ABS FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 3 of 171

Mains Electricity

Avoid the use of mains electricity when working on the vehicle,

whenever possible. Use rechargeable tools and a DC inspection

lamp, powered from a remote 12V battery

-

both are much

safer. However, if you do use mains-powered equipment,

ensure that the appliance is wired correctly to its plug, that

where necessary it is properly earthed (grounded), and that the

fuse is of the correct rating for the appliance. Do not use any

mains powered equipment in damp conditions or in the vicinity

of fuel, fuel vapour or the vehicle battery.

Always use an RCD (Residual Current Device) circuit breaker

with mains electricity. Then, if there is a short, the RCD circuit

breaker minimises the risk of electrocution by instantly cutting

the power supply.

Ignition System

Never work on the ignition system with the ignition switched

on, or with the engine being turned over on the starter, or

running and you are recommended never to do so.

Touching certain parts of the ignition system, such as the HT

leads, distributor cap, ignition coil etc., can result in a severe

electric shock or physical injury as a hand is pulled sharply away.

Voltages produced by electronic ignition systems are much

higher than those produced by conventional systems and could

prove fatal, particularly to people with cardiac pacemaker

implants. Consult your handbook or main dealer if in any

doubt.

Cooling Fan

On many vehicles, the electric cooling fan can switch itself on

even with the ignition turned off. This is especially likely after

driving the car and parking it before turning off, after which

heat rises to the top of the engine and turns the fan on,

suddenly and without warning. If you intend working in the

engine bay, it's best to do so when the engine is cold, to

disconnect the battery, or keep away from the fan, if neither of

these are possible.

Battery

Never cause a spark, smoke, or allow a naked light near the

vehicle's battery, even in a well ventilated area. Highly explosive

hydrogen gas is given off as part of the charging process.

Battery terminals on the car should be shielded, since a spark

can be caused by any metal object which touches the battery's

terminals or connecting straps.

IMPORTANT NOTE: Before disconnecting the battery earth

(ground) terminal read the relevant FACT FILE in Chapter 5

regarding saving computer and radio settings.)

When using a battery charger, switch off the power supply

before the battery charger leads are connected or disconnected.

If the battery is not of the 'sealed-for-life' type, loosen the filler

plugs or remove the cover before charging. For best results the

battery should be given a low rate trickle charge overnight. Do

not charge at an excessive rate or the battery may burst.

Always wear gloves and goggles when carrying or when

topping up the battery. Acid electrolyte is extremely corrosive

and must not be allowed to contact the eyes, skin or clothes.

Brakes and Asbestos

Obviously, a car's brakes are among its most important safety

related items. ONLY work on your vehicle's braking system if

you are trained and competent to do so. If you have not been

trained in this work, but wish to carry out the jobs described in

this book, we strongly recommend that you have a garage or

qualified mechanic check your work before using the car.

Whenever you work on the braking system components, or

remove front or rear brake pads or shoes: i) wear an efficient

particle mask; ii) wipe off all brake dust from the brakes after

spraying on a proprietary brand of brake cleaner (never blow

dust off with compressed air); iii) dispose of brake dust and

discarded shoes or pads in a sealed plastic bag; iv) wash your

hands thoroughly after you have finished working on the

brakes and certainly before you eat or smoke; v) replace shoes

and pads only with asbestos-free shoes or pads. Note that

asbestos brake dust can cause cancer if inhaled; vi) always

replace brake pads and/or shoes in complete 'axle' sets of four

-

never replace the pads/shoes on one wheel only.

Brake Fluid

Brake fluid absorbs moisture rapidly from the air and can

become dangerous resulting in brake failure. You should

change the fluid in accordance with your vehicle manufacturer's

recommendations or as advised in this book. Never store (or

use) an opened container of brake fluid. Dispose of the

remainder at your Local Authority Waste Disposal Site, in the

designated disposal unit, not with general waste or with waste

oil.

Engine Oils

Always wear disposable plastic or rubber gloves when draining

the oil from your engine, i) Note that the drain plug and the oil

are often hotter than you expect. Wear gloves if the plug is too

hot to touch and keep your hand to one side so that you are

not scalded by the spurt of oil as the plug comes away; ii) There

are very real health hazards associated with used engine oil. In

the words of one manufacturer's handbook "Prolonged and

repeated contact may cause serious skin disorders, including

dermatitis and cancer." Use a barrier cream on your hands and

try not to get oil on them. Always wear gloves and wash your

hands with hand cleaner soon after carrying out the work. Keep

oil out of the reach of children; iii) NEVER, EVER dispose of old

engine oil into the ground or down a drain. In the UK, and in

most EC countries, every local authority must provide a safe

means of oil disposal. In the UK, try your local Environmental

Health Department for advice on waste disposal facilities.

Plastic Materials

Many of the materials used (polymers, resins, adhesives and

materials acting as catalysts and accelerators) contain dangers in

the form of poisonous fumes, skin irritants, and the risk of fire

Page 6 of 171

• Repeat this operation three more times until the

complete code number has been entered, if the code

has been entered in correctly LED B will start flashing.

• Release button A (see illustration

1B).

Red LED B

flashes for 8 seconds indicating the new remote unit's

code has been stored.

IMPORTANT NOTE: If the LED does not illuminate

when remote unit button (illustration 1B, button

O is pressed, change the remote unit's battery.

• Insert the emergency key A into the emergency switch

slot in the glove compartment turn the key to the left to

switch the alarm off (see inset).

• Turn the key back towards its original position to

switch the alarm system back on.

IMPORTANT NOTE: As the alarm system absorbs

energy, if you are not planning on using the car

for a long period of time, turn the alarm exclusion

key to the off position, so as not to run the vehicle

battery down.

• 2. IGNITION SWITCH AND

STEERING COLUMN LOCK

IGNITION SWITCH

2. The ignition/steering column lock key, once inserted

in the ignition lock, can be placed in any of the

following four positions:

• PARK

-

With the key in this

position the side and tail lights

can be turned on, the steering

column locked and the keys

can be removed. Press button

A to turn the key to PARK.

• STOP

-

When the key is

turned to the STOP position the steering column will be

locked, and the keys can be removed.

• MAR

-

This is the driving position. When the key is in

this position all the electrical devices are energised.

• AW

-

Turning the key to this position starts the

engine.

STEERING COLUMN LOCK

• LOCKING

-

To apply the steering wheel lock turn the

steering wheel slightly to the left or right when the key is

at STOP or PARK.

• UNLOCKING

-

Rocking the steering wheel gently back

and forth while turning the ignition key to MAR unlocks

the steering wheel.

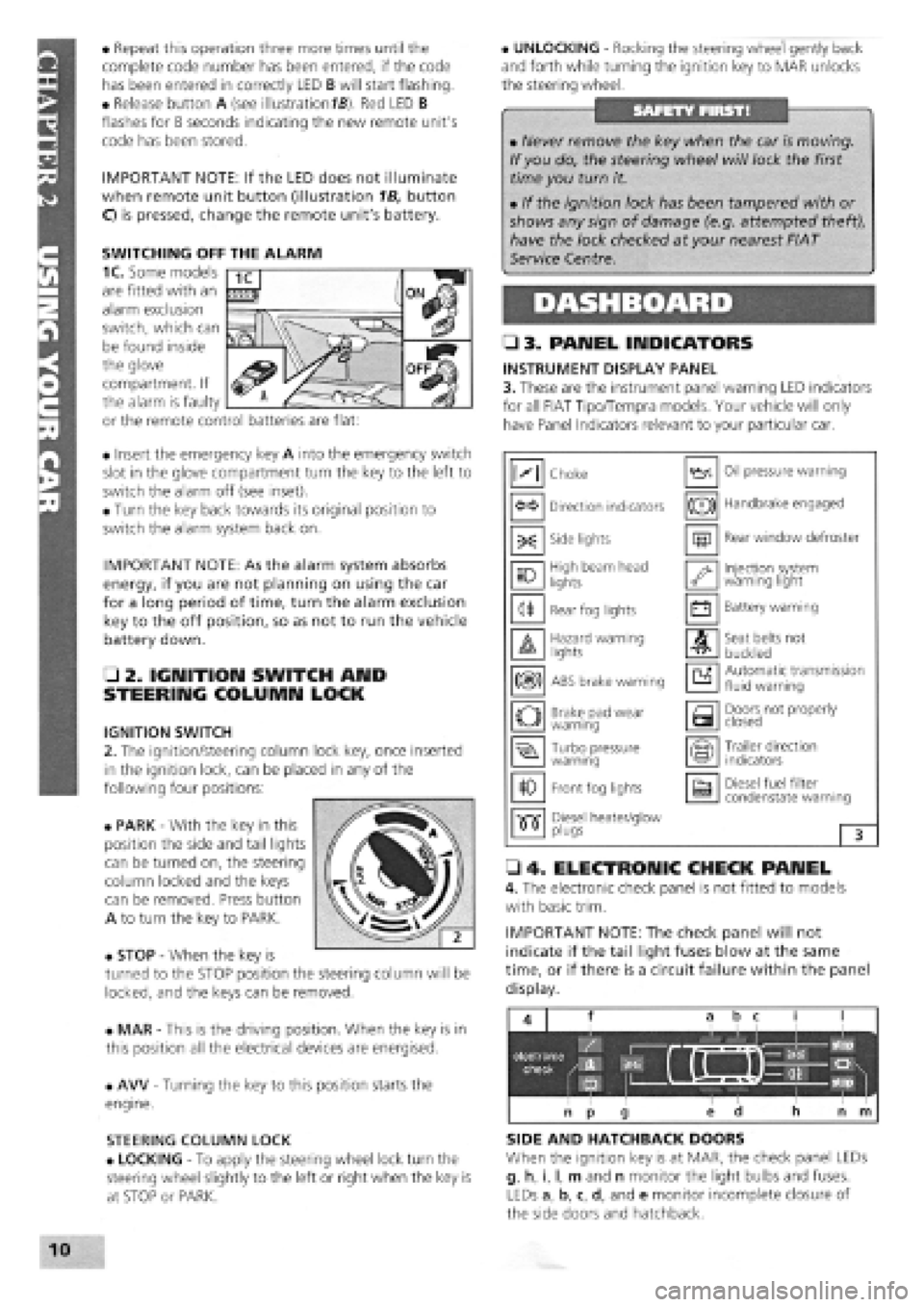

• 3. PANEL INDICATORS

INSTRUMENT DISPLAY PANEL

3. These are the instrument panel warning LED indicators

for all FIAT Tipo/Tempra models. Your vehicle will only

have Panel Indicators relevant to your particular car.

• 4. ELECTRONIC CHECK PANEL

4. The electronic check panel is not fitted to models

with basic trim.

IMPORTANT NOTE: The check panel will not

indicate if the tail light fuses blow at the same

time, or if there is a circuit failure within the panel

display.

SIDE AND HATCHBACK DOORS

When the ignition key is at MAR, the check panel LEDs

g, h, i, I, m and n monitor the light bulbs and fuses.

LEDs a, b, c, d, and e monitor incomplete closure of

the side doors and hatchback.

• Never remove the key when the car is moving.

If you do, the steering wheel will lock the first

time you turn it.

• If the ignition lock has been tampered with or

shows any sign of damage (e.g. attempted theft),

have the lock checked at your nearest FIAT

Service Centre.

M Choke Oil pressure warning

Direction indicators (®) Handbrake engaged

-X: Side lights m Rear window defroster

10 High beam head

lights '•y Injection system warning light

<1* Rear fog lights • Battery warning

A Hazard warning lights A Seat belts not

buckled

m ABS brake warning a Automatic transmission fluid warning

o Brake pad wear warning a Doors not properly closed

Turbo pressure warning Trailer direction indicators

10 Front fog lights a Diesel fuel filter condenstate warning

•515" Diesel heater/glow •515" plugs 3

SWITCHING OFF THE ALARM

1C. Some models

are fitted with an

alarm exclusion

switch, which can

be found inside

the glove

compartment. If

the alarm is faulty

or the remote control batteries are flat:

Page 14 of 171

October 1991 2.0 i.e. 16v introduced, with 1995cc, 16 valve

high-performance DOHC engine, catalytic converter, sports

suspension, front and rear disc brakes. ABS available as

option.

January 1992 Existing Tipo models lightly facelifted and

redesignated 1.4 Formula, 1.45, 1.6S, 1.6SX, 1.9TD SX,

1.8 i.e. SX. 1.7D discontinued. SX versions with digital

instruments.

Tempra 1.9 TDS (turbo diesel) Station Wagon introduced. 1.4

and 1.9D saloons discontinued.

May 1992 Tempra 1.8 i.e. SX Saloon and Station Wagon

discontinued.

June 1992 Tempra 2.0 i.e. SX saloon and station wagon

models introduced, with high performance 1995cc DOHC fuel

injected engine, catalytic converter and disc brakes front and

rear.

Tipo 1.4 and all Tipo and Tempra 1.6 models (except Selecta)

now with a catalytic converter and fuel injection in place of

Weber twin-choke carburettor. Designated i.e. in badging.

December 1992 Tipo 1.8 i.e. and 1.6 Selecta discontinued.

February 1993 Tipo 2.0 i.e. GT introduced. Slightly lower

performance and spec, version of the 16v model.

July 1993 Tipo 1.4 now available as a 3-door or 5-door

hatchback. 2.0 i.e. 16v now only available as 3-door. Tipo 2.0

i.e. GT replaced by similar spec. 2.0 i.e. SLX.

Tempra 2.0 i.e. SX saloons and estates now only available

with auto, gearbox. Otherwise, SX models become known as

SLX, with colour-coded mirrors and ABS brakes. Most Tempras

now with body-coloured bumpers. 1.9D (non turbo Diesel re-

introduced).

All Tipo and Tempra models now with revised front-end

styling

-

narrower headlights and revised grille. Improved crash

protection, including side impact beams, safety steering wheel

and uprated brakes. Power steering, central locking, electric

windows all standard.

February 1994 Tipo 1.7 non-turbo diesel re-introduced as

1.7 DS.

May 1994 Tempra 1.9DS Station Wagon introduced.

September 1994 Most models available with driver's airbag,

fire prevention system and seat belt pre-tensioners.

December 1994 Tempra 1.6 i.e. versions get M.P.I, engine.

February/March 1995 All models with VIN number window

etching and immobiliser standard on all Tempra petrol models.

October 1995 Immobiliser fitted to Tempra D and TD models.

End of 1995 Tipo discontinued.

Mid-1996 Tempra discontinued.

PART B: VITAL STATISTICS

All Tipo models

-

55 litres, except petrol with catalytic converter

- 51

litres.

All Tempra models

-

65 litres, except petrol with catalytic converter

-

62 litres.

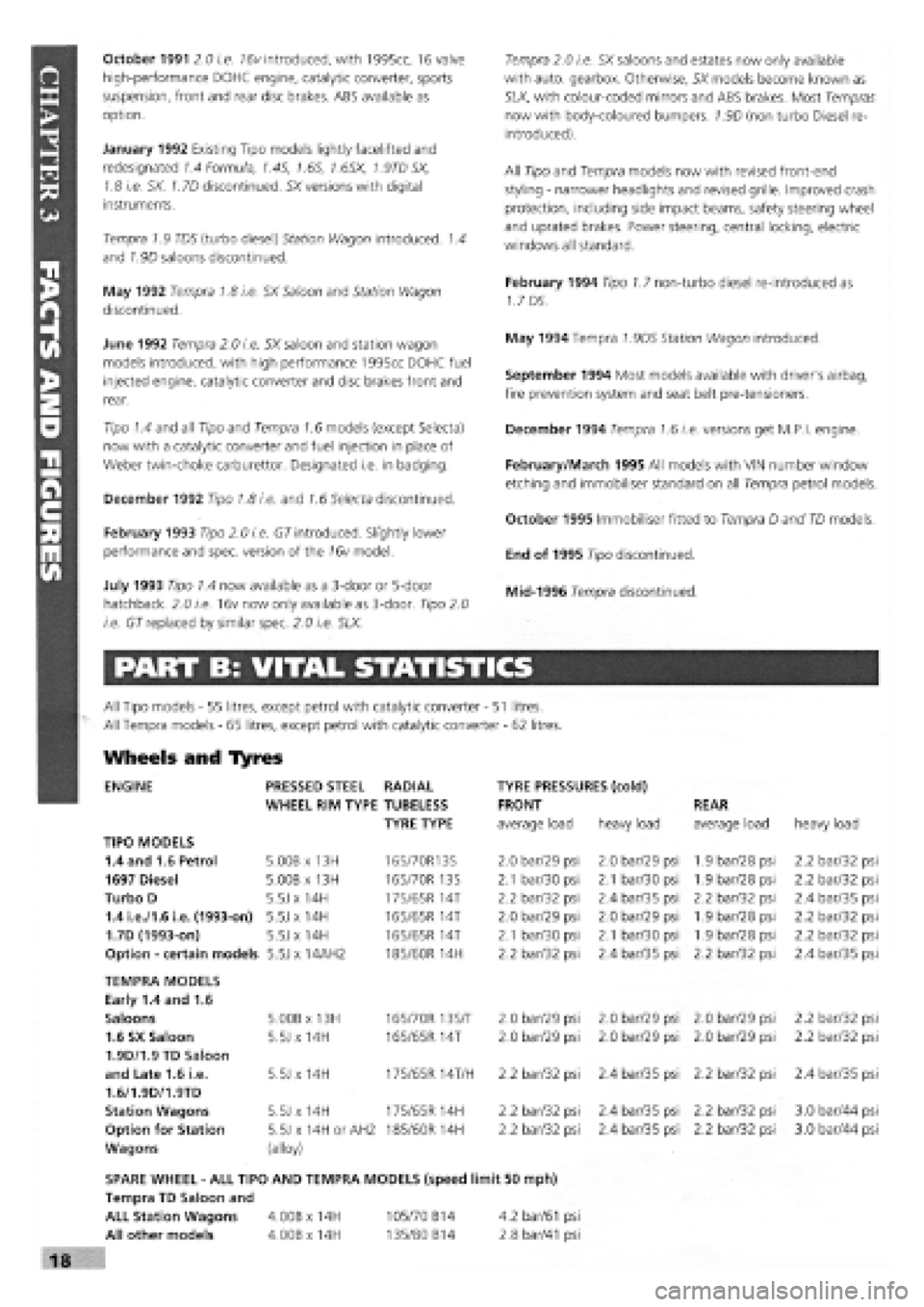

Wheels and Tyres

ENGINE PRESSED STEEL RADIAL TYRE PRESSURES (cold)

WHEEL RIM TYPE TUBELESS FRONT REAR

TYRE TYPE average load heavy load average load heavy load

TIPO MODELS

1.4 and 1.6 Petrol 5.00B x 13H 165/70R13S 2.0 bar/29 psi 2.0 bar/29 psi 1.9 bar/28 psi 2.2 bar/32 psi

1697 Diesel 5.00B x 13H 165/70R 13S 2.1 bar/30 psi 2.1 bar/30 psi 1.9 bar/28 psi 2.2 bar/32 psi

Turbo D 5.5J x 14H

175/65 R

14T 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

1.4 i.e./1.6 i.e. (1993-on) 5.5J x 14H

165/65 R

14T 2.0 bar/29 psi 2.0 bar/29 psi 1.9 bar/28 psi 2.2 bar/32 psi

1.7D (1993-on) 5.5J x 14H 165/65R 14T 2.1 bar/30 psi 2.1 bar/30 psi 1.9 bar/28 psi 2.2 bar/32 psi

Option

-

certain models 5.5J x 14AH2 185/60R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

TEMPRA MODELS

Early 1.4 and 1.6

Saloons 5.00B x 13H 165/70R 13S/T 2.0 bar/29 psi 2.0 bar/29 psi 2.0 bar/29 psi 2.2 bar/32 psi

1.6 SX Saloon 5.5J x 14H 165/65R 14T 2.0 bar/29 psi 2.0 bar/29 psi 2.0 bar/29 psi 2.2 bar/32 psi

1.9D/1.9 TD Saloon

and Late 1.6 i.e. 5.5J x 14H 175/65R 14T/H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

1.6/1.9D/1.9TD

Station Wagons 5.5J x 14H 175/65R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 3.0 bar/44 psi

Option for Station 5.5J x 14H or AH2 185/60 R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 3.0 bar/44 psi

Wagons (alloy)

SPARE WHEEL

-

ALL TIPO AND TEMPRA MODELS (speed limit 50 mph)

Tempra TD Saloon and

ALL Station Wagons 4.00B x 14H 105/70 B14 4.2

bar/61

psi

All other models 4.00Bx14H 135/80 B14 2.8

bar/41

psi

Page 15 of 171

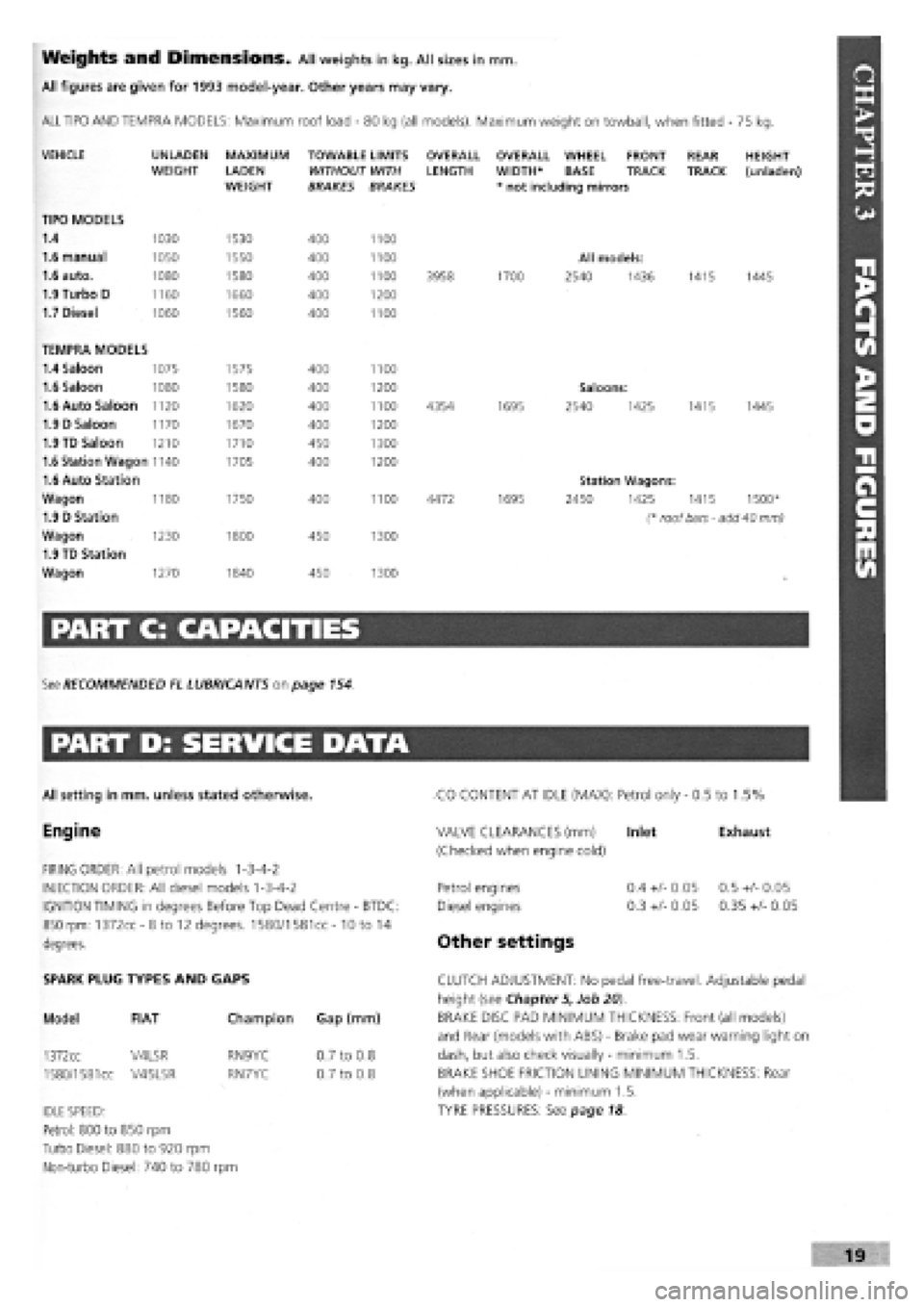

Weights and Dimensions. All weights in kg. All sizes in mm.

All figures are given for 1993 model-year. Other years may vary.

ALL TIPO AND TEMPRA MODELS: Maximum roof load

-

80 kg (all models). Maximum weight on towball, when fitted - 75 kg.

VEHICLE

TIPO MODELS

1.4

1.6 manual

1.6 auto.

1.9 Turbo D

1.7 Diesel

UNLADEN WEIGHT

1030

1050

1080

1160

1060

MAXIMUM

LADEN WEIGHT

1530

1550

1580

1660

1560

TOWABLE LIMITS WITHOUT WITH BRAKES BRAKES

400

400

400

400

400

1100

1100

1100

1200

1100

OVERALL LENGTH

3958

OVERALL WHEEL FRONT WIDTH* BASE TRACK * not including mirrors

1700

All models:

2540 1436

REAR TRACK

1415

HEIGHT (unladen)

1445

TEMPRA MODELS

1.4 Saloon 1075 1575 400 1100

1.6 Saloon 1080 1580 400 1200 Saloons:

1.6 Auto Saloon 1120 1620 400 1100 4354 1695 2540 1425 1415 1445

1.9 D Saloon 1170 1670 400 1200

1.9 TD Saloon 1210 1710 450 1300

1.6 Station Wagon 1140 1705 400 1200

1.6 Auto Station Station Wagons:

Wagon 1180 1750 400 1100 4472 1695 2450 1425 1415 1500*

1.9 D Station (* roof bars - add 40 mm)

Wagon 1230 1800 450 1300

1.9 TD Station

Wagon 1270 1840 450 1300

PART C: CAPACITIES

See RECOMMENDED EL LUBRICANTS on page 154.

PART D: SERVICE DATA

All setting in mm. unless stated otherwise.

Engine

FIRING ORDER: All petrol models 1-3-4-2

INJECTION ORDER: All diesel models 1-3-4-2

IGNITION TIMING in degrees Before Top Dead Centre

-

BTDC:

850 rpm: 1372cc-8to 12 degrees. 1580/1581cc- 10 to 14

degrees.

CO CONTENT AT IDLE (MAX): Petrol only

-

0.5 to 1.5%

Exhaust VALVE CLEARANCES (mm) Inlet

(Checked when engine cold)

Petrol engines

Diesel engines

Other settings

0.4

+/-

0.05

0.3

+/-

0.05

0.5

+/-

0.05

0.35

+/-

0.05

SPARK PLUG TYPES AND GAPS

Model FIAT

1372cc V4LSR

1580/1581

cc V45LSR

Champion Gap (mm)

RN9YC

RN7YC

IDLE SPEED:

Petrol: 800 to 850 rpm

Turbo Diesel: 880 to 920 rpm

Non-turbo Diesel: 740 to 780 rpm

0.7 to 0.8

0.7 to 0.8

CLUTCH ADJUSTMENT: No pedal free-travel. Adjustable pedal

height (see Chapter 5, Job 20).

BRAKE DISC PAD MINIMUM THICKNESS: Front (all models)

and Rear (models with ABS)

-

Brake pad wear warning light on

dash, but also check visually

-

minimum 1.5.

BRAKE SHOE FRICTION LINING MINIMUM THICKNESS: Rear

(when applicable)

-

minimum 1.5.

TYRE PRESSURES: See page 18

Page 18 of 171

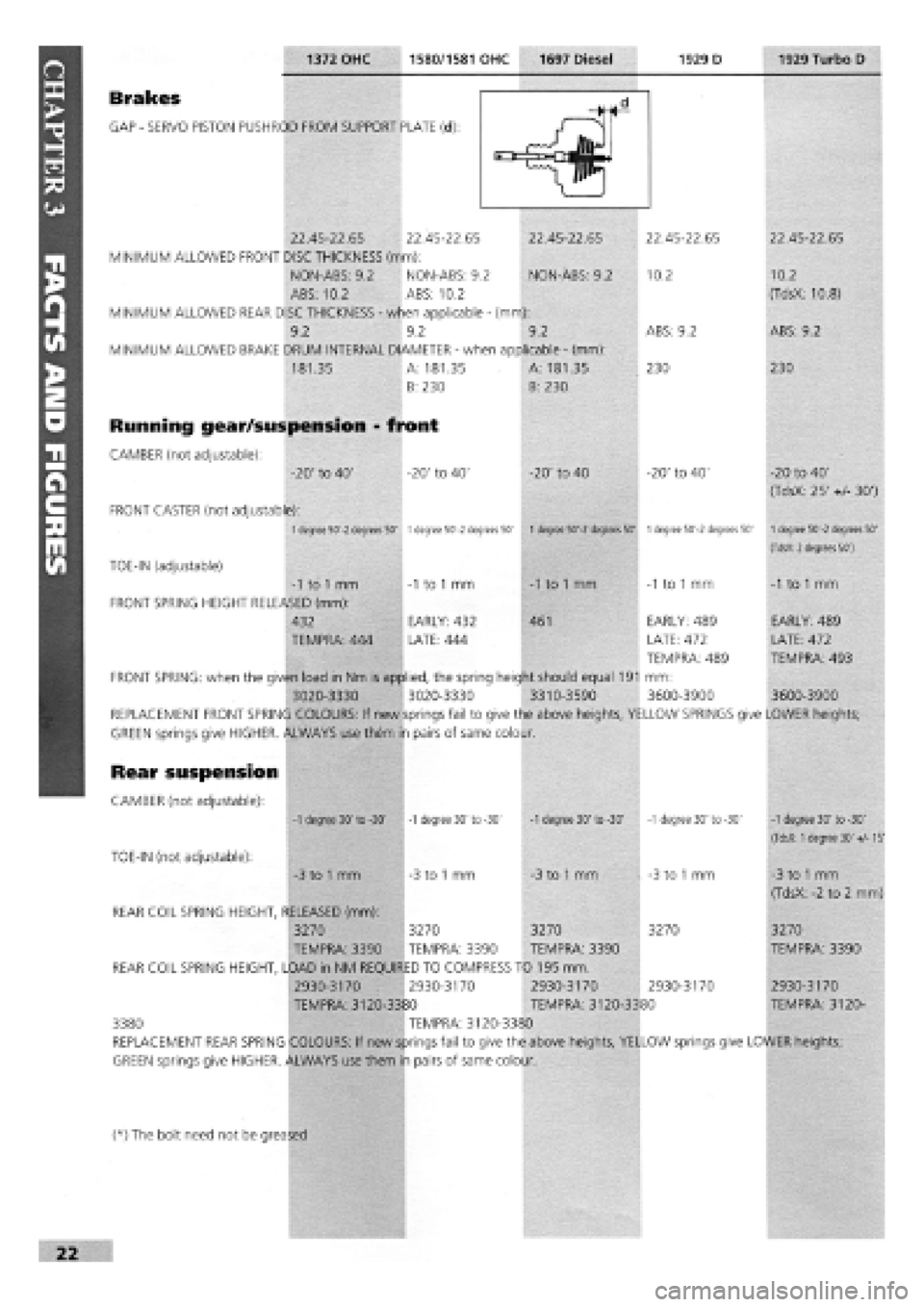

1372 OHC 1580/1581 OHC 1697 Diesel 1929 D 1929 Turbo D

Brakes

GAP

-

SERVO PISTON PUSHROD FROM SUPPORT PLATE (d):

22.45-22.65 22.45-22.65 22.45-22.65

MINIMUM ALLOWED FRONT DISC THICKNESS (mm):

NON-ABS: 9.2 NON-ABS: 9.2 NON-ABS: 9.2

ABS: 10.2 ABS: 10.2

MINIMUM ALLOWED REAR DISC THICKNESS

-

when applicable

-

(mm):

9.2 9.2 9.2

MINIMUM ALLOWED BRAKE DRUM INTERNAL DIAMETER

-

when applicable

-

(mm):

181.35 A: 181.35

B: 230

Running gear/suspension - front

CAMBER (not adjustable):

-20' to 40' -20' to 40'

A: 181.35

B: 230

-20' to 40

22.45-22.65

10.2

ABS: 9.2

230

22.45-22.65

10.2

(TdsX: 10.8)

ABS: 9.2

230

-20' to 40' -20 to 40'

(TdsX: 25'

+/-

30')

FRONT CASTER (not adjustable):

1 degree 50'-2 degrees 50'

1

degree 50'-2 degrees 50'

1

degree 50'-2 degrees 50'

1

degree 50'-2 degrees 50' 1 degree 50'-2 degrees 50'

(TdsX: 2 degrees 50')

TOE-IN (adjustable)

-1

to

1

mm

-1

to

1

mm

-1

to

1

mm

-1

to

1

mm

FRONT SPRING HEIGHT RELEASED (mm):

432 EARLY: 432 461 EARLY: 489

TEMPRA: 444 LATE: 444 LATE: 472

TEMPRA: 489

FRONT SPRING: when the given load in Nm is applied, the spring height should equal 191 mm:

3020-3330 3020-3330 3310-3590 3600-3900

REPLACEMENT FRONT SPRING COLOURS: If new springs fail to give the above heights, YELLOW SPRINGS give LOWER heights;

GREEN springs give HIGHER. ALWAYS use them in pairs of same colour.

Rear suspension

CAMBER (not adjustable):

TOE-IN (not adjustable):

-1

to

1

mm

EARLY: 489

LATE: 472

TEMPRA: 493

3600-3900

-1 degree 30' to -30' -1 degree 30' to -30' -1 degree 30' to -30' -1 degree 30' to -30'

-3

to

1

mm

-3

to

1

mm

-3

to

1

mm -3 to

1

mm

-1 degree 30' to -30'

(TdsX: 1 degree 30' +/-15'

-3

to

1

mm

(TdsX:

-2

to 2 mm)

REAR COIL SPRING HEIGHT, RELEASED (mm):

3270 3270 3270 3270 3270

TEMPRA: 3390 TEMPRA: 3390 TEMPRA: 3390 TEMPRA: 3390

REAR COIL SPRING HEIGHT, LOAD in NM REQUIRED TO COMPRESS TO 195 mm.

2930-3170 2930-3170 2930-3170 2930-3170 2930-3170

TEMPRA: 3120-3380 TEMPRA: 3120-3380 TEMPRA: 3120-

3380 TEMPRA: 3120-3380

REPLACEMENT REAR SPRING COLOURS: If new springs fail to give the above heights, YELLOW springs give LOWER heights;

GREEN springs give HIGHER. ALWAYS use them in pairs of same colour.

(*) The bolt need not be greased

Page 21 of 171

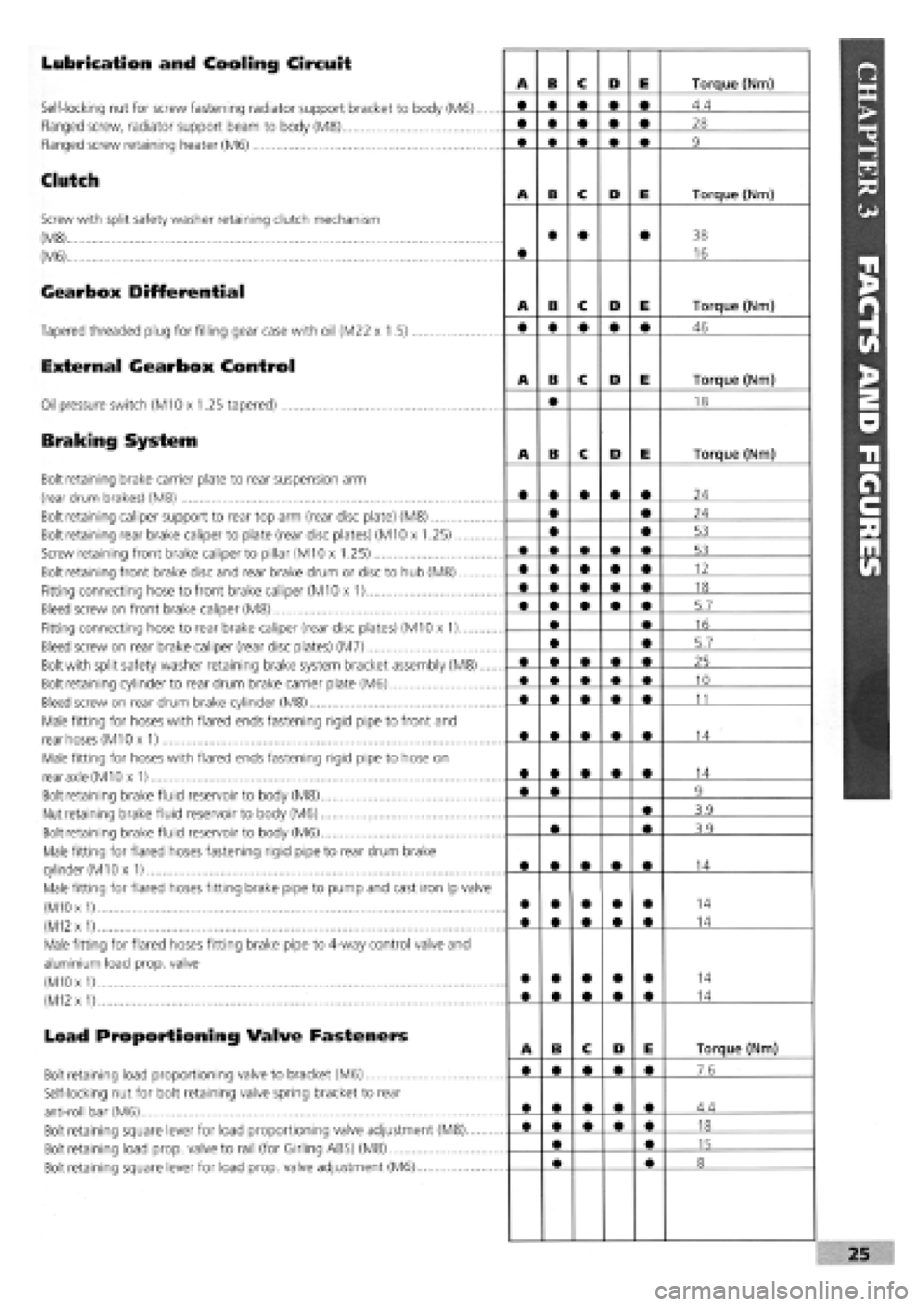

Lubrication and Cooling Circuit

Self-locking nut for screw fastening radiator support bracket to body (M6)....

Flanged screw, radiator support beam to body (M8)

Flanged screw retaining heater (M6)

Clutch

Screw with split safety washer retaining clutch mechanism

(M8)

(M6)

Gearbox Differential

Tapered threaded plug for filling gear case with oil (M22 x 1.5)

External Gearbox Control

Oil pressure switch (M10 x 1.25 tapered)

Braking System

Bolt retaining brake carrier plate to rear suspension arm

(rear drum brakes) (M8)

Bolt retaining caliper support to rear top arm (rear disc plate) (M8)

Bolt retaining rear brake caliper to plate (rear disc plates) (M10 x 1.25)

Screw retaining front brake caliper to pillar (M10 x 1.25)

Bolt retaining front brake disc and rear brake drum or disc to hub (M8)

Fitting connecting hose to front brake caliper (M10 x 1)

Bleed screw on front brake caliper (M8)

Fitting connecting hose to rear brake caliper (rear disc plates) (M10 x 1)

Bleed screw on rear brake caliper (rear disc plates) (M7)

Bolt with split safety washer retaining brake system bracket assembly (M8)....

Bolt retaining cylinder to rear drum brake carrier plate (M6)

Bleed screw on rear drum brake cylinder (M8)

Male fitting for hoses with flared ends fastening rigid pipe to front and

rear hoses (M10 x 1)

Male fitting for hoses with flared ends fastening rigid pipe to hose on

rear axle (M10 x 1)

Bolt retaining brake fluid reservoir to body (M8)

Nut retaining brake fluid reservoir to body (M6)

Bolt retaining brake fluid reservoir to body (M6)

Male fitting for flared hoses fastening rigid pipe to rear drum brake

cylinder

(M1

Ox 1)

Male fitting for flared hoses fitting brake pipe to pump and cast iron Ip valve

(M10

x

1)

(M12

x

1)

Male fitting for flared hoses fitting brake pipe to 4-way control valve and

aluminium load prop, valve

(M10 x

1)

(M12

x

1)

Load Proportioning Valve Fasteners

Bolt retaining load proportioning valve to bracket (M6)

Self-locking nut for bolt retaining valve spring bracket to rear

anti-roll bar (M6)

Bolt retaining square lever for load proportioning valve adjustment (M8)

Bolt retaining load prop, valve to rail (for Girling ABS) (M8)

Bolt retaining square lever for load prop, valve adjustment (M6)

Page 26 of 171

PART C: VEHICLE RAISED OFF THE GROUND

Bodywork Structure

01

.

Any sharp edges on the external bodywork, caused by damage or corrosion will cause the vehicle to fail.

02 . Check all load bearing areas for corrosion. Open the doors and check the sills inside and out, above and below. Any corrosion in structural metalwork within 30 cm (12 in.) of seat belt mounting, steering and suspension attachment points will cause the vehicle to fail.

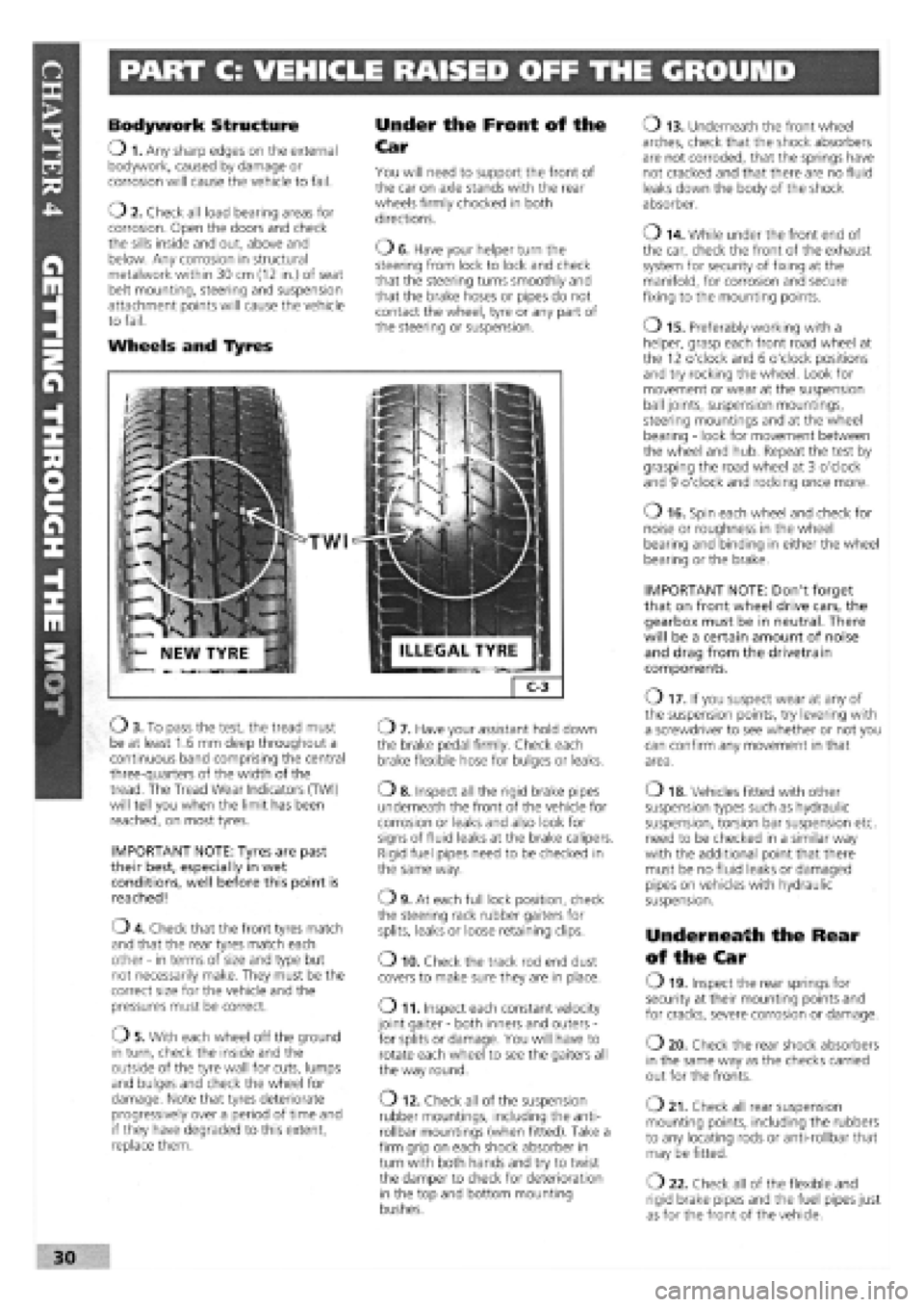

Wheels and Tyres

Under the Front of the

Car

You will need to support the front of the car on axle stands with the rear wheels firmly chocked in both directions.

OE . Have your helper turn the steering from lock to lock and check that the steering turns smoothly and that the brake hoses or pipes do not contact the wheel, tyre or any part of the steering or suspension.

TWI

Ob . To pass the test, the tread must be at least 1.6 mm deep throughout a continuous band comprising the central three-quarters of the width of the tread. The Tread Wear Indicators (TWI) will tell you when the limit has been reached, on most tyres.

IMPORTANT NOTE: Tyres are past their best, especially in wet conditions, well before this point is reached!

04 . Check that the front tyres match and that the rear tyres match each other

-

in terms of size and type but not necessarily make. They must be the correct size for the vehicle and the pressures must be correct.

05 . With each wheel off the ground in turn, check the inside and the outside of the tyre wall for cuts, lumps and bulges and check the wheel for damage. Note that tyres deteriorate progressively over a period of time and if they have degraded to this extent, replace them.

07 . Have your assistant hold down the brake pedal firmly. Check each brake flexible hose for bulges or leaks.

o 8. Inspect all the rigid brake pipes underneath the front of the vehicle for corrosion or leaks and also look for signs of fluid leaks at the brake calipers. Rigid fuel pipes need to be checked in the same way.

09 . At each full lock position, check the steering rack rubber gaiters for splits, leaks or loose retaining clips.

o 10. Check the track rod end dust covers to make sure they are in place.

o 11. Inspect each constant velocity joint gaiter

-

both inners and outers

-

for splits or damage. You will have to rotate each wheel to see the gaiters all the way round.

O 12. Check all of the suspension rubber mountings, including the anti-rollbar mountings (when fitted). Take a firm grip on each shock absorber in turn with both hands and try to twist the damper to check for deterioration in the top and bottom mounting bushes.

o 13. Underneath the front wheel arches, check that the shock absorbers are not corroded, that the springs have not cracked and that there are no fluid leaks down the body of the shock absorber.

o 14. While under the front end of the car, check the front of the exhaust system for security of fixing at the manifold, for corrosion and secure fixing to the mounting points.

o 15. Preferably working with a helper, grasp each front road wheel at the 12 o'clock and 6 o'clock positions and try rocking the wheel. Look for movement or wear at the suspension ball joints, suspension mountings, steering mountings and at the wheel bearing

-

look for movement between the wheel and hub. Repeat the test by grasping the road wheel at 3 o'clock and 9 o'clock and rocking once more.

o 16. Spin each wheel and check for noise or roughness in the wheel bearing and binding in either the wheel bearing or the brake.

IMPORTANT NOTE: Don't forget that on front wheel drive cars, the gearbox must be in neutral. There will be a certain amount of noise and drag from the drivetrain components.

O 17. If you suspect wear at any of the suspension points, try levering with a screwdriver to see whether or not you can confirm any movement in that area.

o 18. Vehicles fitted with other suspension types such as hydraulic suspension, torsion bar suspension etc. need to be checked in a similar way with the additional point that there must be no fluid leaks or damaged pipes on vehicles with hydraulic suspension.

Underneath the Rear

of the Car

O 19. Inspect the rear springs for security at their mounting points and for cracks, severe corrosion or damage.

o 20. Check the rear shock absorbers in the same way as the checks carried out for the fronts.

o 21. Check all rear suspension mounting points, including the rubbers to any locating rods or anti-rollbar that may be fitted.

O 22. Check all of the flexible and rigid brake pipes and the fuel pipes just as for the front of the vehicle.

30

Page 31 of 171

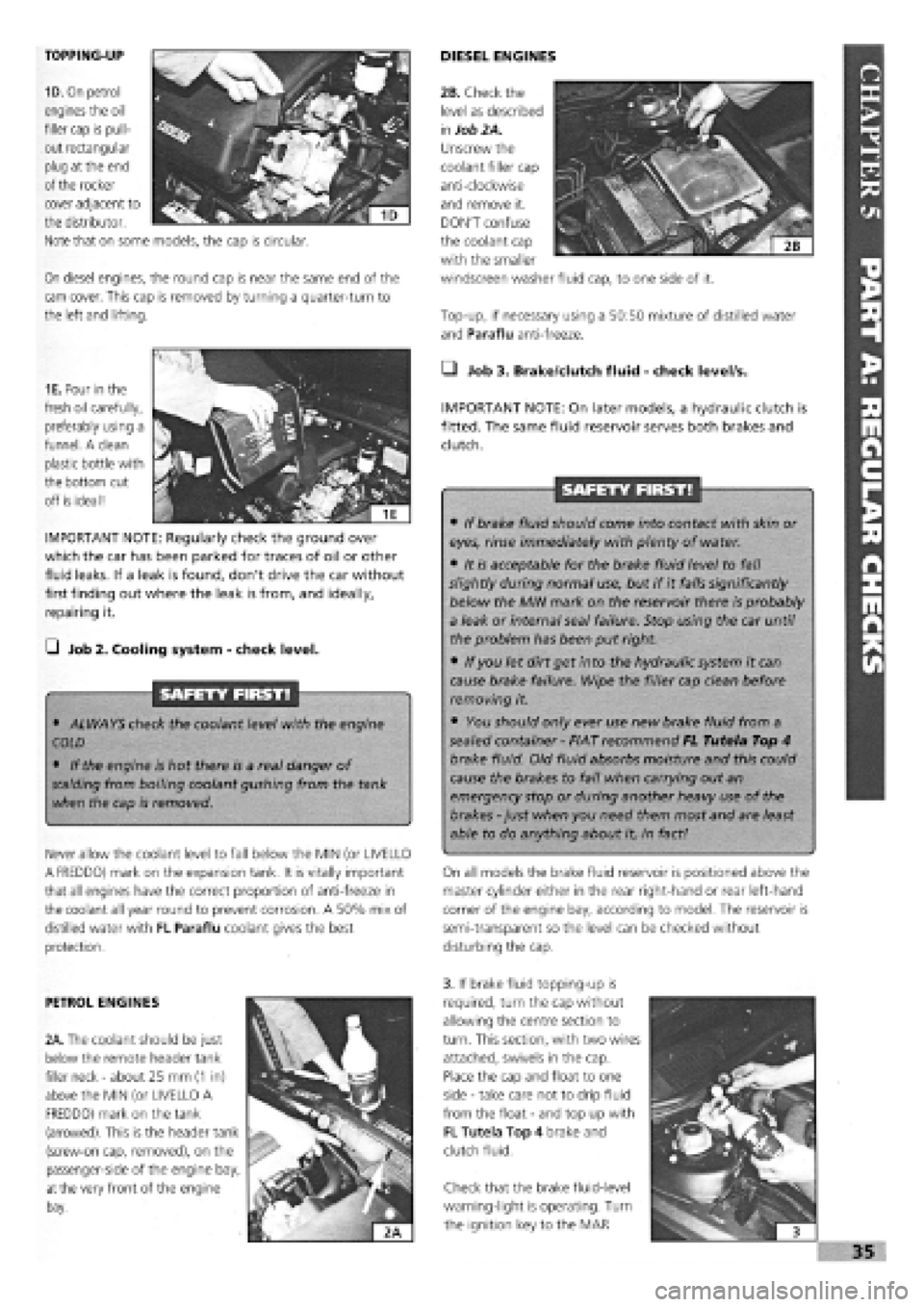

TOPPING-UP

1D. On petrol

engines the oil

filler cap is pull-

out rectangular

plug at the end

of the rocker

On diesel engines, the round cap is near the same end of the

cam cover. This cap is removed by turning a quarter-turn to

the left and lifting.

DIESEL ENGINES

Top-up, if necessary using a 50:50 mixture of distilled water

and Paraflu anti-freeze.

cover adjacent to

the distributor.

Note that on some models, the cap is circular.

1E. Pour in the

fresh oil carefully,

preferably using a

funnel. A clean

plastic bottle with

the bottom cut

off is ideal!

IMPORTANT NOTE: Regularly check the ground over

which the car has been parked for traces of oil or other

fluid leaks. If a leak is found, don't drive the car without

first finding out where the leak is from, and ideally,

repairing it.

G Job 2. Cooling system

-

check level.

SAFETY FIRST!

• ALWAYS check the coolant level with the engine

COLD

• If the engine is hot there is a real danger of

scalding

from boiling coolant gushing from the tank

when the cap is removed.

Never allow the coolant level to fall below the MIN (or UVELLO

A FREDDO) mark on the expansion tank. It is vitally important

that all engines have the correct proportion of anti-freeze in

the coolant all year round to prevent corrosion. A 50% mix of

distilled water with FL Paraflu coolant gives the best

protection.

• Job 3. Brake/dutch fluid

-

check level/s.

IMPORTANT NOTE: On later models, a hydraulic clutch is

fitted. The same fluid reservoir serves both brakes and

clutch.

SAFETY FIRST!

• If brake fluid should come into contact with skin or

eyes, rinse immediately with plenty of water.

• It is acceptable for the brake fluid level to fall

slightly during normal use, but if it falls significantly

below the MIN mark on the reservoir there is probably

a leak or internal seal failure. Stop using the car until

the problem has been put right.

• If you let dirt get into the hydraulic system it can

cause brake failure. Wipe the filler cap clean before

removing it.

• You should only ever use new brake fluid from a

sealed container

-

FIAT recommend FL Tutela Top 4

brake fluid. Old fluid absorbs moisture and this could

cause the brakes to fail when carrying out an

emergency stop or during another heavy use of the

brakes

-

just when you need them most and are least

able to do anything about it, in fact!

On all models the brake fluid reservoir is positioned above the

master cylinder either in the rear right-hand or rear left-hand

corner of the engine bay, according to model. The reservoir is

semi-transparent so the level can be checked without

disturbing the cap.

PETROL ENGINES

2A. The coolant should be just

below the remote header tank

filler neck

-

about 25 mm

(1

in)

above the MIN (or UVELLO A

FREDDO) mark on the tank

(arrowed). This is the header tank

(screw-on cap, removed), on the

passenger-side of the engine bay,

at

the very front of the engine

bay.

3. If brake fluid topping-up is

required, turn the cap without

allowing the centre section to

turn. This section, with two wires

attached, swivels in the cap.

Place the cap and float to one

side

-

take care not to drip fluid

from the float

-

and top up with

FL Tutela Top 4 brake and

clutch fluid.

Check that the brake fluid-level

warning-light is operating. Turn

the ignition key to the MAR

I

i 3

»35

2B. Check the

level as described

in

Job 2A.

Unscrew the

coolant filler cap

anti-clockwise

and remove it.

DON'T confuse

the coolant cap

with the smaller

windscreen washer fluid cap, to one side of it.

Page 35 of 171

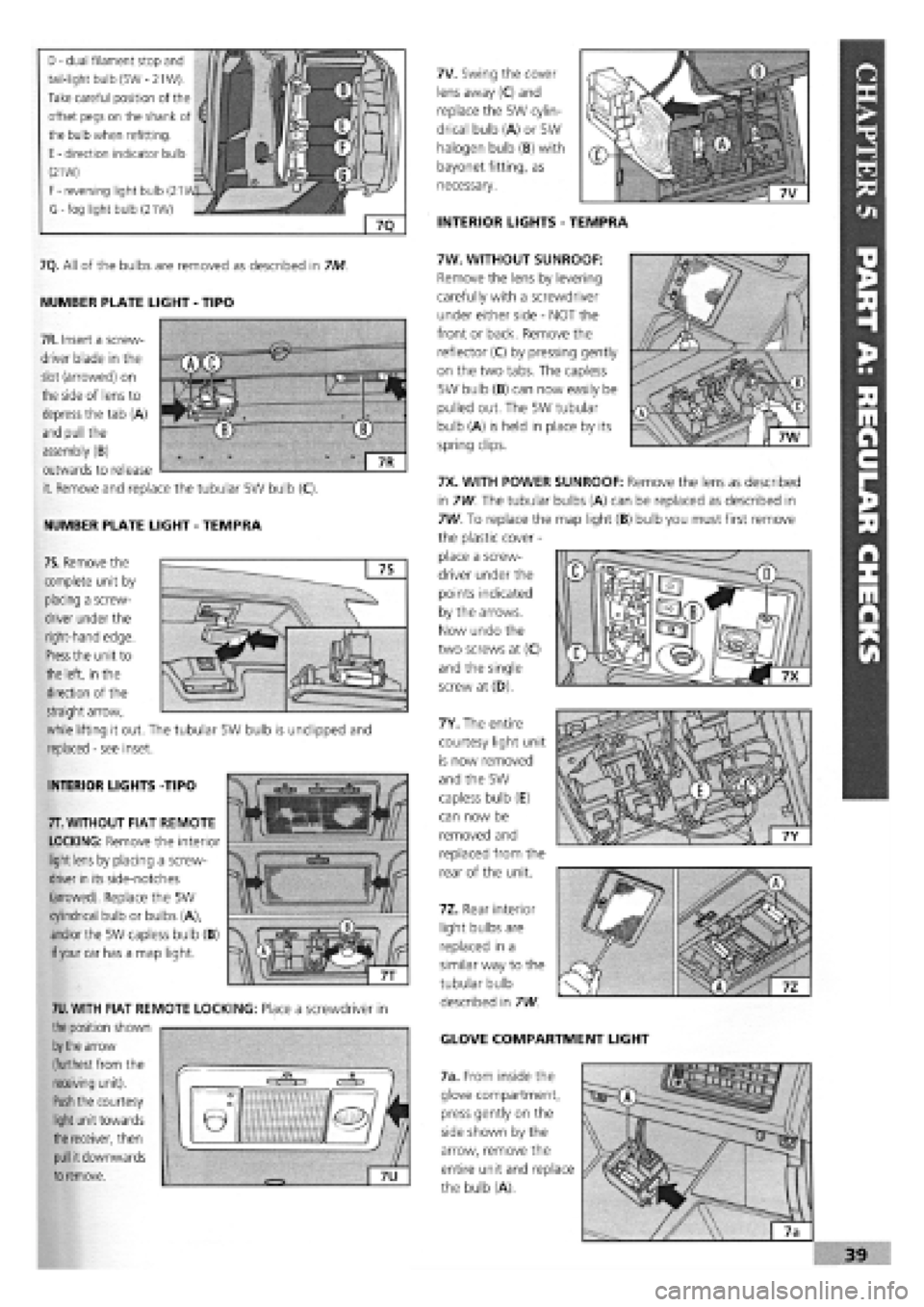

D

-

dual filament stop and

tail-light bulb (5W

-

21W).

Take careful position of the

offset pegs on the shank of

the bulb when refitting.

E

-

direction indicator bulb

(21W)

F

-

reversing light bulb (21

G-fog light bulb (21W)

7V. Swing the cover

lens away (C) and

replace the 5W cylin-

drical bulb (A) or 5W

halogen bulb (B) with

bayonet fitting, as

necessary.

INTERIOR LIGHTS

-

TEMPRA

7Q. All of the bulbs are removed as described in 7M

NUMBER PLATE LIGHT

-

TIPO

NUMBER PLATE LIGHT

-

TEMPRA

7W. WITHOUT SUNROOF:

Remove the lens by levering

carefully with a screwdriver

under either side

-

NOT the

front or back. Remove the

reflector (C) by pressing gently

on the two tabs. The capless

5W bulb (B) can now easily be

pulled out. The 5W tubular

bulb (A) is held in place by its

spring clips.

7X. WITH POWER SUNROOF: Remove the lens as described

in 7W. The tubular bulbs (A) can be replaced as described in

7W. To replace the map light (B) bulb you must first remove

the plastic cover

-

place a screw-

driver under the

points indicated

by the arrows.

Now undo the

two screws at (C)

and the single

screw at (D).

7Y. The entire

courtesy light unit

is now removed

and the 5W

capless bulb (E)

can now be

removed and

replaced from the

rear of the unit.

7Z. Rear interior

light bulbs are

replaced in a

similar way to the

tubular bulb

described in 7W

GLOVE COMPARTMENT LIGHT

7a. From inside the

glove compartment,

press gently on the

side shown by the

arrow, remove the

entire unit and replace

the bulb (A).

INTERIOR LIGHTS -TIPO

7T.

WITHOUT FIAT REMOTE

LOCKING: Remove the interior

light

lens

by placing a screw-

driver

in

its side-notches

(arrowed). Replace the 5W

cylindrical bulb or bulbs (A),

and/or

the 5W capless bulb (B)

if your

car has a map light.

7U.

WITH FIAT REMOTE LOCKING: Place a screwdriver in

the position shown

by the

arrow

(furthest

from

the

receiving unit).

Push

the courtesy

light

unit towards

the receiver, then

pull

it downwards

to

remove.

7R. Insert a screw-

driver blade in the

slot (arrowed) on

the side of lens to

depress the tab (A)

and pull the

assembly (B)

outwards to release

it. Remove and replace the tubular 5W bulb (C).

7S. Remove the

complete unit by

placing a screw-

driver under the

right-hand edge.

Press

the unit to

the left, in the

direction of the

straight arrow,

while lifting it out. The tubular 5W bulb is undipped and

replaced

-

see inset.

Page 47 of 171

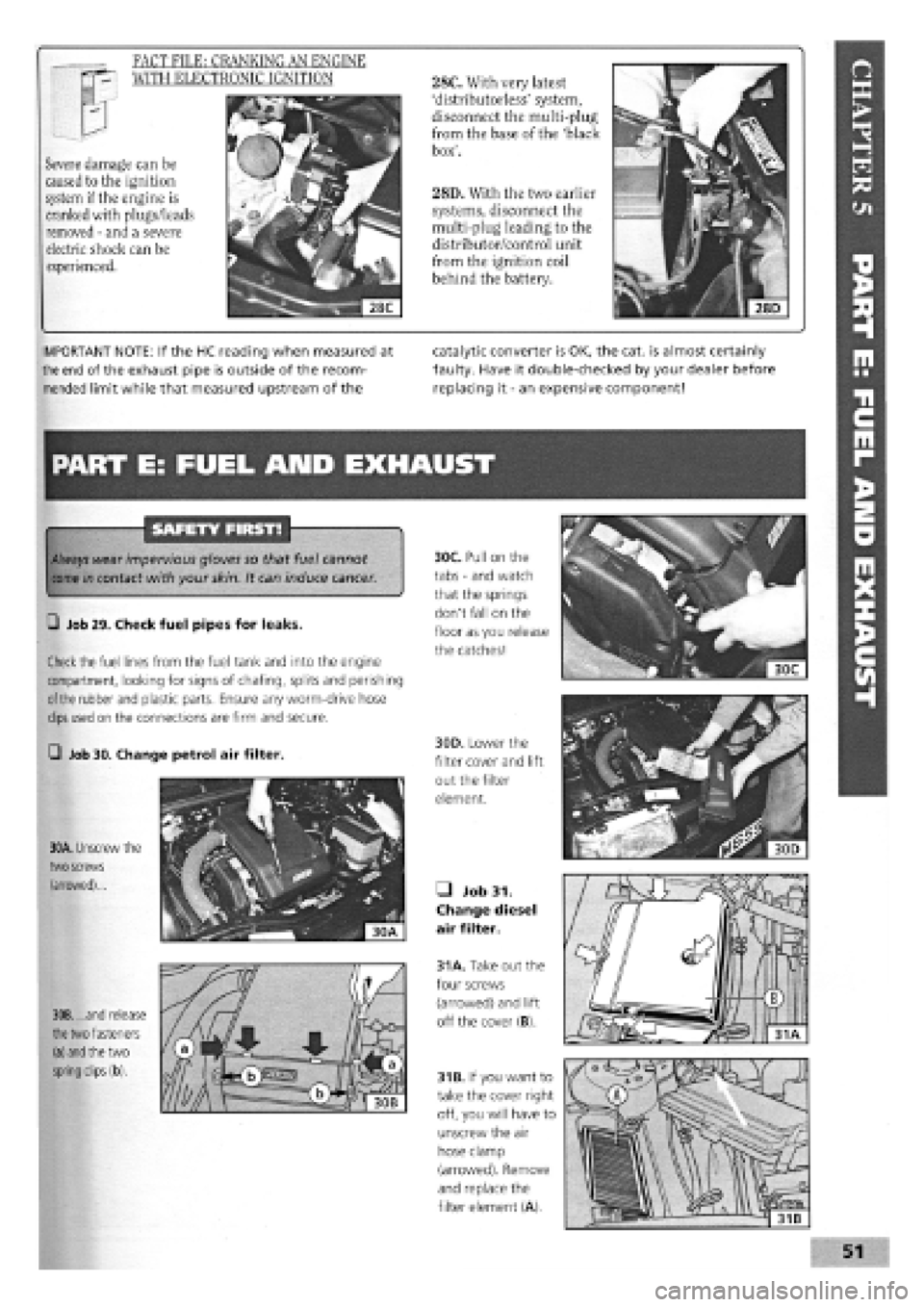

28C. With very latest

'distributorless' system,

disconnect the multi-plug

from the base of the 'black

box'.

28D. With the two earlier

systems, disconnect the

multi-plug leading to the

distributor/control unit

from the ignition coil

behind the battery.

FACT FILE: CRANKING AN ENGINE

WITH ELECTRONIC IGNITION

Severe damage can be

caused to the ignition

system if the engine is

cranked with plugs/leads

removed

-

and a severe

electric shock can be

experienced.

PART E: FUEL AND EXHAUST

SAFETY FIRST!

Always

wear impervious gloves so that fuel cannot

come

in contact with your

skin.

It can induce cancer.

Q Job 29. Check fuel pipes for leaks.

Check the fuel lines from the fuel tank and into the engine

compartment, looking for signs of chafing, splits and perishing

of the

rubber and plastic parts. Ensure any worm-drive hose

clips used

on the connections are firm and secure.

Q Job 30. Change petrol air filter.

IMPORTANT NOTE: If the HC reading when measured at

the end of the exhaust pipe is outside of the recom-

mended limit while that measured upstream of the

catalytic converter is OK, the cat. is almost certainly

faulty. Have it double-checked by your dealer before

replacing it

-

an expensive component!

30C. Pull on the

tabs

-

and watch

that the springs

don't fall on the

floor as you release

the catches!

30D. Lower the

filter cover and lift

out the filter

element.

31B. If you want to

take the cover right

off, you will have to

unscrew the air

hose clamp

(arrowed). Remove

and replace the

filter element (A).

• Job 31.

Change diesel

air filter.

31A. Take out the

four screws

(arrowed) and lift

off the cover (B). 30B. ...and release

the two

fasteners

(a) and the

two

spring clips

(b).

30A. Unscrew the

two

screws

(arrowed)...

51