glove box FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 2 of 171

Running The Vehicle

NEVER start the engine unless the gearbox is in neutral (or

'Park' in the case of automatic transmission) and the hand

brake is fully applied.

NEVER run catalytic converter equipped vehicles without the

exhaust system heat shields in place.

TAKE CARE when parking vehicles fitted with catalytic

converters. The 'cat' reaches extremely high temperatures and

any combustible materials under the car, such as long dry

grass, could be ignited.

Personal Safety

NEVER siphon fuel, antifreeze, brake fluid or other such toxic

liquids by mouth, or allow contact with your skin. Use a

suitable hand pump and wear gloves.

BEFORE undertaking dirty jobs, use a barrier cream on your

hands as a protection against infection. Preferably, wear

suitable gloves, available from DIY outlets.

WEAR IMPERVIOUS GLOVES for sure when there is a risk of

used engine oil coming into contact with your skin. It can

cause cancer.

WIPE UP any spilt oil, grease or water off the floor

immediately.

MAKE SURE that spanners and all other tools are the right size

for the job and are not likely to slip. Never try to 'double-up'

spanners to gain more leverage.

SEEK HELP if you need to lift something heavy which may be

beyond your capability. Don't forget that when lifting a heavy

weight, you should keep your back straight and bend your

knees to avoid injuring your back.

NEVER take risky short-cuts or rush to finish a job. Plan ahead

and allow plenty of time.

BE METICULOUS and keep the work area tidy

-

you'll avoid

frustration, work better and lose less.

KEEP children and animals right-away from the work area and

from unattended vehicles.

ALWAYS tell someone what you're doing and have them

regularly check that all is well, especially when working alone

on, or under, the vehicle.

Fire!

Petrol (gasoline) is a dangerous and highly flammable liquid

requiring special precautions. When working on the fuel

system, disconnect the vehicle battery earth (ground) terminal

whenever possible and always work outside, or in a very well

ventilated area. Any form of spark, such as that caused by an

electrical fault, by two metal surfaces striking against each

other, by a central heating boiler in the garage 'firing up', or

even by static electricity built up in your clothing can, in a

confined space, ignite petrol vapour causing an explosion.

Take great care not to spill petrol on to the engine or exhaust

system, never allow any naked flame anywhere near the work

area and, above all, don't smoke.

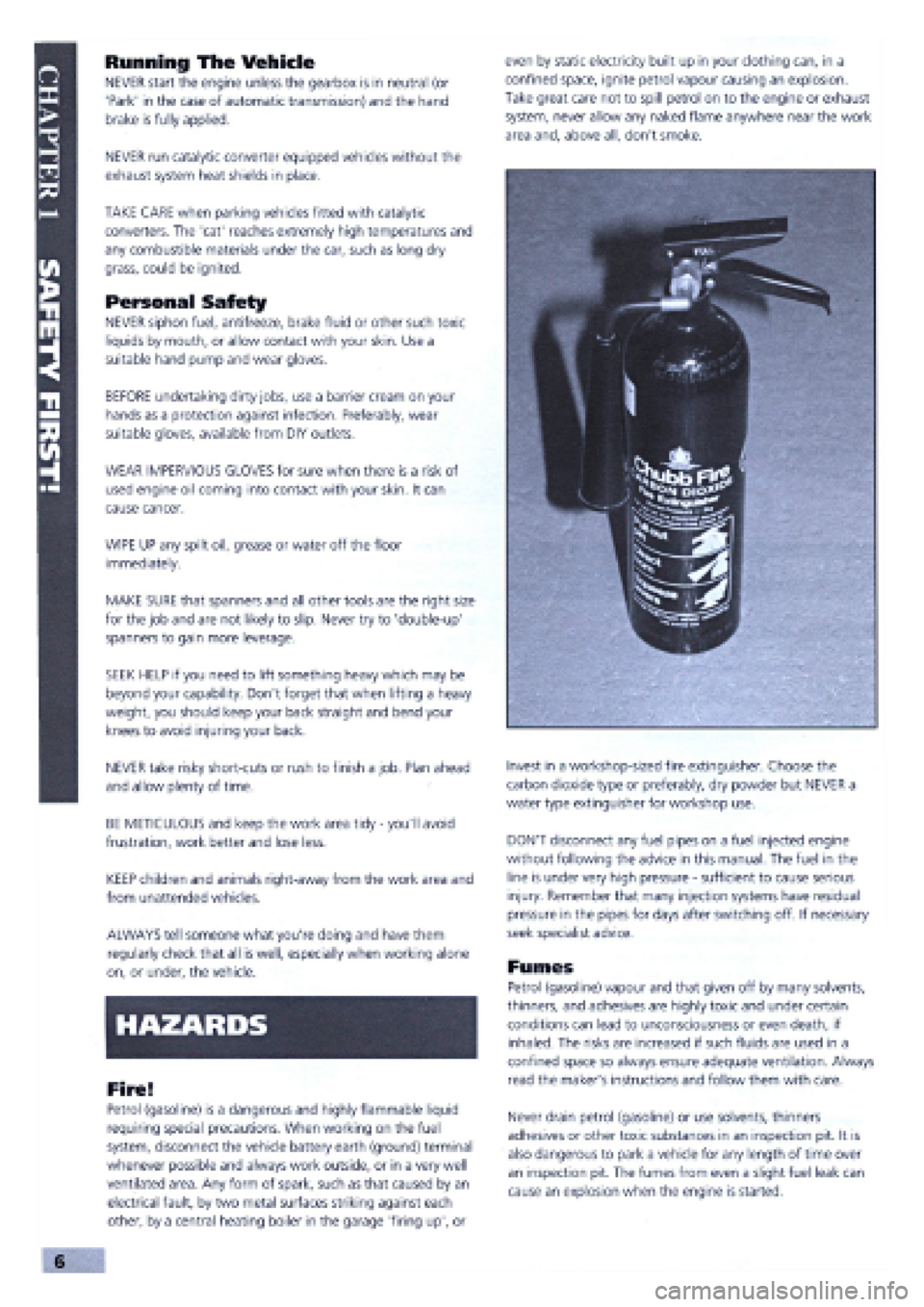

Invest in a workshop-sized fire extinguisher. Choose the

carbon dioxide type or preferably, dry powder but NEVER a

water type extinguisher for workshop use.

DON'T disconnect any fuel pipes on a fuel injected engine

without following the advice in this manual. The fuel in the

line is under very high pressure

-

sufficient to cause serious

injury. Remember that many injection systems have residual

pressure in the pipes for days after switching off. If necessary

seek specialist advice.

Fumes

Petrol (gasoline) vapour and that given off by many solvents,

thinners, and adhesives are highly toxic and under certain

conditions can lead to unconsciousness or even death, if

inhaled. The risks are increased if such fluids are used in a

confined space so always ensure adequate ventilation. Always

read the maker's instructions and follow them with care.

Never drain petrol (gasoline) or use solvents, thinners

adhesives or other toxic substances in an inspection pit. It is

also dangerous to park a vehicle for any length of time over

an inspection pit. The fumes from even a slight fuel leak can

cause an explosion when the engine is started.

v ,,, Oil;::;s

Page 4 of 171

and explosions. Do not allow resin or 2-pack adhesive hardener,

or that supplied with filler or 2-pack stopper, to come into

contact with skin or eyes. Read carefully the safety notes

supplied on the can, tube or packaging and always wear

impervious gloves and goggles when working with them.

Fluoroelastomers

Fluoroelastomers are commonly used for oil seals, wiring and

cabling, bearing surfaces, gaskets, diaphragms, hoses and '0'

rings. If they are subjected to temperatures greater than 315

degrees C, they will decompose and can be potentially

hazardous. Some decomposition may occur at temperatures

above 200 degrees C, and it is obvious that when a car has

been in a fire or has been dismantled with the assistance of a

cutting torch or blow torch, the fluoroelastomers can

decompose in the manner indicated above.

According to the Health and Safety Executive, "Skin contact

with this liquid or decomposition residues can cause painful and

penetrating burns. Permanent irreversible skin and tissue

damage can occur". Damage can also be caused to eyes or by

the inhalation of fumes created as fluoroelastomers are burned

or heated.

After a vehicle has been exposed to fire or high temperatures:

1. Do not touch blackened or charred seals or equipment.

2. Preferably, don't handle parts containing decomposed

fluoroelastomers, but if you must, wear goggles and PVC

(polyvinyl chloride) or neoprene protective gloves whilst doing

so. Never handle such parts unless they are completely cool.

3. Contaminated parts, residues, materials and clothing,

including protective clothing and gloves, should be disposed of

by an approved contractor to landfill or by incineration

according to national or local regulations. Oil seals, gaskets and

'0' rings, along with contaminated material, must not

be burned.

1. Always have a fire extinguisher of the correct type at arm's

length when working on the fuel system. If you do have a fire,

DON'T PANIC. Use the extinguisher effectively by directing it at

the base of the fire.

2. NEVER use a naked flame anywhere in the workplace.

3. KEEP your inspection lamp well away from any source of

petrol (gasoline) such as when disconnecting a carburettor float

bowl or fuel line.

4. NEVER use petrol (gasoline) to clean parts. Use paraffin

(kerosene), white spirits, or, a proprietary degreaser.

5. NO SMOKING. There's a risk of fire or of transferring

dangerous substances to your mouth and, in any case, ash

falling into mechanical components is to be avoided.

FACT FILE: FOUR WHEEL DRIVE CARS

• Whenever you have to raise a wheel off the

ground and turn it by hand, always ensure that

the opposite-side's wheel to the one being lifted is

also off the ground and free to turn and that both wheels remaining

on the ground are held by the parking brake (if possible) and

securely chocked in both directions.

• ALWAYS have the gearbox in neutral (or 'N' in the case of

automatics). In the case of

some

4 wheel drive automatics and those

with permanent 4WD, it is necessary to disengage the 4WD system

by special means.

• Consult your handbook or seek advice from your main dealer.

6. BE METHODICAL in everything you do, use common sense,

and think of safety at all times.

ENVIRONMENT FIRST!

The used oil from the sump of

just

one car

can

cover

an

area of

water the size of two football pitches, cutting off the oxygen

supply

and

harming swans, ducks, fish and other river lift.

When you drain your engine oil

-

don't oil the drain!

Pouring oil

down the

drain will

cause

pollution. It is

also an

offense.

Don't mix used

oil with other

materials, such

as paint and

solvents,

because this

makes

recycling

difficult.

Take used oil

to an oil

recycling bank.

Telephone

FREE on 0800 663366 to find the location of your nearest oil

bank, or contact you local authority recycling officer.

OIL POLLUTES WATER

USE YOUR BRAIN-

NOT THE DRAIN!

Page 37 of 171

FACT FILE: FUSES contd. 7h. CERTAIN TIPO MODELS: Other

fuses are i) a set of three fuses (15A, 30A

and 40A) protecting the air conditioning,

when fitted, located in the engine bay,

near the horns (A). Press in the two sides

(arrowed) to remove the cover.

And ii) there is a 60A

fuse, located near the

fuse box, protecting

the fan on Diesel

vehicles.

7i. On latest vehicles,

there are two 10A

fuses (a) protecting

the electric petrol

pump and the

Lambda sensor

preheater. Remove

the screws (arrowed)

and the cover.

7g. TEMPRAS WITH

AIR CONDITIONING

30A The Air conditioning

system fuse is housed on

a bracket on the engine

compartment bulkhead.

The following two fuses

are located under the

front crossmember near

the right headlight.

3A High-speed radiator fan relay.

7.5A Electromagnetic air conditioner compressor clutch.

The relays housed near the fuses are part of the air

conditioner circuit.

IMPORTANT NOTE: Replace the sealed cover carefully

after changing a fuse. Ensure the gasket is correctly

positioned and the screws are fully tightened.

PART B: ENGIIME AND COOLING SYSTEM

Q Job 8. Change engine oil and filter.

SAFETY FIRST!

• Refer to the section on ENGINE OILS and RAISING

THE

CAR SAFELY in Chapter f, Safety First! before

carrying

out this work.

• You must wear plastic gloves when changing the oil.

Used

engine oil can severely irritate the skin and

is

carcinogenic.

Used diesel engine oil is an even greater

health

hazard.

•

Oil

drain plugs are often over-tightened, so take

care

that the spanner does not slip.

Take

care that the effort needed to undo the drain

plug

doesn't tip the car off its supports

-

remember to

use

wheel

chocks!

rtj&^si ' # °nly dram theu 0,7 fr°m a ff (y warm engine

-

but not

so

hot that the oil can scald!

• Allow the oil to drain for at least ten minutes before

replacing the sump plug.

• You can use this time by renewing the oil filter.

IMPORTANT NOTE: The plug is a taper-fit and can

become very tight, necessitating the use of a long drive-

bar for its removal.

H INSIDE INFORMATION: On side-mounted drain holes,

as the oil empties, the angle of 'spurt' will change, so be

prepared to move the container. E3

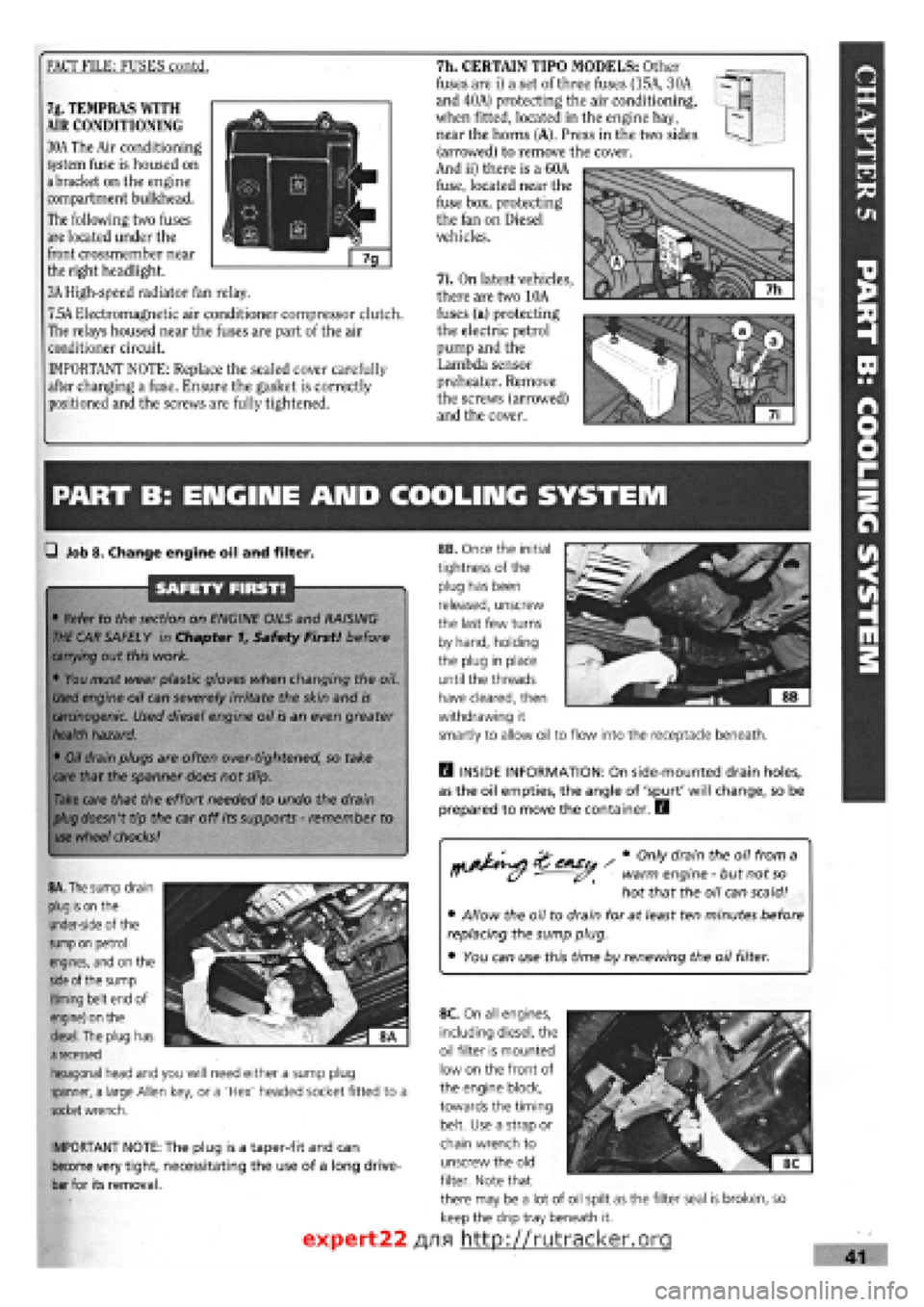

8A. The

sump drain

plug is on

the

under-side of the

sump on

petrol

engines, and on the

side

of the sump

(timing belt end of

engine) on the

diesel.

The plug has

a

recessed

hexagonal head and you will need either a sump plug

spanner, a large Allen key, or a 'Hex' headed socket fitted to a

socket

wrench.

8B. Once the initial

tightness of the

plug has been

released, unscrew

the last few turns

by hand, holding

the plug in place

until the threads

have cleared, then

withdrawing it

smartly to allow oil to flow into the receptacle beneath.

expert22

8C. On all engines,

including diesel, the

oil filter is mounted

low on the front of

the engine block,

towards the timing

belt. Use a strap or

chain wrench to

unscrew the old

filter. Note that

there may be a lot of oil spilt as the filter seal is broken, so

keep the drip tray beneath it.

/yifl http://rutracker.org

Page 42 of 171

• Job 20. Check/adjust clutch. CABLE OPERATED CLUTCH

The clutch mechanism is self-adjusting, although the cable

linkage can stretch over a period of time and may need

adjustment. The adjuster is on top of the gearbox, reached

from inside the engine bay.

20C. 'Work' the clutch pedal

(X) a few times, pull back the

carpet from under the pedal,

then measure the full travel of

the pedal, which should be

between 140 and 150 mm.

/

\

/ \

/ u / Xl

1 ' ' / . V y 2

Jdi V 1 \

X. 1 —

20C

HYDRAULIC CLUTCH

20B. Check the

pipework and slave

cylinder, on the

gearbox casing,

from beneath the

20D. If not, note that after

slackening the locknut, turning

the adjusting nut inwards

along the threaded rod

(arrowed) will increase pedal

travel. Tighten the lock-nut

against the inner nut after

adjustment.

• Job 21. Check auto, transmission selector cable.

It should only be possible to start the engine when the gear

selector is in the 'P' or 'N' position. Place it in each of the

other positions and try to start the car. If it starts, the fault

must be put right! Also check that, with the ignition off and

the selector lever in 'D' (Drive), 'L' (Low), 'R' (Reverse) or 'N'

(Neutral), the timed warning buzzer should sound. If it

doesn't, the selector cable adjustment may be faulty.

See Chapter

6,

Repairs and Replacements, PART B:

TRANSMISSION AND CLUTCH, Job 8 for adjustment details.

PART D: IGNITION AND ELECTRICS

See FACT FILE: DISCONNECTING THE BATTERY on page 36

SAFETY FIRST!

• You may minimise the risk of shock when the engine is running by wearing thick rubber gloves and by NEVER

working on the system in damp weather or when standing on damp ground. Read Chapter 1, Safety First! before

carrying out any work on the ignition system.

• ELECTRONIC IGNITION SYSTEMS INVOLVE VERY HIGH VOLTAGES! All manufacturers recommend that only trained

personnel should go near the high-tension circuit (coil, distributor and HT wiring) and it is ESSENTIAL that anyone

wearing a medical pacemaker device does not go near the ignition system.

• Stroboscopic timing requires the engine to be running

-

take great care that parts of the timing light or parts of

you don't get caught up in moving components!

• Don't have loose clothing or hair.

46

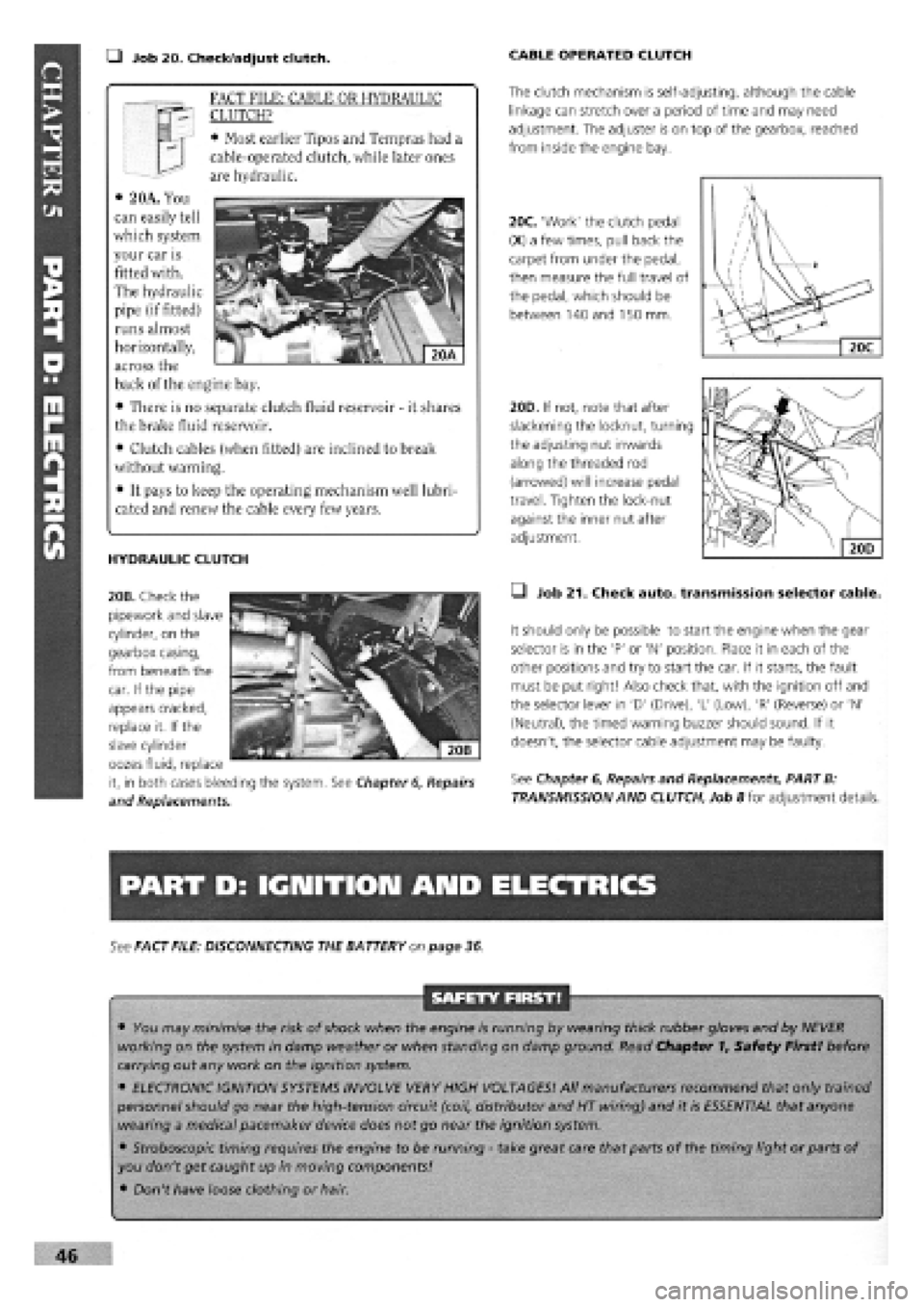

FACT FILE: CABLE OR HYDRAULIC

CLUTCH?

• Most earlier Tipos and Tempras had a

cable-operated clutch, while later ones

are hydraulic.

• 2 OA. You

can easily tell

which system

your car is

fitted with.

The hydraulic

pipe (if fitted)

runs almost

horizontally,

across the

back of the engine bay.

• There is no separate clutch fluid reservoir

-

it shares

the brake fluid reservoir.

• Clutch cables (when fitted) are inclined to break

without warning.

• It pays to keep the operating mechanism well lubri-

cated and renew the cable every few years.

car. If the pipe

appears cracked,

replace it. If the

slave cylinder

oozes fluid, replace

it, in both cases bleeding the system. See Chapter

6,

Repairs

and Replacements.

Page 46 of 171

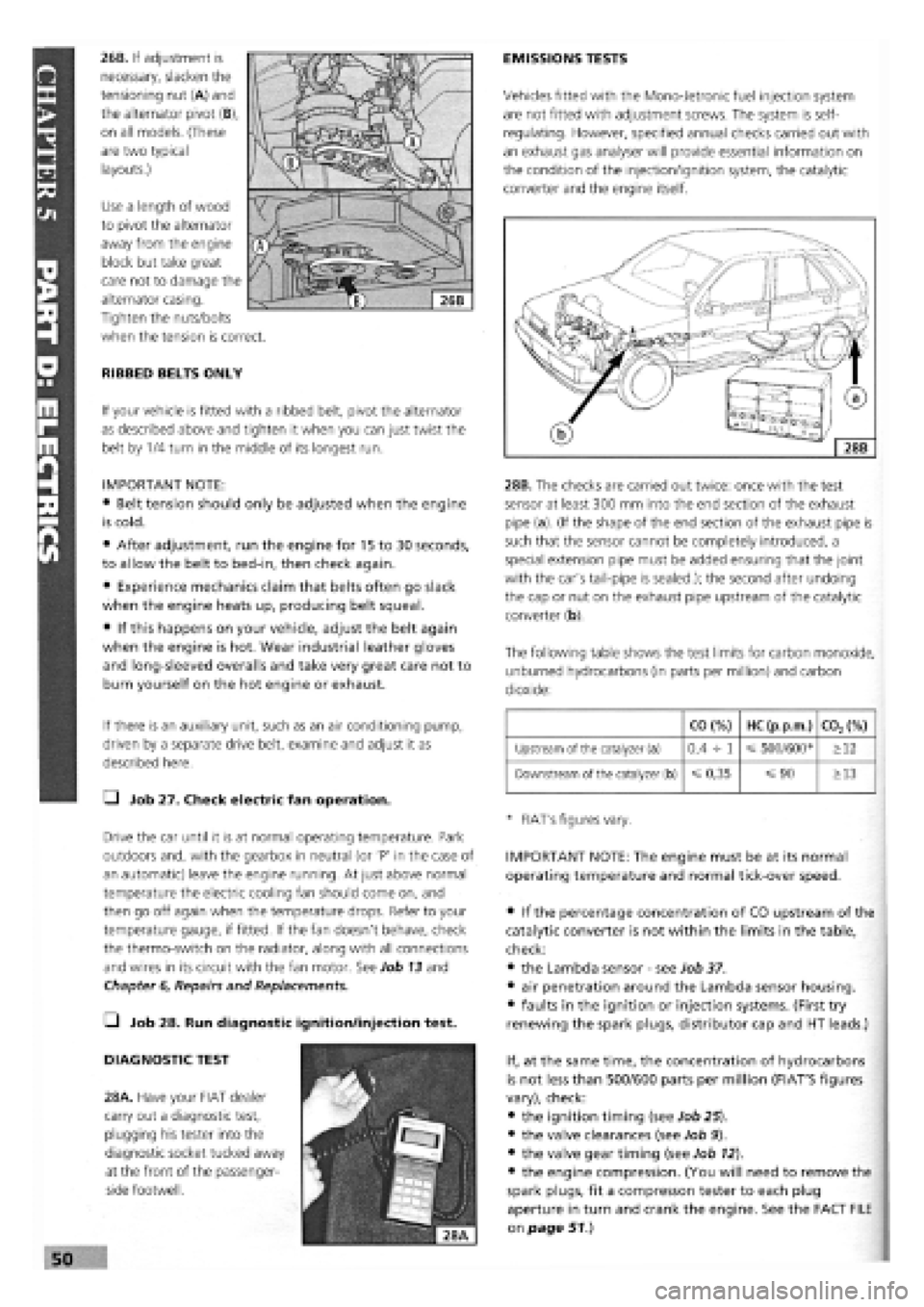

26B. If adjustment is

necessary, slacken the

tensioning nut (A) and

the alternator pivot (B),

on all models. (These

are two typical

layouts.)

Use a length of wood

to pivot the alternator

away from the engine

block but take great

care not to damage the

alternator casing.

Tighten the nuts/bolts

when the tension is correct.

RIBBED BELTS ONLY

If your vehicle is fitted with a ribbed belt, pivot the alternator

as described above and tighten it when you can just twist the

belt by 1/4 turn in the middle of its longest run.

IMPORTANT NOTE:

• Belt tension should only be adjusted when the engine

is cold.

• After adjustment, run the engine for 15 to 30 seconds,

to allow the belt to bed-in, then check again.

• Experience mechanics claim that belts often go slack

when the engine heats up, producing belt squeal.

• If this happens on your vehicle, adjust the belt again

when the engine is hot. Wear industrial leather gloves

and long-sleeved overalls and take very great care not to

burn yourself on the hot engine or exhaust.

If there is an auxiliary unit, such as an air conditioning pump,

driven by a separate drive belt, examine and adjust it as

described here.

Q Job 27. Check electric fan operation.

Drive the car until it is at normal operating temperature. Park

outdoors and, with the gearbox in neutral (or 'P' in the case of

an automatic) leave the engine running. At just above normal

temperature the electric cooling fan should come on, and

then go off again when the temperature drops. Refer to your

temperature gauge, if fitted. If the fan doesn't behave, check

the thermo-switch on the radiator, along with all connections

and wires in its circuit with the fan motor. See Job 13 and

Chapter

6,

Repairs and Replacements.

• Job 28. Run diagnostic ignition/injection test.

DIAGNOSTIC TEST

28A. Have your FIAT dealer

carry out a diagnostic test,

plugging his tester into the

diagnostic socket tucked away

at the front of the passenger-

side footwell.

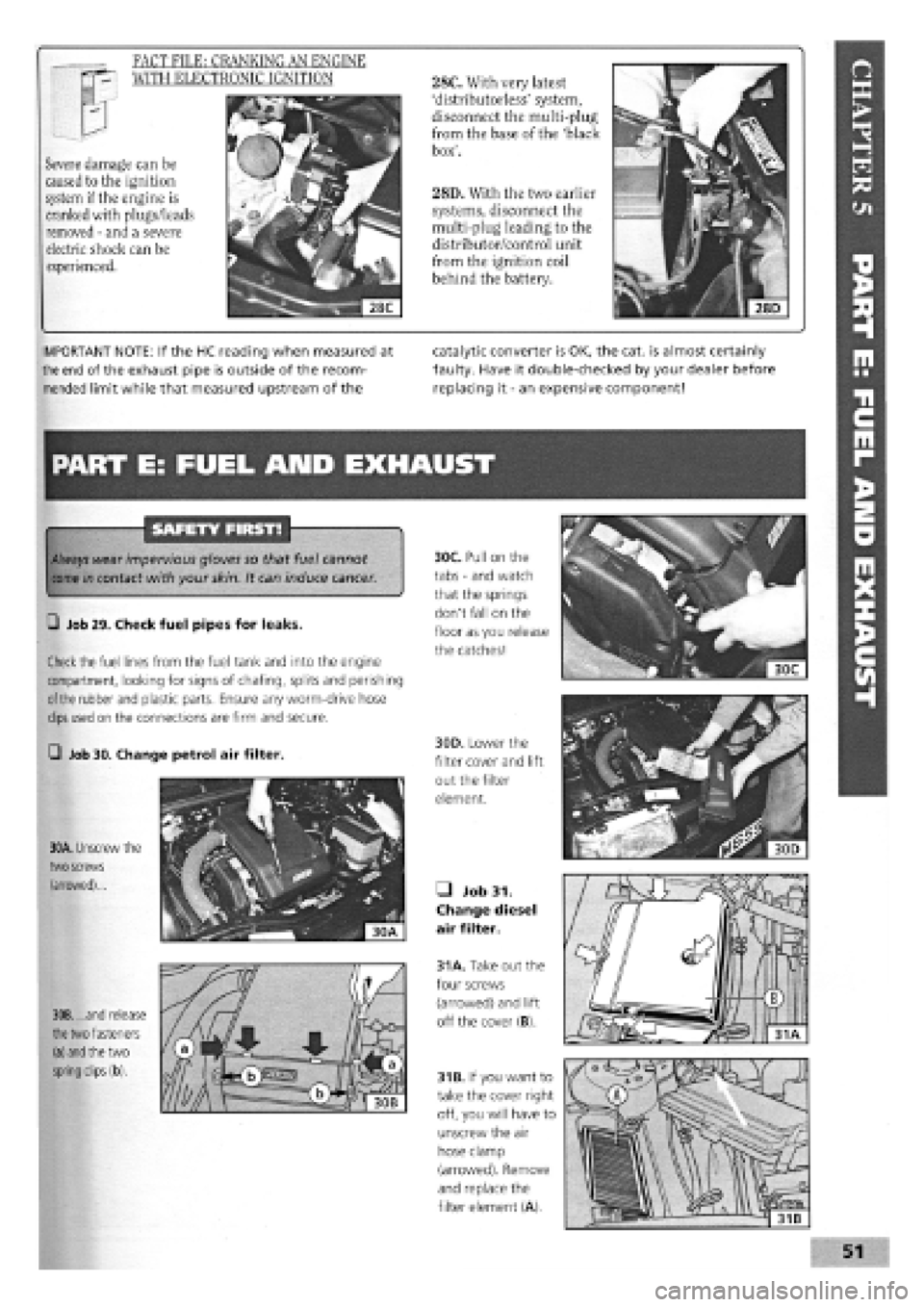

EMISSIONS TESTS

Vehicles fitted with the Mono-Jetronic fuel injection system

are not fitted with adjustment screws. The system is self-

regulating. However, specified annual checks carried out with

an exhaust gas analyser will provide essential information on

the condition of the injection/ignition system, the catalytic

converter and the engine itself.

28B. The checks are carried out twice: once with the test

sensor at least 300 mm into the end section of the exhaust

pipe (a). (If the shape of the end section of the exhaust pipe is

such that the sensor cannot be completely introduced, a

special extension pipe must be added ensuring that the joint

with the car's tail-pipe is sealed.); the second after undoing

the cap or nut on the exhaust pipe upstream of the catalytic

converter (b).

The following table shows the test limits for carbon monoxide,

unburned hydrocarbons (in parts per million) and carbon

dioxide:

CO (%) HC (p.p.m.) C02(%)

Upstream of the catalyzer (a) 0,4 -h 1 500/600* >12

Downstream of the catalyzer (b)

=£

0,35 =s 90 >13

* FIAT's figures vary.

IMPORTANT NOTE: The engine must be at its normal

operating temperature and normal tick-over speed.

• if the percentage concentration of CO upstream of the

catalytic converter is not within the limits in the table,

check:

• the Lambda sensor

-

see Job 37.

• air penetration around the Lambda sensor housing.

• faults in the ignition or injection systems. (First try

renewing the spark plugs, distributor cap and HT leads.)

If, at the same time, the concentration of hydrocarbons

is not less than 500/600 parts per million (FIAT'S figures

vary), check:

• the ignition timing (see Job 25).

• the valve clearances (see Job 9).

• the valve gear timing (see Job 12).

• the engine compression. (You will need to remove the

spark plugs, fit a compresson tester to each plug

aperture in turn and crank the engine. See the FACT FILE

on page 51.)

Page 47 of 171

28C. With very latest

'distributorless' system,

disconnect the multi-plug

from the base of the 'black

box'.

28D. With the two earlier

systems, disconnect the

multi-plug leading to the

distributor/control unit

from the ignition coil

behind the battery.

FACT FILE: CRANKING AN ENGINE

WITH ELECTRONIC IGNITION

Severe damage can be

caused to the ignition

system if the engine is

cranked with plugs/leads

removed

-

and a severe

electric shock can be

experienced.

PART E: FUEL AND EXHAUST

SAFETY FIRST!

Always

wear impervious gloves so that fuel cannot

come

in contact with your

skin.

It can induce cancer.

Q Job 29. Check fuel pipes for leaks.

Check the fuel lines from the fuel tank and into the engine

compartment, looking for signs of chafing, splits and perishing

of the

rubber and plastic parts. Ensure any worm-drive hose

clips used

on the connections are firm and secure.

Q Job 30. Change petrol air filter.

IMPORTANT NOTE: If the HC reading when measured at

the end of the exhaust pipe is outside of the recom-

mended limit while that measured upstream of the

catalytic converter is OK, the cat. is almost certainly

faulty. Have it double-checked by your dealer before

replacing it

-

an expensive component!

30C. Pull on the

tabs

-

and watch

that the springs

don't fall on the

floor as you release

the catches!

30D. Lower the

filter cover and lift

out the filter

element.

31B. If you want to

take the cover right

off, you will have to

unscrew the air

hose clamp

(arrowed). Remove

and replace the

filter element (A).

• Job 31.

Change diesel

air filter.

31A. Take out the

four screws

(arrowed) and lift

off the cover (B). 30B. ...and release

the two

fasteners

(a) and the

two

spring clips

(b).

30A. Unscrew the

two

screws

(arrowed)...

51

Page 91 of 171

Q Step 2: Before starting the engine, make sure all your

electrical connections are sound and your fuel, oil and coolant

connections are correct and secure.

Q Step 3: Run the engine to working temperature and then

allow to cool. Re-check all fluid levels.

Job 20. Diesel engine.

Mountings - replacement.

See

Job

12

and Job

18,

Step 20

Job 21. Diesel engine/

transmission (removed from car)

- separation.

Q Step 1: Remove the starter motor.

• Step 2: On the turbo version, undo the flange bolts see

Job

18,

Step 16A and withdraw the drive-shaft extension, if

still

fitted.

Q Step 3: Unbolt and remove the rear engine plate and the

gearbox, being careful to support the gearbox weight as it is

withdrawn.

Job 22. Diesel engine/

transmission (removed from car)

- reconnection.

Q Step 1: Before proceeding, check the condition of the

clutch and

its release mechanism. Make sure the driven plate

is

properly centred on the flywheel

-

see PART B: TRANS-

MISSION.

Q Step 2: Now reverse the order of separation, but be

careful when

engaging the gearbox input shaft with the

clutch

driven plate that you don't 'hang' its weight on the

splines.

Also,

see

Job 11.

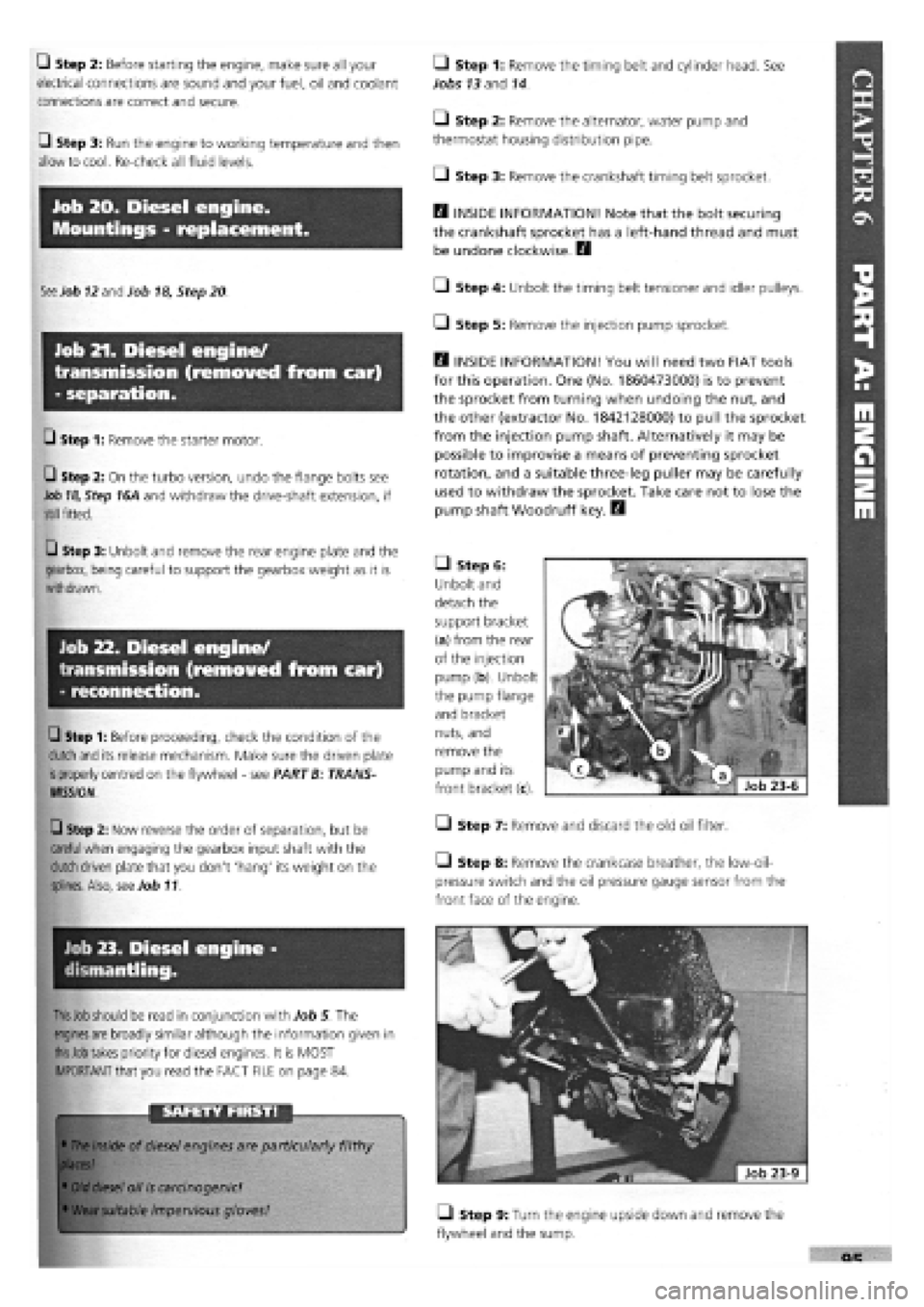

Job 23. Diesel engine -

dismantling.

This Job should

be read in conjunction with Job 5 The

engines are

broadly similar although the information given in

this Job takes

priority for diesel engines. It is MOST

IMPORTANT that you read the FACT FILE on page 84.

SAFETY FIRST!

•

The inside

of diesel engines are particularly filthy

places!

•

Old diesel

oil

is

carcinogenic!

•

Wear suitable

impervious gloves!

I

• Step 1: Remove the timing belt and cylinder head. See

Jobs

13

and 14.

Q Step 2: Remove the alternator, water pump and

thermostat housing distribution pipe.

• Step 3: Remove the crankshaft timing belt sprocket.

Q INSIDE INFORMATION! Note that the bolt securing

the crankshaft sprocket has a left-hand thread and must

be undone clockwise. D

• Step 4: Unbolt the timing belt tensioner and idler pulleys.

• Step 5: Remove the injection pump sprocket.

Q INSIDE INFORMATION! You will need two FIAT tools

for this operation. One (No. 1860473000) is to prevent

the sprocket from turning when undoing the nut, and

the other (extractor No. 1842128000) to pull the sprocket

from the injection pump shaft. Alternatively it may be

possible to improvise a means of preventing sprocket

rotation, and a suitable three-leg puller may be carefully

used to withdraw the sprocket. Take care not to lose the

pump shaft Woodruff key. B

• Step 6:

Unbolt and

detach the

support bracket

(a) from the rear

of the injection

pump (b). Unbolt

the pump flange

and bracket

nuts, and

remove the

pump and its

front bracket (c).

• Step 7: Remove and discard the old oil filter.

Step 8: Remove the crankcase breather, the low-oil-

pressure switch and the oil pressure gauge sensor from the

front face of the engine.

• Step 9: Turn the engine upside down and remove the

flywheel and the sump.