heater FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 6 of 171

• Repeat this operation three more times until the

complete code number has been entered, if the code

has been entered in correctly LED B will start flashing.

• Release button A (see illustration

1B).

Red LED B

flashes for 8 seconds indicating the new remote unit's

code has been stored.

IMPORTANT NOTE: If the LED does not illuminate

when remote unit button (illustration 1B, button

O is pressed, change the remote unit's battery.

• Insert the emergency key A into the emergency switch

slot in the glove compartment turn the key to the left to

switch the alarm off (see inset).

• Turn the key back towards its original position to

switch the alarm system back on.

IMPORTANT NOTE: As the alarm system absorbs

energy, if you are not planning on using the car

for a long period of time, turn the alarm exclusion

key to the off position, so as not to run the vehicle

battery down.

• 2. IGNITION SWITCH AND

STEERING COLUMN LOCK

IGNITION SWITCH

2. The ignition/steering column lock key, once inserted

in the ignition lock, can be placed in any of the

following four positions:

• PARK

-

With the key in this

position the side and tail lights

can be turned on, the steering

column locked and the keys

can be removed. Press button

A to turn the key to PARK.

• STOP

-

When the key is

turned to the STOP position the steering column will be

locked, and the keys can be removed.

• MAR

-

This is the driving position. When the key is in

this position all the electrical devices are energised.

• AW

-

Turning the key to this position starts the

engine.

STEERING COLUMN LOCK

• LOCKING

-

To apply the steering wheel lock turn the

steering wheel slightly to the left or right when the key is

at STOP or PARK.

• UNLOCKING

-

Rocking the steering wheel gently back

and forth while turning the ignition key to MAR unlocks

the steering wheel.

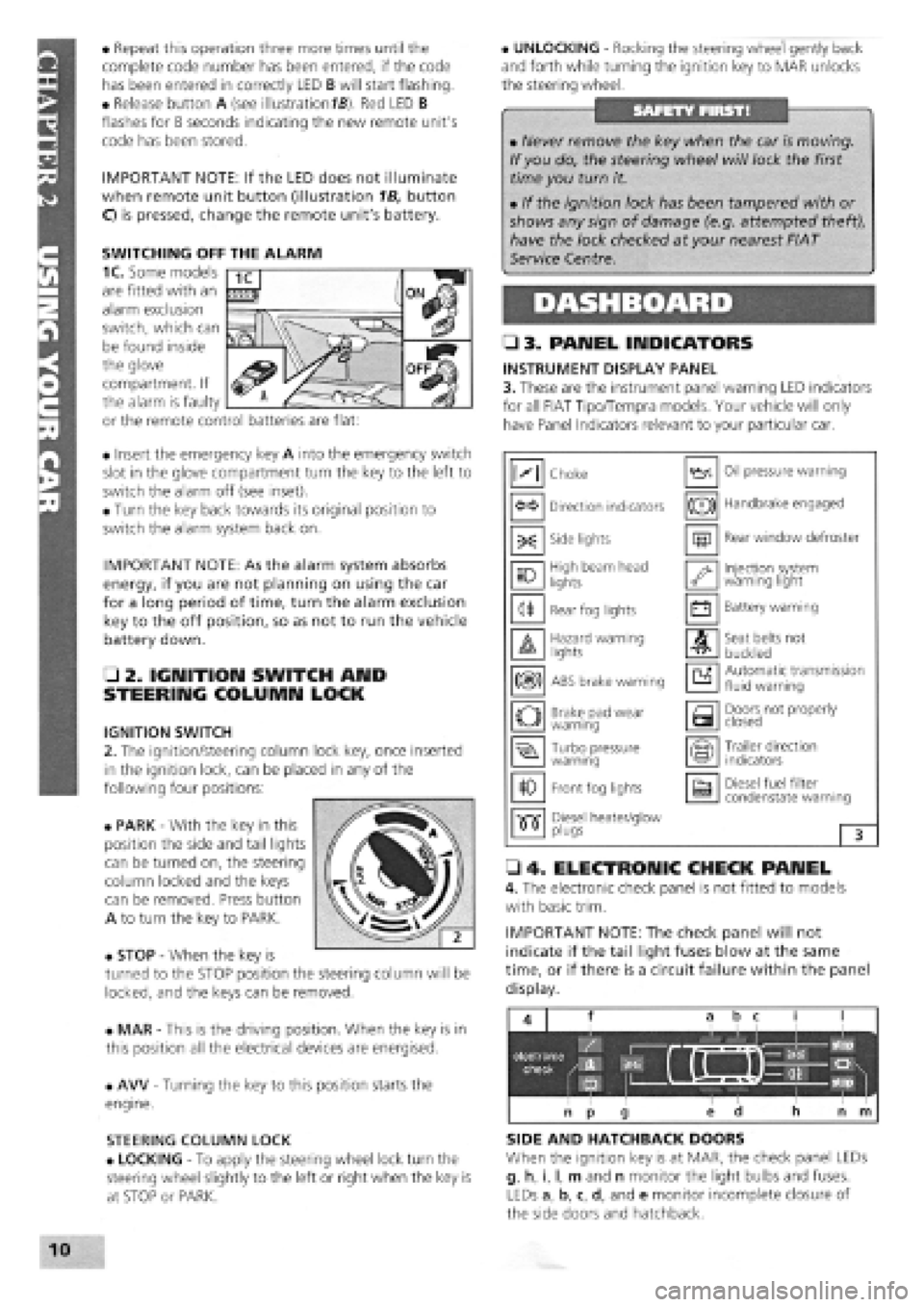

• 3. PANEL INDICATORS

INSTRUMENT DISPLAY PANEL

3. These are the instrument panel warning LED indicators

for all FIAT Tipo/Tempra models. Your vehicle will only

have Panel Indicators relevant to your particular car.

• 4. ELECTRONIC CHECK PANEL

4. The electronic check panel is not fitted to models

with basic trim.

IMPORTANT NOTE: The check panel will not

indicate if the tail light fuses blow at the same

time, or if there is a circuit failure within the panel

display.

SIDE AND HATCHBACK DOORS

When the ignition key is at MAR, the check panel LEDs

g, h, i, I, m and n monitor the light bulbs and fuses.

LEDs a, b, c, d, and e monitor incomplete closure of

the side doors and hatchback.

• Never remove the key when the car is moving.

If you do, the steering wheel will lock the first

time you turn it.

• If the ignition lock has been tampered with or

shows any sign of damage (e.g. attempted theft),

have the lock checked at your nearest FIAT

Service Centre.

M Choke Oil pressure warning

Direction indicators (®) Handbrake engaged

-X: Side lights m Rear window defroster

10 High beam head

lights '•y Injection system warning light

<1* Rear fog lights • Battery warning

A Hazard warning lights A Seat belts not

buckled

m ABS brake warning a Automatic transmission fluid warning

o Brake pad wear warning a Doors not properly closed

Turbo pressure warning Trailer direction indicators

10 Front fog lights a Diesel fuel filter condenstate warning

•515" Diesel heater/glow •515" plugs 3

SWITCHING OFF THE ALARM

1C. Some models

are fitted with an

alarm exclusion

switch, which can

be found inside

the glove

compartment. If

the alarm is faulty

or the remote control batteries are flat:

Page 8 of 171

AIR CONDITIONING (EARLY MODELS)

Air conditioning is an optional extra fitted to some

models of Tipo and Tempra.

AIR CONDITIONING SWITCH

5D. When you turn on the air

conditioning it will initially operate at

the first fan speed even if set at

position 0.

AIR RECIRCULATION SWITCH

5E. When pressed, no outside air

enters the passenger compartment.

Use the recirculation feature for fast

cooling or heating. Select

recirculation whenever you drive in

heavy traffic, in a tunnel or under any conditions where

the air is heavily polluted.

Use the following settings for maximum cooling:

• Turn the air temperature adjustment knob to the blue

zone.

• Turn the air conditioner switch ON.

• Turn the air volume control knob to position Mil.

• Turn the air distribution control knob to 5.

AIR CONDITIONER HEATING

Turning the air temperature adjustment knob to the red

zone:

• Turn the air volume control knob to the desired fan

speed.

• Turn the air distribution control knob (illustration 50

to 2 cold, sunny weather or 3 heating.

IMPORTANT NOTE: The air conditioner and heater

may be used at the same time during winter or

whenever the weather is particularly humid, for

optimal demisting .

DEFROSTING THE WINDSCREEN AND WINDOWS

• Turn the air temperature adjustment knob (illustration

56) to the red zone.

• Select fan speed 3 or 4.

• Turn the air distribution control knob to 4.

• Press the air conditioner switch for efficient demisting.

VENTILATION

• Turn the air temperature control knob (illustration SB)

to the blue zone.

• Select the fan speed desired.

• Turn the air distribution control knob (illustration 50

to position 5.

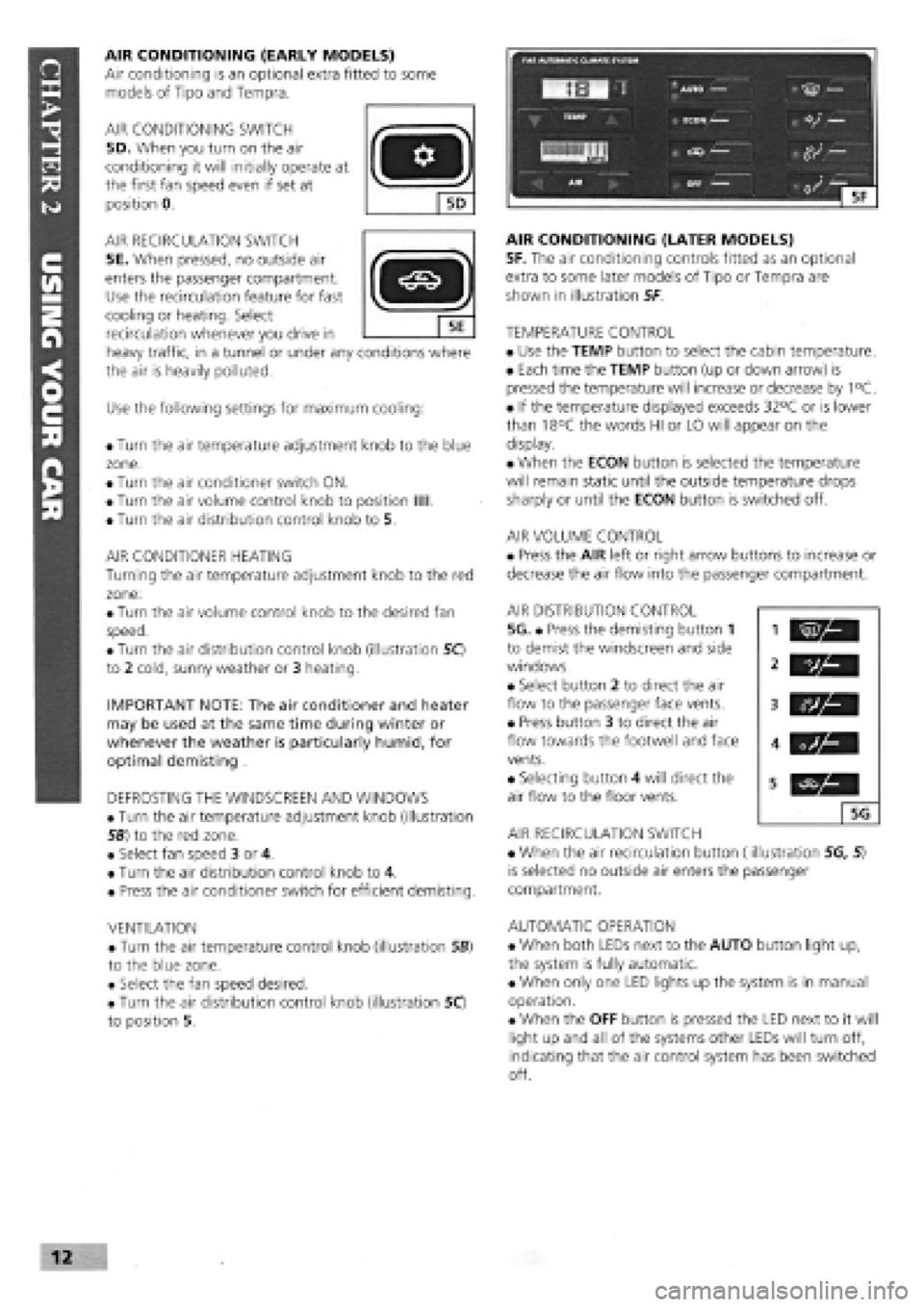

AIR CONDITIONING (LATER MODELS)

5F. The air conditioning controls fitted as an optional

extra to some later models of Tipo or Tempra are

shown in illustration 5F

TEMPERATURE CONTROL

• Use the TEMP button to select the cabin temperature.

• Each time the TEMP button (up or down arrow) is

pressed the temperature will increase or decrease by 1°C.

• If the temperature displayed exceeds 32°C or is lower

than 18°C the words HI or LO will appear on the

display.

• When the ECON button is selected the temperature

will remain static until the outside temperature drops

sharply or until the ECON button is switched off.

AIR VOLUME CONTROL

• Press the AIR left or right arrow buttons to increase or

decrease the air flow into the passenger compartment.

AIR DISTRIBUTION CONTROL

5G. • Press the demisting button 1

to demist the windscreen and side

windows.

• Select button 2 to direct the air

flow to the passenger face vents.

• Press button 3 to direct the air

flow towards the footwell and face

vents.

• Selecting button 4 will direct the

air flow to the floor vents.

AIR RECIRCULATION SWITCH

• When the air recirculation button (illustration 5G, 5)

is selected no outside air enters the passenger

compartment.

AUTOMATIC OPERATION

• When both LEDs next to the AUTO button light up,

the system is fully automatic.

• When only one LED lights up the system is in manual

operation.

• When the OFF button is pressed the LED next to it will

light up and all of the systems other LEDs will turn off,

indicating that the air control system has been switched

off.

vh

5G

Page 21 of 171

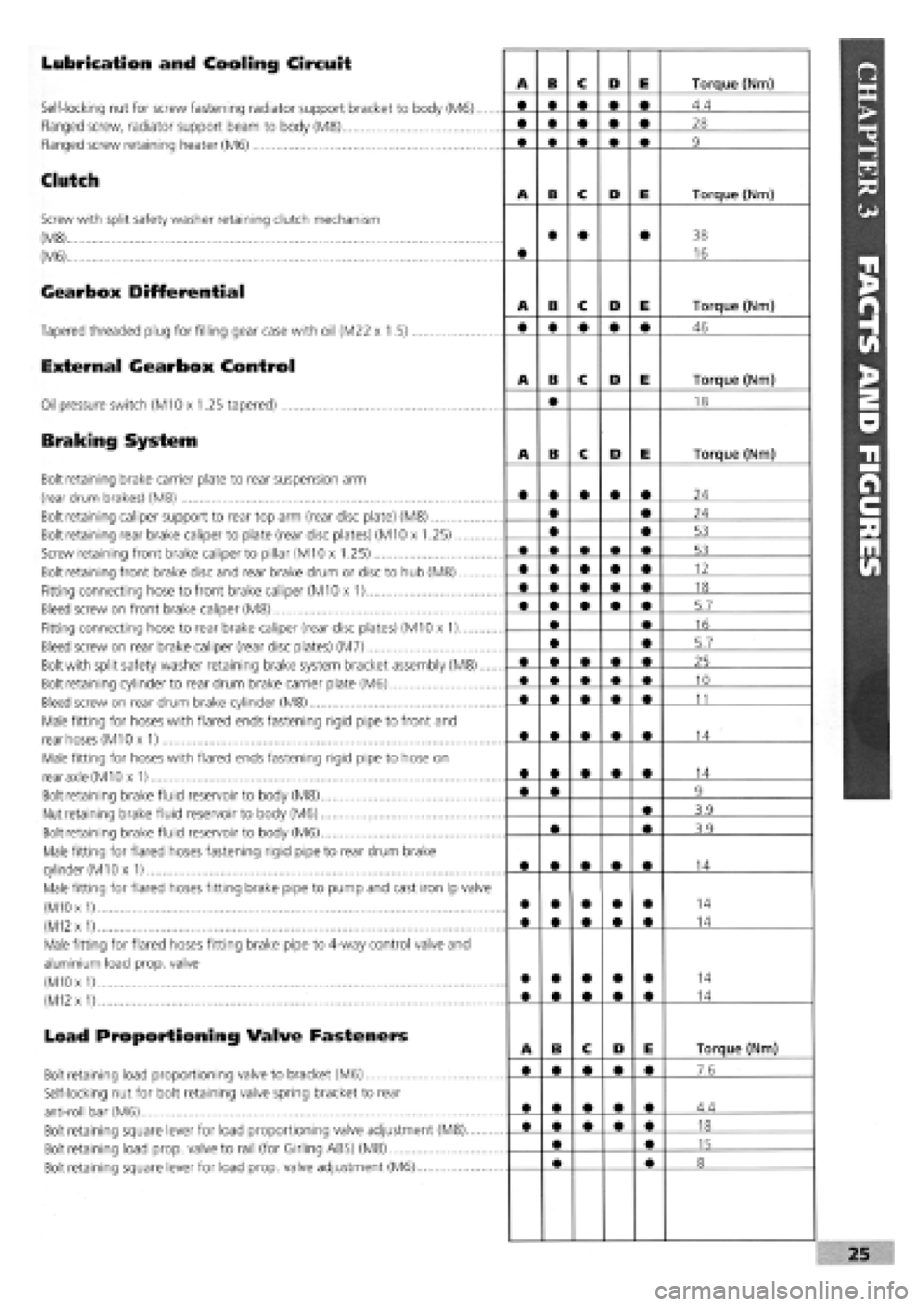

Lubrication and Cooling Circuit

Self-locking nut for screw fastening radiator support bracket to body (M6)....

Flanged screw, radiator support beam to body (M8)

Flanged screw retaining heater (M6)

Clutch

Screw with split safety washer retaining clutch mechanism

(M8)

(M6)

Gearbox Differential

Tapered threaded plug for filling gear case with oil (M22 x 1.5)

External Gearbox Control

Oil pressure switch (M10 x 1.25 tapered)

Braking System

Bolt retaining brake carrier plate to rear suspension arm

(rear drum brakes) (M8)

Bolt retaining caliper support to rear top arm (rear disc plate) (M8)

Bolt retaining rear brake caliper to plate (rear disc plates) (M10 x 1.25)

Screw retaining front brake caliper to pillar (M10 x 1.25)

Bolt retaining front brake disc and rear brake drum or disc to hub (M8)

Fitting connecting hose to front brake caliper (M10 x 1)

Bleed screw on front brake caliper (M8)

Fitting connecting hose to rear brake caliper (rear disc plates) (M10 x 1)

Bleed screw on rear brake caliper (rear disc plates) (M7)

Bolt with split safety washer retaining brake system bracket assembly (M8)....

Bolt retaining cylinder to rear drum brake carrier plate (M6)

Bleed screw on rear drum brake cylinder (M8)

Male fitting for hoses with flared ends fastening rigid pipe to front and

rear hoses (M10 x 1)

Male fitting for hoses with flared ends fastening rigid pipe to hose on

rear axle (M10 x 1)

Bolt retaining brake fluid reservoir to body (M8)

Nut retaining brake fluid reservoir to body (M6)

Bolt retaining brake fluid reservoir to body (M6)

Male fitting for flared hoses fastening rigid pipe to rear drum brake

cylinder

(M1

Ox 1)

Male fitting for flared hoses fitting brake pipe to pump and cast iron Ip valve

(M10

x

1)

(M12

x

1)

Male fitting for flared hoses fitting brake pipe to 4-way control valve and

aluminium load prop, valve

(M10 x

1)

(M12

x

1)

Load Proportioning Valve Fasteners

Bolt retaining load proportioning valve to bracket (M6)

Self-locking nut for bolt retaining valve spring bracket to rear

anti-roll bar (M6)

Bolt retaining square lever for load proportioning valve adjustment (M8)

Bolt retaining load prop, valve to rail (for Girling ABS) (M8)

Bolt retaining square lever for load prop, valve adjustment (M6)

Page 36 of 171

LUGGAGE COMPARTMENT LIGHT

7b. TIPO: Pull the lens

downwards to remove

it. Remove and replace

the 5W tubular bulb.

7c. TEMPRA SALOON:

From inside the boot,

lever the light unit out

of its slot with a screw-

driver. Remove and

replace the 5W tubular

bulb (A).

DASH BULBS

See Chapter 6, Repairs and Replacements for details of

instrument panel removal for access to its light bulbs. The

bulbs are a quarter-turn fit in the back of the panel.

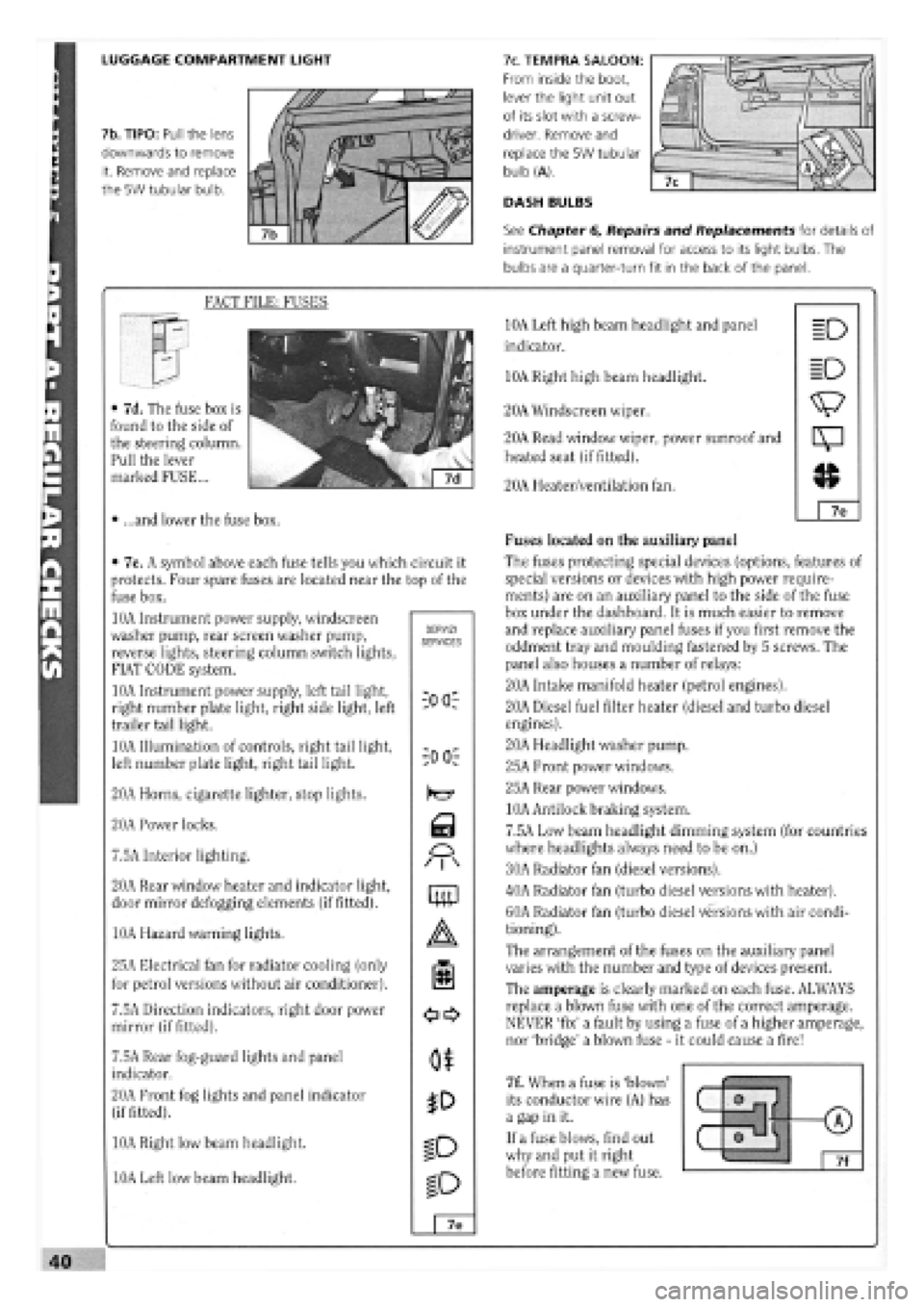

FACT FILE: FUSES

• 7d. The fuse box is

found to the side of

the steering column.

Pull the lever

marked FUSE...

• ...and lower the fuse box.

• 7e. A symbol above each fuse tells you which circuit it

protects. Four spare fuses are located near the top of the

fuse box.

10A Instrument power supply, windscreen

washer pump, rear screen washer pump,

reverse lights, steering column switch lights,

FIAT CODE system.

10A Instrument power supply, left tail light,

right number plate light, right side light, left

trailer tail light.

10A Illumination of controls, right tail light,

left number plate light, right tail light.

20A Horns, cigarette lighter, stop lights.

20A Power locks.

7.5A Interior lighting.

20A Rear window heater and indicator light,

door mirror defogging elements (if fitted).

10A Hazard warning lights.

25A Electrical fan for radiator cooling (only

for petrol versions without air conditioner).

7.5A Direction indicators, right door power

mirror (if fitted).

7.5A Rear fog-guard lights and panel

indicator.

20A Front fog lights and panel indicator

(if fitted).

10A Right low beam headlight.

10A Left low beam headlight.

SERVIZI SERVICES

iOO:

-00 r

Q

M

mp

o$

ID

ID

7e

10A Left high beam headlight and panel

indicator.

10A Right high beam headlight.

20A Windscreen wiper.

20A Read window wiper, power sunroof and

heated seat (if fitted).

20A Heater/ventilation fan.

Fuses located on the auxiliary panel

The fuses protecting special devices (options, features of

special versions or devices with high power require-

ments) are on an auxiliary panel to the side of the fuse

box under the dashboard. It is much easier to remove

and replace auxiliary panel fuses if you first remove the

oddment tray and moulding fastened by 5 screws. The

panel also houses a number of relays:

20A Intake manifold heater (petrol engines).

20A Diesel fuel filter heater (diesel and turbo diesel

engines).

20A Headlight washer pump.

25A Front power windows.

25A Rear power windows.

10A Antilock braking system.

7.5A Low beam headlight dimming system (for countries

where headlights always need to be on.)

30A Radiator fan (diesel versions).

40A Radiator fan (turbo diesel versions with heater).

60A Radiator fan (turbo diesel versions with air condi-

tioning).

The arrangement of the fuses on the auxiliary panel

varies with the number and type of devices present.

The amperage is clearly marked on each fuse. ALWAYS

replace a blown fuse with one of the correct amperage.

NEVER 'fix' a fault by using a fuse of a higher amperage,

nor 'bridge' a blown fuse

-

it could cause a fire!

7f. When a fuse is 'blown'

its conductor wire (A) has

a gap in it.

If a fuse blows, find out

why and put it right

before fitting a new fuse.

(7)

o m f (7) (7)

0 tJ 7f

Page 37 of 171

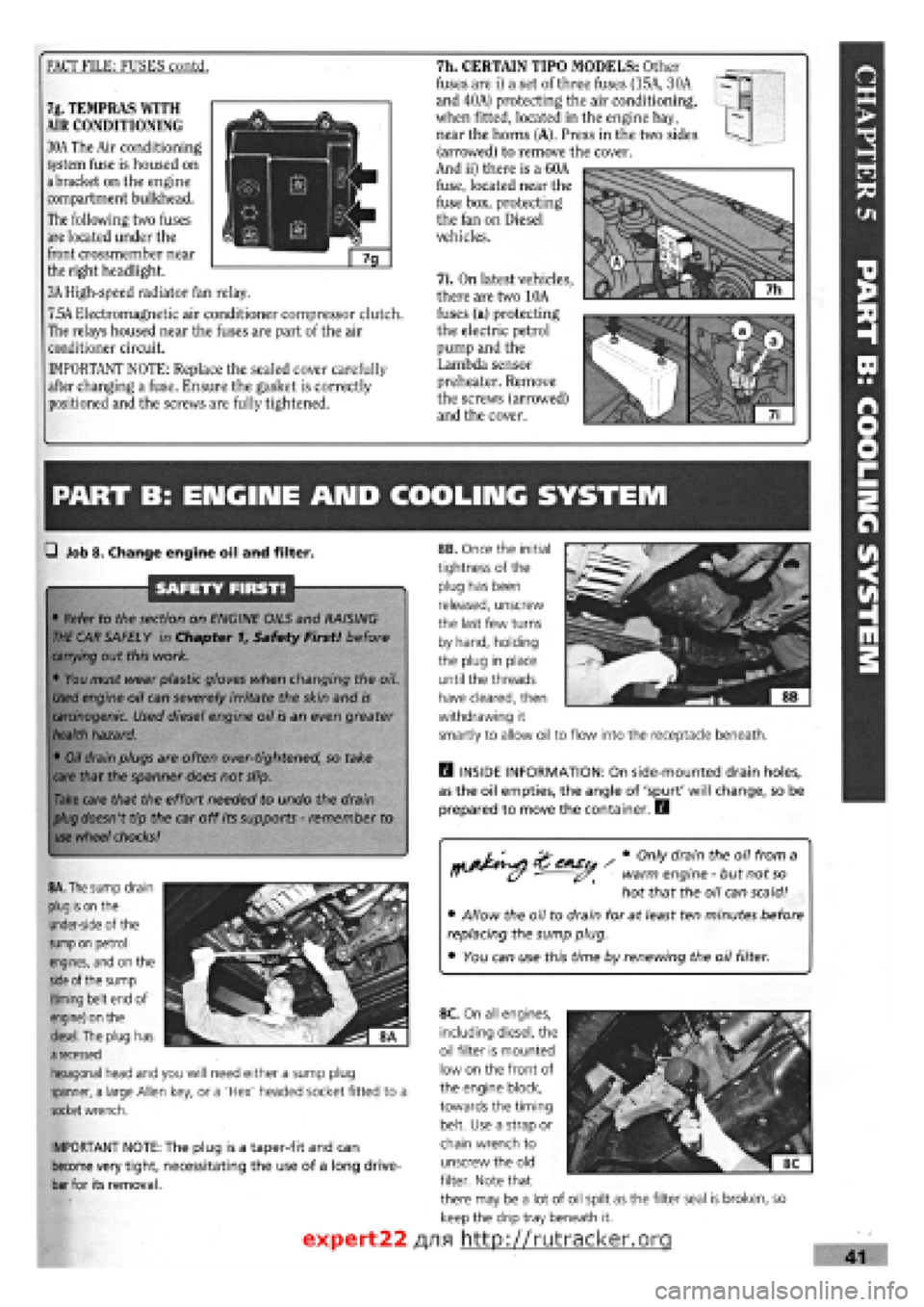

FACT FILE: FUSES contd. 7h. CERTAIN TIPO MODELS: Other

fuses are i) a set of three fuses (15A, 30A

and 40A) protecting the air conditioning,

when fitted, located in the engine bay,

near the horns (A). Press in the two sides

(arrowed) to remove the cover.

And ii) there is a 60A

fuse, located near the

fuse box, protecting

the fan on Diesel

vehicles.

7i. On latest vehicles,

there are two 10A

fuses (a) protecting

the electric petrol

pump and the

Lambda sensor

preheater. Remove

the screws (arrowed)

and the cover.

7g. TEMPRAS WITH

AIR CONDITIONING

30A The Air conditioning

system fuse is housed on

a bracket on the engine

compartment bulkhead.

The following two fuses

are located under the

front crossmember near

the right headlight.

3A High-speed radiator fan relay.

7.5A Electromagnetic air conditioner compressor clutch.

The relays housed near the fuses are part of the air

conditioner circuit.

IMPORTANT NOTE: Replace the sealed cover carefully

after changing a fuse. Ensure the gasket is correctly

positioned and the screws are fully tightened.

PART B: ENGIIME AND COOLING SYSTEM

Q Job 8. Change engine oil and filter.

SAFETY FIRST!

• Refer to the section on ENGINE OILS and RAISING

THE

CAR SAFELY in Chapter f, Safety First! before

carrying

out this work.

• You must wear plastic gloves when changing the oil.

Used

engine oil can severely irritate the skin and

is

carcinogenic.

Used diesel engine oil is an even greater

health

hazard.

•

Oil

drain plugs are often over-tightened, so take

care

that the spanner does not slip.

Take

care that the effort needed to undo the drain

plug

doesn't tip the car off its supports

-

remember to

use

wheel

chocks!

rtj&^si ' # °nly dram theu 0,7 fr°m a ff (y warm engine

-

but not

so

hot that the oil can scald!

• Allow the oil to drain for at least ten minutes before

replacing the sump plug.

• You can use this time by renewing the oil filter.

IMPORTANT NOTE: The plug is a taper-fit and can

become very tight, necessitating the use of a long drive-

bar for its removal.

H INSIDE INFORMATION: On side-mounted drain holes,

as the oil empties, the angle of 'spurt' will change, so be

prepared to move the container. E3

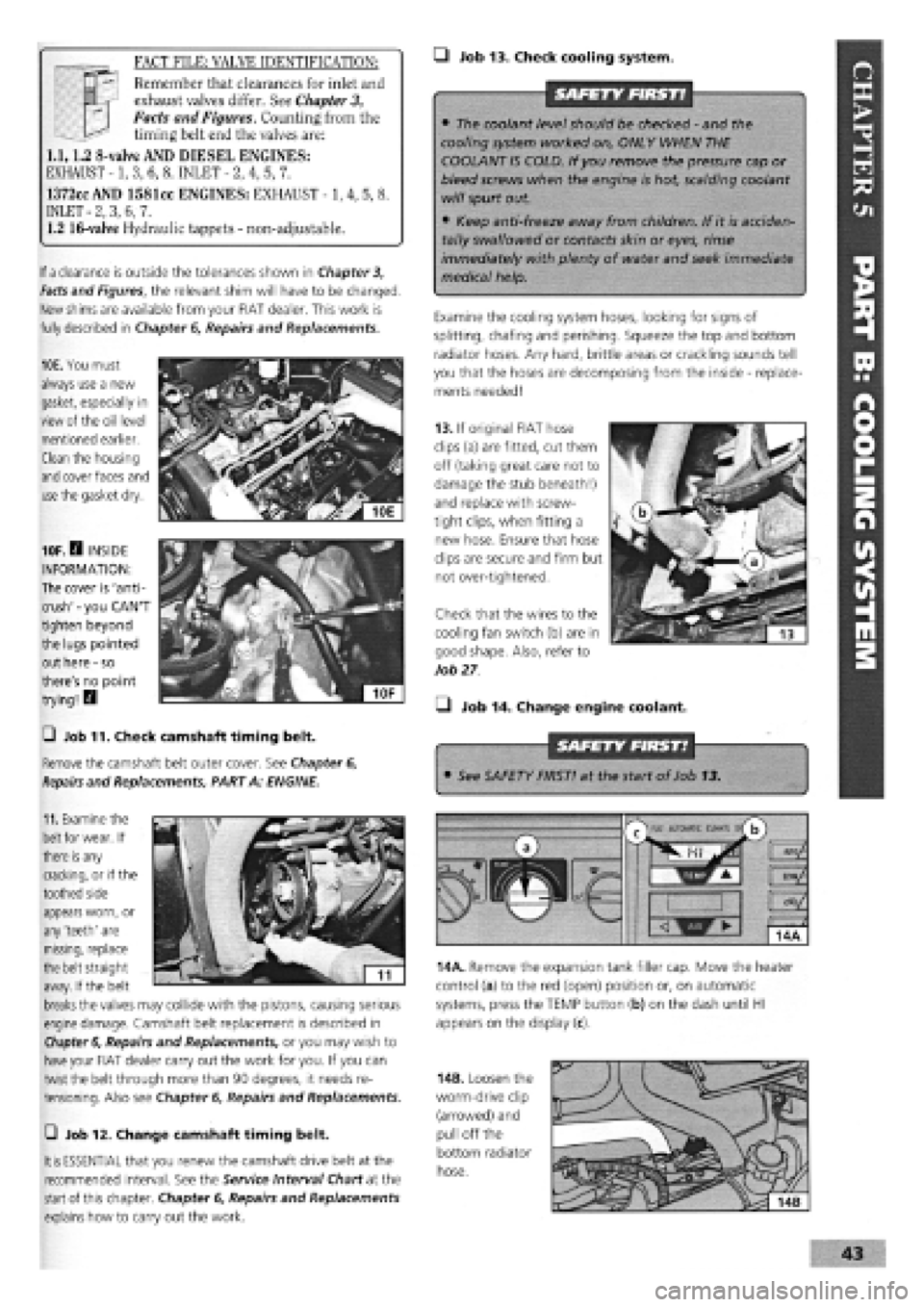

8A. The

sump drain

plug is on

the

under-side of the

sump on

petrol

engines, and on the

side

of the sump

(timing belt end of

engine) on the

diesel.

The plug has

a

recessed

hexagonal head and you will need either a sump plug

spanner, a large Allen key, or a 'Hex' headed socket fitted to a

socket

wrench.

8B. Once the initial

tightness of the

plug has been

released, unscrew

the last few turns

by hand, holding

the plug in place

until the threads

have cleared, then

withdrawing it

smartly to allow oil to flow into the receptacle beneath.

expert22

8C. On all engines,

including diesel, the

oil filter is mounted

low on the front of

the engine block,

towards the timing

belt. Use a strap or

chain wrench to

unscrew the old

filter. Note that

there may be a lot of oil spilt as the filter seal is broken, so

keep the drip tray beneath it.

/yifl http://rutracker.org

Page 39 of 171

—I Job 13. Check cooling system.

SAFETY FIRST!

• The coolant level should be checked

-

and the

cooling system worked on, ONLY WHEN THE

COOLANT IS COLD. If you remove the pressure cap or

bleed screws when the engine is hot, scalding coolant

will spurt out.

• Keep anti-freeze away from children. If it is acciden-

tally swallowed or contacts skin or eyes, rinse

immediately with plenty of water and seek immediate

medical help.

Examine the cooling system hoses, looking for signs of

splitting, chafing and perishing. Squeeze the top and bottom

radiator hoses. Any hard, brittle areas or crackling sounds tell

you that the hoses are decomposing from the inside

-

replace-

ments needed!

SAFETY FIRST!

If

a

clearance is outside the tolerances shown in Chapter 3,

Facts

and Figures, the relevant shim will have to be changed.

New

shims

are available from your FIAT dealer. This work is

fully described in Chapter

6,

Repairs and Replacements.

10E. You must

always use a new

gasket, especially in

view of the oil level

mentioned earlier.

Clean the housing

and

cover faces and

use

the gasket dry.

11.

Examine the

belt

for wear. If

there

is

any

cracking, or if the

toothed side

10F.H INSIDE

INFORMATION:

The cover is 'anti-

crush'

-

you CAN'T

tighten beyond

the lugs pointed

out here

-

so

there's no point

trying! H

0 Job 11. Check camshaft timing belt.

Remove the camshaft belt outer cover. See Chapter 6,

Repairs

and Replacements, PART A: ENGINE.

FACT FILE: VALVE IDENTIFICATION:

T

—

Remember that clearances for inlet and

3™ exhaust valves differ. See

Chapter

3,

Facts and Figures. Counting from the

—^ timing belt end the valves are:

1.1,1.2 8-valve AND DIESEL ENGINES:

EXHAUST -1, 3, 6, 8. INLET

-

2, 4, 5, 7.

1372cc AND 1581cc ENGINES: EXHAUST -1, 4, 5, 8.

INLET

-

2, 3, 6, 7.

1.2 16-valve Hydraulic tappets

-

non-adjustable.

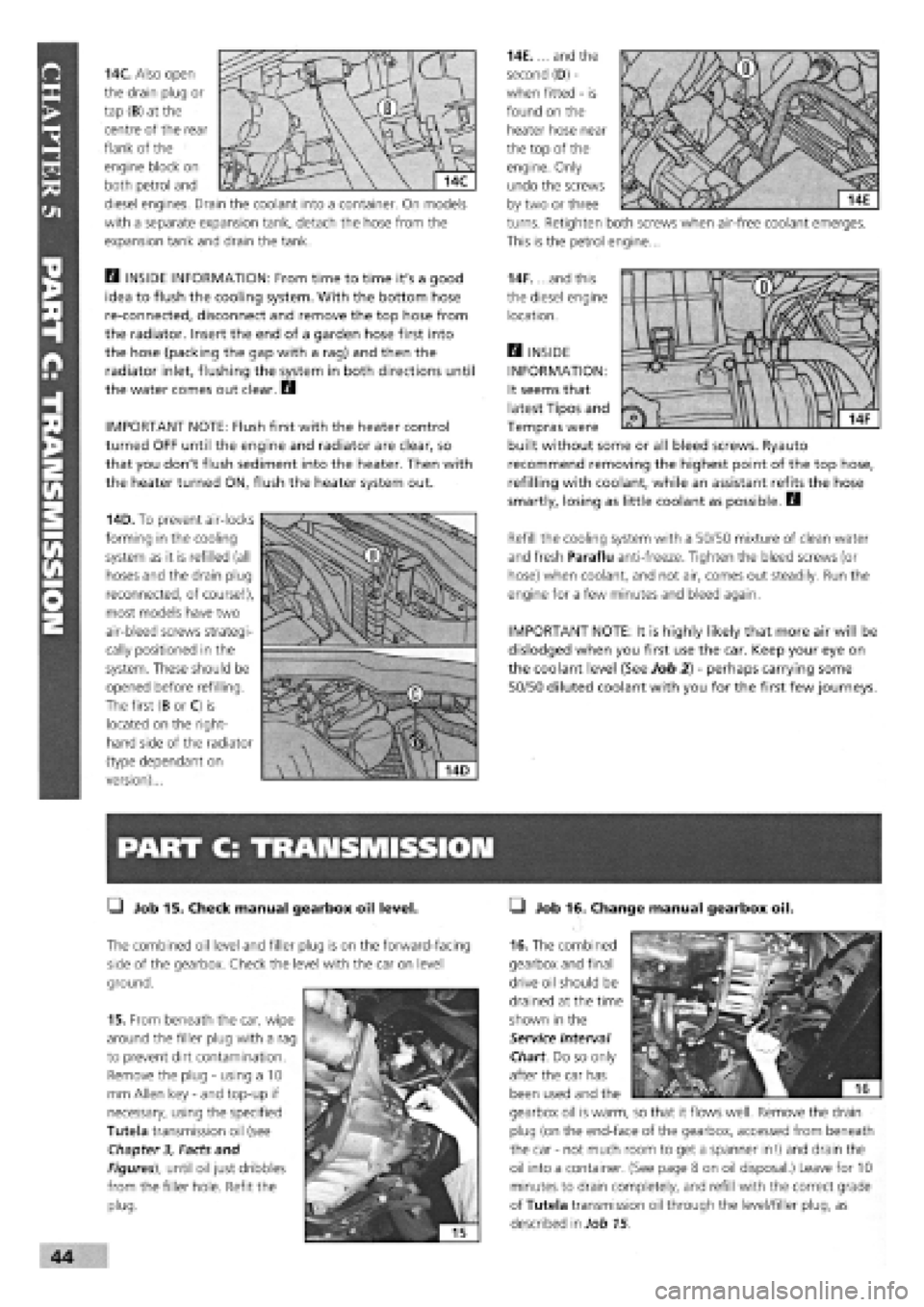

13. If original FIAT hose

clips (a) are fitted, cut them

off (taking great care not to

damage the stub beneath!)

and replace with screw-

tight clips, when fitting a

new hose. Ensure that hose

clips are secure and firm but

not over-tightened.

Check that the wires to the

cooling fan switch (b) are in

good shape. Also, refer to

Job

27

• Job 14. Change engine coolant.

• See SAFETY FIRST! at the start of Job 13.

appears worn, or

any 'teeth' are

missing, replace

the belt straight

away. If the belt

breaks

the valves may collide with the pistons, causing serious

engine damage. Camshaft belt replacement is described in

Chapter 6,

Repairs and Replacements, or you may wish to

have

your FIAT dealer carry out the work for you. If you can

twist the belt through more than 90 degrees, it needs re-

tensioning. Also see Chapter

6,

Repairs and Replacements.

m

AUtOKAlIC CtMAU s/

b

14A. Remove the expansion tank filler cap. Move the heater

control (a) to the red (open) position or, on automatic

systems, press the TEMP button (b) on the dash until HI

appears on the display (c).

—i Job 12. Change camshaft timing belt.

It is

ESSENTIAL that you renew the camshaft drive belt at the

recommended interval. See the Service Interval Chart at the

start

of this chapter. Chapter

6,

Repairs and Replacements

explains how to carry out the work.

14B. Loosen the

worm-drive clip

(arrowed) and

pull off the

bottom radiator

hose.

Page 40 of 171

14C. Also open

the drain plug or

tap (B) at the

centre of the rear

flank of the

engine block on

both petrol and

diesel engines. Drain the coolant into a container. On models

with a separate expansion tank, detach the hose from the

expansion tank and drain the tank.

Q INSIDE INFORMATION: From time to time it's a good

idea to flush the cooling system. With the bottom hose

re-connected, disconnect and remove the top hose from

the radiator. Insert the end of a garden hose first into

the hose (packing the gap with a rag) and then the

radiator inlet, flushing the system in both directions until

the water comes out clear. Q

IMPORTANT NOTE: Flush first with the heater control

turned OFF until the engine and radiator are clear, so

that you don't flush sediment into the heater. Then with

the heater turned ON, flush the heater system out.

14D. To prevent air-locks

forming in the cooling

system as it is refilled (all

hoses and the drain plug

reconnected, of course!),

most models have two

air-bleed screws strategi-

cally positioned in the

system. These should be

opened before refilling.

The first (B or C) is

located on the right-

hand side of the radiator

(type dependant on

version)...

PART C: TRANSMISSION

• Job 15. Check manual gearbox oil level.

The combined oil level and filler plug is on the forward-facing

side of the gearbox. Check the level with the car on level

ground.

15. From beneath the car, wipe

around the filler plug with a rag

to prevent dirt contamination.

Remove the plug

-

using a 10

mm Allen key

-

and top-up if

necessary, using the specified

Tutela transmission oil (see

Chapter

3,

Facts and

Figures), until oil just dribbles

from the filler hole. Refit the

plug.

14E.... and the

second (D)

-

when fitted

-

is

found on the

heater hose near

the top of the

engine. Only

undo the screws

by two or three

turns. Retighten both screws when air-free coolant emerges.

This is the petrol engine...

14F. ...and this

the diesel engine

location.

H INSIDE

INFORMATION:

It seems that

latest Tipos and

Tempras were

built without some or all bleed screws. Ryauto

recommend removing the highest point of the top hose,

refilling with coolant, while an assistant refits the hose

smartly, losing as little coolant as possible. D

Refill the cooling system with a 50/50 mixture of clean water

and fresh Paraflu anti-freeze. Tighten the bleed screws (or

hose) when coolant, and not air, comes out steadily. Run the

engine for a few minutes and bleed again.

IMPORTANT NOTE: It is highly likely that more air will be

dislodged when you first use the car. Keep your eye on

the coolant level (See Job 2)

-

perhaps carrying some

50/50 diluted coolant with you for the first few journeys.

• Job 16. Change manual gearbox oil.

16. The combined

gearbox and final

drive oil should be

drained at the time

shown in the

Service Interval

Chart. Do so only

after the car has

been used and the

gearbox oil is warm, so that it flows well. Remove the drain

plug (on the end-face of the gearbox, accessed from beneath

the car

-

not much room to get a spanner in!) and drain the

oil into a container. (See page 8 on oil disposal.) Leave for 10

minutes to drain completely, and refill with the correct grade

of Tutela transmission oil through the level/filler plug, as

described in Job 15.

Page 84 of 171

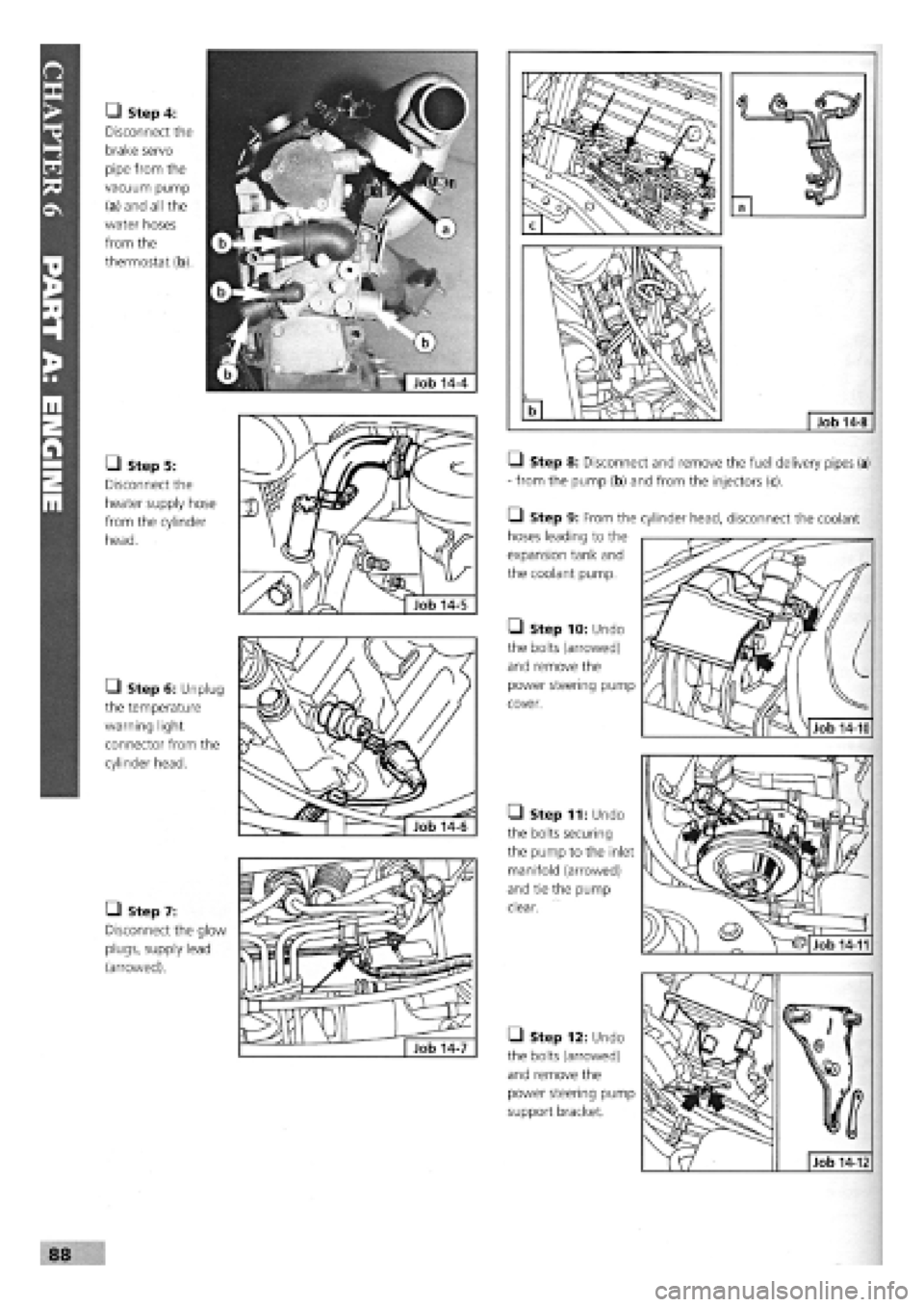

• Step 4:

Disconnect the

brake servo

pipe from the

vacuum pump

(a) and all the

water hoses

from the

thermostat (b).

• Step 5:

Disconnect the

heater supply hose

from the cylinder

head.

• Step 6: Unplug

the temperature

warning light

connector from the

cylinder head.

• Step 7:

Disconnect the glow

plugs, supply lead

(arrowed).

Q Step 8: Disconnect and remove the fuel delivery pipes (a)

- from the pump (b) and from the injectors (c).

• Step 9: From the

hoses leading to the

expansion tank and

the coolant pump.

• Step 10: Undo

the bolts (arrowed)

and remove the

power steering pump

cover.

• Step 11: Undo

the bolts securing

the pump to the inlet

manifold (arrowed)

and tie the pump

clear.

• Step 12: Undo

the bolts (arrowed)

and remove the

power steering pump

support bracket.

88

cylinder head, disconnect the coolant

Job 14-10

Job 14-12

Job 14-11

Page 117 of 171

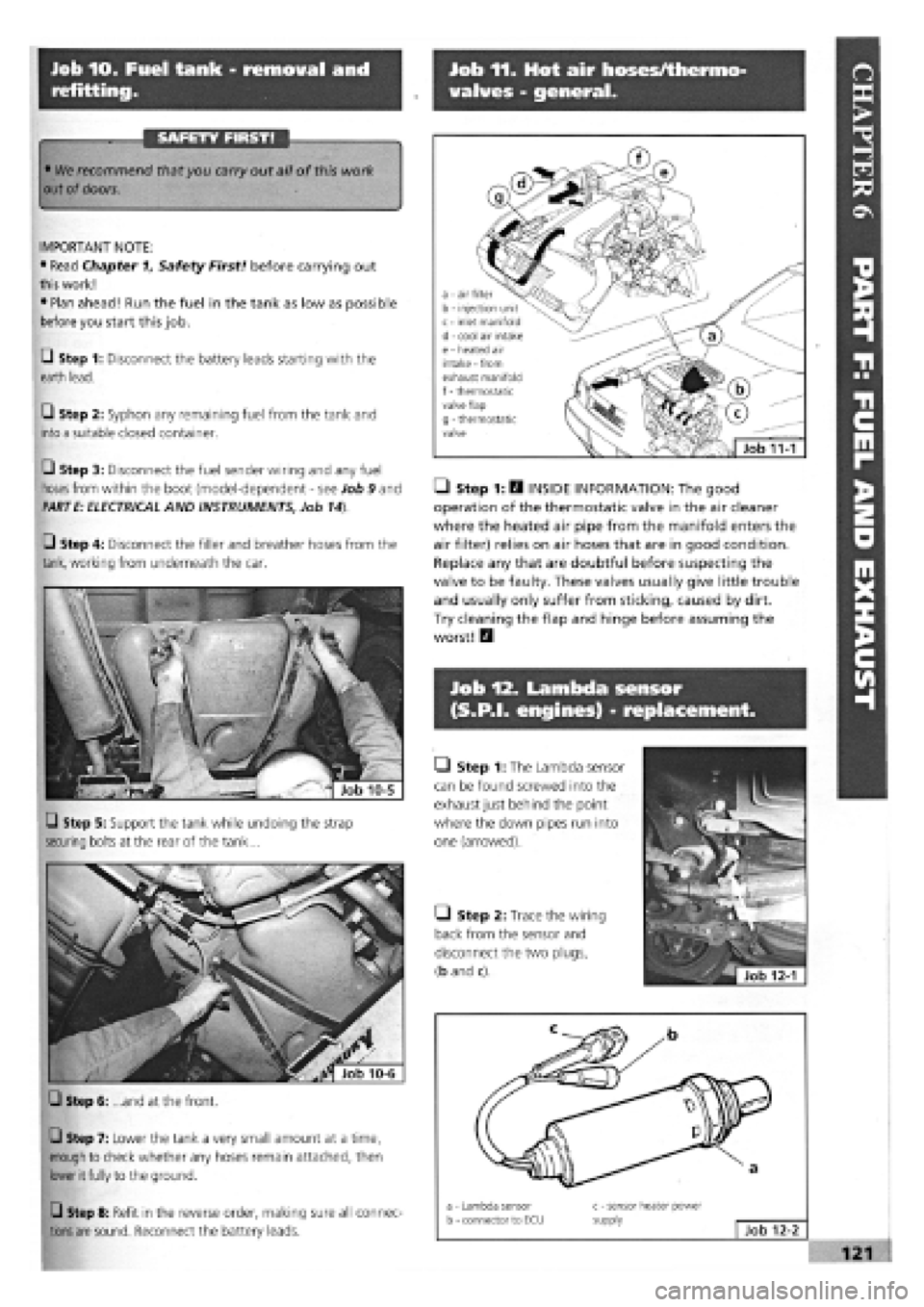

Job 10. Fuel tank - removal and

refitting.

Job 11. Hot air hoses/thermo-

valves - general.

SAFETY FIRST!

Job 12. Lambda sensor

(S.P.I, engines) - replacement.

• We recommend that you carry out all of this work

out of

doors.

I

IMPORTANT NOTE:

• Read Chapter 1, Safety First! before carrying out

this

work!

• Plan ahead! Run the fuel in the tank as low as possible

before you start this job.

Q Step 1: Disconnect the battery leads starting with the

earth lead.

• Step 2: Syphon any remaining fuel from the tank and

into a suitable closed container.

Q Step 3: Disconnect the fuel sender wiring and any fuel

hoses

from within the boot (model-dependent

-

see Job 9 and

PARTE: ELECTRICAL AND INSTRUMENTS, Job 14).

• Step 4: Disconnect the filler and breather hoses from the

tank,

working from underneath the car.

a - Lambda sensor b - connector to ECU c - sensor heater power supply Job 12-2

Q Step 5: Support the tank while undoing the strap

securing bolts at the rear of the tank...

Q Step 6: ...and at the front.

Q Step 7: Lower the tank a very small amount at a time,

enough to check whether any hoses remain attached, then

lower it fully to the ground.

Q Step 8: Refit in the reverse order, making sure all connec-

tions are

sound. Reconnect the battery leads.

• Step 1: H INSIDE INFORMATION: The good

operation of the thermostatic valve in the air cleaner

where the heated air pipe from the manifold enters the

air filter) relies on air hoses that are in good condition.

Replace any that are doubtful before suspecting the

valve to be faulty. These valves usually give little trouble

and usually only suffer from sticking, caused by dirt.

Try cleaning the flap and hinge before assuming the

worst! Q

• Step 1: The Lambda sensor

can be found screwed into the

exhaust just behind the point

where the down pipes run into

one (arrowed).

Q Step 2: Trace the wiring

back from the sensor and

disconnect the two plugs,

(b and c).

a - air filter b - injection unit c - inlet manifold d - cool air intake e - heated air intake - from exhaust manifold f

-

thermostatic valve flap g - thermostatic valve

Job 11-1

Page 151 of 171

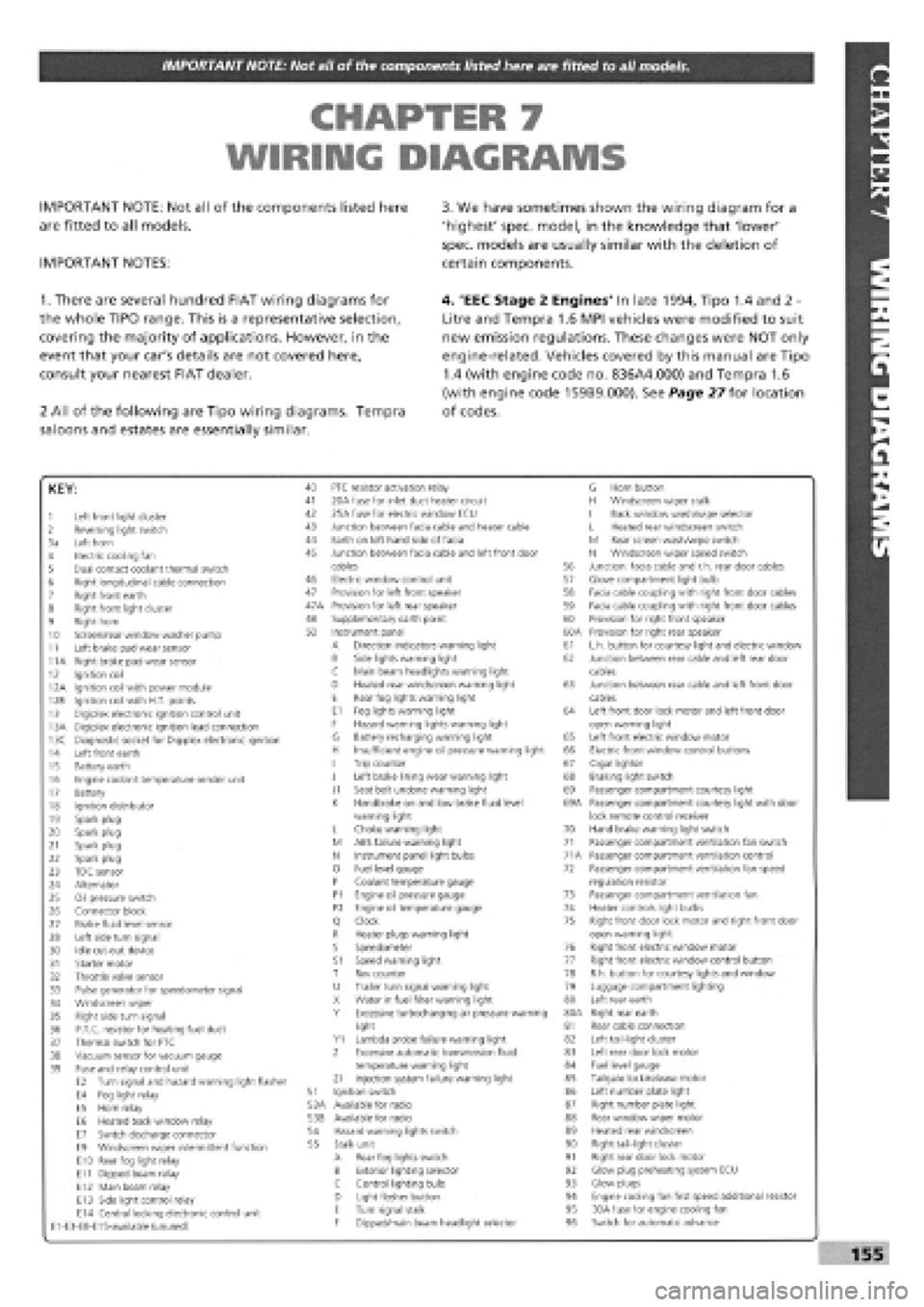

IMPORTANT NOTE: Not all of the components listed here are fitted to all models.

CHAPTER 7

WIRING DIAGRAMS

IMPORTANT NOTE: Not all of the components listed here

are fitted to all models.

IMPORTANT NOTES:

3. We have sometimes shown the wiring diagram for a

'highest' spec, model, in the knowledge that 'lower'

spec, models are usually similar with the deletion of

certain components.

1. There are several hundred FIAT wiring diagrams for

the whole TIPO range. This is a representative selection,

covering the majority of applications. However, in the

event that your car's details are not covered here,

consult your nearest FIAT dealer.

2 All of the following are Tipo wiring diagrams. Tempra

saloons and estates are essentially similar.

4. 'EEC Stage 2 Engines' In late 1994, Tipo 1.4 and 2 -

Litre and Tempra 1.6 MPI vehicles were modified to suit

new emission regulations. These changes were NOT only

engine-related. Vehicles covered by this manual are Tipo

1.4 (with engine code no. 836A4.000) and Tempra 1.6

(with engine code 159B9.000). See Page 27 for location

of codes.

KEY:

1 Left front light cluster 2 Reversing light switch 3a Left horn 4 Electric cooling fan 5 Dual contact coolant thermal switch 6 Right longitudinal cable connection 7 Right front earth 8 Right front light cluster 9 Right horn 10 Screen/rear window washer pump 11 Left brake pad wear sensor 11A Right brake pad wear sensor 12 Ignition coil 12A Ignition coil with power module 12B Ignition coil with H.T. points 13 Digiplex electronic ignition control unit 13A Digiplex electronic ignition lead connection 13C Diagnostic socket for Digiplex electronic ignition 14 Left front earth 15 Battery earth 16 Engine coolant temperature sender unit 17 Battery 18 Ignition distributor 19 Sparkplug 20 Spark plug 21 Sparkplug 22 Spark plug 23 TDC sensor 24 Alternator 25 Oil pressure switch 26 Connector block 27 Brake fluid level sensor 28 Left side turn signal 30 Idle cut-out device 31 Starter motor 32 Throttle valve sensor 33 Pulse generator for speedometer signal 34 Windscreen wiper 35 Right side turn signal 36 P.T.C. resistor for heating fuel duct 37 Thermal switch for PTC 38 Vacuum sensor for vacuum gauge 39 Fuse and relay control unit E2 Turn signal and hazard warning light flasher E4 Fog light relay E5 Horn relay E6 Heated back window relay E7 Switch discharge connector E9 Windscreen wiper intermittent function E10 Rear fog light relay E11 Dipped beam relay E12 Main beam relay E13 Side light control relay E14 Central locking electronic control unit E1-E3-E8-E15-available (unused)

40 PTC resistor activation relay 41 20A fuse for inlet duct heater circuit 42 25A fuse for electric window ECU 43 Junction between facia cable and heater cable 44 Earth on left hand side of facia 45 Junction between facia cable and left front door

G Horn button H Windscreen wiper stalk I Back window wash/wipe selector L Heated rear windscreen switch M Rear screen wash/wipe switch N Windscreen wiper speed switch cables 56 Junction: facia cable and r.h. rear door cables Electric window control unit 57 Glove compartment light bulb Provision for left front speaker 58 Facia cable coupling with right front door cables Provision for left rear speaker 59 Facia cable coupling with right front door cables Supplementary earth point 60 Provision for right front speaker Instrument panel 60A Provision for right rear speaker A Direction indicators warning light 61 L.h. button for courtesy light and electric window B Side lights warning light 62 Junction between rear cable and left rear door C Main beam headlights warning light cables D Heated rear windscreen warning light 63 Junction between rear cable and left front door E Rear fog lights warning light cables E1 Fog lights warning light 64 Left front door lock motor and left front door F Hazard warning lights warning light open warning light G Battery recharging warning light 65 Left front electric window motor H Insufficient engine oil pressure warning light 66 Electric front window control buttons I Trip counter 67 Cigar lighter J Left brake lining wear warning light 68 Braking light switch J1 Seat belt undone warning light 69 Passenger compartment courtesy light K Handbrake on and low brake fluid level 69A Passenger compartment courtesy light with door warning light lock remote control receiver L Choke warning light 70 Hand brake warning light switch M ABS failure warning light 71 Passenger compartment ventilation fan switch N Instrument panel light bulbs 71A Passenger compartment ventilation control 0 Fuel level gauge 72 Passenger compartment ventilation fan speed P Coolant temperature gauge regulation resistor P1 Engine oil pressure gauge 73 Passenger compartment ventilation fan P2 Engine oil temperature gauge 74 Heater controls light bulbs Q Clock 75 Right front door lock motor and right front door R Heater plugs warning light open warning light S Speedometer 76 Right front electric window motor S1 Speed warning light 77 Right front electric window control button T Rev counter 78 R.h. button for courtesy lights and window U Trailer turn signal warning light 79 Luggage compartment lighting X Water in fuel filter warning light 80 Left rear earth Y Excessive turbocharging air pressure warning 80A Right rear earth light 81 Rear cable connection Y1 Lambda probe failure warning light 82 Left tail-light cluster Z Excessive automatic transmission fluid 83 Left rear door lock motor temperature warning light 84 Fuel level gauge Z1 Injection system failure warning light 85 Tailgate lock/release motor Ignition switch 86 Left number plate light Available for radio 87 Right number plate light Available for radio 88 Rear window wiper motor Hazard warning lights switch 89 Heated rear windscreen Stalk unit 90 Right tail-light cluster A Rear fog lights switch 91 Right rear door lock motor B Exterior lighting selector 92 Glow plug preheating system ECU c Control lighting bulb 93 Glow plugs D Light flasher button 94 Engine cooling fan first speed additional resistor E Turn signal stalk 95 30A fuse for engine cooling fan F Dipped/main beam headlight selector 96 Switch for automatic advance

155