sensor FIAT TEMPRA 1988 Service And Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 116 of 171

over stop and will also reach its 'maximum speed' stop with

the pedal fully depressed.

Job 8. Mechanical fuel pump,

petrol engine (carburettored) -

replacement.

O Step 1: Disconnect the battery earth lead.

• Step 2: Find the pump on the forward facing side of the

cylinder block near the timing cover end. Disconnect the two

fuel lines from the pump and plug the ends, (labelling them

for correct refitment).

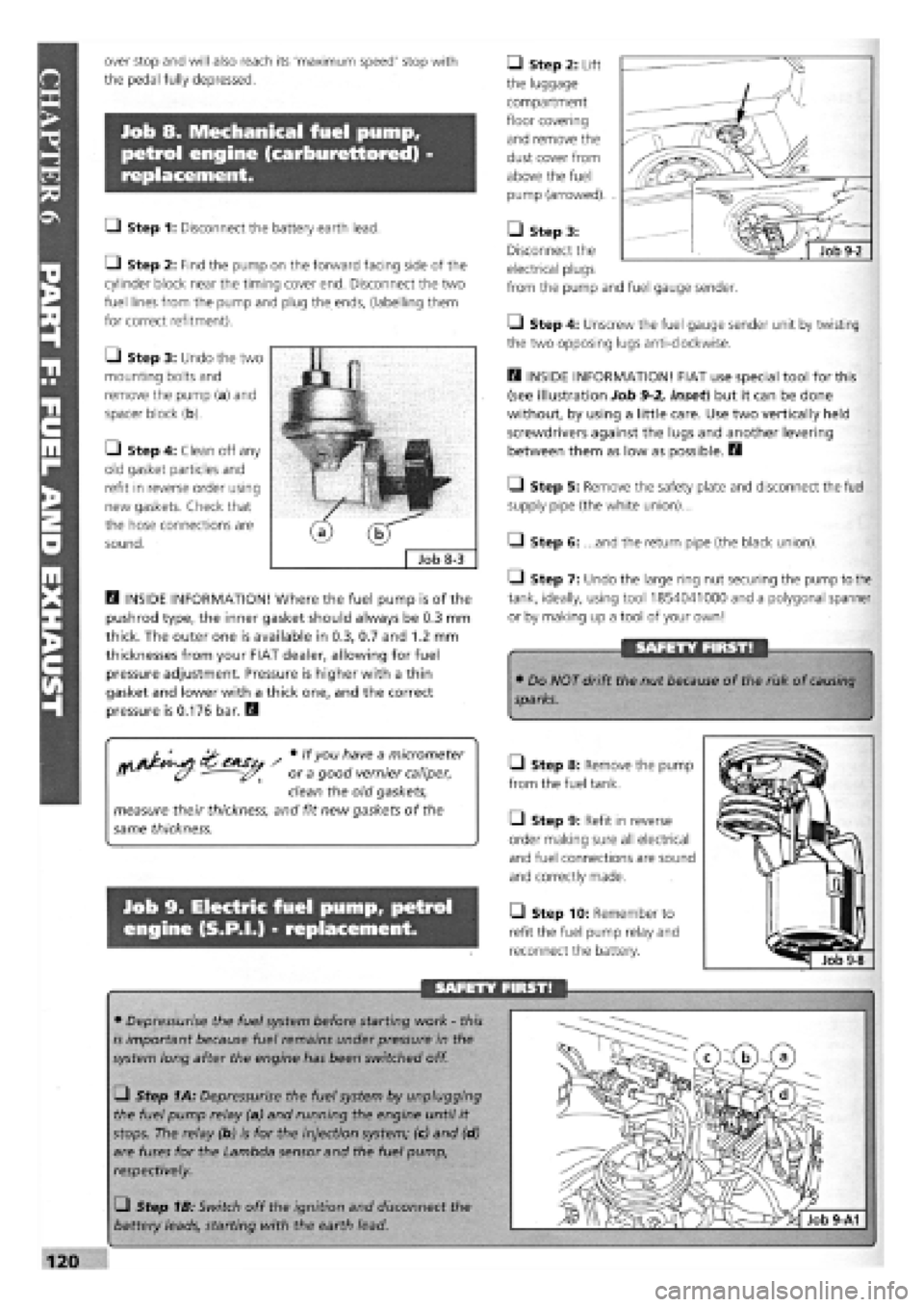

• Step 3: Undo the two

mounting bolts and

remove the pump (a) and

spacer block (b).

• Step 4: Clean off any

old gasket particles and

refit in reverse order using

new gaskets. Check that

the hose connections are

sound.

D INSIDE INFORMATION! Where the fuel pump is of the

pushrod type, the inner gasket should always be 0.3 mm

thick. The outer one is available in 0.3, 0.7 and 1.2 mm

thicknesses from your FIAT dealer, allowing for fuel

pressure adjustment. Pressure is higher with a thin

gasket and lower with a thick one, and the correct

pressure is 0.176 bar. Q

/ # lfyou h"ve a m/cromefer

ff (y - or a good vernier caliper,

clean the old gaskets,

measure their thickness, and fit new gaskets of the

same thickness.

Job 9. Electric fuel pump, petrol

engine (S.P.I.) - replacement.

• Step 2: Lift

the luggage

compartment

floor covering

and remove the

dust cover from

above the fuel

pump (arrowed). .

• Step 3:

Disconnect the

electrical plugs

from the pump and fuel gauge sender.

• Step 4: Unscrew the fuel gauge sender unit by twisting

the two opposing lugs anti-clockwise.

D INSIDE INFORMATION! FIAT use special tool for this

(see illustration Job

9-2,

inset) but it can be done

without, by using a little care. Use two vertically held

screwdrivers against the lugs and another levering

between them as low as possible. H

Q Step 5: Remove the safety plate and disconnect the fuel

supply pipe (the white union)...

Q Step 6: ...and the return pipe (the black union).

1-1 Step 7: Undo the large ring nut securing the pump to the

tank, ideally, using tool 1854041000 and a polygonal spanner

or by making up a tool of your own!

SAFETY FIRST!

• Do NOT drift the nut because of the risk of

causing

sparks.

Q Step 8: Remove the pump

from the fuel tank.

Q Step 9: Refit in reverse

order making sure all electrical

and fuel connections are sound

and correctly made.

• Step 10: Remember to

refit the fuel pump relay and

reconnect the battery.

SAFETY FIRST!

• Depressurise the fuel system before starting work

-

this

is important because fuel remains under pressure in the

system long after the engine has been switched off.

• Step 1A: Depressurise the fuel system by unplugging

the fuel pump relay (a) and running the engine until it

stops. The relay (b) is for the injection system; (c) and (d)

are fuses for the Lambda sensor and the fuel pump,

respectively.

• Step 1B: Switch off the ignition and disconnect the

battery leads, starting with the earth lead.

Page 117 of 171

Job 10. Fuel tank - removal and

refitting.

Job 11. Hot air hoses/thermo-

valves - general.

SAFETY FIRST!

Job 12. Lambda sensor

(S.P.I, engines) - replacement.

• We recommend that you carry out all of this work

out of

doors.

I

IMPORTANT NOTE:

• Read Chapter 1, Safety First! before carrying out

this

work!

• Plan ahead! Run the fuel in the tank as low as possible

before you start this job.

Q Step 1: Disconnect the battery leads starting with the

earth lead.

• Step 2: Syphon any remaining fuel from the tank and

into a suitable closed container.

Q Step 3: Disconnect the fuel sender wiring and any fuel

hoses

from within the boot (model-dependent

-

see Job 9 and

PARTE: ELECTRICAL AND INSTRUMENTS, Job 14).

• Step 4: Disconnect the filler and breather hoses from the

tank,

working from underneath the car.

a - Lambda sensor b - connector to ECU c - sensor heater power supply Job 12-2

Q Step 5: Support the tank while undoing the strap

securing bolts at the rear of the tank...

Q Step 6: ...and at the front.

Q Step 7: Lower the tank a very small amount at a time,

enough to check whether any hoses remain attached, then

lower it fully to the ground.

Q Step 8: Refit in the reverse order, making sure all connec-

tions are

sound. Reconnect the battery leads.

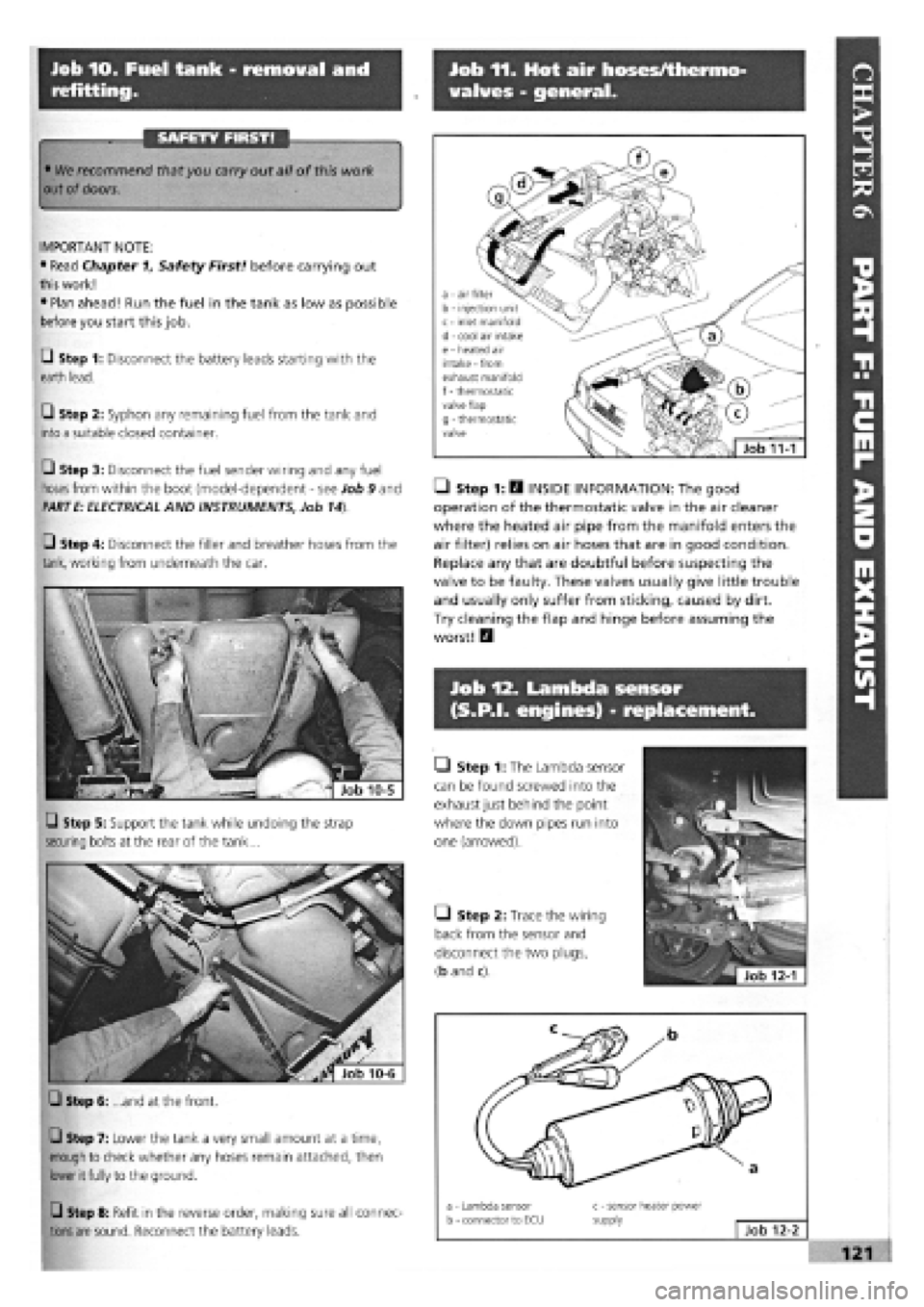

• Step 1: H INSIDE INFORMATION: The good

operation of the thermostatic valve in the air cleaner

where the heated air pipe from the manifold enters the

air filter) relies on air hoses that are in good condition.

Replace any that are doubtful before suspecting the

valve to be faulty. These valves usually give little trouble

and usually only suffer from sticking, caused by dirt.

Try cleaning the flap and hinge before assuming the

worst! Q

• Step 1: The Lambda sensor

can be found screwed into the

exhaust just behind the point

where the down pipes run into

one (arrowed).

Q Step 2: Trace the wiring

back from the sensor and

disconnect the two plugs,

(b and c).

a - air filter b - injection unit c - inlet manifold d - cool air intake e - heated air intake - from exhaust manifold f

-

thermostatic valve flap g - thermostatic valve

Job 11-1

Page 118 of 171

Job 14. Exhaust system -

replacement.

FACT FILE: LAMBDA SENSOR

• The Lambda sensor is very fragile and

should not be knocked or dropped.

• We recommend that a new one is fitted

only by your FIAT dealer, who can test the

old one to see whether it is working properly.

• No cleaners should be used on the sensor.

Q Step 3: Before refitting, check that the sensor sealing ring

is in good condition, and lubricate the thread of the sensor

with a high-temperature anti-seize compound.

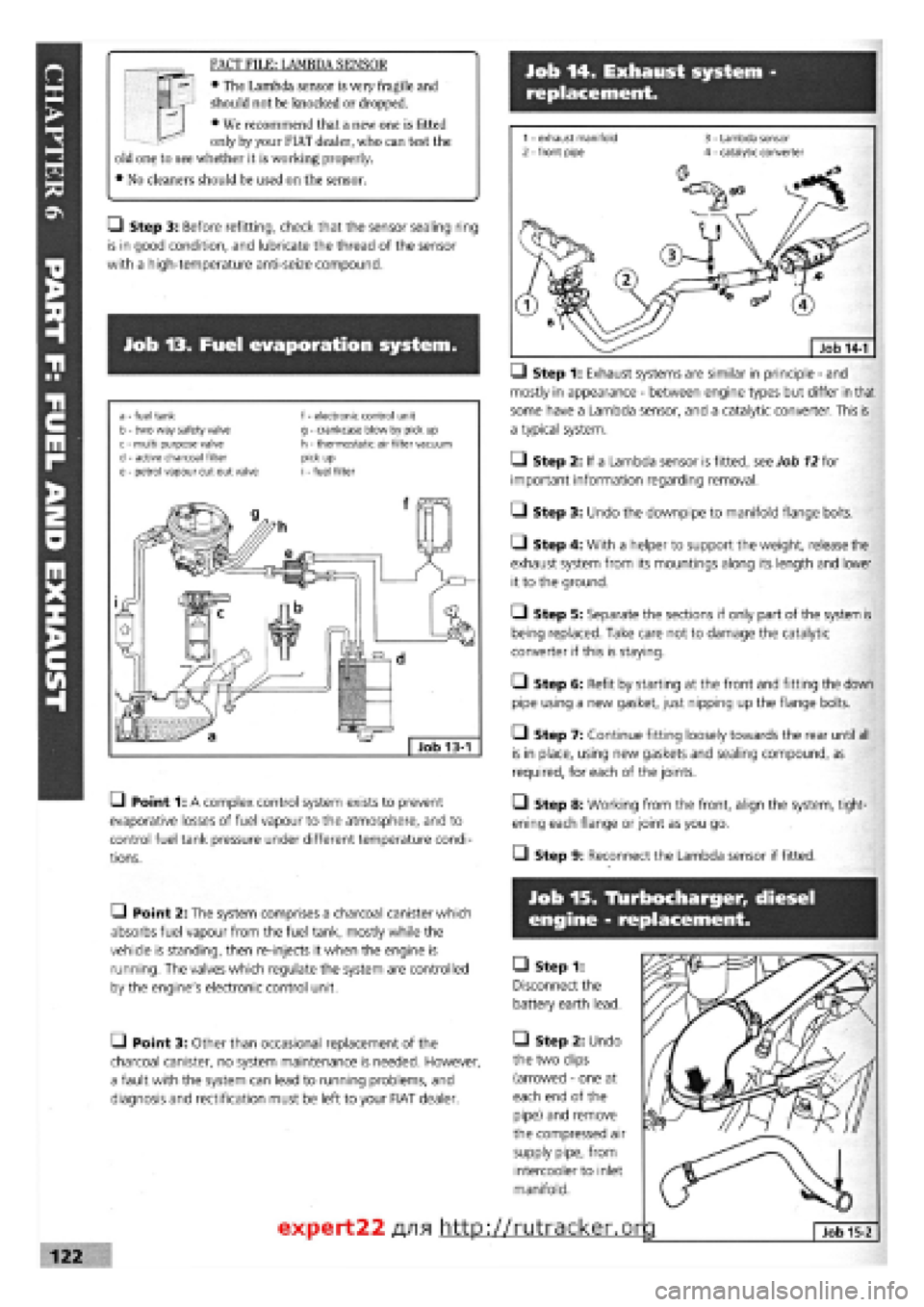

Job 13. Fuel evaporation system.

a - fuel tank b - two way safety valve c - multi purpose valve d

-

active charcoal filter e - petrol vapour cut out valve

f - electronic control unit g - crankcase blow by pick up h - thermostatic air filter vacuum pick up i - fuel filter

• Point 1: A complex control system exists to prevent

evaporative losses of fuel vapour to the atmosphere, and to

control fuel tank pressure under different temperature condi-

tions.

—) Step 1: Exhaust systems are similar in principle

-

and

mostly in appearance

-

between engine types but differ in that

some have a Lambda sensor, and a catalytic converter. This is

a typical system.

• Step 2: If a Lambda sensor is fitted, see Job

12

for

important information regarding removal.

• Step 3: Undo the downpipe to manifold flange bolts.

• Step 4: With a helper to support the weight, release the

exhaust system from its mountings along its length and lower

it to the ground.

O Step 5: Separate the sections if only part of the system is

being replaced. Take care not to damage the catalytic

converter if this is staying.

• Step 6: Refit by starting at the front and fitting the down

pipe using a new gasket, just nipping up the flange bolts.

• Step 7: Continue fitting loosely towards the rear until all

is in place, using new gaskets and sealing compound, as

required, for each of the joints.

• Step 8: Working from the front, align the system, tight-

ening each flange or joint as you go.

• Step 9: Reconnect the Lambda sensor if fitted.

• Point 2: The system comprises a charcoal canister which

absorbs fuel vapour from the fuel tank, mostly while the

vehicle is standing, then re-injects it when the engine is

running. The valves which regulate the system are controlled

by the engine's electronic control unit.

• Point 3: Other than occasional replacement of the

charcoal canister, no system maintenance is needed. However,

a fault with the system can lead to running problems, and

diagnosis and rectification must be left to your FIAT dealer.

Job 15. Tlurbocharger, diesel

engine - replacement.

• Step 1:

Disconnect the

battery earth lead.

• Step 2: Undo

the two clips

(arrowed

-

one at

each end of the

pipe) and remove

the compressed air

supply pipe, from

intercooler to inlet

manifold.

expert22 fl/i* http://rutracker.or

Page 130 of 171

• Step 8:

Support the

axle beam with

the jack and

undo the

mounting bolts

(arrowed and

indicated by

operator with

socket bar).

Lower the

complete unit

from the car.

IMPORTANT NOTE: In this shot, the top shock absorber

mountings have been disconnected, leaving the shock

absorber fitted to the suspension and the coil springs in

place. We recommend 'our' approach, covered in Step 7!

• Step 9: Undo the bolts securing the anti-roll bar and

remove it. (See Job 9.) Disconnect the brake pipes from the

side to be worked on and remove the brake drum.

Q Step 10: Remove the hub cap (see illustration Job 1-1D,

part 13) by carefully tapping and levering with a screwdriver.

• Step 11: Undo the hub nut (see illustration Job 1-1D,

part

10).

PART H: BRAKES

• Step 12: A special tool

(1857508000) or a VERY

strong Allen key (a) will be

required to reach into the

hub (b), and plenty of

leverage!

Q Step 13: Remove the

hub and inspect the bearing

for roughness or noise or

roughness when turning it by hand.

E3 INSIDE INFORMATION! The bearing is lubricated for

life and is only supplied as an assembly with the hub. B

• Step 14: Inspect the stub axle pin (see illustration Job

1-

1D, part

12)

for any signs of damage or distortion. Replace if

in doubt.

Q Step 15: Refitting is the reverse of removal but note the

following:

• See Chapter

3,

Facts and Figures for all tightening

torques as you progress through the assembling.

• Use new hub nuts and fully tighten once the suspension is

mounted to give you stability.

• Refer to PART H: BRAKES when refitting the brake parts

and bleeding the brakes.

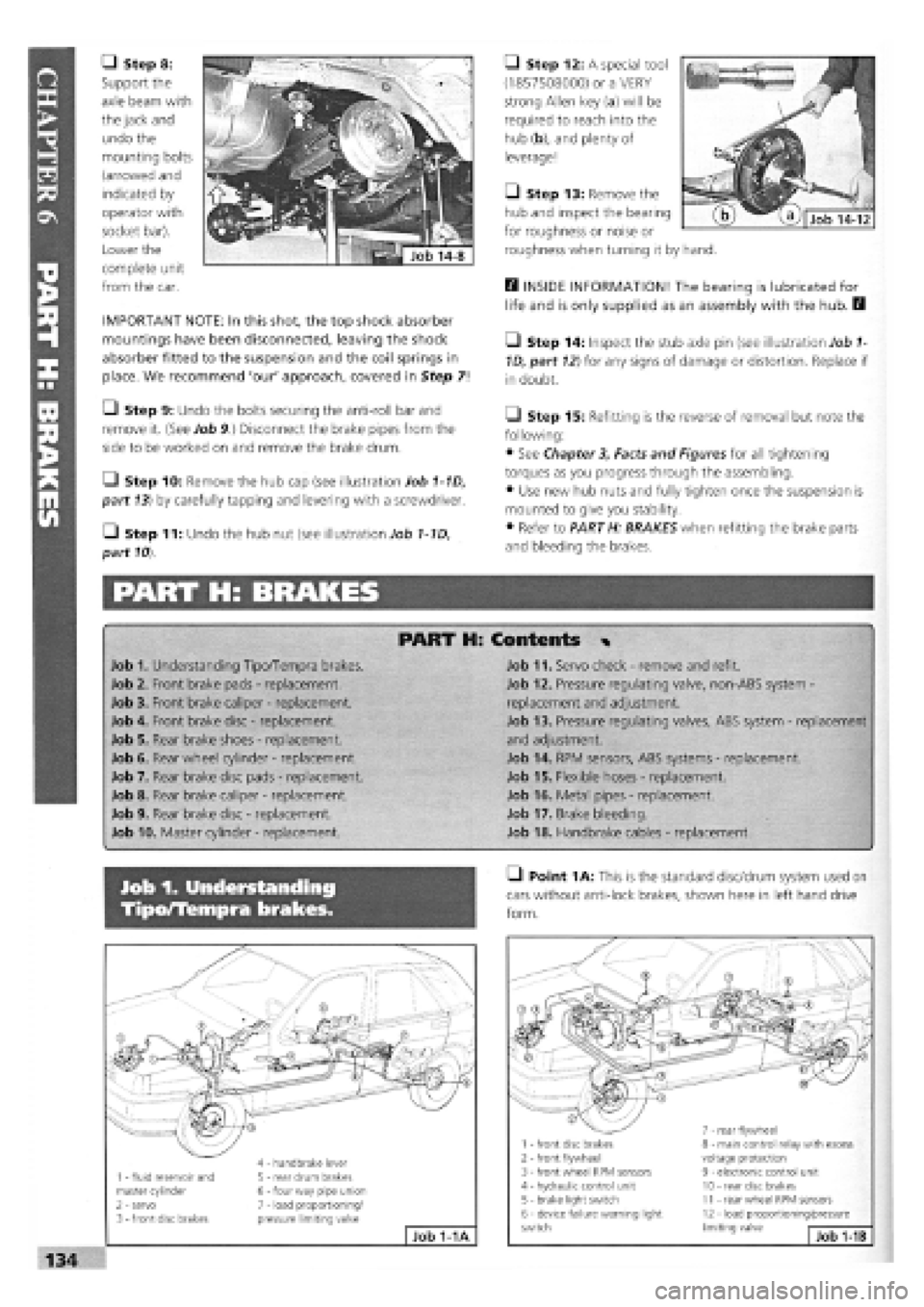

PART H: Contents %

Job 1. Understanding Tipo/Tempra brakes.

Job 2. Front brake pads

-

replacement.

Job 3. Front brake caliper

-

replacement.

Job 4. Front brake disc

-

replacement.

Job 5. Rear brake shoes

-

replacement.

Job 6. Rear wheel cylinder

-

replacement.

Job 7. Rear brake disc pads

-

replacement.

Job 8. Rear brake caliper

-

replacement.

Job 9. Rear brake disc

-

replacement.

Job 10. Master cylinder

-

replacement.

Job 11. Servo check

-

remove and refit.

Job 12. Pressure regulating valve, non-ABS system -

replacement and adjustment.

Job 13. Pressure regulating valves, ABS system

-

replacement

and adjustment.

Job 14. RPM sensors, ABS systems

-

replacement.

Job 15. Flexible hoses

-

replacement.

Job 16. Metal pipes

-

replacement.

Job 17. Brake bleeding.

Job 18. Handbrake cables

-

replacement.

Job 1. Understanding

Tipo/Tempra brakes.

• Point

1

A: This is the standard disc/drum system used on

cars without anti-lock brakes, shown here in left hand drive

form.

1 - fluid reservoir and master cylinder 2 - servo 3

-

front disc brakes

4 - handbrake lever 5 - rear drum brakes 6

-

four way pipe union 7 - load proportioning/ pressure limiting valve

Job 1-1A

1 - front disc brakes 2

-

front flywheel 3 - front wheel RPM sensors 4 - hydraulic control unit 5 - brake light switch 6 - device failure warning light switch

7 - rear flywheel 8 - main control relay with excess voltage protection 9 - electronic control unit 10 - rear disc brakes 11 - rear wheel RPM sensors 12 - load proportioning/pressure limiting valve Job

1-1B

Page 131 of 171

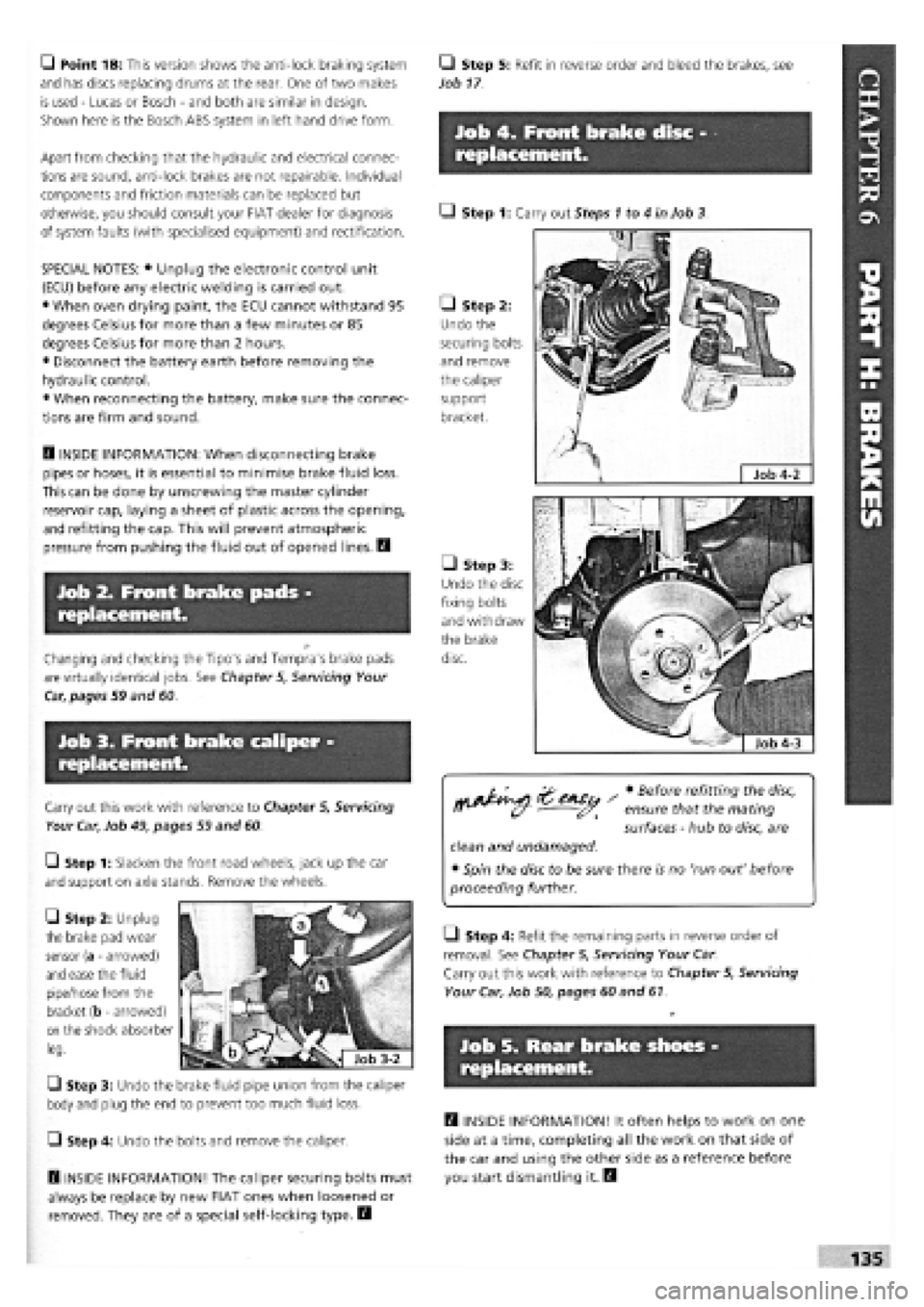

Q Point 1B: This version shows the anti-lock braking system

and has discs replacing drums at the rear. One of two makes

is used

-

Lucas or Bosch

-

and both are similar in design.

Shown here is the Bosch ABS system in left hand drive form.

Apart from checking that the hydraulic and electrical connec-

tions are sound, anti-lock brakes are not repairable. Individual

components and friction materials can be replaced but

otherwise, you should consult your FIAT dealer for diagnosis

of system faults (with specialised equipment) and rectification.

SPECIAL NOTES: • Unplug the electronic control unit

(ECU) before any electric welding is carried out.

• When oven drying paint, the ECU cannot withstand 95

degrees Celsius for more than a few minutes or 85

degrees Celsius for more than 2 hours.

• Disconnect the battery earth before removing the

hydraulic control.

• When reconnecting the battery, make sure the connec-

tions are firm and sound.

Q INSIDE INFORMATION: When disconnecting brake

pipes or hoses, it is essential to minimise brake fluid loss.

This can be done by unscrewing the master cylinder

reservoir cap, laying a sheet of plastic across the opening,

and refitting the cap. This will prevent atmospheric

pressure from pushing the fluid out of opened lines. D

Job 2. Front brake pads -

replacement.

Changing and checking the Tipo's and Tempra's brake pads

are virtually identical jobs. See Chapter 5, Servicing Your

Car, pages 59 and 60

Job 3. Front brake caliper -

replacement.

Carry out this work with reference to Chapter 5, Servicing

Your Car, Job 49, pages 59 and 60.

Q Step 1: Slacken the front road wheels, jack up the car

and support on axle stands. Remove the wheels.

Q Step 2: Unplug

the brake pad wear

sensor (a

-

arrowed)

and ease the fluid

pipe/hose from the

bracket (b

-

arrowed)

on

the shock absorber

leg.

Q Step 3: Undo the brake fluid pipe union from the caliper

body and plug the end to prevent too much fluid loss.

Q Step 4: Undo the bolts and remove the caliper.

D INSIDE INFORMATION! The caliper securing bolts must

always be replace by new FIAT ones when loosened or

removed. They are of a special self-locking type. B

Q Step 5: Refit in reverse order and bleed the brakes, see

Job 17

Job 4. Front brake disc -

replacement.

Q Step 1: Carry out Steps 1 to 4 in Job 3.

• Step 2:

Undo the

securing bolts

and remove

the caliper

support

bracket.

• Step 3:

Undo the disc

fixing bolts

and withdraw

the brake

disc.

Q Step 4: Refit the remaining parts in reverse order of

removal. See Chapter 5, Servicing Your Car.

Carry out this work with reference to Chapter 5, Servicing

Your Car, Job 50, pages 60 and 61.

Job 5. Rear brake shoes -

replacement.

H INSIDE INFORMATION! It often helps to work on one

side at a time, completing all the work on that side of

the car and using the other side as a reference before

you start dismantling it. Q

• Before refitting the disc,

ensure that the mating

surfaces

-

hub to disc, are

clean and undamaged.

• Spin the disc to be sure there is no 'run out' before

proceeding further.

Job 4-2

Page 136 of 171

Job 13. Pressure regulating

valves, ABS system - replacement

and adjustment.

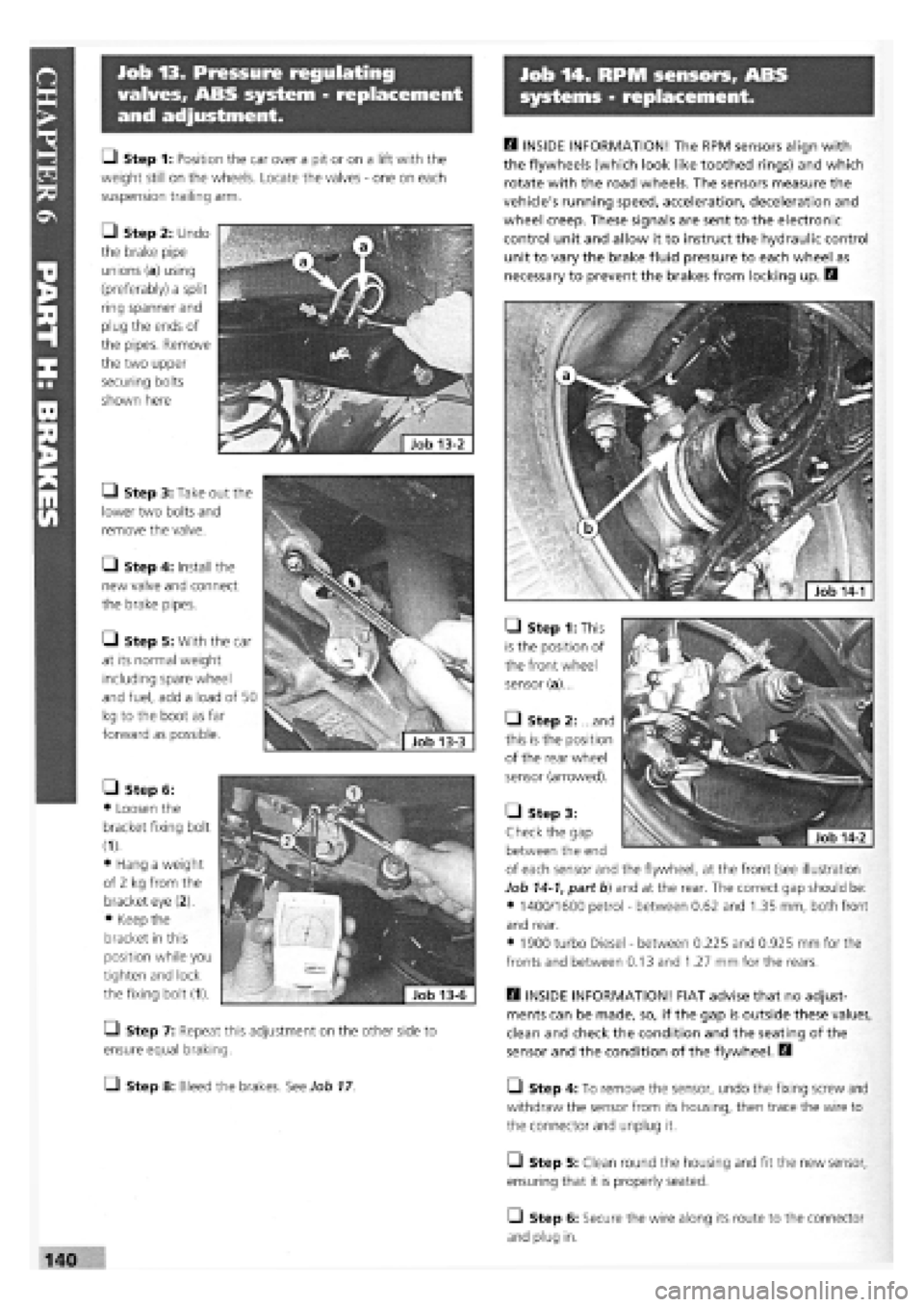

Job 14. RPM sensors, ABS

systems - replacement.

H INSIDE INFORMATION! The RPM sensors align with

the flywheels (which look like toothed rings) and which

rotate with the road wheels. The sensors measure the

vehicle's running speed, acceleration, deceleration and

wheel creep. These signals are sent to the electronic

control unit and allow it to instruct the hydraulic control

unit to vary the brake fluid pressure to each wheel as

necessary to prevent the brakes from locking up. E3

• Step 1: This

is the position of

the front wheel

sensor (a)...

• Step 2: ...and

this is the position

of the rear wheel

sensor (arrowed).

H INSIDE INFORMATION! FIAT advise that no adjust-

ments can be made, so, if the gap is outside these values,

clean and check the condition and the seating of the

sensor and the condition of the flywheel. D

L_l Step 4: To remove the sensor, undo the fixing screw and

withdraw the sensor from its housing, then trace the wire to

the connector and unplug it.

• Step 5: Clean round the housing and fit the new sensor,

ensuring that it is properly seated.

O Step 6: Secure the wire along its route to the connector

and plug in.

• Step 1: Position the car over a pit or on a lift with the

weight still on the wheels. Locate the valves

-

one on each

suspension trailing arm.

• Step 2: Undo

the brake pipe

unions (a) using

(preferably) a split

ring spanner and

plug the ends of

the pipes. Remove

the two upper

securing bolts

shown here

• Step 3: Take out the

lower two bolts and

remove the valve.

• Step 4: Install the

new valve and connect

the brake pipes.

• Step 5: With the car

at its normal weight

including spare wheel

and fuel, add a load of 50

kg to the boot as far

forward as possible.

• Step 6:

• Loosen the

bracket fixing bolt

(1).

• Hang a weight

of 2 kg from the

bracket eye (2).

• Keep the

bracket in this

position while you

tighten and lock

the fixing bolt (1).

Q Step 7: Repeat this adjustment on the other side to

ensure equal braking.

• Step 8: Bleed the brakes. See Job

17

• Step 3:

Check the gap

between the end

of each sensor and the flywheel, at the front (see illustration

Job

14-1,

part b) and at the rear. The correct gap should be:

• 1400/1600 petrol

-

between 0.62 and 1.35 mm, both front

and rear.

• 1900 turbo Diesel

-

between 0.225 and 0.925 mm for the

fronts and between 0.13 and 1.27 mm for the rears.

Page 137 of 171

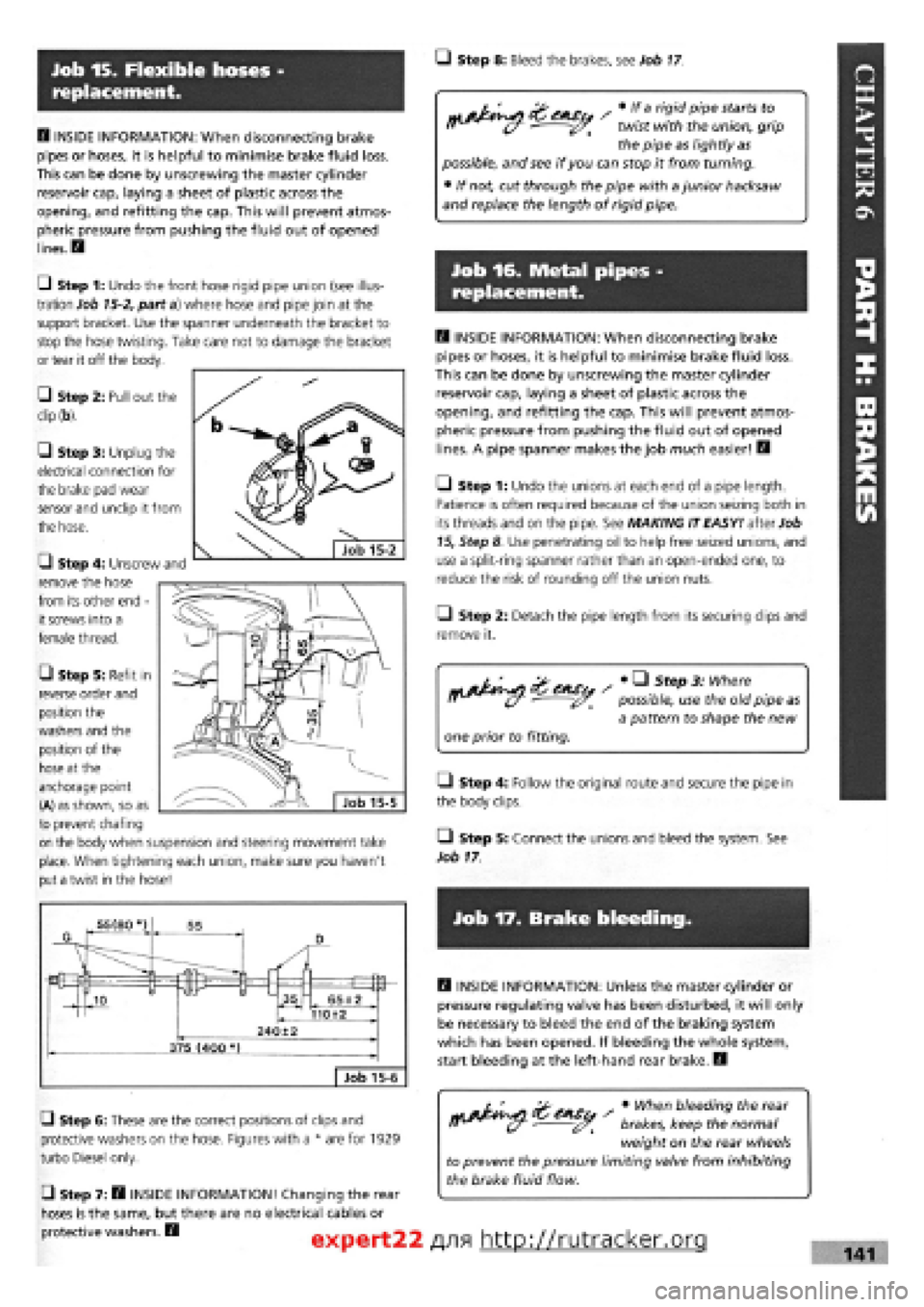

Job 15. Flexible hoses -

replacement.

• Step 8: Bleed the brakes, see Job

17

H INSIDE INFORMATION: When disconnecting brake

pipes or hoses, it is helpful to minimise brake fluid loss.

This can be done by unscrewing the master cylinder

reservoir cap, laying a sheet of plastic across the

opening, and refitting the cap. This will prevent atmos-

pheric pressure from pushing the fluid out of opened

lines. D

/ • If a rigid pipe starts to

twist with the union, grip

the pipe as lightly as

possible, and see if you can stop it from turning.

• If not, cut through the pipe with a junior hacksaw

and replace the length of rigid pipe.

Job 16. Metal pipes -

replacement.

B INSIDE INFORMATION: When disconnecting brake

pipes or hoses, it is helpful to minimise brake fluid loss.

This can be done by unscrewing the master cylinder

reservoir cap, laying a sheet of plastic across the

opening, and refitting the cap. This will prevent atmos-

pheric pressure from pushing the fluid out of opened

lines. A pipe spanner makes the job much easier! B

Step 1: Undo the unions at each end of a pipe length.

Patience is often required because of the union seizing both in

its threads and on the pipe. See MAKING IT EASY! after Job

15,

Step 8 Use penetrating oil to help free seized unions, and

use a split-ring spanner rather than an open-ended one, to

reduce the risk of rounding off the union nuts.

• Step 2: Detach the pipe length from its securing clips and

remove it.

i^vj ens s * ^ step 3: where possible, use the old pipe as

a pattern to shape the new

one prior to fitting.

• Step 4: Follow the original route and secure the pipe in

the body clips.

Q Step 5: Connect the unions and bleed the system. See

Job

17

Job 17. Brake bleeding.

B INSIDE INFORMATION: Unless the master cylinder or

pressure regulating valve has been disturbed, it will only

be necessary to bleed the end of the braking system

which has been opened. If bleeding the whole system,

start bleeding at the left-hand rear brake. B

G Step 6: These are the correct positions of clips and

protective washers on the hose. Figures with a * are for 1929

turbo Diesel only.

• Step 7: B INSIDE INFORMATION! Changing the rear

hoses is the same, but there are no electrical cables or

protective washers. B

s • When bleeding the rear

brakes, keep the normal

weight on the rear wheels

to prevent the pressure limiting valve from inhibiting

the brake fluid flow.

expert22 f

\9\ http://rutracker.org 141

Ul Step 1: Undo the front hose rigid pipe union (see illus-

tration Job

15-2,

part a) where hose and pipe join at the

support bracket. Use the spanner underneath the bracket to

stop the hose twisting. Take care not to damage the bracket

or tear it off the body.

• Step 2: Pull out the

dip (b).

G Step 3: Unplug the

electrical connection for

the brake pad wear

sensor and unclip it from

the hose.

G Step 4: Unscrew and

remove the hose

from its other end -

it screws into a

female thread.

• Step 5: Refit in

reverse order and

position the

washers and the

position of the

hose at the

anchorage point

(A) as shown, so as

to prevent chafing

on the body when suspension and steering movement take

place. When tightening each union, make sure you haven't

put a twist in the hose!

Page 148 of 171

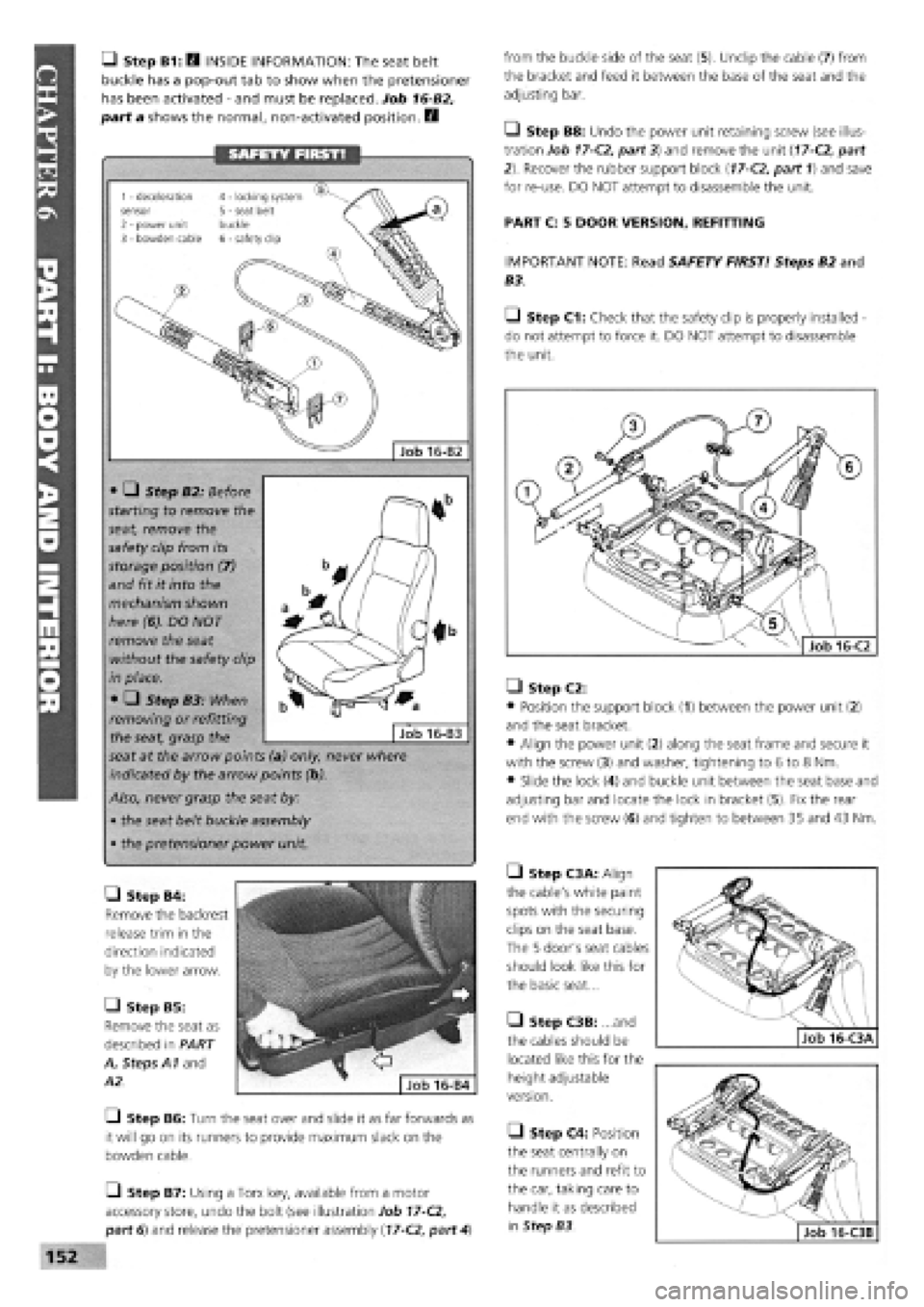

• Step B1: Q INSIDE INFORMATION: The seat belt

buckle has a pop-out tab to show when the pretensioner

has been activated

-

and must be replaced. Job 16-B2,

part a shows the normal, non-activated position. E3

from the buckle side of the seat (5). Unclip the cable (7) from

the bracket and feed it between the base of the seat and the

adjusting bar.

Q Step B8: Undo the power unit retaining screw (see illus-

tration Job

17-C2,

part 3) and remove the unit

(17-C2,

part

2). Recover the rubber support block

(17-C2,

part 1) and save

for re-use. DO NOT attempt to disassemble the unit.

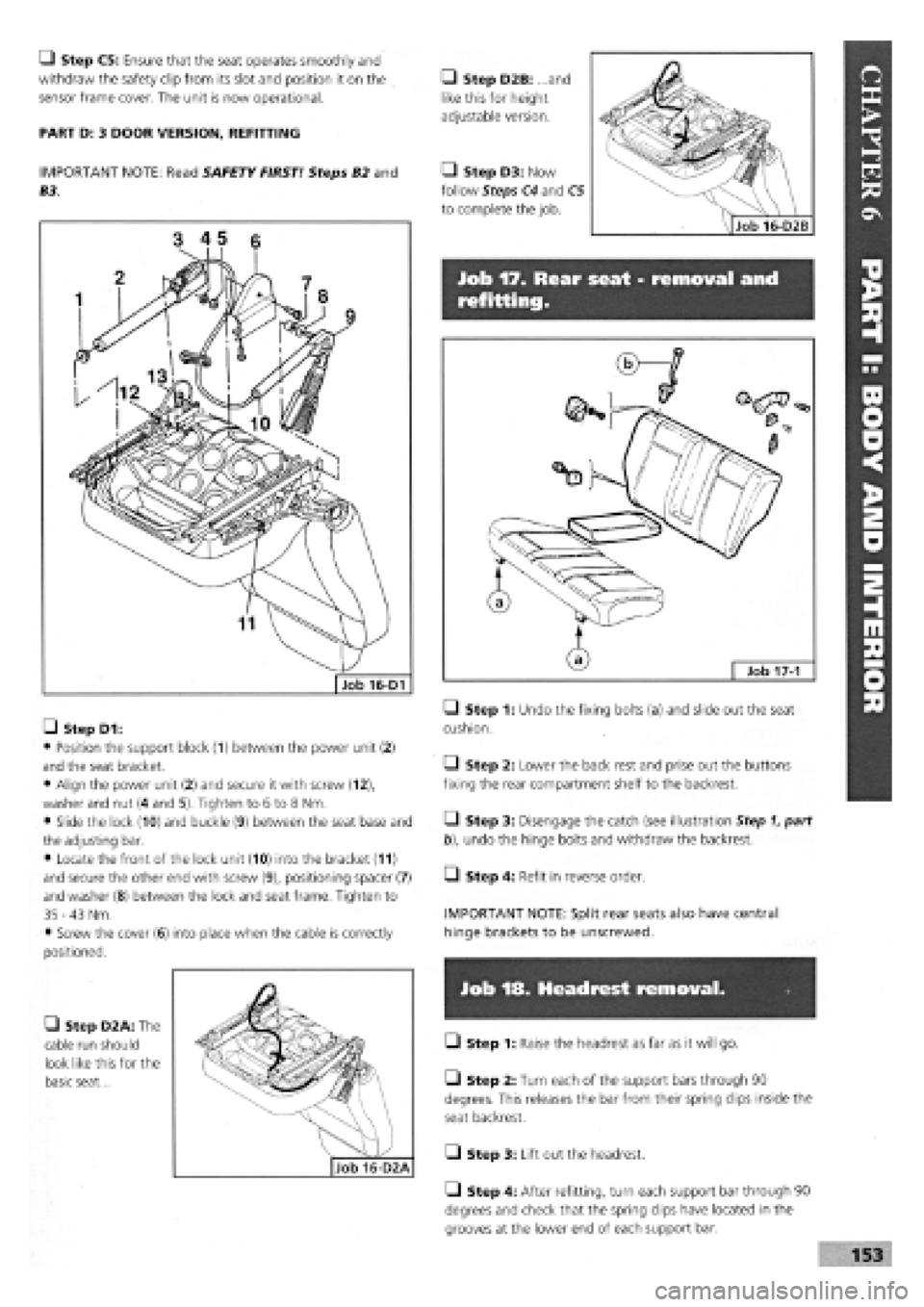

PART C: 5 DOOR VERSION, REFITTING

IMPORTANT NOTE: Read SAFETY FIRST! Steps B2 and

B3.

Q Step C1: Check that the safety clip is properly installed -

do not attempt to force it. DO NOT attempt to disassemble

the unit.

• Step B4:

Remove the backrest

release trim in the

direction indicated

by the lower arrow.

• Step B5:

Remove the seat as

described in PART

A, Steps A1 and

A2.

—I Step B6: Turn the seat over and slide it as far forwards as

it will go on its runners to provide maximum slack on the

bowden cable.

O Step B7: Using a Torx key, available from a motor

accessory store, undo the bolt (see illustration Job

17-C2,

part 6) and release the pretensioner assembly

(17-C2,

part

4)

• Step C2:

• Position the support block (1) between the power unit (2)

and the seat bracket.

• Align the power unit (2) along the seat frame and secure it

with the screw (3) and washer, tightening to 6 to 8 Nm.

• Slide the lock (4) and buckle unit between the seat base and

adjusting bar and locate the lock in bracket (5). Fix the rear

end with the screw (6) and tighten to between 35 and 43 Nm.

• Step C3A: Align

the cable's white paint

spots with the securing

clips on the seat base.

The 5 door's seat cables

should look like this for

the basic seat...

• Step C3B: ...and

the cables should be

located like this for the

height adjustable

version.

• Step C4: Position

the seat centrally on

the runners and refit to

the car, taking care to

handle it as described

in Step B3.

SAFETY FIRST!

• • Step B2: Before

starting to remove the

seat, remove the

safety clip from its

storage position (7)

and fit it into the

mechanism shown

here (6). DO NOT

remove the seat

without the safety clip

in place.

• • Step B3: When

removing or refitting

the seat, grasp the

seat at the arrow points (a) only, never where

indicated by the arrow points (b).

Also, never grasp the seat by:

• the seat belt buckle assembly

• the pretensioner power unit.

Job 16-B3

• •

Job 16-B2

1 - deceleration sensor 2 - power unit 3 - bowden cable

4 - locking system 5 - seat belt buckle 6 - safety clip

Page 149 of 171

Job 17. Rear seat - removal and

refitting.

Job 16-D1

Q Step C5: Ensure that the seat operates smoothly and

withdraw the safety clip from its slot and position it on the

sensor frame cover. The unit is now operational.

PART D: 3 DOOR VERSION, REFITTING

IMPORTANT NOTE: Read SAFETY FIRST! Steps B2 and

B3.

• Step D2B: .. and

like this for height

adjustable version.

• Step D3: Now

follow Steps C4 and C5

to complete the job.

• Step D1:

• Position the support block (1) between the power unit (2)

and the seat bracket.

• Align the power unit (2) and secure it with screw (12),

washer and nut (4 and 5). Tighten to 6 to 8 Nm.

• Slide the lock (10) and buckle (9) between the seat base and

the adjusting bar.

• Locate the front of the lock unit (10) into the bracket (11)

and secure the other end with screw (9), positioning spacer (7)

and washer

(8)

between the lock and seat frame. Tighten to

35 -43

Nm.

• Screw the cover

(6)

into place when the cable is correctly

positioned.

• Step D2A: The

cable run should

look like this for the

basic seat...

• Step 1: Undo the fixing bolts (a) and slide out the seat

cushion.

Q Step 2: Lower the back rest and prise out the buttons

fixing the rear compartment shelf to the backrest.

• Step 3: Disengage the catch (see illustration Step 1, part

b), undo the hinge bolts and withdraw the backrest.

Q Step 4: Refit in reverse order.

IMPORTANT NOTE: Split rear seats also have central

hinge brackets to be unscrewed.

Job 18. Headrest removal.

• Step 1: Raise the headrest as far as it will go.

• Step 2: Turn each of the support bars through 90

degrees. This releases the bar from their spring clips inside the

seat backrest.

Q Step 3: Lift out the headrest.

Q Step 4: After refitting, turn each support bar through 90

degrees and check that the spring clips have located in the

grooves at the lower end of each support bar.

Page 151 of 171

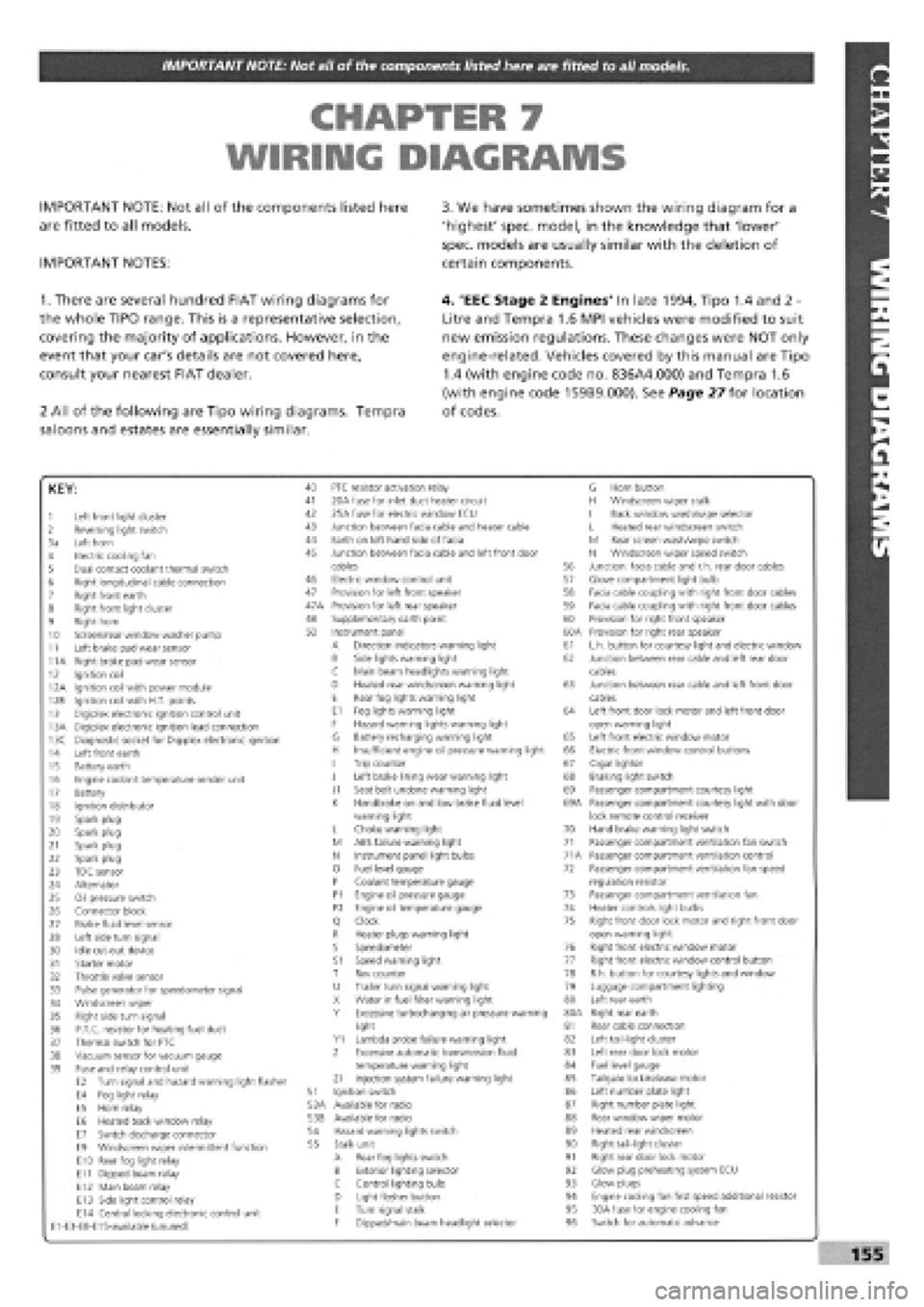

IMPORTANT NOTE: Not all of the components listed here are fitted to all models.

CHAPTER 7

WIRING DIAGRAMS

IMPORTANT NOTE: Not all of the components listed here

are fitted to all models.

IMPORTANT NOTES:

3. We have sometimes shown the wiring diagram for a

'highest' spec, model, in the knowledge that 'lower'

spec, models are usually similar with the deletion of

certain components.

1. There are several hundred FIAT wiring diagrams for

the whole TIPO range. This is a representative selection,

covering the majority of applications. However, in the

event that your car's details are not covered here,

consult your nearest FIAT dealer.

2 All of the following are Tipo wiring diagrams. Tempra

saloons and estates are essentially similar.

4. 'EEC Stage 2 Engines' In late 1994, Tipo 1.4 and 2 -

Litre and Tempra 1.6 MPI vehicles were modified to suit

new emission regulations. These changes were NOT only

engine-related. Vehicles covered by this manual are Tipo

1.4 (with engine code no. 836A4.000) and Tempra 1.6

(with engine code 159B9.000). See Page 27 for location

of codes.

KEY:

1 Left front light cluster 2 Reversing light switch 3a Left horn 4 Electric cooling fan 5 Dual contact coolant thermal switch 6 Right longitudinal cable connection 7 Right front earth 8 Right front light cluster 9 Right horn 10 Screen/rear window washer pump 11 Left brake pad wear sensor 11A Right brake pad wear sensor 12 Ignition coil 12A Ignition coil with power module 12B Ignition coil with H.T. points 13 Digiplex electronic ignition control unit 13A Digiplex electronic ignition lead connection 13C Diagnostic socket for Digiplex electronic ignition 14 Left front earth 15 Battery earth 16 Engine coolant temperature sender unit 17 Battery 18 Ignition distributor 19 Sparkplug 20 Spark plug 21 Sparkplug 22 Spark plug 23 TDC sensor 24 Alternator 25 Oil pressure switch 26 Connector block 27 Brake fluid level sensor 28 Left side turn signal 30 Idle cut-out device 31 Starter motor 32 Throttle valve sensor 33 Pulse generator for speedometer signal 34 Windscreen wiper 35 Right side turn signal 36 P.T.C. resistor for heating fuel duct 37 Thermal switch for PTC 38 Vacuum sensor for vacuum gauge 39 Fuse and relay control unit E2 Turn signal and hazard warning light flasher E4 Fog light relay E5 Horn relay E6 Heated back window relay E7 Switch discharge connector E9 Windscreen wiper intermittent function E10 Rear fog light relay E11 Dipped beam relay E12 Main beam relay E13 Side light control relay E14 Central locking electronic control unit E1-E3-E8-E15-available (unused)

40 PTC resistor activation relay 41 20A fuse for inlet duct heater circuit 42 25A fuse for electric window ECU 43 Junction between facia cable and heater cable 44 Earth on left hand side of facia 45 Junction between facia cable and left front door

G Horn button H Windscreen wiper stalk I Back window wash/wipe selector L Heated rear windscreen switch M Rear screen wash/wipe switch N Windscreen wiper speed switch cables 56 Junction: facia cable and r.h. rear door cables Electric window control unit 57 Glove compartment light bulb Provision for left front speaker 58 Facia cable coupling with right front door cables Provision for left rear speaker 59 Facia cable coupling with right front door cables Supplementary earth point 60 Provision for right front speaker Instrument panel 60A Provision for right rear speaker A Direction indicators warning light 61 L.h. button for courtesy light and electric window B Side lights warning light 62 Junction between rear cable and left rear door C Main beam headlights warning light cables D Heated rear windscreen warning light 63 Junction between rear cable and left front door E Rear fog lights warning light cables E1 Fog lights warning light 64 Left front door lock motor and left front door F Hazard warning lights warning light open warning light G Battery recharging warning light 65 Left front electric window motor H Insufficient engine oil pressure warning light 66 Electric front window control buttons I Trip counter 67 Cigar lighter J Left brake lining wear warning light 68 Braking light switch J1 Seat belt undone warning light 69 Passenger compartment courtesy light K Handbrake on and low brake fluid level 69A Passenger compartment courtesy light with door warning light lock remote control receiver L Choke warning light 70 Hand brake warning light switch M ABS failure warning light 71 Passenger compartment ventilation fan switch N Instrument panel light bulbs 71A Passenger compartment ventilation control 0 Fuel level gauge 72 Passenger compartment ventilation fan speed P Coolant temperature gauge regulation resistor P1 Engine oil pressure gauge 73 Passenger compartment ventilation fan P2 Engine oil temperature gauge 74 Heater controls light bulbs Q Clock 75 Right front door lock motor and right front door R Heater plugs warning light open warning light S Speedometer 76 Right front electric window motor S1 Speed warning light 77 Right front electric window control button T Rev counter 78 R.h. button for courtesy lights and window U Trailer turn signal warning light 79 Luggage compartment lighting X Water in fuel filter warning light 80 Left rear earth Y Excessive turbocharging air pressure warning 80A Right rear earth light 81 Rear cable connection Y1 Lambda probe failure warning light 82 Left tail-light cluster Z Excessive automatic transmission fluid 83 Left rear door lock motor temperature warning light 84 Fuel level gauge Z1 Injection system failure warning light 85 Tailgate lock/release motor Ignition switch 86 Left number plate light Available for radio 87 Right number plate light Available for radio 88 Rear window wiper motor Hazard warning lights switch 89 Heated rear windscreen Stalk unit 90 Right tail-light cluster A Rear fog lights switch 91 Right rear door lock motor B Exterior lighting selector 92 Glow plug preheating system ECU c Control lighting bulb 93 Glow plugs D Light flasher button 94 Engine cooling fan first speed additional resistor E Turn signal stalk 95 30A fuse for engine cooling fan F Dipped/main beam headlight selector 96 Switch for automatic advance

155