fuse FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 3 of 171

Mains Electricity

Avoid the use of mains electricity when working on the vehicle,

whenever possible. Use rechargeable tools and a DC inspection

lamp, powered from a remote 12V battery

-

both are much

safer. However, if you do use mains-powered equipment,

ensure that the appliance is wired correctly to its plug, that

where necessary it is properly earthed (grounded), and that the

fuse is of the correct rating for the appliance. Do not use any

mains powered equipment in damp conditions or in the vicinity

of fuel, fuel vapour or the vehicle battery.

Always use an RCD (Residual Current Device) circuit breaker

with mains electricity. Then, if there is a short, the RCD circuit

breaker minimises the risk of electrocution by instantly cutting

the power supply.

Ignition System

Never work on the ignition system with the ignition switched

on, or with the engine being turned over on the starter, or

running and you are recommended never to do so.

Touching certain parts of the ignition system, such as the HT

leads, distributor cap, ignition coil etc., can result in a severe

electric shock or physical injury as a hand is pulled sharply away.

Voltages produced by electronic ignition systems are much

higher than those produced by conventional systems and could

prove fatal, particularly to people with cardiac pacemaker

implants. Consult your handbook or main dealer if in any

doubt.

Cooling Fan

On many vehicles, the electric cooling fan can switch itself on

even with the ignition turned off. This is especially likely after

driving the car and parking it before turning off, after which

heat rises to the top of the engine and turns the fan on,

suddenly and without warning. If you intend working in the

engine bay, it's best to do so when the engine is cold, to

disconnect the battery, or keep away from the fan, if neither of

these are possible.

Battery

Never cause a spark, smoke, or allow a naked light near the

vehicle's battery, even in a well ventilated area. Highly explosive

hydrogen gas is given off as part of the charging process.

Battery terminals on the car should be shielded, since a spark

can be caused by any metal object which touches the battery's

terminals or connecting straps.

IMPORTANT NOTE: Before disconnecting the battery earth

(ground) terminal read the relevant FACT FILE in Chapter 5

regarding saving computer and radio settings.)

When using a battery charger, switch off the power supply

before the battery charger leads are connected or disconnected.

If the battery is not of the 'sealed-for-life' type, loosen the filler

plugs or remove the cover before charging. For best results the

battery should be given a low rate trickle charge overnight. Do

not charge at an excessive rate or the battery may burst.

Always wear gloves and goggles when carrying or when

topping up the battery. Acid electrolyte is extremely corrosive

and must not be allowed to contact the eyes, skin or clothes.

Brakes and Asbestos

Obviously, a car's brakes are among its most important safety

related items. ONLY work on your vehicle's braking system if

you are trained and competent to do so. If you have not been

trained in this work, but wish to carry out the jobs described in

this book, we strongly recommend that you have a garage or

qualified mechanic check your work before using the car.

Whenever you work on the braking system components, or

remove front or rear brake pads or shoes: i) wear an efficient

particle mask; ii) wipe off all brake dust from the brakes after

spraying on a proprietary brand of brake cleaner (never blow

dust off with compressed air); iii) dispose of brake dust and

discarded shoes or pads in a sealed plastic bag; iv) wash your

hands thoroughly after you have finished working on the

brakes and certainly before you eat or smoke; v) replace shoes

and pads only with asbestos-free shoes or pads. Note that

asbestos brake dust can cause cancer if inhaled; vi) always

replace brake pads and/or shoes in complete 'axle' sets of four

-

never replace the pads/shoes on one wheel only.

Brake Fluid

Brake fluid absorbs moisture rapidly from the air and can

become dangerous resulting in brake failure. You should

change the fluid in accordance with your vehicle manufacturer's

recommendations or as advised in this book. Never store (or

use) an opened container of brake fluid. Dispose of the

remainder at your Local Authority Waste Disposal Site, in the

designated disposal unit, not with general waste or with waste

oil.

Engine Oils

Always wear disposable plastic or rubber gloves when draining

the oil from your engine, i) Note that the drain plug and the oil

are often hotter than you expect. Wear gloves if the plug is too

hot to touch and keep your hand to one side so that you are

not scalded by the spurt of oil as the plug comes away; ii) There

are very real health hazards associated with used engine oil. In

the words of one manufacturer's handbook "Prolonged and

repeated contact may cause serious skin disorders, including

dermatitis and cancer." Use a barrier cream on your hands and

try not to get oil on them. Always wear gloves and wash your

hands with hand cleaner soon after carrying out the work. Keep

oil out of the reach of children; iii) NEVER, EVER dispose of old

engine oil into the ground or down a drain. In the UK, and in

most EC countries, every local authority must provide a safe

means of oil disposal. In the UK, try your local Environmental

Health Department for advice on waste disposal facilities.

Plastic Materials

Many of the materials used (polymers, resins, adhesives and

materials acting as catalysts and accelerators) contain dangers in

the form of poisonous fumes, skin irritants, and the risk of fire

Page 6 of 171

• Repeat this operation three more times until the

complete code number has been entered, if the code

has been entered in correctly LED B will start flashing.

• Release button A (see illustration

1B).

Red LED B

flashes for 8 seconds indicating the new remote unit's

code has been stored.

IMPORTANT NOTE: If the LED does not illuminate

when remote unit button (illustration 1B, button

O is pressed, change the remote unit's battery.

• Insert the emergency key A into the emergency switch

slot in the glove compartment turn the key to the left to

switch the alarm off (see inset).

• Turn the key back towards its original position to

switch the alarm system back on.

IMPORTANT NOTE: As the alarm system absorbs

energy, if you are not planning on using the car

for a long period of time, turn the alarm exclusion

key to the off position, so as not to run the vehicle

battery down.

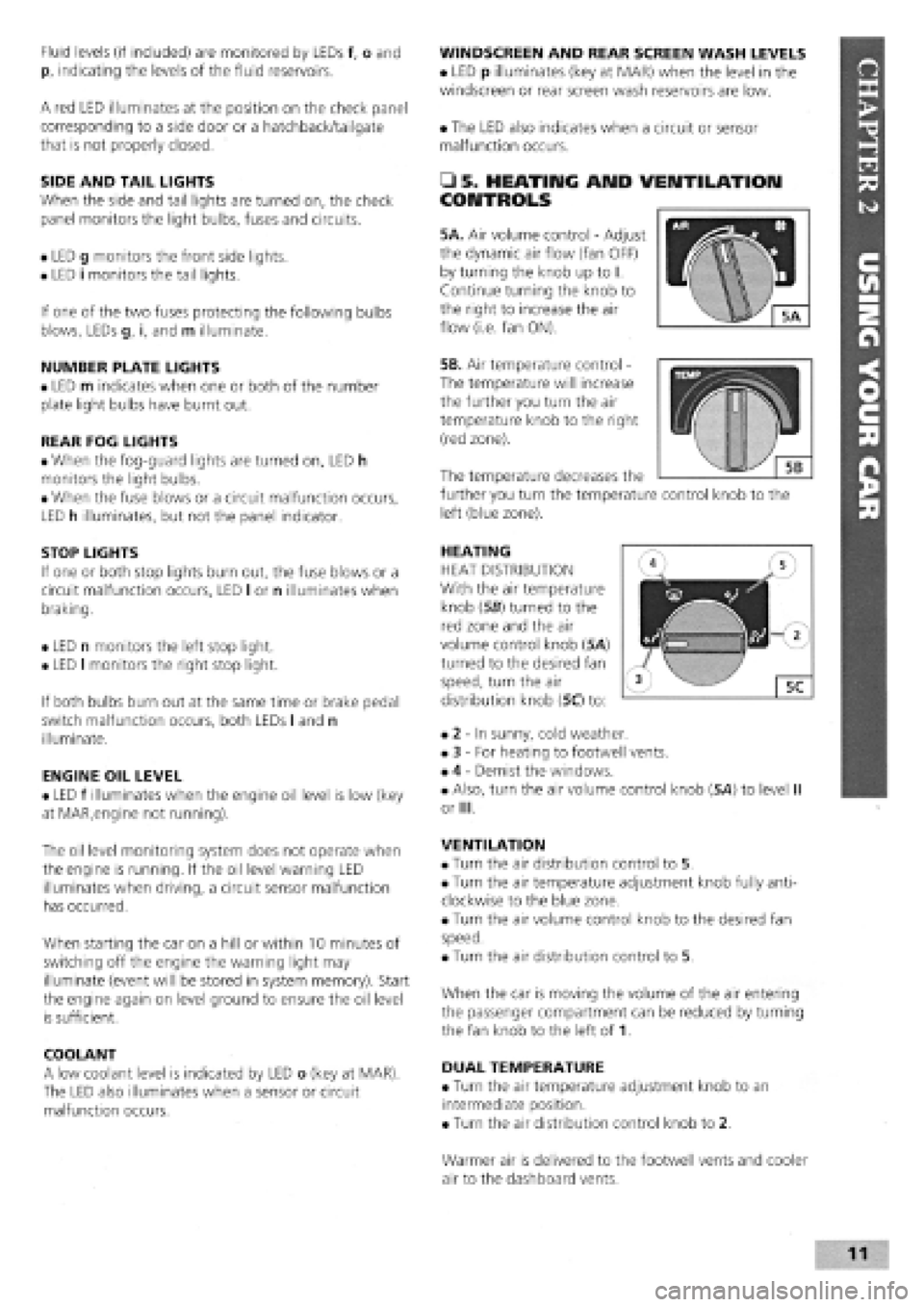

• 2. IGNITION SWITCH AND

STEERING COLUMN LOCK

IGNITION SWITCH

2. The ignition/steering column lock key, once inserted

in the ignition lock, can be placed in any of the

following four positions:

• PARK

-

With the key in this

position the side and tail lights

can be turned on, the steering

column locked and the keys

can be removed. Press button

A to turn the key to PARK.

• STOP

-

When the key is

turned to the STOP position the steering column will be

locked, and the keys can be removed.

• MAR

-

This is the driving position. When the key is in

this position all the electrical devices are energised.

• AW

-

Turning the key to this position starts the

engine.

STEERING COLUMN LOCK

• LOCKING

-

To apply the steering wheel lock turn the

steering wheel slightly to the left or right when the key is

at STOP or PARK.

• UNLOCKING

-

Rocking the steering wheel gently back

and forth while turning the ignition key to MAR unlocks

the steering wheel.

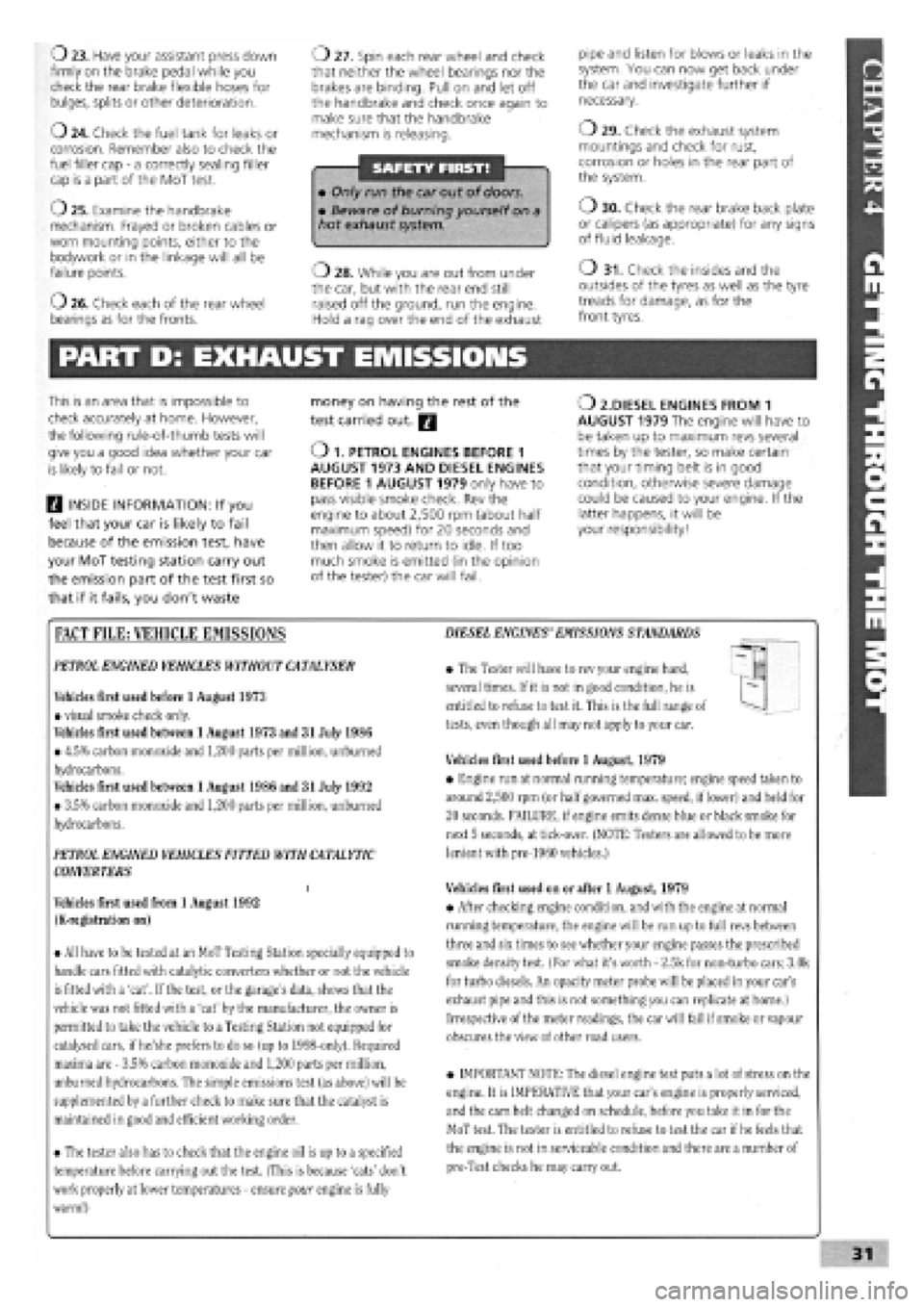

• 3. PANEL INDICATORS

INSTRUMENT DISPLAY PANEL

3. These are the instrument panel warning LED indicators

for all FIAT Tipo/Tempra models. Your vehicle will only

have Panel Indicators relevant to your particular car.

• 4. ELECTRONIC CHECK PANEL

4. The electronic check panel is not fitted to models

with basic trim.

IMPORTANT NOTE: The check panel will not

indicate if the tail light fuses blow at the same

time, or if there is a circuit failure within the panel

display.

SIDE AND HATCHBACK DOORS

When the ignition key is at MAR, the check panel LEDs

g, h, i, I, m and n monitor the light bulbs and fuses.

LEDs a, b, c, d, and e monitor incomplete closure of

the side doors and hatchback.

• Never remove the key when the car is moving.

If you do, the steering wheel will lock the first

time you turn it.

• If the ignition lock has been tampered with or

shows any sign of damage (e.g. attempted theft),

have the lock checked at your nearest FIAT

Service Centre.

M Choke Oil pressure warning

Direction indicators (®) Handbrake engaged

-X: Side lights m Rear window defroster

10 High beam head

lights '•y Injection system warning light

<1* Rear fog lights • Battery warning

A Hazard warning lights A Seat belts not

buckled

m ABS brake warning a Automatic transmission fluid warning

o Brake pad wear warning a Doors not properly closed

Turbo pressure warning Trailer direction indicators

10 Front fog lights a Diesel fuel filter condenstate warning

•515" Diesel heater/glow •515" plugs 3

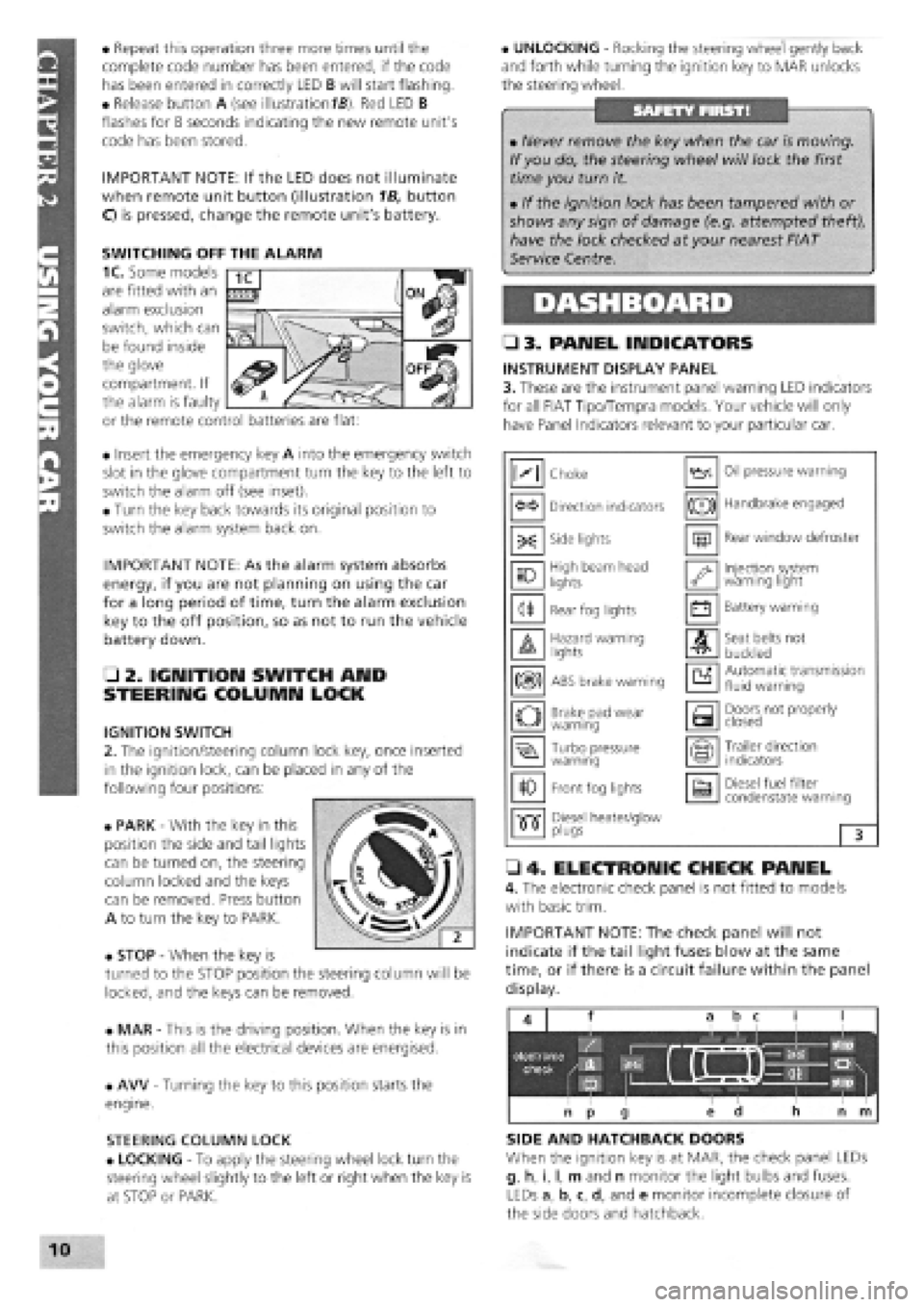

SWITCHING OFF THE ALARM

1C. Some models

are fitted with an

alarm exclusion

switch, which can

be found inside

the glove

compartment. If

the alarm is faulty

or the remote control batteries are flat:

Page 7 of 171

Fluid levels (if included) are monitored by LEDs f, o and

p, indicating the levels of the fluid reservoirs.

A red LED illuminates at the position on the check panel

corresponding to a side door or a hatchback/tailgate

that is not properly closed.

SIDE AND TAIL LIGHTS

When the side and tail lights are turned on, the check

panel monitors the light bulbs, fuses and circuits.

• LED g monitors the front side lights.

• LED i monitors the tail lights.

If one of the two fuses protecting the following bulbs

blows, LEDs g, i, and m illuminate.

NUMBER PLATE LIGHTS

• LED m indicates when one or both of the number

plate light bulbs have burnt out.

REAR FOG LIGHTS

• When the fog-guard lights are turned on, LED h

monitors the light bulbs.

• When the fuse blows or a circuit malfunction occurs,

LED h illuminates, but not the panel indicator.

STOP LIGHTS

If one or both stop lights burn out, the fuse blows or a

circuit malfunction occurs, LED I or n illuminates when

braking.

• LED n monitors the left stop light.

• LED I monitors the right stop light.

If both bulbs burn out at the same time or brake pedal

switch malfunction occurs, both LEDs I and n

illuminate.

ENGINE OIL LEVEL

• LED f illuminates when the engine oil level is low (key

at MAR,engine not running).

The oil level monitoring system does not operate when

the engine is running. If the oil level warning LED

illuminates when driving, a circuit sensor malfunction

has occurred.

When starting the car on a hill or within 10 minutes of

switching off the engine the warning light may

illuminate (event will be stored in system memory). Start

the engine again on level ground to ensure the oil level

is sufficient.

COOLANT

A low coolant level is indicated by LED o (key at MAR).

The LED also illuminates when a sensor or circuit

malfunction occurs.

WINDSCREEN AND REAR SCREEN WASH LEVELS

• LED p illuminates (key at MAR) when the level in the

windscreen or rear screen wash reservoirs are low.

• The LED also indicates when a circuit or sensor

malfunction occurs.

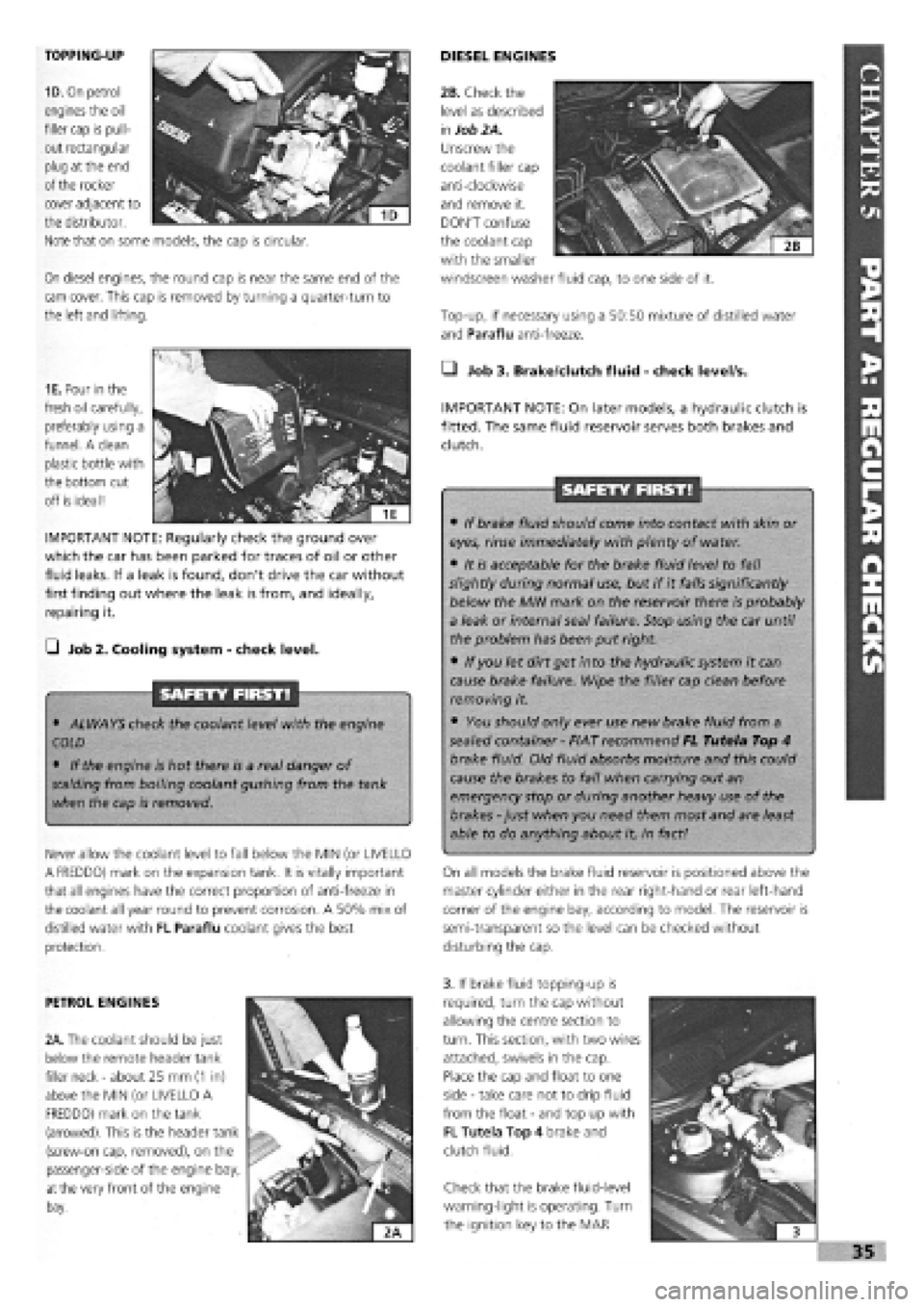

• 5. HE ATI IMG AMD VENTILATION

CONTROLS

5A. Air volume control

-

Adjust

the dynamic air flow (fan OFF)

by turning the knob up to I.

Continue turning the knob to

the right to increase the air

flow (i.e. fan ON).

5B. Air temperature control -

The temperature will increase

the further you turn the air

temperature knob to the right

(red zone).

HEATING

HEAT DISTRIBUTION

With the air temperature

knob (56) turned to the

red zone and the air

volume control knob (5A)

turned to the desired fan

speed, turn the air

distribution knob (5C) to:

• 2

-

In sunny, cold weather.

• 3

-

For heating to footwell vents.

• 4

-

Demist the windows.

• Also, turn the air volume control knob (5A) to level II

or III.

VENTILATION

• Turn the air distribution control to 5.

• Turn the air temperature adjustment knob fully anti-

clockwise to the blue zone.

• Turn the air volume control knob to the desired fan

speed.

• Turn the air distribution control to 5.

When the car is moving the volume of the air entering

the passenger compartment can be reduced by turning

the fan knob to the left of 1.

DUAL TEMPERATURE

• Turn the air temperature adjustment knob to an

intermediate position.

• Turn the air distribution control knob to 2.

The temperature decreases the

further you turn the temperature control knob to the

left (blue zone).

Warmer air is delivered to the footwell vents and cooler

air to the dashboard vents.

Page 27 of 171

O 23. Have your assistant press down firmly on the brake pedal while you check the rear brake flexible hoses for bulges, splits or other deterioration.

o 24. Check the fuel tank for leaks or corrosion. Remember also to check the fuel filler cap

-

a correctly sealing filler cap is a part of the MoT test.

O 25. Examine the handbrake mechanism. Frayed or broken cables or worn mounting points, either to the bodywork or in the linkage will all be failure points.

o 26. Check each of the rear wheel

bearings as for the fronts.

o 27. Spin each rear wheel and check that neither the wheel bearings nor the brakes are binding. Pull on and let off the handbrake and check once again to make sure that the handbrake mechanism is releasing.

SAFETY FIRST!

• Only run the car out of doors.

• Beware of burning yourself on a hot exhaust system.

o 28. While you are out from under the car, but with the rear end still raised off the ground, run the engine. Hold a rag over the end of the exhaust

pipe and listen for blows or leaks in the system. You can now get back under the car and investigate further if necessary.

o 29. Check the exhaust system mountings and check for rust, corrosion or holes in the rear part of the system.

o 30. Check the rear brake back plate or calipers (as appropriate) for any signs of fluid leakage.

o 31. Check the insides and the outsides of the tyres as well as the tyre treads for damage, as for the front tyres.

PART D: EXHAUST EMISSIONS

This is an area that is impossible to

check accurately at home. However,

the following rule-of-thumb tests will

give you a good idea whether your car

is likely to fail or not.

H INSIDE INFORMATION: If you

feel that your car is likely to fail

because of the emission test, have

your MoT testing station carry out

the emission part of the test first so

that if it fails, you don't waste

money on having the rest of the

test carried out. Q

O 1. PETROL ENGINES BEFORE 1 AUGUST 1973 AND DIESEL ENGINES BEFORE 1 AUGUST 1979 only have to pass visible smoke check. Rev the engine to about 2,500 rpm (about half maximum speed) for 20 seconds and then allow it to return to idle. If too much smoke is emitted (in the opinion of the tester) the car will fail.

O 2.DIESEL ENGINES FROM 1 AUGUST 1979 The engine will have to be taken up to maximum revs several times by the tester, so make certain that your timing belt is in good condition, otherwise severe damage could be caused to your engine. If the latter happens, it will be your responsibility!

FACT FILE: VEHICLE EMISSIONS

PETROL

ENGINED VEHICLES WITHOUT

CATALYSER

Vehicles first used before 1 August 1973

• visual smoke check only.

Vehicles first used between 1 August 1973 and 31 July 1986

• 4.5% carbon monoxide and 1,200 parts per million, unburned

hydrocarbons.

Vehicles first used between 1 August 1986 and 31 July 1992

• 3.5% carbon monoxide and 1,200 parts per million, unburned

hydrocarbons.

PETROL ENGINED VEHICLES FITTED WITH

CATALYTIC

CONVERTERS

i

Vehicles first used from 1 August 1992

(K-registration on)

• All have to be tested at an MoT Testing Station specially equipped to

handle cars fitted with catalytic converters whether or not the vehicle

is fitted with a 'cat'. If

the

test, or the garage's data, shows that the

vehicle was not fitted with a 'cat' by the manufacturer, the owner is

permitted to take the vehicle to

a

Testing Station not equipped for

catalysed cars, if he/she prefers to do so (up to 1998-only). Required

maxima are

-

3.5% carbon monoxide and 1,200 parts per million,

unburned hydrocarbons. The simple emissions test (as above) will be

supplemented by a further check to make sure that the catalyst is

maintained in

good

and efficient working order.

• The tester also has to check that the engine oil is up to a specified

temperature before carrying out the test. (This is because 'cats' don't

work properly at lower temperatures

-

ensure your engine is fully

warm!)

DIESEL ENGINES'EMISSIONS

STANDARDS

• The Tester will have to rev your engine hard,

several times. If it is not in good condition, he is

entitled to refuse to test it. This is the full range of

tests, even though all may not apply to your car.

Vehicles first used before 1 August, 1979

• Engine run at normal running temperature; engine speed taken to

around 2,500 rpm (or half

governed

max. speed, if lower) and held for

20 seconds. FAILURE, if engine emits dense blue or black smoke for

next 5 seconds, at tick-over. (NOTE: Testers are allowed to be more

lenient with pre-1960 vehicles.)

Vehicles first used on or after 1 August, 1979

• After checking engine condition, and with the engine at normal

running temperature, the engine will be run up to full revs between

three and six times to see whether your engine passes the prescribed

smoke density test. (For what it's worth

-

2.5k for non-turbo cars; 3.0k

for turbo diesels. An opacity meter probe will be placed in your car's

exhaust pipe and this is not something you can replicate at home.)

Irrespective of the meter readings, the car will fail if

smoke

or vapour

obscures the view of other road users.

• IMPORTANT NOTE: The diesel engine test puts a lot of stress on the

engine. It is IMPERATIVE that your car's engine is properly serviced,

and the cam belt changed on schedule, before you take it in for the

MoT test. The tester is entitled to refuse to test the car if

he

feels that

the engine is not in serviceable condition and there are a number of

pre-Test checks he may carry out.

Page 31 of 171

TOPPING-UP

1D. On petrol

engines the oil

filler cap is pull-

out rectangular

plug at the end

of the rocker

On diesel engines, the round cap is near the same end of the

cam cover. This cap is removed by turning a quarter-turn to

the left and lifting.

DIESEL ENGINES

Top-up, if necessary using a 50:50 mixture of distilled water

and Paraflu anti-freeze.

cover adjacent to

the distributor.

Note that on some models, the cap is circular.

1E. Pour in the

fresh oil carefully,

preferably using a

funnel. A clean

plastic bottle with

the bottom cut

off is ideal!

IMPORTANT NOTE: Regularly check the ground over

which the car has been parked for traces of oil or other

fluid leaks. If a leak is found, don't drive the car without

first finding out where the leak is from, and ideally,

repairing it.

G Job 2. Cooling system

-

check level.

SAFETY FIRST!

• ALWAYS check the coolant level with the engine

COLD

• If the engine is hot there is a real danger of

scalding

from boiling coolant gushing from the tank

when the cap is removed.

Never allow the coolant level to fall below the MIN (or UVELLO

A FREDDO) mark on the expansion tank. It is vitally important

that all engines have the correct proportion of anti-freeze in

the coolant all year round to prevent corrosion. A 50% mix of

distilled water with FL Paraflu coolant gives the best

protection.

• Job 3. Brake/dutch fluid

-

check level/s.

IMPORTANT NOTE: On later models, a hydraulic clutch is

fitted. The same fluid reservoir serves both brakes and

clutch.

SAFETY FIRST!

• If brake fluid should come into contact with skin or

eyes, rinse immediately with plenty of water.

• It is acceptable for the brake fluid level to fall

slightly during normal use, but if it falls significantly

below the MIN mark on the reservoir there is probably

a leak or internal seal failure. Stop using the car until

the problem has been put right.

• If you let dirt get into the hydraulic system it can

cause brake failure. Wipe the filler cap clean before

removing it.

• You should only ever use new brake fluid from a

sealed container

-

FIAT recommend FL Tutela Top 4

brake fluid. Old fluid absorbs moisture and this could

cause the brakes to fail when carrying out an

emergency stop or during another heavy use of the

brakes

-

just when you need them most and are least

able to do anything about it, in fact!

On all models the brake fluid reservoir is positioned above the

master cylinder either in the rear right-hand or rear left-hand

corner of the engine bay, according to model. The reservoir is

semi-transparent so the level can be checked without

disturbing the cap.

PETROL ENGINES

2A. The coolant should be just

below the remote header tank

filler neck

-

about 25 mm

(1

in)

above the MIN (or UVELLO A

FREDDO) mark on the tank

(arrowed). This is the header tank

(screw-on cap, removed), on the

passenger-side of the engine bay,

at

the very front of the engine

bay.

3. If brake fluid topping-up is

required, turn the cap without

allowing the centre section to

turn. This section, with two wires

attached, swivels in the cap.

Place the cap and float to one

side

-

take care not to drip fluid

from the float

-

and top up with

FL Tutela Top 4 brake and

clutch fluid.

Check that the brake fluid-level

warning-light is operating. Turn

the ignition key to the MAR

I

i 3

»35

2B. Check the

level as described

in

Job 2A.

Unscrew the

coolant filler cap

anti-clockwise

and remove it.

DON'T confuse

the coolant cap

with the smaller

windscreen washer fluid cap, to one side of it.

Page 32 of 171

(ignition-ON) position and press down the button between the

two terminals on the reservoir cap

-

when fitted. The warning

light on the dash should light up. When no button is fitted,

unscrew and raise the cap (ignition key ON) to check the

warning light. Check the bulb, check the fuse, or have your

FIAT dealer repair the warning system, if faulty.

• Job 4. Battery

-

check electrolyte level.

FACT FILE: DISCONNECTING THE

BATTERY

• Many vehicles depend on a constant

power supply from the battery; with

these you find yourself in trouble if you

simply disconnect the battery. You

might find the car alarm goes off, or that the engine

management system forgets all it ever 'learned', making

the car feel odd to drive until it has re-programmed

itself. You might also find that the radio refuses to

operate until its correct security code is keyed into it.

• On cars with engine management systems and/or

coded radios, you must ensure the car has a constant

electrical supply, even with the battery removed. You

will need a separate 12 volt battery; put a self-tapping

screw into the positive lead near the battery terminal

before disconnecting it, and put a positive connection

to your other battery via this screw.

• Be EXTREMELY CAREFUL to wrap insulation tape

around the connection so that no short is caused. The

negative terminal on the other battery must be

connected to the car's bodywork.

SAFETY FIRST!

• The gas given off by a battery is highly explosive.

Never smoke, use a naked flame or allow a spark in

the battery compartment.

• Never disconnect the battery (it can cause sparking)

with the battery caps removed.

• All vehicle batteries contain sulphuric acid. If the

acid comes into contact with the skin or eyes, wash

immediately with copious amounts of cold water and

seek medjcal advice.

• Do not check the battery levels within half an hour

of the battery being charged with a separate battery

charger because the addition of fresh water could

cause electrolyte to flood out.

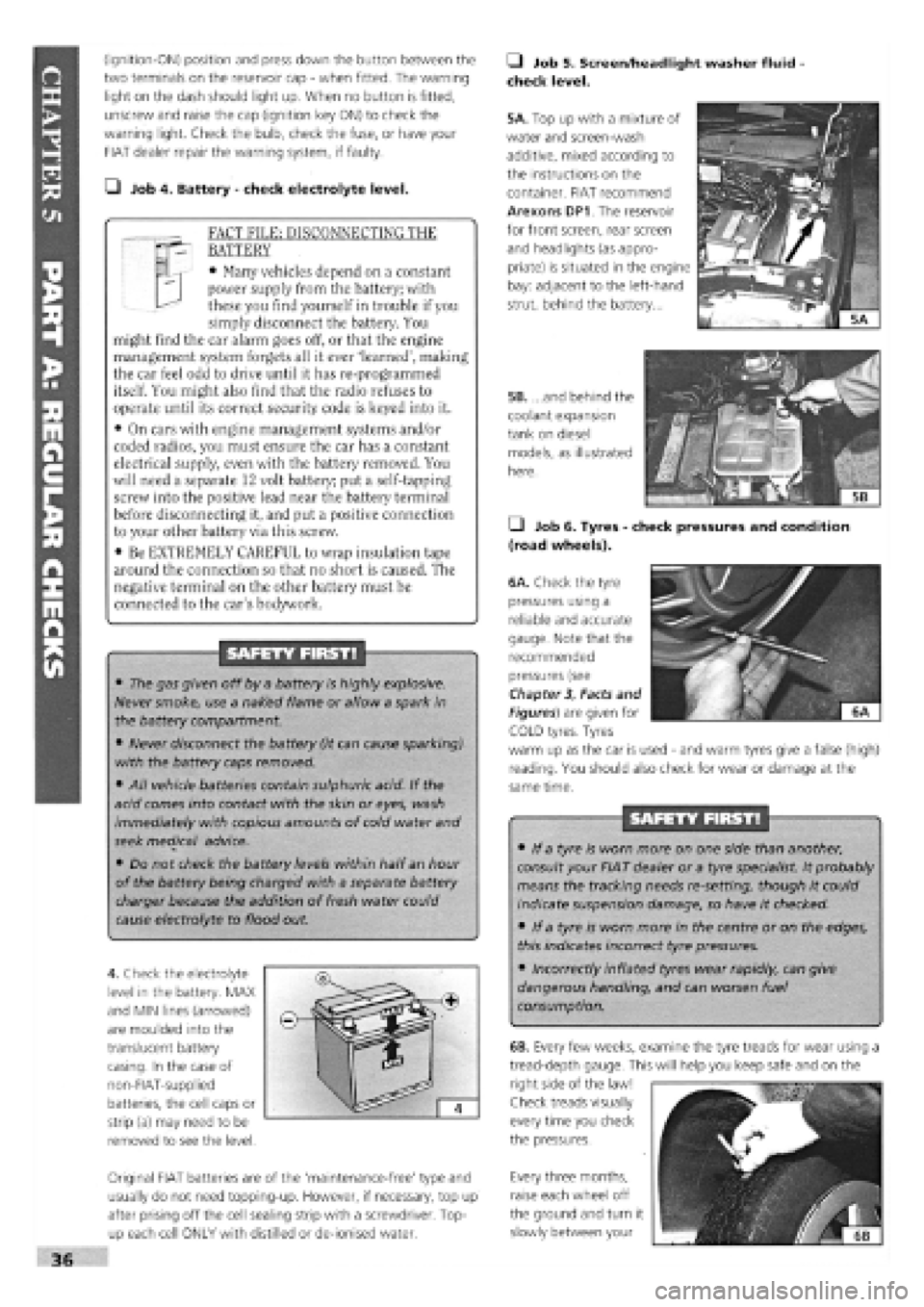

4. Check the electrolyte

level in the battery. MAX

and MIN lines (arrowed)

are moulded into the

translucent battery

casing. In the case of

non-FIAT-supplied

batteries, the cell caps or

strip (a) may need to be

removed to see the level.

Original FIAT batteries are of the 'maintenance-free' type and

usually do not need topping-up. However, if necessary, top up

after prising off the cell sealing strip with a screwdriver. Top-

up each cell ONLY with distilled or de-ionised water.

• Job 5. Screen/headlight washer fluid

check level.

5A. Top up with a mixture of

water and screen-wash

additive, mixed according to

the instructions on the

container. FIAT recommend

Arexons DP1. The reservoir

for front screen, rear screen

and headlights (as appro-

priate) is situated in the engine

bay: adjacent to the left-hand

strut, behind the battery...

5B. ...and behind the

coolant expansion

tank on diesel

models, as illustrated

here.

• Job 6. Tyres

-

check pressures and condition

(road wheels).

/

6A. Check the tyre

pressures using a

reliable and accurate

gauge. Note that the

recommended

pressures (see

Chapter

3,

Facts and

Figures) are given for ^^

iH^KKSEI ^ "'

COLD tyres. Tyres

warm up as the car is used

-

and warm tyres give a false (high)

reading. You should also check for wear or damage at the

same time.

SAFETY FIRST!

• If a tyre is worn more on one side than another,

consult your FIAT dealer or a tyre specialist. It probably

means the tracking needs re-setting, though it could

indicate suspension damage, so have it checked.

• If a tyre is worn more in the centre or on the edges,

this indicates incorrect tyre pressures.

• Incorrectly inflated tyres wear rapidly, can give

dangerous handling, and can worsen fuel

consumption.

Every three months,

raise each wheel off

the ground and turn it

slowly between your

36

6B. Every few weeks, examine the tyre treads for wear using a

tread-depth gauge. This will help you keep safe and on the

right side of the law!

Check treads visually

every time you check

the pressures.

Page 33 of 171

• Whenever a light fails to

work, check its fuse before

replacing the bulb.

• A blown bulb often causes a fuse to 'go' in

sympathy.

hands, looking and feeling for any bulges, tears or splits in the

tyre walls, especially the inner sidewalls. (See Job 59 for spare

tyre checks.)

H INSIDE INFORMATION: In time, rubber deteriorates,

increasing the risk of a blow-out. Keep your eye on the

sidewalls of older tyres. If you see any cracking, splits or

other damage scrap the tyre. If you're not sure, consult

your FIAT dealer or tyre specialist. Q

_) Job 7. Check lights/change bulbs.

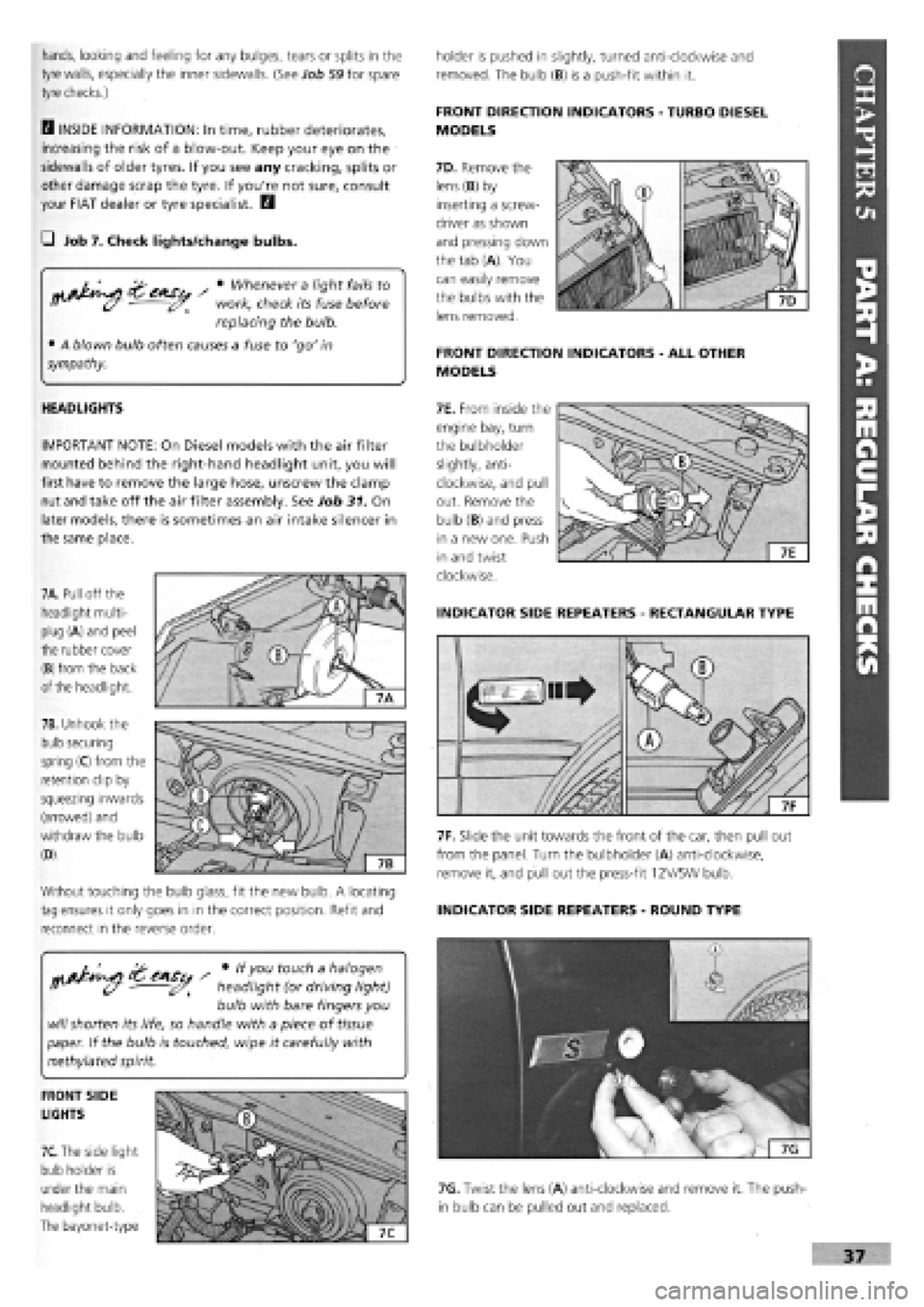

7A. Pull off the

headlight multi-

plug (A) and peel

the rubber cover

(B) from the back

of the headlight.

7B. Unhook the

bulb securing

spring (C) from the

retention clip by

squeezing inwards

(arrowed) and

withdraw the bulb

(D).

Without touching the bulb glass, fit the new bulb. A locating

tag ensures it only goes in in the correct position. Refit and

reconnect in the reverse order.

HEADLIGHTS

IMPORTANT NOTE: On Diesel models with the air filter

mounted behind the right-hand headlight unit, you will

first have to remove the large hose, unscrew the clamp

nut and take off the air filter assembly. See Job 31. On

later models, there is sometimes an air intake silencer in

the same place.

7F. Slide the unit towards the front of the car, then pull out

from the panel. Turn the bulbholder (A) anti-clockwise,

remove it, and pull out the press-fit 12V/5W bulb.

INDICATOR SIDE REPEATERS

-

ROUND TYPE

holder is pushed in slightly, turned anti-clockwise and

removed. The bulb (B) is a push-fit within it.

FRONT DIRECTION INDICATORS

-

TURBO DIESEL

MODELS

7D. Remove the

lens (B) by

inserting a screw-

driver as shown

and pressing down

the tab (A). You

can easily remove

the bulbs with the

lens removed.

FRONT DIRECTION INDICATORS

-

ALL OTHER

MODELS

7E. From inside the

engine bay, turn

the bulbholder

slightly, anti-

clockwise, and pull

out. Remove the

bulb (B) and press

in a new one. Push

in and twist

clockwise.

INDICATOR SIDE REPEATERS

-

RECTANGULAR TYPE

CAS / * touc^ a halogen

• headlight (or driving light)

bulb with bare fingers you

will

shorten its life, so handle with a piece of

tissue

paper. If the bulb is touched, wipe it carefully with

methylated spirit.

FRONT SIDE

LIGHTS

7C.

The side light

bulb holder is

under the main

headlight bulb.

The bayonet-type

7G. Twist the lens (A) anti-clockwise and remove it. The push-

in bulb can be pulled out and replaced.

Page 36 of 171

LUGGAGE COMPARTMENT LIGHT

7b. TIPO: Pull the lens

downwards to remove

it. Remove and replace

the 5W tubular bulb.

7c. TEMPRA SALOON:

From inside the boot,

lever the light unit out

of its slot with a screw-

driver. Remove and

replace the 5W tubular

bulb (A).

DASH BULBS

See Chapter 6, Repairs and Replacements for details of

instrument panel removal for access to its light bulbs. The

bulbs are a quarter-turn fit in the back of the panel.

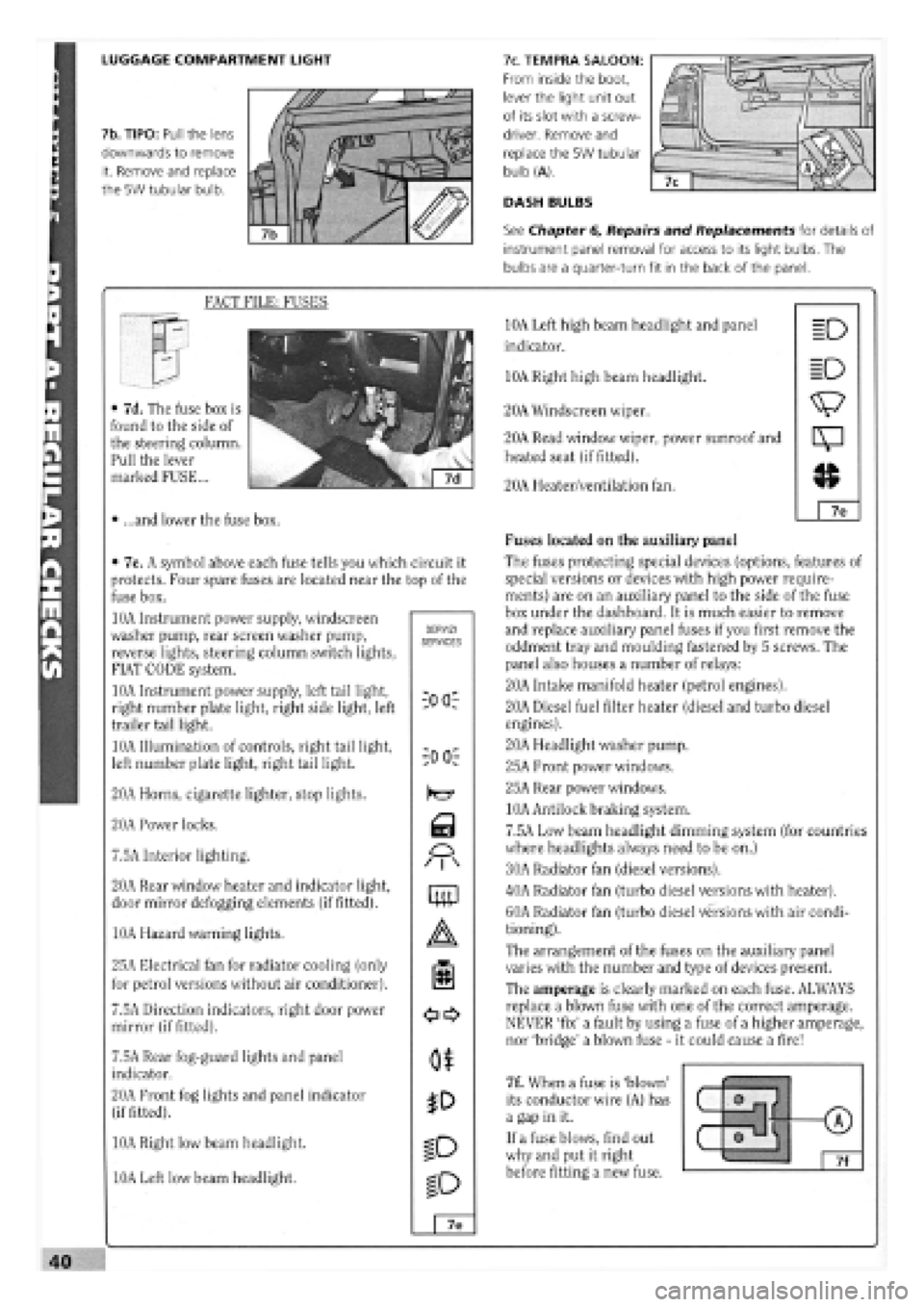

FACT FILE: FUSES

• 7d. The fuse box is

found to the side of

the steering column.

Pull the lever

marked FUSE...

• ...and lower the fuse box.

• 7e. A symbol above each fuse tells you which circuit it

protects. Four spare fuses are located near the top of the

fuse box.

10A Instrument power supply, windscreen

washer pump, rear screen washer pump,

reverse lights, steering column switch lights,

FIAT CODE system.

10A Instrument power supply, left tail light,

right number plate light, right side light, left

trailer tail light.

10A Illumination of controls, right tail light,

left number plate light, right tail light.

20A Horns, cigarette lighter, stop lights.

20A Power locks.

7.5A Interior lighting.

20A Rear window heater and indicator light,

door mirror defogging elements (if fitted).

10A Hazard warning lights.

25A Electrical fan for radiator cooling (only

for petrol versions without air conditioner).

7.5A Direction indicators, right door power

mirror (if fitted).

7.5A Rear fog-guard lights and panel

indicator.

20A Front fog lights and panel indicator

(if fitted).

10A Right low beam headlight.

10A Left low beam headlight.

SERVIZI SERVICES

iOO:

-00 r

Q

M

mp

o$

ID

ID

7e

10A Left high beam headlight and panel

indicator.

10A Right high beam headlight.

20A Windscreen wiper.

20A Read window wiper, power sunroof and

heated seat (if fitted).

20A Heater/ventilation fan.

Fuses located on the auxiliary panel

The fuses protecting special devices (options, features of

special versions or devices with high power require-

ments) are on an auxiliary panel to the side of the fuse

box under the dashboard. It is much easier to remove

and replace auxiliary panel fuses if you first remove the

oddment tray and moulding fastened by 5 screws. The

panel also houses a number of relays:

20A Intake manifold heater (petrol engines).

20A Diesel fuel filter heater (diesel and turbo diesel

engines).

20A Headlight washer pump.

25A Front power windows.

25A Rear power windows.

10A Antilock braking system.

7.5A Low beam headlight dimming system (for countries

where headlights always need to be on.)

30A Radiator fan (diesel versions).

40A Radiator fan (turbo diesel versions with heater).

60A Radiator fan (turbo diesel versions with air condi-

tioning).

The arrangement of the fuses on the auxiliary panel

varies with the number and type of devices present.

The amperage is clearly marked on each fuse. ALWAYS

replace a blown fuse with one of the correct amperage.

NEVER 'fix' a fault by using a fuse of a higher amperage,

nor 'bridge' a blown fuse

-

it could cause a fire!

7f. When a fuse is 'blown'

its conductor wire (A) has

a gap in it.

If a fuse blows, find out

why and put it right

before fitting a new fuse.

(7)

o m f (7) (7)

0 tJ 7f

Page 37 of 171

FACT FILE: FUSES contd. 7h. CERTAIN TIPO MODELS: Other

fuses are i) a set of three fuses (15A, 30A

and 40A) protecting the air conditioning,

when fitted, located in the engine bay,

near the horns (A). Press in the two sides

(arrowed) to remove the cover.

And ii) there is a 60A

fuse, located near the

fuse box, protecting

the fan on Diesel

vehicles.

7i. On latest vehicles,

there are two 10A

fuses (a) protecting

the electric petrol

pump and the

Lambda sensor

preheater. Remove

the screws (arrowed)

and the cover.

7g. TEMPRAS WITH

AIR CONDITIONING

30A The Air conditioning

system fuse is housed on

a bracket on the engine

compartment bulkhead.

The following two fuses

are located under the

front crossmember near

the right headlight.

3A High-speed radiator fan relay.

7.5A Electromagnetic air conditioner compressor clutch.

The relays housed near the fuses are part of the air

conditioner circuit.

IMPORTANT NOTE: Replace the sealed cover carefully

after changing a fuse. Ensure the gasket is correctly

positioned and the screws are fully tightened.

PART B: ENGIIME AND COOLING SYSTEM

Q Job 8. Change engine oil and filter.

SAFETY FIRST!

• Refer to the section on ENGINE OILS and RAISING

THE

CAR SAFELY in Chapter f, Safety First! before

carrying

out this work.

• You must wear plastic gloves when changing the oil.

Used

engine oil can severely irritate the skin and

is

carcinogenic.

Used diesel engine oil is an even greater

health

hazard.

•

Oil

drain plugs are often over-tightened, so take

care

that the spanner does not slip.

Take

care that the effort needed to undo the drain

plug

doesn't tip the car off its supports

-

remember to

use

wheel

chocks!

rtj&^si ' # °nly dram theu 0,7 fr°m a ff (y warm engine

-

but not

so

hot that the oil can scald!

• Allow the oil to drain for at least ten minutes before

replacing the sump plug.

• You can use this time by renewing the oil filter.

IMPORTANT NOTE: The plug is a taper-fit and can

become very tight, necessitating the use of a long drive-

bar for its removal.

H INSIDE INFORMATION: On side-mounted drain holes,

as the oil empties, the angle of 'spurt' will change, so be

prepared to move the container. E3

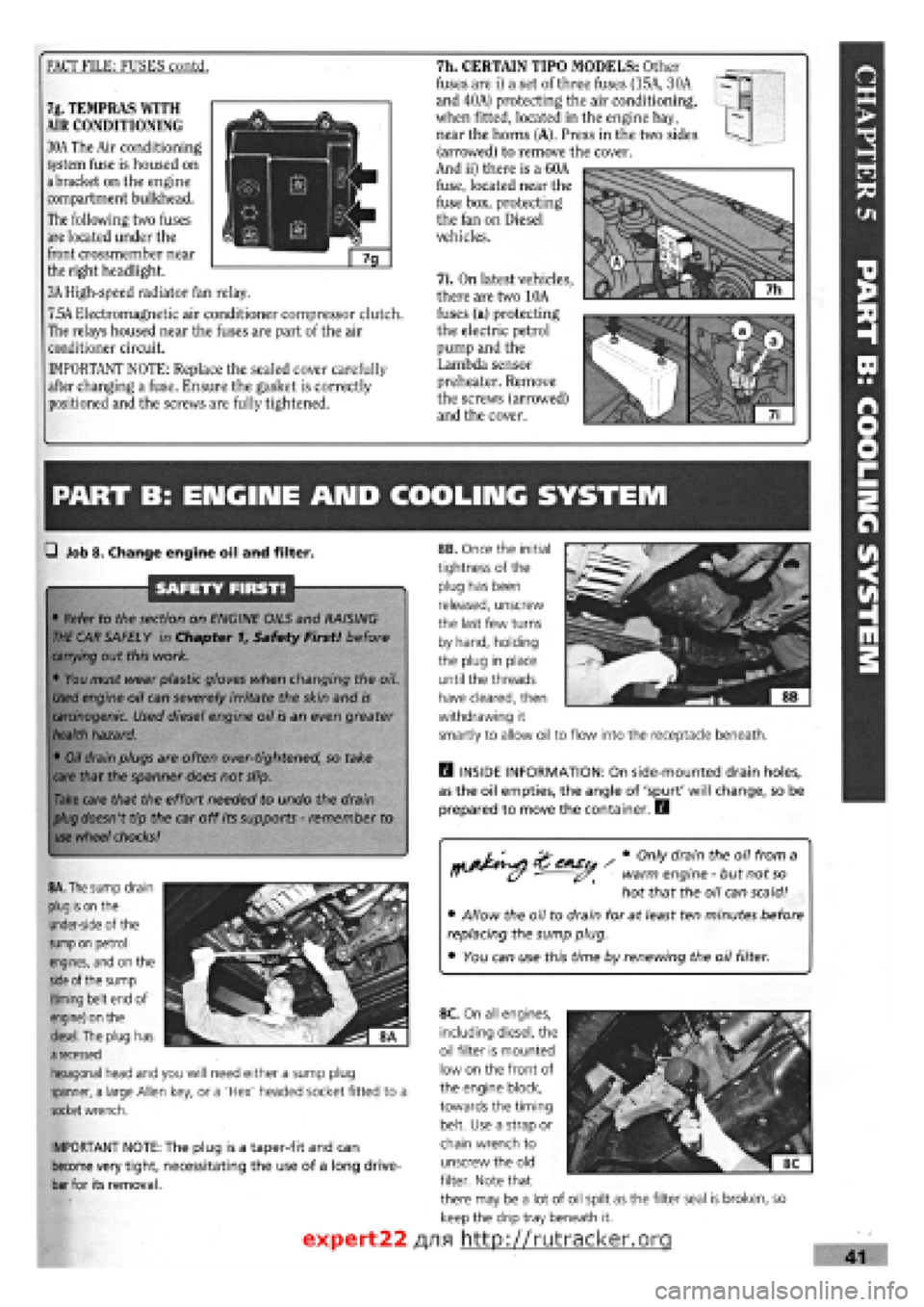

8A. The

sump drain

plug is on

the

under-side of the

sump on

petrol

engines, and on the

side

of the sump

(timing belt end of

engine) on the

diesel.

The plug has

a

recessed

hexagonal head and you will need either a sump plug

spanner, a large Allen key, or a 'Hex' headed socket fitted to a

socket

wrench.

8B. Once the initial

tightness of the

plug has been

released, unscrew

the last few turns

by hand, holding

the plug in place

until the threads

have cleared, then

withdrawing it

smartly to allow oil to flow into the receptacle beneath.

expert22

8C. On all engines,

including diesel, the

oil filter is mounted

low on the front of

the engine block,

towards the timing

belt. Use a strap or

chain wrench to

unscrew the old

filter. Note that

there may be a lot of oil spilt as the filter seal is broken, so

keep the drip tray beneath it.

/yifl http://rutracker.org

Page 58 of 171

51. Apply the

handbrake lever by

one 'click' of the

ratchet. From inside

the car, turn the

adjusting nut (a)

until the cable is

drawn taut. Pull the

handbrake up two

more 'clicks' and check that both rear wheels are now

'locked'. Check also that both rear wheels are completely free

when the handbrake is fully OFF. When everything works

properly, lower the car to the ground, and check again that

moving the handbrake through about three notches is suffi-

cient to hold the car stationary. A proper check of handbrake

efficiency can only be carried out by a garage with a 'rolling

road' brake tester.

Q Job 52. Check brake pipes.

FLEXIBLE HOSES

Check the flexible brake pipes that connect the calipers to the

metal pipes on the body. Try bending back on themselves

those that are not contained in a protective coil, and look for

any signs of cracking, particularly at the bends. Check them all

for signs of rubbing, splitting, kinks and perishing of the

rubber. Check hoses for 'ballooning' with the brake pedal

pressed.

RIGID PIPES

Check all rigid pipes for signs of damage or corrosion and

check that all of the locating clips are sound and in place.

• Job 53. Change brake hydraulic fluid.

Change the brake fluid at the recommended interval. See

Chapter

6,

Repairs and Replacements, PART H: BRAKES,

Job 15.

H INSIDE INFORMATION: Brake fluid absorbs water from

the air. This corrodes brake components and can cause

total brake failure. With brakes applied heavily, the fluid

can heat to above 100 degrees Celsius, the water

vaporises, and the pedal goes to the floor! B

PART H: BODYWORK & INTERIOR

• Job 54. Lubricate hinges and locks.

Apply a few drops of light oil (from either an aerosol or oil

can) to the hinges of the bonnet, doors and tailgate. Dip the

door/tailgate key in graphite powder and insert the key to

lubricate the lock barrels. Grease the door and tailgate latch

mechanism (aerosol grease is handy), the bonnet release

mechanism (and the tailgate's, if applicable) and the cable

end. Don't forget the fuel tank flap hinge and the locking cap

- it's a stopper when it jams!

• Job 55. Check windscreen.

Clean the windscreen with a proprietary glass cleaner and

examine it for stone chips, cracks and scoring. While some

degree of damage is acceptable, the strict MoT Test regula-

tions limit the amount and position of such defects. Some

screen chips can be repaired and made invisible.

• Job 56. Check seat and seat belt mountings.

Your car's seat and safety belt mountings and backrest

adjustment locking mechanism will be checked as part of the

annual test, but it pays to check them beforehand. Also,

regularly check that the seat belts: a) retract easily and

smoothly, and b) 'hold' when you snatch them, or under

sharp braking.

Q Job 57. Check headlight alignment.

Some vehicles are fitted with an automatic headlight levelling

device. On these vehicles, each of the headlights is adjusted

according to the vehicle height and no height levelling

adjustment is possible.

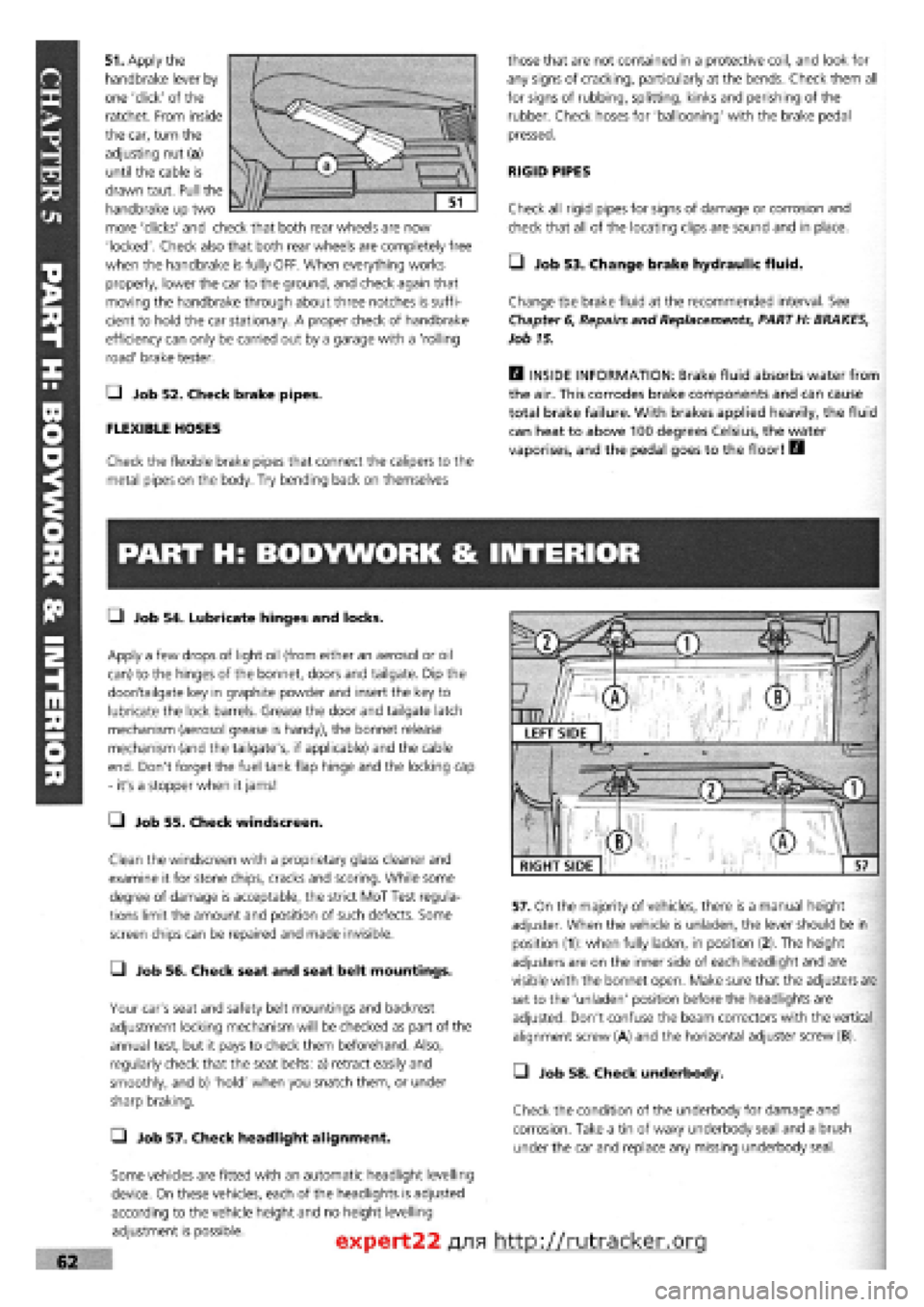

57. On the majority of vehicles, there is a manual height

adjuster. When the vehicle is unladen, the lever should be in

position (1): when fully laden, in position (2). The height

adjusters are on the inner side of each headlight and are

visible with the bonnet open. Make sure that the adjusters are

set to the 'unladen' position before the headlights are

adjusted. Don't confuse the beam correctors with the vertical

alignment screw (A) and the horizontal adjuster screw (B).

• Job 58. Check underbody.

Check the condition of the underbody for damage and

corrosion. Take a tin of waxy underbody seal and a brush

under the car and replace any missing underbody seal.

expert22 fl/ia http://rutracker.org

RIGHT SIDE