Fuel FIAT TIPO 4DOORS 2017 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: TIPO 4DOORS, Model: FIAT TIPO 4DOORS 2017 1.GPages: 240, PDF Size: 4.15 MB

Page 121 of 240

Versions with LPG system

(where provided)

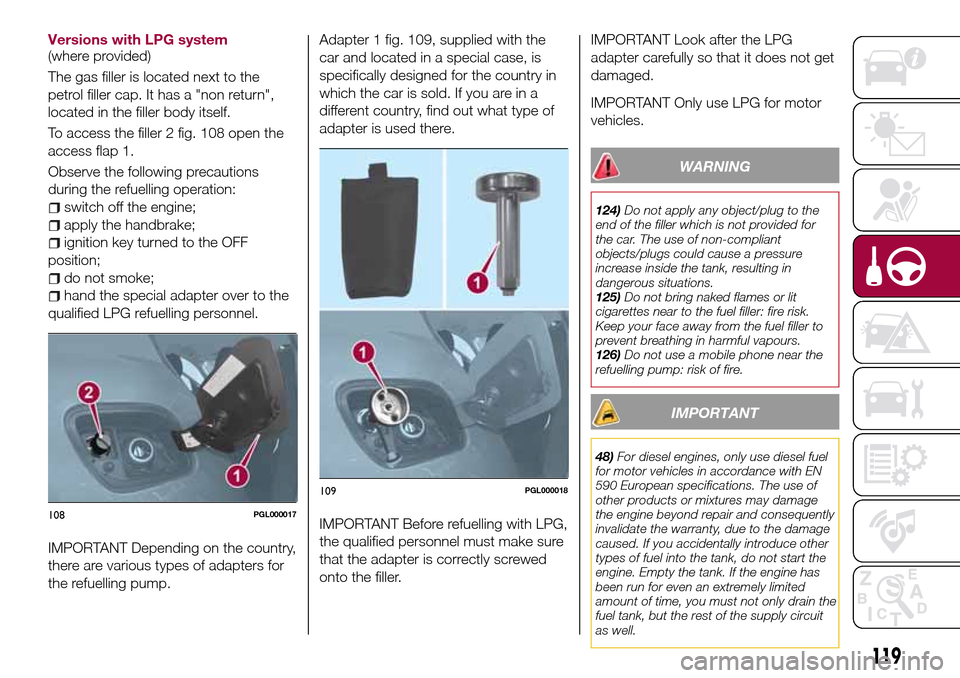

The gas filler is located next to the

petrol filler cap. It has a "non return",

located in the filler body itself.

To access the filler 2 fig. 108 open the

access flap 1.

Observe the following precautions

during the refuelling operation:

switch off the engine;

apply the handbrake;

ignition key turned to the OFF

position;

do not smoke;

hand the special adapter over to the

qualified LPG refuelling personnel.

IMPORTANT Depending on the country,

there are various types of adapters for

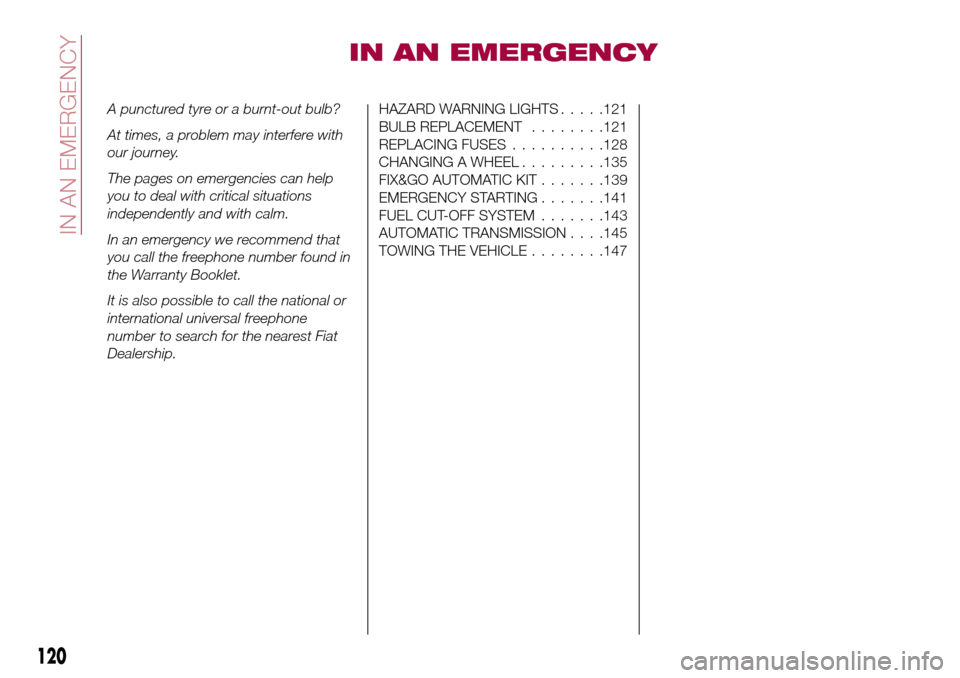

the refuelling pump.Adapter 1 fig. 109, supplied with the

car and located in a special case, is

specifically designed for the country in

which the car is sold. If you are in a

different country, find out what type of

adapter is used there.

IMPORTANT Before refuelling with LPG,

the qualified personnel must make sure

that the adapter is correctly screwed

onto the filler.IMPORTANT Look after the LPG

adapter carefully so that it does not get

damaged.

IMPORTANT Only use LPG for motor

vehicles.

WARNING

124)Do not apply any object/plug to the

end of the filler which is not provided for

the car. The use of non-compliant

objects/plugs could cause a pressure

increase inside the tank, resulting in

dangerous situations.

125)Do not bring naked flames or lit

cigarettes near to the fuel filler: fire risk.

Keep your face away from the fuel filler to

prevent breathing in harmful vapours.

126)Do not use a mobile phone near the

refuelling pump: risk of fire.

IMPORTANT

48)For diesel engines, only use diesel fuel

for motor vehicles in accordance with EN

590 European specifications. The use of

other products or mixtures may damage

the engine beyond repair and consequently

invalidate the warranty, due to the damage

caused. If you accidentally introduce other

types of fuel into the tank, do not start the

engine. Empty the tank. If the engine has

been run for even an extremely limited

amount of time, you must not only drain the

fuel tank, but the rest of the supply circuit

as well.

108PGL000017

109PGL000018

119

Page 122 of 240

IN AN EMERGENCY

A punctured tyre or a burnt-out bulb?

At times, a problem may interfere with

our journey.

The pages on emergencies can help

you to deal with critical situations

independently and with calm.

In an emergency we recommend that

you call the freephone number found in

the Warranty Booklet.

It is also possible to call the national or

international universal freephone

number to search for the nearest Fiat

Dealership.HAZARD WARNING LIGHTS.....121

BULB REPLACEMENT........121

REPLACING FUSES..........128

CHANGING A WHEEL.........135

FIX&GO AUTOMATIC KIT.......139

EMERGENCY STARTING.......141

FUEL CUT-OFF SYSTEM.......143

AUTOMATIC TRANSMISSION. . . .145

TOWING THE VEHICLE........147

120

IN AN EMERGENCY

Page 141 of 240

FIX&GO AUTOMATIC

KIT

(where provided)

DESCRIPTION

140)

54) 55)

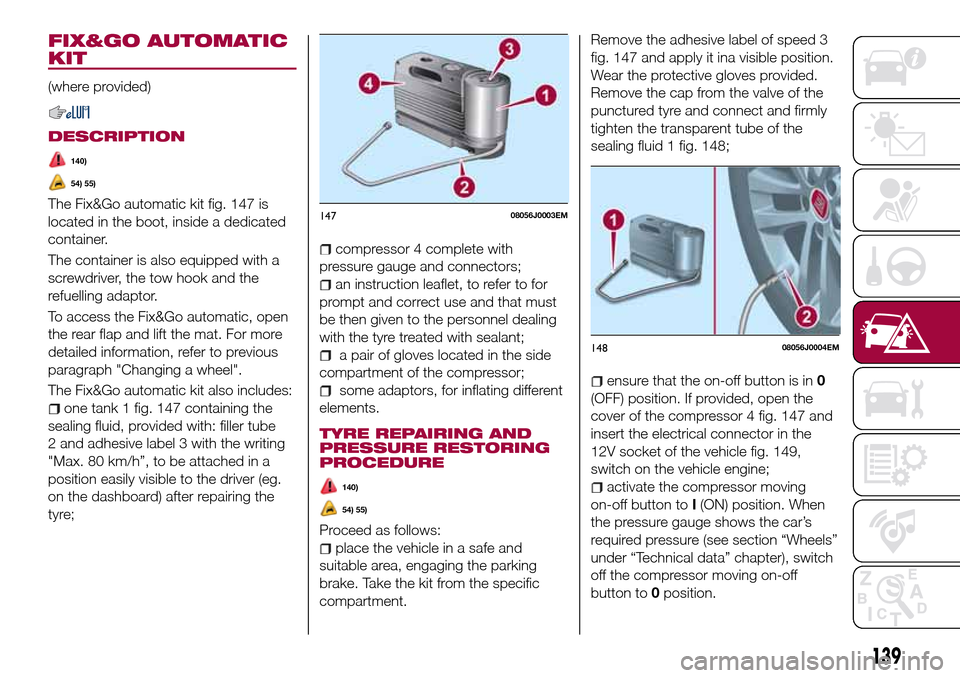

The Fix&Go automatic kit fig. 147 is

located in the boot, inside a dedicated

container.

The container is also equipped with a

screwdriver, the tow hook and the

refuelling adaptor.

To access the Fix&Go automatic, open

the rear flap and lift the mat. For more

detailed information, refer to previous

paragraph "Changing a wheel".

The Fix&Go automatic kit also includes:

one tank 1 fig. 147 containing the

sealing fluid, provided with: filler tube

2 and adhesive label 3 with the writing

"Max. 80 km/h”, to be attached in a

position easily visible to the driver (eg.

on the dashboard) after repairing the

tyre;

compressor 4 complete with

pressure gauge and connectors;

an instruction leaflet, to refer to for

prompt and correct use and that must

be then given to the personnel dealing

with the tyre treated with sealant;

a pair of gloves located in the side

compartment of the compressor;

some adaptors, for inflating different

elements.

TYRE REPAIRING AND

PRESSURE RESTORING

PROCEDURE

140)

54) 55)

Proceed as follows:

place the vehicle in a safe and

suitable area, engaging the parking

brake. Take the kit from the specific

compartment.Remove the adhesive label of speed 3

fig. 147 and apply it ina visible position.

Wear the protective gloves provided.

Remove the cap from the valve of the

punctured tyre and connect and firmly

tighten the transparent tube of the

sealing fluid 1 fig. 148;

ensure that the on-off button is in0

(OFF) position. If provided, open the

cover of the compressor 4 fig. 147 and

insert the electrical connector in the

12V socket of the vehicle fig. 149,

switch on the vehicle engine;

activate the compressor moving

on-off button toI(ON) position. When

the pressure gauge shows the car’s

required pressure (see section “Wheels”

under “Technical data” chapter), switch

off the compressor moving on-off

button to0position.

14708056J0003EM

14808056J0004EM

139

Page 144 of 240

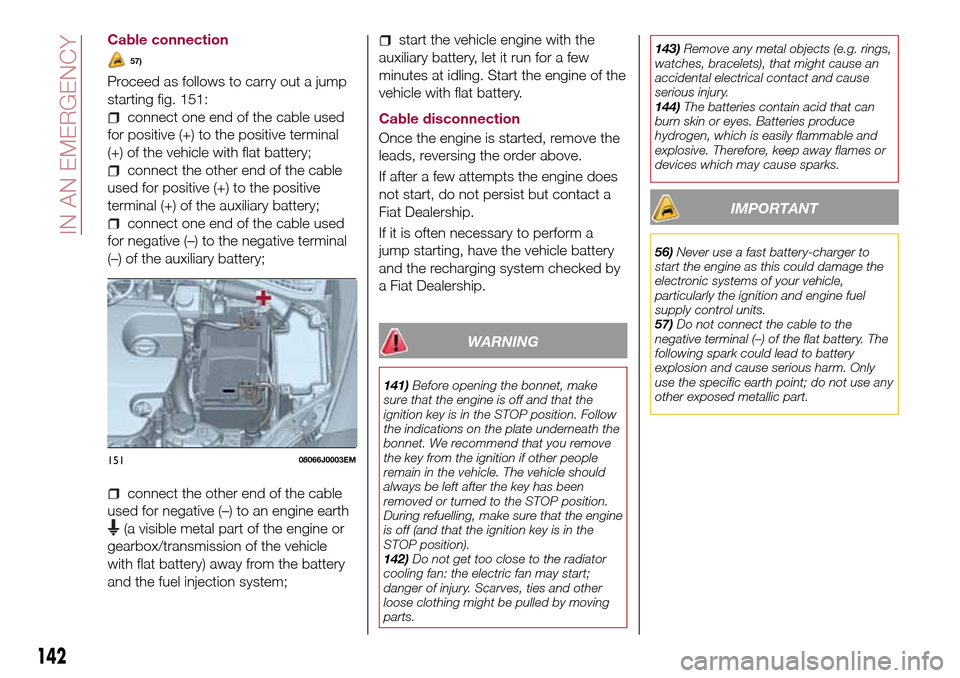

Cable connection

57)

Proceed as follows to carry out a jump

starting fig. 151:

connect one end of the cable used

for positive (+) to the positive terminal

(+) of the vehicle with flat battery;

connect the other end of the cable

used for positive (+) to the positive

terminal (+) of the auxiliary battery;

connect one end of the cable used

for negative (–) to the negative terminal

(–) of the auxiliary battery;

connect the other end of the cable

used for negative (–) to an engine earth

(a visible metal part of the engine or

gearbox/transmission of the vehicle

with flat battery) away from the battery

and the fuel injection system;

start the vehicle engine with the

auxiliary battery, let it run for a few

minutes at idling. Start the engine of the

vehicle with flat battery.

Cable disconnection

Once the engine is started, remove the

leads, reversing the order above.

If after a few attempts the engine does

not start, do not persist but contact a

Fiat Dealership.

If it is often necessary to perform a

jump starting, have the vehicle battery

and the recharging system checked by

a Fiat Dealership.

WARNING

141)Before opening the bonnet, make

sure that the engine is off and that the

ignition key is in the STOP position. Follow

the indications on the plate underneath the

bonnet. We recommend that you remove

the key from the ignition if other people

remain in the vehicle. The vehicle should

always be left after the key has been

removed or turned to the STOP position.

During refuelling, make sure that the engine

is off (and that the ignition key is in the

STOP position).

142)Do not get too close to the radiator

cooling fan: the electric fan may start;

danger of injury. Scarves, ties and other

loose clothing might be pulled by moving

parts.143)Remove any metal objects (e.g. rings,

watches, bracelets), that might cause an

accidental electrical contact and cause

serious injury.

144)The batteries contain acid that can

burn skin or eyes. Batteries produce

hydrogen, which is easily flammable and

explosive. Therefore, keep away flames or

devices which may cause sparks.

IMPORTANT

56)Never use a fast battery-charger to

start the engine as this could damage the

electronic systems of your vehicle,

particularly the ignition and engine fuel

supply control units.

57)Do not connect the cable to the

negative terminal (–) of the flat battery. The

following spark could lead to battery

explosion and cause serious harm. Only

use the specific earth point; do not use any

other exposed metallic part.

15108066J0003EM

142

IN AN EMERGENCY

Page 145 of 240

FUEL CUT-OFF

SYSTEM

DESCRIPTION

Diesel and petrol versions

This intervenes in the case of an impact

causing:

the interruption of the fuel supply

with the engine consequently switching

off;

the automatic unlocking of the

doors;

turning on of the lights inside the

vehicle;

deactivation of climate control

system ventilation;

switching on of the hazard warning

lights (to deactivate the lights press the

button on the dashboard).

On some versions, the intervention of

the system is indicated by a message

shown on the display. In the same way,

a dedicated message on the display

warns the driver if system operation is

compromised.

IMPORTANT Carefully check the vehicle

for fuel leaks, for instance in the engine

compartment, under the vehicle or near

the tank area. After a collision, bring the

ignition device to STOP to prevent the

battery from running down.

LPG versions

(where provided)

On LPG versions, in addition to the

above, the fuel cut-off system stops

petrol supply immediately, closes the

LPG safety solenoid valve and stops

injection, consequently shutting off the

engine.

143

Page 146 of 240

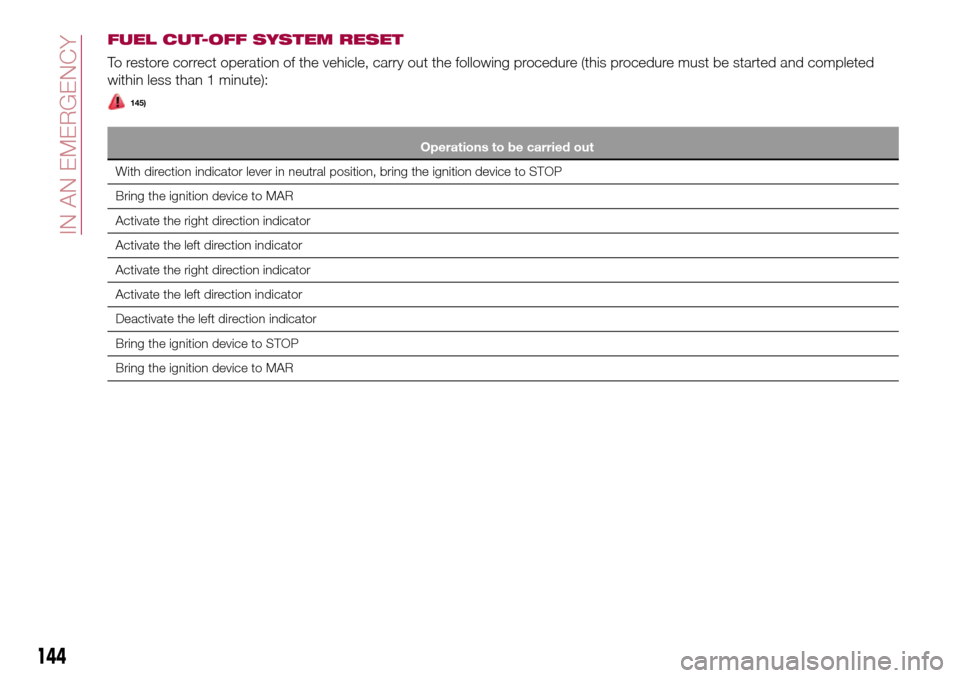

FUEL CUT-OFF SYSTEM RESET

To restore correct operation of the vehicle, carry out the following procedure (this procedure must be started and completed

within less than 1 minute):

145)

Operations to be carried out

With direction indicator lever in neutral position, bring the ignition device to STOP

Bring the ignition device to MAR

Activate the right direction indicator

Activate the left direction indicator

Activate the right direction indicator

Activate the left direction indicator

Deactivate the left direction indicator

Bring the ignition device to STOP

Bring the ignition device to MAR

144

IN AN EMERGENCY

Page 147 of 240

WARNING

145)If, after an impact, you smell fuel or

notice leaks from the fuel system, do not

reactivate the system to avoid the risk of

fire.

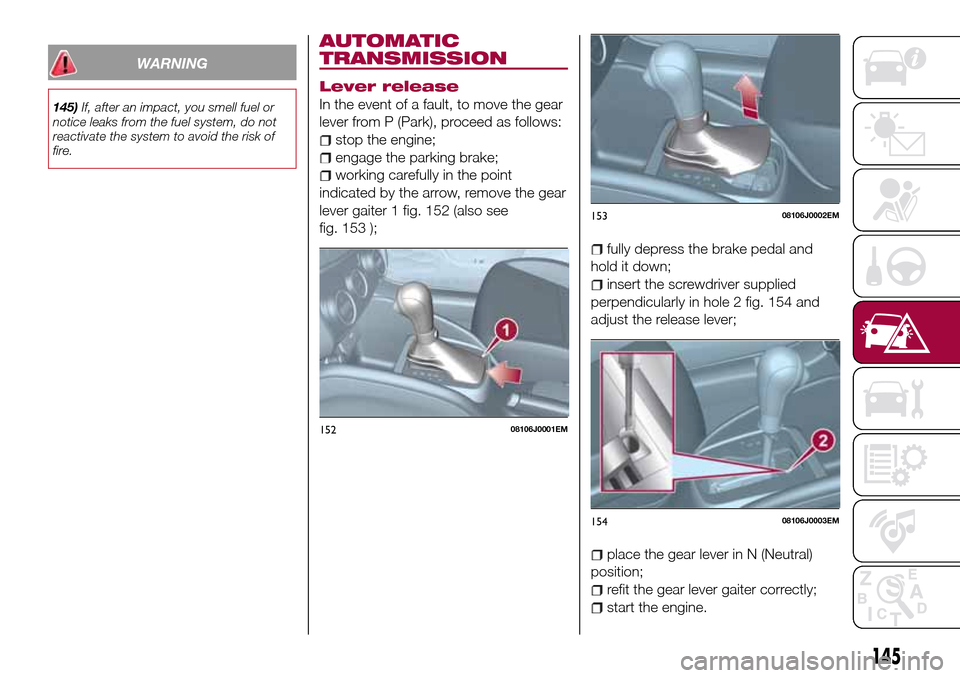

AUTOMATIC

TRANSMISSION

Lever release

In the event of a fault, to move the gear

lever from P (Park), proceed as follows:

stop the engine;

engage the parking brake;

working carefully in the point

indicated by the arrow, remove the gear

lever gaiter 1 fig. 152 (also see

fig. 153 );

fully depress the brake pedal and

hold it down;

insert the screwdriver supplied

perpendicularly in hole 2 fig. 154 and

adjust the release lever;

place the gear lever in N (Neutral)

position;

refit the gear lever gaiter correctly;

start the engine.

15208106J0001EM

15308106J0002EM

15408106J0003EM

145

Page 153 of 240

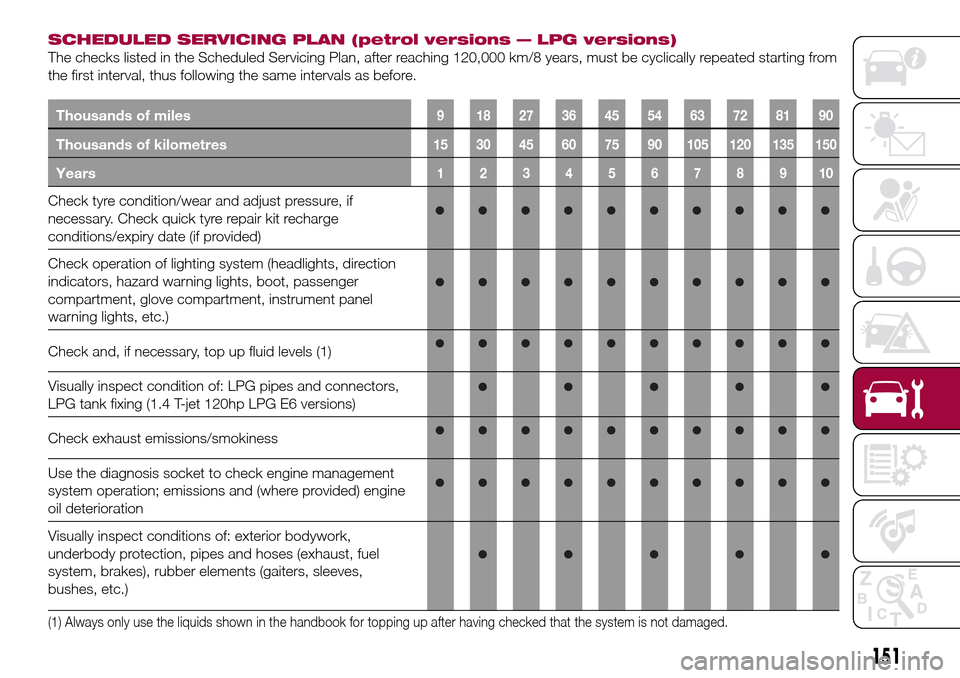

SCHEDULED SERVICING PLAN (petrol versions — LPG versions)

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/8 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of miles9 182736455463728190

Thousands of kilometres15 30 45 60 75 90 105 120 135 150

Years12345678910

Check tyre condition/wear and adjust pressure, if

necessary. Check quick tyre repair kit recharge

conditions/expiry date (if provided)

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, boot, passenger

compartment, glove compartment, instrument panel

warning lights, etc.)

Check and, if necessary, top up fluid levels (1)

Visually inspect condition of: LPG pipes and connectors,

LPG tank fixing (1.4 T-jet 120hp LPG E6 versions)

Check exhaust emissions/smokiness

Use the diagnosis socket to check engine management

system operation; emissions and (where provided) engine

oil deterioration

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

151

Page 158 of 240

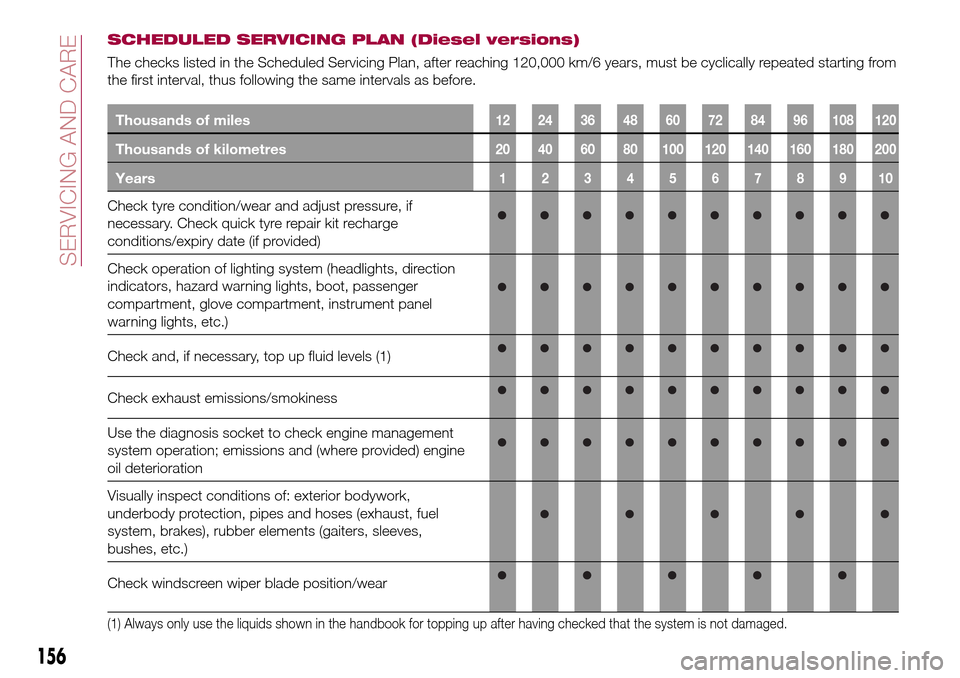

SCHEDULED SERVICING PLAN (Diesel versions)

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/6 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of miles12 24 36 48 60 72 84 96 108 120

Thousands of kilometres20 40 60 80 100 120 140 160 180 200

Years12345678910

Check tyre condition/wear and adjust pressure, if

necessary. Check quick tyre repair kit recharge

conditions/expiry date (if provided)

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, boot, passenger

compartment, glove compartment, instrument panel

warning lights, etc.)

Check and, if necessary, top up fluid levels (1)

Check exhaust emissions/smokiness

Use the diagnosis socket to check engine management

system operation; emissions and (where provided) engine

oil deterioration

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)

Check windscreen wiper blade position/wear

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

156

SERVICING AND CARE

Page 160 of 240

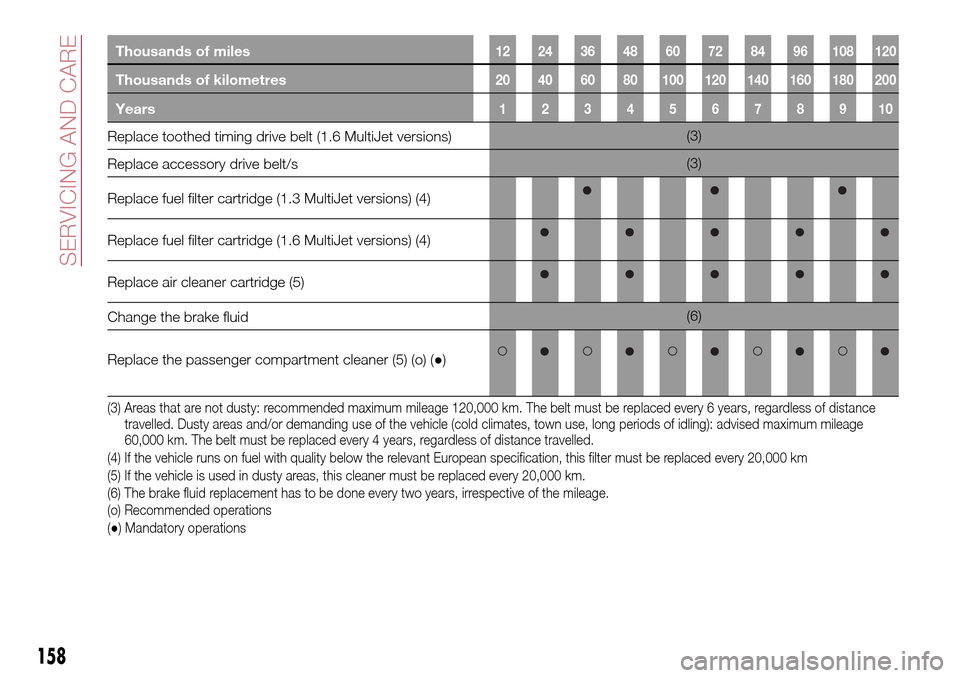

Thousands of miles12 24 36 48 60 72 84 96 108 120

Thousands of kilometres20 40 60 80 100 120 140 160 180 200

Years12345678910

Replace toothed timing drive belt (1.6 MultiJet versions)(3)

Replace accessory drive belt/s(3)

Replace fuel filter cartridge (1.3 MultiJet versions) (4)

Replace fuel filter cartridge (1.6 MultiJet versions) (4)

Replace air cleaner cartridge (5)

Change the brake fluid(6)

Replace the passenger compartment cleaner (5) (o) (●)

(3) Areas that are not dusty: recommended maximum mileage 120,000 km. The belt must be replaced every 6 years, regardless of distance

travelled. Dusty areas and/or demanding use of the vehicle (cold climates, town use, long periods of idling): advised maximum mileage

60,000 km. The belt must be replaced every 4 years, regardless of distance travelled.

(4) If the vehicle runs on fuel with quality below the relevant European specification, this filter must be replaced every 20,000 km

(5) If the vehicle is used in dusty areas, this cleaner must be replaced every 20,000 km.

(6) The brake fluid replacement has to be done every two years, irrespective of the mileage.

(o) Recommended operations

(●) Mandatory operations

158

SERVICING AND CARE