ESP FIAT TEMPRA 1988 Service And User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 34 of 171

ruvj

uivjh I

uuluj

^ Use a magnetic screw-

driver or place some thick

grease on the end of the

screwdriver to prevent the screws from falling

-

especially when replacing the lens.

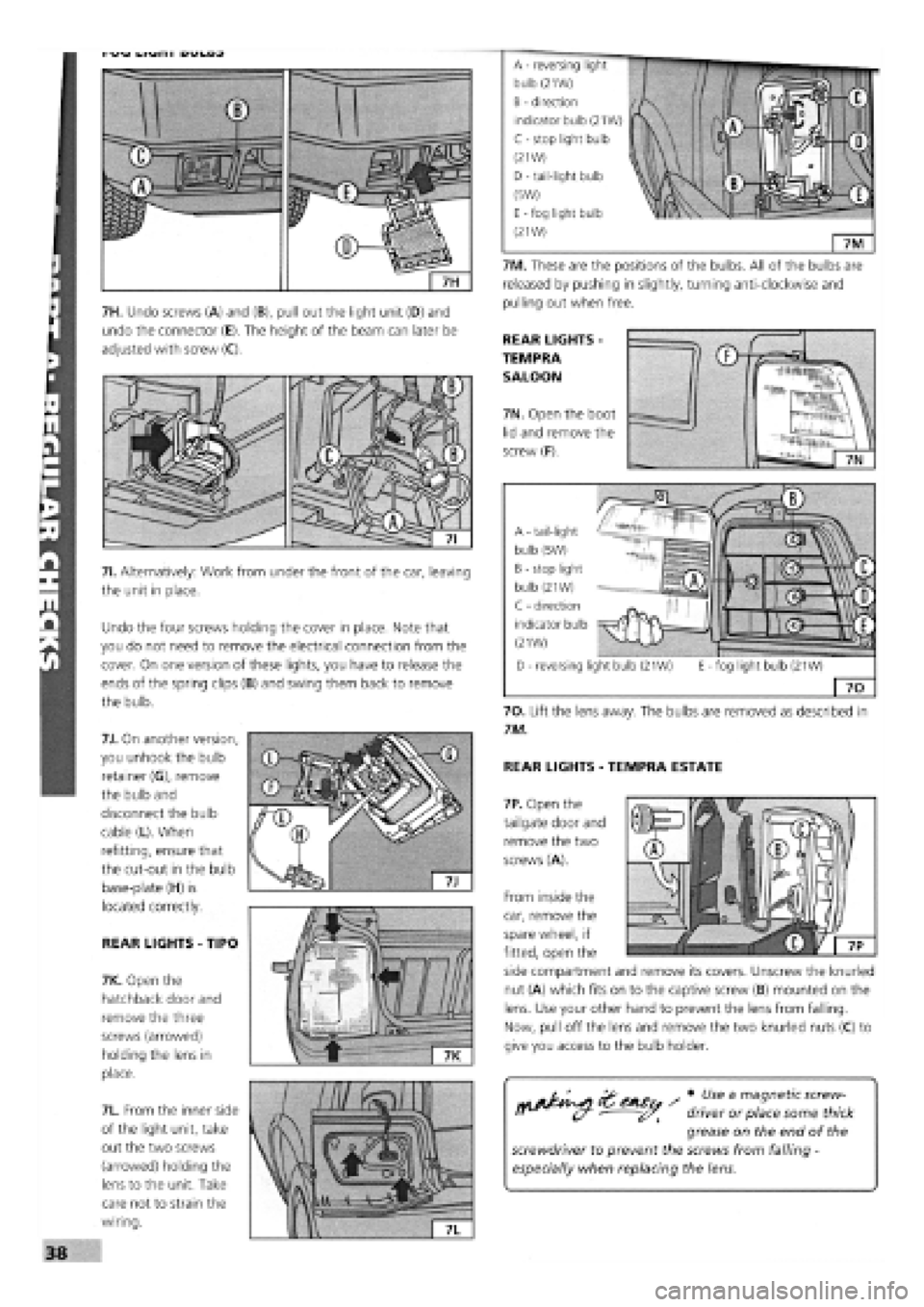

7H. Undo screws (A) and (B), pull out the light unit (D) and

undo the connector (E). The height of the beam can later be

adjusted with screw (C).

71. Alternatively: Work from under the front of the car, leaving

the unit in place.

Undo the four screws holding the cover in place. Note that

you do not need to remove the electrical connection from the

cover. On one version of these lights, you have to release the

ends of the spring clips (B) and swing them back to remove

the bulb.

7J. On another version,

you unhook the bulb

retainer (G), remove

the bulb and

disconnect the bulb

cable (L). When

refitting, ensure that

the cut-out in the bulb

base-plate (H) is

located correctly.

REAR LIGHTS

-

TIPO

7K. Open the

hatchback door and

remove the three

screws (arrowed)

holding the lens in

place.

7L. From the inner side

of the light unit, take

out the two screws

(arrowed) holding the

lens to the unit. Take

care not to strain the

wiring.

7M. These are the positions of the bulbs. All of the bulbs are

released by pushing in slightly, turning anti-clockwise and

pulling out when free.

REAR LIGHTS -

TEMPRA

SALOON

7N. Open the boot

lid and remove the

screw (F).

-fog light bulb (21W)

70

70. Lift the lens away. The bulbs are removed as described in

7M.

REAR LIGHTS

-

TEMPRA ESTATE

7P. Open the

tailgate door and

remove the two

screws (A).

From inside the

car, remove the

spare wheel, if

fitted, open the

side compartment and remove its covers. Unscrew the knurled

nut (A) which fits on to the captive screw (B) mounted on the

lens. Use your other hand to prevent the lens from falling.

Now, pull off the lens and remove the two knurled nuts (C) to

give you access to the bulb holder.

A - tail-light

bulb (5W)

B - stop light

bulb (21W)

C - direction

indicator bulb

(21W)

D - reversing light bulb (21W) E

A - reversing

bulb (21W)

B - direction

indicator bulb (21W)

C - stop light bulb

(21W)

D

-

tail-light bulb

(5W)

E - fog light bulb

(21W)

Page 39 of 171

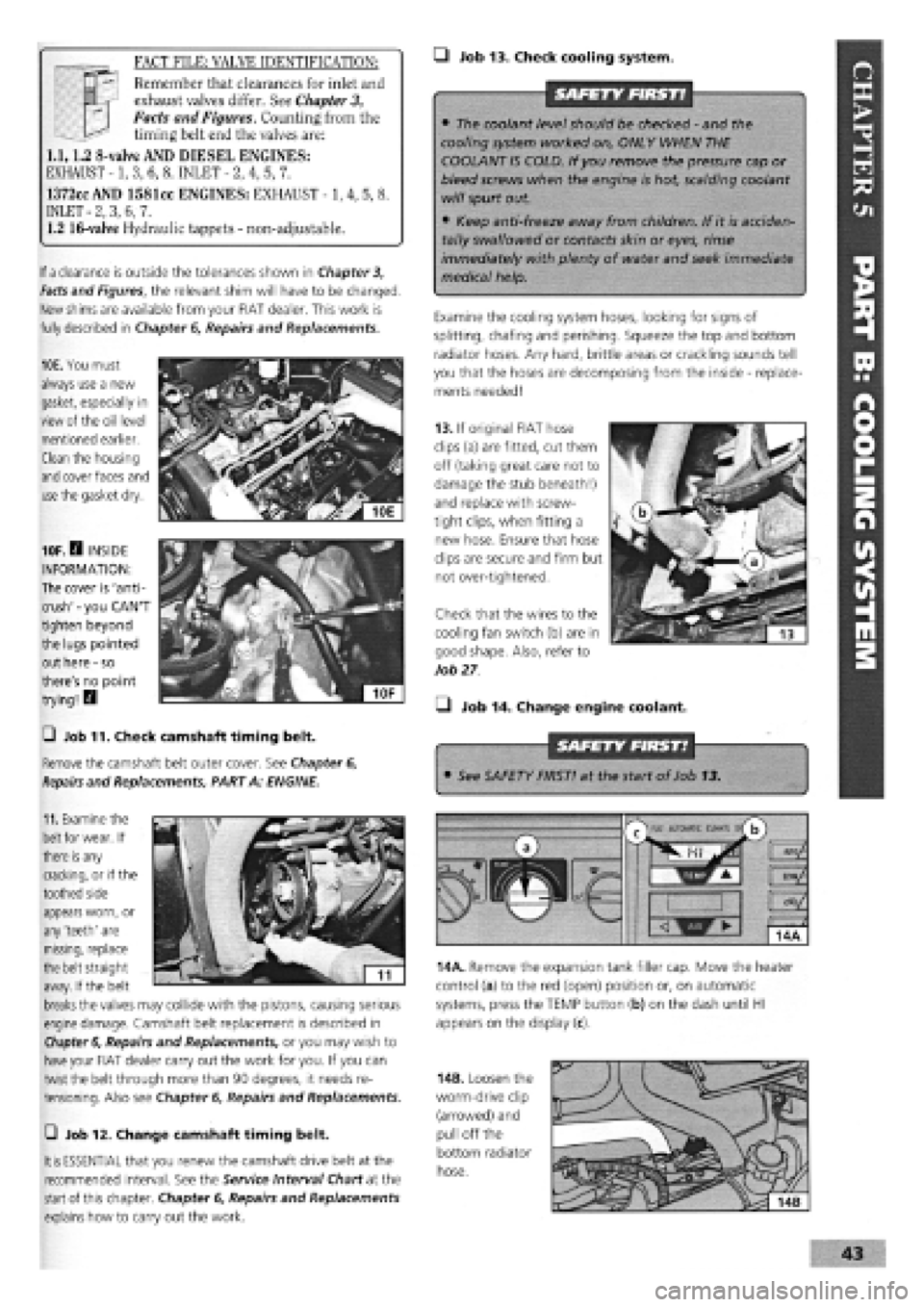

—I Job 13. Check cooling system.

SAFETY FIRST!

• The coolant level should be checked

-

and the

cooling system worked on, ONLY WHEN THE

COOLANT IS COLD. If you remove the pressure cap or

bleed screws when the engine is hot, scalding coolant

will spurt out.

• Keep anti-freeze away from children. If it is acciden-

tally swallowed or contacts skin or eyes, rinse

immediately with plenty of water and seek immediate

medical help.

Examine the cooling system hoses, looking for signs of

splitting, chafing and perishing. Squeeze the top and bottom

radiator hoses. Any hard, brittle areas or crackling sounds tell

you that the hoses are decomposing from the inside

-

replace-

ments needed!

SAFETY FIRST!

If

a

clearance is outside the tolerances shown in Chapter 3,

Facts

and Figures, the relevant shim will have to be changed.

New

shims

are available from your FIAT dealer. This work is

fully described in Chapter

6,

Repairs and Replacements.

10E. You must

always use a new

gasket, especially in

view of the oil level

mentioned earlier.

Clean the housing

and

cover faces and

use

the gasket dry.

11.

Examine the

belt

for wear. If

there

is

any

cracking, or if the

toothed side

10F.H INSIDE

INFORMATION:

The cover is 'anti-

crush'

-

you CAN'T

tighten beyond

the lugs pointed

out here

-

so

there's no point

trying! H

0 Job 11. Check camshaft timing belt.

Remove the camshaft belt outer cover. See Chapter 6,

Repairs

and Replacements, PART A: ENGINE.

FACT FILE: VALVE IDENTIFICATION:

T

—

Remember that clearances for inlet and

3™ exhaust valves differ. See

Chapter

3,

Facts and Figures. Counting from the

—^ timing belt end the valves are:

1.1,1.2 8-valve AND DIESEL ENGINES:

EXHAUST -1, 3, 6, 8. INLET

-

2, 4, 5, 7.

1372cc AND 1581cc ENGINES: EXHAUST -1, 4, 5, 8.

INLET

-

2, 3, 6, 7.

1.2 16-valve Hydraulic tappets

-

non-adjustable.

13. If original FIAT hose

clips (a) are fitted, cut them

off (taking great care not to

damage the stub beneath!)

and replace with screw-

tight clips, when fitting a

new hose. Ensure that hose

clips are secure and firm but

not over-tightened.

Check that the wires to the

cooling fan switch (b) are in

good shape. Also, refer to

Job

27

• Job 14. Change engine coolant.

• See SAFETY FIRST! at the start of Job 13.

appears worn, or

any 'teeth' are

missing, replace

the belt straight

away. If the belt

breaks

the valves may collide with the pistons, causing serious

engine damage. Camshaft belt replacement is described in

Chapter 6,

Repairs and Replacements, or you may wish to

have

your FIAT dealer carry out the work for you. If you can

twist the belt through more than 90 degrees, it needs re-

tensioning. Also see Chapter

6,

Repairs and Replacements.

m

AUtOKAlIC CtMAU s/

b

14A. Remove the expansion tank filler cap. Move the heater

control (a) to the red (open) position or, on automatic

systems, press the TEMP button (b) on the dash until HI

appears on the display (c).

—i Job 12. Change camshaft timing belt.

It is

ESSENTIAL that you renew the camshaft drive belt at the

recommended interval. See the Service Interval Chart at the

start

of this chapter. Chapter

6,

Repairs and Replacements

explains how to carry out the work.

14B. Loosen the

worm-drive clip

(arrowed) and

pull off the

bottom radiator

hose.

Page 41 of 171

IMPORTANT NOTE: Take care not to allow any dirt or grit

to get into the gearbox.

• Job 19. Check driveshaft gaiters.

45

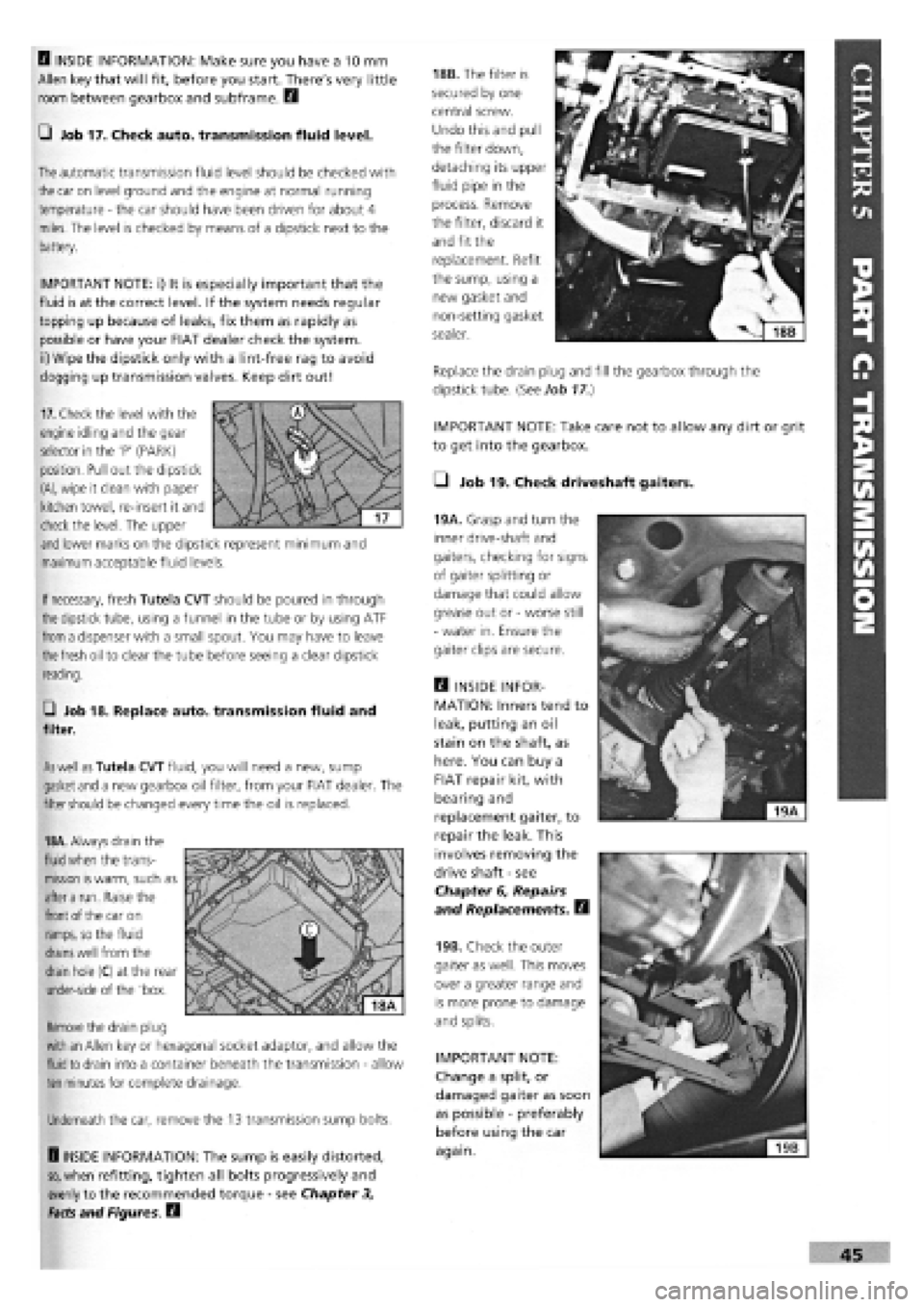

B INSIDE INFORMATION: Make sure you have a 10 mm

Allen key that will fit, before you start. There's very little

room between gearbox and subframe. B

Q Job 17. Check auto, transmission fluid level.

The

automatic transmission fluid level should be checked with

the

car on level ground and the engine at normal running

temperature

-

the car should have been driven for about 4

miles. The level is checked by means of a dipstick next to the

battery.

IMPORTANT NOTE: i) It is especially important that the

fluid is at the correct level. If the system needs regular

topping up because of leaks, fix them as rapidly as

possible or have your FIAT dealer check the system,

ii) Wipe the dipstick only with a lint-free rag to avoid

clogging up transmission valves. Keep dirt out!

18B. The filter is

secured by one

central screw.

Undo this and pull

the filter down,

detaching its upper

fluid pipe in the

process. Remove

the filter, discard it

and fit the

replacement. Refit

the sump, using a

new gasket and

non-setting gasket

sealer.

Replace the drain plug and fill the gearbox through the

dipstick tube. {See Job

17.)

19A. Grasp and turn the

inner drive-shaft and

gaiters, checking for signs

of gaiter splitting or

damage that could allow

grease out or

-

worse still

-

water in. Ensure the

gaiter clips are secure.

Q INSIDE INFOR-

MATION: Inners tend to

leak, putting an oil

stain on the shaft, as

here. You can buy a

FIAT repair kit, with

bearing and

replacement gaiter, to

repair the leak. This

involves removing the

drive shaft

-

see

Chapter 6, Repairs

and Replacements. B

19B. Check the outer

gaiter as well. This moves

over a greater range and

is more prone to damage

and splits.

IMPORTANT NOTE:

Change a split, or

damaged gaiter as soon

as possible

-

preferably

before using the car

again.

If

necessary,

fresh Tutela CVT should be poured in through

the

dipstick tube, using a funnel in the tube or by using ATF

from

a dispenser with a small spout. You may have to leave

the fresh

oil to clear the tube before seeing a clear dipstick

reading.

G Job 18. Replace auto, transmission fluid and

filter.

As well as

Tutela CVT fluid, you will need a new, sump

gasket

and

a new gearbox oil filter, from your FIAT dealer. The

filter

should

be changed every time the oil is replaced.

18A.

Always drain the

fluid when

the trans-

mission

is

warm, such as

after a

run. Raise the

front

of the car on

ramps,

so the fluid

drains well

from the

drain

hole (C) at the rear

under-side of the 'box.

Remove

the drain plug

with an

Allen key or hexagonal socket adaptor, and allow the

fluid to

drain into a container beneath the transmission

-

allow

ten

minutes for complete drainage.

Underneath the car, remove the 13 transmission sump bolts.

H INSIDE INFORMATION: The sump is easily distorted,

so,

when refitting, tighten all bolts progressively and

evenly to the recommended torque

-

see Chapter 3,

Facts and Figures. B

17.

Check the level with the

engine idling and the gear

selector in the 'P' (PARK)

position. Pull out the dipstick

(A),

wipe it clean with paper

kitchen towel, re-insert it and

check the level. The upper

and

lower marks on the dipstick represent minimum and

maximum acceptable fluid levels.

Page 69 of 171

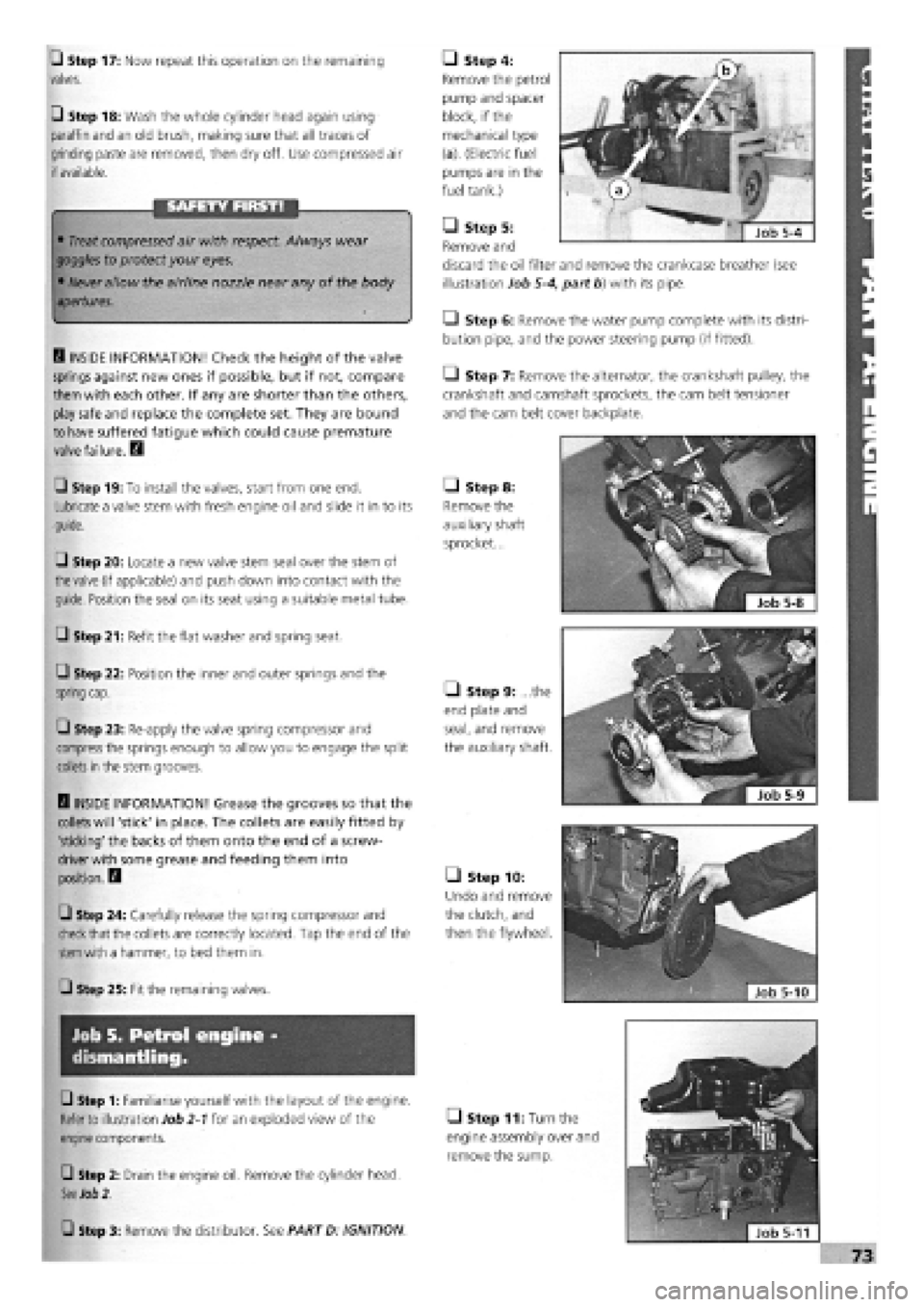

G Step 17: Now repeat this operation on the remaining

valves.

G Step 18: Wash the whole cylinder head again using

paraffin and an old brush, making sure that all traces of

grinding paste are removed, then dry off. Use compressed air

if

available.

SAFETY FIRST!

•

Treat

compressed air with respect. Always wear

goggles

to protect your eyes.

•

Never

allow the airline nozzle near any of the body Sep apertures.

H INSIDE INFORMATION! Check the height of the valve

springs against new ones if possible, but if not, compare

them with each other. If any are shorter than the others,

play safe and replace the complete set. They are bound

to have suffered fatigue which could cause premature

valve failure. H

G Step 19: To install the valves, start from one end.

Lubricate a valve stem with fresh engine oil and slide it in to its

guide.

G Step 20: Locate a new valve stem seal over the stem of

the valve

(if applicable) and push down into contact with the

guide. Position the seal on its seat using a suitable metal tube.

G Step 21: Refit the flat washer and spring seat.

G Step 22: Position the inner and outer springs and the

spring

cap.

G Step 23: Re-apply the valve spring compressor and

compress

the springs enough to allow you to engage the split

collets

in

the stem grooves.

D INSIDE INFORMATION! Grease the grooves so that the

collets will 'stick' in place. The collets are easily fitted by

'sticking' the backs of them onto the end of a screw-

driver with some grease and feeding them into

position. B

G Step 24: Carefully release the spring compressor and

check

that the collets are correctly located. Tap the end of the

stem with

a hammer, to bed them in.

G Step 25: Fit the remaining valves.

Job 5. Petrol engine -

dismantling.

G Step 1: Familiarise yourself with the layout of the engine.

Refer to

illustration Job

2-1

for an exploded view of the

engine

components.

G Step 2: Drain the engine oil. Remove the cylinder head.

See

Job 2.

G Step 3: Remove the distributor. See PART D: IGNITION

• Step 4:

Remove the petrol

pump and spacer

block, if the

mechanical type

(a). (Electric fuel

pumps are in the

fuel tank.)

• Step 5:

Remove and

discard the oil filter

illustration Job

5-4,

• Step 6: Remove the water pump complete with its distri-

bution pipe, and the power steering pump (if fitted).

Q Step 7: Remove the alternator, the crankshaft pulley, the

crankshaft and camshaft sprockets, the cam belt tensioner

and the cam belt cover backplate.

• Step 8:

Remove the

auxiliary shaft

sprocket...

• Step 9: ...the

end plate and

seal, and remove

the auxiliary shaft.

• Step 10:

Undo and remove

the clutch, and

then the flywheel.

• Step 11: Turr

engine assembly c

remove the sump

and remove the crankcase breather (see

part b) with its pipe.

Page 71 of 171

• Step 24:

Remember to retrieve

the

two thrust

washers from the

end

main bearing in

the block. There are

none in the cap.

If so, you will probably need a new housing. If you are

replacing the camshaft, fit new followers as well.

IMPORTANT NOTE: All bearings, shells, piston rings and

ALL seals that bear on moving parts MUST be copiously

lubricated with fresh engine oil as the engine is being

reassembled. Work ONLY in clean conditions, with clean

components and clean hands. Re-assemble in the reverse

order of the dismantling procedure and take note of the

following steps which will help you carry out a smooth

operation.

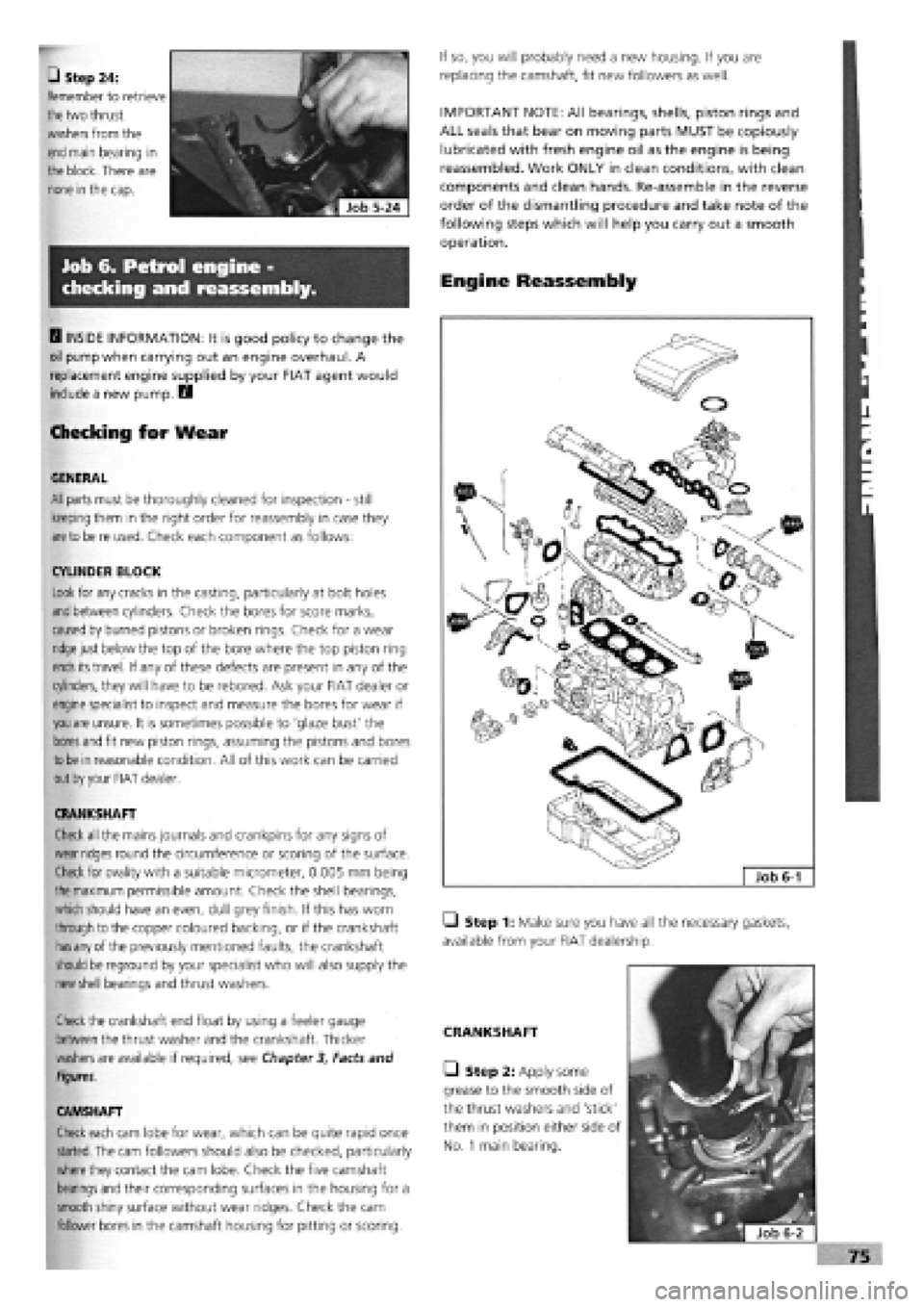

Engine Reassembly lob 6. Petrol engine -

checking and reassembly.

Q INSIDE INFORMATION: It is good policy to change the

oil pump when carrying out an engine overhaul. A

replacement engine supplied by your FIAT agent would

include a new pump. D

Checking for Wear

GENERAL

All parts must be thoroughly cleaned for inspection

-

still

keeping them in the right order for reassembly in case they

are to

be re used. Check each component as follows:

CYLINDER BLOCK

Look

for any cracks in the casting, particularly at bolt holes

and

between cylinders. Check the bores for score marks,

caused by burned pistons or broken rings. Check for a wear

ridge just

below the top of the bore where the top piston ring

ends its

travel. If any of these defects are present in any of the

cylinders, they will have to be rebored. Ask your FIAT dealer or

engine

specialist to inspect and measure the bores for wear if

you

are unsure. It is sometimes possible to 'glaze bust' the

bores and

fit new piston rings, assuming the pistons and bores

to be in

reasonable condition. All of this work can be carried

out by

your FIAT dealer.

CRANKSHAFT

Check

all

the mains journals and crankpins for any signs of

wear ridges round the circumference or scoring of the surface.

Check

for ovality with a suitable micrometer, 0.005 mm being

the maximum

permissible amount. Check the shell bearings,

which

should have an even, dull grey finish. If this has worn

through

to the copper coloured backing, or if the crankshaft

has any

of the previously mentioned faults, the crankshaft

should

be reground by your specialist who will also supply the

new shell

bearings and thrust washers.

Check

the crankshaft end float by using a feeler gauge

between the thrust washer and the crankshaft. Thicker

washers

are available if required, see Chapter

3,

Facts and

Figures.

CAMSHAFT

Check each cam lobe for wear, which can be quite rapid once

started. The cam followers should also be checked, particularly

where

they contact the cam lobe. Check the five camshaft

bearings

and their corresponding surfaces in the housing for a

smooth

shiny surface without wear ridges. Check the cam

follower bores in the camshaft housing for pitting or scoring.

Job 6-1

Q Step 1: Make sure you have all the necessary gaskets,

available from your FIAT dealership.

CRANKSHAFT

• Step 2: Apply some

grease to the smooth side of

the thrust washers and 'stick'

them in position either side of

No. 1 main bearing.

Page 75 of 171

G Step 43: Stop the engine and allow it to cool, check the

oil

and coolant levels and look for any leaks.

G Step 44: Avoid over-rewing or overloading the engine

during its settling down period of 600 miles. We recommend

an oil

and filter change at this mileage

-

this will help to

extend the life of your new engine.

Job 7. Petrol engine.

Valve clearances - adjustment.

0 INSIDE INFORMATION! Adjustment should always be

made with the engine cold. B

G Step 1: Remove the camshaft cover and the spark plugs.

Jack up a front wheel and engage top gear. Turning the wheel

will rotate the engine and therefore the camshaft. If the

engine

is

out of the car, use a socket and long lever on the

crankshaft pulley nut. If the cylinder head is detached, turn

the

camshaft belt sprocket, by hand.

G Step 2: The inlet and exhaust valves use different clear-

ances

which are checked when each cam lobe is pointing

directly away from its follower. See Chapter

3,

Facts and

Figures.

G Step 3: The order in which the valves are fitted in the

cylinder head is:

Inlet: 2-3-6-7

Exhaust: 1-4-5-8

from

the timing cover end.

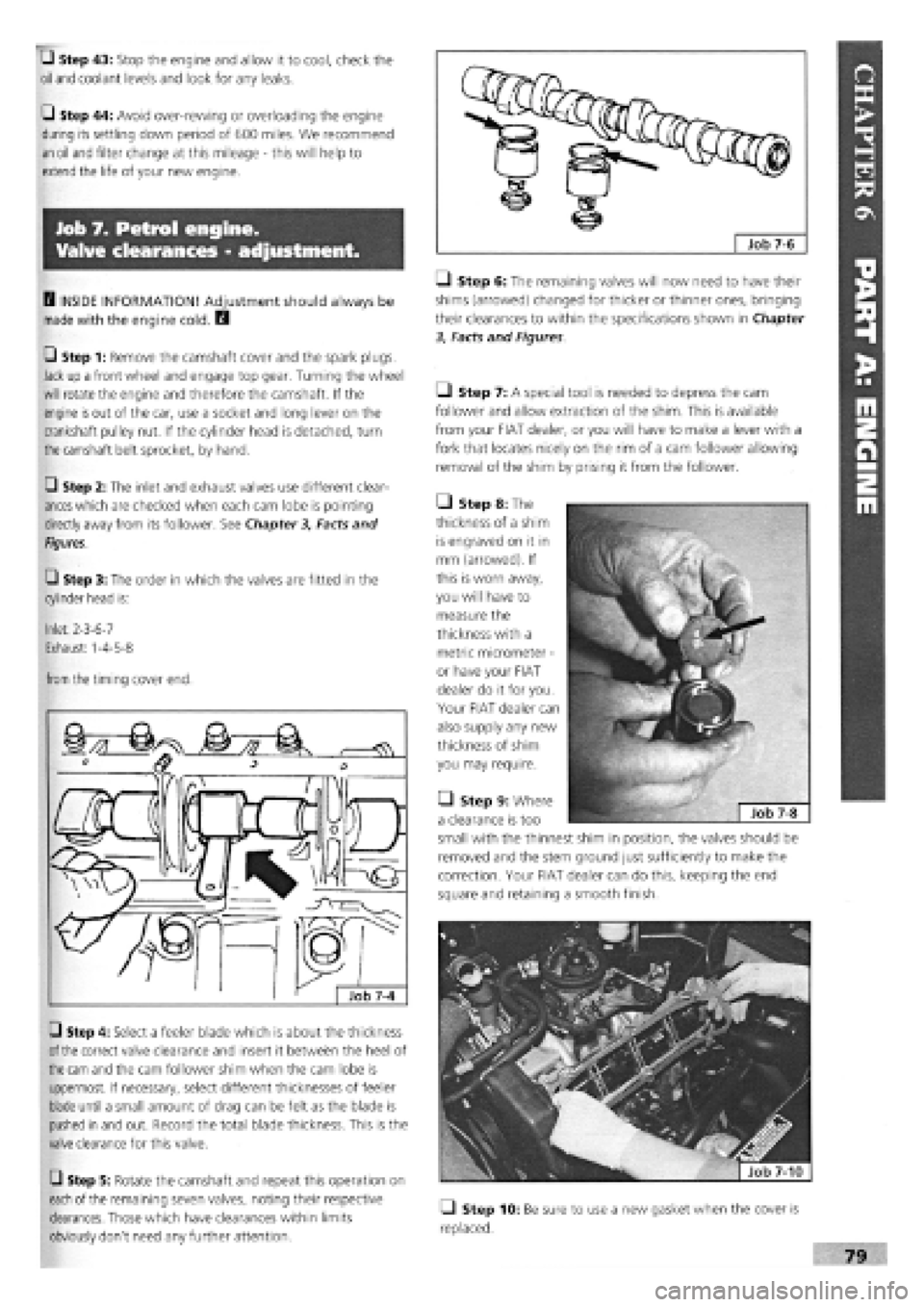

G Step 4: Select a feeler blade which is about the thickness

of the

correct valve clearance and insert it between the heel of

the cam

and the cam follower shim when the cam lobe is

uppermost. If necessary, select different thicknesses of feeler

blade until a small amount of drag can be felt as the blade is

pushed in and out. Record the total blade thickness. This is the

valve clearance for this valve.

G Step 5: Rotate the camshaft and repeat this operation on

each

of the remaining seven valves, noting their respective

clearances. Those which have clearances within limits

obviously don't need any further attention.

Q Step 6: The remaining valves will now need to have their

shims (arrowed) changed for thicker or thinner ones, bringing

their clearances to within the specifications shown in Chapter

3, Facts and Figures

Ll Step 7: A special tool is needed to depress the cam

follower and allow extraction of the shim. This is available

from your FIAT dealer, or you will have to make a lever with a

fork that locates nicely on the rim of a cam follower allowing

removal of the shim by prising it from the follower.

• Step 8: The

thickness of a shim

is engraved on it in

mm (arrowed). If

this is worn away,

you will have to

measure the

thickness with a

metric micrometer

-

or have your FIAT

dealer do it for you.

Your FIAT dealer can

also supply any new

thickness of shim

you may require.

• Step 9: Where

a clearance is too

small with the thinnest shim in position, the valves should be

removed and the stem ground just sufficiently to make the

correction. Your FIAT dealer can do this, keeping the end

square and retaining a smooth finish.

fjfefe^ | Job 7-10

Q Step 10: Be sure to use a new gasket when the cover is

replaced.

Page 82 of 171

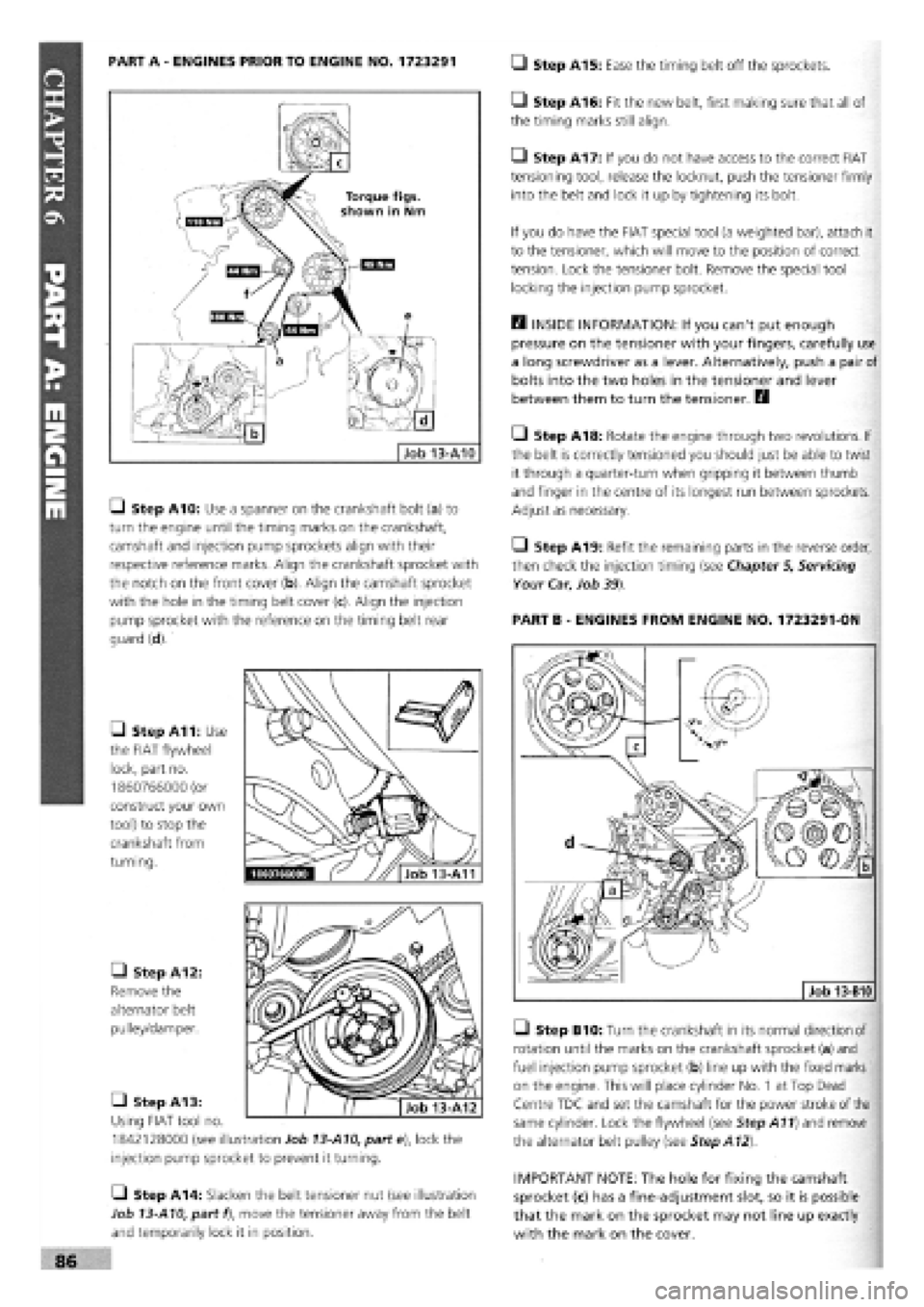

PART A

-

ENGINES PRIOR TO ENGINE NO. 1723291 • Step A15: Ease the timing belt off the sprockets.

Gl Step A10: Use a spanner on the crankshaft bolt (a) to

turn the engine until the timing marks on the crankshaft,

camshaft and injection pump sprockets align with their

respective reference marks. Align the crankshaft sprocket with

the notch on the front cover (b). Align the camshaft sprocket

with the hole in the timing belt cover (c). Align the injection

pump sprocket with the reference on the timing belt rear

guard (d).

• Step A11: Use

the FIAT flywheel

lock, part no.

1860766000 (or

construct your own

tool) to stop the

crankshaft from

turning.

• Step A12:

Remove the

alternator belt

pulley/damper.

• Step A13:

Using FIAT tool no.

1842128000 (see illustration Job

13-A10,

parte), lock the

injection pump sprocket to prevent it turning.

• Step A14: Slacken the belt tensioner nut (see illustration

Job

13-A10,

part f), move the tensioner away from the belt

and temporarily lock it in position.

• Step A16: Fit the new belt, first making sure that all of

the timing marks still align.

• Step A17: If you do not have access to the correct FIAT

tensioning tool, release the locknut, push the tensioner firmly

into the belt and lock it up by tightening its bolt.

If you do have the FIAT special tool (a weighted bar), attach it

to the tensioner, which will move to the position of correct

tension. Lock the tensioner bolt. Remove the special tool

locking the injection pump sprocket.

E3 INSIDE INFORMATION: If you can't put enough

pressure on the tensioner with your fingers, carefully use

a long screwdriver as a lever. Alternatively, push a pair of

bolts into the two holes in the tensioner and lever

between them to turn the tensioner. E9

Q Step A18: Rotate the engine through two revolutions. If

the belt is correctly tensioned you should just be able to twist

it through a quarter-turn when gripping it between thumb

and finger in the centre of its longest run between sprockets.

Adjust as necessary.

Q Step A19: Refit the remaining parts in the reverse order,

then check the injection timing (see Chapter

5,

Servicing

Your Car, Job

39)

PART B

-

ENGINES FROM ENGINE NO. 1723291-ON

Job 13-B10

Q Step B10: Turn the crankshaft in its normal direction of

rotation until the marks on the crankshaft sprocket (a) and

fuel injection pump sprocket (b) line up with the fixed marks

on the engine. This will place cylinder No. 1 at Top Dead

Centre TDC and set the camshaft for the power stroke of the

same cylinder. Lock the flywheel (see Step A11) and remove

the alternator belt pulley (see Step A12).

IMPORTANT NOTE: The hole for fixing the camshaft

sprocket (c) has a fine-adjustment slot, so it is possible

that the mark on the sprocket may not line up exactly

with the mark on the cover.

Page 85 of 171

SAFETY FIRST!

• The cylinder head is heavy and should be lifted from

the engine bay by two people.

Job 15. Diesel engine.

Cylinder head - refitting.

• Step 1: Put the

pistons at TDC

-

two

at a time

-

and

measure how much

they protrude above

the block surface.

This is ideally done

using a dial gauge

and holder (FIAT tools

1895882000 and

1870404000, respec-

tively) but if surfaces

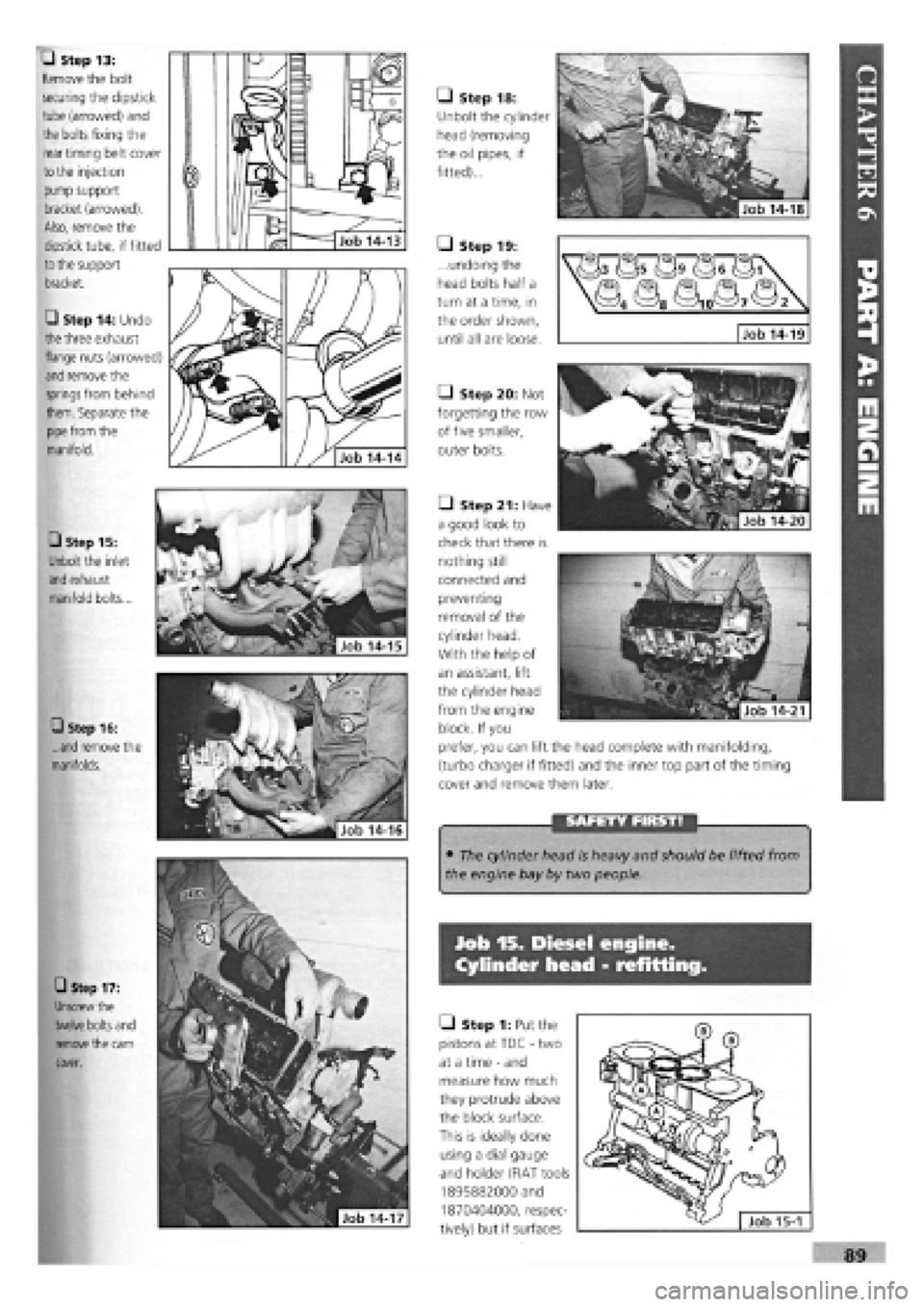

• Step 15:

Unbolt the inlet

and

exhaust

manifold bolts...

• Step 16:

...and remove the

manifolds.

• Step 17:

Unscrew the

twelve bolts

and

remove

the cam

cover.

• Step 18:

Unbolt the cylinder

head (removing

the oil pipes, if

fitted)...

• Step 20: Not

forgetting the row

of five smaller,

outer bolts.

• Step 13:

Remove the bolt

securing the dipstick

tube (arrowed) and

the bolts fixing the

rear timing belt cover

to

the injection

pump support

bracket (arrowed).

Also, remove the

dipstick tube, if fitted

to the

support

bracket.

• Step 14: Undo

the

three exhaust

flange nuts (arrowed)

and

remove the

springs

from behind

them. Separate the

pipe from

the

manifold.

• Step 19:

...undoing the

head bolts half a

turn at a time, in

the order shown,

until all are loose. Job 14-19

• Step 21: Have

a good look to

check that there is

nothing still

connected and

preventing

removal of the

cylinder head.

With the help of

an assistant, lift

the cylinder head

from the engine

block. If you

prefer, you can lift the head complete with manifolding,

(turbo charger if fitted) and the inner top part of the timing

cover and remove them later.

Page 88 of 171

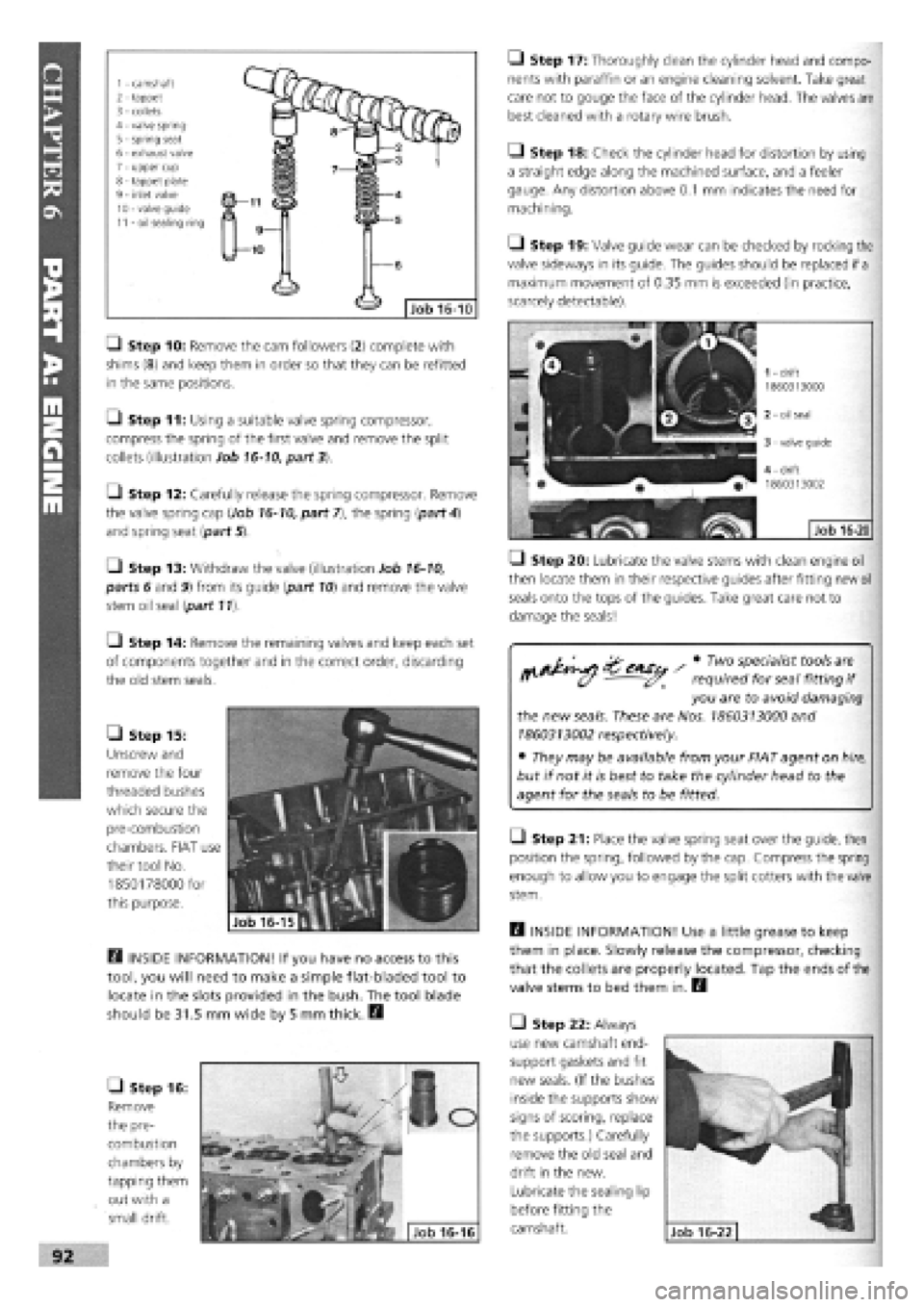

1 - camshaft 2 - tappet 3 - collets 4 - valve spring 5

-

spring seat 6 - exhaust valve 7 - upper cup 8 - tappet plate 9 - inlet valve 10 - valve guide 11 - oil sealing ring

• Step 10: Remove the cam followers (2) complete with

shims

(8)

and keep them in order so that they can be refitted

in the same positions.

O Step 11: Using a suitable valve spring compressor,

compress the spring of the first valve and remove the split

collets (illustration Job

16-10,

part 3).

[J Step 12: Carefully release the spring compressor. Remove

the valve spring cap (Job

16-10,

part 7), the spring {part

4)

and spring seat {part 5).

•

Step 13: Withdraw the valve (illustration Job

16-10,

parts 6 and 9) from its guide {part

10)

and remove the valve

stem oil seal {part 11).

Q Step 14: Remove the remaining valves and keep each set

of components together and in the correct order, discarding

the old stem seals.

• Step 15:

Unscrew and

remove the four

threaded bushes

which secure the

pre-combustion

chambers. FIAT use

their tool No.

1850178000 for

this purpose.

Q INSIDE INFORMATION! If you have no access to this

tool, you will need to make a simple flat-bladed tool to

locate in the slots provided in the bush. The tool blade

should be 31.5 mm wide by 5 mm thick. B

• Step 16:

Remove

the pre-

combustion

chambers by

tapping them

out with a

small drift.

Q Step 17: Thoroughly clean the cylinder head and compo-

nents with paraffin or an engine cleaning solvent. Take great

care not to gouge the face of the cylinder head. The valves are

best cleaned with a rotary wire brush.

• Step 18: Check the cylinder head for distortion by using

a straight edge along the machined surface, and a feeler

gauge. Any distortion above

0.1

mm indicates the need for

machining.

Q Step 19: Valve guide wear can be checked by rocking the

valve sideways in its guide. The guides should be replaced if

a

maximum movement of 0.35 mm is exceeded (in practice,

scarcely detectable).

• Step 20: Lubricate the valve stems with clean engine oil

then locate them in their respective guides after fitting new

oil

seals onto the tops of the guides. Take great care not to

damage the seals!

^ ^^iSu / * TW°

VfaliSt*?0lS

"'I

f' (y - required for seal fitting

if

you are to avoid damaging

the new

seals.

These are Nos.

1860313000

and

1860313002

respectively.

• They may be available from your FIAT agent on

hire,

but if not it is best to take the cylinder head to the

agent for the seals to be fitted.

Q Step 21: Place the valve spring seat over the guide, then

position the spring, followed by the cap. Compress the spring

enough to allow you to engage the split cotters with the valve

stem.

Q INSIDE INFORMATION! Use a little grease to keep

them in place. Slowly release the compressor, checking

that the collets are properly located. Tap the ends of the

valve stems to bed them in. B

• Step 22: Always

use new camshaft end-

support gaskets and fit

new seals. (If the bushes

inside the supports show

signs of scoring, replace

the supports.) Carefully

remove the old seal and

drift in the new.

Lubricate the sealing lip

before fitting the

camshaft.

Page 115 of 171

Job 6. Accelerator cable, petrol

injection engines - replacement

and adjustment.

Q Step 2: From inside the car,

unhook the cable nipple from the

fork (arrowed) at the top of the

pedal arm.

• Step 3: Pull out the bulkhead

grommet and release the cable.

^ • There are many different

cables, so take your old

cable as a pattern when

buying a replacement to make sure the new one is

exactly

the same.

Q Step 4: Refit in the reverse order

-

not forgetting the

grommet in the bulkhead!

Q Step 5: Check that, when the new cable is fitted:

• there

is

just the slightest amount of free-play in the cable

with the throttle closed.

• the carburettor lever is back against its stop with the throttle

fully open.

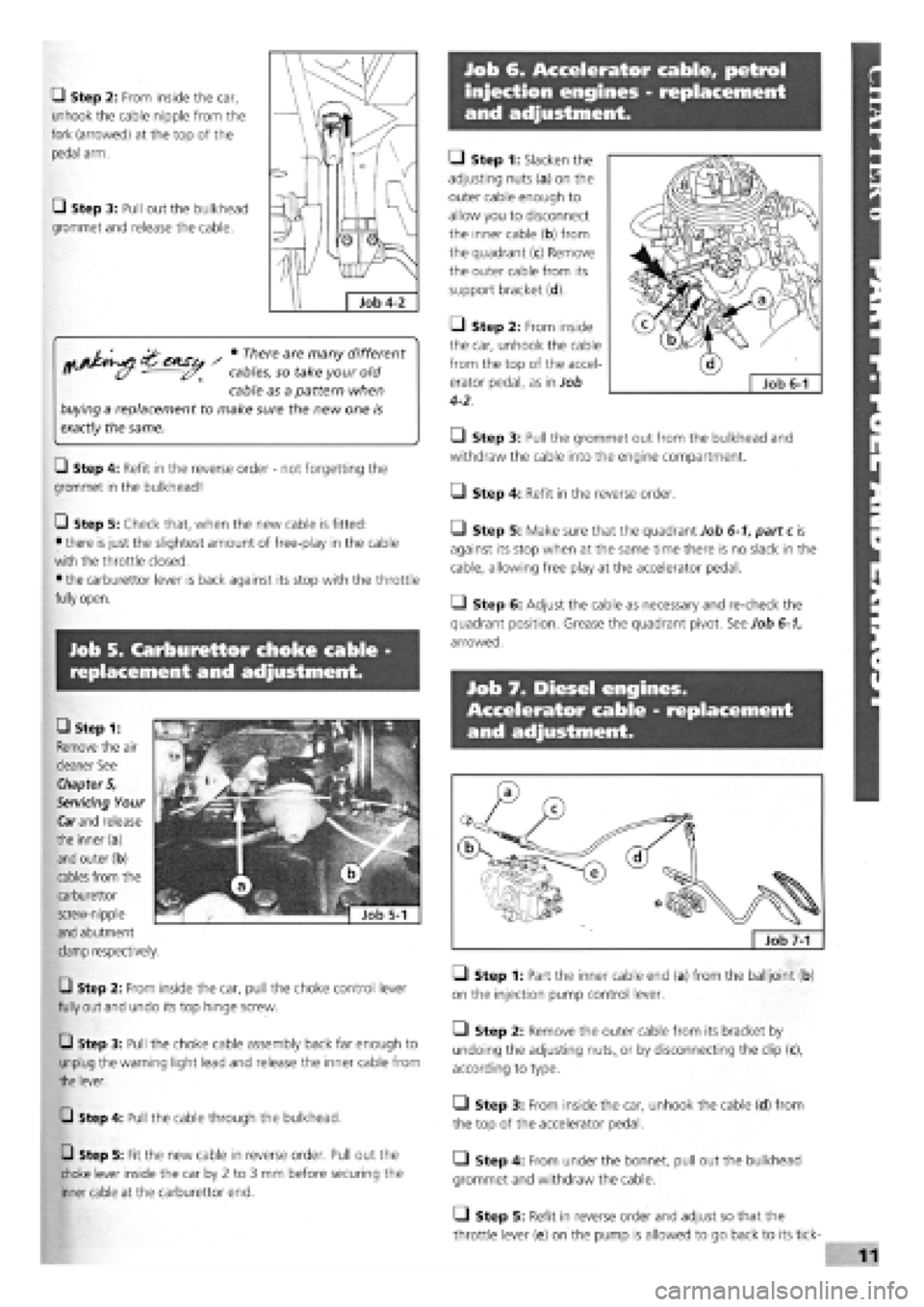

• Step 1: Slacken the

adjusting nuts (a) on the

outer cable enough to

allow you to disconnect

the inner cable (b) from

the quadrant (c) Remove

the outer cable from its

support bracket (d).

Q Step 2: From inside

the car, unhook the cable

from the top of the accel-

erator pedal, as in Job

4-2.

• Step 3: Pull the grommet out from the bulkhead and

withdraw the cable into the engine compartment.

O Step 4: Refit in the reverse order.

• Step 5: Make sure that the quadrant Job 6-1, part c is

against its stop when at the same time there is no slack in the

cable, allowing free play at the accelerator pedal.

• Step 6: Adjust the cable as necessary and re-check the

quadrant position. Grease the quadrant pivot. See Job 6-1,

arrowed.

Job 7. Diesel engines.

Accelerator cable - replacement

and adjustment.

Job 5. Carburettor choke cable -

replacement and adjustment.

Q Step 2: From inside the car, pull the choke control lever

fully out and undo its top hinge screw.

Q Step 3: Pull the choke cable assembly back far enough to

unplug the warning light lead and release the inner cable from

the lever.

Q Step 4: Pull the cable through the bulkhead.

Q Step 5: Fit the new cable in reverse order. Pull out the

choke lever inside the car by 2 to 3 mm before securing the

inner cable at the carburettor end.

Q Step 1: Part the inner cable end (a) from the balljoint (b)

on the injection pump control lever.

• Step 2: Remove the outer cable from its bracket by

undoing the adjusting

nuts,,

or by disconnecting the clip (c),

according to type.

• Step 3: From inside the car, unhook the cable (d) from

the top of the accelerator pedal.

• Step 4: From under the bonnet, pull out the bulkhead

grommet and withdraw the cable.

Q Step 5: Refit in reverse order and adjust so that the

throttle lever (e) on the pump is allowed to go back to its tick-

CD Step 1:

Remove the air

cleaner See

Chapter 5,

Servicing Your

Car

and

release

the inner(a)

and outer (b)

cables from the

carburettor

screw-nipple

and abutment

clamp respectively.