clock FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 7 of 171

Fluid levels (if included) are monitored by LEDs f, o and

p, indicating the levels of the fluid reservoirs.

A red LED illuminates at the position on the check panel

corresponding to a side door or a hatchback/tailgate

that is not properly closed.

SIDE AND TAIL LIGHTS

When the side and tail lights are turned on, the check

panel monitors the light bulbs, fuses and circuits.

• LED g monitors the front side lights.

• LED i monitors the tail lights.

If one of the two fuses protecting the following bulbs

blows, LEDs g, i, and m illuminate.

NUMBER PLATE LIGHTS

• LED m indicates when one or both of the number

plate light bulbs have burnt out.

REAR FOG LIGHTS

• When the fog-guard lights are turned on, LED h

monitors the light bulbs.

• When the fuse blows or a circuit malfunction occurs,

LED h illuminates, but not the panel indicator.

STOP LIGHTS

If one or both stop lights burn out, the fuse blows or a

circuit malfunction occurs, LED I or n illuminates when

braking.

• LED n monitors the left stop light.

• LED I monitors the right stop light.

If both bulbs burn out at the same time or brake pedal

switch malfunction occurs, both LEDs I and n

illuminate.

ENGINE OIL LEVEL

• LED f illuminates when the engine oil level is low (key

at MAR,engine not running).

The oil level monitoring system does not operate when

the engine is running. If the oil level warning LED

illuminates when driving, a circuit sensor malfunction

has occurred.

When starting the car on a hill or within 10 minutes of

switching off the engine the warning light may

illuminate (event will be stored in system memory). Start

the engine again on level ground to ensure the oil level

is sufficient.

COOLANT

A low coolant level is indicated by LED o (key at MAR).

The LED also illuminates when a sensor or circuit

malfunction occurs.

WINDSCREEN AND REAR SCREEN WASH LEVELS

• LED p illuminates (key at MAR) when the level in the

windscreen or rear screen wash reservoirs are low.

• The LED also indicates when a circuit or sensor

malfunction occurs.

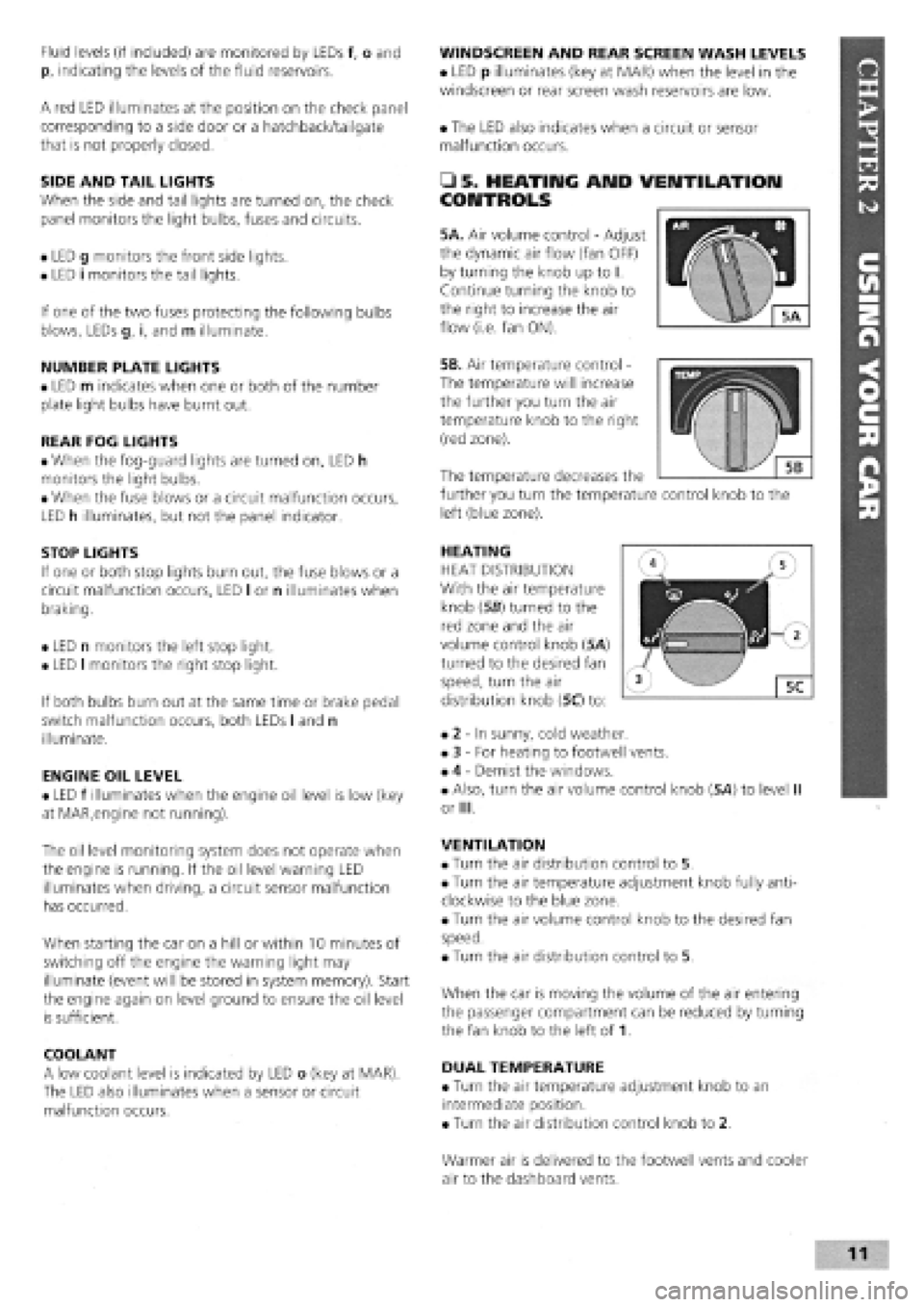

• 5. HE ATI IMG AMD VENTILATION

CONTROLS

5A. Air volume control

-

Adjust

the dynamic air flow (fan OFF)

by turning the knob up to I.

Continue turning the knob to

the right to increase the air

flow (i.e. fan ON).

5B. Air temperature control -

The temperature will increase

the further you turn the air

temperature knob to the right

(red zone).

HEATING

HEAT DISTRIBUTION

With the air temperature

knob (56) turned to the

red zone and the air

volume control knob (5A)

turned to the desired fan

speed, turn the air

distribution knob (5C) to:

• 2

-

In sunny, cold weather.

• 3

-

For heating to footwell vents.

• 4

-

Demist the windows.

• Also, turn the air volume control knob (5A) to level II

or III.

VENTILATION

• Turn the air distribution control to 5.

• Turn the air temperature adjustment knob fully anti-

clockwise to the blue zone.

• Turn the air volume control knob to the desired fan

speed.

• Turn the air distribution control to 5.

When the car is moving the volume of the air entering

the passenger compartment can be reduced by turning

the fan knob to the left of 1.

DUAL TEMPERATURE

• Turn the air temperature adjustment knob to an

intermediate position.

• Turn the air distribution control knob to 2.

The temperature decreases the

further you turn the temperature control knob to the

left (blue zone).

Warmer air is delivered to the footwell vents and cooler

air to the dashboard vents.

Page 11 of 171

SAFETY FIRST!

If an air bag has been fitted to your vehicle:

• DO NOT apply stickers or any other objects to

the steering wheel as this may restrict the

operation of the air bag.

• NEVER travel with anything on your lap or in

front of your chest

• NEVER drive with a cigarette, pipe, pen or any

other object in your mouth.

• 12. INTERIOR LIGHTS

COURTESY LIGHT

On most models the courtesy light is positioned in the

centre of the roof.

• With the light switch in the central position the light

turns on when either of the front doors is opened.

• When the switch is in the right position the light

remains on.

• With the switch in the left position the light is

switched off.

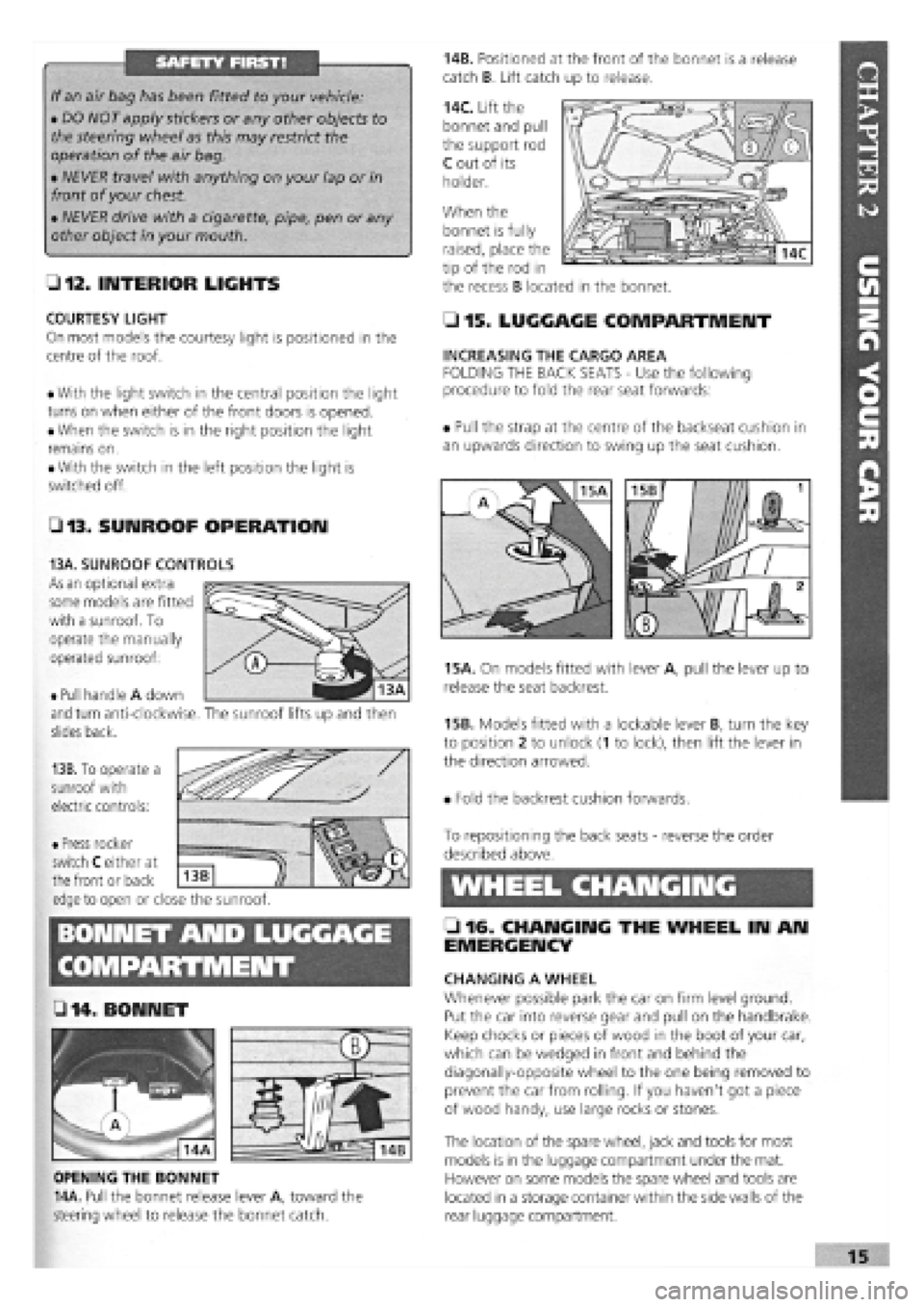

• 13. SUNROOF OPERATION

14B. Positioned at the front of the bonnet is a release

catch B. Lift catch up to release.

14C. Lift the

bonnet and pull

the support rod

C out of its

holder.

When the

• 15. LUGGAGE COMPARTMENT

INCREASING THE CARGO AREA

FOLDING THE BACK SEATS

-

Use the following

procedure to fold the rear seat forwards:

• Pull the strap at the centre of the backseat cushion in

an upwards direction to swing up the seat cushion.

15A. On models fitted with lever A, pull the lever up to

release the seat backrest.

15B. Models fitted with a lockable lever B, turn the key

to position 2 to unlock (1 to lock), then lift the lever in

the direction arrowed.

• Fold the backrest cushion forwards.

BONNET AND LUGGAGE

L 2 . fj§

• 14 .BONNET

OPENING THE BONNET

14A. Pull the bonnet release lever A, toward the

steering wheel to release the bonnet catch.

To repositioning the back seats

-

reverse the order

described above.

WHEEL CHANGING

• 16. CHANGING THE WHEEL IN AN

EMERGENCY

CHANGING A WHEEL

Whenever possible park the car on firm level ground.

Put the car into reverse gear and pull on the handbrake.

Keep chocks or pieces of wood in the boot of your car,

which can be wedged in front and behind the

diagonally-opposite wheel to the one being removed to

prevent the car from rolling. If you haven't got a piece

of wood handy, use large rocks or stones.

The location of the spare wheel, jack and tools for most

models is in the luggage compartment under the mat.

However on some models the spare wheel and tools are

located in a storage container within the side walls of the

rear luggage compartment.

bonnet is fully

raised, place the

tip of the rod in

the recess B located in the bonnet.

• Pull handle A down

and turn anti-clockwise,

slides back.

13B. To operate a

sunroof with

electric controls:

13A. SUNROOF CONTROLS

As an optional extra

some models are fitted

with a sunroof. To

operate the manually

operated sunroof:

The sunroof lifts up and then

• Press rocker

switch C either at

the front or back

edge to open or close the sunroof.

Z3

Page 26 of 171

PART C: VEHICLE RAISED OFF THE GROUND

Bodywork Structure

01

.

Any sharp edges on the external bodywork, caused by damage or corrosion will cause the vehicle to fail.

02 . Check all load bearing areas for corrosion. Open the doors and check the sills inside and out, above and below. Any corrosion in structural metalwork within 30 cm (12 in.) of seat belt mounting, steering and suspension attachment points will cause the vehicle to fail.

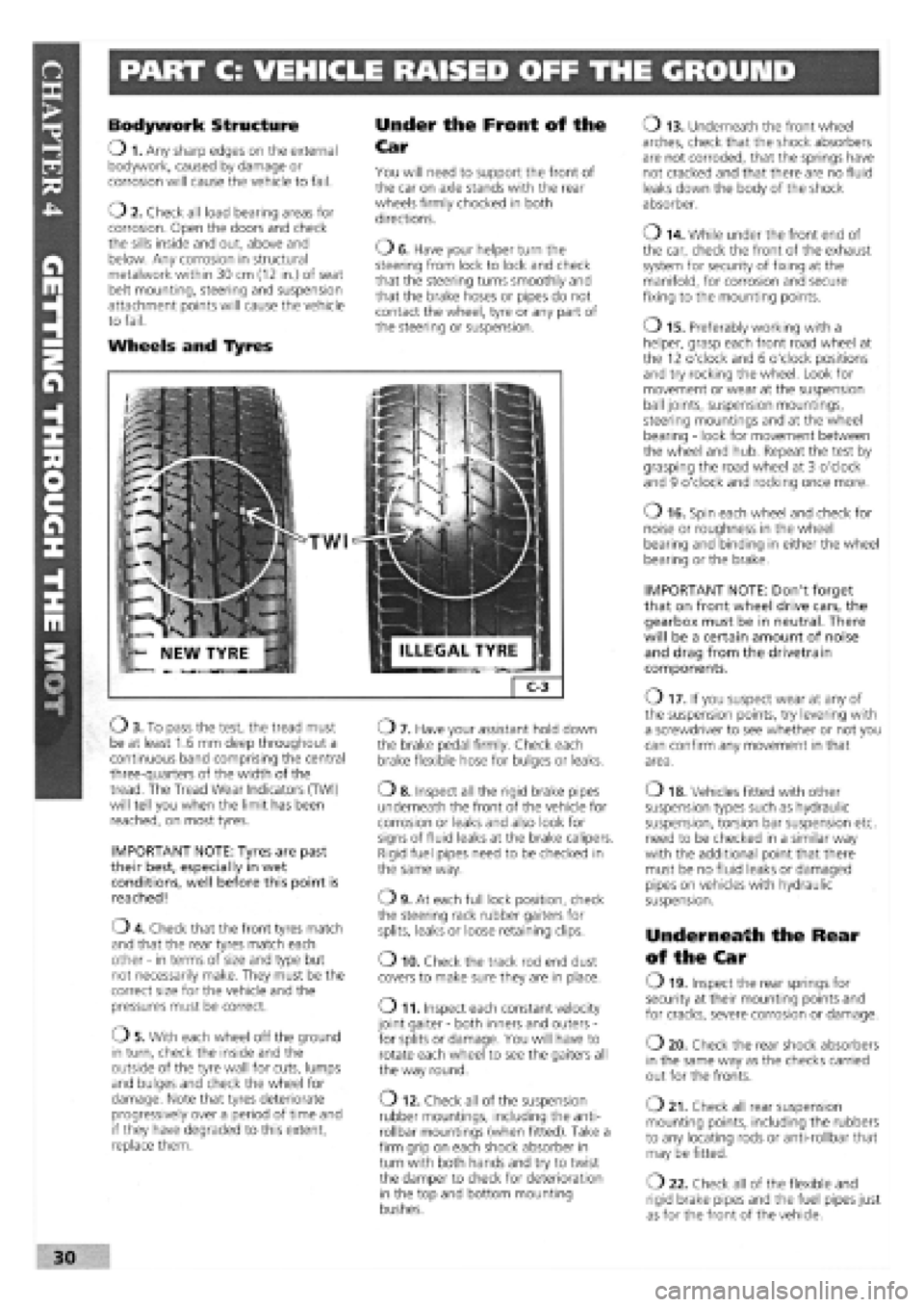

Wheels and Tyres

Under the Front of the

Car

You will need to support the front of the car on axle stands with the rear wheels firmly chocked in both directions.

OE . Have your helper turn the steering from lock to lock and check that the steering turns smoothly and that the brake hoses or pipes do not contact the wheel, tyre or any part of the steering or suspension.

TWI

Ob . To pass the test, the tread must be at least 1.6 mm deep throughout a continuous band comprising the central three-quarters of the width of the tread. The Tread Wear Indicators (TWI) will tell you when the limit has been reached, on most tyres.

IMPORTANT NOTE: Tyres are past their best, especially in wet conditions, well before this point is reached!

04 . Check that the front tyres match and that the rear tyres match each other

-

in terms of size and type but not necessarily make. They must be the correct size for the vehicle and the pressures must be correct.

05 . With each wheel off the ground in turn, check the inside and the outside of the tyre wall for cuts, lumps and bulges and check the wheel for damage. Note that tyres deteriorate progressively over a period of time and if they have degraded to this extent, replace them.

07 . Have your assistant hold down the brake pedal firmly. Check each brake flexible hose for bulges or leaks.

o 8. Inspect all the rigid brake pipes underneath the front of the vehicle for corrosion or leaks and also look for signs of fluid leaks at the brake calipers. Rigid fuel pipes need to be checked in the same way.

09 . At each full lock position, check the steering rack rubber gaiters for splits, leaks or loose retaining clips.

o 10. Check the track rod end dust covers to make sure they are in place.

o 11. Inspect each constant velocity joint gaiter

-

both inners and outers

-

for splits or damage. You will have to rotate each wheel to see the gaiters all the way round.

O 12. Check all of the suspension rubber mountings, including the anti-rollbar mountings (when fitted). Take a firm grip on each shock absorber in turn with both hands and try to twist the damper to check for deterioration in the top and bottom mounting bushes.

o 13. Underneath the front wheel arches, check that the shock absorbers are not corroded, that the springs have not cracked and that there are no fluid leaks down the body of the shock absorber.

o 14. While under the front end of the car, check the front of the exhaust system for security of fixing at the manifold, for corrosion and secure fixing to the mounting points.

o 15. Preferably working with a helper, grasp each front road wheel at the 12 o'clock and 6 o'clock positions and try rocking the wheel. Look for movement or wear at the suspension ball joints, suspension mountings, steering mountings and at the wheel bearing

-

look for movement between the wheel and hub. Repeat the test by grasping the road wheel at 3 o'clock and 9 o'clock and rocking once more.

o 16. Spin each wheel and check for noise or roughness in the wheel bearing and binding in either the wheel bearing or the brake.

IMPORTANT NOTE: Don't forget that on front wheel drive cars, the gearbox must be in neutral. There will be a certain amount of noise and drag from the drivetrain components.

O 17. If you suspect wear at any of the suspension points, try levering with a screwdriver to see whether or not you can confirm any movement in that area.

o 18. Vehicles fitted with other suspension types such as hydraulic suspension, torsion bar suspension etc. need to be checked in a similar way with the additional point that there must be no fluid leaks or damaged pipes on vehicles with hydraulic suspension.

Underneath the Rear

of the Car

O 19. Inspect the rear springs for security at their mounting points and for cracks, severe corrosion or damage.

o 20. Check the rear shock absorbers in the same way as the checks carried out for the fronts.

o 21. Check all rear suspension mounting points, including the rubbers to any locating rods or anti-rollbar that may be fitted.

O 22. Check all of the flexible and rigid brake pipes and the fuel pipes just as for the front of the vehicle.

30

Page 31 of 171

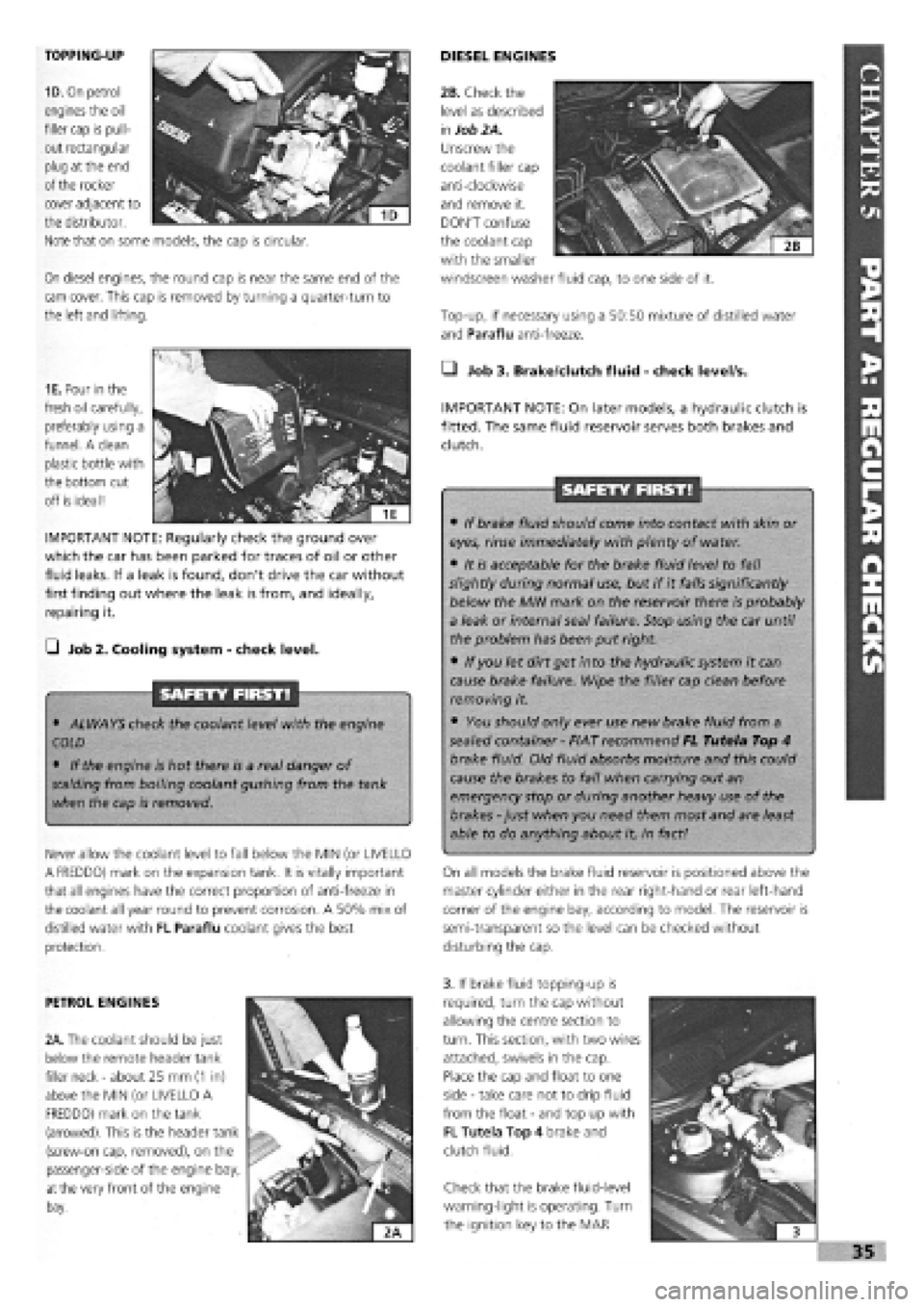

TOPPING-UP

1D. On petrol

engines the oil

filler cap is pull-

out rectangular

plug at the end

of the rocker

On diesel engines, the round cap is near the same end of the

cam cover. This cap is removed by turning a quarter-turn to

the left and lifting.

DIESEL ENGINES

Top-up, if necessary using a 50:50 mixture of distilled water

and Paraflu anti-freeze.

cover adjacent to

the distributor.

Note that on some models, the cap is circular.

1E. Pour in the

fresh oil carefully,

preferably using a

funnel. A clean

plastic bottle with

the bottom cut

off is ideal!

IMPORTANT NOTE: Regularly check the ground over

which the car has been parked for traces of oil or other

fluid leaks. If a leak is found, don't drive the car without

first finding out where the leak is from, and ideally,

repairing it.

G Job 2. Cooling system

-

check level.

SAFETY FIRST!

• ALWAYS check the coolant level with the engine

COLD

• If the engine is hot there is a real danger of

scalding

from boiling coolant gushing from the tank

when the cap is removed.

Never allow the coolant level to fall below the MIN (or UVELLO

A FREDDO) mark on the expansion tank. It is vitally important

that all engines have the correct proportion of anti-freeze in

the coolant all year round to prevent corrosion. A 50% mix of

distilled water with FL Paraflu coolant gives the best

protection.

• Job 3. Brake/dutch fluid

-

check level/s.

IMPORTANT NOTE: On later models, a hydraulic clutch is

fitted. The same fluid reservoir serves both brakes and

clutch.

SAFETY FIRST!

• If brake fluid should come into contact with skin or

eyes, rinse immediately with plenty of water.

• It is acceptable for the brake fluid level to fall

slightly during normal use, but if it falls significantly

below the MIN mark on the reservoir there is probably

a leak or internal seal failure. Stop using the car until

the problem has been put right.

• If you let dirt get into the hydraulic system it can

cause brake failure. Wipe the filler cap clean before

removing it.

• You should only ever use new brake fluid from a

sealed container

-

FIAT recommend FL Tutela Top 4

brake fluid. Old fluid absorbs moisture and this could

cause the brakes to fail when carrying out an

emergency stop or during another heavy use of the

brakes

-

just when you need them most and are least

able to do anything about it, in fact!

On all models the brake fluid reservoir is positioned above the

master cylinder either in the rear right-hand or rear left-hand

corner of the engine bay, according to model. The reservoir is

semi-transparent so the level can be checked without

disturbing the cap.

PETROL ENGINES

2A. The coolant should be just

below the remote header tank

filler neck

-

about 25 mm

(1

in)

above the MIN (or UVELLO A

FREDDO) mark on the tank

(arrowed). This is the header tank

(screw-on cap, removed), on the

passenger-side of the engine bay,

at

the very front of the engine

bay.

3. If brake fluid topping-up is

required, turn the cap without

allowing the centre section to

turn. This section, with two wires

attached, swivels in the cap.

Place the cap and float to one

side

-

take care not to drip fluid

from the float

-

and top up with

FL Tutela Top 4 brake and

clutch fluid.

Check that the brake fluid-level

warning-light is operating. Turn

the ignition key to the MAR

I

i 3

»35

2B. Check the

level as described

in

Job 2A.

Unscrew the

coolant filler cap

anti-clockwise

and remove it.

DON'T confuse

the coolant cap

with the smaller

windscreen washer fluid cap, to one side of it.

Page 33 of 171

• Whenever a light fails to

work, check its fuse before

replacing the bulb.

• A blown bulb often causes a fuse to 'go' in

sympathy.

hands, looking and feeling for any bulges, tears or splits in the

tyre walls, especially the inner sidewalls. (See Job 59 for spare

tyre checks.)

H INSIDE INFORMATION: In time, rubber deteriorates,

increasing the risk of a blow-out. Keep your eye on the

sidewalls of older tyres. If you see any cracking, splits or

other damage scrap the tyre. If you're not sure, consult

your FIAT dealer or tyre specialist. Q

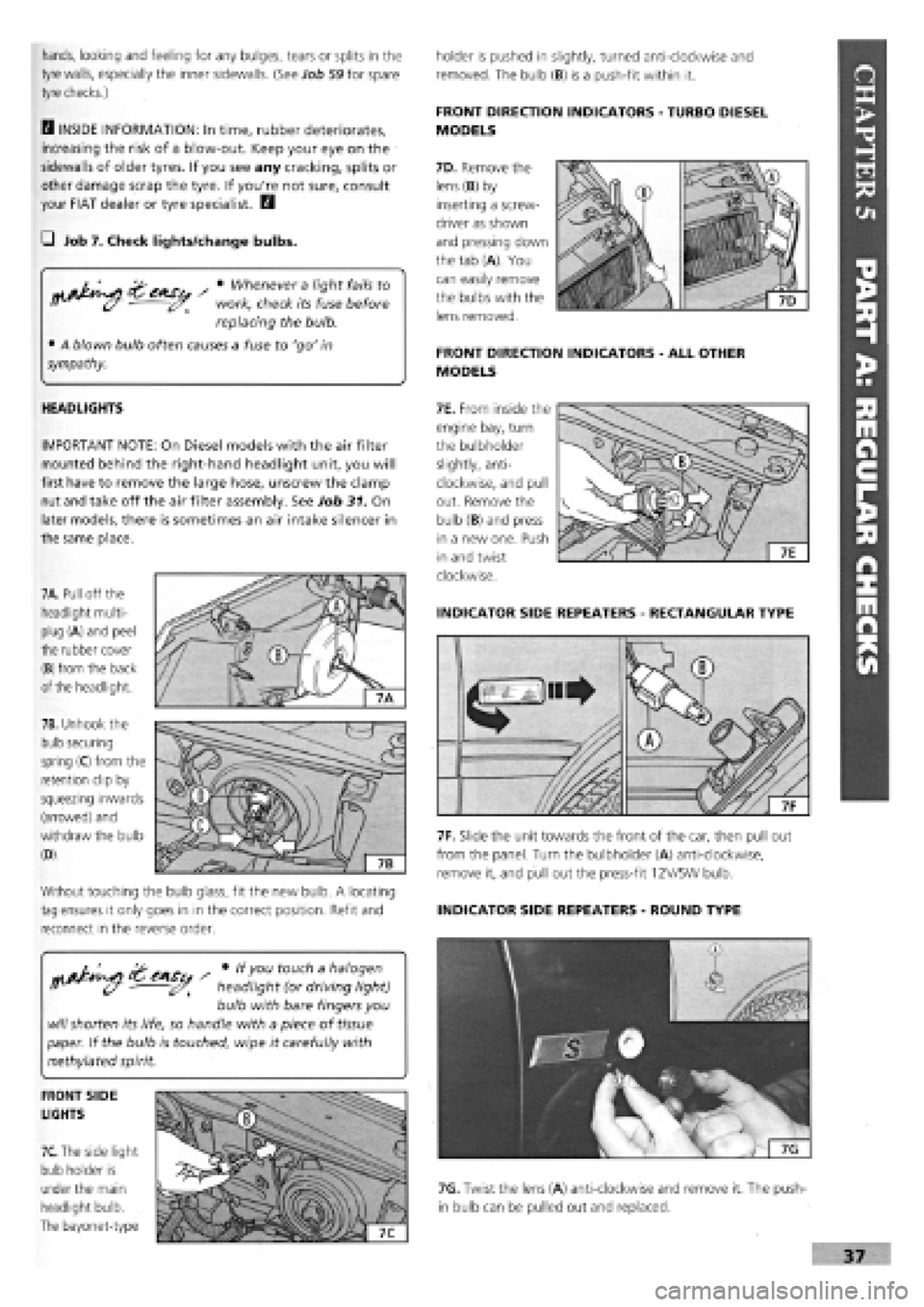

_) Job 7. Check lights/change bulbs.

7A. Pull off the

headlight multi-

plug (A) and peel

the rubber cover

(B) from the back

of the headlight.

7B. Unhook the

bulb securing

spring (C) from the

retention clip by

squeezing inwards

(arrowed) and

withdraw the bulb

(D).

Without touching the bulb glass, fit the new bulb. A locating

tag ensures it only goes in in the correct position. Refit and

reconnect in the reverse order.

HEADLIGHTS

IMPORTANT NOTE: On Diesel models with the air filter

mounted behind the right-hand headlight unit, you will

first have to remove the large hose, unscrew the clamp

nut and take off the air filter assembly. See Job 31. On

later models, there is sometimes an air intake silencer in

the same place.

7F. Slide the unit towards the front of the car, then pull out

from the panel. Turn the bulbholder (A) anti-clockwise,

remove it, and pull out the press-fit 12V/5W bulb.

INDICATOR SIDE REPEATERS

-

ROUND TYPE

holder is pushed in slightly, turned anti-clockwise and

removed. The bulb (B) is a push-fit within it.

FRONT DIRECTION INDICATORS

-

TURBO DIESEL

MODELS

7D. Remove the

lens (B) by

inserting a screw-

driver as shown

and pressing down

the tab (A). You

can easily remove

the bulbs with the

lens removed.

FRONT DIRECTION INDICATORS

-

ALL OTHER

MODELS

7E. From inside the

engine bay, turn

the bulbholder

slightly, anti-

clockwise, and pull

out. Remove the

bulb (B) and press

in a new one. Push

in and twist

clockwise.

INDICATOR SIDE REPEATERS

-

RECTANGULAR TYPE

CAS / * touc^ a halogen

• headlight (or driving light)

bulb with bare fingers you

will

shorten its life, so handle with a piece of

tissue

paper. If the bulb is touched, wipe it carefully with

methylated spirit.

FRONT SIDE

LIGHTS

7C.

The side light

bulb holder is

under the main

headlight bulb.

The bayonet-type

7G. Twist the lens (A) anti-clockwise and remove it. The push-

in bulb can be pulled out and replaced.

Page 34 of 171

ruvj

uivjh I

uuluj

^ Use a magnetic screw-

driver or place some thick

grease on the end of the

screwdriver to prevent the screws from falling

-

especially when replacing the lens.

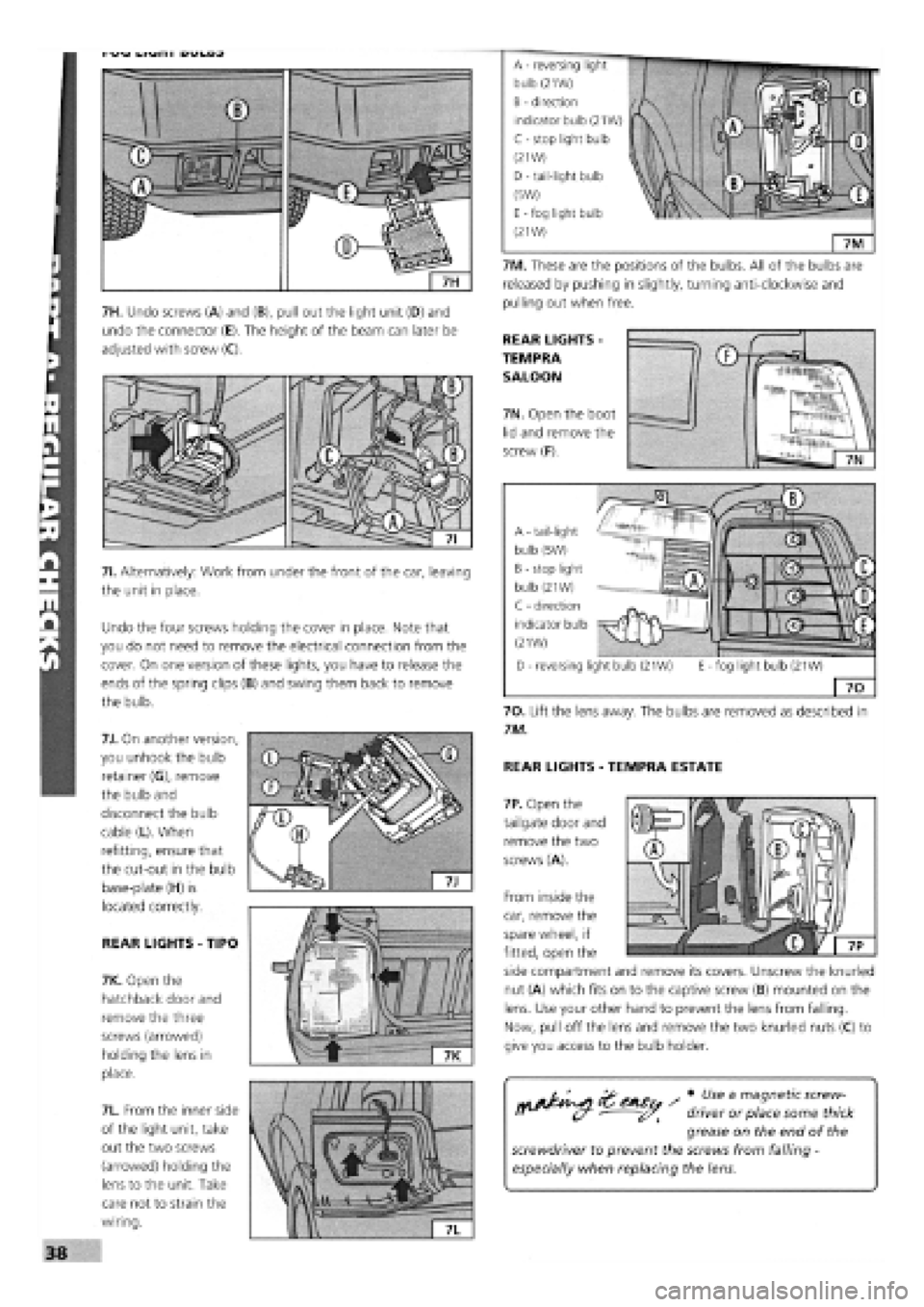

7H. Undo screws (A) and (B), pull out the light unit (D) and

undo the connector (E). The height of the beam can later be

adjusted with screw (C).

71. Alternatively: Work from under the front of the car, leaving

the unit in place.

Undo the four screws holding the cover in place. Note that

you do not need to remove the electrical connection from the

cover. On one version of these lights, you have to release the

ends of the spring clips (B) and swing them back to remove

the bulb.

7J. On another version,

you unhook the bulb

retainer (G), remove

the bulb and

disconnect the bulb

cable (L). When

refitting, ensure that

the cut-out in the bulb

base-plate (H) is

located correctly.

REAR LIGHTS

-

TIPO

7K. Open the

hatchback door and

remove the three

screws (arrowed)

holding the lens in

place.

7L. From the inner side

of the light unit, take

out the two screws

(arrowed) holding the

lens to the unit. Take

care not to strain the

wiring.

7M. These are the positions of the bulbs. All of the bulbs are

released by pushing in slightly, turning anti-clockwise and

pulling out when free.

REAR LIGHTS -

TEMPRA

SALOON

7N. Open the boot

lid and remove the

screw (F).

-fog light bulb (21W)

70

70. Lift the lens away. The bulbs are removed as described in

7M.

REAR LIGHTS

-

TEMPRA ESTATE

7P. Open the

tailgate door and

remove the two

screws (A).

From inside the

car, remove the

spare wheel, if

fitted, open the

side compartment and remove its covers. Unscrew the knurled

nut (A) which fits on to the captive screw (B) mounted on the

lens. Use your other hand to prevent the lens from falling.

Now, pull off the lens and remove the two knurled nuts (C) to

give you access to the bulb holder.

A - tail-light

bulb (5W)

B - stop light

bulb (21W)

C - direction

indicator bulb

(21W)

D - reversing light bulb (21W) E

A - reversing

bulb (21W)

B - direction

indicator bulb (21W)

C - stop light bulb

(21W)

D

-

tail-light bulb

(5W)

E - fog light bulb

(21W)

Page 45 of 171

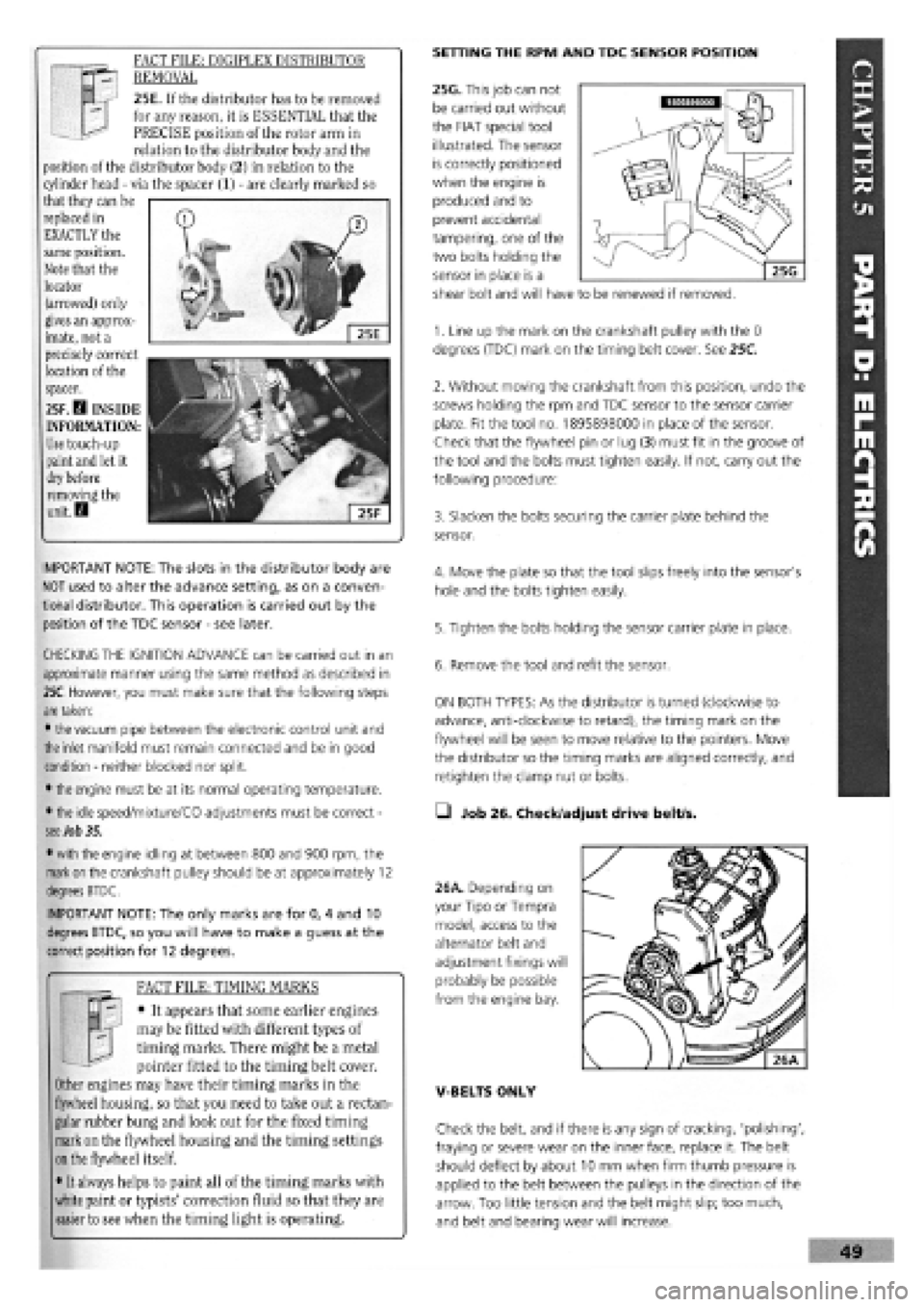

FACT FILE: DIGIPLEX DISTRIBUTOR

REMOVAL

25E. If the distributor has to be removed

for any reason, it is ESSENTIAL that the

PRECISE position of the rotor arm in

relation to the distributor body and the

position of the distributor body (2) in relation to the

cylinder head

-

via the spacer (1)

-

are clearly marked so

that they can be

replaced in

EXACTLY the

same position.

Note that the

locator

(arrowed) only

gives an approx-

imate, not a

precisely correct

location of the

spacer.

25F. D INSIDE

INFORMATION:

Use

touch-up

paint

and

let it

dry before

removing the

unit. D

SETTING THE RPM AND TDC SENSOR POSITION

25G. This job can not

be carried out without

the FIAT special tool

illustrated. The sensor

is correctly positioned

when the engine is

produced and to

prevent accidental

tampering, one of the

two bolts holding the

sensor in place is a

shear bolt and will have to be renewed if removed.

IMPORTANT NOTE: The slots in the distributor body are

NOT used to alter the advance setting, as on a conven-

tional distributor. This operation is carried out by the

position of the TDC sensor

-

see later.

CHECKING THE IGNITION ADVANCE can be carried out in an

approximate manner using the same method as described in

25C.

However, you must make sure that the following steps

are

taken:

•

the

vacuum pipe between the electronic control unit and

the

inlet manifold must remain connected and be in good

condition

-

neither blocked nor split.

•

the

engine must be at its normal operating temperature.

•

the

idle speed/mixture/CO adjustments must be correct

-

see Job 35.

•

with

the engine idling at between 800 and 900 rpm, the

mark on

the crankshaft pulley should be at approximately 12

degrees BTDC.

IMPORTANT NOTE: The only marks are for 0, 4 and 10

degrees BTDC, so you will have to make a guess at the

correct position for 12 degrees.

FACT FILE: TIMING MARKS

y-; • It appears that some earlier engines

H. j may be fitted with different types of

J timing marks. There might be a metal

pointer fitted to the timing belt cover.

Other engines may have their timing marks in the

flywheel housing, so that you need to take out a rectan-

gular rubber bung and look out for the fixed timing

mark on the flywheel housing and the timing settings

on

the flywheel itself.

• It always helps to paint all of the timing marks with

white paint or typists' correction fluid so that they are

easier to see when the timing light is operating.

1. Line up the mark on the crankshaft pulley with the 0

degrees (TDC) mark on the timing belt cover. See 25C.

2. Without moving the crankshaft from this position, undo the

screws holding the rpm and TDC sensor to the sensor carrier

plate. Fit the tool no. 1895898000 in place of the sensor.

Check that the flywheel pin or lug (3) must fit in the groove of

the tool and the bolts must tighten easily. If not, carry out the

following procedure:

3. Slacken the bolts securing the carrier plate behind the

sensor.

4. Move the plate so that the tool slips freely into the sensor's

hole and the bolts tighten easily.

5. Tighten the bolts holding the sensor carrier plate in place.

6. Remove the tool and refit the sensor.

ON BOTH TYPES: As the distributor is turned (clockwise to

advance, anti-clockwise to retard), the timing mark on the

flywheel will be seen to move relative to the pointers. Move

the distributor so the timing marks are aligned correctly, and

retighten the clamp nut or bolts.

• Job 26. Check/adjust drive belt/s.

26A. Depending on

your Tipo or Tempra

model, access to the

alternator belt and

adjustment fixings will

probably be possible

from the engine bay.

V-BELTS ONLY

Check the belt, and if there is any sign of cracking, 'polishing',

fraying or severe wear on the inner face, replace it. The belt

should deflect by about 10 mm when firm thumb pressure is

applied to the belt between the pulleys in the direction of the

arrow. Too little tension and the belt might slip; too much,

and belt and bearing wear will increase.

Page 49 of 171

IMPORTANT NOTE: • All Tipo/Tempra diesel engines are

self-bleeding and there should be no need to bleed air

out of the system manually.

• If the engine does not eventually re-start, check all the

unions for the fuel inlet pipe and the other unions,

replacing the sealing washers if necessary, to eliminate

any air leaks.

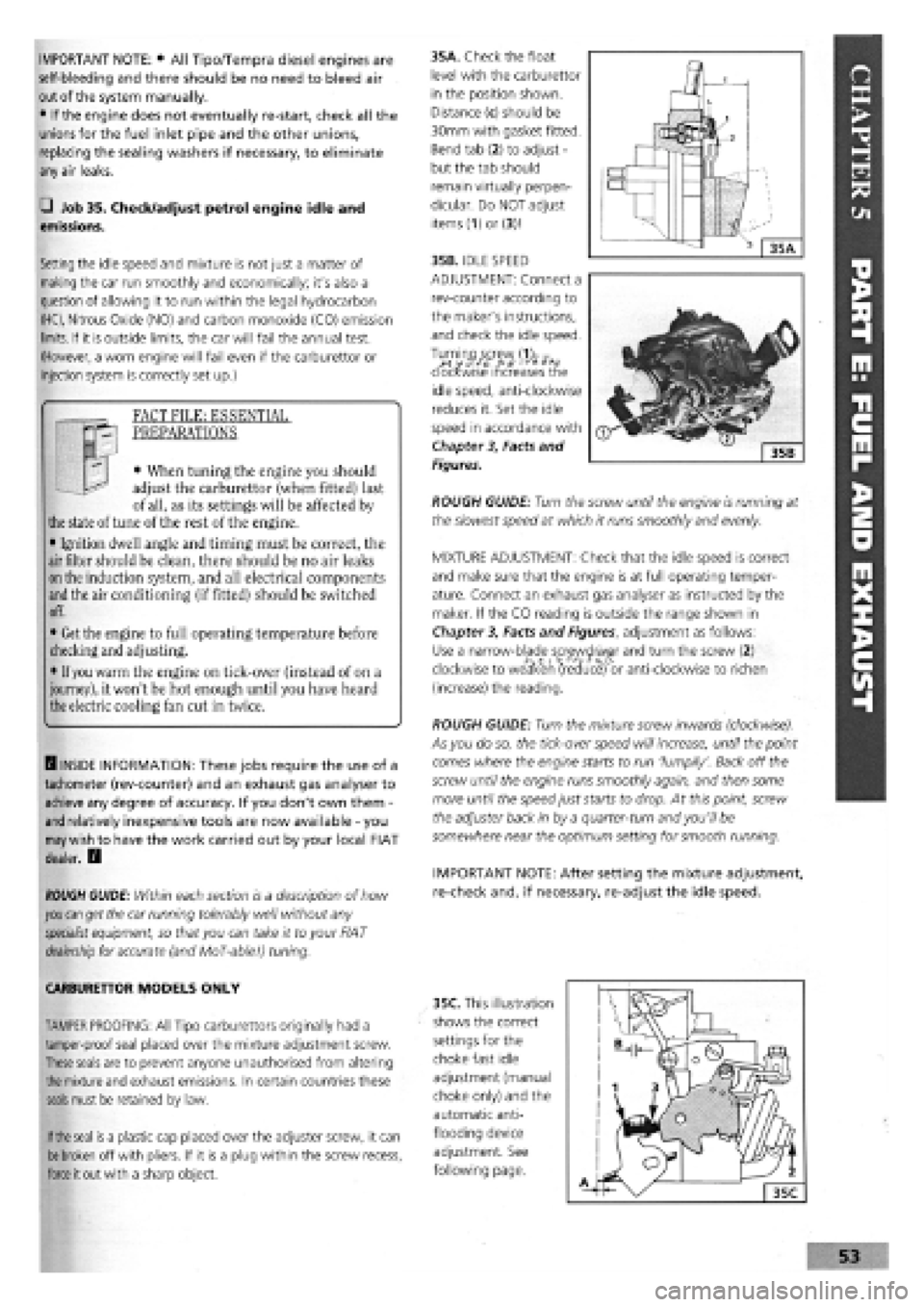

Q Job 35. Check/adjust petrol engine idle and

emissions.

Setting the idle speed and mixture is not just a matter of

making

the car run smoothly and economically; it's also a

question of allowing it to run within the legal hydrocarbon

(HC), Nitrous Oxide (NO) and carbon monoxide (CO) emission

limits. If it

is

outside limits, the car will fail the annual test.

(However, a worn engine will fail even if the carburettor or

injection system is correctly set up.)

FACT FILE: ESSENTIAL

PREPARATIONS

• When tuning the engine you should

adjust the carburettor (when fitted) last

of all, as its settings will be affected by

the state of tune of the rest of the engine.

• Ignition dwell angle and timing must be correct, the

air

filter

should be clean, there should be no air leaks

on

the induction system, and all electrical components

and

the air conditioning (if fitted) should be switched

off.

• Get the engine to full operating temperature before

checking and adjusting.

• If

you

warm the engine on tick-over (instead of on a

journey), it won't be hot enough until you have heard

the electric cooling fan cut in twice.

Q INSIDE INFORMATION: These jobs require the use of a

tachometer (rev-counter) and an exhaust gas analyser to

achieve any degree of accuracy. If you don't own them -

and relatively inexpensive tools are now available

-

you

may

wish

to have the work carried out by your local FIAT

dealer. D

ROUGH

GUIDE: Within each section is a description of how

you

can

get the car running tolerably well without any

specialist

equipment, so that you can take it to your FIAT

dealership

for accurate (and MoT-able!) tuning.

35A. Check the float

level with the carburettor

in the position shown.

Distance (c) should be

30mm with gasket fitted.

Bend tab (2) to adjust

-

but the tab should

remain virtually perpen-

dicular. Do NOT adjust

items (1)or (3)1

35B. IDLE SPEED

ADJUSTMENT: Connect a

rev-counter according to

the maker's instructions,

and check the idle speed.

clockwise increases the

idle speed, anti-clockwise

reduces it. Set the idle

speed in accordance with

Chapter

3,

Facts and

Figures.

ROUGH GUIDE: Turn the screw until the engine is running at

the slowest speed at which it runs smoothly and evenly.

MIXTURE ADJUSTMENT: Check that the idle speed is correct

and make sure that the engine is at full operating temper-

ature. Connect an exhaust gas analyser as instructed by the

maker. If the CO reading is outside the range shown in

Chapter

3,

Facts and Figures, adjustment as follows:

Use a narrow-blade screwdriver and turn the screw (2)

clockwise to weaken (reduce) or anti-clockwise to richen

(increase) the reading.

ROUGH GUIDE: Turn the mixture screw inwards (clockwise).

As you do so, the tick-over speed will increase, until the point

comes where the engine starts to run 'lumpily'. Back off the

screw until the engine runs smoothly again, and then some

more until the speed just starts to drop. At this point, screw

the adjuster back in by a quarter-turn and you'll be

somewhere near the optimum setting for smooth running.

IMPORTANT NOTE: After setting the mixture adjustment,

re-check and, if necessary, re-adjust the idle speed.

CARBURETTOR MODELS ONLY

TAMPER PROOFING: All Tipo carburettors originally had a

tamper-proof seal placed over the mixture adjustment screw.

These

seals are to prevent anyone unauthorised from altering

the

mixture and exhaust emissions. In certain countries these

seals

must be retained by law.

If the

seal

is

a plastic cap placed over the adjuster screw, it can

be

broken

off with pliers. If it is a plug within the screw recess,

force

it out with a sharp object.

35C. This illustration

shows the correct

settings for the

choke fast idle

adjustment (manual

choke only) and the

automatic anti-

flooding device

adjustment. See

following page.

Page 57 of 171

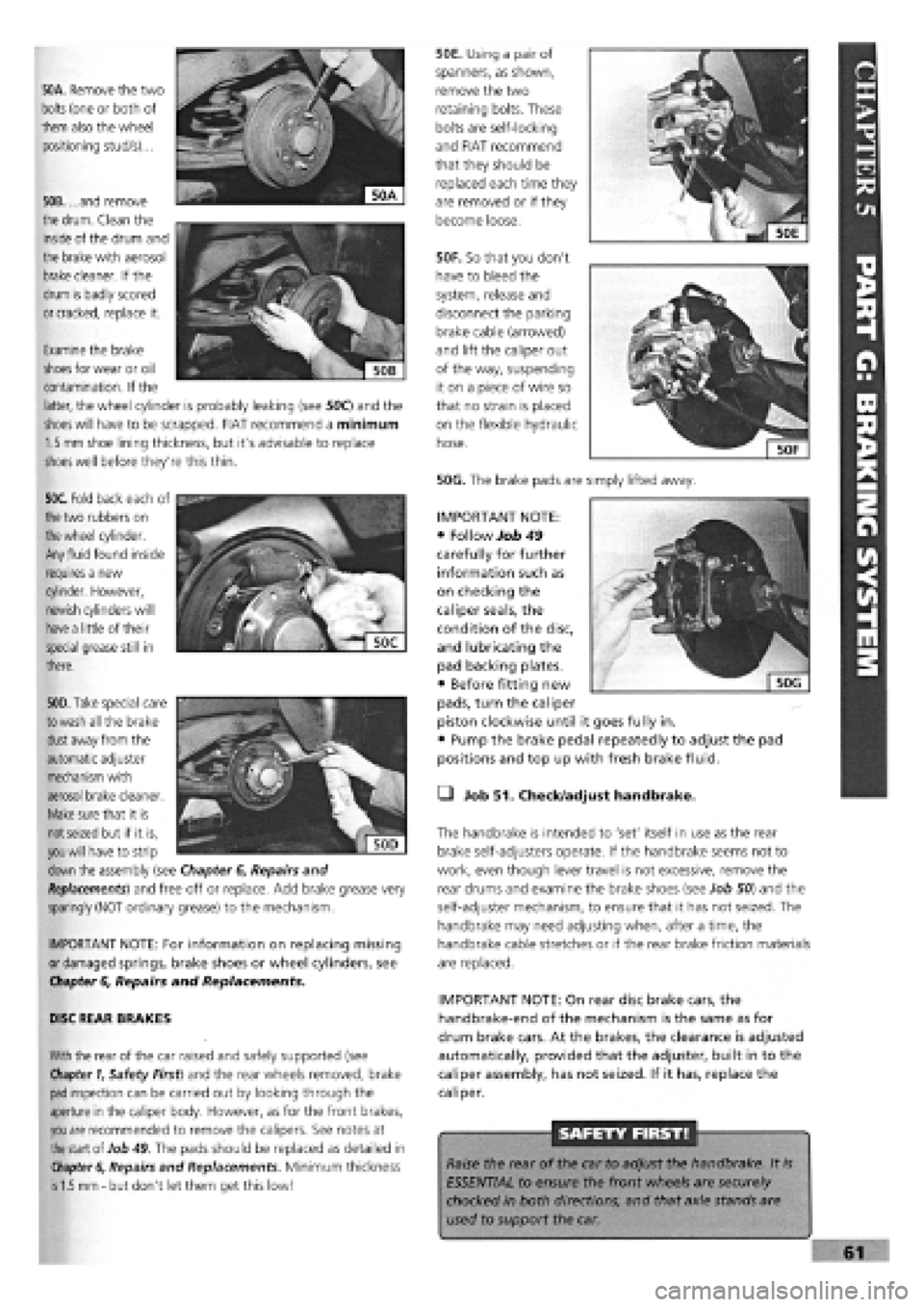

50A. Remove the two

bolts

(one or both of

them also the wheel

positioning stud/s)...

50B. ...and remove

the

drum.

Clean the

inside of the drum and

the brake with aerosol

brake

cleaner. If the

drum is badly scored

or cracked,

replace it.

50F. So that you don't

have to bleed the

system, release and

disconnect the parking

brake cable (arrowed)

and lift the caliper out

of the way, suspending

it on a piece of wire so

that no strain is placed

on the flexible hydraulic

hose.

50G. The brake pads are simply lifted away.

50E. Using a pair of

spanners, as shown,

remove the two

retaining bolts. These

bolts are self-locking

and FIAT recommend

that they should be

replaced each time they

are removed or if they

become loose.

Examine the brake

shoes

for wear or oil

contamination. If the

latter, the wheel cylinder is probably leaking (see 50C) and the

shoes will

have to be scrapped. FIAT recommend a minimum

1.5 mm

shoe lining thickness, but it's advisable to replace

shoes

well before they're this thin.

50C. Fold back each of

the

two rubbers on

the wheel

cylinder.

Any

fluid

found inside

requires a new

cylinder. However,

newish cylinders will

have a

little of their

special grease still in

there.

. """

€

Sjjj

KV,1

| 50D|

50D. Take

special care

to wash

all the brake

dust

away from the

automatic adjuster

mechanism with

aerosol brake cleaner.

Make

sure that it is

not seized

but if it is,

you will

have to strip

down

the assembly (see Chapter

6,

Repairs and

Replacements)

and free off or replace. Add brake grease very

sparingly (NOT ordinary grease) to the mechanism.

IMPORTANT NOTE: For information on replacing missing

or damaged springs, brake shoes or wheel cylinders, see

Chapter

6,

Repairs and Replacements.

DISC REAR BRAKES

With

the rear of the car raised and safely supported (see

Chapter 1,

Safety First) and the rear wheels removed, brake

pad

inspection can be carried out by looking through the

aperture in the caliper body. However, as for the front brakes,

you are

recommended to remove the calipers. See notes at

the

start of Job

49.

The pads should be replaced as detailed in

Chapter 6,

Repairs and Replacements. Minimum thickness

is 1.5 mm -

but don't let them get this low!

• Job 51. Check/adjust handbrake.

The handbrake is intended to 'set' itself in use as the rear

brake self-adjusters operate. If the handbrake seems not to

work, even though lever travel is not excessive, remove the

rear drums and examine the brake shoes (see Job 50) and the

self-adjuster mechanism, to ensure that it has not seized. The

handbrake may need adjusting when, after a time, the

handbrake cable stretches or if the rear brake friction materials

are replaced.

IMPORTANT NOTE: On rear disc brake cars, the

handbrake-end of the mechanism is the same as for

drum brake cars. At the brakes, the clearance is adjusted

automatically, provided that the adjuster, built in to the

caliper assembly, has not seized. If it has, replace the

caliper.

SAFETY FIRST!

Raise the rear of the car to adjust the handbrake. It

is

ESSENTIAL to ensure the front wheels are securely

chocked in both directions, and that axle stands are

used to support the car.

IMPORTANT NOTE:

• Follow Job 49

carefully for further

information such as

on checking the

caliper seals, the

condition of the disc,

and lubricating the

pad backing plates.

• Before fitting new

pads, turn the caliper

piston clockwise until it goes fully in.

• Pump the brake pedal repeatedly to adjust the pad

positions and top up with fresh brake fluid.

Page 61 of 171

PART A: ENGINE

PART A: Contents

Job 1. Petrol engine. Timing belt

-

replacement and Job 12. Petrol engine. Mountings

-

replacement.

adjustment. Job 13. Diesel engine. Timing belt

-

replacement and

Job 2. Petrol engine. Cylinder head

-

removal. adjustment. •

Job 3. Petrol engine. Cylinder head and camshaft housing -Job 14. Diesel engine. Cylinder head

-

removal.

refitting. Job 15. Diesel engine. Cylinder head

-

refitting.

Job

4.

Petrol engine. Cylinder head

-

dismantling and Job 16. Diesel engine. Cylinder head

-

overhaul.

overhauling. Job 17. Diesel engine. Valve clearances

-

adjustment.

Job 5. Petrol engine

-

dismantling. Job 18. Diesel engine

-

removal.

Job

6.

Petrol engine

-

checking and reassembly. Job 19. Diesel engine

-

refitting.

Job

7.

Petrol engine. Valve clearances

-

adjustment. Job 20. Diesel engine. Mountings

-

replacement.

Job 8. Petrol engine/transmission

-

removal. Job 21. Diesel engine/transmission (removed from car)

-

Job

9.

Petrol engine/transmission

-

refitting. separation.

Job 10. Petrol engine/transmission (removed from car)

-

Job 22. Diesel engine/transmission (removed from car)

-

separation. reconnection.

Job 11. Petrol engine/transmission (removed from car)

-

Job 23. Diesel engine

-

dismantling.

reconnection. Job 24. Diesel engine

-

reassembly.

Job 1. Petrol engine. Timing belt

- replacement and adjustment.

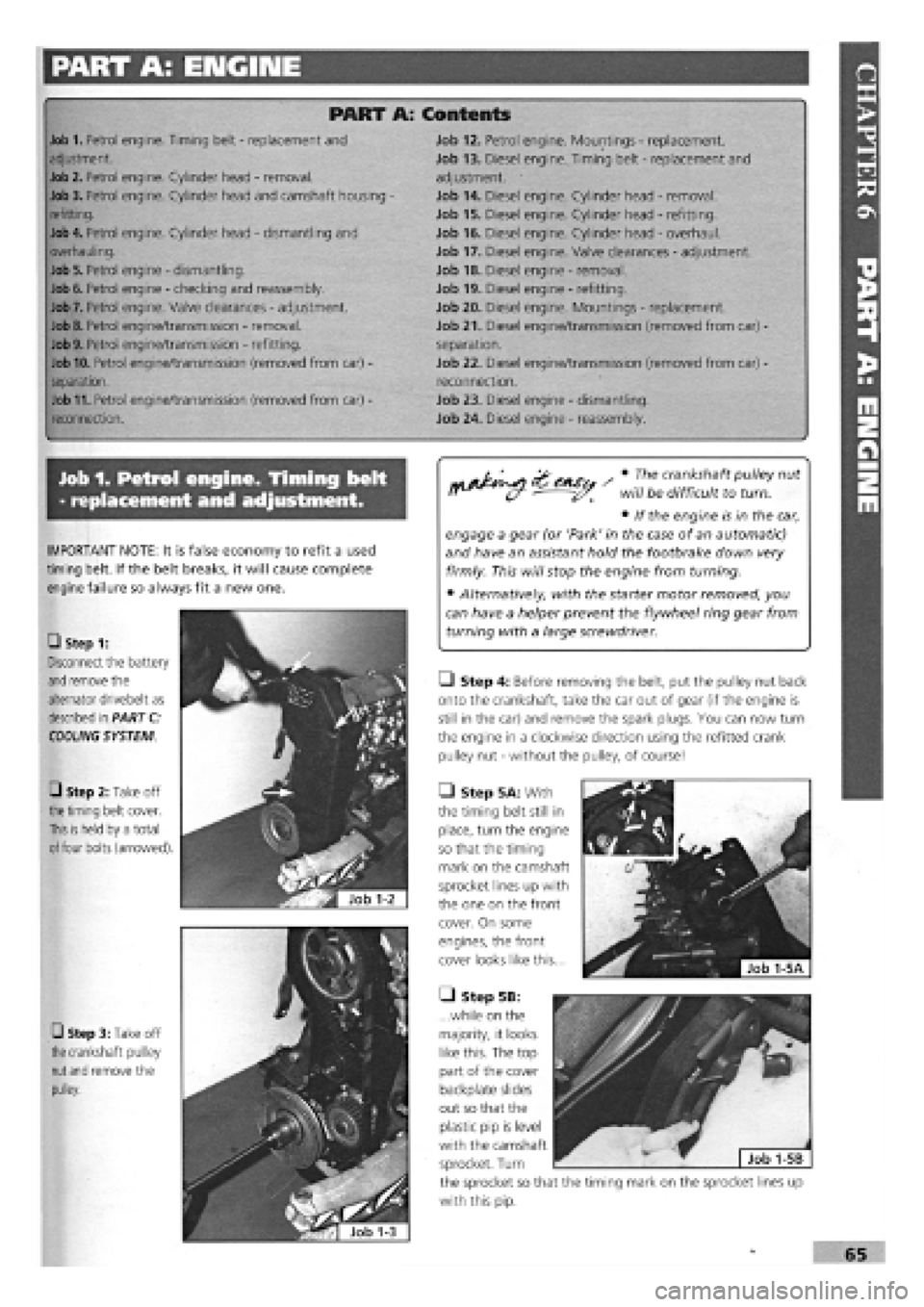

Mi*^^ Zc+sc, / • The crankshaft pulley nut

n^^ will be difficult to turn.

• If the engine is in the car,

engage a gear (or 'Park' in the case of an automatic)

and have an assistant hold the footbrake down very

firmly. This will stop the engine from turning.

• Alternatively, with the starter motor removed, you

can have a helper prevent the flywheel ring gear from

turning with a large screwdriver.

• Step 4: Before removing the belt, put the pulley nut back

onto the crankshaft, take the car out of gear (if the engine is

still in the car) and remove the spark plugs. You can now turn

the engine in a clockwise direction using the refitted crank

pulley nut

-

without the pulley, of course!

• Step 5A: With

the timing belt still in

place, turn the engine

so that the timing

mark on the camshaft

sprocket lines up with

the one on the front

cover. On some

engines, the front

cover looks like this...

• Step 5B:

...while on the

majority, it looks

like this. The top

part of the cover

backplate slides

out so that the

plastic pip is level

with the camshaft

sprocket. Turn

the sprocket so that the timing mark on the sprocket lines up

with this pip.

IMPORTANT NOTE: It is false economy to refit a used

timing belt. If the belt breaks, it will cause complete

engine failure so always fit a new one.

• Step 1:

Disconnect the battery

and

remove the

alternator drivebelt as

described in PART C:

COOLING

SYSTEM

0 Step 2: Take off

the timing

belt cover.

This is held

by a total

of

four bolts (arrowed).

• Step 3: Take off

the

crankshaft pulley

nut and

remove the

pulley.