag system components. The airbag inflation devices contain explosive material and legislation exists to control their handling and storage, in addition, specialised test equipment Is needed to check that the airbag system Is fully operational following reassembly.

2 Front hub bearings -renewal *

Note: A balljoint separator tool, and a press or suitable alternative tools (see text) will be required for this operation. The bearing will be destroyed during the removal procedure.

Removal 1 Chock the rear wheels, apply the handbrake, then jack up the front of the vehicle and support on axle stands (see Jacking and vehicle support). Remove the appropriate roadwheel. 2 Remove the brake disc and caliper, with reference to Chapter 9. Note that the caliper body can remain bolted to its bracket: there is no need lo disconnect the brake fluid hose from the caliper. 3 With reference to Chapter 8. slacken and remove the driveshaft hub nut. 4 On models with ABS, unbolt the ABS wheel sensor, and remove the screw securing the

ABS sensor wiring to the hub carrier. Suspend the sensor away from the working ares, to avoid the possibility of damage. 5 With reference to Section 17, separate

th»

track-rod end from the hub carrier, using

a

suitable balljoint splitter. 6 Remove the two nuts from tho botts securing Ihe hub carrier to the base of th» suspension strut (refer to Section

3).

Withdrew the bolts and separate the top of hub earrtt from the strut. 7 Disconnect the outboard end of Ito driveshaft from the hub, as described durirg the driveshaft removal and refitting procedm in Chapter 8. Note: There is no naod fo disconnect the Inboard end of the

drivestett

from the transmission. Caution: Do not allow the end of tin driveshaft to hang down under its

own

weight, as this places strain on the

CV

joints; support the end of the shaft uskg wire or string. 8 Slacken and remove the nut and clamp bolt, then push the lower arm down anc separate the balljoint from the base of the tab carrier (see illustrations). 9 At this stage, it is recommended that

the bub

carrier be taken to a engineering workshop,

as

the hub and bearing should ideally be removed from the hub carrier using a hydraulic press

2.8a ... Slacken and remove the nut...