clock FIAT TEMPRA 1988 Service And User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 62 of 171

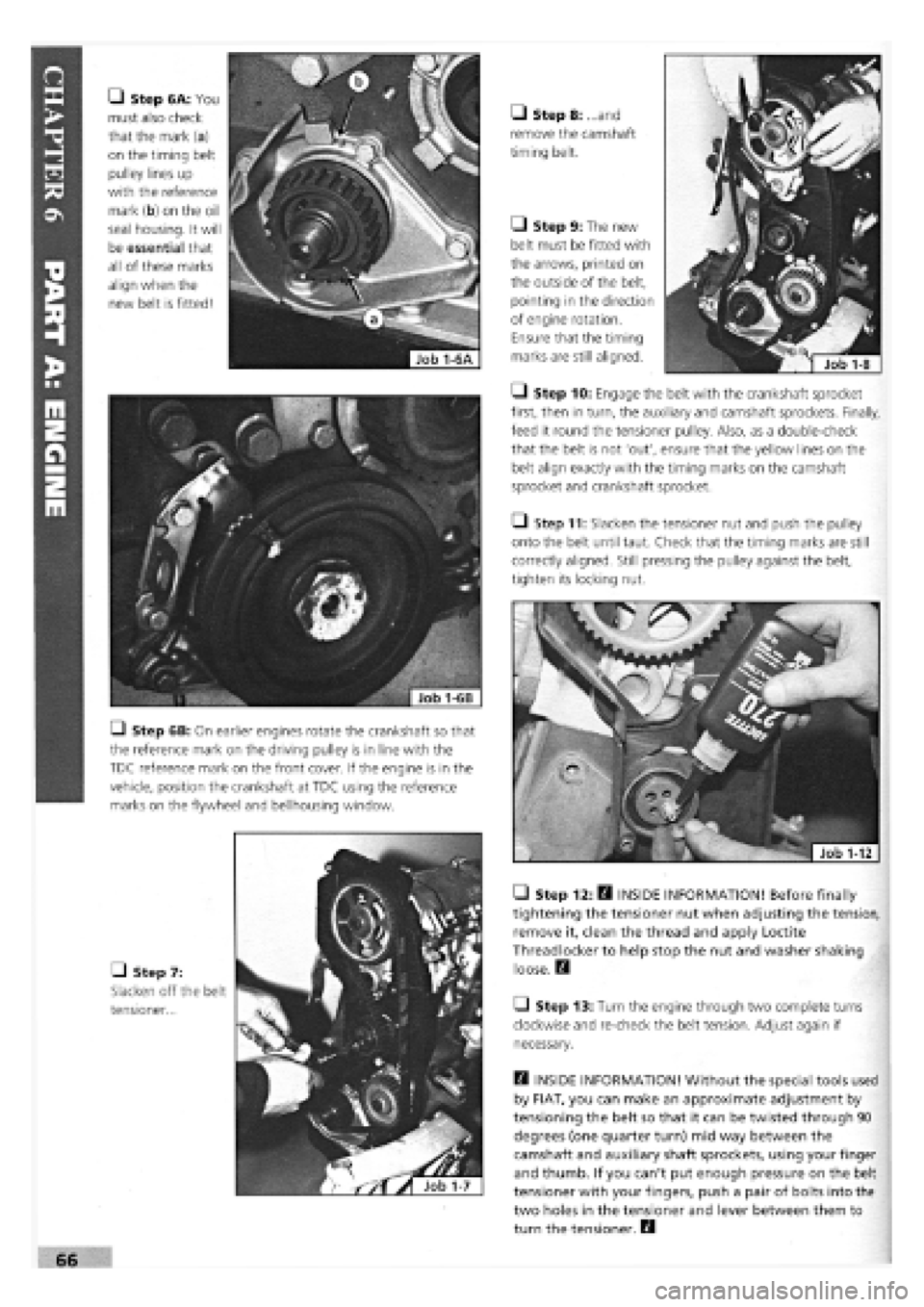

• Step 6A: You

must also check

that the mark (a)

on the timing belt

pulley lines up

with the reference

mark (b) on the oil

seal housing. It will

be essential that

all of these marks

align when the

new belt is fitted!

Q Step 6B: On earlier engines rotate the crankshaft so that

the reference mark on the driving pulley is in line with the

TDC reference mark on the front cover. If the engine is in the

vehicle, position the crankshaft at TDC using the reference

marks on the flywheel and bellhousing window.

• Step 7:

Slacken off the belt

tensioner...

• Step 8: ...and

remove the camshaft

timing belt.

Q Step 9: The new

belt must be fitted with

the arrows, printed on

the outside of the belt,

pointing in the direction

of engine rotation.

Ensure that the timing

marks are still aligned.

• Step 10: Engage the belt with the crankshaft sprocket

first, then in turn, the auxiliary and camshaft sprockets. Finally,

feed it round the tensioner pulley. Also, as a double-check

that the belt is not 'out', ensure that the yellow lines on the

belt align exactly with the timing marks on the camshaft

sprocket and crankshaft sprocket.

Q Step 11: Slacken the tensioner nut and push the pulley

onto the belt until taut. Check that the timing marks are still

correctly aligned. Still pressing the pulley against the belt,

tighten its locking nut.

• Step 12: H INSIDE INFORMATION! Before finally

tightening the tensioner nut when adjusting the tension,

remove it, clean the thread and apply Loctite

Threadlocker to help stop the nut and washer shaking

loose. Q

Q Step 13: Turn the engine through two complete turns

clockwise and re-check the belt tension. Adjust again if

necessary.

Q INSIDE INFORMATION! Without the special tools used

by FIAT, you can make an approximate adjustment by

tensioning the belt so that it can be twisted through 90

degrees (one quarter turn) mid way between the

camshaft and auxiliary shaft sprockets, using your finger

and thumb. If you can't put enough pressure on the belt

tensioner with your fingers, push a pair of bolts into the

two holes in the tensioner and lever between them to

turn the tensioner. B

Page 83 of 171

Q Step B11: Undo the belt tensioner nut (see illustration

Job 13-B10, part d), then remove the timing belt.

Q Step B12: Undo the nuts securing the brake vacuum

pump to the cylinder head (see illustration Job

16-1),

and

remove it.

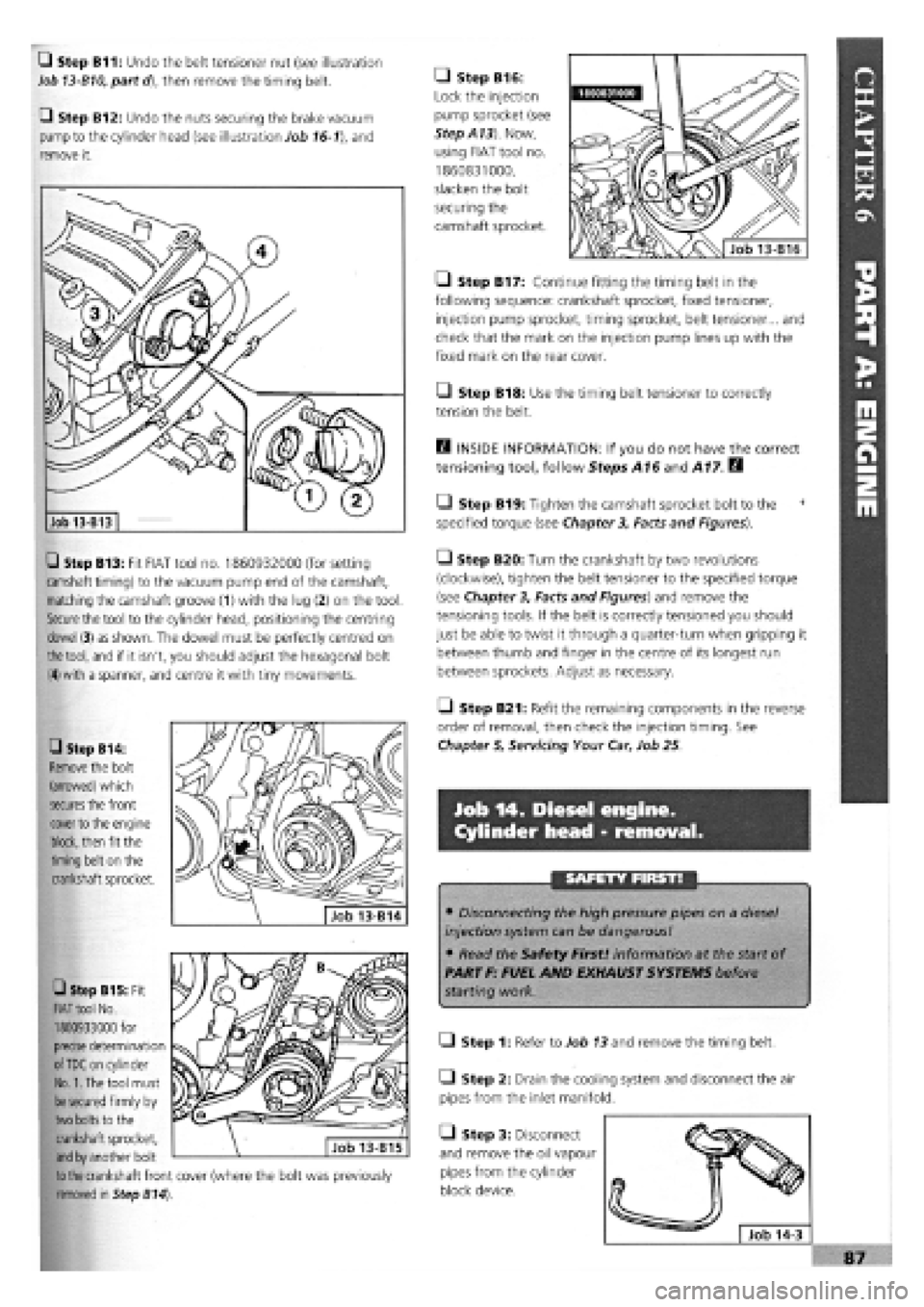

• Step B13: Fit FIAT tool no. 1860932000 (for setting

camshaft timing) to the vacuum pump end of the camshaft,

matching the camshaft groove (1) with the lug (2) on the tool

Secure

the tool to the cylinder head, positioning the centring

dowel

(3) as shown. The dowel must be perfectly centred on

the tool,

and if it isn't, you should adjust the hexagonal bolt

(4) with

a spanner, and centre it with tiny movements.

• Step B14:

Remove

the bolt

(arrowed) which

secures

the front

cover

to the engine

block,

then fit the

timing belt on the

crankshaft sprocket.

• Step B16:

Lock the injection

pump sprocket (see

StepA13). Now,

using FIAT tool no.

1860831000,

slacken the bolt

securing the

camshaft sprocket.

• Step B17: Continue fitting the timing belt in the

following sequence: crankshaft sprocket, fixed tensioner,

injection pump sprocket, timing sprocket, belt tensioner... and

check that the mark on the injection pump lines up with the

fixed mark on the rear cover.

• Step B18: Use the timing belt tensioner to correctly

tension the belt.

B INSIDE INFORMATION: If you do not have the correct

tensioning tool, follow Steps A16 and A17. B

• Step B19: Tighten the camshaft sprocket bolt to the 1

specified torque (see Chapter

3,

Facts and Figures).

Q Step B20: Turn the crankshaft by two revolutions

(clockwise), tighten the belt tensioner to the specified torque

(see Chapter

3,

Facts and Figures) and remove the

tensioning tools. If the belt is correctly tensioned you should

just be able to twist it through a quarter-turn when gripping it

between thumb and finger in the centre of its longest run

between sprockets. Adjust as necessary.

O Step B21: Refit the remaining components in the reverse

order of removal, then check the injection timing. See

Chapter

5,

Servicing Your Car, Job 25.

Job 14. Diesel engine.

Cylinder head - removal.

• Disconnecting the high pressure pipes on a diesel

injection system can be dangerous!

• Read the Safety First! information at the start of

PART F: FUEL AND EXHAUST SYSTEMS before

starting work.

Q Step 1: Refer to Job

13

and remove the timing belt.

• Step 2: Drain the cooling system and disconnect the air

pipes from the inlet manifold.

Q Step 3: Disconnect

and remove the oil vapour

pipes from the cylinder

block device.

Job 13-B13

• Step B15: Fit

FIAT tool

No.

1860933000 for

precise

determination

of TDC

on cylinder

No. 1. The

tool must

be secured

firmly by

two bolts

to the

crankshaft sprocket,

and by

another bolt

to the

crankshaft front cover (where the bolt was previously

removed in Step B14).

Page 91 of 171

Q Step 2: Before starting the engine, make sure all your

electrical connections are sound and your fuel, oil and coolant

connections are correct and secure.

Q Step 3: Run the engine to working temperature and then

allow to cool. Re-check all fluid levels.

Job 20. Diesel engine.

Mountings - replacement.

See

Job

12

and Job

18,

Step 20

Job 21. Diesel engine/

transmission (removed from car)

- separation.

Q Step 1: Remove the starter motor.

• Step 2: On the turbo version, undo the flange bolts see

Job

18,

Step 16A and withdraw the drive-shaft extension, if

still

fitted.

Q Step 3: Unbolt and remove the rear engine plate and the

gearbox, being careful to support the gearbox weight as it is

withdrawn.

Job 22. Diesel engine/

transmission (removed from car)

- reconnection.

Q Step 1: Before proceeding, check the condition of the

clutch and

its release mechanism. Make sure the driven plate

is

properly centred on the flywheel

-

see PART B: TRANS-

MISSION.

Q Step 2: Now reverse the order of separation, but be

careful when

engaging the gearbox input shaft with the

clutch

driven plate that you don't 'hang' its weight on the

splines.

Also,

see

Job 11.

Job 23. Diesel engine -

dismantling.

This Job should

be read in conjunction with Job 5 The

engines are

broadly similar although the information given in

this Job takes

priority for diesel engines. It is MOST

IMPORTANT that you read the FACT FILE on page 84.

SAFETY FIRST!

•

The inside

of diesel engines are particularly filthy

places!

•

Old diesel

oil

is

carcinogenic!

•

Wear suitable

impervious gloves!

I

• Step 1: Remove the timing belt and cylinder head. See

Jobs

13

and 14.

Q Step 2: Remove the alternator, water pump and

thermostat housing distribution pipe.

• Step 3: Remove the crankshaft timing belt sprocket.

Q INSIDE INFORMATION! Note that the bolt securing

the crankshaft sprocket has a left-hand thread and must

be undone clockwise. D

• Step 4: Unbolt the timing belt tensioner and idler pulleys.

• Step 5: Remove the injection pump sprocket.

Q INSIDE INFORMATION! You will need two FIAT tools

for this operation. One (No. 1860473000) is to prevent

the sprocket from turning when undoing the nut, and

the other (extractor No. 1842128000) to pull the sprocket

from the injection pump shaft. Alternatively it may be

possible to improvise a means of preventing sprocket

rotation, and a suitable three-leg puller may be carefully

used to withdraw the sprocket. Take care not to lose the

pump shaft Woodruff key. B

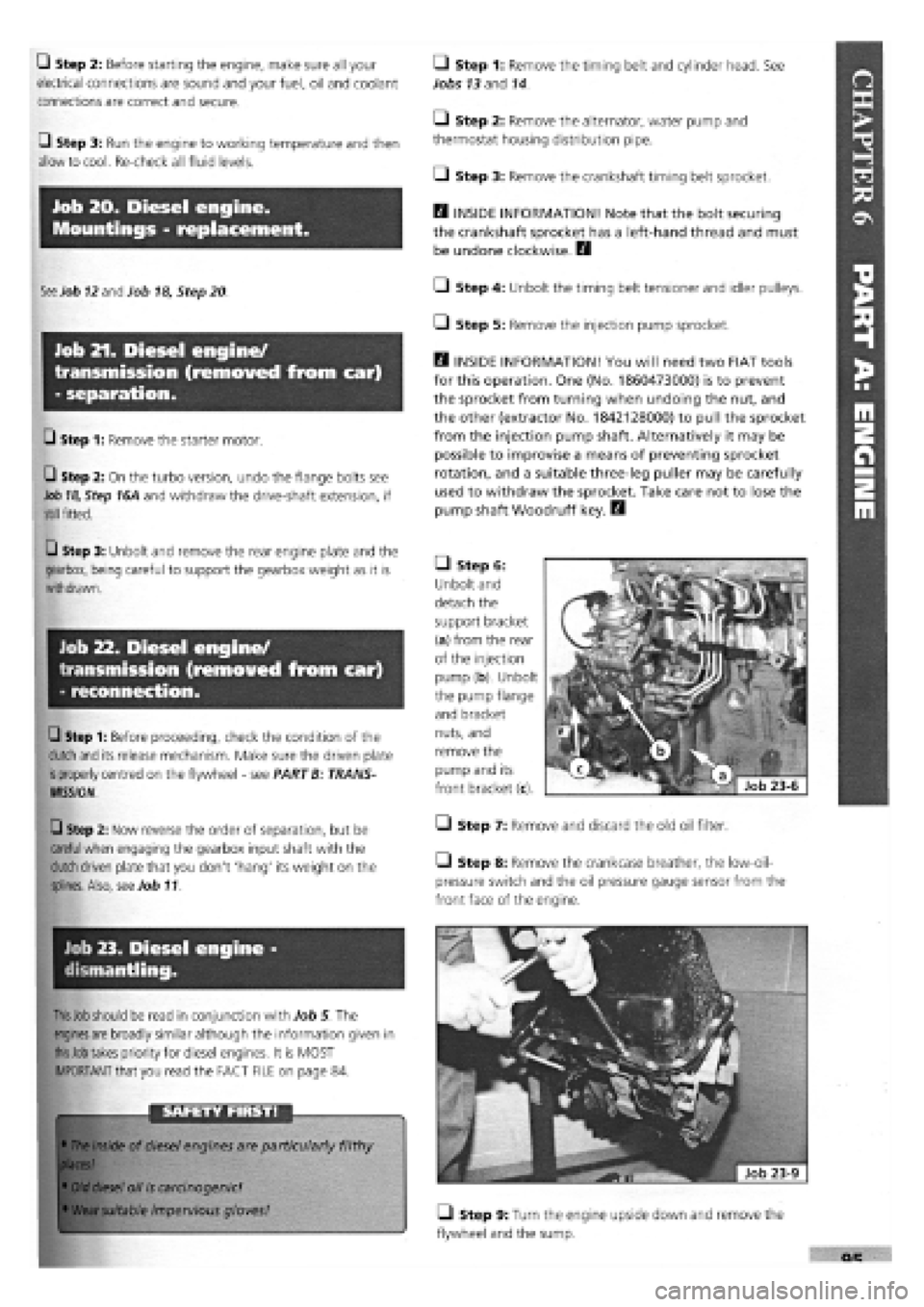

• Step 6:

Unbolt and

detach the

support bracket

(a) from the rear

of the injection

pump (b). Unbolt

the pump flange

and bracket

nuts, and

remove the

pump and its

front bracket (c).

• Step 7: Remove and discard the old oil filter.

Step 8: Remove the crankcase breather, the low-oil-

pressure switch and the oil pressure gauge sensor from the

front face of the engine.

• Step 9: Turn the engine upside down and remove the

flywheel and the sump.

Page 110 of 171

Job 15. Central locking -

replacement off components.

Job 14. Fuel gauge sender unit

removal and refitting.

SAFETY FIRST!

• Carry out this work out of doors, away from sources

of ignition.

• Make the open aperture on top of the fuel tank air

tight as quickly as possible.

• You should carry out this job when the fuel is at a

low level.

VEHICLES WITH ELECTRIC FUEL PUMPS

(NOT ENGINE MOUNTED)

Job 16. Electric windows -

replacement of components.

courtesy light lens and/or panel. The connectors are on

the rear of the unit.

• Step 3: The estate car has a rear courtesy light which is

removed as in Step 1 and 2

LJ Step 4: Refit in the reverse order.

PART A: ELECTRONIC CONTROL UNIT

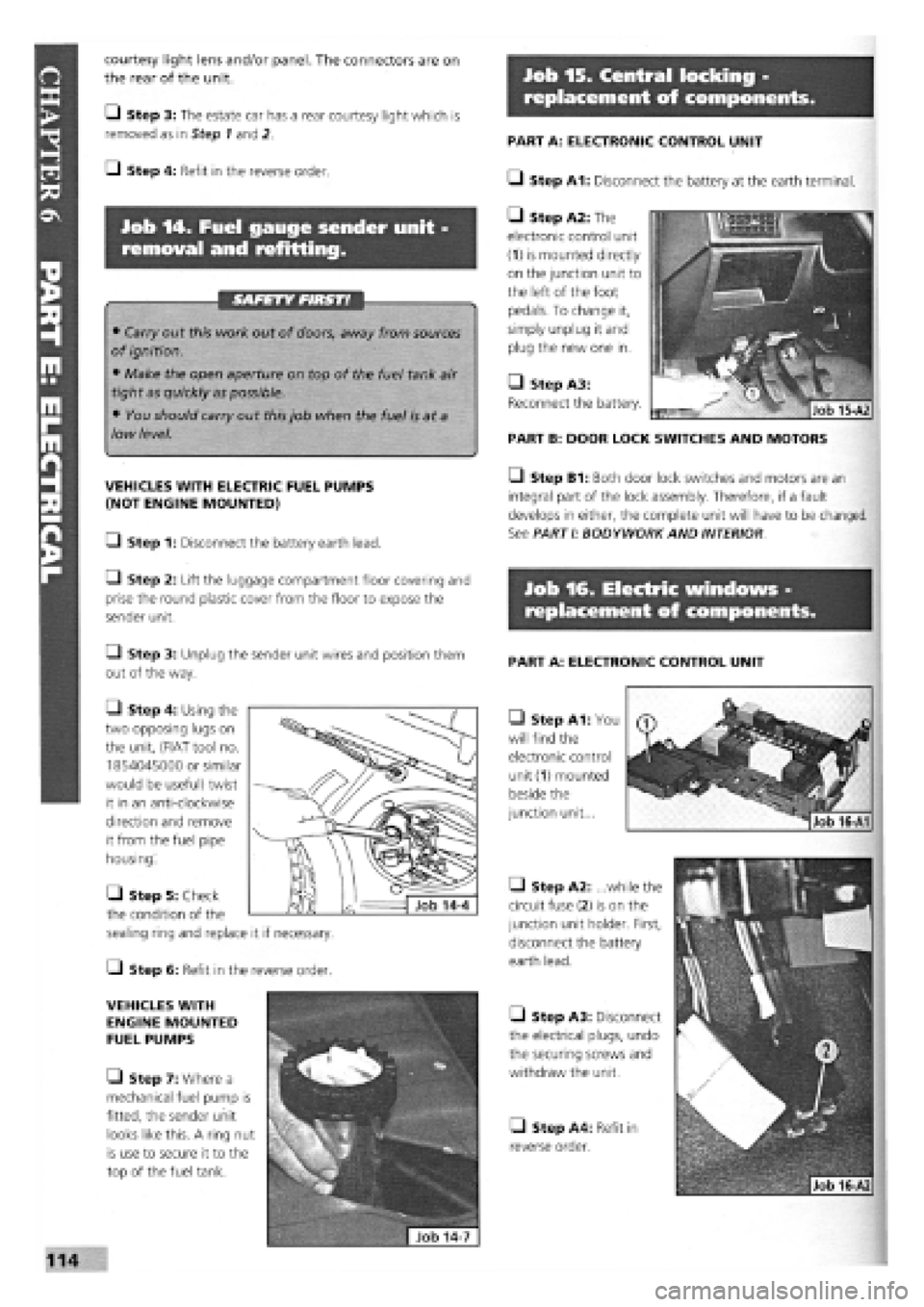

• Step A1: You

will find the

electronic control

unit

(1)

mounted

beside the

junction unit...

PART A: ELECTRONIC CONTROL UNIT

• Step A1: Disconnect the battery at the earth terminal.

• Step A2: The

electronic control unit

(1) is mounted directly

on the junction unit to

the left of the foot

pedals. To change it,

simply unplug it and

plug the new one in.

• Step A3:

Reconnect the battery.

PART B: DOOR LOCK SWITCHES AND MOTORS

• Step B1: Both door lock switches and motors are an

integral part of the lock assembly. Therefore, if a fault

develops in either, the complete unit will have to be changed.

See PARTI: BODYWORK AND INTERIOR

• Step A2: ...while the

circuit fuse (2) is on the

junction unit holder. First,

disconnect the battery

earth lead.

• Step A3: Disconnect

the electrical plugs, undo

the securing screws and

withdraw the unit.

• Step A4: Refit in

reverse order.

Q Step 1: Disconnect the battery earth lead.

Q Step 2: Lift the luggage compartment floor covering and

prise the round plastic cover from the floor to expose the

sender unit.

Q Step 3: Unplug the sender unit wires and position them

out of the way.

• Step 4: Using the

two opposing lugs on

the unit, (FIAT tool no.

1854045000 or similar

would be useful) twist

it in an anti-clockwise

direction and remove

it from the fuel pipe

housing.

C-) Step 6: Refit in the reverse order.

VEHICLES WITH

ENGINE MOUNTED

FUEL PUMPS

• Step 7: Where a

mechanical fuel pump is

fitted, the sender unit

looks like this. A ring nut

is use to secure it to the

top of the fuel tank.

• Step 5: Check

the condition of the

sealing ring and replace it if necessary.

Job 16-A1

Page 116 of 171

over stop and will also reach its 'maximum speed' stop with

the pedal fully depressed.

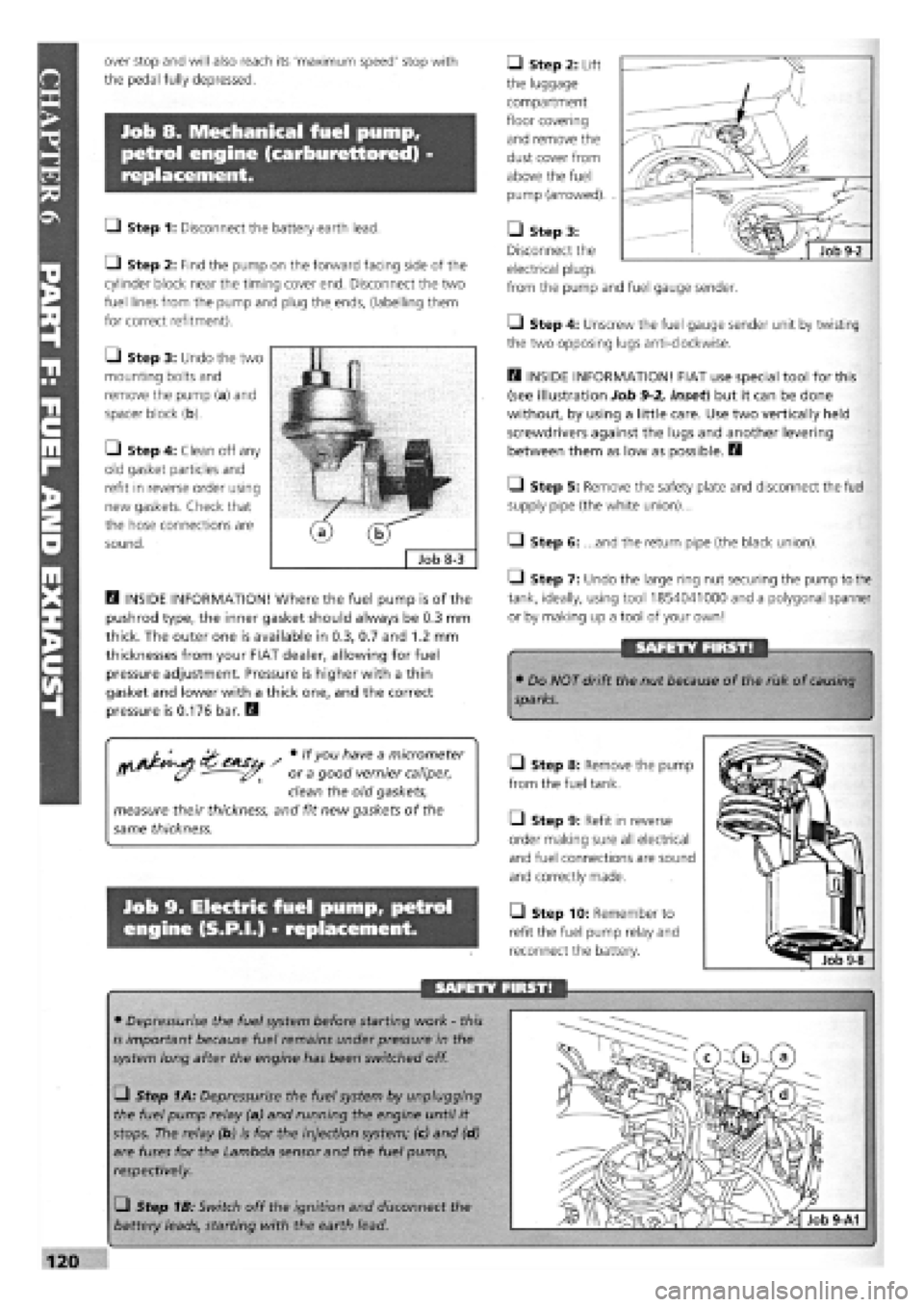

Job 8. Mechanical fuel pump,

petrol engine (carburettored) -

replacement.

O Step 1: Disconnect the battery earth lead.

• Step 2: Find the pump on the forward facing side of the

cylinder block near the timing cover end. Disconnect the two

fuel lines from the pump and plug the ends, (labelling them

for correct refitment).

• Step 3: Undo the two

mounting bolts and

remove the pump (a) and

spacer block (b).

• Step 4: Clean off any

old gasket particles and

refit in reverse order using

new gaskets. Check that

the hose connections are

sound.

D INSIDE INFORMATION! Where the fuel pump is of the

pushrod type, the inner gasket should always be 0.3 mm

thick. The outer one is available in 0.3, 0.7 and 1.2 mm

thicknesses from your FIAT dealer, allowing for fuel

pressure adjustment. Pressure is higher with a thin

gasket and lower with a thick one, and the correct

pressure is 0.176 bar. Q

/ # lfyou h"ve a m/cromefer

ff (y - or a good vernier caliper,

clean the old gaskets,

measure their thickness, and fit new gaskets of the

same thickness.

Job 9. Electric fuel pump, petrol

engine (S.P.I.) - replacement.

• Step 2: Lift

the luggage

compartment

floor covering

and remove the

dust cover from

above the fuel

pump (arrowed). .

• Step 3:

Disconnect the

electrical plugs

from the pump and fuel gauge sender.

• Step 4: Unscrew the fuel gauge sender unit by twisting

the two opposing lugs anti-clockwise.

D INSIDE INFORMATION! FIAT use special tool for this

(see illustration Job

9-2,

inset) but it can be done

without, by using a little care. Use two vertically held

screwdrivers against the lugs and another levering

between them as low as possible. H

Q Step 5: Remove the safety plate and disconnect the fuel

supply pipe (the white union)...

Q Step 6: ...and the return pipe (the black union).

1-1 Step 7: Undo the large ring nut securing the pump to the

tank, ideally, using tool 1854041000 and a polygonal spanner

or by making up a tool of your own!

SAFETY FIRST!

• Do NOT drift the nut because of the risk of

causing

sparks.

Q Step 8: Remove the pump

from the fuel tank.

Q Step 9: Refit in reverse

order making sure all electrical

and fuel connections are sound

and correctly made.

• Step 10: Remember to

refit the fuel pump relay and

reconnect the battery.

SAFETY FIRST!

• Depressurise the fuel system before starting work

-

this

is important because fuel remains under pressure in the

system long after the engine has been switched off.

• Step 1A: Depressurise the fuel system by unplugging

the fuel pump relay (a) and running the engine until it

stops. The relay (b) is for the injection system; (c) and (d)

are fuses for the Lambda sensor and the fuel pump,

respectively.

• Step 1B: Switch off the ignition and disconnect the

battery leads, starting with the earth lead.

Page 151 of 171

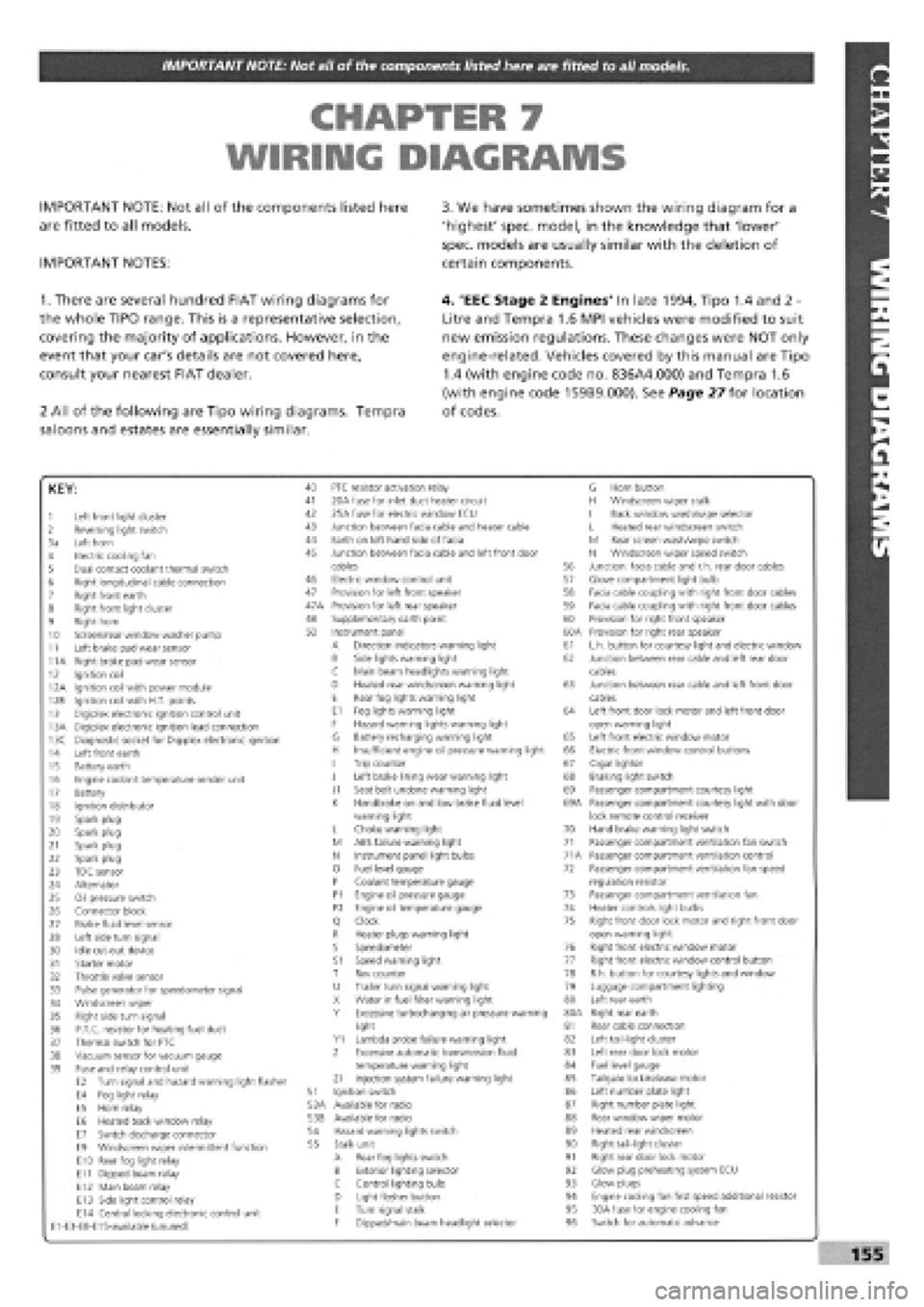

IMPORTANT NOTE: Not all of the components listed here are fitted to all models.

CHAPTER 7

WIRING DIAGRAMS

IMPORTANT NOTE: Not all of the components listed here

are fitted to all models.

IMPORTANT NOTES:

3. We have sometimes shown the wiring diagram for a

'highest' spec, model, in the knowledge that 'lower'

spec, models are usually similar with the deletion of

certain components.

1. There are several hundred FIAT wiring diagrams for

the whole TIPO range. This is a representative selection,

covering the majority of applications. However, in the

event that your car's details are not covered here,

consult your nearest FIAT dealer.

2 All of the following are Tipo wiring diagrams. Tempra

saloons and estates are essentially similar.

4. 'EEC Stage 2 Engines' In late 1994, Tipo 1.4 and 2 -

Litre and Tempra 1.6 MPI vehicles were modified to suit

new emission regulations. These changes were NOT only

engine-related. Vehicles covered by this manual are Tipo

1.4 (with engine code no. 836A4.000) and Tempra 1.6

(with engine code 159B9.000). See Page 27 for location

of codes.

KEY:

1 Left front light cluster 2 Reversing light switch 3a Left horn 4 Electric cooling fan 5 Dual contact coolant thermal switch 6 Right longitudinal cable connection 7 Right front earth 8 Right front light cluster 9 Right horn 10 Screen/rear window washer pump 11 Left brake pad wear sensor 11A Right brake pad wear sensor 12 Ignition coil 12A Ignition coil with power module 12B Ignition coil with H.T. points 13 Digiplex electronic ignition control unit 13A Digiplex electronic ignition lead connection 13C Diagnostic socket for Digiplex electronic ignition 14 Left front earth 15 Battery earth 16 Engine coolant temperature sender unit 17 Battery 18 Ignition distributor 19 Sparkplug 20 Spark plug 21 Sparkplug 22 Spark plug 23 TDC sensor 24 Alternator 25 Oil pressure switch 26 Connector block 27 Brake fluid level sensor 28 Left side turn signal 30 Idle cut-out device 31 Starter motor 32 Throttle valve sensor 33 Pulse generator for speedometer signal 34 Windscreen wiper 35 Right side turn signal 36 P.T.C. resistor for heating fuel duct 37 Thermal switch for PTC 38 Vacuum sensor for vacuum gauge 39 Fuse and relay control unit E2 Turn signal and hazard warning light flasher E4 Fog light relay E5 Horn relay E6 Heated back window relay E7 Switch discharge connector E9 Windscreen wiper intermittent function E10 Rear fog light relay E11 Dipped beam relay E12 Main beam relay E13 Side light control relay E14 Central locking electronic control unit E1-E3-E8-E15-available (unused)

40 PTC resistor activation relay 41 20A fuse for inlet duct heater circuit 42 25A fuse for electric window ECU 43 Junction between facia cable and heater cable 44 Earth on left hand side of facia 45 Junction between facia cable and left front door

G Horn button H Windscreen wiper stalk I Back window wash/wipe selector L Heated rear windscreen switch M Rear screen wash/wipe switch N Windscreen wiper speed switch cables 56 Junction: facia cable and r.h. rear door cables Electric window control unit 57 Glove compartment light bulb Provision for left front speaker 58 Facia cable coupling with right front door cables Provision for left rear speaker 59 Facia cable coupling with right front door cables Supplementary earth point 60 Provision for right front speaker Instrument panel 60A Provision for right rear speaker A Direction indicators warning light 61 L.h. button for courtesy light and electric window B Side lights warning light 62 Junction between rear cable and left rear door C Main beam headlights warning light cables D Heated rear windscreen warning light 63 Junction between rear cable and left front door E Rear fog lights warning light cables E1 Fog lights warning light 64 Left front door lock motor and left front door F Hazard warning lights warning light open warning light G Battery recharging warning light 65 Left front electric window motor H Insufficient engine oil pressure warning light 66 Electric front window control buttons I Trip counter 67 Cigar lighter J Left brake lining wear warning light 68 Braking light switch J1 Seat belt undone warning light 69 Passenger compartment courtesy light K Handbrake on and low brake fluid level 69A Passenger compartment courtesy light with door warning light lock remote control receiver L Choke warning light 70 Hand brake warning light switch M ABS failure warning light 71 Passenger compartment ventilation fan switch N Instrument panel light bulbs 71A Passenger compartment ventilation control 0 Fuel level gauge 72 Passenger compartment ventilation fan speed P Coolant temperature gauge regulation resistor P1 Engine oil pressure gauge 73 Passenger compartment ventilation fan P2 Engine oil temperature gauge 74 Heater controls light bulbs Q Clock 75 Right front door lock motor and right front door R Heater plugs warning light open warning light S Speedometer 76 Right front electric window motor S1 Speed warning light 77 Right front electric window control button T Rev counter 78 R.h. button for courtesy lights and window U Trailer turn signal warning light 79 Luggage compartment lighting X Water in fuel filter warning light 80 Left rear earth Y Excessive turbocharging air pressure warning 80A Right rear earth light 81 Rear cable connection Y1 Lambda probe failure warning light 82 Left tail-light cluster Z Excessive automatic transmission fluid 83 Left rear door lock motor temperature warning light 84 Fuel level gauge Z1 Injection system failure warning light 85 Tailgate lock/release motor Ignition switch 86 Left number plate light Available for radio 87 Right number plate light Available for radio 88 Rear window wiper motor Hazard warning lights switch 89 Heated rear windscreen Stalk unit 90 Right tail-light cluster A Rear fog lights switch 91 Right rear door lock motor B Exterior lighting selector 92 Glow plug preheating system ECU c Control lighting bulb 93 Glow plugs D Light flasher button 94 Engine cooling fan first speed additional resistor E Turn signal stalk 95 30A fuse for engine cooling fan F Dipped/main beam headlight selector 96 Switch for automatic advance

155

Page 164 of 171

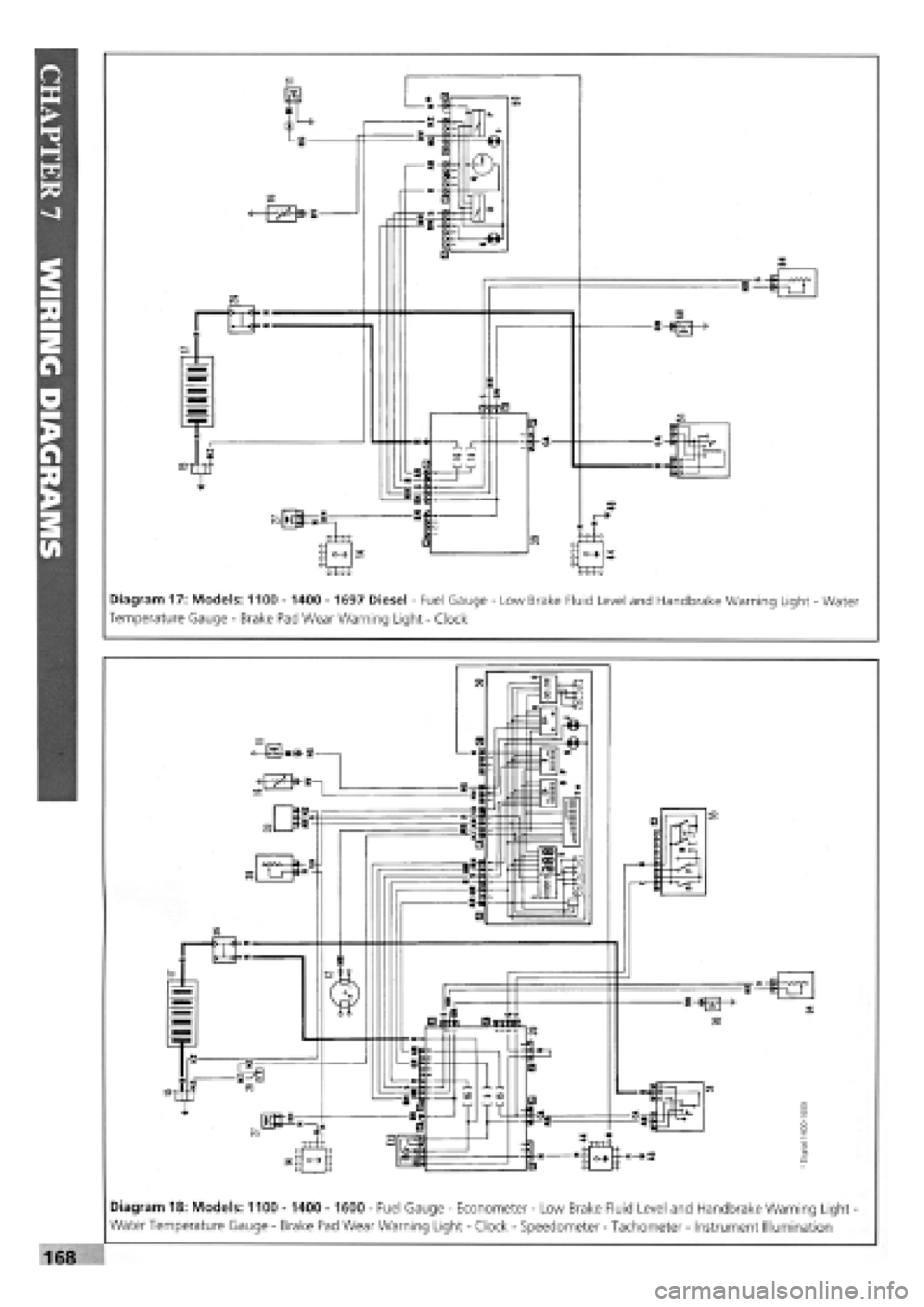

Diagram 17: Models: 1100 -1400

-

1697 Diesel - Fuel Gauge

-

Low Brake Fluid Level and Handbrake Warning Light

-

Water

Temperature Gauge

-

Brake Pad Wear Warning Light

-

Clock

|2n

tnj

•Pf

rrfl,

•5P

-if-•

-Is uu

—

—o— £ —•

i-^-Hi-

a

ZJ

ml

Diagram 18: Models: 1100

-

1400

-

1600

-

Fuel Gauge

-

Econometer

-

Low Brake Fluid Level and Handbrake Warning Light

Water Temperature Gauge

-

Brake Pad Wear Warning Light

-

Clock

-

Speedometer

-

Tachometer

-

Instrument Illumination

Page 165 of 171

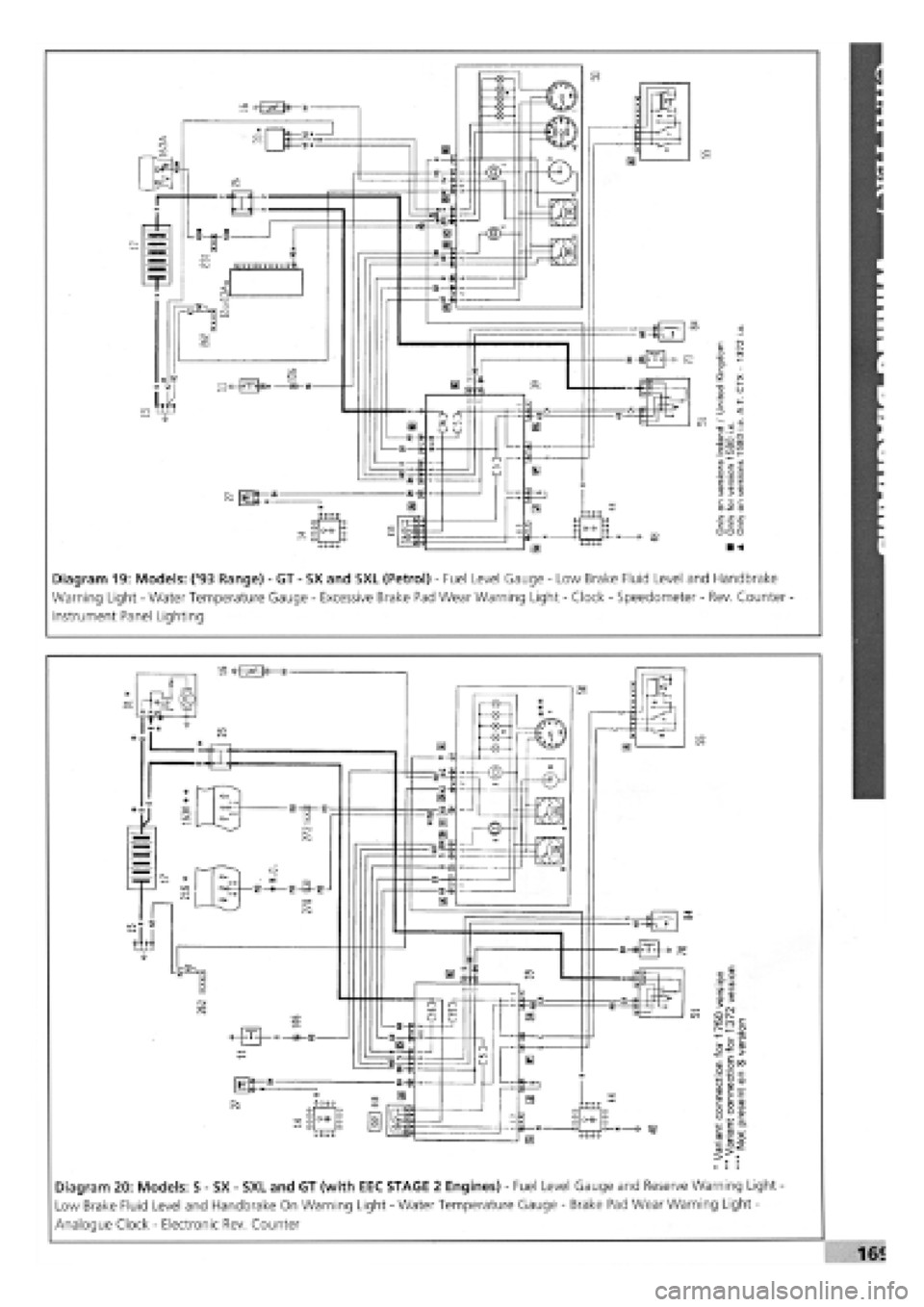

Diagram 19: Models: ('93 Range)

-

GT

-

SX and SXL (Petrol)

-

Fuel Level Gauge

-

Low Brake Fluid Level and Handbrake

Warning Light

-

Water Temperature Gauge

-

Excessive Brake Pad Wear Warning Light

-

Clock

-

Speedometer

-

Rev. Counter

-

Instrument Panel Lighting

.2'55 £

a>

>> Z. CM Ol— £ro c

k. <"

.2 2 c

Sis

8°a> - c Q. C rtj «_ z o

'»-

ra

~z_

2>7

Diagram 20: Models: S

-

SX

-

SXL and GT (with EEC STAGE 2 Engines)

-

Fuel Level Gauge and Reserve Warning Light

Low Brake Fluid Level and Handbrake On Warning Light

-

Water Temperature Gauge

-

Brake Pad Wear Warning Light -

Analogue Clock

-

Electronic Rev. Counter

Page 166 of 171

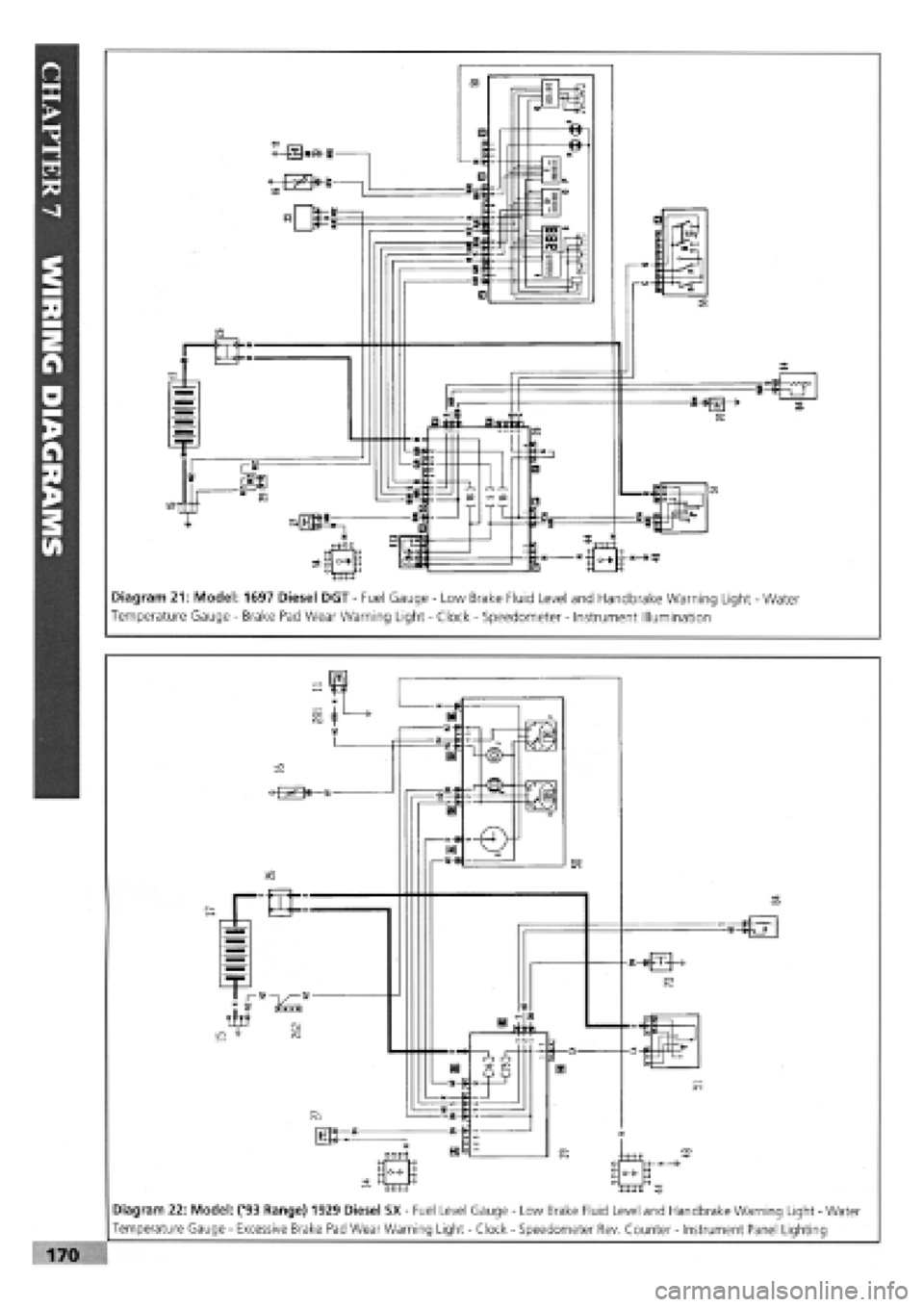

Diagram 21: Model: 1697 Diesel DGT

-

Fuel Gauge

-

Low Brake Fluid Level and Handbrake Warning Light

-

Water

Temperature Gauge

-

Brake Pad Wear Warning Light

-

Clock

-

Speedometer

-

Instrument Illumination

i

V—*

•u |

j* ta—

At

6 S

m

IS a

Diagram 22: Model: ('93 Range) 1929 Diesel SX

-

Fuel Level Gauge

-

Low Brake Fluid Level and Handbrake Warning Light

-

Water

Temperature Gauge

-

Excessive Brake Pad Wear Warning Light

-

Clock

-

Speedometer Rev. Counter

-

Instrument Panel Lighting

Page 167 of 171

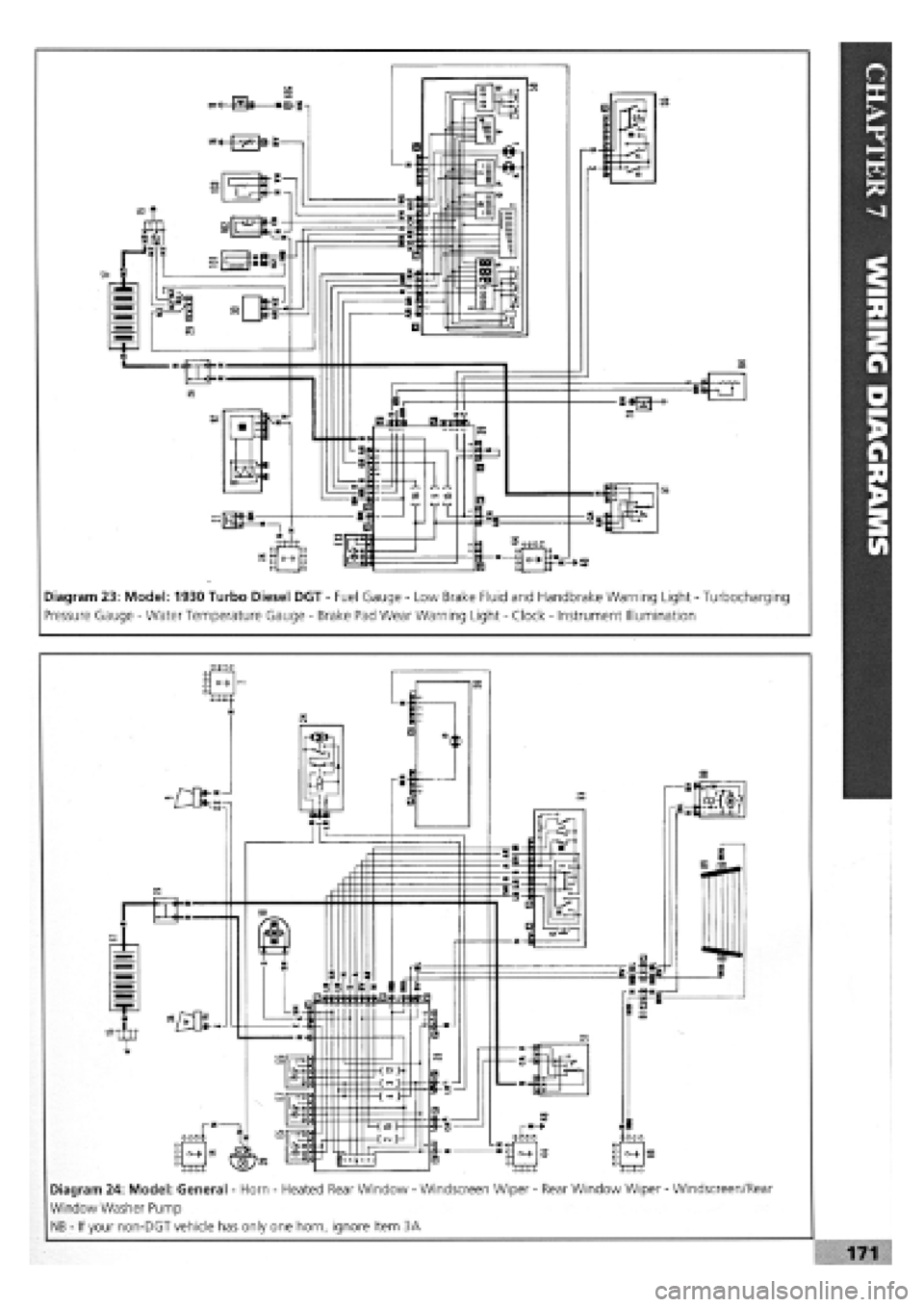

Diagram 23: Model: 1930 Turbo Diesel DGT

-

Fuel Gauge

-

Low Brake Fluid and Handbrake Warning Light

-

Turbocharging

Pressure Gauge

-

Water Temperature Gauge

-

Brake Pad Wear Warning Light

-

Clock

-

Instrument Illumination

Diagram 24: Model: General

-

Horn

-

Heated Rear Window

-

Windscreen Wiper

-

Rear Window Wiper

-

Windscreen/Rear

Window Washer Pump

NB

-

If your non-DGT vehicle has only one horn, ignore Item 3A