light FIAT TIPO 4DOORS 2016 1.G Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: TIPO 4DOORS, Model: FIAT TIPO 4DOORS 2016 1.GPages: 204, PDF Size: 4.94 MB

Page 113 of 204

CHANGING A WHEEL

JACK

132)

37)

Please note that:

the jack weight is 2.15 kg;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another genuine one;

No tool other than its cranking device

may be fitted on the jack.

Servicing

Prevent any dirt from depositing on

the "worm screw";

Keep the "worm screw" lubricated;

Never modify the jack.

Conditions for non-use

Temperatures below −40°C;

On sandy or muddy ground;

On uneven ground;

On steep roads;

In extreme weather conditions:

thunderstorms, typhoons, hurricanes,

blizzards, storms, etc.

In direct contact with the engine or

for repairs under the vehicle.

On boats.

CHANGING PROCEDURE

127) 128) 129) 130) 131)

35) 36)

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can change the wheel safely. The

ground must be flat and sufficiently

compact;

stop the engine, engage the hazard

warning lights and the parking brake;

engage first gear or reverse or, for

versions with automatic transmission (if

present), move the lever to position P

(Park);

wear the reflective safety jacket

before getting out of the car (anyway

comply with the laws in force in the

country you are driving in);

open the luggage compartment and

lift up the mat;

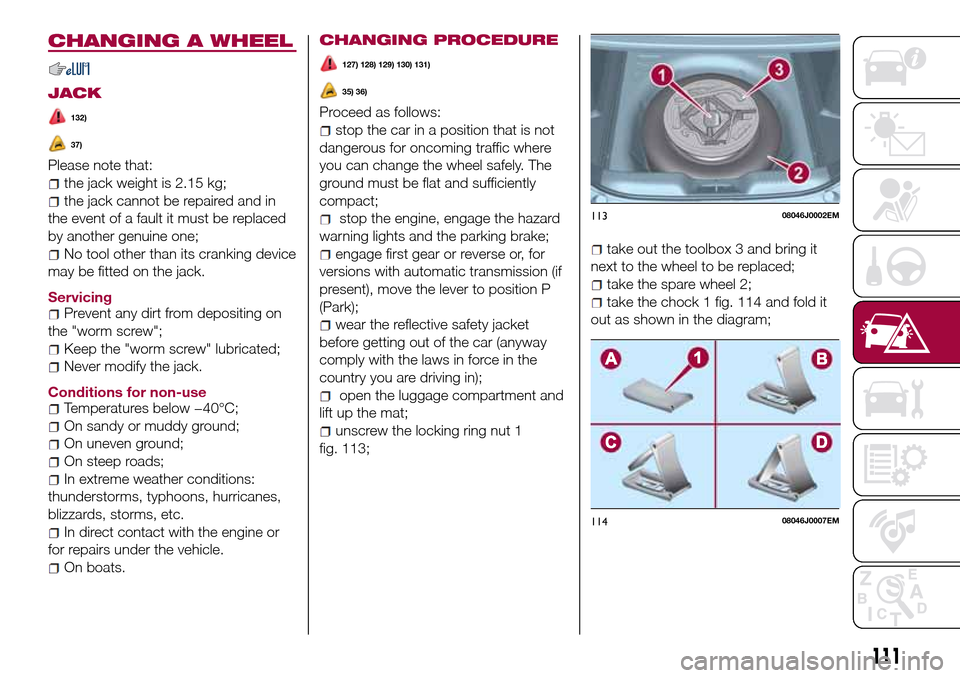

unscrew the locking ring nut 1

fig. 113;

take out the toolbox 3 and bring it

next to the wheel to be replaced;

take the spare wheel 2;

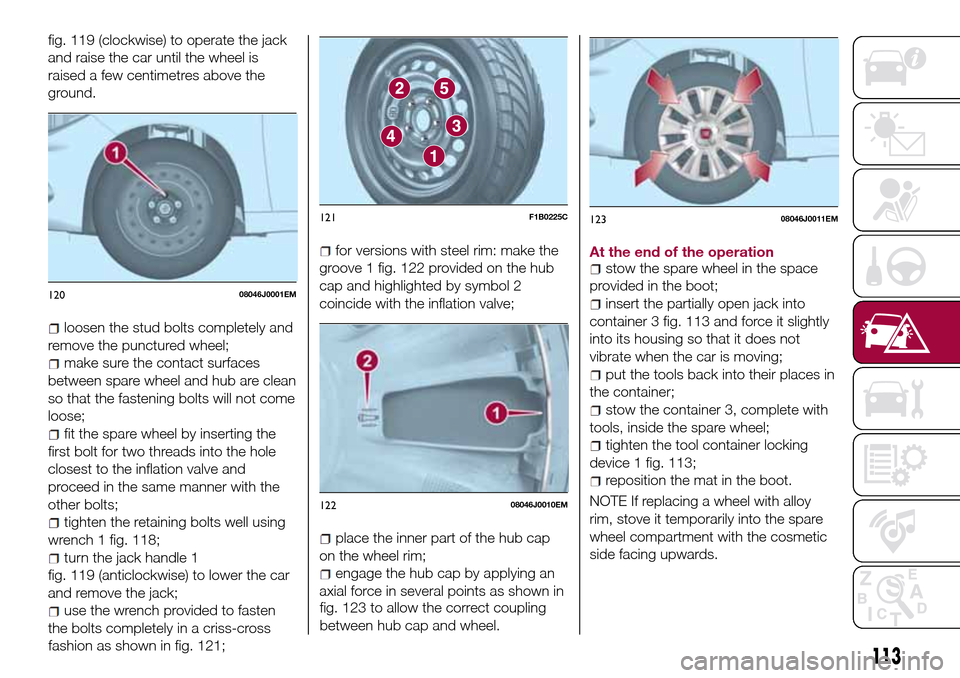

take the chock 1 fig. 114 and fold it

out as shown in the diagram;

11308046J0002EM

11408046J0007EM

111

Page 115 of 204

fig. 119 (clockwise) to operate the jack

and raise the car until the wheel is

raised a few centimetres above the

ground.

loosen the stud bolts completely and

remove the punctured wheel;

make sure the contact surfaces

between spare wheel and hub are clean

so that the fastening bolts will not come

loose;

fit the spare wheel by inserting the

first bolt for two threads into the hole

closest to the inflation valve and

proceed in the same manner with the

other bolts;

tighten the retaining bolts well using

wrench 1 fig. 118;

turn the jack handle 1

fig. 119 (anticlockwise) to lower the car

and remove the jack;

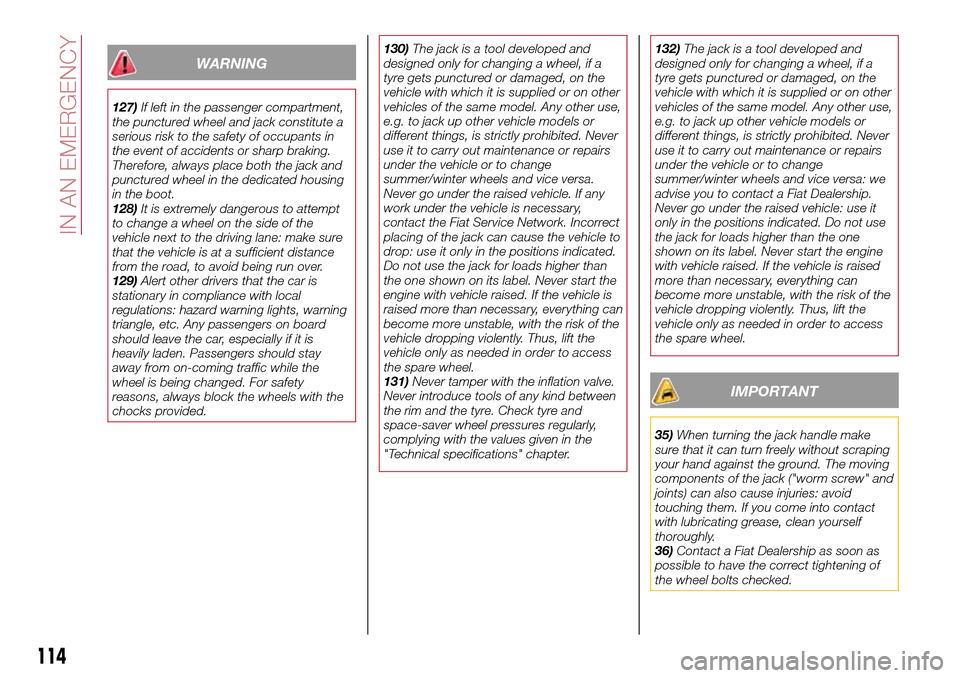

use the wrench provided to fasten

the bolts completely in a criss-cross

fashion as shown in fig. 121;

for versions with steel rim: make the

groove 1 fig. 122 provided on the hub

cap and highlighted by symbol 2

coincide with the inflation valve;

place the inner part of the hub cap

on the wheel rim;

engage the hub cap by applying an

axial force in several points as shown in

fig. 123 to allow the correct coupling

between hub cap and wheel.At the end of the operation

stow the spare wheel in the space

provided in the boot;

insert the partially open jack into

container 3 fig. 113 and force it slightly

into its housing so that it does not

vibrate when the car is moving;

put the tools back into their places in

the container;

stow the container 3, complete with

tools, inside the spare wheel;

tighten the tool container locking

device 1 fig. 113;

reposition the mat in the boot.

NOTE If replacing a wheel with alloy

rim, stove it temporarily into the spare

wheel compartment with the cosmetic

side facing upwards.

12008046J0001EM

121F1B0225C

12208046J0010EM

12308046J0011EM

113

Page 116 of 204

WARNING

127)If left in the passenger compartment,

the punctured wheel and jack constitute a

serious risk to the safety of occupants in

the event of accidents or sharp braking.

Therefore, always place both the jack and

punctured wheel in the dedicated housing

in the boot.

128)It is extremely dangerous to attempt

to change a wheel on the side of the

vehicle next to the driving lane: make sure

that the vehicle is at a sufficient distance

from the road, to avoid being run over.

129)Alert other drivers that the car is

stationary in compliance with local

regulations: hazard warning lights, warning

triangle, etc. Any passengers on board

should leave the car, especially if it is

heavily laden. Passengers should stay

away from on-coming traffic while the

wheel is being changed. For safety

reasons, always block the wheels with the

chocks provided.130)The jack is a tool developed and

designed only for changing a wheel, if a

tyre gets punctured or damaged, on the

vehicle with which it is supplied or on other

vehicles of the same model. Any other use,

e.g. to jack up other vehicle models or

different things, is strictly prohibited. Never

use it to carry out maintenance or repairs

under the vehicle or to change

summer/winter wheels and vice versa.

Never go under the raised vehicle. If any

work under the vehicle is necessary,

contact the Fiat Service Network. Incorrect

placing of the jack can cause the vehicle to

drop: use it only in the positions indicated.

Do not use the jack for loads higher than

the one shown on its label. Never start the

engine with vehicle raised. If the vehicle is

raised more than necessary, everything can

become more unstable, with the risk of the

vehicle dropping violently. Thus, lift the

vehicle only as needed in order to access

the spare wheel.

131)Never tamper with the inflation valve.

Never introduce tools of any kind between

the rim and the tyre. Check tyre and

space-saver wheel pressures regularly,

complying with the values given in the

"Technical specifications" chapter.132)The jack is a tool developed and

designed only for changing a wheel, if a

tyre gets punctured or damaged, on the

vehicle with which it is supplied or on other

vehicles of the same model. Any other use,

e.g. to jack up other vehicle models or

different things, is strictly prohibited. Never

use it to carry out maintenance or repairs

under the vehicle or to change

summer/winter wheels and vice versa: we

advise you to contact a Fiat Dealership.

Never go under the raised vehicle: use it

only in the positions indicated. Do not use

the jack for loads higher than the one

shown on its label. Never start the engine

with vehicle raised. If the vehicle is raised

more than necessary, everything can

become more unstable, with the risk of the

vehicle dropping violently. Thus, lift the

vehicle only as needed in order to access

the spare wheel.

IMPORTANT

35)When turning the jack handle make

sure that it can turn freely without scraping

your hand against the ground. The moving

components of the jack ("worm screw" and

joints) can also cause injuries: avoid

touching them. If you come into contact

with lubricating grease, clean yourself

thoroughly.

36)Contact a Fiat Dealership as soon as

possible to have the correct tightening of

the wheel bolts checked.

114

IN AN EMERGENCY

Page 119 of 204

WARNING

133)The information required by the

applicable regulation is indicated on the

Fix&Go kit package label. Compliance with

the indications on the label is an essential

condition to ensure the safety and the

effectiveness of the Fix&Go kit. Carefully

read the label before use, avoid improper

use. Fix&Go is subject to expiration and

must be replaced periodically. The kit

should be used by adults and cannot be

used by children.

IMPORTANT

38)Show the package and the label to the

personnel charged with handling the tyre

treated with the tyre repair kit.

39)Fix&Go provides a temporary repair,

therefore the tyre must be examined and

repaired by a specialist as soon as

possible. The sealing fluid is effective at

temperatures between -40°C and +50°C. It

is possible to repair tyres which have been

damaged on tread up to a diameter of

4mm; however, tyres damaged on their

side cannot be repaired. Before using

Fix&Go kit, ensure that the tyre isn't

excessively damaged and that the rim is in

good condition, otherwise do not use it and

contact a Fiat Dealership. Do not remove

foreign bodies from the tyre. Do not let the

compressor turned on for more than 20

consecutive minutes - overheating hazard.

EMERGENCY

STARTING

If the battery is flat, a jump starting can

be performed using the battery and the

cables of another vehicle, or using an

auxiliary battery. In all cases, the battery

used must have a capacity equal to or

a little higher than the flat one.

40)

IMPORTANT NOTES

Do not use an auxiliary battery or any

other source of external supply with a

voltage above 12 V: the battery, the

starter, the alternator and the electrical

system of the vehicle could be

damaged.

Do not attempt jump starting if the

battery is frozen. The battery could

break and explode!

PREPARATION TO JUMP

STARTING

The vehicle battery is located in the

engine compartment, behind the left

light cluster.

134) 135) 136) 137)

IMPORTANT The positive terminal (+) of

the battery is shielded by a protective

element. Raise it to access the terminal.

Proceed as follows:

operate the parking brake, move the

lever to P (Park), for versions equipped

with automatic transmission (if present),

or neutral, for versions with manual

gearbox, then set the ignition device to

STOP;

switch off all the other electrical

devices in the vehicle;

should you be using the battery of

another vehicle, park the other vehicle

within the range of the cables used for

the connection, operate the parking

brake and ensure that its ignition is off.

IMPORTANT Never connect the

negative terminals of the two batteries

directly! If the auxiliary battery is

installed on another vehicle, check that

there is no accidental contact of metal

parts between the two vehicles, since

an earth connection may result, with

the risk of serious injury to any people

who may be nearby.

IMPORTANT If the procedure below is

carried out incorrectly, it can cause

severe injury to people or damage the

recharging system of one or both

vehicles. Carefully follow the

instructions given below.

Cable connection

41)

Proceed as follows to carry out a jump

starting fig. 128:

117

Page 121 of 204

FUEL CUT-OFF

SYSTEM

DESCRIPTION

This intervenes in the case of an impact

causing:

the interruption of the fuel supply

with the engine consequently switching

off;

the automatic unlocking of the

doors;

turning on of the lights inside the

vehicle;

deactivation of climate control

system ventilation;

switching on of the hazard warning

lights (to deactivate the lights press the

button on the dashboard).

On some versions, the intervention of

the system is indicated by a message

shown on the display. In the same way,

a dedicated message on the display

warns the driver if system operation is

compromised.

IMPORTANT Carefully check the vehicle

for fuel leaks, for instance in the engine

compartment, under the vehicle or near

the tank area. After a collision, bring the

ignition device to STOP to prevent the

battery from running down.FUEL CUT-OFF SYSTEM

RESET

To restore correct operation of the

vehicle, carry out the following

procedure (this procedure must be

started and completed within less than

1 minute):

138)

Operations to be carried out

With direction indicator lever in neutral

position, bring the ignition device to STOP

Bring the ignition device to MAR

Activate the right direction indicator

Activate the left direction indicator

Activate the right direction indicator

Activate the left direction indicator

Deactivate the left direction indicator

Bring the ignition device to STOP

Bring the ignition device to MAR

WARNING

138)If, after an impact, you smell fuel or

notice leaks from the fuel system, do not

reactivate the system to avoid the risk of

fire.

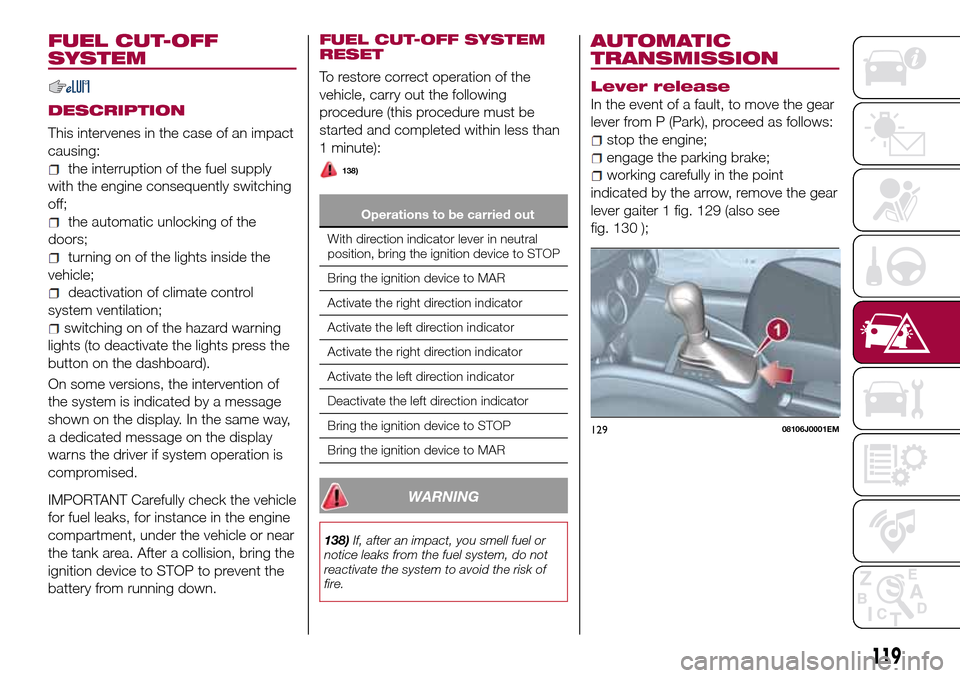

AUTOMATIC

TRANSMISSION

Lever release

In the event of a fault, to move the gear

lever from P (Park), proceed as follows:

stop the engine;

engage the parking brake;

working carefully in the point

indicated by the arrow, remove the gear

lever gaiter 1 fig. 129 (also see

fig. 130 );

12908106J0001EM

119

Page 127 of 204

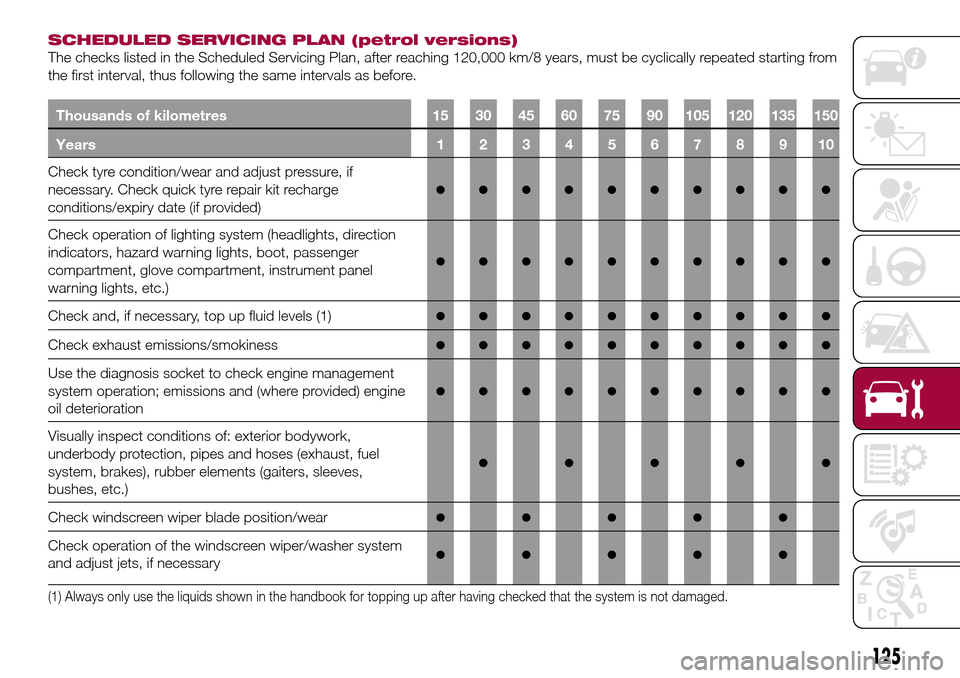

SCHEDULED SERVICING PLAN (petrol versions)

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/8 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of kilometres 15 30 45 60 75 90 105 120 135 150

Years 1 2 3 4 5 6 7 8 9 10

Check tyre condition/wear and adjust pressure, if

necessary. Check quick tyre repair kit recharge

conditions/expiry date (if provided)

●●●●●●●●●●

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, boot, passenger

compartment, glove compartment, instrument panel

warning lights, etc.)

●●●●●●●●●●

Check and, if necessary, top up fluid levels (1)●●●●●●●●●●

Check exhaust emissions/smokiness●●●●●●●●●●

Use the diagnosis socket to check engine management

system operation; emissions and (where provided) engine

oil deterioration

●●●●●●●●●●

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)

●●●●●

Check windscreen wiper blade position/wear●●●●●

Check operation of the windscreen wiper/washer system

and adjust jets, if necessary●●●●●

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

125

Page 130 of 204

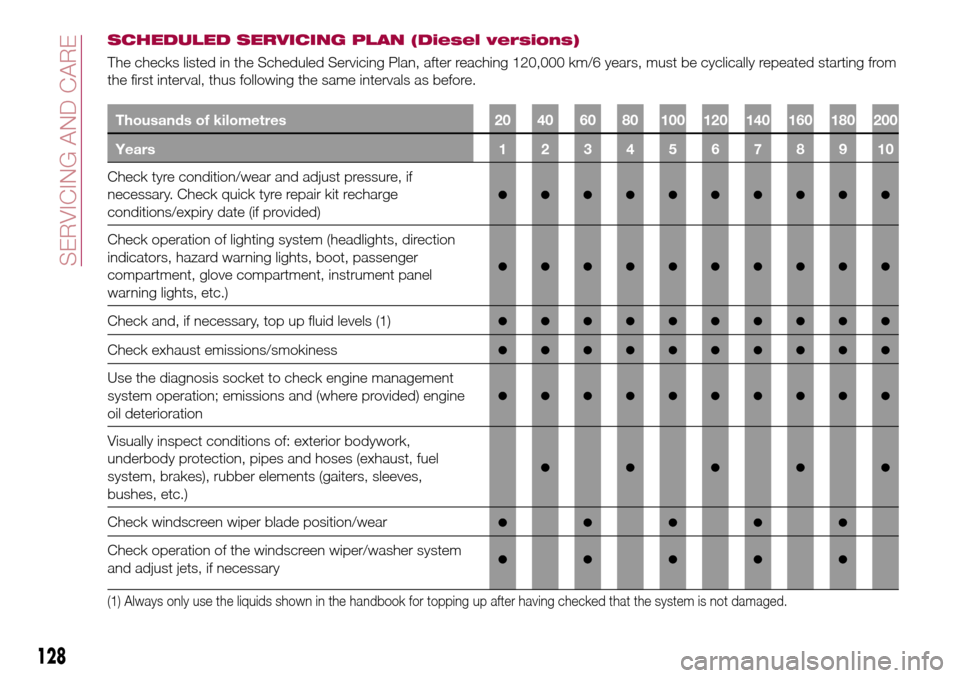

SCHEDULED SERVICING PLAN (Diesel versions)

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/6 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of kilometres 20 40 60 80 100 120 140 160 180 200

Years12345678910

Check tyre condition/wear and adjust pressure, if

necessary. Check quick tyre repair kit recharge

conditions/expiry date (if provided)

●●●●●●●●●●

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, boot, passenger

compartment, glove compartment, instrument panel

warning lights, etc.)

●●●●●●●●●●

Check and, if necessary, top up fluid levels (1)●●●●●●●●●●

Check exhaust emissions/smokiness●●●●●●●●●●

Use the diagnosis socket to check engine management

system operation; emissions and (where provided) engine

oil deterioration

●●●●●●●●●●

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)

●●●●●

Check windscreen wiper blade position/wear●●●●●

Check operation of the windscreen wiper/washer system

and adjust jets, if necessary●●●●●

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

128

SERVICING AND CARE

Page 131 of 204

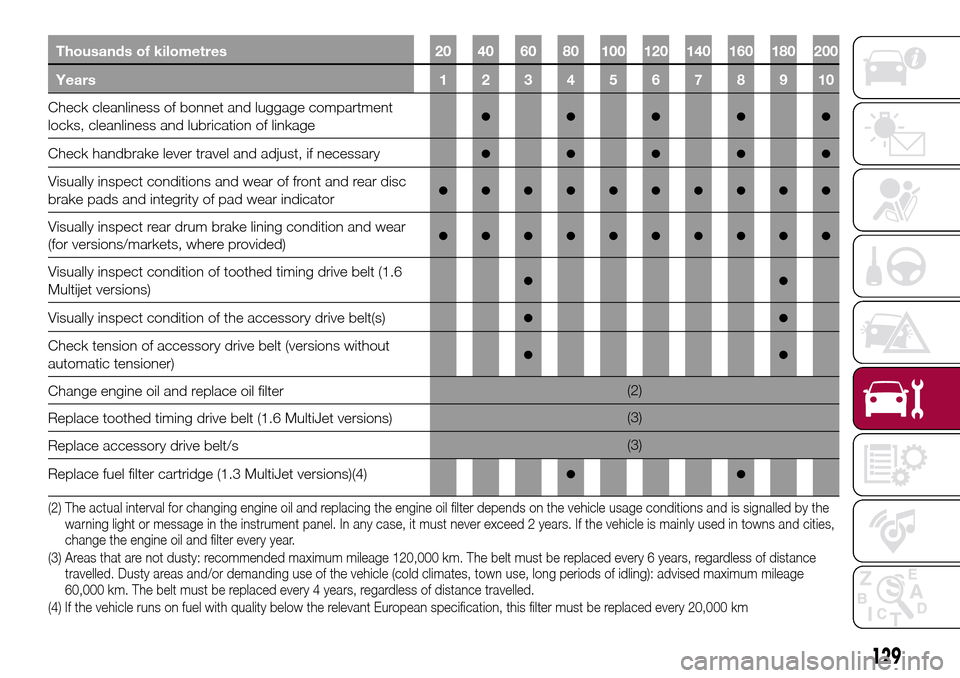

Thousands of kilometres 20 40 60 80 100 120 140 160 180 200

Years12345678910

Check cleanliness of bonnet and luggage compartment

locks, cleanliness and lubrication of linkage●●●●●

Check handbrake lever travel and adjust, if necessary●●●●●

Visually inspect conditions and wear of front and rear disc

brake pads and integrity of pad wear indicator●●●●●●●●●●

Visually inspect rear drum brake lining condition and wear

(for versions/markets, where provided)●●●●●●●●●●

Visually inspect condition of toothed timing drive belt (1.6

Multijet versions)●●

Visually inspect condition of the accessory drive belt(s)●●

Check tension of accessory drive belt (versions without

automatic tensioner)●●

Change engine oil and replace oil filter(2)

Replace toothed timing drive belt (1.6 MultiJet versions)(3)

Replace accessory drive belt/s(3)

Replace fuel filter cartridge (1.3 MultiJet versions)(4)

●●

(2) The actual interval for changing engine oil and replacing the engine oil filter depends on the vehicle usage conditions and is signalled by the

warning light or message in the instrument panel. In any case, it must never exceed 2 years. If the vehicle is mainly used in towns and cities,

change the engine oil and filter every year.

(3) Areas that are not dusty: recommended maximum mileage 120,000 km. The belt must be replaced every 6 years, regardless of distance

travelled. Dusty areas and/or demanding use of the vehicle (cold climates, town use, long periods of idling): advised maximum mileage

60,000 km. The belt must be replaced every 4 years, regardless of distance travelled.

(4) If the vehicle runs on fuel with quality below the relevant European specification, this filter must be replaced every 20,000 km

129

Page 133 of 204

PERIODIC CHECKS

Every1,000km or before long trips

check and, if necessary, top up:

engine coolant level;

brake fluid level;

windscreen washer fluid level;

tyre inflation pressure and condition;

operation of lighting system

(headlights, direction indicators, hazard

warning lights, etc.);

operation of screen washer/wiper

system and positioning/wear of

windscreen.

Every3,000km, check and top up if

required: engine oil level.

HEAVY USAGE OF THE

CAR

If the vehicle is used mainly under one

of the following conditions:

dusty roads;

short, repeated journeys (less than

7-8 km) at sub-zero outside

temperatures;

engine often idling or driving long

distances at low speeds or long periods

of inactivity;

the following checks must be carried

out more often than indicated in the

Scheduled Servicing Plan:

check front disc brake pad condition

and wear;

check cleanliness of bonnet and

luggage compartment locks,cleanliness and lubrication of linkage;

visually inspect conditions of: engine,

gearbox, transmission, pipes and hoses

(exhaust/fuel system/brakes) and

rubber elements (gaiters/sleeves/

bushes, etc.);

check battery charge and battery

fluid level (electrolyte);

visually inspect conditions of the

accessory drive belts;

check and, if necessary, change

engine oil and replace oil filter;

check and, if necessary, replace

pollen filter;

check and, if necessary, replace air

cleaner.

On versions with AT6 automatic

transmission, change the oil and

replace filters every 90,000 km (or 2

years) if the vehicle is used in the

following conditions: city driving, short

and repeated journeys (less than

78 km) or frequent towing of trailers or

caravans.

131

Page 140 of 204

USEFUL ADVICE FOR

EXTENDING THE LIFE OF

YOUR BATTERY

Useful advice for extending the life

of your battery

To avoid draining your battery and

make it last longer, observe the

following instructions:

when you park the car, ensure that

the doors, tailgate and bonnet are

closed properly, to prevent any lights

from remaining on inside the

passenger's compartment;

switch off all roof lights inside the car:

the car is however equipped with a

system which switches all internal lights

off automatically;

do not keep accessories (e.g. radio,

hazard warning lights, etc.) switched on

for a long time when the engine is not

running;

before performing any operation on

the electrical system, disconnect the

negative battery cable.

If, after purchasing the vehicle, you wish

to install electrical accessories which

require permanent electrical supply (e.g.

alarm, etc.) or accessories which

influence the electrical supply

requirements, contact a Fiat Dealership,

whose qualified staff will evaluate the

overall electrical consumption.

49)

IMPORTANT After the battery is

disconnected, the steering must be

initialised. The

warning light on the

instrument panel (or symbol on the

display) switches on to indicate this. To

carry out this procedure, simply turn the

steering wheel all the way from one end

to the other or drive in a straight line for

about a hundred metres.

IMPORTANT If the charge level remains

under 50% for a long time, the battery

is damaged by sulphation, reducing its

capacity and efficiency at start-up. The

battery is also more prone to the risk of

freezing (at temperatures as high as

-10°C). Refer to the "Vehicle inactivity"

paragraph in "Starting and driving"

chapter if the vehicle is left parked for a

long time.

WARNING

142)Never smoke while working in the

engine compartment: gas and inflammable

vapours may be present, with the risk of

fire.

143)Be very careful when working in the

engine compartment when the engine is

hot: you may get burned. Do not get too

close to the radiator cooling fan: the

electric fan may start; danger of injury.

Scarves, ties and other loose clothing

might be pulled by moving parts.144)If the engine oil is being topped up,

wait for the engine to cool down before

loosening the filler cap, particularly for

vehicles with aluminium cap (where

provided). WARNING: risk of burns!

145)The cooling system is pressurised. If

the cap needs replacing, do so with

another original or the effectiveness of the

system may be compromised. Do not

remove the reservoir plug when the engine

is hot: you risk scalding yourself.

146)Do not travel if the windscreen

washer reservoir is empty: using the

windscreen washer is essential for

improving visibility. Repeated operation of

the system without fluid could damage or

cause rapid deterioration of some system

components.

147)Some commercial additives for

windscreen washer fluid are flammable.

The engine compartment contains hot

components which may start a fire.

148)Brake fluid is poisonous and highly

corrosive. In the event of accidental

contact, immediately wash the affected

parts with water and mild soap. Then rinse

thoroughly. Call a doctor immediately if

swallowed.

149)The symbol, on the brake fluid

container indicates if a brake fluid is

synthetic or mineral-based. Use of mineral

type fluids will damage the special rubber

seals of the braking system beyond repair.

150)Battery fluid is poisonous and

corrosive. Avoid contact with the skin and

eyes. Keep open flames away from the

battery and do not use objects that might

create sparks: risk of explosion and fire.

151)Using the battery with insufficient fluid

irreparably damages the battery and may

cause an explosion.

138

SERVICING AND CARE