steering FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 6 of 171

• Repeat this operation three more times until the

complete code number has been entered, if the code

has been entered in correctly LED B will start flashing.

• Release button A (see illustration

1B).

Red LED B

flashes for 8 seconds indicating the new remote unit's

code has been stored.

IMPORTANT NOTE: If the LED does not illuminate

when remote unit button (illustration 1B, button

O is pressed, change the remote unit's battery.

• Insert the emergency key A into the emergency switch

slot in the glove compartment turn the key to the left to

switch the alarm off (see inset).

• Turn the key back towards its original position to

switch the alarm system back on.

IMPORTANT NOTE: As the alarm system absorbs

energy, if you are not planning on using the car

for a long period of time, turn the alarm exclusion

key to the off position, so as not to run the vehicle

battery down.

• 2. IGNITION SWITCH AND

STEERING COLUMN LOCK

IGNITION SWITCH

2. The ignition/steering column lock key, once inserted

in the ignition lock, can be placed in any of the

following four positions:

• PARK

-

With the key in this

position the side and tail lights

can be turned on, the steering

column locked and the keys

can be removed. Press button

A to turn the key to PARK.

• STOP

-

When the key is

turned to the STOP position the steering column will be

locked, and the keys can be removed.

• MAR

-

This is the driving position. When the key is in

this position all the electrical devices are energised.

• AW

-

Turning the key to this position starts the

engine.

STEERING COLUMN LOCK

• LOCKING

-

To apply the steering wheel lock turn the

steering wheel slightly to the left or right when the key is

at STOP or PARK.

• UNLOCKING

-

Rocking the steering wheel gently back

and forth while turning the ignition key to MAR unlocks

the steering wheel.

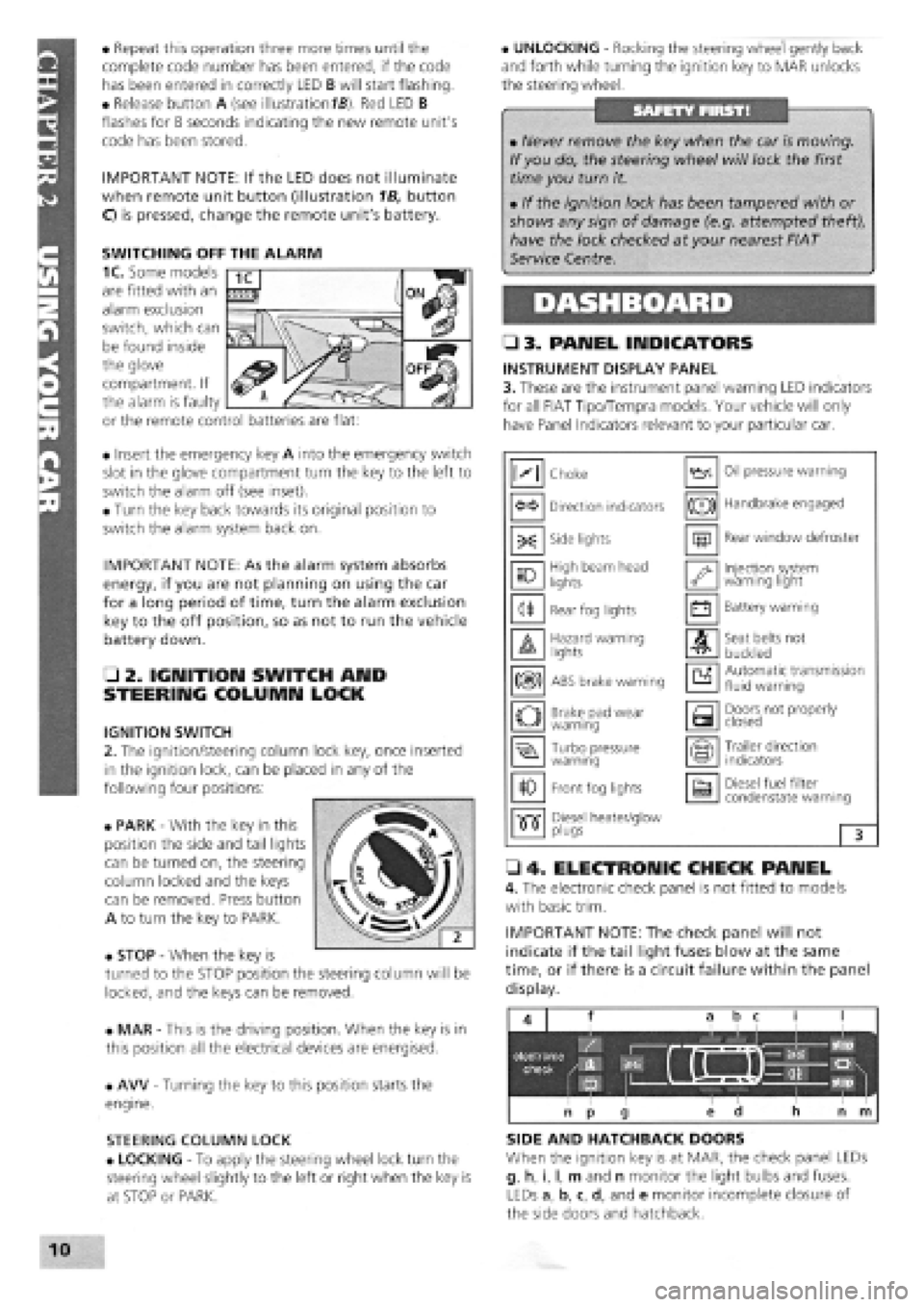

• 3. PANEL INDICATORS

INSTRUMENT DISPLAY PANEL

3. These are the instrument panel warning LED indicators

for all FIAT Tipo/Tempra models. Your vehicle will only

have Panel Indicators relevant to your particular car.

• 4. ELECTRONIC CHECK PANEL

4. The electronic check panel is not fitted to models

with basic trim.

IMPORTANT NOTE: The check panel will not

indicate if the tail light fuses blow at the same

time, or if there is a circuit failure within the panel

display.

SIDE AND HATCHBACK DOORS

When the ignition key is at MAR, the check panel LEDs

g, h, i, I, m and n monitor the light bulbs and fuses.

LEDs a, b, c, d, and e monitor incomplete closure of

the side doors and hatchback.

• Never remove the key when the car is moving.

If you do, the steering wheel will lock the first

time you turn it.

• If the ignition lock has been tampered with or

shows any sign of damage (e.g. attempted theft),

have the lock checked at your nearest FIAT

Service Centre.

M Choke Oil pressure warning

Direction indicators (®) Handbrake engaged

-X: Side lights m Rear window defroster

10 High beam head

lights '•y Injection system warning light

<1* Rear fog lights • Battery warning

A Hazard warning lights A Seat belts not

buckled

m ABS brake warning a Automatic transmission fluid warning

o Brake pad wear warning a Doors not properly closed

Turbo pressure warning Trailer direction indicators

10 Front fog lights a Diesel fuel filter condenstate warning

•515" Diesel heater/glow •515" plugs 3

SWITCHING OFF THE ALARM

1C. Some models

are fitted with an

alarm exclusion

switch, which can

be found inside

the glove

compartment. If

the alarm is faulty

or the remote control batteries are flat:

Page 9 of 171

CONTROLS

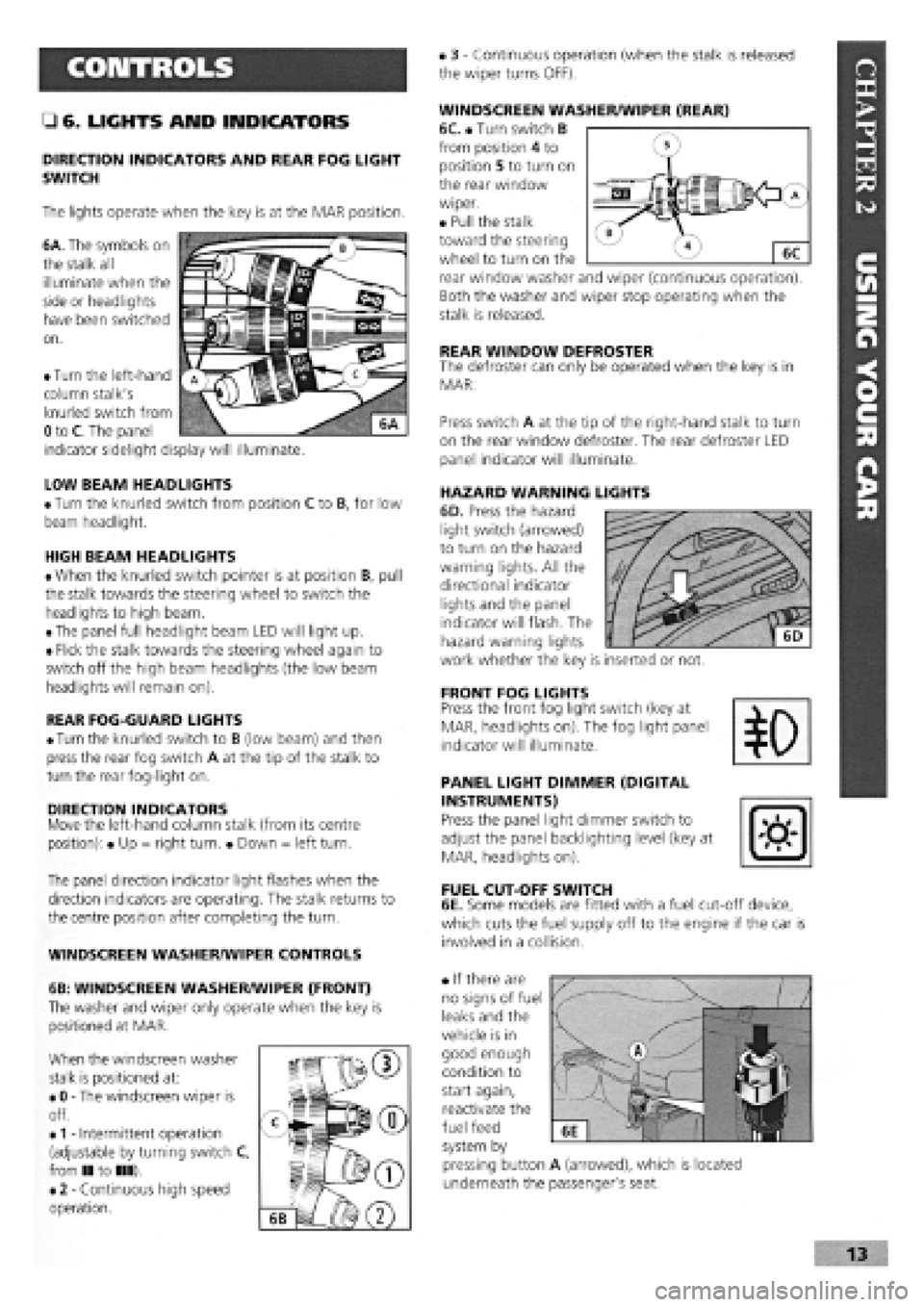

• 6. LIGHTS AND INDICATORS

DIRECTION INDICATORS AND REAR FOG LIGHT

SWITCH

The lights operate when the key is at the MAR position.

6A. The symbols on

the stalk all

illuminate when the

side or headlights

have been switched

on.

• 3

-

Continuous operation (when the stalk is released

the wiper turns OFF).

WINDSCREEN WASHER/WIPER (REAR)

6C. • Turn switch B

from position 4 to

position 5 to turn on

the rear window

wiper.

• Pull the stalk

toward the steering

wheel to turn on the

rear window washer and wiper (continuous operation).

Both the washer and wiper stop operating when the

stalk is released.

REAR WINDOW DEFROSTER The defroster can only be operated when the key is in

MAR:

LOW BEAM HEADLIGHTS

• Turn the knurled switch from position C to B, for low

beam headlight.

HIGH BEAM HEADLIGHTS

• When the knurled switch pointer is at position B, pull

the stalk towards the steering wheel to switch the

headlights to high beam.

• The panel full headlight beam LED will light up.

• Flick the stalk towards the steering wheel again to

switch off the high beam headlights (the low beam

headlights will remain on).

REAR FOG-GUARD LIGHTS

•

Turn

the knurled switch to B (low beam) and then

press the rear fog switch A at the tip of the stalk to

turn the rear fog-light on.

DIRECTION INDICATORS Move the left-hand column stalk (from its centre

position): • Up = right turn. • Down = left turn.

The panel direction indicator light flashes when the

direction indicators are operating. The stalk returns to

the centre position after completing the turn.

WINDSCREEN WASHER/WIPER CONTROLS

6B: WINDSCREEN WASHER/WIPER (FRONT)

The washer and wiper only operate when the key is

positioned at MAR.

When the windscreen washer

stalk is positioned at:

• 0

-

The windscreen wiper is

off.

•

1 -

Intermittent operation

(adjustable by turning switch C,

from II to III).

• 2

-

Continuous high speed

operation.

Press switch A at the tip of the right-hand stalk to turn

on the rear window defroster. The rear defroster LED

panel indicator will illuminate.

HAZARD WARNING LIGHTS

6D. Press the hazard

light switch (arrowed)

to turn on the hazard

warning lights. All the

directional indicator

lights and the panel

indicator will flash. The

hazard warning lights

work whether the key is inserted or not.

FRONT FOG LIGHTS Press the front fog light switch (key at

MAR, headlights on). The fog light panel

indicator will illuminate.

PANEL LIGHT DIMMER (DIGITAL

INSTRUMENTS)

Press the panel light dimmer switch to

adjust the panel backlighting level (key at

MAR, headlights on).

FUEL CUT-OFF SWITCH

6E. Some models are fitted with a fuel cut-off device,

which cuts the fuel supply off to the engine if the car is

involved in a collision.

• If there are

no signs of fuel

leaks and the

vehicle is in

good enough

condition to

start again,

reactivate the

fuel feed

system by

pressing button A (arrowed), which is located

underneath the passenger's seat.

• Turn the left-hand

column stalk's

knurled switch from

0 to C. The panel

indicator sidelight display will illuminate.

Page 10 of 171

• 9. DOOR MIRROR ADJUSTMENT

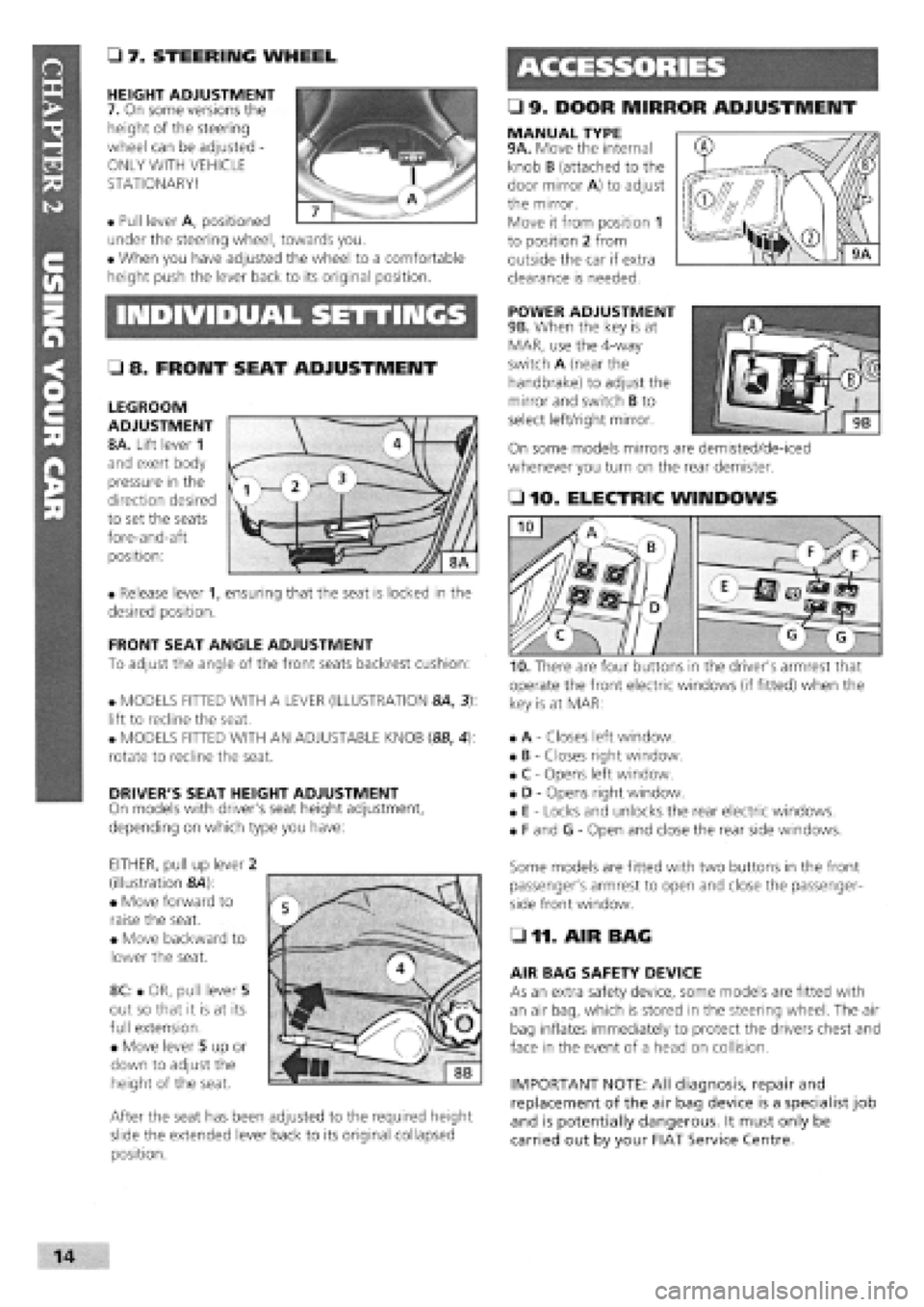

• 7. STEERING WHEEL

HEIGHT ADJUSTMENT

7. On some versions the

height of the steering

wheel can be adjusted -

ONLY WITH VEHICLE

STATIONARY!

• Pull lever A, positioned

under the steering wheel, towards you.

• When you have adjusted the wheel to a comfortable

height push the lever back to its original position.

MANUAL TYPE 9A. Move the internal

knob B (attached to the

door mirror A) to adjust

the mirror.

Move it from position 1

to position 2 from

outside the car if extra

clearance is needed.

INDIVIDUAL SETTINGS POWER ADJUSTMENT

9B. When the key is at

MAR, use the 4-way

switch A (near the

handbrake) to adjust the

mirror and switch B to

select left/right mirror.

On some models mirrors are demisted/de-iced

whenever you turn on the rear demister.

• 8. FRONT SEAT ADJUSTMENT

LEGROOM

ADJUSTMENT

8A. Lift lever 1

and exert body

pressure in the

direction desired

to set the seats

fore-and-aft

position:

• Release lever 1, ensuring that the seat is locked in the

desired position.

FRONT SEAT ANGLE ADJUSTMENT

To adjust the angle of the front seats backrest cushion:

• MODELS FITTED WITH A LEVER (ILLUSTRATION 8A, 3):

lift to recline the seat.

• MODELS FITTED WITH AN ADJUSTABLE KNOB (8B, 4):

rotate to recline the seat.

DRIVER'S SEAT HEIGHT ADJUSTMENT

On models with driver's seat height adjustment,

depending on which type you have:

EITHER, pull up lever 2

(illustration &4):

• Move forward to

raise the seat.

• Move backward to

lower the seat.

8C: • OR, pull lever 5

out so that it is at its

full extension.

• Move lever 5 up or

down to adjust the

height of the seat.

After the seat has been adjusted to the required height

slide the extended lever back to its original collapsed

position.

• 10. ELECTRIC WINDOWS

operate the front electric windows (if fitted) when the

key is at MAR:

• A

-

Closes left window.

• B

-

Closes right window.

• C

-

Opens left window.

• D

-

Opens right window.

• E

-

Locks and unlocks the rear electric windows.

• F and G

-

Open and close the rear side windows.

Some models are fitted with two buttons in the front

passenger's armrest to open and close the passenger-

side front window.

• 11. AIR BAG

AIR BAG SAFETY DEVICE

As an extra safety device, some models are fitted with

an air bag, which is stored in the steering wheel. The air

bag inflates immediately to protect the drivers chest and

face in the event of a head on collision.

IMPORTANT NOTE: All diagnosis, repair and

replacement of the air bag device is a specialist job

and is potentially dangerous. It must only be

carried out by your FIAT Service Centre.

I

Page 11 of 171

SAFETY FIRST!

If an air bag has been fitted to your vehicle:

• DO NOT apply stickers or any other objects to

the steering wheel as this may restrict the

operation of the air bag.

• NEVER travel with anything on your lap or in

front of your chest

• NEVER drive with a cigarette, pipe, pen or any

other object in your mouth.

• 12. INTERIOR LIGHTS

COURTESY LIGHT

On most models the courtesy light is positioned in the

centre of the roof.

• With the light switch in the central position the light

turns on when either of the front doors is opened.

• When the switch is in the right position the light

remains on.

• With the switch in the left position the light is

switched off.

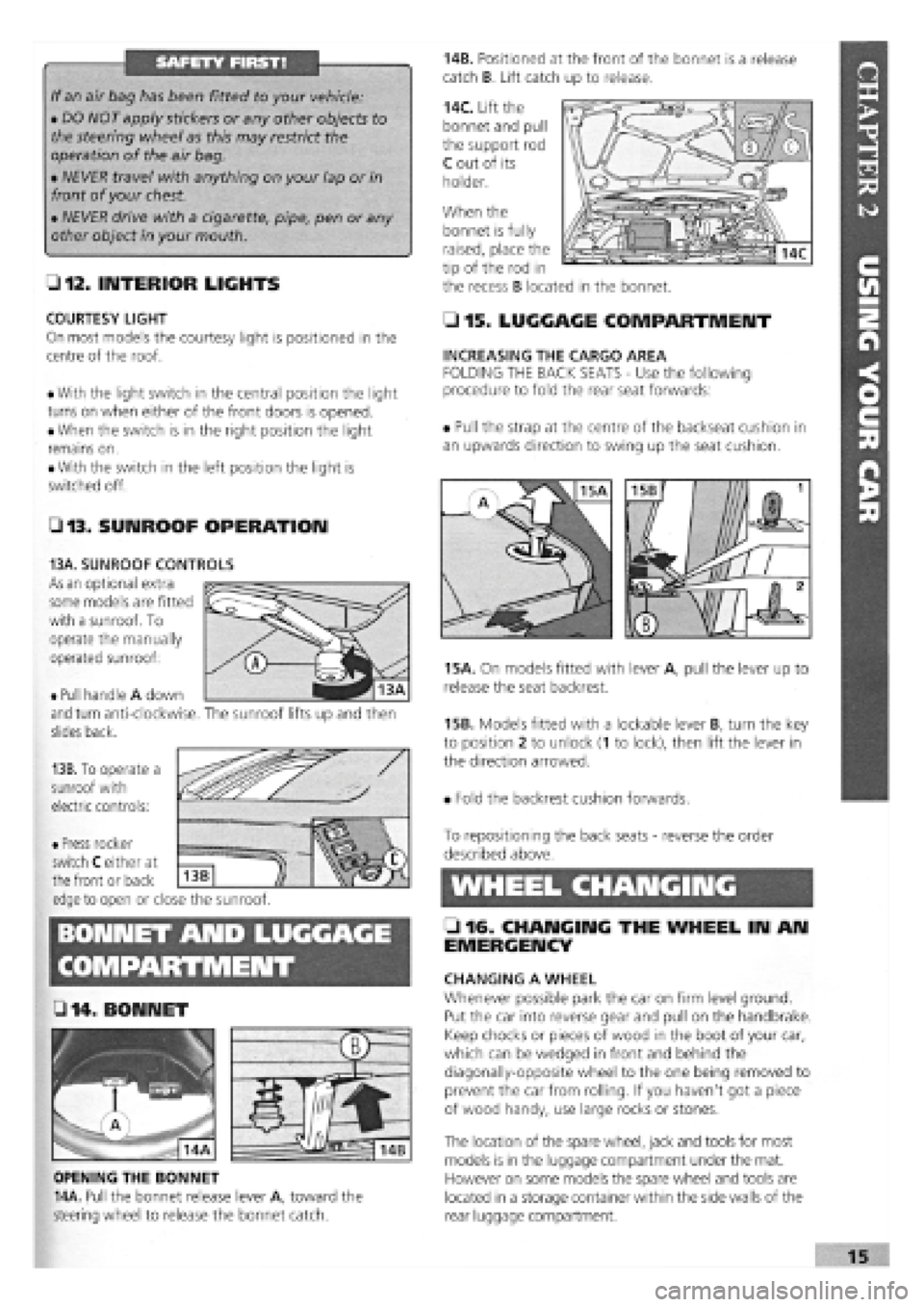

• 13. SUNROOF OPERATION

14B. Positioned at the front of the bonnet is a release

catch B. Lift catch up to release.

14C. Lift the

bonnet and pull

the support rod

C out of its

holder.

When the

• 15. LUGGAGE COMPARTMENT

INCREASING THE CARGO AREA

FOLDING THE BACK SEATS

-

Use the following

procedure to fold the rear seat forwards:

• Pull the strap at the centre of the backseat cushion in

an upwards direction to swing up the seat cushion.

15A. On models fitted with lever A, pull the lever up to

release the seat backrest.

15B. Models fitted with a lockable lever B, turn the key

to position 2 to unlock (1 to lock), then lift the lever in

the direction arrowed.

• Fold the backrest cushion forwards.

BONNET AND LUGGAGE

L 2 . fj§

• 14 .BONNET

OPENING THE BONNET

14A. Pull the bonnet release lever A, toward the

steering wheel to release the bonnet catch.

To repositioning the back seats

-

reverse the order

described above.

WHEEL CHANGING

• 16. CHANGING THE WHEEL IN AN

EMERGENCY

CHANGING A WHEEL

Whenever possible park the car on firm level ground.

Put the car into reverse gear and pull on the handbrake.

Keep chocks or pieces of wood in the boot of your car,

which can be wedged in front and behind the

diagonally-opposite wheel to the one being removed to

prevent the car from rolling. If you haven't got a piece

of wood handy, use large rocks or stones.

The location of the spare wheel, jack and tools for most

models is in the luggage compartment under the mat.

However on some models the spare wheel and tools are

located in a storage container within the side walls of the

rear luggage compartment.

bonnet is fully

raised, place the

tip of the rod in

the recess B located in the bonnet.

• Pull handle A down

and turn anti-clockwise,

slides back.

13B. To operate a

sunroof with

electric controls:

13A. SUNROOF CONTROLS

As an optional extra

some models are fitted

with a sunroof. To

operate the manually

operated sunroof:

The sunroof lifts up and then

• Press rocker

switch C either at

the front or back

edge to open or close the sunroof.

Z3

Page 12 of 171

EMERGENCY STARTING

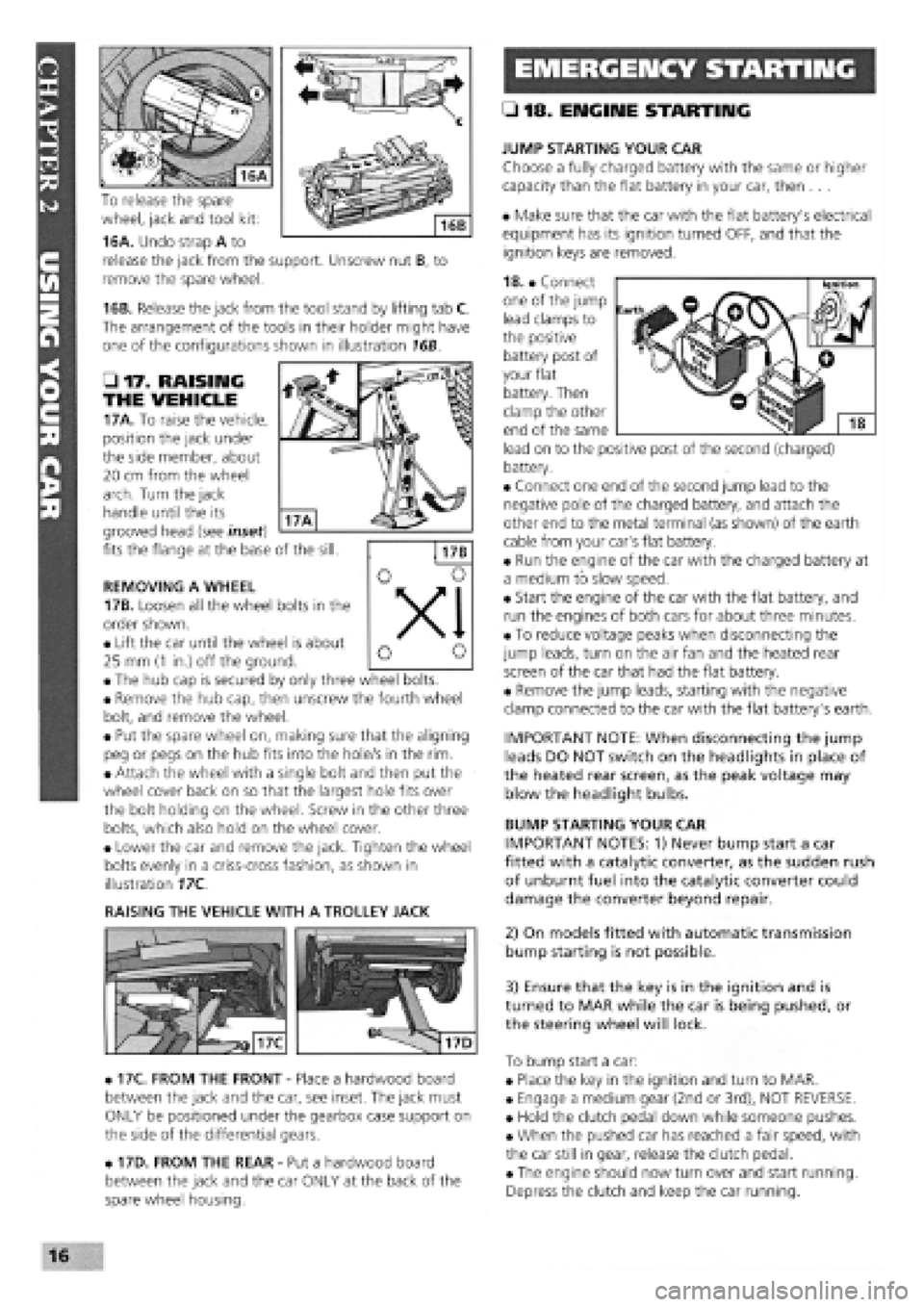

To release the spare

wheel, jack and tool kit:

16A. Undo strap A to

release the jack from the support. Unscrew nut B, to

remove the spare wheel.

16B. Release the jack from the tool stand by lifting tab C.

The arrangement of the tools in their holder might have

one of the configurations shown in illustration 16B.

• 17. RAISING

THE VEHICLE

17A. To raise the vehicle,

position the jack under

the side member, about

20 cm from the wheel

arch. Turn the jack

handle until the its

grooved head (see inset)

fits the flange at the base of the sill.

REMOVING A WHEEL

17B. Loosen all the wheel bolts in the

order shown.

• Lift the car until the wheel is about

25 mm

(1

in.) off the ground.

• The hub cap is secured by only three wheel bolts.

• Remove the hub cap, then unscrew the fourth wheel

bolt, and remove the wheel.

• Put the spare wheel on, making sure that the aligning

peg or pegs on the hub fits into the hole/s in the rim.

• Attach the wheel with a single bolt and then put the

wheel cover back on so that the largest hole fits over

the bolt holding on the wheel. Screw in the other three

bolts, which also hold on the wheel cover.

• Lower the car and remove the jack. Tighten the wheel

bolts evenly in a criss-cross fashion, as shown in

illustration 17C.

RAISING THE VEHICLE WITH A TROLLEY JACK

• 17C. FROM THE FRONT

-

Place a hardwood board

between the jack and the car, see inset. The jack must

ONLY be positioned under the gearbox case support on

the side of the differential gears.

• 17D. FROM THE REAR

-

Put a hardwood board

between the jack and the car ONLY at the back of the

spare wheel housing.

• 18. ENGINE STARTING

JUMP STARTING YOUR CAR

Choose a fully charged battery with the same or higher

capacity than the flat battery in your car, then ...

• Make sure that the car with the flat battery's electrical

equipment has its ignition turned OFF, and that the

ignition keys are removed.

18. • Connect

one of the jump

lead clamps to

the positive

battery post of

your flat

battery. Then

clamp the other

end of the same

lead on to the positive post of the second (charged)

battery.

• Connect one end of the second jump lead to the

negative pole of the charged battery, and attach the

other end to the metal terminal (as shown) of the earth

cable from your car's flat battery.

• Run the engine of the car with the charged battery at

a medium to slow speed.

• Start the engine of the car with the flat battery, and

run the engines of both cars for about three minutes.

• To reduce voltage peaks when disconnecting the

jump leads, turn on the air fan and the heated rear

screen of the car that had the flat battery.

• Remove the jump leads, starting with the negative

clamp connected to the car with the flat battery's earth.

IMPORTANT NOTE: When disconnecting the jump

leads DO NOT switch on the headlights in place of

the heated rear screen, as the peak voltage may

blow the headlight bulbs.

BUMP STARTING YOUR CAR

IMPORTANT NOTES: 1) Never bump start a car

fitted with a catalytic converter, as the sudden rush

of unburnt fuel into the catalytic converter could

damage the converter beyond repair.

2) On models fitted with automatic transmission

bump starting is not possible.

3) Ensure that the key is in the ignition and is

turned to MAR while the car is being pushed, or

the steering wheel will lock.

To bump start a car:

• Place the key in the ignition and turn to MAR.

• Engage a medium gear (2nd or 3rd), NOT REVERSE.

• Hold the clutch pedal down while someone pushes.

• When the pushed car has reached a fair speed, with

the car still in gear, release the clutch pedal.

• The engine should now turn over and start running.

Depress the clutch and keep the car running.

16

Page 14 of 171

October 1991 2.0 i.e. 16v introduced, with 1995cc, 16 valve

high-performance DOHC engine, catalytic converter, sports

suspension, front and rear disc brakes. ABS available as

option.

January 1992 Existing Tipo models lightly facelifted and

redesignated 1.4 Formula, 1.45, 1.6S, 1.6SX, 1.9TD SX,

1.8 i.e. SX. 1.7D discontinued. SX versions with digital

instruments.

Tempra 1.9 TDS (turbo diesel) Station Wagon introduced. 1.4

and 1.9D saloons discontinued.

May 1992 Tempra 1.8 i.e. SX Saloon and Station Wagon

discontinued.

June 1992 Tempra 2.0 i.e. SX saloon and station wagon

models introduced, with high performance 1995cc DOHC fuel

injected engine, catalytic converter and disc brakes front and

rear.

Tipo 1.4 and all Tipo and Tempra 1.6 models (except Selecta)

now with a catalytic converter and fuel injection in place of

Weber twin-choke carburettor. Designated i.e. in badging.

December 1992 Tipo 1.8 i.e. and 1.6 Selecta discontinued.

February 1993 Tipo 2.0 i.e. GT introduced. Slightly lower

performance and spec, version of the 16v model.

July 1993 Tipo 1.4 now available as a 3-door or 5-door

hatchback. 2.0 i.e. 16v now only available as 3-door. Tipo 2.0

i.e. GT replaced by similar spec. 2.0 i.e. SLX.

Tempra 2.0 i.e. SX saloons and estates now only available

with auto, gearbox. Otherwise, SX models become known as

SLX, with colour-coded mirrors and ABS brakes. Most Tempras

now with body-coloured bumpers. 1.9D (non turbo Diesel re-

introduced).

All Tipo and Tempra models now with revised front-end

styling

-

narrower headlights and revised grille. Improved crash

protection, including side impact beams, safety steering wheel

and uprated brakes. Power steering, central locking, electric

windows all standard.

February 1994 Tipo 1.7 non-turbo diesel re-introduced as

1.7 DS.

May 1994 Tempra 1.9DS Station Wagon introduced.

September 1994 Most models available with driver's airbag,

fire prevention system and seat belt pre-tensioners.

December 1994 Tempra 1.6 i.e. versions get M.P.I, engine.

February/March 1995 All models with VIN number window

etching and immobiliser standard on all Tempra petrol models.

October 1995 Immobiliser fitted to Tempra D and TD models.

End of 1995 Tipo discontinued.

Mid-1996 Tempra discontinued.

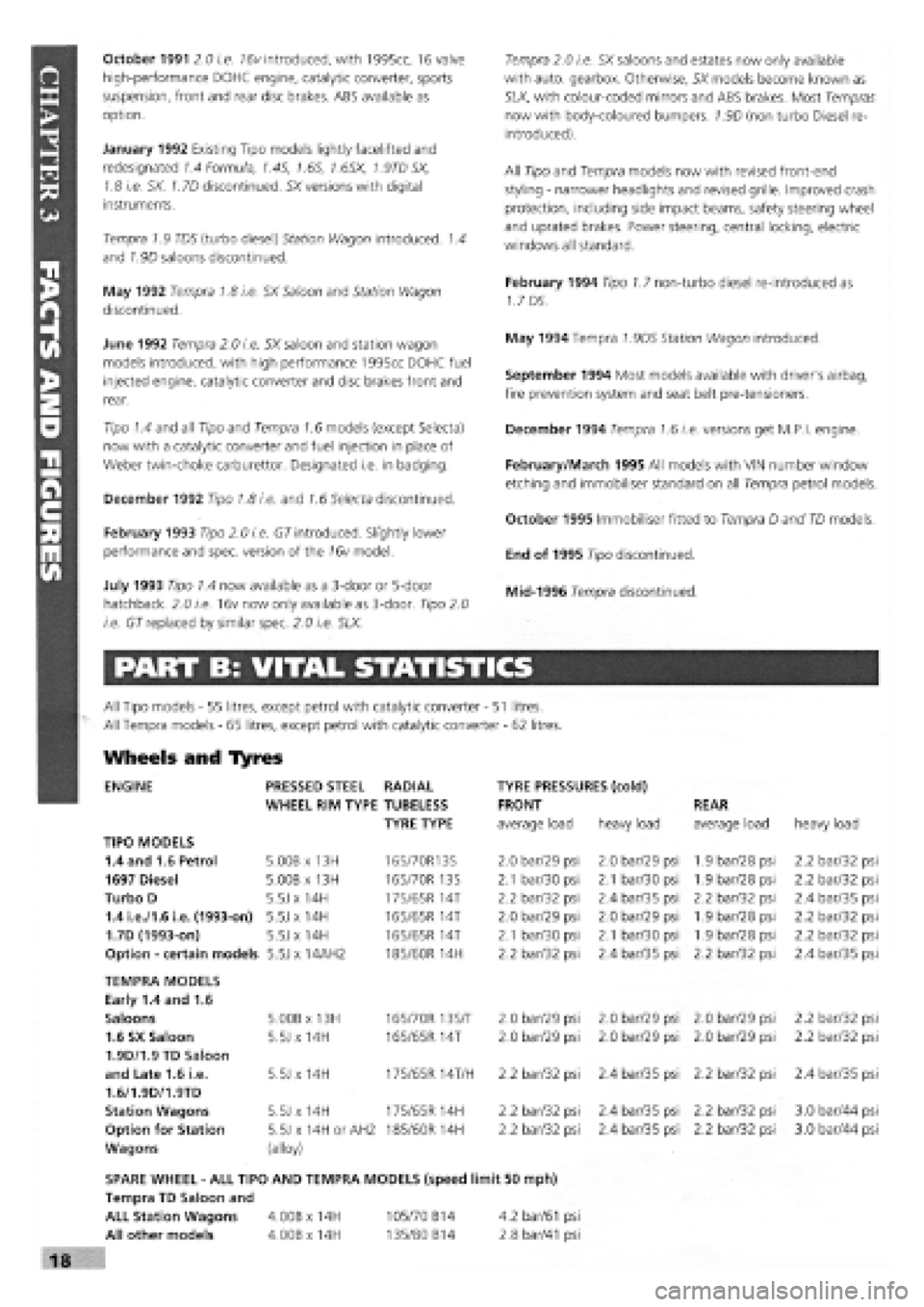

PART B: VITAL STATISTICS

All Tipo models

-

55 litres, except petrol with catalytic converter

- 51

litres.

All Tempra models

-

65 litres, except petrol with catalytic converter

-

62 litres.

Wheels and Tyres

ENGINE PRESSED STEEL RADIAL TYRE PRESSURES (cold)

WHEEL RIM TYPE TUBELESS FRONT REAR

TYRE TYPE average load heavy load average load heavy load

TIPO MODELS

1.4 and 1.6 Petrol 5.00B x 13H 165/70R13S 2.0 bar/29 psi 2.0 bar/29 psi 1.9 bar/28 psi 2.2 bar/32 psi

1697 Diesel 5.00B x 13H 165/70R 13S 2.1 bar/30 psi 2.1 bar/30 psi 1.9 bar/28 psi 2.2 bar/32 psi

Turbo D 5.5J x 14H

175/65 R

14T 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

1.4 i.e./1.6 i.e. (1993-on) 5.5J x 14H

165/65 R

14T 2.0 bar/29 psi 2.0 bar/29 psi 1.9 bar/28 psi 2.2 bar/32 psi

1.7D (1993-on) 5.5J x 14H 165/65R 14T 2.1 bar/30 psi 2.1 bar/30 psi 1.9 bar/28 psi 2.2 bar/32 psi

Option

-

certain models 5.5J x 14AH2 185/60R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

TEMPRA MODELS

Early 1.4 and 1.6

Saloons 5.00B x 13H 165/70R 13S/T 2.0 bar/29 psi 2.0 bar/29 psi 2.0 bar/29 psi 2.2 bar/32 psi

1.6 SX Saloon 5.5J x 14H 165/65R 14T 2.0 bar/29 psi 2.0 bar/29 psi 2.0 bar/29 psi 2.2 bar/32 psi

1.9D/1.9 TD Saloon

and Late 1.6 i.e. 5.5J x 14H 175/65R 14T/H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

1.6/1.9D/1.9TD

Station Wagons 5.5J x 14H 175/65R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 3.0 bar/44 psi

Option for Station 5.5J x 14H or AH2 185/60 R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 3.0 bar/44 psi

Wagons (alloy)

SPARE WHEEL

-

ALL TIPO AND TEMPRA MODELS (speed limit 50 mph)

Tempra TD Saloon and

ALL Station Wagons 4.00B x 14H 105/70 B14 4.2

bar/61

psi

All other models 4.00Bx14H 135/80 B14 2.8

bar/41

psi

Page 22 of 171

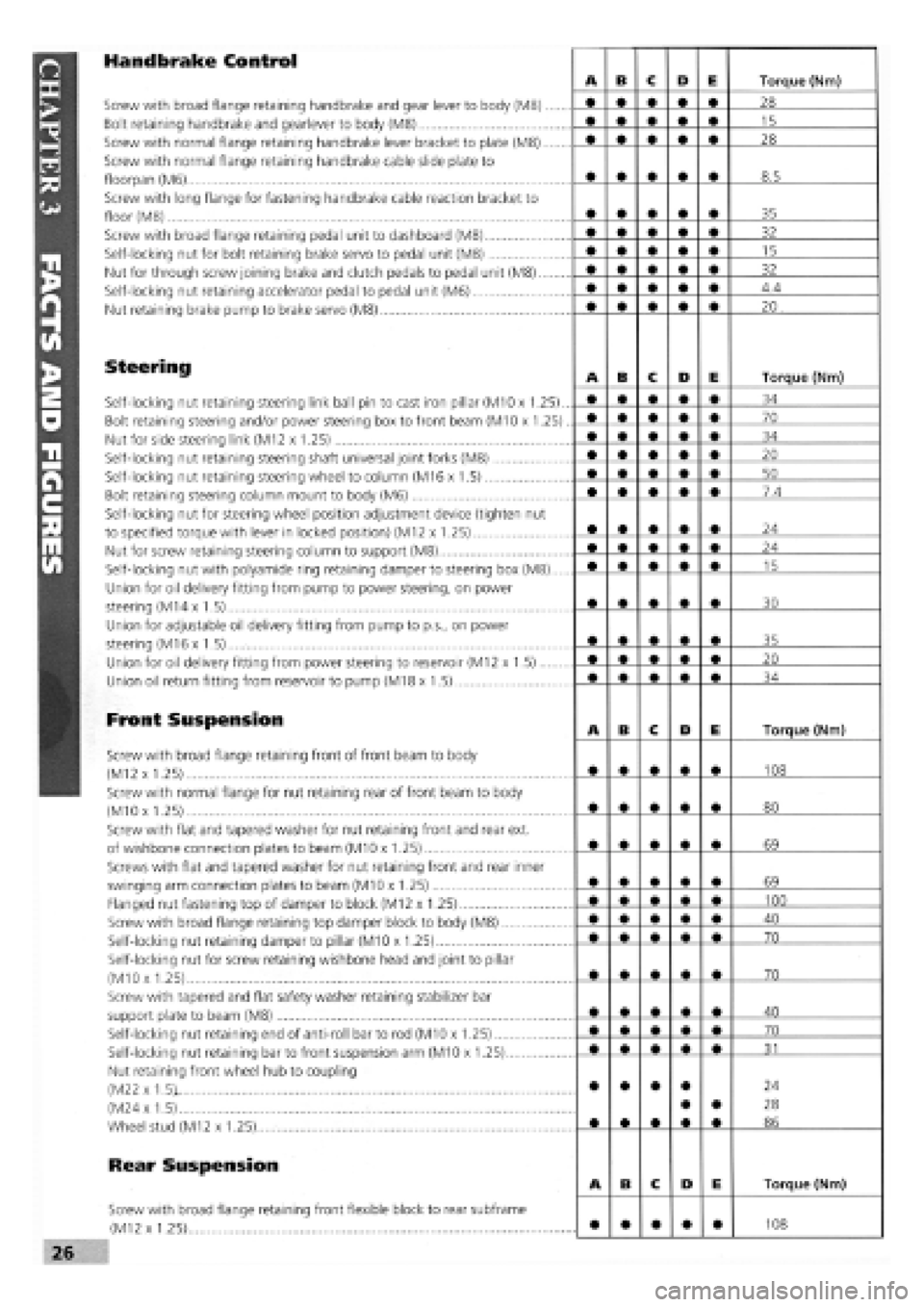

Handbrake Control

Screw with broad flange retaining handbrake and gear lever to body (M8)

Bolt retaining handbrake and gearlever to body (M8)

Screw with normal flange retaining handbrake lever bracket to plate (M8)

Screw with normal flange retaining handbrake cable slide plate to

floorpan (M6)

Screw with long flange for fastening handbrake cable reaction bracket to

floor (M8)

Screw with broad flange retaining pedal unit to dashboard (M8)

Self-locking nut for bolt retaining brake servo to pedal unit (M8)

Nut for through screw joining brake and clutch pedals to pedal unit (M8).

Self-locking nut retaining accelerator pedal to pedal unit (M6)

Nut retaining brake pump to brake servo (M8)

Steering

Self-locking nut retaining steering link ball pin to cast iron pillar (M10 x 1.25)..

Bolt retaining steering and/or power steering box to front beam (M10 x 1.25).

Nut for side steering link (M12 x 1.25)

Self-locking nut retaining steering shaft universal joint forks (M8)

Self-locking nut retaining steering wheel to column (M16 x 1.5)

Bolt retaining steering column mount to body (M6)

Self-locking nut for steering wheel position adjustment device (tighten nut

to specified torque with lever in locked position) (M12 x 1.25)

Nut for screw retaining steering column to support (M8)

Self-locking nut with polyamide ring retaining damper to steering box (M8)

Union for oil delivery fitting from pump to power steering, on power

steering (M14 x 1.5)

Union for adjustable oil delivery fitting from pump to p.s., on power

steering (M16 x 1.5)

Union for oil delivery fitting from power steering to reservoir (M12 x 1.5)

Union oil return fitting from reservoir to pump (M18 x 1.5)

Front Suspension

Screw with broad flange retaining front of front beam to body

(M12 x 1.25)

Screw with normal flange for nut retaining rear of front beam to body

(M10

x

1.25)

Screw with flat and tapered washer for nut retaining front and rear ext.

of wishbone connection plates to beam (M10 x 1.25)

Screws with flat and tapered washer for nut retaining front and rear inner

swinging arm connection plates to beam (M10 x 1.25)

Flanged nut fastening top of damper to block (M12 x 1.25)

Screw with broad flange retaining top damper block to body (M8)

Self-locking nut retaining damper to pillar (M10 x 1.25)

Self-locking nut for screw retaining wishbone head and joint to pillar

(M10

x

1.25)

Screw with tapered and flat safety washer retaining stabilizer bar

support plate to beam (M8)

Self-locking nut retaining end of anti-roll bar to rod (M10 x 1.25)

Self-locking nut retaining bar to front suspension arm (M10 x 1.25)

Nut retaining front wheel hub to coupling

(M22 x 1.5)i

(M24

x

1.5)

Wheel stud (M12 x 1.25).....

Rear Suspension

Screw with broad flange retaining front flexible block to rear subframe

(M12 x 1.25)

A B C D E Torque (Nm)

• • • • • 28

• • • • • 15

• • • • • 28

8.5

35

32

15

32

4.4

20 .

A B C D E Torque (Nm)

• • • • • 34

70

34

• • • • • 20

50

7.4

24

24

15

30

35

20

34

A B c D E Torque (Nm)

108

80

69

69

100

40

70

70

40

70

31

• • • • • •

24

28

86

A B c D E Torque (Nm)

108

Page 24 of 171

Please read the whole of the CHAPTER 1, SAFETY FIRST! before carrying out any work on your car.

fUADTCSA I En Hr

GETTIIMG THROUGH THE MOT

This chapter is for owners in Britain whose

vehicles need to pass the 'MoT' test.

Obviously, you won't be able to examine

your car to the same degree of

thoroughness as the MoT testing station.

But you can reduce the risk of being one of

the 4 out of 10 who fail the test first time by

following this check-list.

iMFTri

The checks shown below are correct at the

time of writing but do note that they are

becoming stricter all the time. Your local

MoT testing station will have the latest

information, should you need it.

1 p Chapter Contents -

Page No. Page No.

PART A: INSIDE THE CAR 28 PART C: VEHICLE RAISED OFF THE GROUND 30

PART B: VEHICLE ON THE GROUND 29 PART D: EXHAUST EMISSIONS 31

PART A: INSIDE THE CAR

Steering Wheel and Column

O 1. Try to move the steering wheel towards and away from you and then from side to side. There should be no appreciable movement or play. Check that the steering wheel is not loose on the column.

02 . Lightly grip the steering wheel between thumb and finger and turn from side to side. Cars with a steering rack: free play should not exceed approximately 13 mm (0.5 in.), assuming a 380 mm (15 in.) diameter steering wheel. Cars fitted with a steering box: free play should not exceed approximately 75 mm (3.0 in.), assuming a 380 mm (15 in.) diameter steering wheel.

Ob . If there is a universal joint at the bottom of the steering column inside the car, check for movement. Place your hand over the joint while turning the steering wheel to-and-fro a little way with your other hand. If ANY free play can be felt, the joint must be replaced.

04. Ensure that there are no breaks or loose components

on the steering wheel itself.

Electrical Equipment

OS . With the ignition turned on, ensure that the horn works okay.

OE . Check that the front wipers work.

07 . Check that the windscreen washers work.

o 8. Check that the internal warnings for the indicator and hazard warning lights work okay.

Checks With An Assistant

O9 . Check that the front and rear side lights and number plate lights work and that the lenses and reflectors are secure, clean and undamaged.

o 10. Check the operation of the headlights (you won't be able to check the alignment yourself) and check that the lenses are undamaged. The reflectors inside the headlights must not be tarnished, nor must there be condensation inside the headlight.

o 11. Turn on the ignition and check the direction

indicators, front and rear and on the side markers.

o 12. Check that the hazard warning lights operate on the

outside of the vehicle, front and rear.

o 13. Check that the rear fog light/s, including the warning

light inside the car, all work correctly.

o 14. Check that the rear brake lights work correctly. These checks are carried out all around the vehicle with all four wheels on the ground.

o 15. Operate the brake lights, side lights and each indicator in turn, all at the same time. None should affect the operation of the others.

SAFETY FIRST!

• Follow the Safety information in CHAPTER 1, SAFETY FIRST! but bear in mind that the vehicle needs

to be even more stable than usual when raised off the ground.

• There must be no risk of it toppling off its stands or ramps while suspension and steering components

are being pushed and pulled in order to test them.

Page 25 of 171

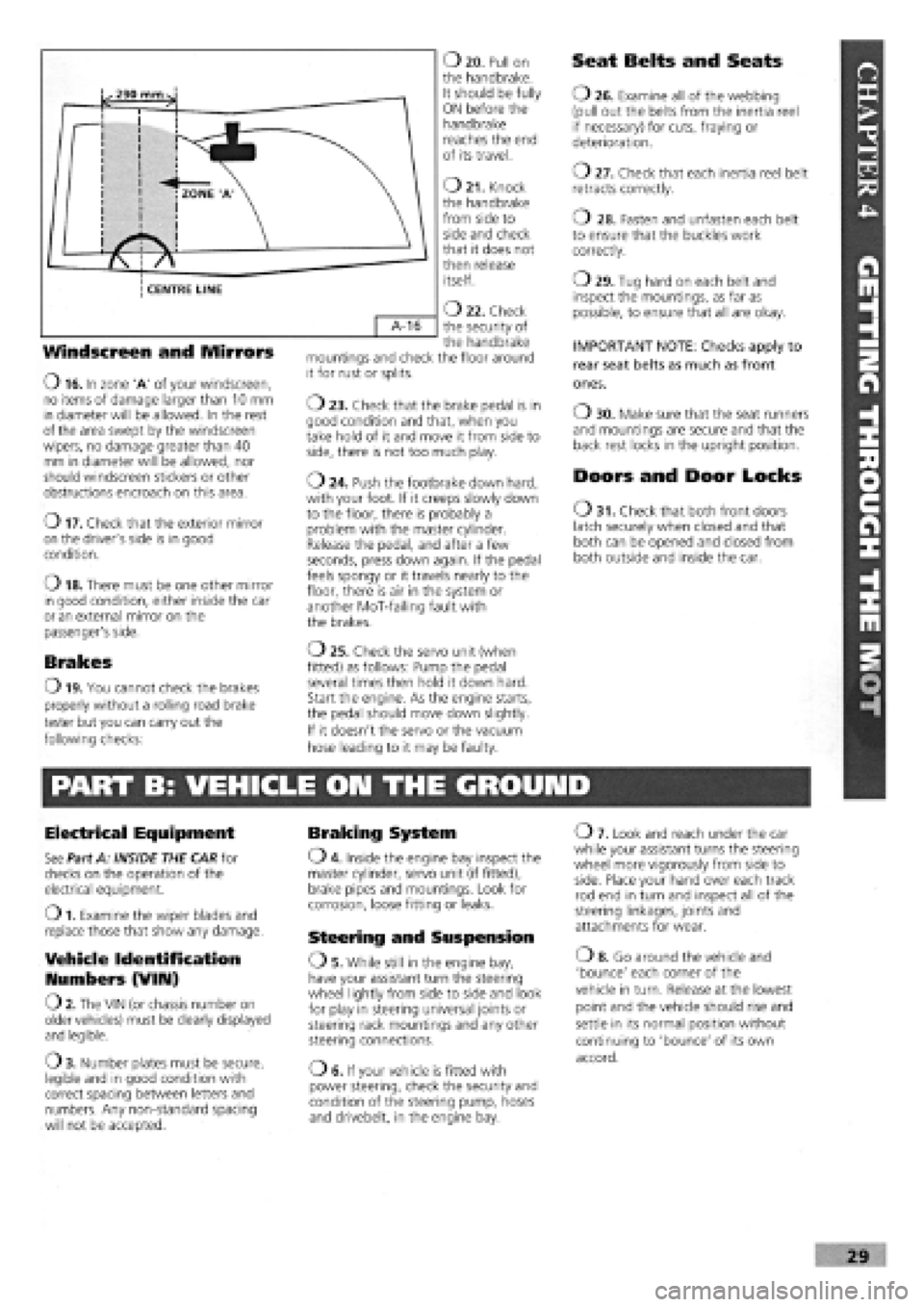

Windscreen and Mirrors

O 16. In zone 'A' of your windscreen, no items of damage larger than 10 mm in diameter will be allowed. In the rest of the area swept by the windscreen wipers, no damage greater than 40 mm in diameter will be allowed, nor should windscreen stickers or other obstructions encroach on this area.

o 17. Check that the exterior mirror on the driver's side is in good condition.

o 18. There must be one other mirror in good condition, either inside the car or an external mirror on the passenger's side.

Brakes

O 19. You cannot check the brakes

properly without a rolling road brake

tester but you can carry out the

following checks:

O 20. Pull on the handbrake. It should be fully ON before the handbrake reaches the end of its travel.

O 21. Knock the handbrake from side to side and check that it does not then release itself.

O 22. Check the security of the handbrake mountings and check the floor around it for rust or splits.

o 23. Check that the brake pedal is in good condition and that, when you take hold of it and move it from side to side, there is not too much play.

o 24. Push the footbrake down hard, with your foot. If it creeps slowly down to the floor, there is probably a problem with the master cylinder. Release the pedal, and after a few seconds, press down again. If the pedal feels spongy or it travels nearly to the floor, there is air in the system or another MoT-failing fault with the brakes.

o 25. Check the servo unit (when

fitted) as follows: Pump the pedal

several times then hold it down hard.

Start the engine. As the engine starts,

the pedal should move down slightly.

If it doesn't the servo or the vacuum

hose leading to it may be faulty.

Seat Belts and Seats

O 26. Examine all of the webbing (pull out the belts from the inertia reel if necessary) for cuts, fraying or deterioration.

o 27. Check that each inertia reel belt retracts correctly.

o 28. Fasten and unfasten each belt to ensure that the buckles work correctly.

o 29. Tug hard on each belt and inspect the mountings, as far as possible, to ensure that all are okay.

IMPORTANT NOTE: Checks apply to

rear seat belts as much as front

ones.

O 30. Make sure that the seat runners and mountings are secure and that the back rest locks in the upright position.

Doors and Door Locks

O 31. Check that both front doors latch securely when closed and that both can be opened and closed from both outside and inside the car.

PART B: VEHICLE ON THE GROUND

Electrical Equipment

See Part A: INSIDE THE CAR for checks on the operation of the electrical equipment.

O 1. Examine the wiper blades and replace those that show any damage.

Vehicle Identification

Numbers (VIIU)

O 2. The VIN (or chassis number on older vehicles) must be clearly displayed and legible.

O 3. Number plates must be secure, legible and in good condition with correct spacing between letters and numbers. Any non-standard spacing will not be accepted.

Braking System

O 4. Inside the engine bay inspect the master cylinder, servo unit (if fitted), brake pipes and mountings. Look for corrosion, loose fitting or leaks.

Steering and Suspension

OS . While still in the engine bay, have your assistant turn the steering wheel lightly from side to side and look for play in steering universal joints or steering rack mountings and any other steering connections.

OE. If your vehicle is fitted with power steering, check the security and condition of the steering pump, hoses and drivebelt, in the engine bay.

O 7. Look and reach under the car while your assistant turns the steering wheel more vigorously from side to side. Place your hand over each track rod end in turn and inspect all of the steering linkages, joints and attachments for wear.

o 8. Go around the vehicle and

'bounce' each corner of the

vehicle in turn. Release at the lowest

point and the vehicle should rise and

settle in its normal position without

continuing to 'bounce' of its own

accord.

Page 26 of 171

PART C: VEHICLE RAISED OFF THE GROUND

Bodywork Structure

01

.

Any sharp edges on the external bodywork, caused by damage or corrosion will cause the vehicle to fail.

02 . Check all load bearing areas for corrosion. Open the doors and check the sills inside and out, above and below. Any corrosion in structural metalwork within 30 cm (12 in.) of seat belt mounting, steering and suspension attachment points will cause the vehicle to fail.

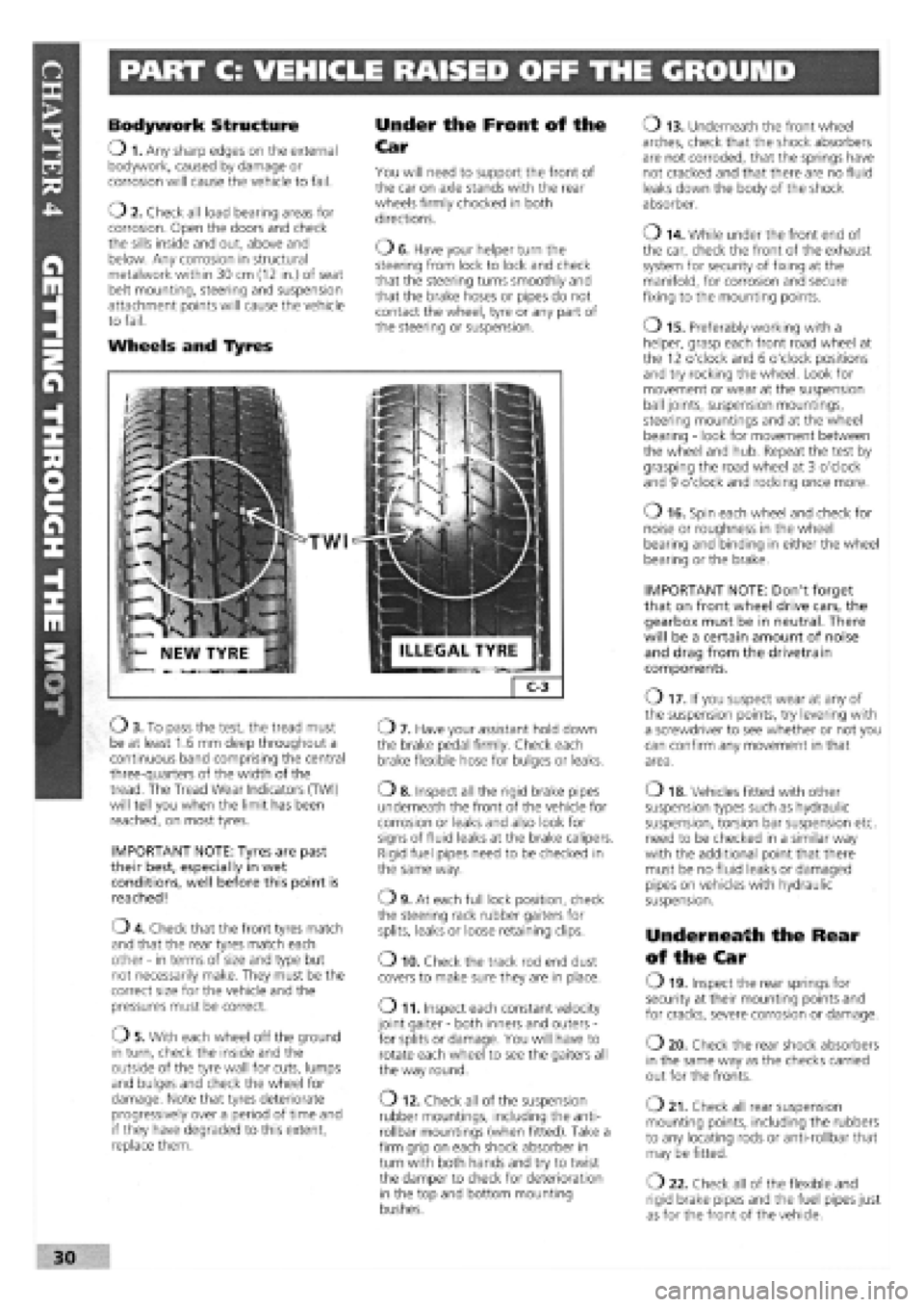

Wheels and Tyres

Under the Front of the

Car

You will need to support the front of the car on axle stands with the rear wheels firmly chocked in both directions.

OE . Have your helper turn the steering from lock to lock and check that the steering turns smoothly and that the brake hoses or pipes do not contact the wheel, tyre or any part of the steering or suspension.

TWI

Ob . To pass the test, the tread must be at least 1.6 mm deep throughout a continuous band comprising the central three-quarters of the width of the tread. The Tread Wear Indicators (TWI) will tell you when the limit has been reached, on most tyres.

IMPORTANT NOTE: Tyres are past their best, especially in wet conditions, well before this point is reached!

04 . Check that the front tyres match and that the rear tyres match each other

-

in terms of size and type but not necessarily make. They must be the correct size for the vehicle and the pressures must be correct.

05 . With each wheel off the ground in turn, check the inside and the outside of the tyre wall for cuts, lumps and bulges and check the wheel for damage. Note that tyres deteriorate progressively over a period of time and if they have degraded to this extent, replace them.

07 . Have your assistant hold down the brake pedal firmly. Check each brake flexible hose for bulges or leaks.

o 8. Inspect all the rigid brake pipes underneath the front of the vehicle for corrosion or leaks and also look for signs of fluid leaks at the brake calipers. Rigid fuel pipes need to be checked in the same way.

09 . At each full lock position, check the steering rack rubber gaiters for splits, leaks or loose retaining clips.

o 10. Check the track rod end dust covers to make sure they are in place.

o 11. Inspect each constant velocity joint gaiter

-

both inners and outers

-

for splits or damage. You will have to rotate each wheel to see the gaiters all the way round.

O 12. Check all of the suspension rubber mountings, including the anti-rollbar mountings (when fitted). Take a firm grip on each shock absorber in turn with both hands and try to twist the damper to check for deterioration in the top and bottom mounting bushes.

o 13. Underneath the front wheel arches, check that the shock absorbers are not corroded, that the springs have not cracked and that there are no fluid leaks down the body of the shock absorber.

o 14. While under the front end of the car, check the front of the exhaust system for security of fixing at the manifold, for corrosion and secure fixing to the mounting points.

o 15. Preferably working with a helper, grasp each front road wheel at the 12 o'clock and 6 o'clock positions and try rocking the wheel. Look for movement or wear at the suspension ball joints, suspension mountings, steering mountings and at the wheel bearing

-

look for movement between the wheel and hub. Repeat the test by grasping the road wheel at 3 o'clock and 9 o'clock and rocking once more.

o 16. Spin each wheel and check for noise or roughness in the wheel bearing and binding in either the wheel bearing or the brake.

IMPORTANT NOTE: Don't forget that on front wheel drive cars, the gearbox must be in neutral. There will be a certain amount of noise and drag from the drivetrain components.

O 17. If you suspect wear at any of the suspension points, try levering with a screwdriver to see whether or not you can confirm any movement in that area.

o 18. Vehicles fitted with other suspension types such as hydraulic suspension, torsion bar suspension etc. need to be checked in a similar way with the additional point that there must be no fluid leaks or damaged pipes on vehicles with hydraulic suspension.

Underneath the Rear

of the Car

O 19. Inspect the rear springs for security at their mounting points and for cracks, severe corrosion or damage.

o 20. Check the rear shock absorbers in the same way as the checks carried out for the fronts.

o 21. Check all rear suspension mounting points, including the rubbers to any locating rods or anti-rollbar that may be fitted.

O 22. Check all of the flexible and rigid brake pipes and the fuel pipes just as for the front of the vehicle.

30