Reference FIAT PUNTO 1998 176 / 1.G Manual PDF

[x] Cancel search | Manufacturer: FIAT, Model Year: 1998, Model line: PUNTO, Model: FIAT PUNTO 1998 176 / 1.GPages: 225, PDF Size: 18.54 MB

Page 208 of 225

Bodywork and fittings

11

*7

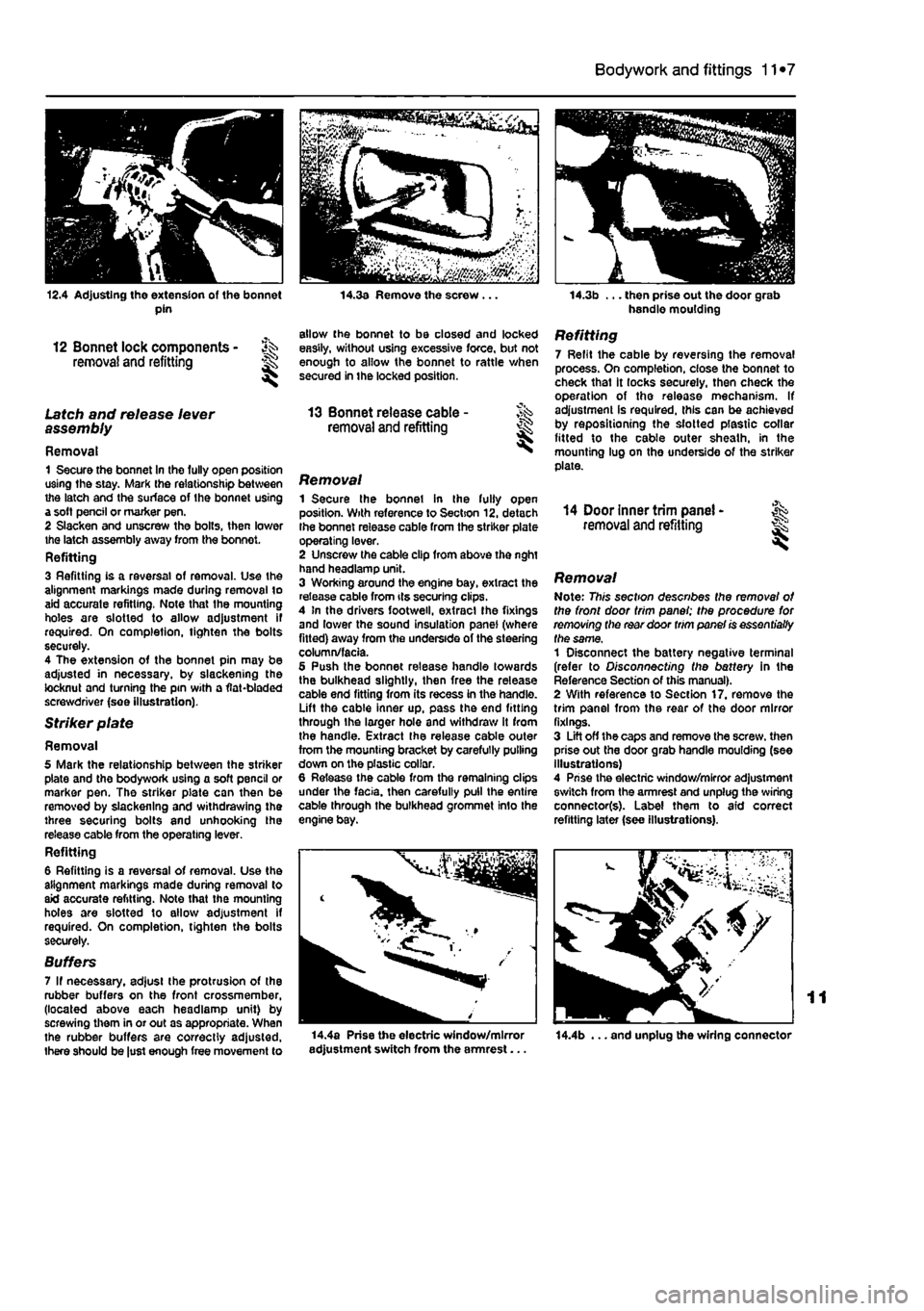

12.4 Adjusting the extension of the bonnet pin

12 Bonnet lock components - ^ removal and refitting H

Latch and release lever assembly

Removal 1 Secure the bonnet In the fully open position using the stay. Mark the relationship between the latch and the surface of the bonnet using a soft pencil or marker pen. 2 Slacken and unscrew the bolts, then lower the latch assembly away from the bonnot. Refitting 3 Refitting is a reversal of removal. Use the alignment markings made during removal to aid accurate refitting. Note that the mounting holes are slotted to allow adjustment if required. On completion, tighten the bolts securely. 4 The extension of the bonnet pin may be adjusted in necessary, by slackening the locknut and turning the pin with a flat-bladed screwdriver (see illustration).

Striker plate

Removal 5 Mark the relationship between the striker plate and the bodywork using a soft pencil or marker pen. The striker plate can then be removed by slackening and withdrawing the three securing bolts and unhooking the release cable from the operating lever. Refitting 6 Refitting is a reversal of removal. Use the alignment markings made during removal to aid accurate refitting. Note that the mounting holes are slotted to allow adjustment if required. On completion, tighten the bolts securely.

Suffers 7 If necessary, adjust the protrusion of the rubber buffers on the front crossmember, (located above each headlamp unit) by screwing them in or out as appropriate. When the rubber buffers are correctly adjusted, there should be just enough free movement to

14.3a Remove the screw .

allow the bonnet to be closed and locked easily, without using excessive force, but not enough to allow the bonnet to rattle when secured in the locked position.

13 Bonnet release cable -removal and refitting I

Removal 1 Secure the bonnet in the fully open position. With reference to Section 12, detach Ihe bonnet release cable from the striker plate operating lever. 2 Unscrew the cable clip from above the nght hand headlamp unit. 3 Working around the engine bay, extract the release cable from its securing clips. 4 In the drivers footweil, extracl Ihe fixings and lower the sound insulation panel (where fitted) away from the underside of the steering column/facia. 5 Push the bonnet release handle towards the bulkhead slightly, then free the release cable end fitting from its recess in the handle. Lift the cable inner up, pass the end fitting through the larger hole and withdraw it from the handle. Extract the release cable outer from the mounting bracket by carefully pulling down on the plastic collar. 6 Release the cable from the remaining clips under the facia, then carefully pull the entire cable through the bulkhead grommet Info the engine bay.

14.3b ... then prise out the door grab handle moulding

Refitting 7 Refit the cable by reversing the removal process. On completion, close the bonnet to check that it locks securely, then check the operation of tho release mechanism. If adjustment is required, this can be achieved by repositioning the slotted plastic collar fitted to the cable outer sheath, in the mounting lug on the underside of the striker plate.

14 Door inner trim panel -removal and refitting I

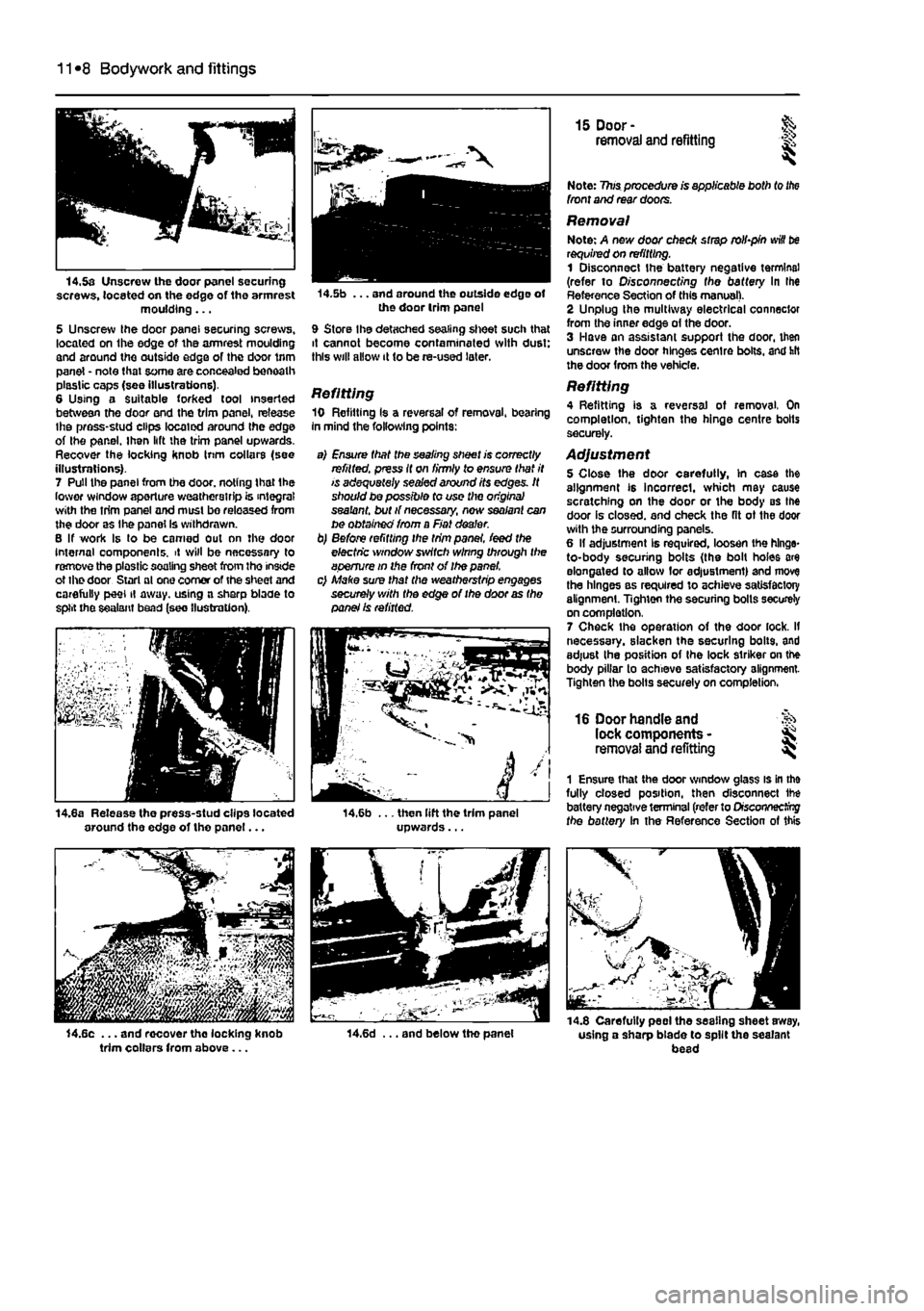

Removal Note: This section describes the removal of the front door trim panel; the procedure for removing the rear door trim panel is essentially the same, 1 Disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual). 2 With reference to Section 17. remove the trim panel from the rear of the door mirror fixings. 3 Lift off the caps and remove the screw, then prise out the door grab handle moulding (see Illustrations) 4 Prise the electric window/mirror adjustment switch from the armrest and unplug the wiring connector(s). Label them to aid correct refitting later (see illustrations).

14.4a Prise the electric window/mirror adjustment switch from the armrest... 14.4b ... and unplug the wiring connector

Page 209 of 225

11

*8 Bodywork and fittings

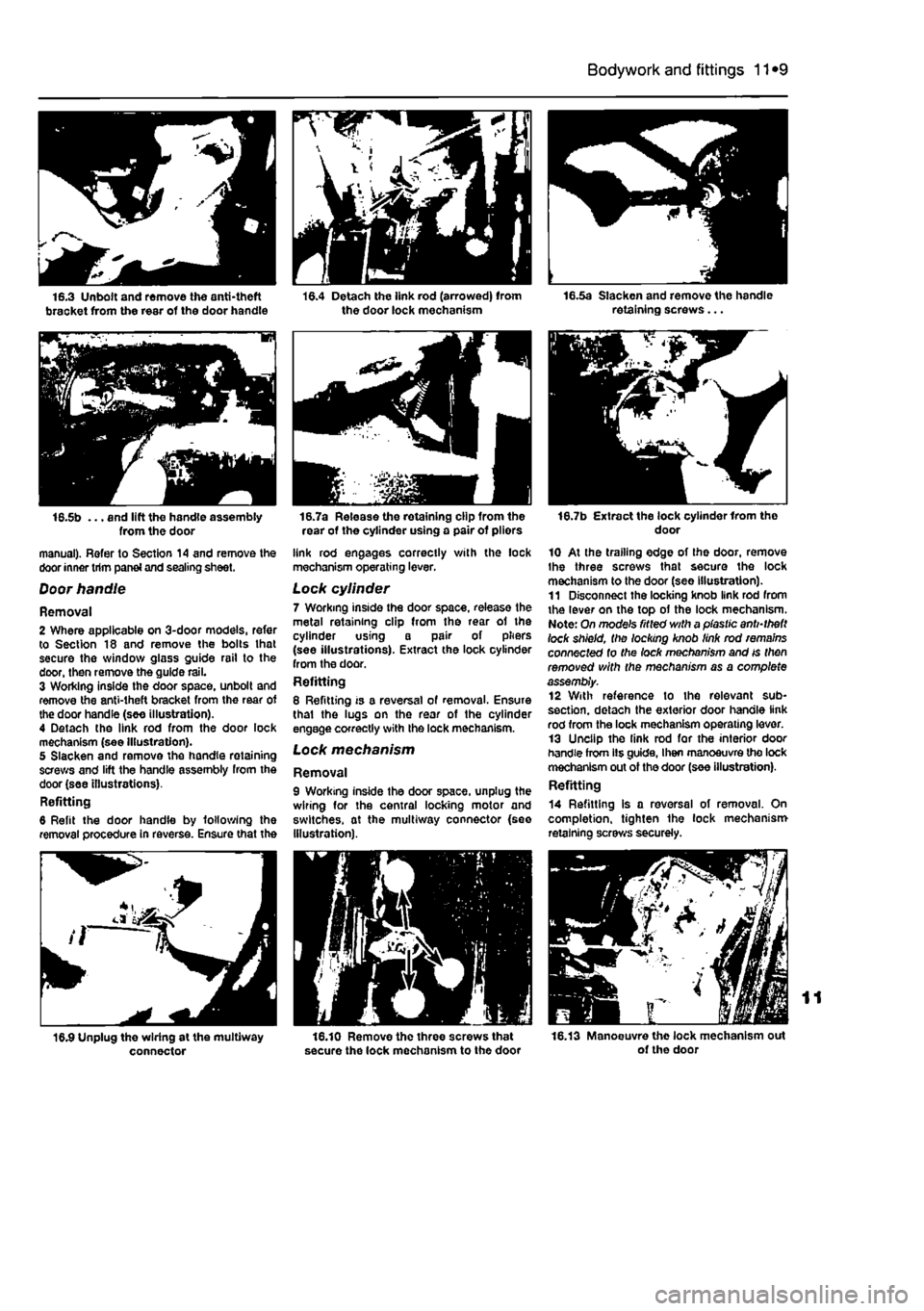

14.5a Unscrew the door panel securing screws, located on the edge of the armrest moulding... 5 Unscrew Ihe door panel securing screws, located on Ihe edge of the armrest moulding and around the outside edge of the door trim panel - note that some are concealed beneath plastic caps (see illustrations). 6 Using a Suitable forked tool inserted between the door end the trim panel, release Ihe press-stud clips located around Ihe edge of Ihe panel. Ihen lift the trim panel upwards. Recover the locking knob Inm collars (see illustrations). 7 Pull the panel from the door, noting that Ihe lower window aperture weatherstrip is integral with the trim panel and must bo released from the door as the panel Is withdrawn. B If work Is lo be earned out nn the door Internal oomponenls. it will be necessary to remove the plastic soaling sheet from tho inside ot the door Starl ol one comer of the sheet and carefully peel il away, using a sharp blade to split the sealant bead (see (lustration).

j

14.8a Release the press-stud clips located around the edge of tho panel...

trim collars from above...

14.5b ... and around the outside edge of the door trim panel

9 Store Ihe detached sealing sheet such that it cannot become contaminated with dust: this will allow it to be re-used later.

Refitting 10 Refilling Is a reversal of removal, bearing in mind the following points:

a) Ensure that the sealing sheet is correctly refitted, press it on firmly to ensure that it is adequately sealed around its edges. It should be possible fo use the origins} sealant, but if necessary, new sealant can be obtained from a Fiat dealer. b) Before refitting the trim panel, feed the electric window switch wlnng through the aperture in the front of Ihe panel. c) Make sure that the weatherstrip engages securely with the edge of the door as the panel Is refitted.

i4,6b ... then lift the trim panel upwards...

14.6d ... and below tho panel

15 Door- & removal and refitting is

Note: 7?ws procedure is applicable both to

the

front and rear doors.

Removal Note: A new door check strap rolbpin

win

be requited on refitting. 1 Disconnect the battery negative terminal (refer to O/sconoecf/ng fhe battery In Ihe Reference Section of this manual). 2 Unplug Ihe multiway electrical connector from the inner edge of the door. 3 Have an assistant support the door, then unscrew the door hinges centre bolts, and hit the door from the vehicle.

Refitting 4 Refitting is a reversal of removal. On completion, tighten the hinge centre bolts securely.

Adjustment 5 Close the door carefully, In case the alignment is incorrect, which may cause scratching on the door or the body BS the door is closed, and check the fit ot the door with the surrounding panels. 6 II adjustment Is required, loosen the hinge-to-body securing bolts (the bolt holes are elongated to allow lor adjustment) and move the hinges as required to achieve satisfactory alignment. Tighten the securing bolls securely on completion. 7 Check the operation of the door lock. If necessary, slacken the securing bolts, and adjust Ihe position of Ihe lock striker on the body pillar to achieve satisfactory alignment-Tighten the bolts securely on completion,

16 Door handle and lock components -removal and refitting ^

1 Ensure that the door window glass is in the fully closed position, then disconnect ihe battery negative terminal (refer to Drscoryiecfrrg fhe battery In the Reference Section of this

•

m-i -14.8 Carefully peel the sealing sheet away, using a sharp blade to spilt the sealant bead

Page 210 of 225

Bodywork and fittings

11

*9

16.5b ... and lift the handle assembly from the door manual). Refer to Section 14 and remove the door inner trim panei and sealing sheet.

Door handle

Removal 2 Where applicable on 3-door models, refer to Section 18 and remove the bolts lhat secure the window glass guide rail to the door, then remove the guide rail. 3 Working inside the door space, unbolt and remove the anti-theft bracket from the rear of the door handle (see illustration). 4 Detach the link rod from the door lock mechanism (see Illustration). 5 Slacken and remove the handle retaining screws and lift the handle assembly from the door (see illustrations). Refitting 6 Refit the door handle by following the removal procedure in reverse. Ensure that the

connector

16.7a Release the retaining clip from the rear of the cylinder using a pair of pliors

link rod engages correctly with the lock mechanism operating lever.

Lock cylinder 7 Working inside the door space, release the metal retaining clip from the rear of the cylinder using a pair of pliers (see illustrations). Extract the lock cylinder from the door. Refitting 8 Refitting is a reversal of removal. Ensure thai the lugs on the rear of the cylinder engage correctly with the lock mechanism. Lock mechanism

Removal 9 Working inside the door space, unplug the wiring for the central locking motor and switches, at the multiway connector {see Illustration).

16.10 Remove the three screws that secure the lock mechanism to the door

16.7b Extract the lock cylinder Irom tho door

10 At the trailing edge of the door, remove Ihe three screws that secure the lock mechanism to the door (see Illustration). 11 Disconnect the locking knob link rod from the lever on the top of the lock mechanism. Note: On mode's fitted with a plastic anti-theft lock shield, the locking knob link rod remains connected to the lock mechanism and is then removed with the mechanism as a complete assembly. 12 With reference to the relevant sub-section. detach the exterior door handle link rod from the lock mechanism operating lever. 13 Unclip the link rod for the interior door handle from lis guide, I hen manoeuvre the lock mechanism out of the door (see illustration). Refitting

14 Refitting is a reversal of removal. On completion, tighten the lock mechanism retaining screws securely.

16.13 Manoeuvre the lock mechanism out of the door

Page 211 of 225

11

*10 Bodywork and fittings

17.3a Prise the rubber cover off the adjustment lever... 17.3b ... then unscrew and remove the locking collar 17.4 Remove the plastic trim panel, to expose the mirror securing screws

Ihe rear of the mirror glass, then push tho glass into position fo engage the securing clips.

To aid re fitting, lightly

grease

^•-.—i the securing dips on the mar IjlllliTj of the mirror glass.

17.5a Remove the securing screws .

17 Exterior mirror components - removal and refitting

Mirror assembly

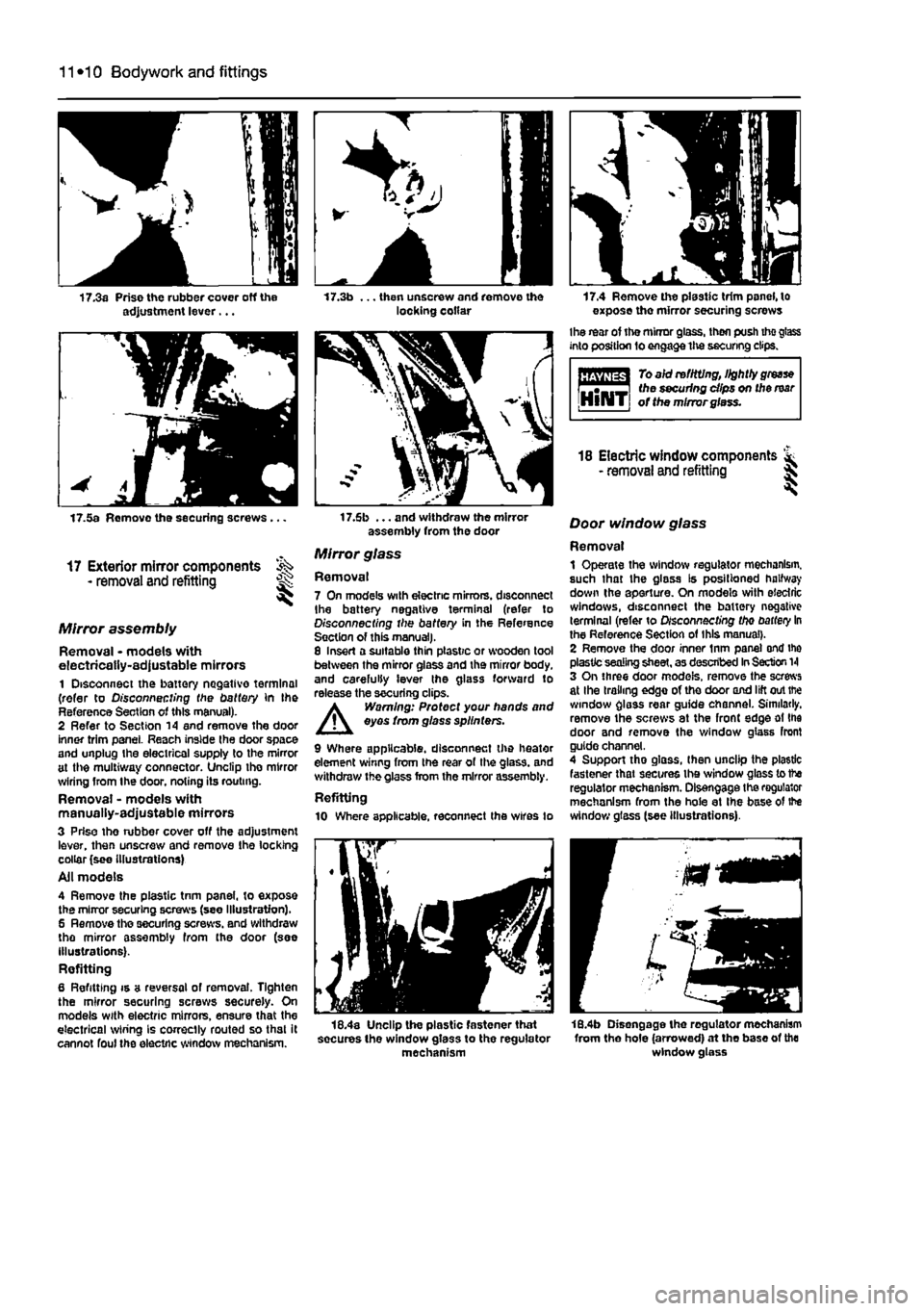

Removal • models with electrically-adjustable mirrors 1 Disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual). 2 Refer to Section 14 and remove the door inner trim panel. Reach inside the door space and unplug the electrical supply to the mirror at the multiway connector. Unclip tho mirror wiring from Ihe door, noting its routing. Removal - models with manually-adjustable mirrors 3 Prise tho nibber cover off the adjustment lever, then unscrew and remove the locking collar (see Illustrations) Ail models 4 Remove the plastic tnm panel, to expose the mirror securing screws (see Illustration). 6 Remove the securing screws, and withdraw the mirror assembly from the door (see illustrations). Refitting 6 Refitting is a reversal of removal. Tighten the mirror securing screws securely. On models with electric mirrors, ensure that the electrical wiring is correctly routed so that it cannot foul the electric window mechanism.

17.6b ... and withdraw the mirror assembly from the door

Mirror glass

Removal 7 On models with electric mirrors, disconnect Ihe battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual). 8 Insert a suitable thin plastic or wooden tool between the mirror glass and the mirror body, and carefully lever the glass forward to release the securing clips. A Warning: Protect your hands and eyes from glass sp//nfers.

9 Where applicable, disconnect the heater element winng from the rear of the glass, and withdraw the glass from the mirror assembly. Refitting 10 Where applicable, reconnect the wires to

18 Electric window components & - removal and refitting 5

Door window glass

Removal 1 Operate the window regulator mechanism, such that the glass Is positioned halfway down the aperture. On modelo with electric windows, disconnect the battery negative terminal (refer to Disconnecting tho

battery

In the Reference Section of this manual). 2 Remove the door inner inm pane) ond ihe plastic sealing sheet, as described

In

Section

1

3 On three door models, remove the screws at Ihe trailing edge of the door and lift out the window glass rear guide channel. Similarly, remove the screws at the front edge at the door and remove the window glass front guide channel. 4 Support tho glass, (hen unclip the plastic fastener that secures the window glass to the regulator mechanism. Disengage the regulator mechanism from the hole at Ihe base of the window glass (see illustrations).

18.4a Unclip the plastic fastener that socures the window glass to the regulator mechanism

18.4b Disengage the regulator mechanism from the hole (arrowed) at the base of the window glass

Page 212 of 225

Bodywork and fittings

11

*11

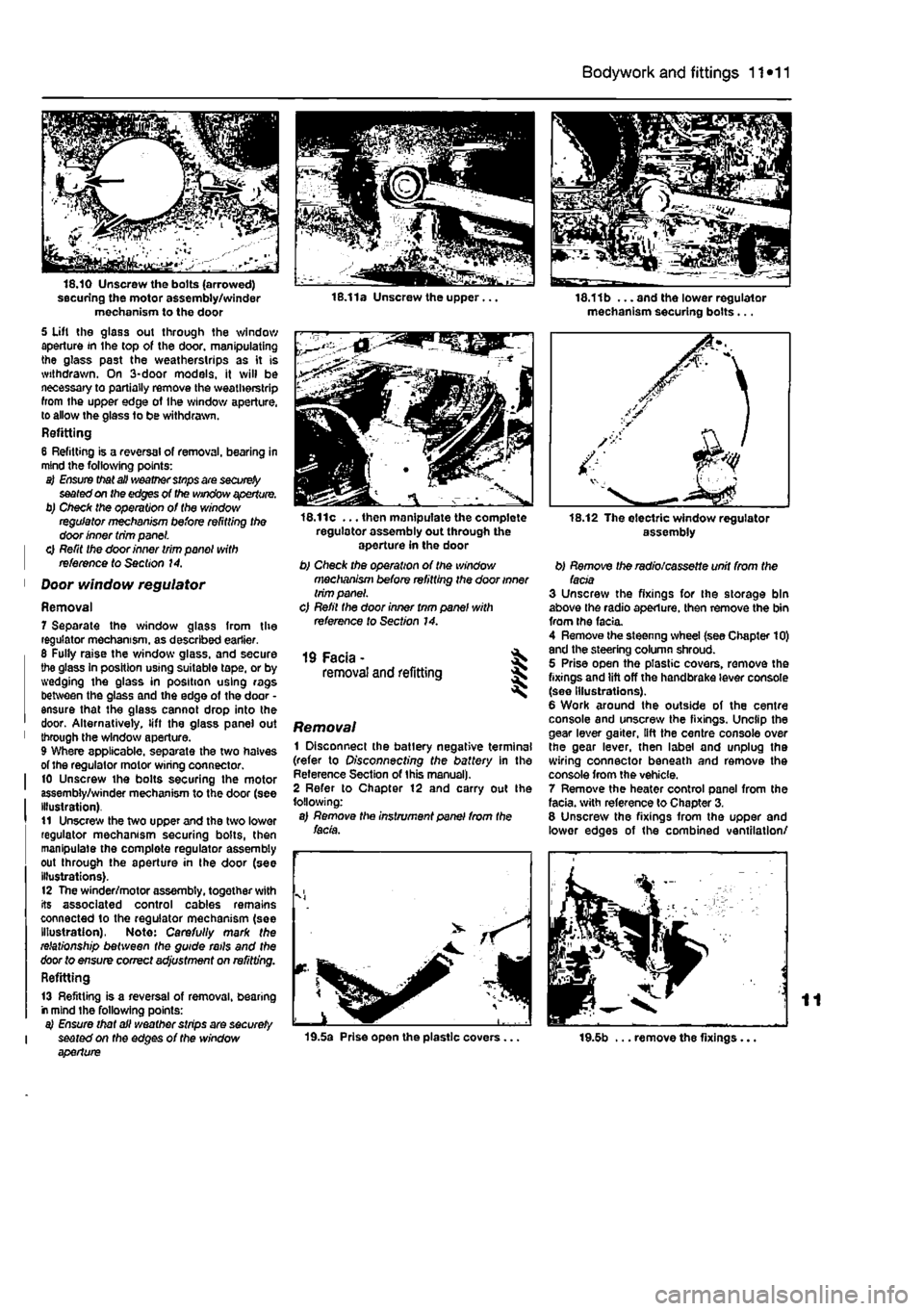

securing the motor assembly/winder mechanism to the door 5 Uft the glass out through the window aperture in the top of the door, manipulating the glass past the weatherstrips as it is withdrawn. On 3-door models, it will be necessary to partially remove the weatherstrip from the upper edge of Ihe window aperture, to allow the glass to be withdrawn. Refitting 6 Refitting is a reversal of removal, bearing in mind the following points: a) Ensure that all weather stnps are

securely

seated on the edges of the window aperture. b) Check the operation of the window regulator mechanism before refitting the door inner trim panel. | 0 Refit the door inner trim panel with | reference to Section 14.

1 Door window regulator

Removal 7 Separate the window glass from the regulator mechanism, as described earlier. 6 Fully raise the window glass, and secure the glass In position using suitable tape, or by wedging the glass in position using rags between the glass and the edge of the door • ensure that the glass cannot drop into the door. Alternatively, lift the glass panel out 1 through the window aperture. 9 Where applicable, separate the two halves of the regulator motor wiring connector. I 10 Unscrew the bolts securing the motor assembly/winder mechanism to the door (see Illustration). t1 Unscrew the two upper and the two lower regulator mechanism securing bolts, then manipulate the complete regulator assembly out through the aperture in the door (see illustrations). 12 The winder/motor assembly, together with its associated control cables remains connected to the regulator mechanism (see Illustration), Note: Carefully mark the relationship between the guide rails and the door to ensure correct adjustment on refitting. Refitting

13 Refitting is a reversal of removal, bearing r mind the following points: a) Ensure that all weather strips are securely I seated on the edges of the window aperture

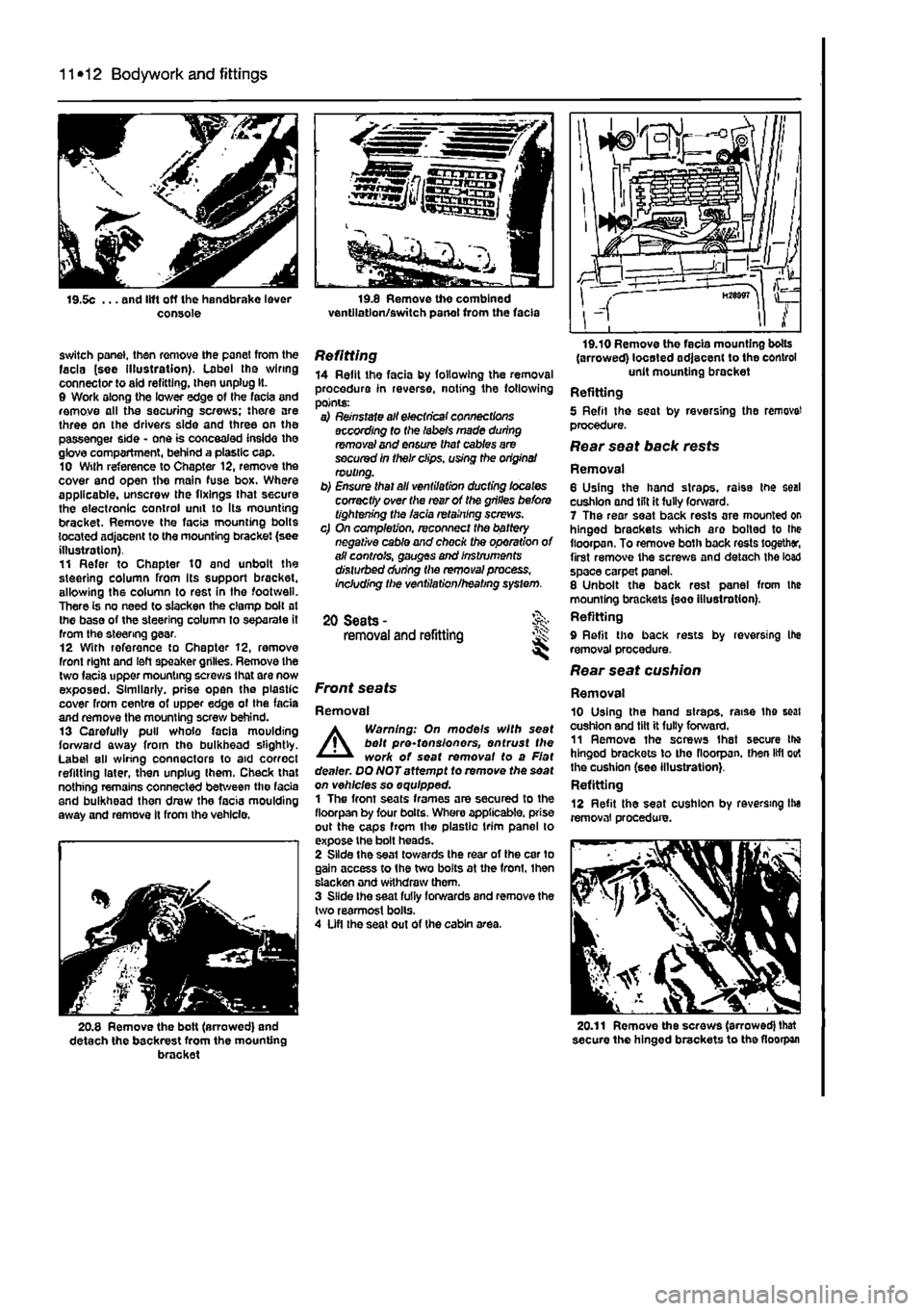

16.11c ... then manipulate the complete regulator assembly out through the aperture in the door b) Check the operation of the window mechanism before refitting the door inner trim panel. c) Refil the door inner tnm panel with reference to Section 14.

19 Facia - ^ removal and refitting 5

Removal 1 Disconnect the batlery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual). 2 Refer to Chapter 12 and carry out Ihe following: a) Remove the instrument panel from the facia.

19.5a Prise open the plastic covers...

18.11b ... and the lower regulator mechanism securing bolts...

assembly

b) Remove the radio/cassette unit from the facia 3 Unscrew the fixings for the storage bin above the radio aperture, then remove the bin from the facia. 4 Remove the steenng wheel (see Chapter 10) and the steering column shroud. 5 Prise open the plastic covers, remove the fixings and lift off the handbrake lever console (see Illustrations). 6 Work around the outside of the centre console and unscrew the fixings. Unclip the gear lever gaiter, lift the centre console over the gear lever, then label and unplug the wiring connector beneath and remove the console from the vehicle. 7 Remove the heater control panel from the facia, with reference to Chapter 3. 8 Unscrew the fixings from the upper and lower edges of the combined ventilation/

19.5b ... remove the fixings...

Page 213 of 225

11 *12 Bodywork and fittings

switch panel, then remove the panel from the facia (see illustration). Label tho wiring connector to aid refitting, then unplug It. 0 Work along the lower edge of Ihe facia and remove all the securing screws; there are three on the drivers side and three on the passenger side - one is concealed inside the glove compartment, behind a plastic cap. 10 Wilh reference to Chapter 12, remove the cover and open the main fuse box. Where applicable, unscrew the fixings that secure the electronic control unit to Its mounting bracket. Remove the facia mounting bolts located adjacent to the mounting bracket (see illustration). 11 Refer to Chapter 10 and unbolt the steering column from Its support bracket, allowing the column to rest in the footwell. There is no need to slacken the clamp bolt at Ihe base of the steering column to separate it from the steering gear. 12 With reference to Chapter 12, remove front right and left speaker grilles. Remove the two facis upper mounting screws ihat are now exposed. Similarly, prise open the plastic cover from centre of upper edge of the fada and remove the mounting screw behind. 13 Carefully pull whole facia moulding forward away from tho bulkhead slightly. Label all wiring connectors to aid correct refitting later, then unplug Ihem. Check that nothing remains connected between the facia and bulkhead then draw the facia moulding away and remove It from the vehicle.

20.8 Remove the bolt (arrowed) and detach the backrest from the mounting bracket

Refitting 14 Refit the facia by following the removal procedure in reverse, noting the following points: a) Reinstate all electrical connections according to (he labels made during removal and ensure that cables are secured in their clips, using the origins/ routing. b) Ensure thai all ventilation ducting locates correctly over the rear of the grilles before tightening the facia retaining screws. c) On completion, reconnect the battery negative cable and chock the operation of all controls, gauges and Instruments disturbed during the removal process, Including the ventilation/heating system.

20 Seats -removal and refitting JS:

Front seats

Removal

A

Warning: On models with seat belt pre-tonsionors, entrust the work of seat removal to a Flat dealer. DQNOTattempt to remove the seat on vehicles so equipped. 1 The front seats frames are secured to the fioorpan by four bolts. Whero applicable, prise out the caps from the plastic trim panel lo expose the bolt heads. 2 Slide the seat towards the rear of the car to gain access to the two bolts at the front, Ihen slacken and withdraw them. 3 Slide Ihe seat fully forwards and remove the two rearmost bolls. 4 Ufl the seat out of the cabin area.

(arrowed) located adjacent to the control unit mounting bracket Refitting 5 Refil the seat by reversing the remove! procedure. Rear seat back rests

Removal 6 Using the hand straps, raise the seal cushion and lilt it fully forward. 7 The rear seat back rests are mounted or hinged brackets which aro boiled to Ihe fioorpan. To remove both back rests together, first remove the screws and detach the load space carpet panel. 8 Unbolt the back rest panel from the mounting brackets (see illustration). Refitting 9 Refit tho back rests by reversing Ihe removal procedure. Rear seat cushion

Removal 10 Using the hand straps, raise the seat cushion and tilt it fully forward. 11 Remove ihe screws Ihat secure Ihe hinged brackets to tho fioorpan. then lift out the cushion (see illustration}. Refitting 12 Refit the seat cushion by reversing Ihe removal procedure.

20.11 Remove the screws (arrowed) that secure the hinged brackets to the fioorpan

Page 214 of 225

10*1

Chapter 12

Body electrical systems

Contents

Bulbs (exterior lights) - renewal 4 Bulbs (interior lights) - renewal 5 Electrical fault finding - general information 2 Exterior light units - removal and refitting 6 Fuses and relays - general Information 3 General information and precautions 1 Headlight beam alignment • general Information 6 Horn • removal and refitting 9 Instrument panel - removal and refitting 7 Loudspeakers - removal and refitting 10

Degrees of difficulty

Radio aerial - removal and refitting 11 Radio/cassette player • removal and refitting 12 Speedometer drive cable - removal and refitting 13 Switches - removal end refitting 14 Tailgate wiper motor - removal and refitting 15 Windscreen wiper motor - removal and refitting 17 Windscreen/tailgate washer system components • removal and refitting 16 Wiper arm • removal and refitting 18

Easy,

statable for ^

novice with liffle

|| experience ^

Fairly

easy,

suitable for beginner with ^ some experience ^

Fabtycffficiit,

suitable

for competent ^

DIY

mechanic ^

Difficult, suitable for

^ experienced DIY JR mechanic

Very difficult,

A,

suitable

for

expert DIY

Sj or professional ^

Specifications

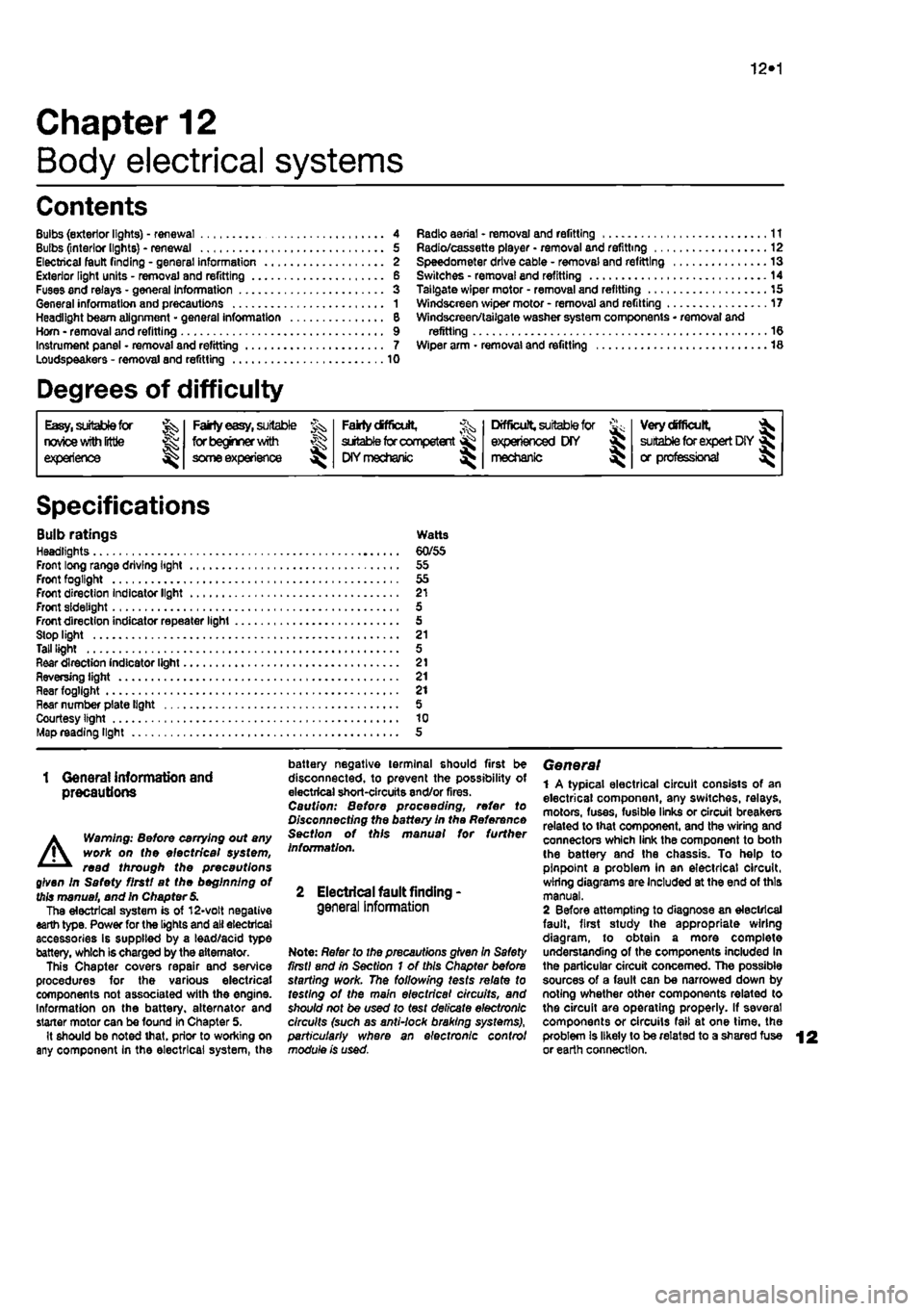

Bulb ratings Watts Headlights 60/55 Front long range driving light 55 Front fogllght 55 Front direction Indicator light 21 Front sidelight 5 Front direction indicator repeater light 5 Stop light 21 Tall light 5 Rear direction indicator light 21 Reversing light 21 near fogllght 21 Hear number plate light 5 Courtesy light 10 Map reading light 5

1 Genera! information and precautions

A

Warning: fie/Ore carrying out any work on the electrical system, read through the precautions given in Safety first! at the beginning of this manual, and in Chapter 8. The electrical system is of 12-volt negative earth type. Power for the lights and all electrical accessories is supplied by a lead/acid type battery, which is charged by the alternator. This Chapter covers repair and service procedures for the various electrical components not associated with the engine. Information on the battery, alternator and starter motor can be found in Chapter 5. It should be noted that, prior to working on any component In the electrical system, the

battery negative terminal should first be disconnected, to prevent the possibility of electrical short-circuits and/or fires. Caution: Before proceeding, refer to Disconnecting the battery In the Reference Section of this manual for further information.

2 Electrical fault finding-general information

Note: Refer to the precautions given In Safety first! and in Section 1 of this Chapter before starting work. The following tests relate to testing ot the main electrical circuits, and should not be used to test delicate electronic circuits (such as antHock braking systems), particularly where an electronic con fro/ module is used.

General 1 A typical electrical circuit consists of an electrical component, any switches, relays, motors, fuses, fusible links or circuit breakers related to that component, and the wiring and connectors which link the component to both the battery and the chassis. To help to pinpoint a problem in an electrical circuit, wiring diagrams are Included at the end of this manual. 2 Before attempting to diagnose an electrical fault, first study the appropriate wiring diagram, to obtain a more complete understanding of the components included In the particular circuit concerned. The possible sources of a fault can be narrowed down by noting whether other components related to the circuit are operating properly. If several components or circuits fait at one time, the problem Is likely to be related to a shared fuse or earth connection.

Page 219 of 225

12*6 Body electrical systems

4.39a Remove the screws...

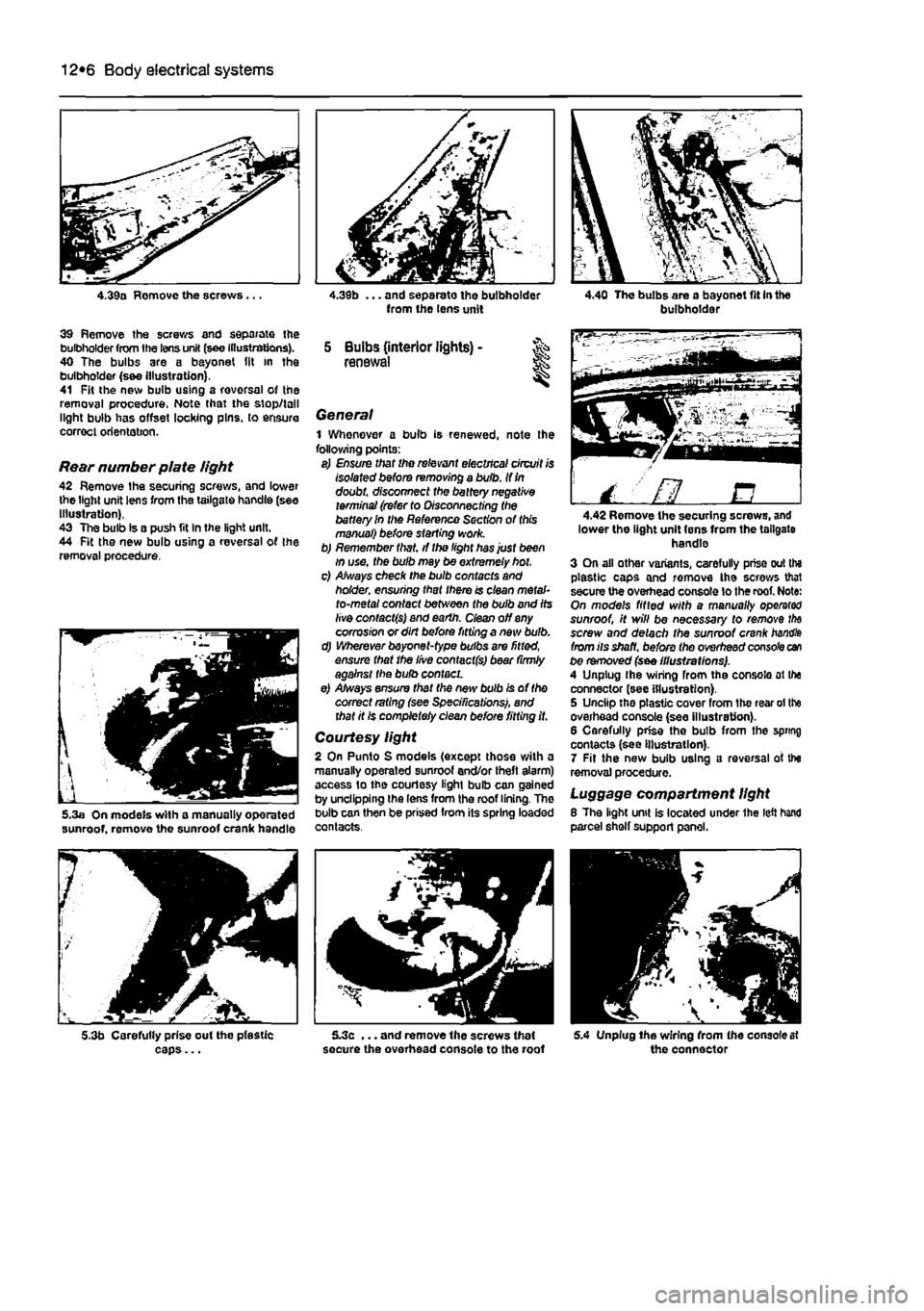

39 Remove the screws and separate the bulbholder from the lens unit (see Illustrations). 40 The bulbs are a bayonet (it in the bulbholder (s&e Illustration), 41 Fit the new bulb using a rovorsal of the removal procedure. Note that the stop/tall light bulb has offset locking pins, to ensure correct orientation.

Rear number plate light 42 Remove the securing screws, and lower the light unit lens from the tailgate handle (see Illustration), 43 The bulb Is a push fit In the light unit. 44 Fit the new bulb using a reversal of the removal procedure.

5.3a On models with a manually oporated sunroof, remove the sunroof crank handle

5.3b Carefully prise out the pfestic caps...

from the lens unit

5 Bulbs (interior lights) -renewal

General 1 Whenever a bulb is renewed, note Ihe following points: a) Ensure that the relevant electrical circuit is Isolated before removing a bulb. If

In

doubt, disconnect the battery negative terminal (refer to Disconnecting the battery In the Reference Section of this manual) before starting work. b) Remember that, if the light has just been in use, the bulb may be extremely hot. c) Always check the bulb contacts and holder, ensuring that there is clean metal-to-metal contact between the bulb and its live contacts) and earth, dean off any corrosion or dirt before fitting a new bulb. d) Wherever bayonet-type bulbs are fitted, ensure that the live contact(s) bear (irmly against the bulb contact. e) Always ensure that the new bulb is of the correct rating (see Specifications), and that it Is completely clean before fitting it.

Courtesy light 2 On Punto S models (except those with a manually operated sunroof end/or theft alarm) access to the courtesy light bulb can gained by unclipping the lens from the roof lining. The bulb can then be prised from its spring loaded contacts.

5.3c ... and remove the screws that secure the overhead console to the roof

buibhoidai

/ ' fl B 4.42 Remove the securing screws, and lower the light unit lens from the tailgate handle 3 On all other variants, carefully prise out the plastic caps and remove the screws that secure the overhead console lo the roof. Note: On models fitted with a manually operator sunroof, it will be necessary to remove

the

screw and detach the sunroof crank

handle

from its shaft, before the overhead console can be removed (see illustrations). A Unplug Ihe wiring from the console at the connector (see illustration). 5 Unciip the plastic cover from the rear ol the overhead console (see illustration). 6 Carefully prise the bulb from the spring contacts (see Illustration). 7 Fit the new bulb using a reversal of the removal procedure.

Luggage compartment light 8 The light unit is located under 1he left hand parcel shelf support panel.

5.4 Unplug Ihe wiring from (he console at the connector

Page 220 of 225

Body electrical systems 12*7

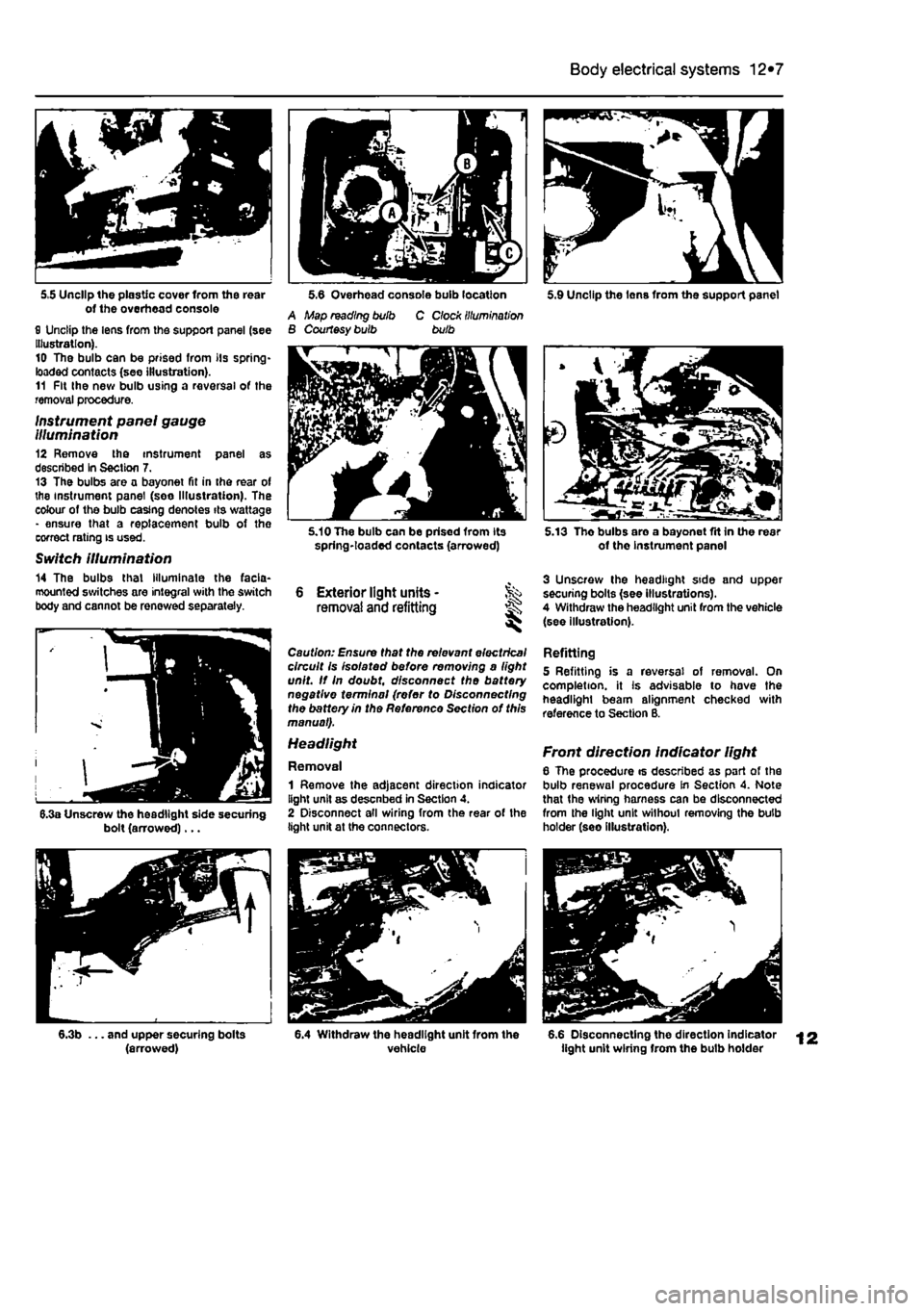

5,5 Unclip the plastic cover from the rear of the overhead console 0 Unclip the lens from the support panel (see Illustration). 10 The bulb can be prised from its spring-loaded contacts (see illustration). 11 Fit the new bulb using a reversal of the removal procedure.

Instrument panel gauge Illumination 12 Remove the instrument panel as described In Section 7. 13 The bulbs are a bayonet fit in the rear of the instrument panel (see Illustration). The colour of the bulb casing denotes its wattage - ensure that a replacement bulb of the correct rating is used.

Switch illumination 14 The bulbs that Illuminate the facia-mounted switches are integral with the switch body and cannot be renewed separately.

5.6 Overhead console bulb location 5.9 Unclip the Ions from the support panel A Map reading bulb B Courtesy bulb C Clock illumination bulb

6.3a Unscrew the headlight side securing bolt (arrowed)...

5.10 The bulb can be prised from its spring-loaded contacts (arrowed)

6 Exterior light units • removal and refitting ^ ^

Caution: Ensure that the relevant electrical circuit is isolated be/ore removing a light unit. If In doubt, disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual).

1 Remove the adjacent direction indicator light unit as descnbed in Section 4. 2 Disconnect all wiring from the rear of the light unit at the connectors.

5.13 Tho bulbs are a bayonet fit in the rear of the instrument panel

3 Unscrew the headlight side and upper securing bolts (see illustrations). 4 Withdraw the headlight unit from the vehicle (see illustration).

Refitting 5 Refitting is a reversal of removal. On completion, it Is advisable to hove the headlight beam alignment checked with reference to Section B.

Front direction indicator light 6 The procedure is described as part of the bulb renewal procedure In Section 4. Note that the wiring harness can be disconnected from the light unit without removing the bulb holder (seo illustration).

6.3b ... and upper securing bolts (arrowed) 6.4 Withdraw the headlight unit from the vehicle 6.6 Disconnecting the direction indicator light unit wiring from the bulb holder

Page 221 of 225

12*8 Body electrical systems

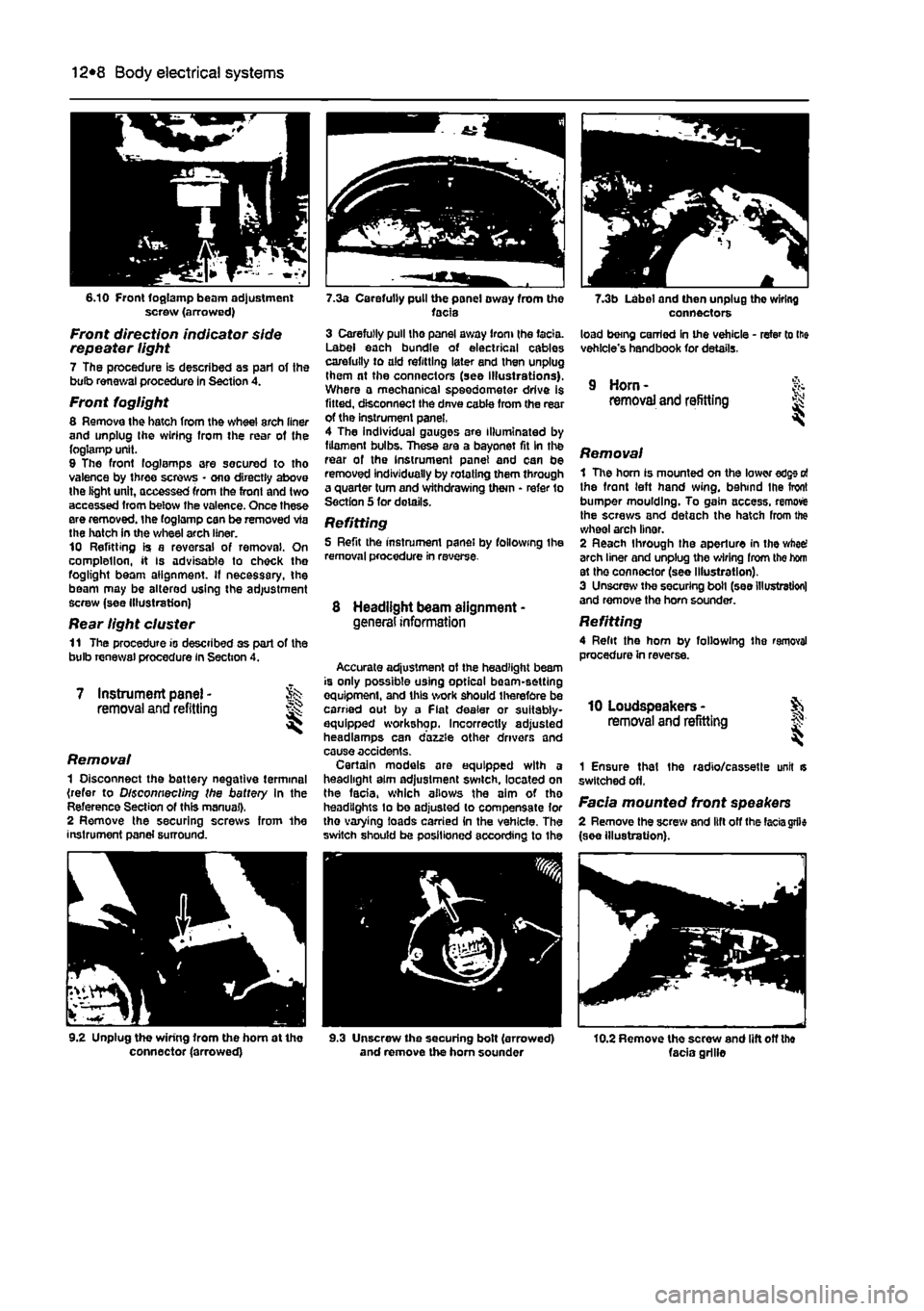

6.10 Front foglamp beam adjustment screw (arrowed)

Front direction indicator side repeater light 7 The procedure is described as pari of the bulb renewal procedure In Section 4.

Front foglight 8 Remove the hatch from the wheel arch liner and unplug Ihe wiring Irom the rear of the foglamp unit. 9 The front foglamps are secured to tho valence by three screws • one directly above the light unit, accessed from the front and two accessed Irom below the valence. Once these ere removed, the foglamp can be removed via the hatch in the wheel arch liner. 10 Refitting is a reversal of removal. On complellon, it Is advisable to check the foglight beam alignment. If necessary, the beam may be altered using the adjustment screw (see Illustration)

Rear light cluster 11 The procedure is described as part of the bulb renewal procedure in Section 4.

7 Instrument panel -removal and refitting

Removal 1 Disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual). 2 Remove the securing screws from 1he instrument panel surround.

9.2 Unplug the wiring from the hom at tho connector (arrowed)

7.3a Carefully pull the panel oway from the facia 3 Carefully pull tho panel away from (he facia. Label each bundle of electrical cables carefully to old refitting later end then unplug them nt the connectors (see illustrations). Where a mechanical speedometer drive is fitted, disconnect the dnve coble from the rear of the instrument panel, 4 The individual gauges are Illuminated by filament bulbs. These are a bayonet fit In the rear of the Instrument panel and can be removed individually by rotating them through a quarter turn and withdrawing them • refer to Section 5 for details.

Refitting 5 Refit the instrument panel by following the removal procedure in reverse

8 Headlight beam alignment -general information

Accurate adjustment ot the headlight beam is only possible using optical beam-setting equipment, and this work should therefore be carried out by a Fiat dealer or suitably-equipped workshop. Incorrectly adjusted headlamps can dazzle other drivers and cause accidents. Certain models are equipped with a headlight aim adjustment switch, located on the facia, which allows the aim of tho headlights lo be adjusted to compensate lor tho varying loads carried in the vehicle. The switch should be positioned according to Ihe

9.3 Unscrew the securing bolt (arrowed) and remove the horn sounder

7.3b Label and then unplug the wiring connectors load being carried in the vehicle - refer to lie vehicle's handbook for details.

9 Horn -removal and refitting

Removal 1 The horn is mounted on the lower edge o! the front left hand wing, behind Ihe front bumper moulding. To gain access, remove the screws and detach the hatch from the wheel arch linor. 2 Reach through the aperture in the wheel arch liner and unplug the wiring Irom the hom st the connector (see Illustration). 3 Unscrew the securing boll (see Illustration) and remove the horn sounder.

Refitting 4 Refit the hom by following the removal procedure in reverse.

10 Loudspeakers -removal and refitting §;

1 Ensure that the radio/cassette unit is switched off.

Facia mounted front speakers 2 Remove the screw and lift off the

facia

grfle (see illustration).

10.2 Remove tho screw and lift off the facia grille