brake FIAT SCUDO 2011 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2011, Model line: SCUDO, Model: FIAT SCUDO 2011Pages: 210, PDF Size: 3.29 MB

Page 141 of 210

140

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

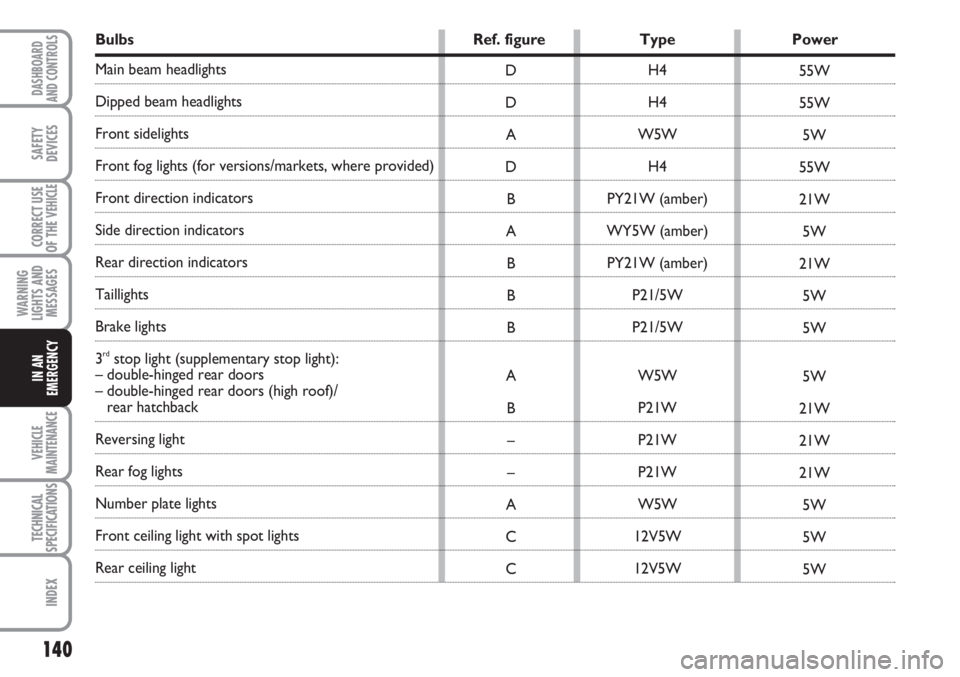

Bulbs Ref. figure Type Power

Main beam headlights

Dipped beam headlights

Front sidelights

Front fog lights (for versions/markets, where provided)

Front direction indicators

Side direction indicators

Rear direction indicators

Taillights

Brake lights

3

rdstop light (supplementary stop light):

– double-hinged rear doors

– double-hinged rear doors (high roof)/

rear hatchback

Reversing light

Rear fog lights

Number plate lights

Front ceiling light with spot lights

Rear ceiling lightH4

H4

W5W

H4

PY21W (amber)

WY5W (amber)

PY21W (amber)

P21/5W

P21/5W

W5W

P21W

P21W

P21W

W5W

12V5W

12V5W D

D

A

D

B

A

B

B

B

A

B

–

–

A

C

C55W

55W

5W

55W

21W

5W

21W

5W

5W

5W

21W

21W

21W

5W

5W

5W

Page 144 of 210

143

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

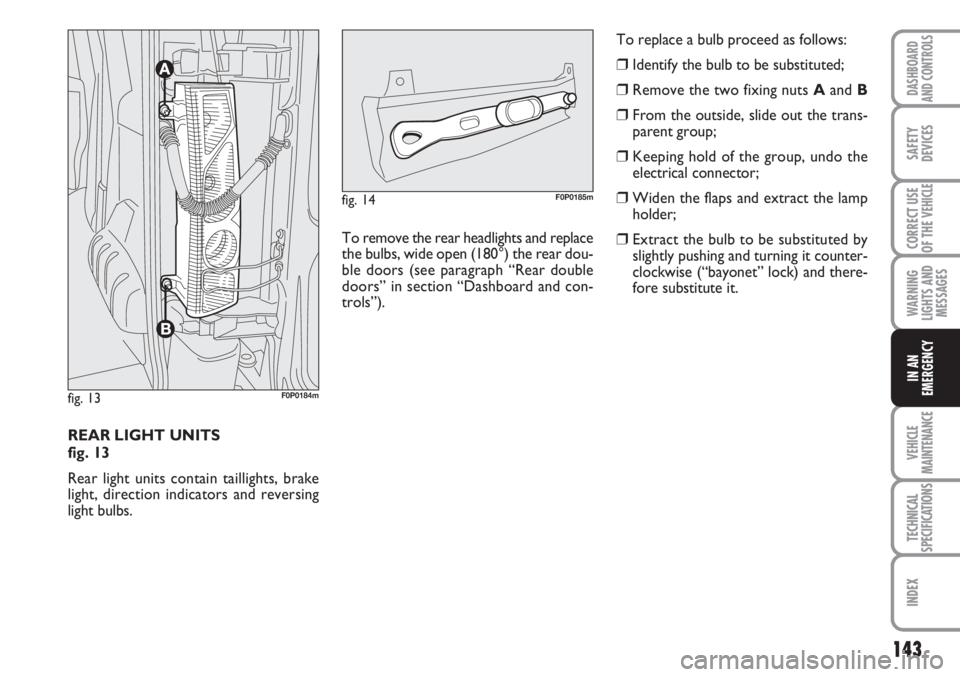

REAR LIGHT UNITS

fig. 13

Rear light units contain taillights, brake

light, direction indicators and reversing

light bulbs.

fig. 13F0P0184m

To remove the rear headlights and replace

the bulbs, wide open (180°) the rear dou-

ble doors (see paragraph “Rear double

doors” in section “Dashboard and con-

trols”).

fig. 14F0P0185m

To replace a bulb proceed as follows:

❒Identify the bulb to be substituted;

❒Remove the two fixing nuts Aand B

❒From the outside, slide out the trans-

parent group;

❒Keeping hold of the group, undo the

electrical connector;

❒Widen the flaps and extract the lamp

holder;

❒Extract the bulb to be substituted by

slightly pushing and turning it counter-

clockwise (“bayonet” lock) and there-

fore substitute it.

Page 145 of 210

144

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

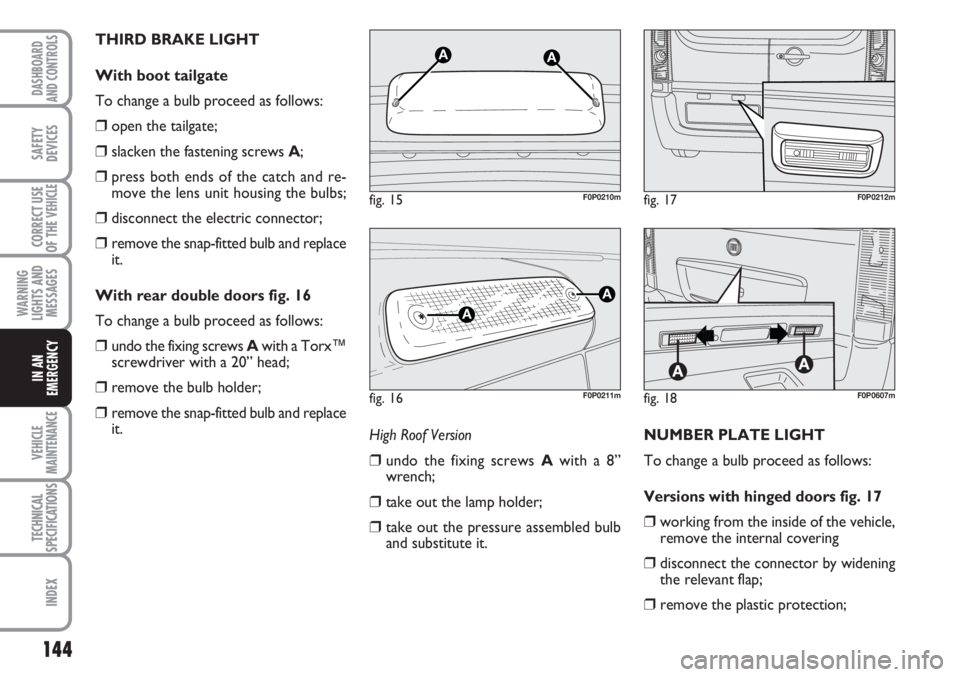

THIRD BRAKE LIGHT

With boot tailgate

To change a bulb proceed as follows:

❒open the tailgate;

❒slacken the fastening screws A;

❒press both ends of the catch and re-

move the lens unit housing the bulbs;

❒disconnect the electric connector;

❒remove the snap-fitted bulb and replace

it.

With rear double doors fig. 16

To change a bulb proceed as follows:

❒undo the fixing screws Awith a Torx™

screwdriver with a 20” head;

❒remove the bulb holder;

❒remove the snap-fitted bulb and replace

it.

NUMBER PLATE LIGHT

To change a bulb proceed as follows:

Versions with hinged doors fig. 17

❒working from the inside of the vehicle,

remove the internal covering

❒disconnect the connector by widening

the relevant flap;

❒remove the plastic protection;

fig. 15

AA

F0P0210m

fig. 16

A

A

F0P0211m

fig. 17F0P0212m

fig. 18F0P0607m

High Roof Version

❒undo the fixing screws Awith a 8”

wrench;

❒take out the lamp holder;

❒take out the pressure assembled bulb

and substitute it.

Page 149 of 210

148

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

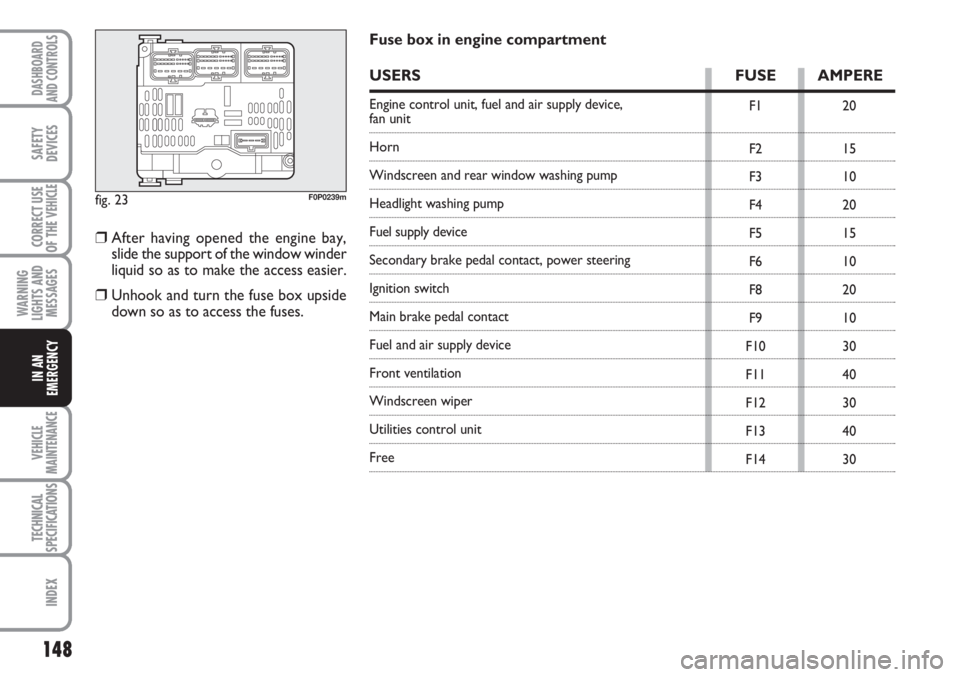

fig. 23F0P0239m

F1

F2

F3

F4

F5

F6

F8

F9

F10

F11

F12

F13

F1420

15

10

20

15

10

20

10

30

40

30

40

30

Fuse box in engine compartment

USERS FUSE AMPERE

Engine control unit, fuel and air supply device, fan unit

Horn

Windscreen and rear window washing pump

Headlight washing pump

Fuel supply device

Secondary brake pedal contact, power steering

Ignition switch

Main brake pedal contact

Fuel and air supply device

Front ventilation

Windscreen wiper

Utilities control unit

Free

❒After having opened the engine bay,

slide the support of the window winder

liquid so as to make the access easier.

❒Unhook and turn the fuse box upside

down so as to access the fuses.

Page 153 of 210

152

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

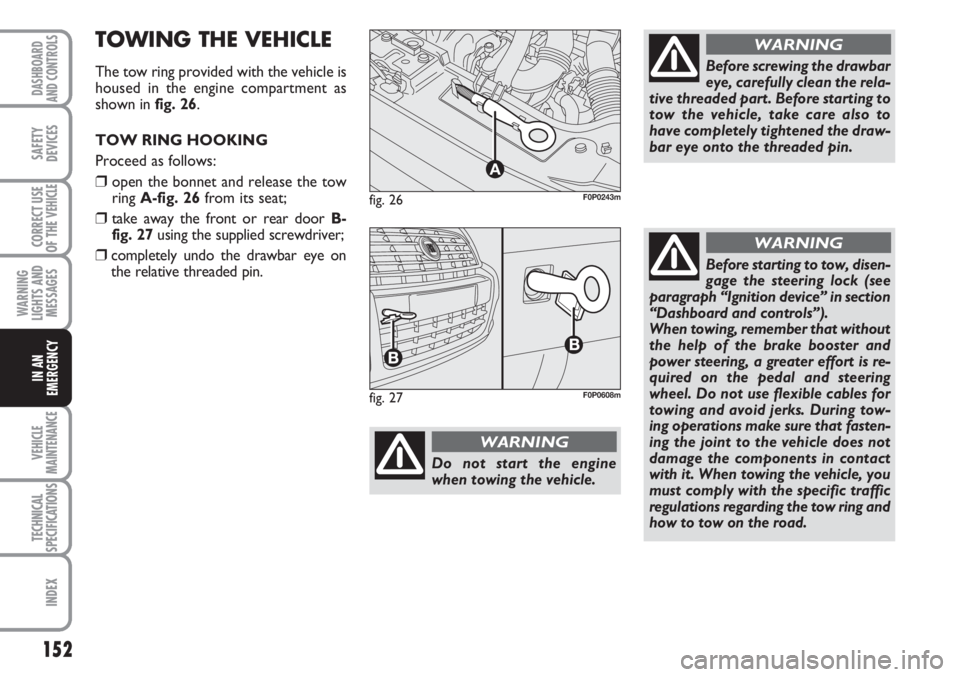

fig. 26

A

F0P0243m

Do not start the engine

when towing the vehicle.

WARNING

Before screwing the drawbar

eye, carefully clean the rela-

tive threaded part. Before starting to

tow the vehicle, take care also to

have completely tightened the draw-

bar eye onto the threaded pin.

WARNING

Before starting to tow, disen-

gage the steering lock (see

paragraph “Ignition device” in section

“Dashboard and controls”).

When towing, remember that without

the help of the brake booster and

power steering, a greater effort is re-

quired on the pedal and steering

wheel. Do not use flexible cables for

towing and avoid jerks. During tow-

ing operations make sure that fasten-

ing the joint to the vehicle does not

damage the components in contact

with it. When towing the vehicle, you

must comply with the specific traffic

regulations regarding the tow ring and

how to tow on the road.

WARNING

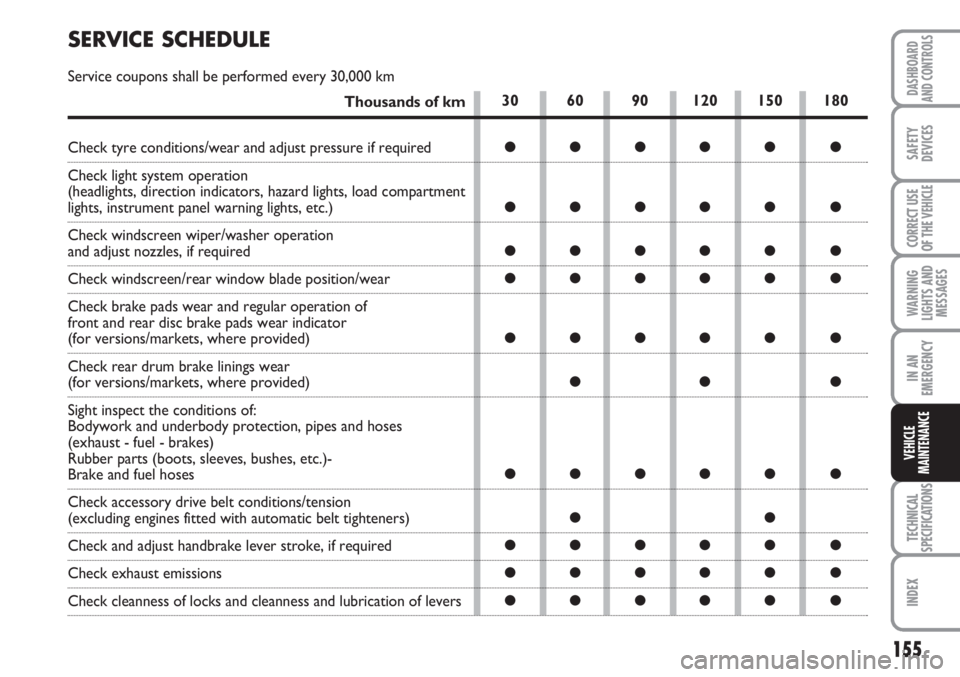

fig. 27F0P0608m

TOWING THE VEHICLE

The tow ring provided with the vehicle is

housed in the engine compartment as

shown in fig. 26.

TOW RING HOOKING

Proceed as follows:

❒open the bonnet and release the tow

ring A-fig. 26from its seat;

❒take away the front or rear door B-

fig. 27using the supplied screwdriver;

❒completely undo the drawbar eye on

the relative threaded pin.

Page 156 of 210

155

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

30 60 90 120 150 180

●●●●● ●

●●●●● ●

●●●●● ●

●●●●● ●

●●●●● ●

●● ●

●●●●● ●

●●

●●●●● ●

●●●●● ●

●●●●● ●

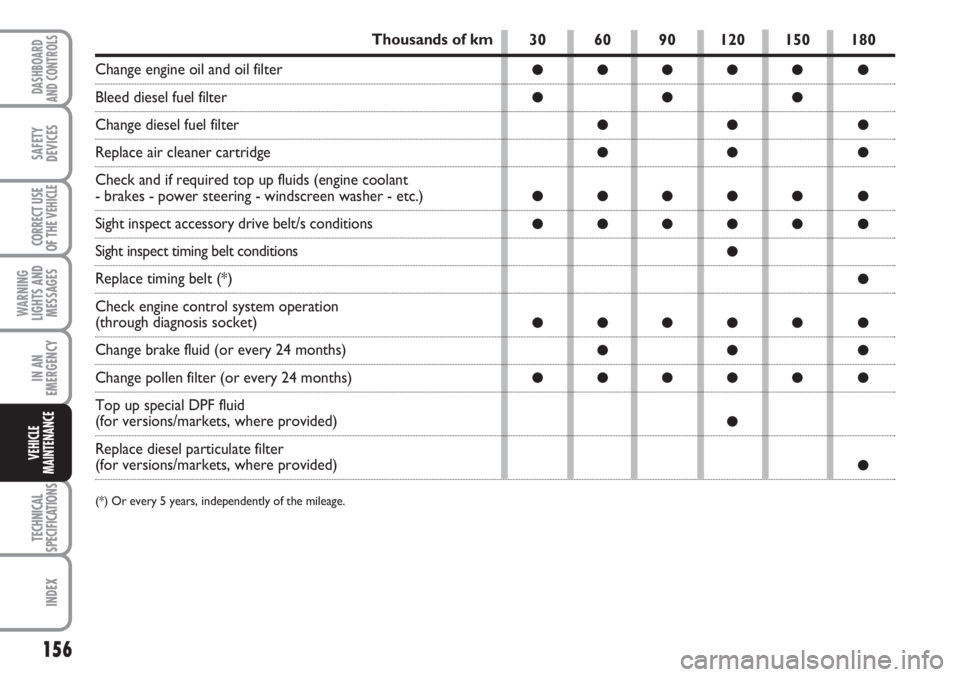

SERVICE SCHEDULE

Service coupons shall be performed every 30,000 km

Thousands of km

Check tyre conditions/wear and adjust pressure if required

Check light system operation

(headlights, direction indicators, hazard lights, load compartment

lights, instrument panel warning lights, etc.)

Check windscreen wiper/washer operation

and adjust nozzles, if required

Check windscreen/rear window blade position/wear

Check brake pads wear and regular operation of

front and rear disc brake pads wear indicator

(for versions/markets, where provided)

Check rear drum brake linings wear

(for versions/markets, where provided)

Sight inspect the conditions of:

Bodywork and underbody protection, pipes and hoses

(exhaust - fuel - brakes)

Rubber parts (boots, sleeves, bushes, etc.)-

Brake and fuel hoses

Check accessory drive belt conditions/tension

(excluding engines fitted with automatic belt tighteners)

Check and adjust handbrake lever stroke, if required

Check exhaust emissions

Check cleanness of locks and cleanness and lubrication of levers

Page 157 of 210

156

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

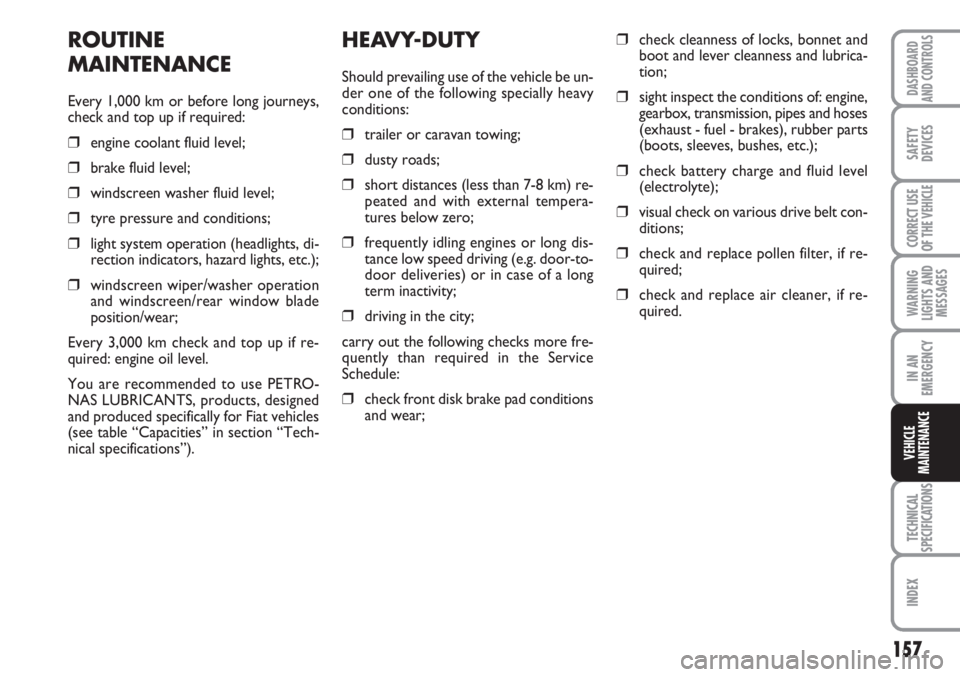

30 60 90 120 150 180

●●●●● ●

●●●

●● ●

●● ●

●●●●● ●

●●●●● ●

●

●

●●●●● ●

●● ●

●●●●● ●

●

●

Thousands of km

Change engine oil and oil filter

Bleed diesel fuel filter

Change diesel fuel filter

Replace air cleaner cartridge

Check and if required top up fluids (engine coolant

- brakes - power steering - windscreen washer - etc.)

Sight inspect accessory drive belt/s conditions

Sight inspect timing belt conditions

Replace timing belt (*)

Check engine control system operation

(through diagnosis socket)

Change brake fluid (or every 24 months)

Change pollen filter (or every 24 months)

Top up special DPF fluid

(for versions/markets, where provided)

Replace diesel particulate filter

(for versions/markets, where provided)

(*) Or every 5 years, independently of the mileage.

Page 158 of 210

157

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

HEAVY-DUTY

Should prevailing use of the vehicle be un-

der one of the following specially heavy

conditions:

❒trailer or caravan towing;

❒dusty roads;

❒short distances (less than 7-8 km) re-

peated and with external tempera-

tures below zero;

❒frequently idling engines or long dis-

tance low speed driving (e.g. door-to-

door deliveries) or in case of a long

term inactivity;

❒driving in the city;

carry out the following checks more fre-

quently than required in the Service

Schedule:

❒check front disk brake pad conditions

and wear;

❒check cleanness of locks, bonnet and

boot and lever cleanness and lubrica-

tion;

❒sight inspect the conditions of: engine,

gearbox, transmission, pipes and hoses

(exhaust - fuel - brakes), rubber parts

(boots, sleeves, bushes, etc.);

❒check battery charge and fluid level

(electrolyte);

❒visual check on various drive belt con-

ditions;

❒check and replace pollen filter, if re-

quired;

❒check and replace air cleaner, if re-

quired.

ROUTINE

MAINTENANCE

Every 1,000 km or before long journeys,

check and top up if required:

❒engine coolant fluid level;

❒brake fluid level;

❒windscreen washer fluid level;

❒tyre pressure and conditions;

❒light system operation (headlights, di-

rection indicators, hazard lights, etc.);

❒windscreen wiper/washer operation

and windscreen/rear window blade

position/wear;

Every 3,000 km check and top up if re-

quired: engine oil level.

You are recommended to use PETRO-

NAS LUBRICANTS, products, designed

and produced specifically for Fiat vehicles

(see table “Capacities” in section “Tech-

nical specifications”).

Page 159 of 210

158

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

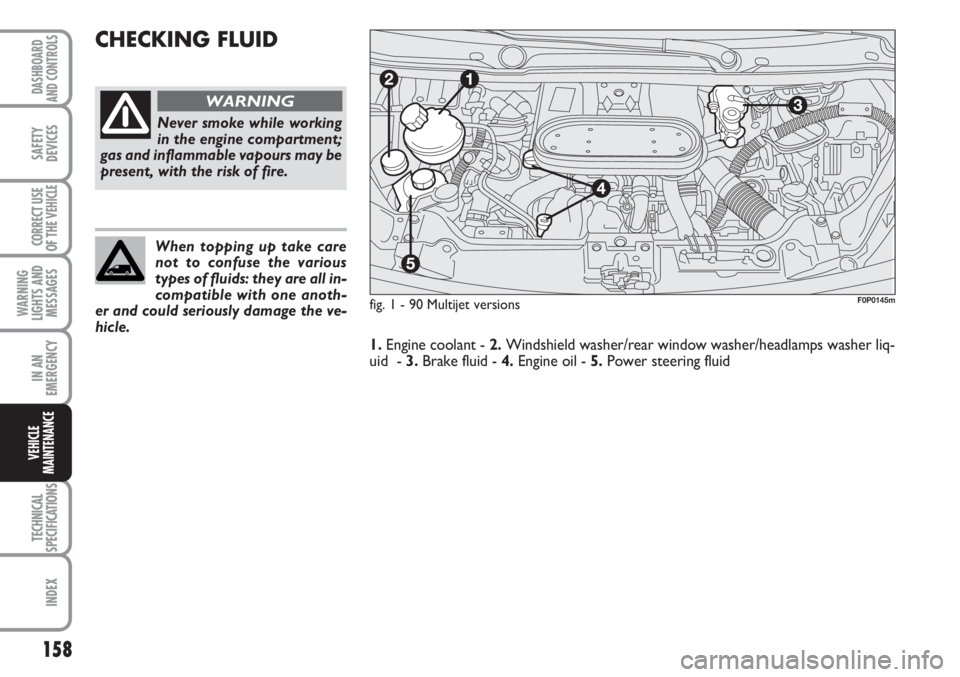

CHECKING FLUID

fig. 1 - 90 Multijet versions

Never smoke while working

in the engine compartment;

gas and inflammable vapours may be

present, with the risk of fire.

WARNING

When topping up take care

not to confuse the various

types of fluids: they are all in-

compatible with one anoth-

er and could seriously damage the ve-

hicle.

F0P0145m

1.Engine coolant - 2.Windshield washer/rear window washer/headlamps washer liq-

uid - 3.Brake fluid - 4.Engine oil - 5.Power steering fluid

Page 160 of 210

159

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

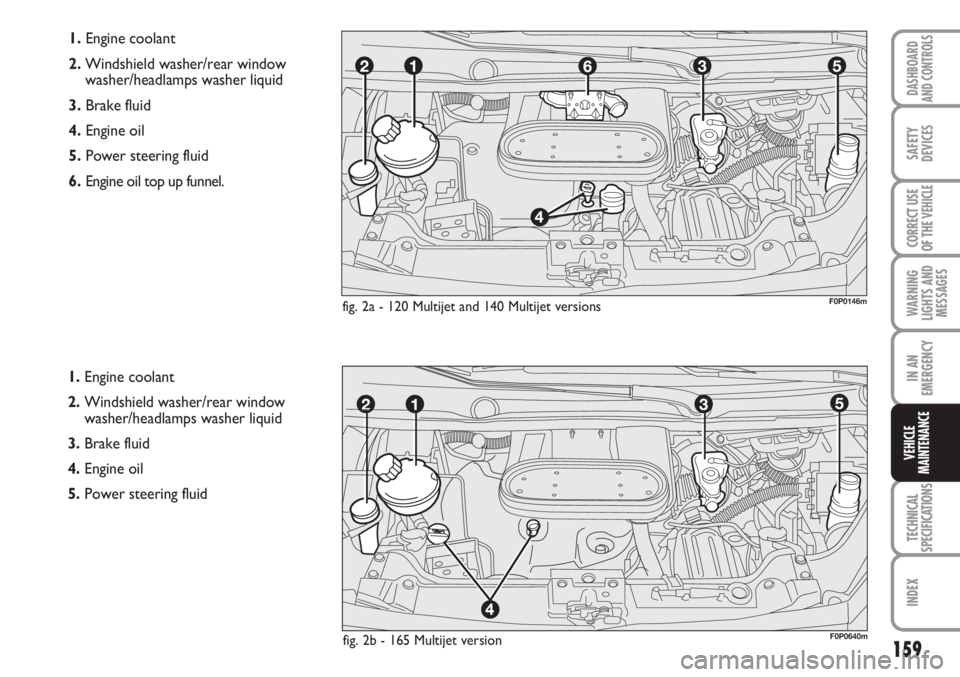

1.Engine coolant

2.Windshield washer/rear window

washer/headlamps washer liquid

3.Brake fluid

4.Engine oil

5.Power steering fluid

6.Engine oil top up funnel.

1.Engine coolant

2.Windshield washer/rear window

washer/headlamps washer liquid

3.Brake fluid

4.Engine oil

5.Power steering fluid

F0P0146mfig. 2a - 120 Multijet and 140 Multijet versions

F0P0640mfig. 2b - 165 Multijet version