trunk FIAT SPIDER ABARTH 2017 Owner's Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: SPIDER ABARTH, Model: FIAT SPIDER ABARTH 2017Pages: 292, PDF Size: 9.24 MB

Page 205 of 292

JACKING AND TIRE

CHANGING Warning!Do not attempt to change a tire on the

side of the vehicle close to moving traffic.

Pull far enough off the road to avoid the

danger of being hit when operating the jack

or changing the wheel.

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed.

Never put any part of your body under a

vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service

center where it can be raised on a lift.

The jack is designed to be used as a

tool for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked on

a firm level surface only. Avoid ice or

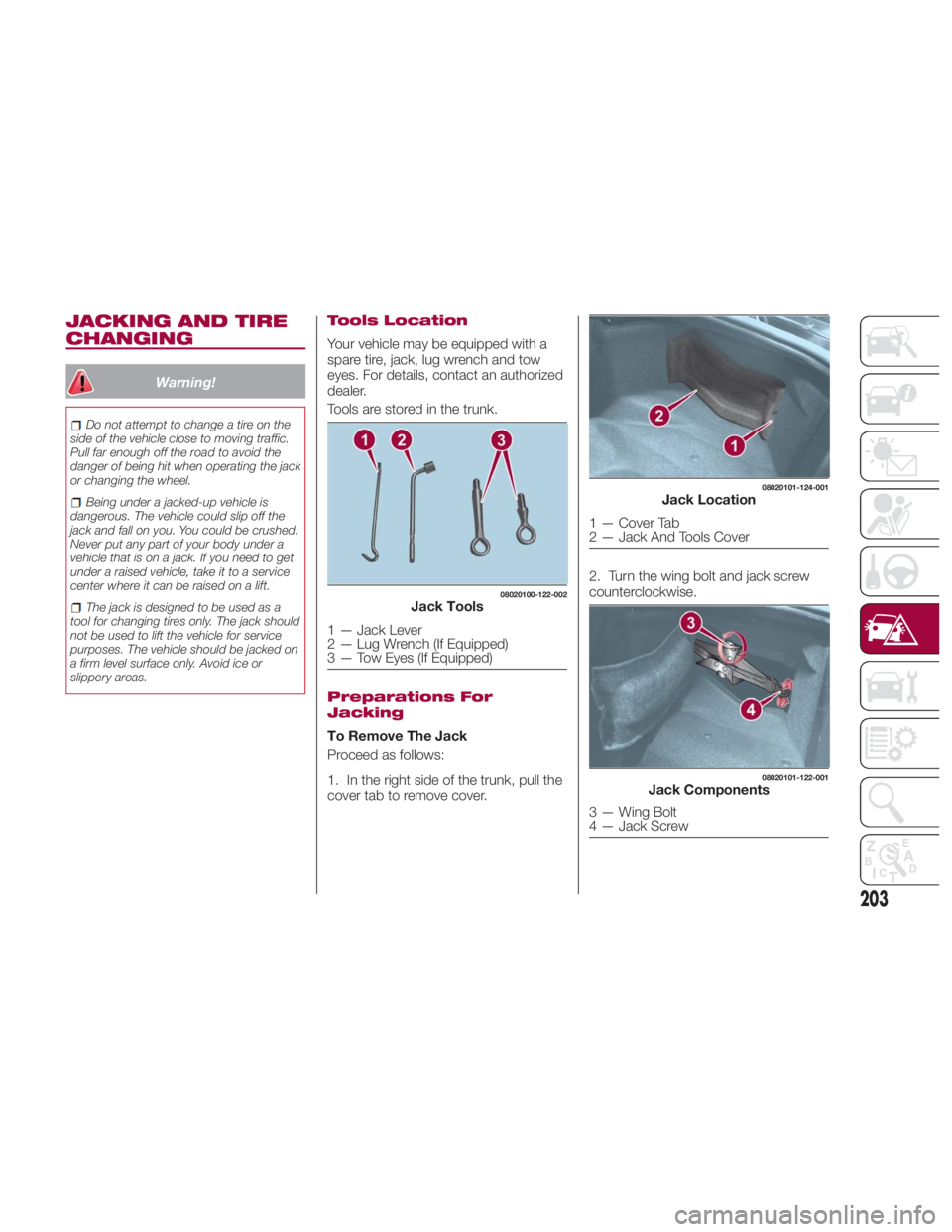

slippery areas. Tools Location

Your vehicle may be equipped with a

spare tire, jack, lug wrench and tow

eyes. For details, contact an authorized

dealer.

Tools are stored in the trunk.

Preparations For

Jacking

To Remove The Jack

Proceed as follows:

1. In the right side of the trunk, pull the

cover tab to remove cover. 2. Turn the wing bolt and jack screw

counterclockwise. 08020100-122-002

Jack Tools

1 — Jack Lever

2 — Lug Wrench (If Equipped)

3 — Tow Eyes (If Equipped) 08020101-124-001

Jack Location

1 — Cover Tab

2 — Jack And Tools Cover 08020101-122-001

Jack Components

3 — Wing Bolt

4 — Jack Screw

203

Page 210 of 292

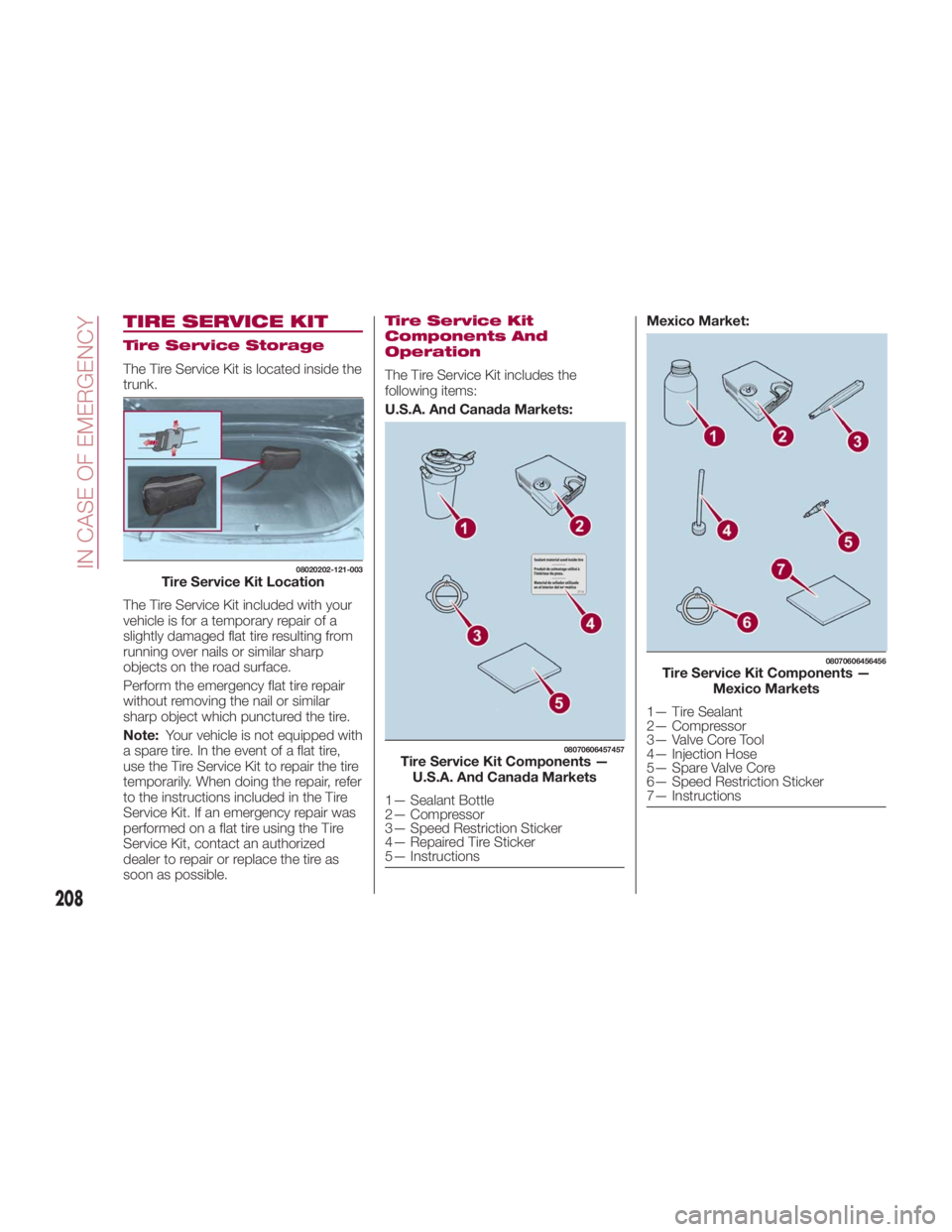

TIRE SERVICE KIT Tire Service Storage

The Tire Service Kit is located inside the

trunk.

The Tire Service Kit included with your

vehicle is for a temporary repair of a

slightly damaged flat tire resulting from

running over nails or similar sharp

objects on the road surface.

Perform the emergency flat tire repair

without removing the nail or similar

sharp object which punctured the tire.

Note: Your vehicle is not equipped with

a spare tire. In the event of a flat tire,

use the Tire Service Kit to repair the tire

temporarily. When doing the repair, refer

to the instructions included in the Tire

Service Kit. If an emergency repair was

performed on a flat tire using the Tire

Service Kit, contact an authorized

dealer to repair or replace the tire as

soon as possible. Tire Service Kit

Components And

Operation

The Tire Service Kit includes the

following items:

U.S.A. And Canada Markets: Mexico Market:08020202-121-003

Tire Service Kit Location 08070606457457

Tire Service Kit Components —

U.S.A. And Canada Markets

1— Sealant Bottle

2— Compressor

3— Speed Restriction Sticker

4— Repaired Tire Sticker

5— Instructions 08070606456456

Tire Service Kit Components —

Mexico Markets

1— Tire Sealant

2— Compressor

3— Valve Core Tool

4— Injection Hose

5— Spare Valve Core

6— Speed Restriction Sticker

7— Instructions

208

IN CASE OF EMERGENCY

Page 227 of 292

At least monthly perform inspection

of:

Tire inflation pressures

At least twice a year (for example,

every spring and fall) perform

inspection of:

Engine coolant

Engine oil

As explained in the “Introduction”

paragraph, several procedures can be

done only by a qualified service

technician with special tools.

For details, read the separate Warranty

Booklet provided with the vehicle. If you

are unsure about any servicing or

maintenance procedure, have it done

by an authorized dealer.

There are strict environmental laws

regarding the disposal of waste oil and

fluids. Please dispose of your waste

properly and with due regard to the

environment.

We recommend that you entrust the oil

and fluid changes of your vehicle to an

authorized dealer. Periodic Checks

Every 620 miles (1,000 km) or before

long trips check and, if necessary, top

off:

Engine coolant level.

Brake fluid level.

Windshield washer fluid level.

Tire inflation pressure and condition.

Operation of lighting system

(headlights, direction indicators, hazard

warning lights, etc.).

Operation of windshield

washer/wiper system and

positioning/wear of windshield wiper

blades.

Every 1860 miles (3,000 km) check

and top off the engine oil level if

required.

Heavy-Duty Use Of The

Vehicle

If the vehicle is used under one of the

following conditions:

Dusty roads.

Short, repeated trips less than 4.4 -

5 miles ( 7-8km)atsub -zero outside

temperatures.

Engine idling for long periods of time

or driving long distances at low speeds

or long periods of inactivity. The following checks must be carried

out more often than indicated in the

Scheduled Servicing Plan:

Check front disc brake pad condition

and wear.

Check cleanliness of underhood area

and all door and trunk locks, cleanliness

and lubrication of linkage.

Visually inspect conditions of the:

engine, transmission, lines and hoses

(exhaust/fuel system/brakes) and

rubber elements (hoses/belts/etc.).

Check battery charge and battery

fluid level.

Visually inspect conditions of the

accessory drive belts.

Check and, if necessary, change

engine oil and replace oil filter.

Check and, if necessary, replace

cabin air filter.

Check and, if necessary, replace air

cleaner.

Severe Duty All Models

Change Engine Oil at 4,000 miles

(6,500 km) if the vehicle is operated in a

dusty and off road environment or is

operated predominately at idle or only

very low engine RPM’s. This type of

vehicle use is considered Severe Duty.

225

Page 230 of 292

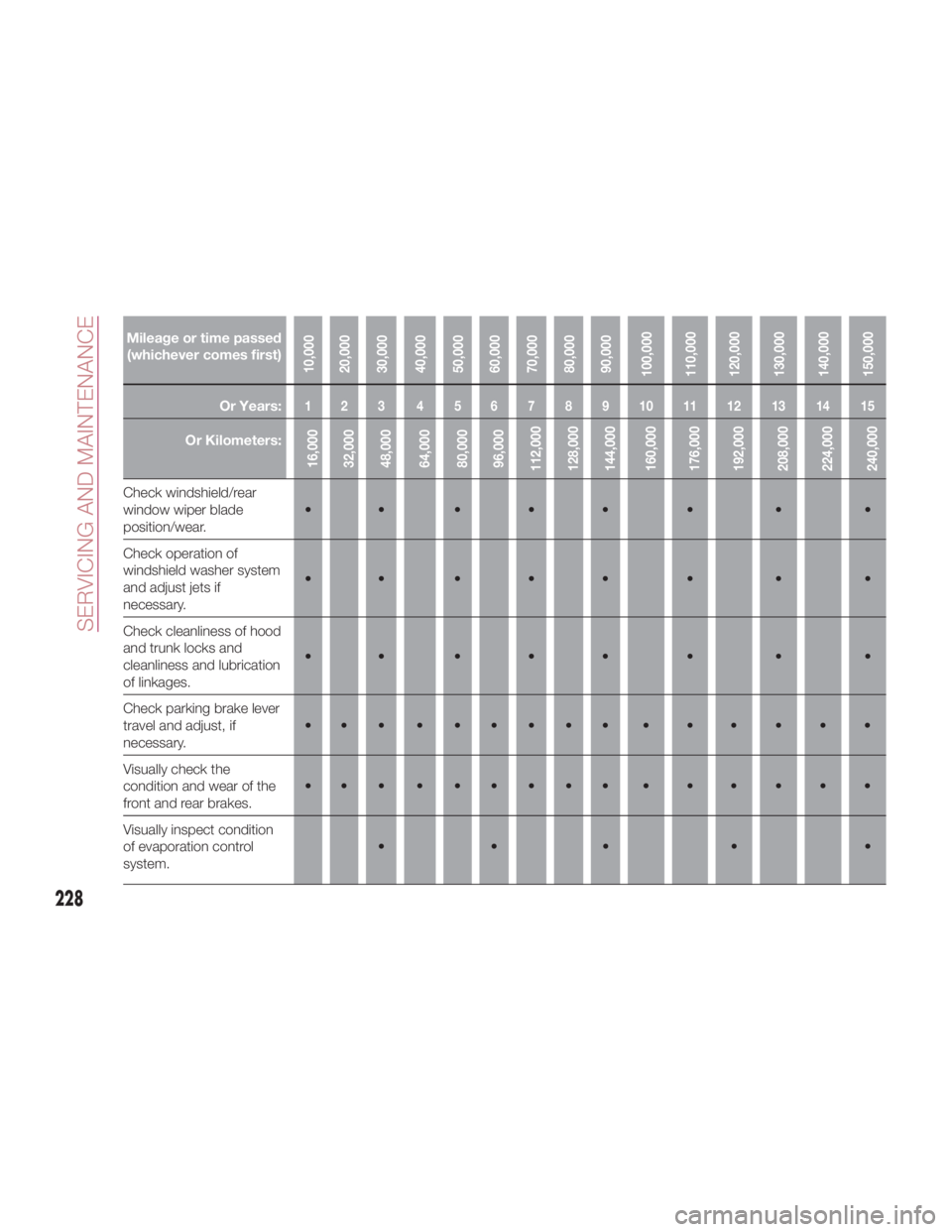

Mileage or time passed

(whichever comes first)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000Or Years: 123 456789101112131415

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000Check windshield/rear

window wiper blade

position/wear. •• •• • • • •

Check operation of

windshield washer system

and adjust jets if

necessary. •• •• • • • •

Check cleanliness of hood

and trunk locks and

cleanliness and lubrication

of linkages. •• •• • • • •

Check parking brake lever

travel and adjust, if

necessary. •••••••••••••••

Visually check the

condition and wear of the

front and rear brakes. •••••••••••••••

Visually inspect condition

of evaporation control

system. ••• • •

228

SERVICING AND MAINTENANCE

Page 237 of 292

BATTERY

RECHARGING BATTERY CHARGING

PROCEDURE

Warning!Battery fluid is a corrosive acid solution

and can burn or even blind you. Do not

allow battery fluid to contact your eyes,

skin, or clothing. Do not lean over a battery

when attaching clamps. If acid splashes in

eyes or on skin, flush the area immediately

with large amounts of water. Refer to

“Jump-Starting Procedure” in “In Case Of

Emergency” for further information.

Battery gas is flammable and explosive.

Keep flame or sparks away from the

battery. Do not use a booster battery or

any other booster source with an output

greater than 12 Volts. Do not allow cable

clamps to touch each other.

Battery posts, terminals, and related

accessories contain lead and lead

compounds. Wash hands after handling. Caution!It is essential when replacing the cables

on the battery that the positive cable is

attached to the positive post and the

negative cable is attached to the negative

post. Battery posts are marked positive (+)

and negative (-) and are identified on the

battery case. Cable clamps should be tight

on the terminal posts and free of corrosion.

If a “fast charger” is used while the

battery is in the vehicle, disconnect both

vehicle battery cables before connecting

the charger to the battery. Do not use a

“fast charger” to provide starting voltage.

Charge battery as follows:

Before recharging the battery, turn off

all accessories and turn the engine off

by placing the ignition in the OFF mode.

Disconnect the negative battery

cable.

Connect the charger cables to the

battery terminals, observing the polarity

(+,–).

Turn on the charger.

When finished, turn the charger off

before disconnecting the battery.

Reconnect the negative battery

terminal. MAINTENANCE

PROCEDURES The following pages contain

instructions on the required

maintenance from the technical

personnel who designed the vehicle.

In addition to these specific

maintenance instructions specified for

routine scheduled servicing, there are

other components which may require

periodic maintenance or replacement

over the vehicle’s life cycle.

Body Lubrication

Ensure that the locks and bodywork

junction points, including components

such as the seat guides, door hinges

(and rollers), trunk and hood are

periodically lubricated with lithium

based grease to ensure correct, silent

operation and to protect them from rust

and wear.

Thoroughly clean the components,

eliminating every trace of dirt and dust.

After lubricating, eliminate excess oil

and grease. Also pay particular

attention to the hood closing devices,

to ensure correct operation.

During operations on the hood, be sure

to perform with the engine cold, also

remember to check, clean and lubricate

the locking, release and safety devices.

Make sure the hood's secondary latch

keeps the hood from opening when the

primary latch is released.

235

Page 276 of 292

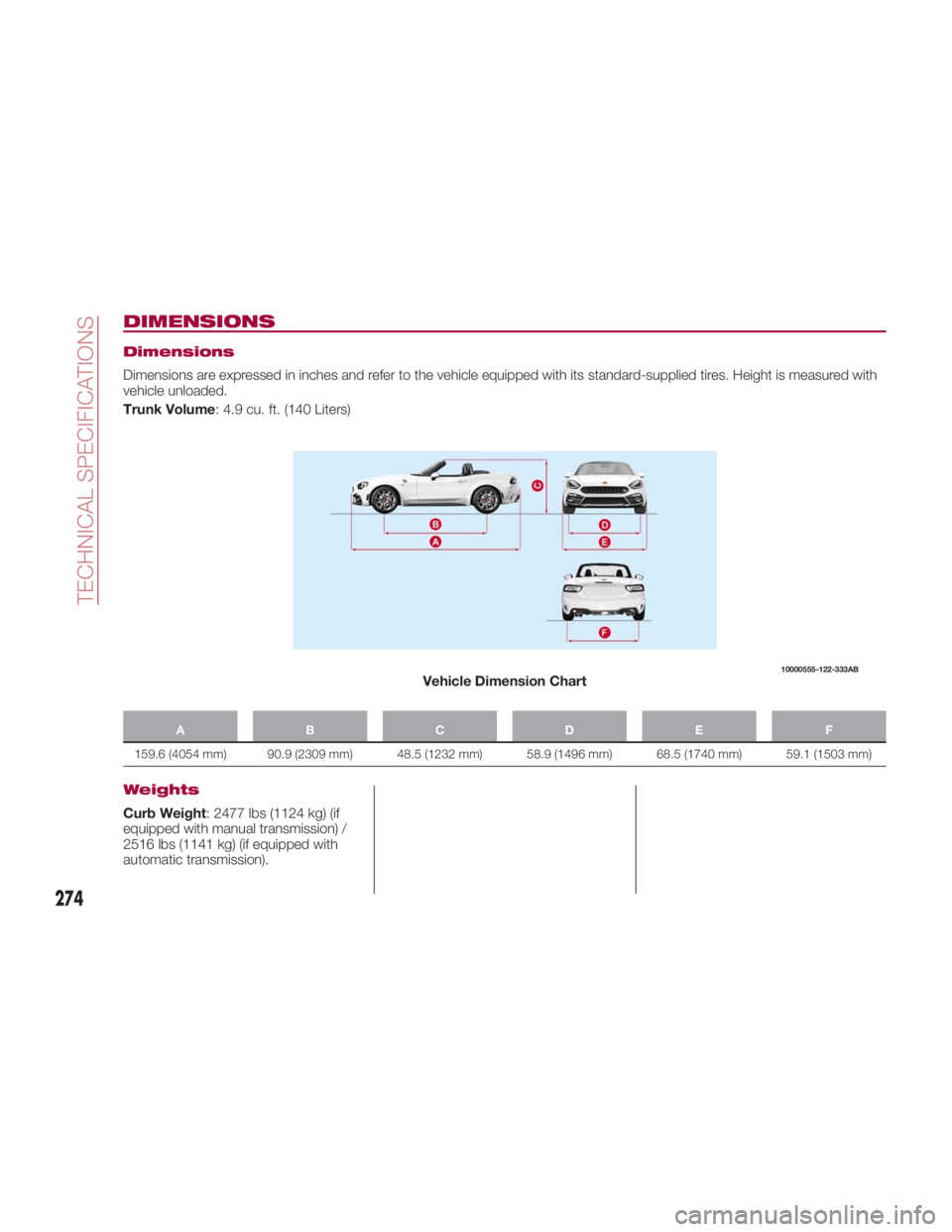

DIMENSIONS Dimensions

Dimensions are expressed in inches and refer to the vehicle equipped with its standard-supplied tires. Height is measured with

vehicle unloaded.

Trunk Volume : 4.9 cu. ft. (140 Liters)

ABCDE F

159.6 (4054 mm) 90.9 (2309 mm) 48.5 (1232 mm) 58.9 (1496 mm) 68.5 (1740 mm) 59.1 (1503 mm)

Weights

Curb Weight : 2477 lbs (1124 kg) (if

equipped with manual transmission) /

2516 lbs (1141 kg) (if equipped with

automatic transmission). 10000555-122-333AB

Vehicle Dimension Chart

274

TECHNICAL SPECIFICATIONS

Page 286 of 292

INDEX About Your Brakes .......... .150

ABS system ............... .112

Active Adaptive Shift (AAS) ..... .156

Adaptive Front Lighting System

(AFS) ...................42

Additives, Fuel ............. .174

Advanced Keyless Entry System

Key Left In Trunk ............21

Key left In Vehicle ...........21

Locking Doors .............21

Passive Entry ..............21

Request Switch ............21

Unlocking Doors ............21

AirBag............... .131,135

Advance Front Air Bag . . . .131,135

Air Bag Warning Light ...... .147

Event Data Recorder (EDR) .145,222

FrontAirBag ............ .147

Maintaining Your Air Bag

System ............... .145

Air Bag Maintenance ......... .145

Air Pressure, Tires ........... .246

Alarm

Vehicle Security Alarm ..... .24,25

Alarm (Security Alarm) ....... .24,25

Aluminium wheel maintenance . . . .259

Automatic Dimming Mirror ........36

Automatic Headlights ...........40 Automatic Temperature Control

(ATC) ...................52

Automatic Transmission ....... .153

Auxiliary Power Outlet ..........63

B-Pillar Location ............ .242

Battery (maintenance) ......... .234

Battery charging procedure ..... .235

Battery recharging ........... .235

Blind Spot Monitoring ......... .114

Body and underbody warranty . . . .256

Body lubrication ............ .235

Bodywork (care and maintenance). .256

Boot, Convertible Top Lowering ....70

Boot, Convertible Top Precautions . .73

Boot, Convertible Top Raising .....71

Brake System .............. .150

Brake/clutch fluid (level check) . . . .233

Brakes ............... .150,271

Bright-metal maintenance ......

.259

Camera,

Rear ..............

.167

Carbon Monoxide Warning ..... .175

Center Seat Storage Compartment .......................60

Certification Label ........... .176

Changing A Flat Tire .... .203,204,237

Chart, Tire Sizing ............ .239

Check Engine Light (Malfunction

Indicator Light) ........... .110 Checking levels ............. .231

Child Restraint ............. .128

Child Restraints

Child Restraints .......... .128

Clean Air Gasoline ........... .173

Cleaning

Wheels ............... .251

Climate Control ..............45

Close The Hood ..............69

Compact Spare Tire .......... .250

Contract, Service ........... .281

Convertible Top ..............70

Convertible top maintenance .... .260

Cooling

Air Conditioning ............50

Cupholders .................64

Customer Assistance ......... .280

Data Recorder, Event ......... .145

Daytime Running Lights .........40

Diagnostic System, Onboard .... .109

Dimensions ............... .274

Disabled Vehicle Towing .... .220,221

Driver's Seat Back Tilt ..........33

Driving in flooded area ........ .181

Driving tips ............... .178

Electric power steering ..........74

Electric Remote Mirrors .........37

INDEX

Page 290 of 292

Pressure Monitor System

(TPMS) ............... .114

Quality Grading .......... .254

Radial ................ .247

Replacement ............ .248

Safety ............. .238,246

Sizes ................. .239

Snow Tires ............. .249

Spare Tire ........ .203,250,251

Spinning .............. .247

Tread Wear Indicators ...... .248

ToOpenDeckLid.............66

ToOpenHood...............68

Towing

Disabled Vehicle ....... .220,221

Towing Eyes ............... .220

Towing trailers ............. .178

TPMS (Tire Pressure Monitoring

System) ................ .119 Transmission .............. .270

Tread Wear Indicators ......... .248

Trunk Lid

Closing ..................67

Opening .................66

Trunk light (bulb replacement) .... .194

Turn Signals .................41

Undercoating .............. .259

Uniform Tire Quality Grades ..... .254

Vehicle Loading ......... .176,243

Vehicle modifications/alterations .....4

Vent Operation ...............45

Warning Flasher, Hazard ....... .184

Warranty Information ......... .282

Washer Operation .......... .42,44

Washers, Windshield ...........42 Wheel And Wheel Trim ........ .251

Wheel And Wheel Trim Care ..... .251

Wheels and tires ............ .238

Window and headlight washer fluid

(level check) ............. .234

Window interiors (cleaning) ..... .263

Windows

Driver/Passenger

W

indow

Controls .................56

Power Windows ...........56

Window Lockout ...........58

Windshield wiper blades (replacing) ..................... .236

Windshield Wipers ............42

Windstop ..................65

Winter driving .............. .180

Wiper blades .............. .236

Wrecker Towing ......... .220,221

INDEX