dashboard FIAT TIPO 4DOORS 2017 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: TIPO 4DOORS, Model: FIAT TIPO 4DOORS 2017 1.GPages: 240, PDF Size: 4.15 MB

Page 135 of 240

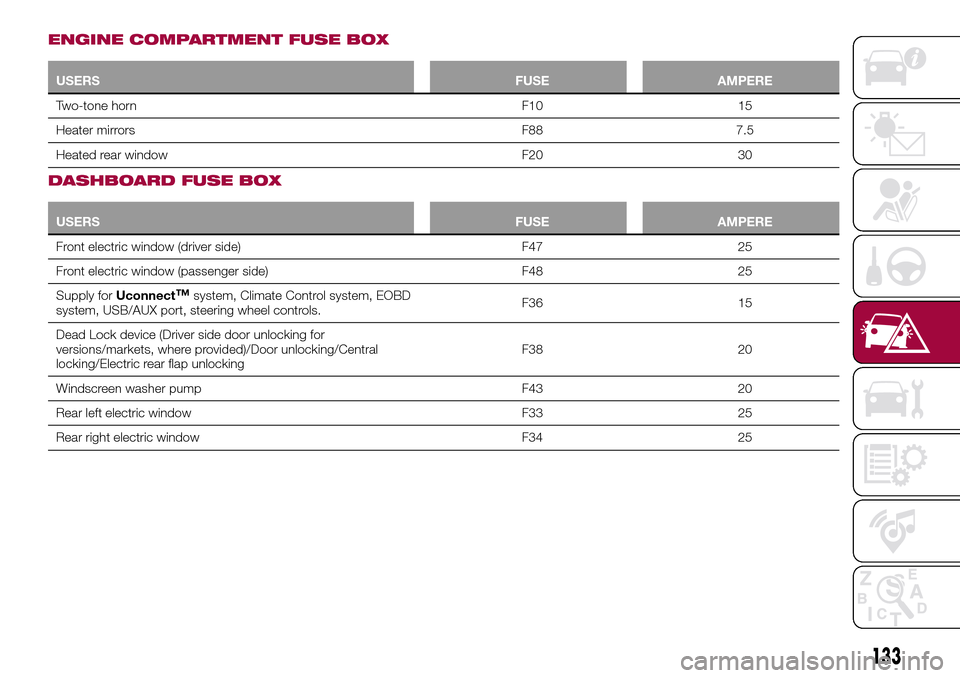

ENGINE COMPARTMENT FUSE BOX

USERSFUSE AMPERE

Two-tone horn F10 15

Heater mirrors F88 7.5

Heated rear window F20 30

DASHBOARD FUSE BOX

USERSFUSE AMPERE

Front electric window (driver side) F47 25

Front electric window (passenger side) F48 25

Supply forUconnect

™system, Climate Control system, EOBD

system, USB/AUX port, steering wheel controls.F36 15

Dead Lock device (Driver side door unlocking for

versions/markets, where provided)/Door unlocking/Central

locking/Electric rear flap unlockingF38 20

Windscreen washer pump F43 20

Rear left electric window F33 25

Rear right electric window F34 25

133

Page 141 of 240

FIX&GO AUTOMATIC

KIT

(where provided)

DESCRIPTION

140)

54) 55)

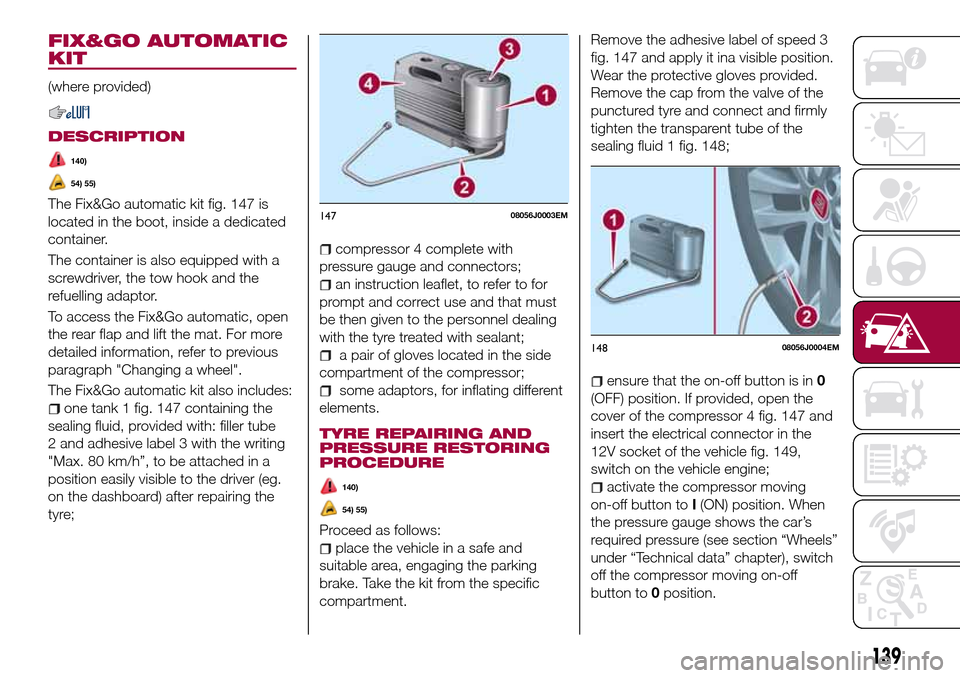

The Fix&Go automatic kit fig. 147 is

located in the boot, inside a dedicated

container.

The container is also equipped with a

screwdriver, the tow hook and the

refuelling adaptor.

To access the Fix&Go automatic, open

the rear flap and lift the mat. For more

detailed information, refer to previous

paragraph "Changing a wheel".

The Fix&Go automatic kit also includes:

one tank 1 fig. 147 containing the

sealing fluid, provided with: filler tube

2 and adhesive label 3 with the writing

"Max. 80 km/h”, to be attached in a

position easily visible to the driver (eg.

on the dashboard) after repairing the

tyre;

compressor 4 complete with

pressure gauge and connectors;

an instruction leaflet, to refer to for

prompt and correct use and that must

be then given to the personnel dealing

with the tyre treated with sealant;

a pair of gloves located in the side

compartment of the compressor;

some adaptors, for inflating different

elements.

TYRE REPAIRING AND

PRESSURE RESTORING

PROCEDURE

140)

54) 55)

Proceed as follows:

place the vehicle in a safe and

suitable area, engaging the parking

brake. Take the kit from the specific

compartment.Remove the adhesive label of speed 3

fig. 147 and apply it ina visible position.

Wear the protective gloves provided.

Remove the cap from the valve of the

punctured tyre and connect and firmly

tighten the transparent tube of the

sealing fluid 1 fig. 148;

ensure that the on-off button is in0

(OFF) position. If provided, open the

cover of the compressor 4 fig. 147 and

insert the electrical connector in the

12V socket of the vehicle fig. 149,

switch on the vehicle engine;

activate the compressor moving

on-off button toI(ON) position. When

the pressure gauge shows the car’s

required pressure (see section “Wheels”

under “Technical data” chapter), switch

off the compressor moving on-off

button to0position.

14708056J0003EM

14808056J0004EM

139

Page 145 of 240

FUEL CUT-OFF

SYSTEM

DESCRIPTION

Diesel and petrol versions

This intervenes in the case of an impact

causing:

the interruption of the fuel supply

with the engine consequently switching

off;

the automatic unlocking of the

doors;

turning on of the lights inside the

vehicle;

deactivation of climate control

system ventilation;

switching on of the hazard warning

lights (to deactivate the lights press the

button on the dashboard).

On some versions, the intervention of

the system is indicated by a message

shown on the display. In the same way,

a dedicated message on the display

warns the driver if system operation is

compromised.

IMPORTANT Carefully check the vehicle

for fuel leaks, for instance in the engine

compartment, under the vehicle or near

the tank area. After a collision, bring the

ignition device to STOP to prevent the

battery from running down.

LPG versions

(where provided)

On LPG versions, in addition to the

above, the fuel cut-off system stops

petrol supply immediately, closes the

LPG safety solenoid valve and stops

injection, consequently shutting off the

engine.

143

Page 180 of 240

WARNING

168)Never use flammable products, such

as petrol ether or rectified petrol to clean

the inside of the car. The electrostatic

charges which are generated by rubbing

during the cleaning operation may cause a

fire.

169)Do not keep aerosol cans in the car:

they might explode. Aerosol cans must not

be exposed to a temperature exceeding

50°C. When the vehicle is exposed to

sunlight, the internal temperature can

greatly exceed this value.

170)There must be no obstacles on the

floor underneath the pedals; make sure

that mats are always flat and do not

interfere with the pedals.

IMPORTANT

77)Never use alcohol, petrols and

derivatives to clean the dashboard and

instrument panel lens.

178

SERVICING AND CARE

Page 182 of 240

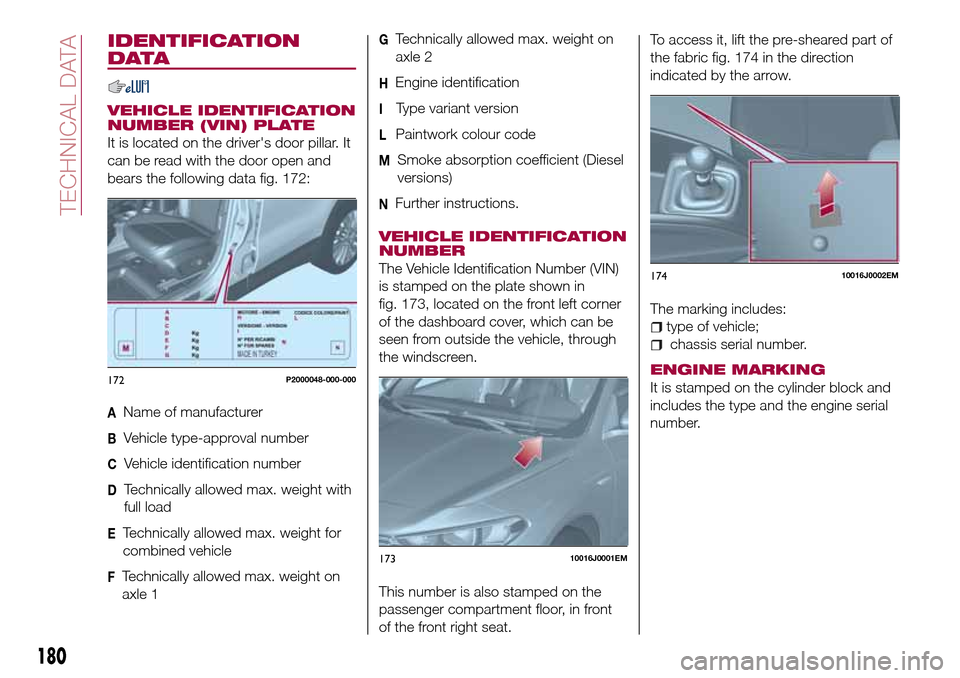

IDENTIFICATION

DATA

VEHICLE IDENTIFICATION

NUMBER (VIN) PLATE

It is located on the driver's door pillar. It

can be read with the door open and

bears the following data fig. 172:

AName of manufacturer

BVehicle type-approval number

CVehicle identification number

DTechnically allowed max. weight with

full load

ETechnically allowed max. weight for

combined vehicle

FTechnically allowed max. weight on

axle 1

GTechnically allowed max. weight on

axle 2

HEngine identification

IType variant version

LPaintwork colour code

MSmoke absorption coefficient (Diesel

versions)

NFurther instructions.

VEHICLE IDENTIFICATION

NUMBER

The Vehicle Identification Number (VIN)

is stamped on the plate shown in

fig. 173, located on the front left corner

of the dashboard cover, which can be

seen from outside the vehicle, through

the windscreen.

This number is also stamped on the

passenger compartment floor, in front

of the front right seat.To access it, lift the pre-sheared part of

the fabric fig. 174 in the direction

indicated by the arrow.

The marking includes:

type of vehicle;

chassis serial number.

ENGINE MARKING

It is stamped on the cylinder block and

includes the type and the engine serial

number.172P2000048-000-000

17310016J0001EM

17410016J0002EM

180

TECHNICAL DATA