air suspension FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 13 of 171

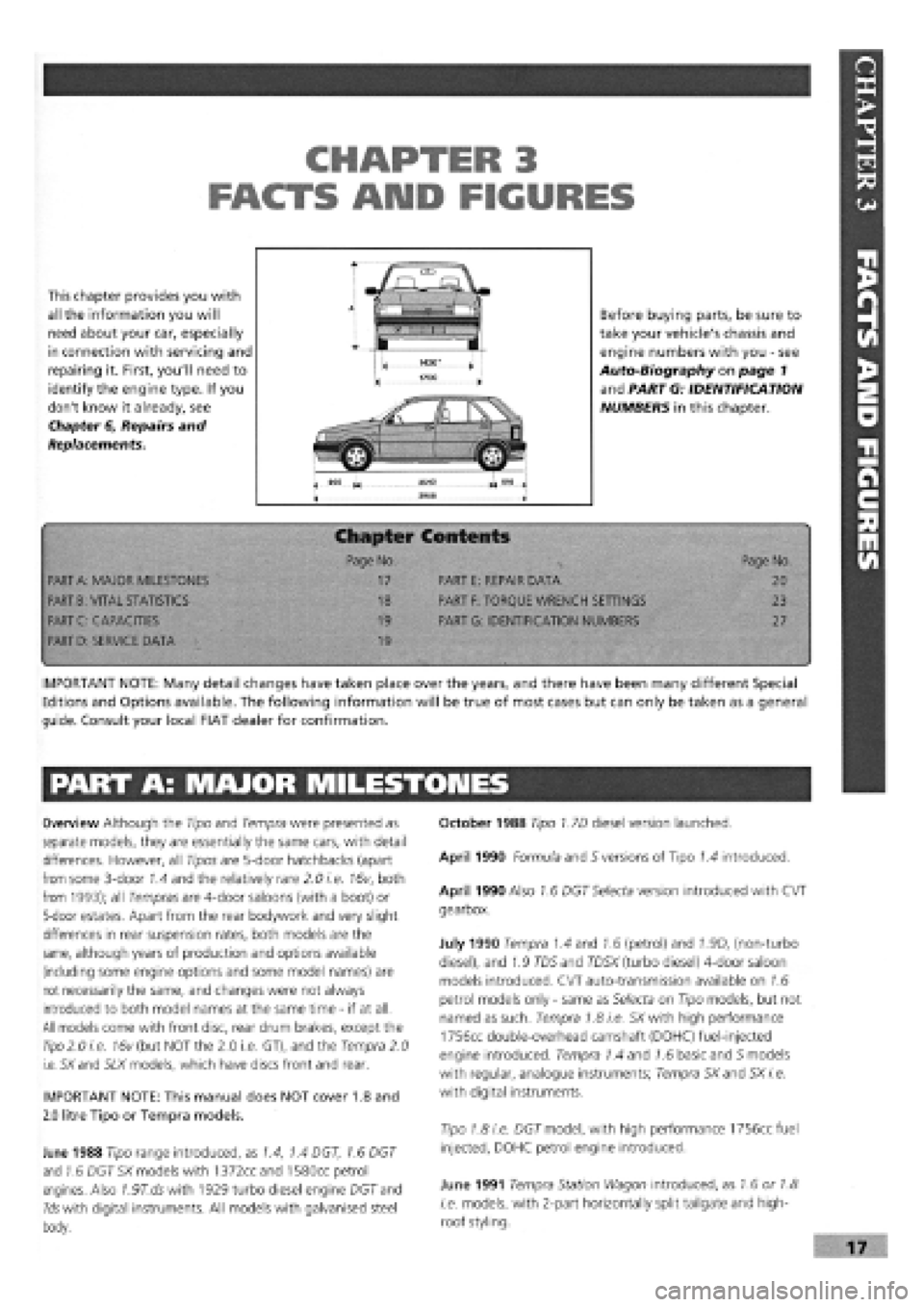

CHAPTER 3

FACTS ARID FIGURES

This chapter provides you with

all the information you will

need about your car, especially

in connection with servicing and

repairing it. First, you'll need to

identify the engine type. If you

don't know it already, see

Chapter 6, Repairs and

Replacements.

Before buying parts, be sure to

take your vehicle's chassis and

engine numbers with you

-

see

Auto-Biography on page 1

and PART G: IDENTIFICATION

NUMBERS in this chapter.

Chapter Contents

• -< Page No. Page No.

PART

A:

MAJOR MILESTONES 17 PART E: REPAIR DATA 20

PART

B:

VITAL STATISTICS 18 PART

F:

TORQUE WRENCH SETTINGS 23

PART C: CAPACITIES 19 PART G: IDENTIFICATION NUMBERS 27

PART

D:

SERVICE DATA 19

•

IMPORTANT NOTE: Many detail changes have taken place over the years, and there have been many different Special

Editions and Options available. The following information will be true of most cases but can only be taken as a general

guide. Consult your local FIAT dealer for confirmation.

PART A: MAJOR MILESTONES

Overview Although the Tipo and Tempra were presented as

separate models, they are essentially the same cars, with detail

differences. However, all Tipos are 5-door hatchbacks (apart

from some 3-door 1.4 and the relatively rare 2.0 i.e. 16v, both

from 1993); all Tempras are 4-door saloons (with a boot) or

5-door estates. Apart from the rear bodywork and very slight

differences in rear suspension rates, both models are the

same, although years of production and options available

(including some engine options and some model names) are

not necessarily the same, and changes were not always

introduced to both model names at the same time

-

if at all.

All models come with front disc, rear drum brakes, except the

Tipo

2.0 i.e. 16v (but NOT the 2.0 i.e. GT), and the Tempra 2.0

i.e. SXand SLX models, which have discs front and rear.

IMPORTANT NOTE: This manual does NOT cover 1.8 and

2.0 litre Tipo or Tempra models.

June 1988 Tipo range introduced, as 1.4, 1.4 DGT, 1.6 DGT

and 1.6 DGT SX models with 1372ccand 1580cc petrol

engines. Also 7.97".dswith 1929 turbo diesel engine DGT and

Ids with digital instruments. All models with galvanised steel

body.

October 1988 Tipo 1.7D diesel version launched.

April 1990 Formula and S versions of Tipo 1.4 introduced.

April 1990 Also 1.6 DGT Selecta version introduced with CVT

gearbox.

July 1990 Tempra 1.4 and 1.6 (petrol) and 1.9D, (non-turbo

diesel), and 1.9 TD5 and TD5X (turbo diesel) 4-door saloon

models introduced. CVT auto-transmission available on 1.6

petrol models only

-

same as Selecta on Tipo models, but not

named as such. Tempra 1.8 i.e. SX with high performance

1756cc double-overhead camshaft (DOHC) fuel-injected

engine introduced. Tempra 1.4 and 1.6 basic and 5 models

with regular, analogue instruments; Tempra SXand SX i.e.

with digital instruments.

Tipo 1.8 i.e. DGT model, with high performance 1756cc fuel

injected, DOHC petrol engine introduced.

June 1991 Tempra Station Wagon introduced, as 1.6 or 1.8

i.e. models, with 2-part horizontally split tailgate and high-

roof styling.

Page 14 of 171

October 1991 2.0 i.e. 16v introduced, with 1995cc, 16 valve

high-performance DOHC engine, catalytic converter, sports

suspension, front and rear disc brakes. ABS available as

option.

January 1992 Existing Tipo models lightly facelifted and

redesignated 1.4 Formula, 1.45, 1.6S, 1.6SX, 1.9TD SX,

1.8 i.e. SX. 1.7D discontinued. SX versions with digital

instruments.

Tempra 1.9 TDS (turbo diesel) Station Wagon introduced. 1.4

and 1.9D saloons discontinued.

May 1992 Tempra 1.8 i.e. SX Saloon and Station Wagon

discontinued.

June 1992 Tempra 2.0 i.e. SX saloon and station wagon

models introduced, with high performance 1995cc DOHC fuel

injected engine, catalytic converter and disc brakes front and

rear.

Tipo 1.4 and all Tipo and Tempra 1.6 models (except Selecta)

now with a catalytic converter and fuel injection in place of

Weber twin-choke carburettor. Designated i.e. in badging.

December 1992 Tipo 1.8 i.e. and 1.6 Selecta discontinued.

February 1993 Tipo 2.0 i.e. GT introduced. Slightly lower

performance and spec, version of the 16v model.

July 1993 Tipo 1.4 now available as a 3-door or 5-door

hatchback. 2.0 i.e. 16v now only available as 3-door. Tipo 2.0

i.e. GT replaced by similar spec. 2.0 i.e. SLX.

Tempra 2.0 i.e. SX saloons and estates now only available

with auto, gearbox. Otherwise, SX models become known as

SLX, with colour-coded mirrors and ABS brakes. Most Tempras

now with body-coloured bumpers. 1.9D (non turbo Diesel re-

introduced).

All Tipo and Tempra models now with revised front-end

styling

-

narrower headlights and revised grille. Improved crash

protection, including side impact beams, safety steering wheel

and uprated brakes. Power steering, central locking, electric

windows all standard.

February 1994 Tipo 1.7 non-turbo diesel re-introduced as

1.7 DS.

May 1994 Tempra 1.9DS Station Wagon introduced.

September 1994 Most models available with driver's airbag,

fire prevention system and seat belt pre-tensioners.

December 1994 Tempra 1.6 i.e. versions get M.P.I, engine.

February/March 1995 All models with VIN number window

etching and immobiliser standard on all Tempra petrol models.

October 1995 Immobiliser fitted to Tempra D and TD models.

End of 1995 Tipo discontinued.

Mid-1996 Tempra discontinued.

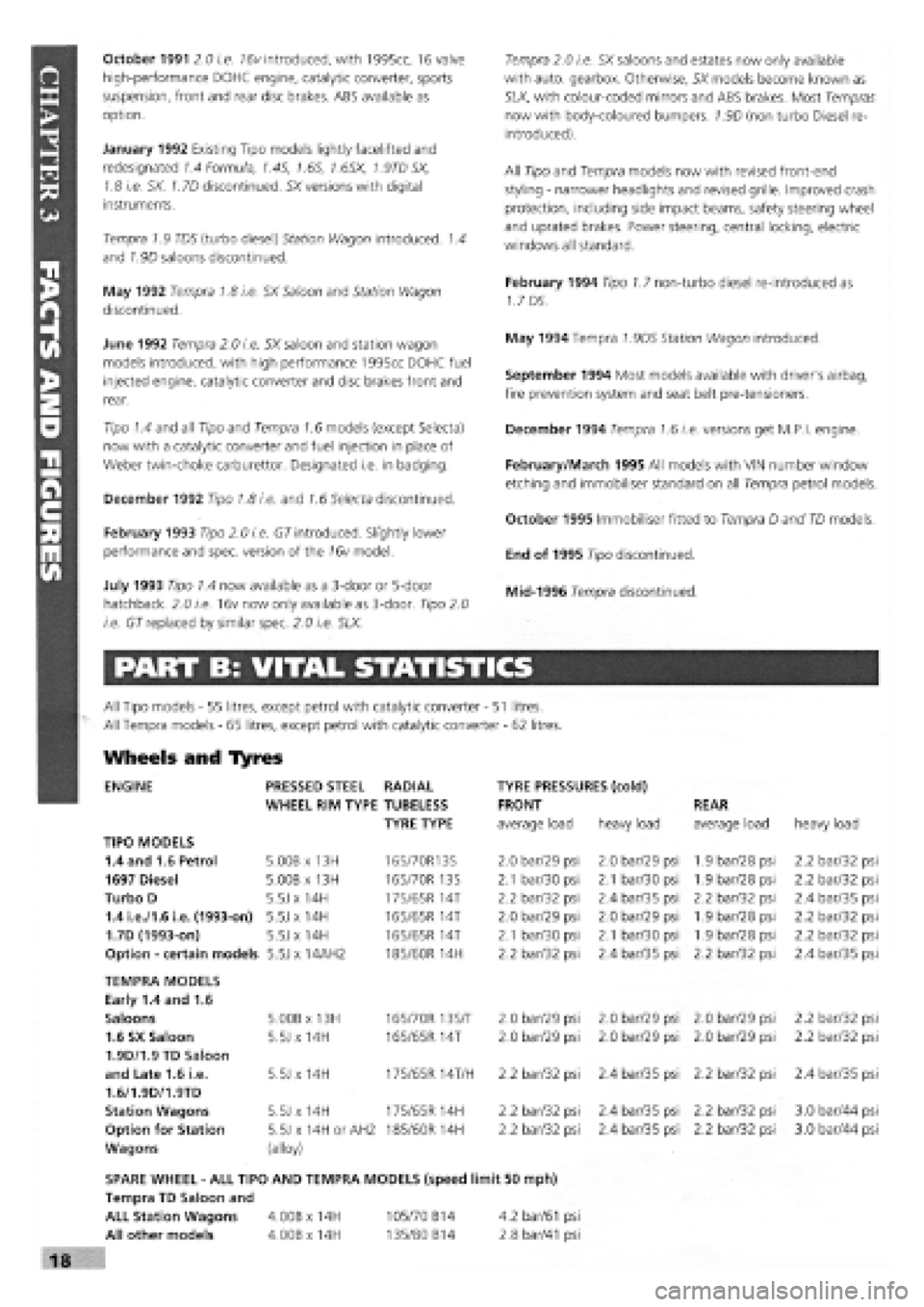

PART B: VITAL STATISTICS

All Tipo models

-

55 litres, except petrol with catalytic converter

- 51

litres.

All Tempra models

-

65 litres, except petrol with catalytic converter

-

62 litres.

Wheels and Tyres

ENGINE PRESSED STEEL RADIAL TYRE PRESSURES (cold)

WHEEL RIM TYPE TUBELESS FRONT REAR

TYRE TYPE average load heavy load average load heavy load

TIPO MODELS

1.4 and 1.6 Petrol 5.00B x 13H 165/70R13S 2.0 bar/29 psi 2.0 bar/29 psi 1.9 bar/28 psi 2.2 bar/32 psi

1697 Diesel 5.00B x 13H 165/70R 13S 2.1 bar/30 psi 2.1 bar/30 psi 1.9 bar/28 psi 2.2 bar/32 psi

Turbo D 5.5J x 14H

175/65 R

14T 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

1.4 i.e./1.6 i.e. (1993-on) 5.5J x 14H

165/65 R

14T 2.0 bar/29 psi 2.0 bar/29 psi 1.9 bar/28 psi 2.2 bar/32 psi

1.7D (1993-on) 5.5J x 14H 165/65R 14T 2.1 bar/30 psi 2.1 bar/30 psi 1.9 bar/28 psi 2.2 bar/32 psi

Option

-

certain models 5.5J x 14AH2 185/60R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

TEMPRA MODELS

Early 1.4 and 1.6

Saloons 5.00B x 13H 165/70R 13S/T 2.0 bar/29 psi 2.0 bar/29 psi 2.0 bar/29 psi 2.2 bar/32 psi

1.6 SX Saloon 5.5J x 14H 165/65R 14T 2.0 bar/29 psi 2.0 bar/29 psi 2.0 bar/29 psi 2.2 bar/32 psi

1.9D/1.9 TD Saloon

and Late 1.6 i.e. 5.5J x 14H 175/65R 14T/H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

1.6/1.9D/1.9TD

Station Wagons 5.5J x 14H 175/65R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 3.0 bar/44 psi

Option for Station 5.5J x 14H or AH2 185/60 R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 3.0 bar/44 psi

Wagons (alloy)

SPARE WHEEL

-

ALL TIPO AND TEMPRA MODELS (speed limit 50 mph)

Tempra TD Saloon and

ALL Station Wagons 4.00B x 14H 105/70 B14 4.2

bar/61

psi

All other models 4.00Bx14H 135/80 B14 2.8

bar/41

psi

Page 18 of 171

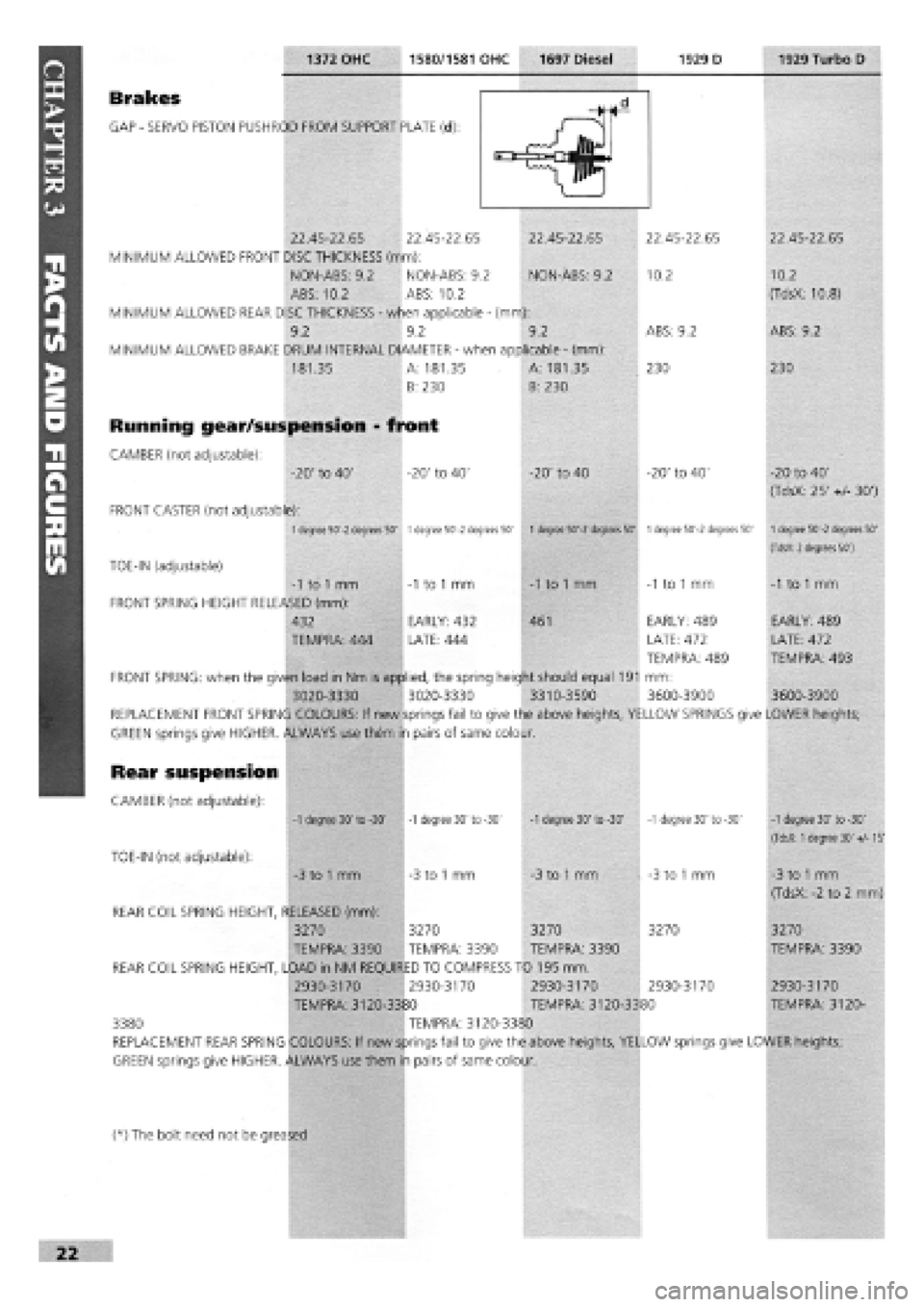

1372 OHC 1580/1581 OHC 1697 Diesel 1929 D 1929 Turbo D

Brakes

GAP

-

SERVO PISTON PUSHROD FROM SUPPORT PLATE (d):

22.45-22.65 22.45-22.65 22.45-22.65

MINIMUM ALLOWED FRONT DISC THICKNESS (mm):

NON-ABS: 9.2 NON-ABS: 9.2 NON-ABS: 9.2

ABS: 10.2 ABS: 10.2

MINIMUM ALLOWED REAR DISC THICKNESS

-

when applicable

-

(mm):

9.2 9.2 9.2

MINIMUM ALLOWED BRAKE DRUM INTERNAL DIAMETER

-

when applicable

-

(mm):

181.35 A: 181.35

B: 230

Running gear/suspension - front

CAMBER (not adjustable):

-20' to 40' -20' to 40'

A: 181.35

B: 230

-20' to 40

22.45-22.65

10.2

ABS: 9.2

230

22.45-22.65

10.2

(TdsX: 10.8)

ABS: 9.2

230

-20' to 40' -20 to 40'

(TdsX: 25'

+/-

30')

FRONT CASTER (not adjustable):

1 degree 50'-2 degrees 50'

1

degree 50'-2 degrees 50'

1

degree 50'-2 degrees 50'

1

degree 50'-2 degrees 50' 1 degree 50'-2 degrees 50'

(TdsX: 2 degrees 50')

TOE-IN (adjustable)

-1

to

1

mm

-1

to

1

mm

-1

to

1

mm

-1

to

1

mm

FRONT SPRING HEIGHT RELEASED (mm):

432 EARLY: 432 461 EARLY: 489

TEMPRA: 444 LATE: 444 LATE: 472

TEMPRA: 489

FRONT SPRING: when the given load in Nm is applied, the spring height should equal 191 mm:

3020-3330 3020-3330 3310-3590 3600-3900

REPLACEMENT FRONT SPRING COLOURS: If new springs fail to give the above heights, YELLOW SPRINGS give LOWER heights;

GREEN springs give HIGHER. ALWAYS use them in pairs of same colour.

Rear suspension

CAMBER (not adjustable):

TOE-IN (not adjustable):

-1

to

1

mm

EARLY: 489

LATE: 472

TEMPRA: 493

3600-3900

-1 degree 30' to -30' -1 degree 30' to -30' -1 degree 30' to -30' -1 degree 30' to -30'

-3

to

1

mm

-3

to

1

mm

-3

to

1

mm -3 to

1

mm

-1 degree 30' to -30'

(TdsX: 1 degree 30' +/-15'

-3

to

1

mm

(TdsX:

-2

to 2 mm)

REAR COIL SPRING HEIGHT, RELEASED (mm):

3270 3270 3270 3270 3270

TEMPRA: 3390 TEMPRA: 3390 TEMPRA: 3390 TEMPRA: 3390

REAR COIL SPRING HEIGHT, LOAD in NM REQUIRED TO COMPRESS TO 195 mm.

2930-3170 2930-3170 2930-3170 2930-3170 2930-3170

TEMPRA: 3120-3380 TEMPRA: 3120-3380 TEMPRA: 3120-

3380 TEMPRA: 3120-3380

REPLACEMENT REAR SPRING COLOURS: If new springs fail to give the above heights, YELLOW springs give LOWER heights;

GREEN springs give HIGHER. ALWAYS use them in pairs of same colour.

(*) The bolt need not be greased

Page 20 of 171

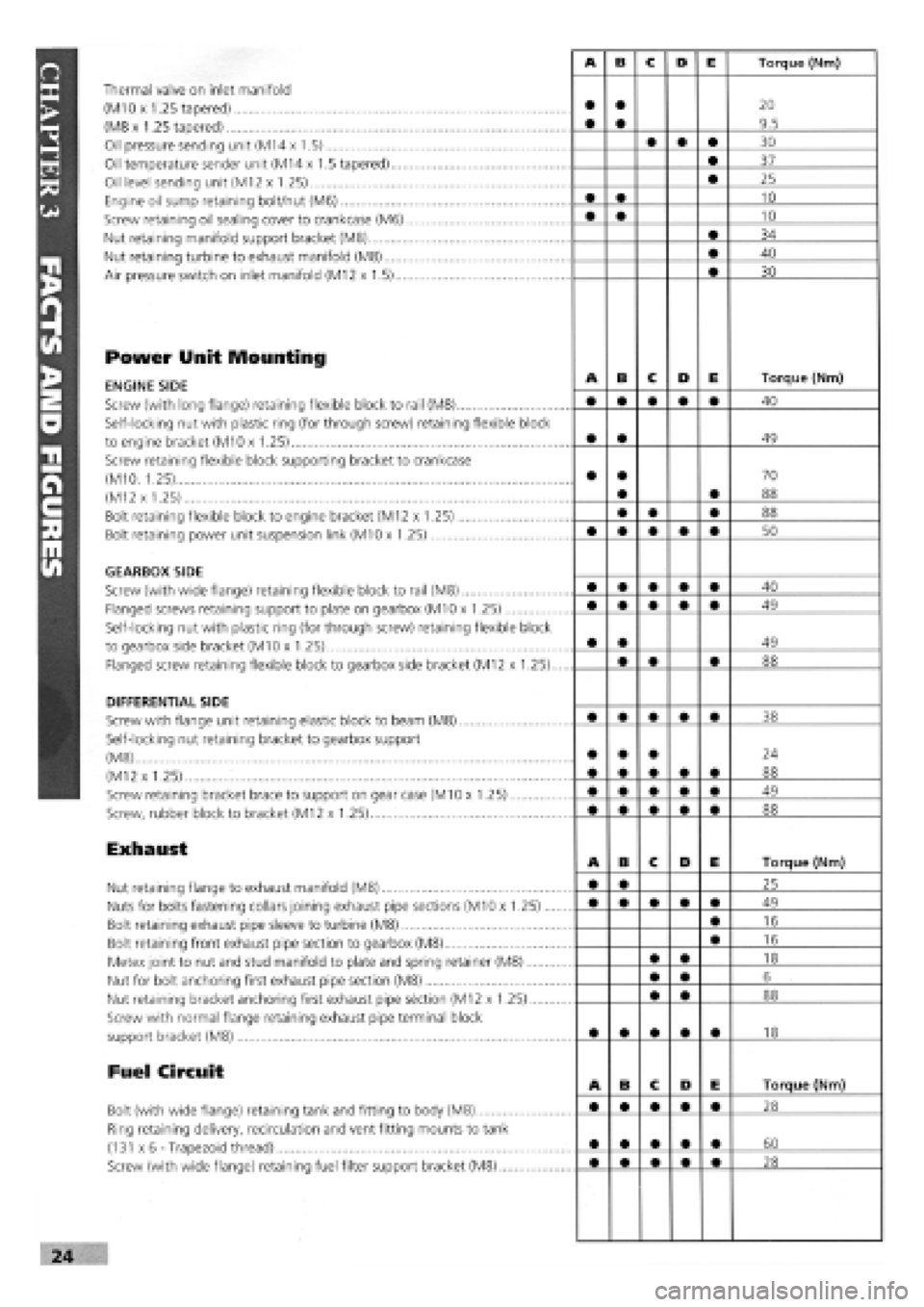

Thermal valve on inlet manifold

(M10 x 1.25 tapered)

(M8 x 1.25 tapered)

Oil pressure sending unit (M14 x 1.5)

Oil temperature sender unit (M14 x 1.5 tapered)....

Oil level sending unit (M12 x 1.25)

Engine oil sump retaining bolt/nut (M6)

Screw retaining oil sealing cover to crankcase (M6)

Nut retaining manifold support bracket (M8)

Nut retaining turbine to exhaust manifold (M8)

Air pressure switch on inlet manifold (M12 x 1.5)...

Power Unit Mounting

ENGINE SIDE

Screw (with long flange) retaining flexible block to rail (M8)

Self-locking nut with plastic ring (for through screw) retaining flexible block

to engine bracket (M10 x 1.25)

Screw retaining flexible block supporting bracket to crankcase

(M10. 1.25)

(M12 x 1.25)

Bolt retaining flexible block to engine bracket (M12 x 1.25)

Bolt retaining power unit suspension link (M10 x 1.25)

GEARBOX SIDE

Screw (with wide flange) retaining flexible block to rail (M8)

Flanged screws retaining support to plate on gearbox (M10 x 1.25)

Self-locking nut with plastic ring (for through screw) retaining flexible block

to gearbox side bracket (M10 x 1.25)

Flanged screw retaining flexible block to gearbox side bracket (M12 x 1.25).

DIFFERENTIAL SIDE

Screw with flange unit retaining elastic block to beam (M8)

Self-locking nut retaining bracket to gearbox support

(M8)

(M12 x 1.25)

Screw retaining bracket brace to support on gear case (M10 x 1.25)

Screw, rubber block to bracket (M12 x 1.25)

Exhaust

Nut retaining flange to exhaust manifold (M8)

Nuts for bolts fastening collars joining exhaust pipe sections (M10 x 1.25)...

Bolt retaining exhaust pipe sleeve to turbine (M8)

Bolt retaining front exhaust pipe section to gearbox (M8)

Metex joint to nut and stud manifold to plate and spring retainer (M8)

Nut for bolt anchoring first exhaust pipe section (M8)

Nut retaining bracket anchoring first exhaust pipe section (M12 x 1.25)

Screw with normal flange retaining exhaust pipe terminal block

support bracket (M8)

Fuel Circuit

Bolt (with wide flange) retaining tank and fitting to body (M8)

Ring retaining delivery, recirculation and vent fitting mounts to tank

(131 x 6-Trapezoid thread)

Screw (with wide flange) retaining fuel filter support bracket (M8)

Page 25 of 171

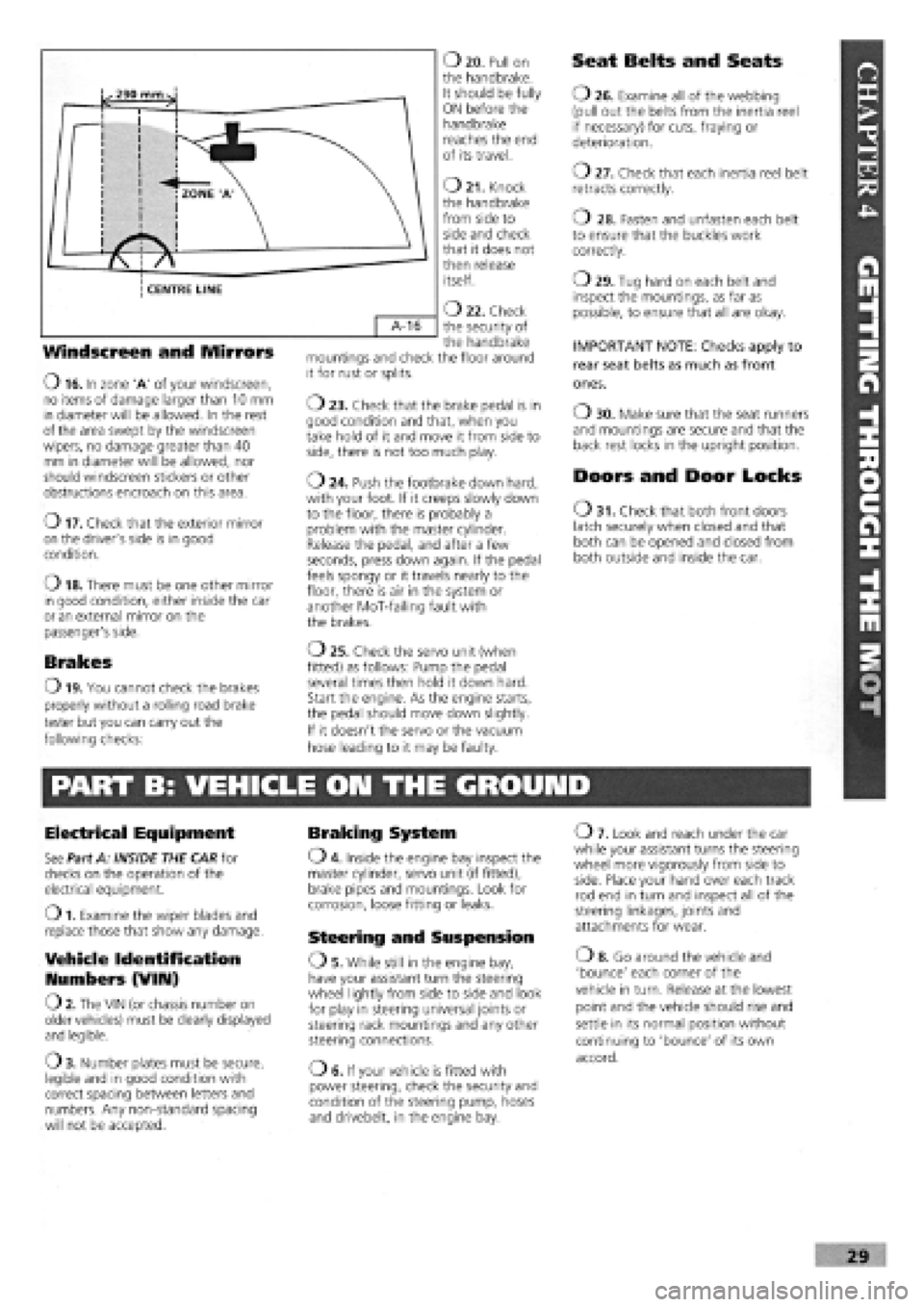

Windscreen and Mirrors

O 16. In zone 'A' of your windscreen, no items of damage larger than 10 mm in diameter will be allowed. In the rest of the area swept by the windscreen wipers, no damage greater than 40 mm in diameter will be allowed, nor should windscreen stickers or other obstructions encroach on this area.

o 17. Check that the exterior mirror on the driver's side is in good condition.

o 18. There must be one other mirror in good condition, either inside the car or an external mirror on the passenger's side.

Brakes

O 19. You cannot check the brakes

properly without a rolling road brake

tester but you can carry out the

following checks:

O 20. Pull on the handbrake. It should be fully ON before the handbrake reaches the end of its travel.

O 21. Knock the handbrake from side to side and check that it does not then release itself.

O 22. Check the security of the handbrake mountings and check the floor around it for rust or splits.

o 23. Check that the brake pedal is in good condition and that, when you take hold of it and move it from side to side, there is not too much play.

o 24. Push the footbrake down hard, with your foot. If it creeps slowly down to the floor, there is probably a problem with the master cylinder. Release the pedal, and after a few seconds, press down again. If the pedal feels spongy or it travels nearly to the floor, there is air in the system or another MoT-failing fault with the brakes.

o 25. Check the servo unit (when

fitted) as follows: Pump the pedal

several times then hold it down hard.

Start the engine. As the engine starts,

the pedal should move down slightly.

If it doesn't the servo or the vacuum

hose leading to it may be faulty.

Seat Belts and Seats

O 26. Examine all of the webbing (pull out the belts from the inertia reel if necessary) for cuts, fraying or deterioration.

o 27. Check that each inertia reel belt retracts correctly.

o 28. Fasten and unfasten each belt to ensure that the buckles work correctly.

o 29. Tug hard on each belt and inspect the mountings, as far as possible, to ensure that all are okay.

IMPORTANT NOTE: Checks apply to

rear seat belts as much as front

ones.

O 30. Make sure that the seat runners and mountings are secure and that the back rest locks in the upright position.

Doors and Door Locks

O 31. Check that both front doors latch securely when closed and that both can be opened and closed from both outside and inside the car.

PART B: VEHICLE ON THE GROUND

Electrical Equipment

See Part A: INSIDE THE CAR for checks on the operation of the electrical equipment.

O 1. Examine the wiper blades and replace those that show any damage.

Vehicle Identification

Numbers (VIIU)

O 2. The VIN (or chassis number on older vehicles) must be clearly displayed and legible.

O 3. Number plates must be secure, legible and in good condition with correct spacing between letters and numbers. Any non-standard spacing will not be accepted.

Braking System

O 4. Inside the engine bay inspect the master cylinder, servo unit (if fitted), brake pipes and mountings. Look for corrosion, loose fitting or leaks.

Steering and Suspension

OS . While still in the engine bay, have your assistant turn the steering wheel lightly from side to side and look for play in steering universal joints or steering rack mountings and any other steering connections.

OE. If your vehicle is fitted with power steering, check the security and condition of the steering pump, hoses and drivebelt, in the engine bay.

O 7. Look and reach under the car while your assistant turns the steering wheel more vigorously from side to side. Place your hand over each track rod end in turn and inspect all of the steering linkages, joints and attachments for wear.

o 8. Go around the vehicle and

'bounce' each corner of the

vehicle in turn. Release at the lowest

point and the vehicle should rise and

settle in its normal position without

continuing to 'bounce' of its own

accord.

Page 29 of 171

Thanks

are due to the excellent, knowledgeable and helpful staff at FIAT main dealers, Ryauto of Amblecote, in the West

Midlands for supplying vehicles and for their assistance with this chapter. In particular, thanks are due to the efficient Maurice

Hough, Service Manager, the experienced Foreman, Tony Morris, and young demon mechanic, Matthew Worsfold.

Some of the suggested inspection/replacement intervals may not correspond to those shown in the original handbook. The suggested

schedule, based on FIAT'S recommendations, takes into account the age of the vehicle and the annual MoT test in the UK.

In practice, because of the split between (mainly) 12 month/9,000 mile and 18 month/13,500 mile intervals, you will need to

service your Tipo or Tempra at most, if not every, 6 month interval.

IMPORTANT NOTE: Each service should be carried out at EITHER the recommended mileage OR the recommended time

interval, whichever comes first.

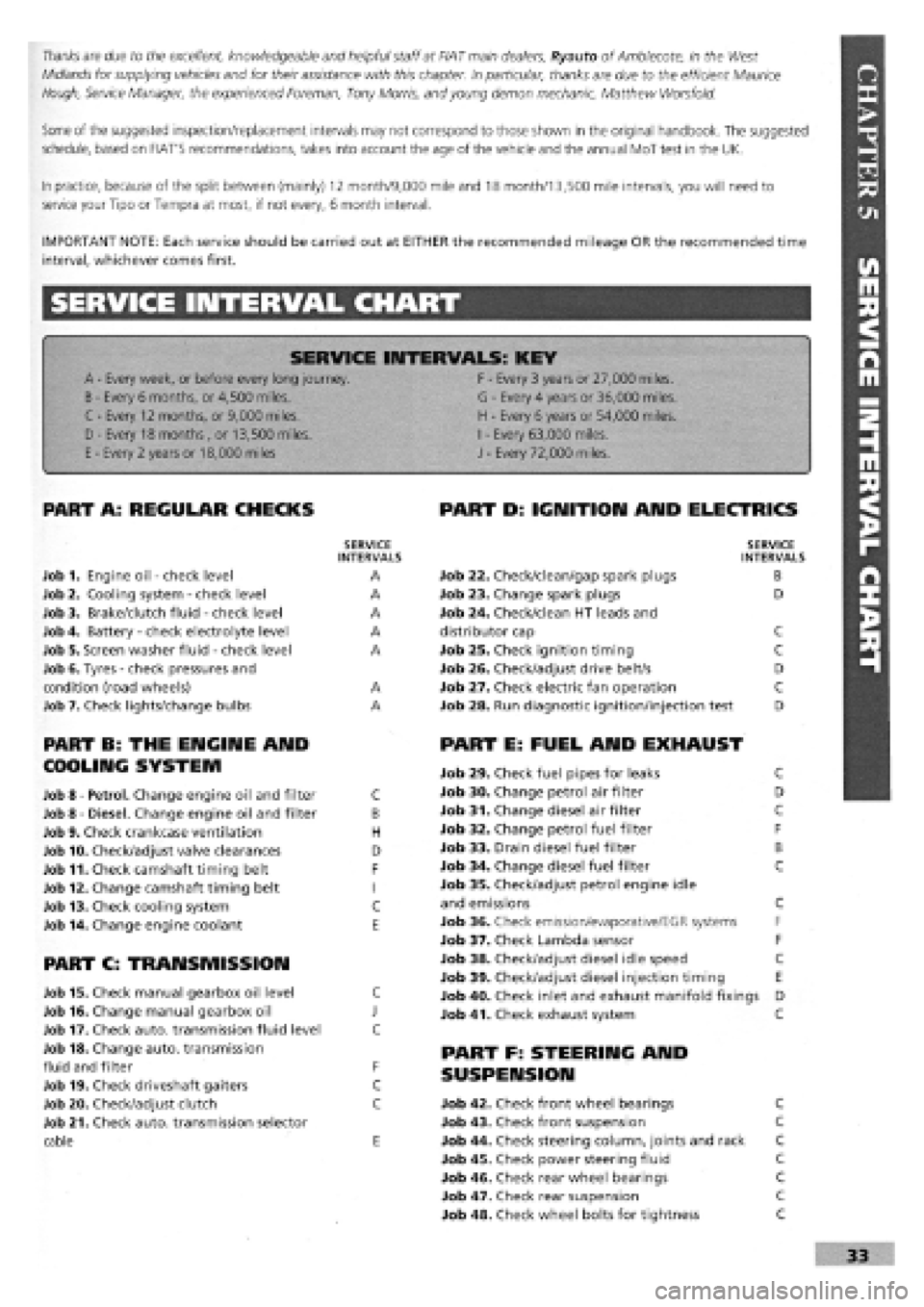

SERVICE INTERVAL CHART

SERVICE INTERVALS: KEY

A

-

Every week, or before every long journey. F

-

Every 3 years or 27,000 miles.

B

-

Every 6 months, or 4,500 miles. G

-

Every 4 years or 36,000 miles.

C - Every 12 months, or 9,000 miles. H

-

Every 6 years or 54,000 miles.

I

-

Every 63,000 miles. D - Every 18 months , or 13,500 miles.

H

-

Every 6 years or 54,000 miles.

I

-

Every 63,000 miles.

E

-

Every 2 years or 18,000 miles J

-

Every 72,000 miles.

PART A: REGULAR CHECKS

SERVICE INTERVALS

Job 1. Engine oil

-

check level A

Job 2. Cooling system

-

check level A

Job 3. Brake/clutch fluid

-

check level A

Job 4. Battery

-

check electrolyte level A

Job 5. Screen washer fluid

-

check level A

Job 6. Tyres

-

check pressures and

condition (road wheels) A

Job 7. Check lights/change bulbs A

PART B: THE ENGINE AND

COOLING SYSTEM

Job 8

-

Petrol. Change engine oil and filter C

Job 8

-

Diesel. Change engine oil and filter B

Job 9. Check crankcase ventilation H

Job 10. Check/adjust valve clearances D

Job 11. Check camshaft timing belt F

Job 12. Change camshaft timing belt I

Job 13. Check cooling system C

Job 14. Change engine coolant E

PART C: TRANSMISSION

Job 15. Check manual gearbox oil level C

Job 16. Change manual gearbox oil J

Job 17. Check auto, transmission fluid level C

Job 18. Change auto, transmission

fluid and filter F

Job 19. Check driveshaft gaiters C

Job 20. Check/adjust clutch C

Job 21. Check auto, transmission selector

cable E

PART D: IGNITION AND ELECTRICS

SERVICE INTERVALS

Job 22. Check/clean/gap spark plugs B

Job 23. Change spark plugs D

Job 24. Check/clean HT leads and

distributor cap C

Job 25. Check ignition timing C

Job 26. Check/adjust drive belt/s D

Job 27. Check electric fan operation C

Job 28. Run diagnostic ignition/injection test D

PART E: FUEL AND EXHAUST

Job 29. Check fuel pipes for leaks C

Job 30. Change petrol air filter D

Job 31. Change diesel air filter C

Job 32. Change petrol fuel filter F

Job 33. Drain diesel fuel filter B

Job 34. Change diesel fuel filter C

Job 35. Check/adjust petrol engine idle

and emissions C

Job 36. Check emission/evaporative/EGR systems F

Job 37. Check Lambda sensor F

Job 38. Check/adjust diesel idle speed C

Job 39. Check/adjust diesel injection timing E

Job 40. Check inlet and exhaust manifold fixings D

Job 41. Check exhaust system C

PART F: STEERING AND

SUSPENSION

Job 42. Check front wheel bearings C

Job 43. Check front suspension C

Job 44. Check steering column, joints and rack C

Job 45. Check power steering fluid C

Job 46. Check rear wheel bearings C

Job 47. Check rear suspension C

Job 48. Check wheel bolts for tightness C

Page 32 of 171

(ignition-ON) position and press down the button between the

two terminals on the reservoir cap

-

when fitted. The warning

light on the dash should light up. When no button is fitted,

unscrew and raise the cap (ignition key ON) to check the

warning light. Check the bulb, check the fuse, or have your

FIAT dealer repair the warning system, if faulty.

• Job 4. Battery

-

check electrolyte level.

FACT FILE: DISCONNECTING THE

BATTERY

• Many vehicles depend on a constant

power supply from the battery; with

these you find yourself in trouble if you

simply disconnect the battery. You

might find the car alarm goes off, or that the engine

management system forgets all it ever 'learned', making

the car feel odd to drive until it has re-programmed

itself. You might also find that the radio refuses to

operate until its correct security code is keyed into it.

• On cars with engine management systems and/or

coded radios, you must ensure the car has a constant

electrical supply, even with the battery removed. You

will need a separate 12 volt battery; put a self-tapping

screw into the positive lead near the battery terminal

before disconnecting it, and put a positive connection

to your other battery via this screw.

• Be EXTREMELY CAREFUL to wrap insulation tape

around the connection so that no short is caused. The

negative terminal on the other battery must be

connected to the car's bodywork.

SAFETY FIRST!

• The gas given off by a battery is highly explosive.

Never smoke, use a naked flame or allow a spark in

the battery compartment.

• Never disconnect the battery (it can cause sparking)

with the battery caps removed.

• All vehicle batteries contain sulphuric acid. If the

acid comes into contact with the skin or eyes, wash

immediately with copious amounts of cold water and

seek medjcal advice.

• Do not check the battery levels within half an hour

of the battery being charged with a separate battery

charger because the addition of fresh water could

cause electrolyte to flood out.

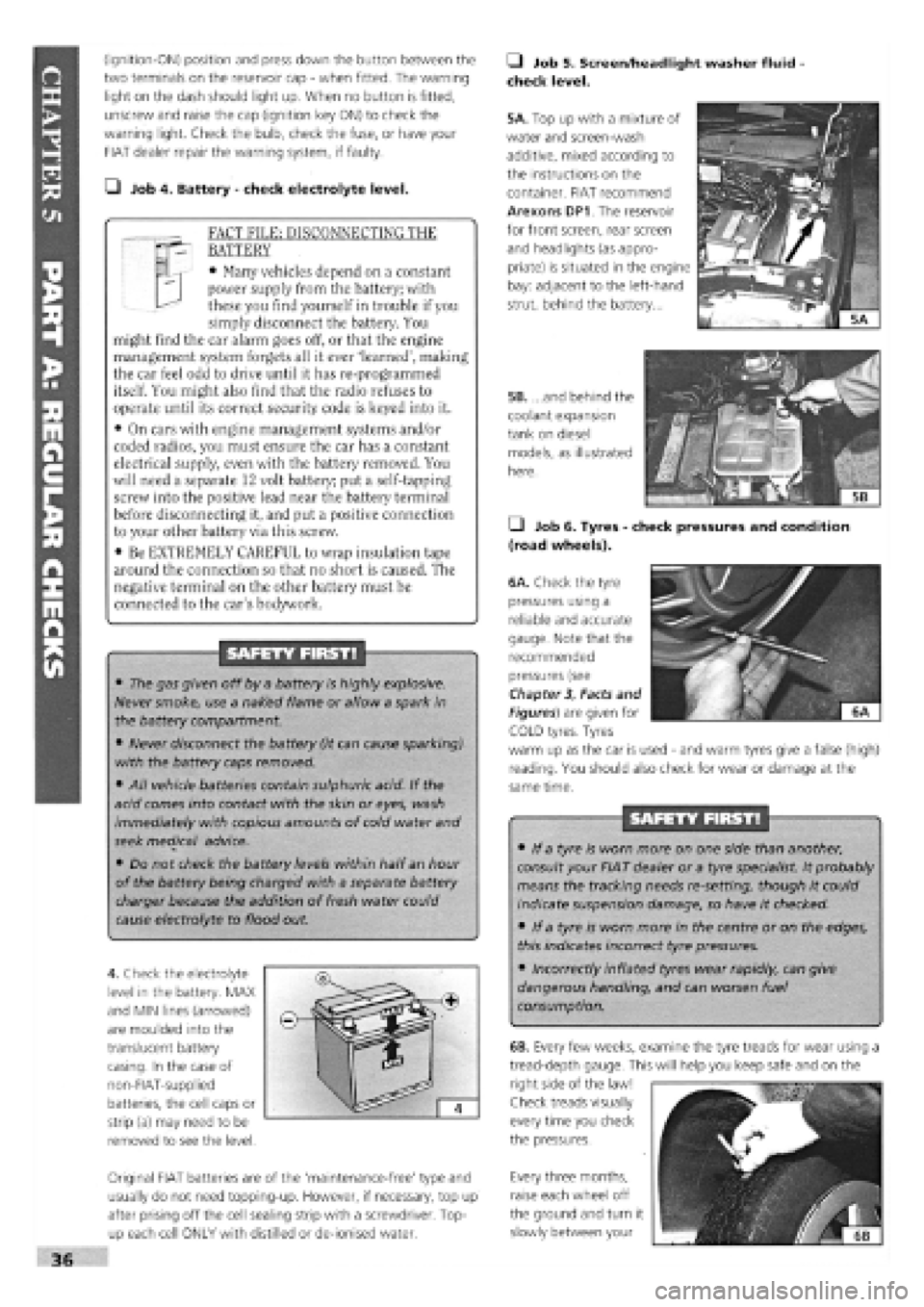

4. Check the electrolyte

level in the battery. MAX

and MIN lines (arrowed)

are moulded into the

translucent battery

casing. In the case of

non-FIAT-supplied

batteries, the cell caps or

strip (a) may need to be

removed to see the level.

Original FIAT batteries are of the 'maintenance-free' type and

usually do not need topping-up. However, if necessary, top up

after prising off the cell sealing strip with a screwdriver. Top-

up each cell ONLY with distilled or de-ionised water.

• Job 5. Screen/headlight washer fluid

check level.

5A. Top up with a mixture of

water and screen-wash

additive, mixed according to

the instructions on the

container. FIAT recommend

Arexons DP1. The reservoir

for front screen, rear screen

and headlights (as appro-

priate) is situated in the engine

bay: adjacent to the left-hand

strut, behind the battery...

5B. ...and behind the

coolant expansion

tank on diesel

models, as illustrated

here.

• Job 6. Tyres

-

check pressures and condition

(road wheels).

/

6A. Check the tyre

pressures using a

reliable and accurate

gauge. Note that the

recommended

pressures (see

Chapter

3,

Facts and

Figures) are given for ^^

iH^KKSEI ^ "'

COLD tyres. Tyres

warm up as the car is used

-

and warm tyres give a false (high)

reading. You should also check for wear or damage at the

same time.

SAFETY FIRST!

• If a tyre is worn more on one side than another,

consult your FIAT dealer or a tyre specialist. It probably

means the tracking needs re-setting, though it could

indicate suspension damage, so have it checked.

• If a tyre is worn more in the centre or on the edges,

this indicates incorrect tyre pressures.

• Incorrectly inflated tyres wear rapidly, can give

dangerous handling, and can worsen fuel

consumption.

Every three months,

raise each wheel off

the ground and turn it

slowly between your

36

6B. Every few weeks, examine the tyre treads for wear using a

tread-depth gauge. This will help you keep safe and on the

right side of the law!

Check treads visually

every time you check

the pressures.

Page 53 of 171

PART F: STEERING AMD SUSPENSION

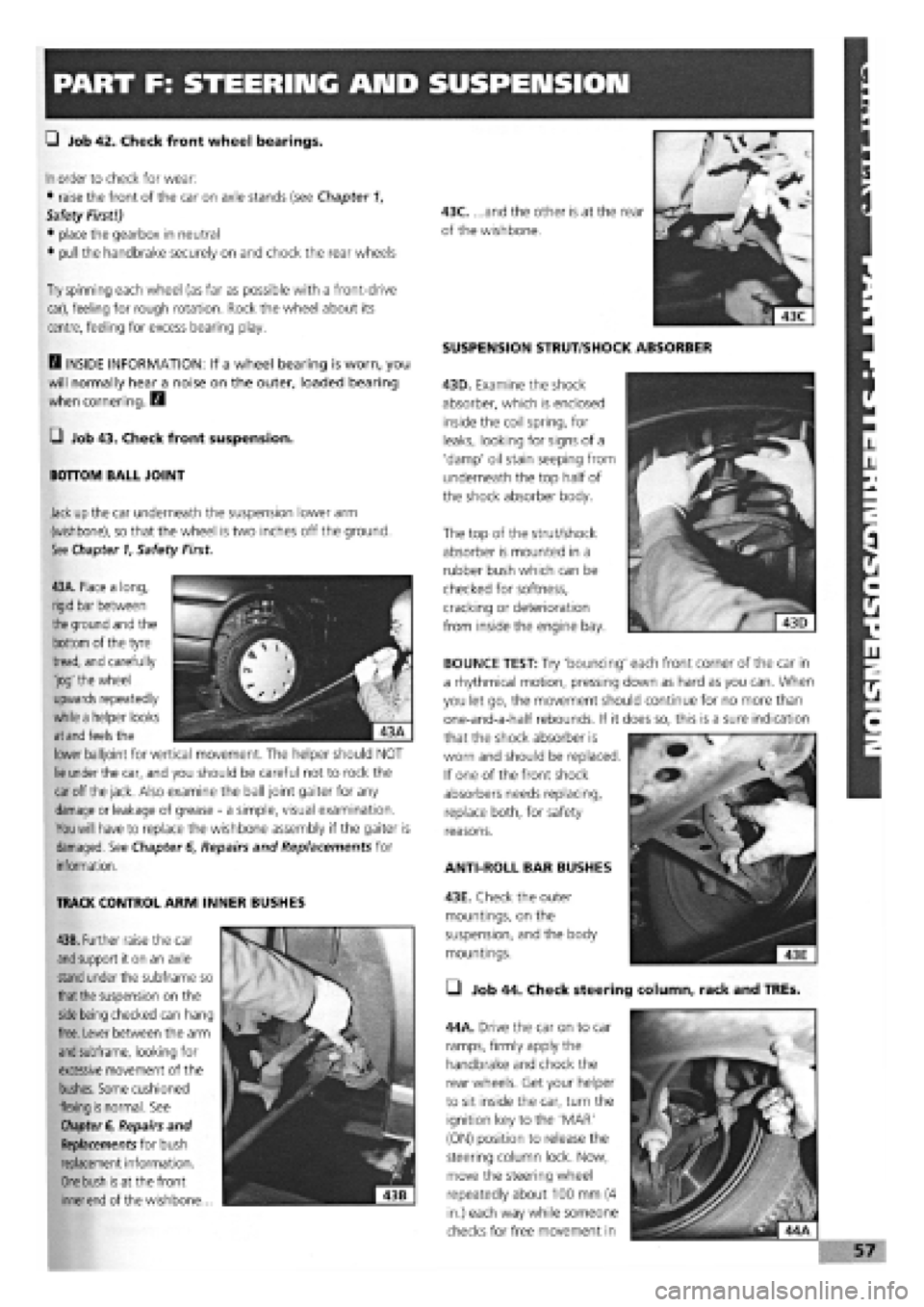

G Job 42. Check front wheel bearings.

In

order to check for wear:

• raise the front of the car on axle stands (see Chapter 1,

Safety First!)

• place the gearbox in neutral

• pull the handbrake securely on and chock the rear wheels

Try

spinning each wheel (as far as possible with a front-drive

car), feeling for rough rotation. Rock the wheel about its

centre, feeling for excess bearing play.

D INSIDE INFORMATION: If a wheel bearing is worn, you

will normally hear a noise on the outer, loaded bearing

when cornering. D

G Job 43. Check front suspension.

BOTTOM BALL JOINT

Jack

up

the car underneath the suspension lower arm

(wishbone), so that the wheel is two inches off the ground.

See Chapter

1,

Safety First.

SUSPENSION STRUT/SHOCK ABSORBER

43D. Examine the shock

absorber, which is enclosed

inside the coil spring, for

leaks, looking for signs of a

'damp' oil stain seeping from

underneath the top half of

the shock absorber body.

The top of the strut/shock

absorber is mounted in a

rubber bush which can be

checked for softness,

cracking or deterioration

from inside the engine bay.

43A. Place a long,

rigid bar between

the

ground and the

bottom of the tyre

tread, and carefully

'jog' the wheel

upwards repeatedly

while a helper looks

at and

feels the

lower balljoint for vertical movement. The helper should NOT

lie

under the car, and you should be careful not to rock the

car

off

the jack.

Also examine the ball joint gaiter for any

damage

or leakage of grease

-

a simple, visual examination.

You will

have to replace the wishbone assembly if the gaiter is

damaged. See Chapter

6,

Repairs and Replacements for

information.

TRACK CONTROL ARM INNER BUSHES

43B. Further raise the car

and

support it on an axle

stand

under the subframe so

that the

suspension on the

side being

checked can hang

free. Lever between the arm

and

subframe, looking for

excessive movement of the

bushes. Some cushioned

flexing

is

normal. See

Chapter

6, Repairs and

Replacements for bush

replacement information.

One bush is

at the front

inner end

of the wishbone...

ANTI-ROLL BAR BUSHES

43E. Check the outer

mountings, on the

suspension, and the body

mountings.

• Job 44. Check steering column, rack and TREs.

44A. Drive the car on to car

ramps, firmly apply the

handbrake and chock the

rear wheels. Get your helper

to sit inside the car, turn the

ignition key to the 'MAR'

(ON) position to release the

steering column lock. Now,

move the steering wheel

repeatedly about 100 mm (4

in.) each way while someone

checks for free movement in

BOUNCE TEST: Try 'bouncing' each front corner of the car in

a rhythmical motion, pressing down as hard as you can. When

you let go, the movement should continue for no more than

one-and-a-half rebounds. If it does so, this is a sure indication

that the shock absorber is

worn and should be replaced.

If one of the front shock

absorbers needs replacing,

replace both, for safety

reasons.

Page 54 of 171

each track rod end (TRE). Also, look out for a split gaiter.

Replace the TRE if the gaiter is split, or it will rapidly fail.

E3 INSIDE INFORMATION: Try placing your hand over the

TRE as the steering is moved. If there are any signs of

wear, replace the TRE. Q

STEERING COLUMN

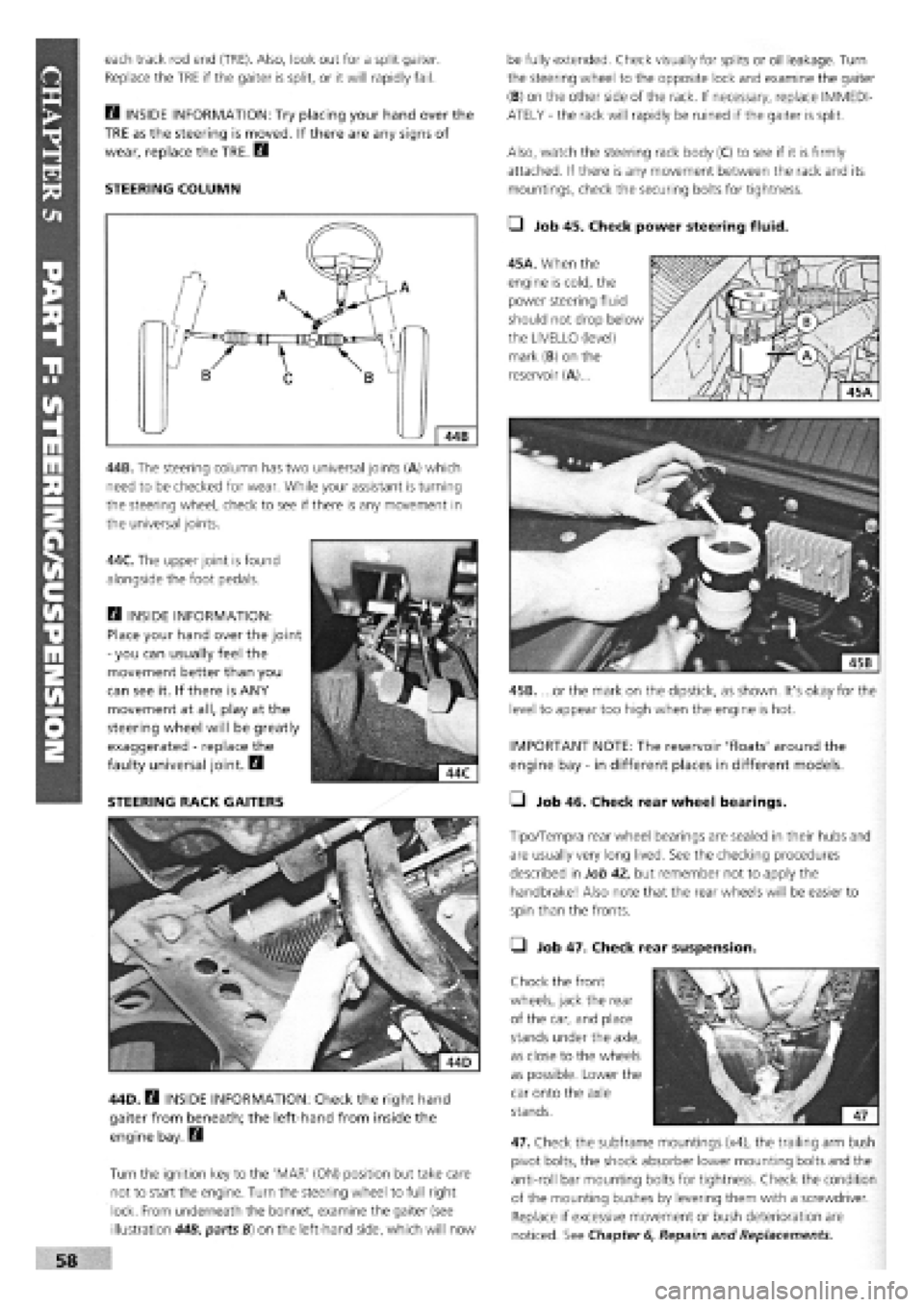

44B. The steering column has two universal joints (A) which

need to be checked for wear. While your assistant is turning

the steering wheel, check to see if there is any movement in

the universal joints.

44C. The upper joint is found

alongside the foot pedals.

Q INSIDE INFORMATION:

Place your hand over the joint

-

you can usually feel the

movement better than you

can see it. If there is ANY

movement at all, play at the

steering wheel will be greatly

exaggerated

-

replace the

faulty universal joint. B

STEERING RACK GAITERS

44D. B INSIDE INFORMATION: Check the right hand

gaiter from beneath; the left-hand from inside the

engine bay. Q

Turn the ignition key to the 'MAR' (ON) position but take care

not to start the engine. Turn the steering wheel to full right

lock. From underneath the bonnet, examine the gaiter (see

illustration 44B, parts B) on the left-hand side, which will now

be fully extended. Check visually for splits or oil leakage. Turn

the steering wheel to the opposite lock and examine the gaiter

(B) on the other side of the rack. If necessary, replace IMMEDI-

ATELY

-

the rack will rapidly be ruined if the gaiter is split.

Also, watch the steering rack body (C) to see if it is firmly

attached. If there is any movement between the rack and its

mountings, check the securing bolts for tightness.

• Job 45. Check power steering fluid.

45A. When the

engine is cold, the

power steering fluid

should not drop below

the LIVELLO (level)

mark (B) on the

reservoir (A)...

45B. ...or the mark on the dipstick, as shown. It's okay for the

level to appear too high when the engine is hot.

IMPORTANT NOTE: The reservoir 'floats' around the

engine bay

-

in different places in different models.

• Job 46. Check rear wheel bearings.

Tipo/Tempra rear wheel bearings are sealed in their hubs and

are usually very long lived. See the checking procedures

described in Job 42, but remember not to apply the

handbrake! Also note that the rear wheels will be easier to

spin than the fronts.

• Job 47. Check rear suspension.

Chock the front

wheels, jack the rear

of the car, and place

stands under the axle,

as close to the wheels

as possible. Lower the

car onto the axle

stands.

47. Check the subframe mountings (x4), the trailing arm bush

pivot bolts, the shock absorber lower mounting bolts and the

anti-roll bar mounting bolts for tightness. Check the condition

of the mounting bushes by levering them with a screwdriver.

Replace if excessive movement or bush deterioration are

noticed. See Chapter

6,

Repairs and Replacements.

Page 60 of 171

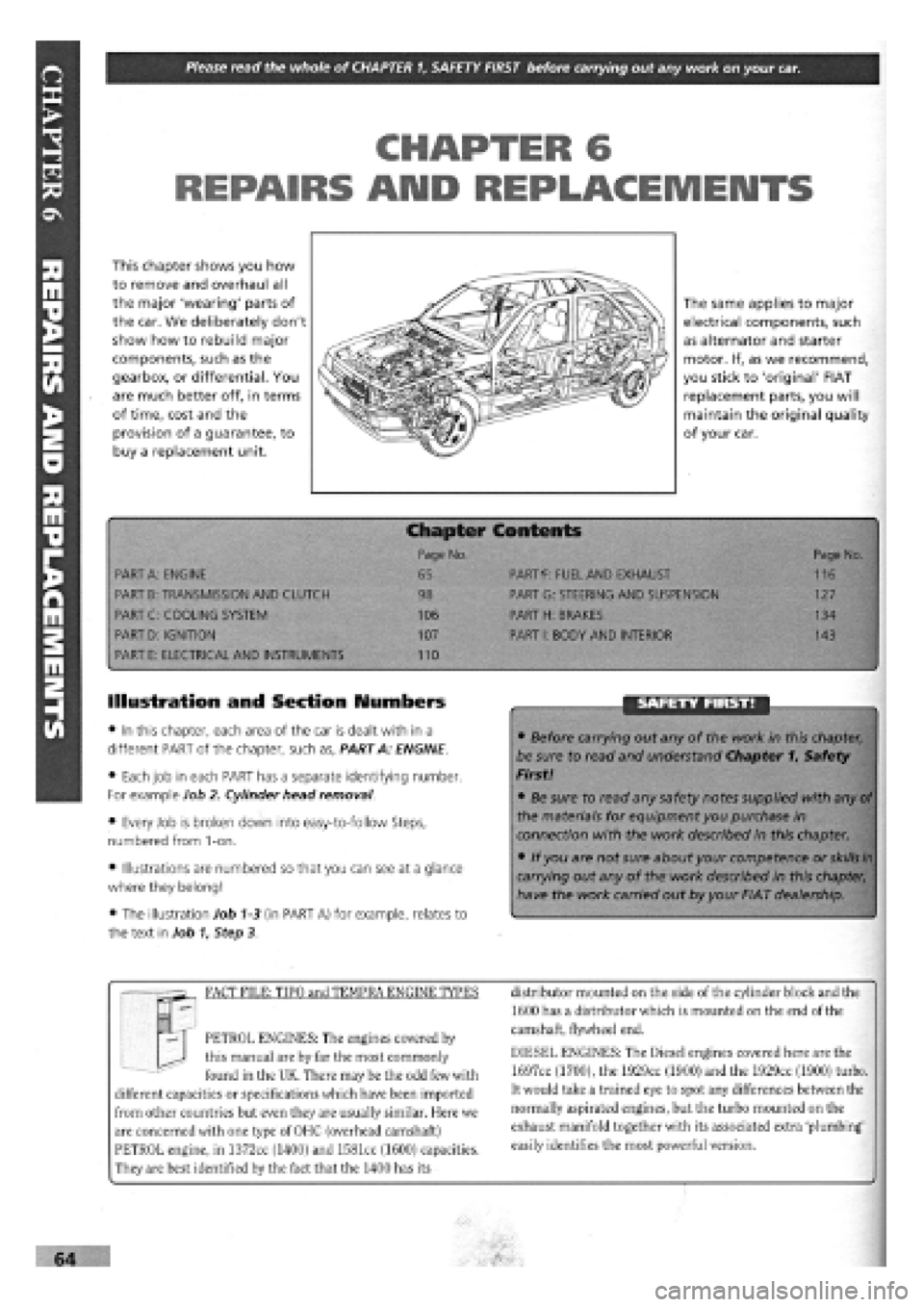

Please read the whole of CHAPTER

1,

SAFETY FIRST before carrying out any work on your car.

CHAPTER 6

REPAIRS AND REPLACEMENTS

This chapter shows you how

to remove and overhaul all

the major 'wearing' parts of

the car. We deliberately don't

show how to rebuild major

components, such as the

gearbox, or differential. You

are much better off, in terms

of time, cost and the

provision of a guarantee, to

buy a replacement unit.

The same applies to major

electrical components, such

as alternator and starter

motor. If, as we recommend,

you stick to 'original' FIAT

replacement parts, you will

maintain the original quality

of your car.

PART A: ENGINE

PART B: TRANSMISSION AND CLUTCH

PART C: COOLING SYSTEM

PART D: IGNITION

PART E: ELECTRICAL AND INSTRUMENTS

:er Contents

PARTf: FUEL AND EXHAUST

PART G: STEERING AND SUSPENSION

PART H: BRAKES

PART I: BODY AND INTERIOR

110

Page No.

116

127

134

143

Illustration and Section Numbers

• In this chapter, each area of the car is dealt with in a

different PART of the chapter, such as, PART A: ENGINE.

• Each job in each PART has a separate identifying number.

For example Job 2. Cylinder head removal.

• Every Job is broken down into easy-to-follow Steps,

numbered from 1-on.

• Illustrations are numbered so that you can see at a glance

where they belong!

• The illustration Job

1-3

(in PART A) for example, relates to

the text in Job 1, Step 3.

SAFETY FIRST!

• Before carrying out any of the work in this chapter,

be sure to read and understand Chapter 1, Safety

First!

• Be sure to read any safety notes supplied with any

of

the materials for equipment you purchase in

connection with the work described in this chapter.

• If you are not sure about your competence or

skills in

carrying out any of the work described in this chapter,

have the work carried out by your FIAT dealership.

FACT FILE: TIPO and TEMPRA ENGINE TYPES

PETROL ENGINES: The engines covered by

this manual are by far the most commonly

found in the UK. There may be the odd few with

different capacities or specifications which have been imported

from other countries but even they are usually similar. Here we

are concerned with one type of OHC (overhead camshaft)

PETROL engine, in 1372cc (1400) and 1581cc (1600) capacities.

They are best identified by the fact that the 1400 has its

distributor mounted on the side of the cylinder block and the

1600 has a distributor which is mounted on the end of the

camshaft, flywheel end.

DIESEL ENGINES: The Diesel engines covered here are the

1697cc (1700), the 1929cc (1900) and the 1929cc (1900) turbo.

It would take a trained eye to spot any differences between the

normally aspirated engines, but the turbo mounted on the

exhaust manifold together with its associated extra 'plumbing'

easily identifies the most powerful version.