FIAT TIPO 4DOORS 2020 Owner handbook (in English)

Manufacturer: FIAT, Model Year: 2020, Model line: TIPO 4DOORS, Model: FIAT TIPO 4DOORS 2020Pages: 252, PDF Size: 7.29 MB

Page 141 of 252

CHANGING A WHEEL

JACK

Please note that:

the jack weight is 2.15 kg;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another genuine one;

No tool other than its cranking device

may be fitted on the jack.

Maintenance

Prevent any dirt from depositing on

the "worm screw";

Keep the "worm screw" lubricated;

Never modify the jack.

Conditions for non-use

Temperatures below −40°C;

On sandy or muddy ground;

On uneven ground;

On steep roads;

In extreme weather conditions:

thunderstorms, typhoons, hurricanes,

blizzards, storms, etc.

In direct contact with the engine or

for repairs under the vehicle;

On boats.

CHANGING PROCEDURE

137) 138) 139) 140) 141) 142)

53) 54)

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can change the wheel safely. The

ground must be flat and sufficiently

compact;

stop the engine, engage the hazard

warning lights and the parking brake;

engage first gear or reverse or, for

versions with automatic transmission (if

present), move the gear lever to

position P (Park);

wear the reflective safety jacket

before getting out of the car (anyway

comply with the laws in force in the

country you are driving in);

open the luggage compartment and

lift up the mat;

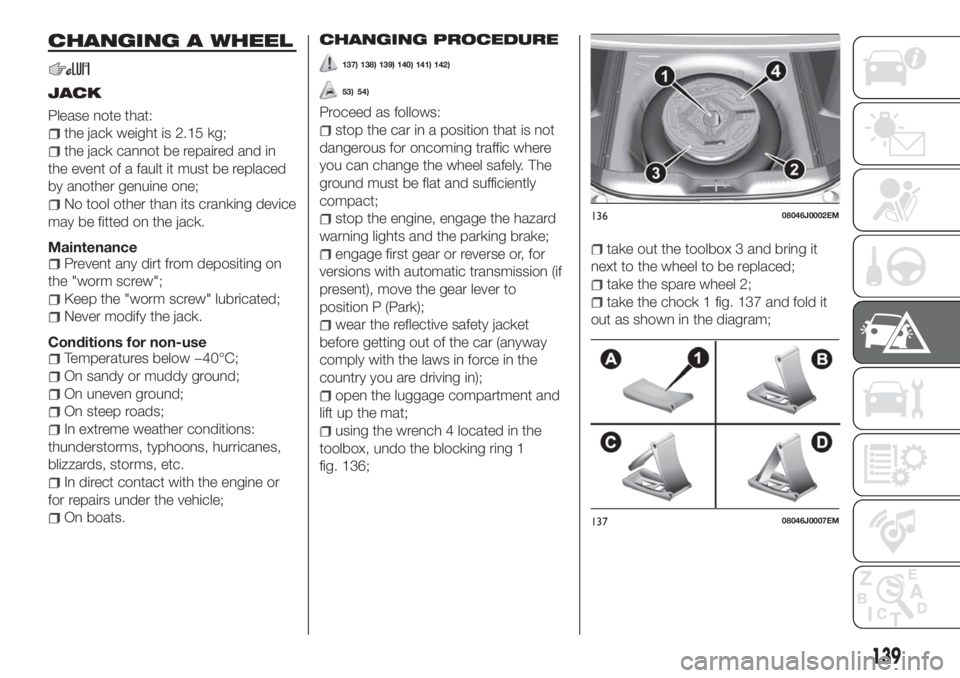

using the wrench 4 located in the

toolbox, undo the blocking ring 1

fig. 136;

take out the toolbox 3 and bring it

next to the wheel to be replaced;

take the spare wheel 2;

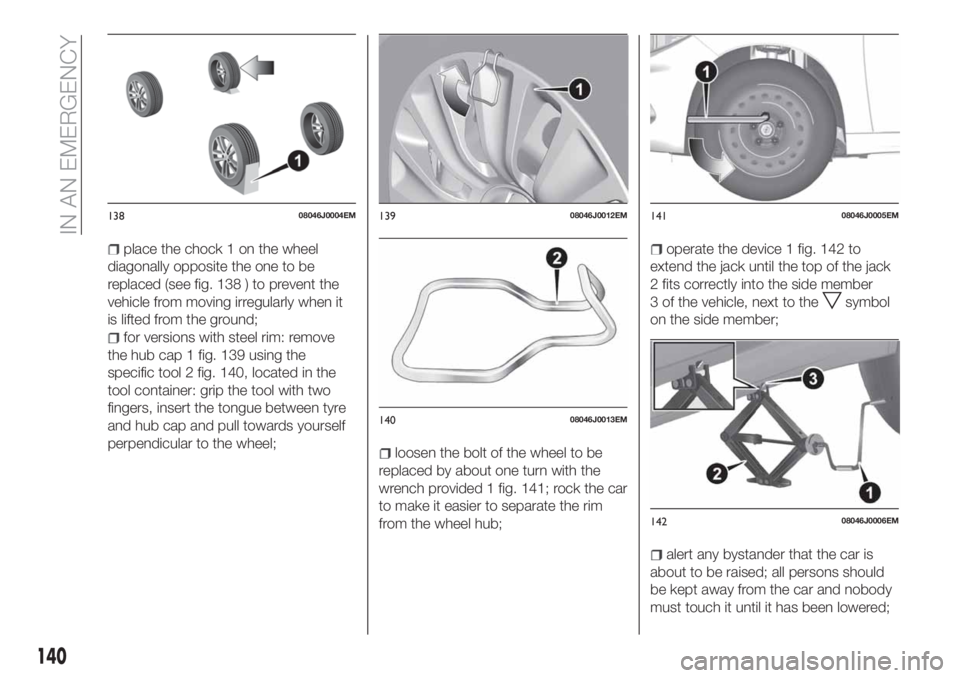

take the chock 1 fig. 137 and fold it

out as shown in the diagram;

13608046J0002EM

13708046J0007EM

139

Page 142 of 252

place the chock 1 on the wheel

diagonally opposite the one to be

replaced (see fig. 138 ) to prevent the

vehicle from moving irregularly when it

is lifted from the ground;

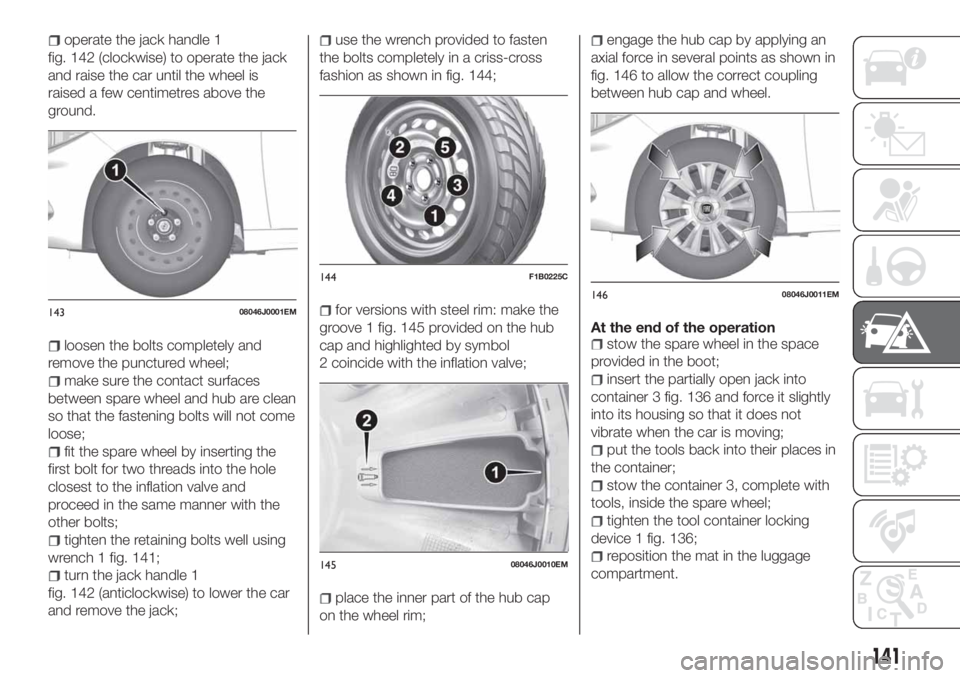

for versions with steel rim: remove

the hub cap 1 fig. 139 using the

specific tool 2 fig. 140, located in the

tool container: grip the tool with two

fingers, insert the tongue between tyre

and hub cap and pull towards yourself

perpendicular to the wheel;

loosen the bolt of the wheel to be

replaced by about one turn with the

wrench provided 1 fig. 141; rock the car

to make it easier to separate the rim

from the wheel hub;

operate the device 1 fig. 142 to

extend the jack until the top of the jack

2 fits correctly into the side member

3 of the vehicle, next to the

symbol

on the side member;

alert any bystander that the car is

about to be raised; all persons should

be kept away from the car and nobody

must touch it until it has been lowered;

13808046J0004EM13908046J0012EM

14008046J0013EM

14108046J0005EM

14208046J0006EM

140

IN AN EMERGENCY

Page 143 of 252

operate the jack handle 1

fig. 142 (clockwise) to operate the jack

and raise the car until the wheel is

raised a few centimetres above the

ground.

loosen the bolts completely and

remove the punctured wheel;

make sure the contact surfaces

between spare wheel and hub are clean

so that the fastening bolts will not come

loose;

fit the spare wheel by inserting the

first bolt for two threads into the hole

closest to the inflation valve and

proceed in the same manner with the

other bolts;

tighten the retaining bolts well using

wrench 1 fig. 141;

turn the jack handle 1

fig. 142 (anticlockwise) to lower the car

and remove the jack;

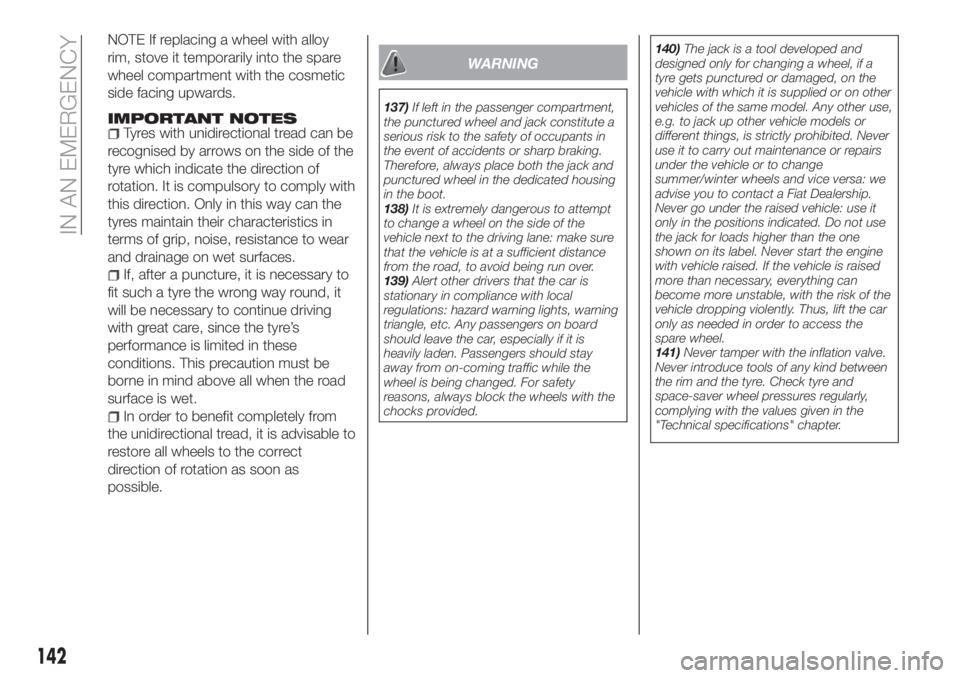

use the wrench provided to fasten

the bolts completely in a criss-cross

fashion as shown in fig. 144;

for versions with steel rim: make the

groove 1 fig. 145 provided on the hub

cap and highlighted by symbol

2 coincide with the inflation valve;

place the inner part of the hub cap

on the wheel rim;

engage the hub cap by applying an

axial force in several points as shown in

fig. 146 to allow the correct coupling

between hub cap and wheel.

At the end of the operation

stow the spare wheel in the space

provided in the boot;

insert the partially open jack into

container 3 fig. 136 and force it slightly

into its housing so that it does not

vibrate when the car is moving;

put the tools back into their places in

the container;

stow the container 3, complete with

tools, inside the spare wheel;

tighten the tool container locking

device 1 fig. 136;

reposition the mat in the luggage

compartment.

14308046J0001EM

144F1B0225C

14508046J0010EM

14608046J0011EM

141

Page 144 of 252

NOTE If replacing a wheel with alloy

rim, stove it temporarily into the spare

wheel compartment with the cosmetic

side facing upwards.

IMPORTANT NOTESTyres with unidirectional tread can be

recognised by arrows on the side of the

tyre which indicate the direction of

rotation. It is compulsory to comply with

this direction. Only in this way can the

tyres maintain their characteristics in

terms of grip, noise, resistance to wear

and drainage on wet surfaces.

If, after a puncture, it is necessary to

fit such a tyre the wrong way round, it

will be necessary to continue driving

with great care, since the tyre’s

performance is limited in these

conditions. This precaution must be

borne in mind above all when the road

surface is wet.

In order to benefit completely from

the unidirectional tread, it is advisable to

restore all wheels to the correct

direction of rotation as soon as

possible.

WARNING

137)If left in the passenger compartment,

the punctured wheel and jack constitute a

serious risk to the safety of occupants in

the event of accidents or sharp braking.

Therefore, always place both the jack and

punctured wheel in the dedicated housing

in the boot.

138)It is extremely dangerous to attempt

to change a wheel on the side of the

vehicle next to the driving lane: make sure

that the vehicle is at a sufficient distance

from the road, to avoid being run over.

139)Alert other drivers that the car is

stationary in compliance with local

regulations: hazard warning lights, warning

triangle, etc. Any passengers on board

should leave the car, especially if it is

heavily laden. Passengers should stay

away from on-coming traffic while the

wheel is being changed. For safety

reasons, always block the wheels with the

chocks provided.140)The jack is a tool developed and

designed only for changing a wheel, if a

tyre gets punctured or damaged, on the

vehicle with which it is supplied or on other

vehicles of the same model. Any other use,

e.g. to jack up other vehicle models or

different things, is strictly prohibited. Never

use it to carry out maintenance or repairs

under the vehicle or to change

summer/winter wheels and vice versa: we

advise you to contact a Fiat Dealership.

Never go under the raised vehicle: use it

only in the positions indicated. Do not use

the jack for loads higher than the one

shown on its label. Never start the engine

with vehicle raised. If the vehicle is raised

more than necessary, everything can

become more unstable, with the risk of the

vehicle dropping violently. Thus, lift the car

only as needed in order to access the

spare wheel.

141)Never tamper with the inflation valve.

Never introduce tools of any kind between

the rim and the tyre. Check tyre and

space-saver wheel pressures regularly,

complying with the values given in the

"Technical specifications" chapter.

142

IN AN EMERGENCY

Page 145 of 252

142)A 16” spare wheel is provided with

17” and 18” tyres. The space-saver wheel

(for versions/markets where provided) is

specific to your car, do not use it on other

models, or use the space-saver wheel of

other models on your car. The space-saver

wheel must only be used in the event of an

emergency. Never use it for more than

strictly necessary and never exceed

80 km/h. Important! For temporary use

only! 80km/h max! Replace with standard

wheel as soon as possible. Never remove

or cover the sticker on the space-saver

wheel. Never apply a wheel cap on a

space-saver wheel. The vehicle's driving

characteristics will be modified with the

space-saver wheel fitted. Avoid violent

acceleration and braking, abrupt steering

and fast cornering. Have the wheel

repaired and refitted as soon as possible.

Using two or more spare wheels at the

same time is forbidden. Do not apply

grease to the bolt threads before fitting:

they could come unscrewed.

IMPORTANT

53)When turning the jack handle make

sure that it can turn freely without scraping

your hand against the ground. The moving

components of the jack ("worm screw" and

joints) can also cause injuries: avoid

touching them. If you come into contact

with lubricating grease, clean yourself

thoroughly.

54)Contact a Fiat Dealership as soon as

possible to have the correct tightening of

the wheel bolts checked.

FIX&GO KIT

(where provided)

143) 144)

55)

DESCRIPTION

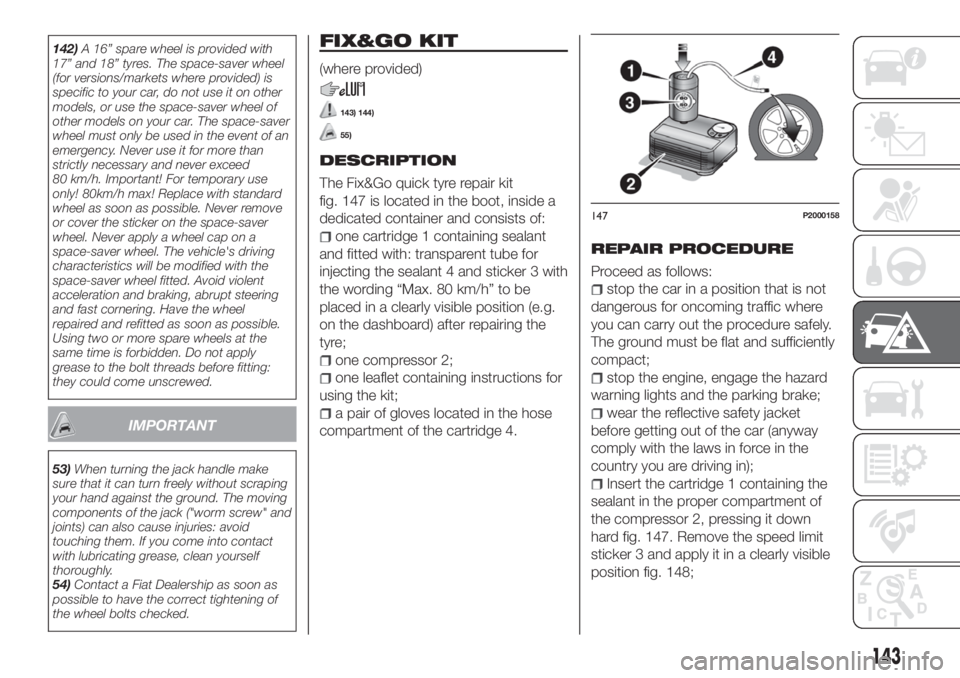

The Fix&Go quick tyre repair kit

fig. 147 is located in the boot, inside a

dedicated container and consists of:

one cartridge 1 containing sealant

and fitted with: transparent tube for

injecting the sealant 4 and sticker 3 with

the wording “Max. 80 km/h” to be

placed in a clearly visible position (e.g.

on the dashboard) after repairing the

tyre;

one compressor 2;

one leaflet containing instructions for

using the kit;

a pair of gloves located in the hose

compartment of the cartridge 4.

REPAIR PROCEDURE

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can carry out the procedure safely.

The ground must be flat and sufficiently

compact;

stop the engine, engage the hazard

warning lights and the parking brake;

wear the reflective safety jacket

before getting out of the car (anyway

comply with the laws in force in the

country you are driving in);

Insert the cartridge 1 containing the

sealant in the proper compartment of

the compressor 2, pressing it down

hard fig. 147. Remove the speed limit

sticker 3 and apply it in a clearly visible

position fig. 148;

147P2000158

143

Page 146 of 252

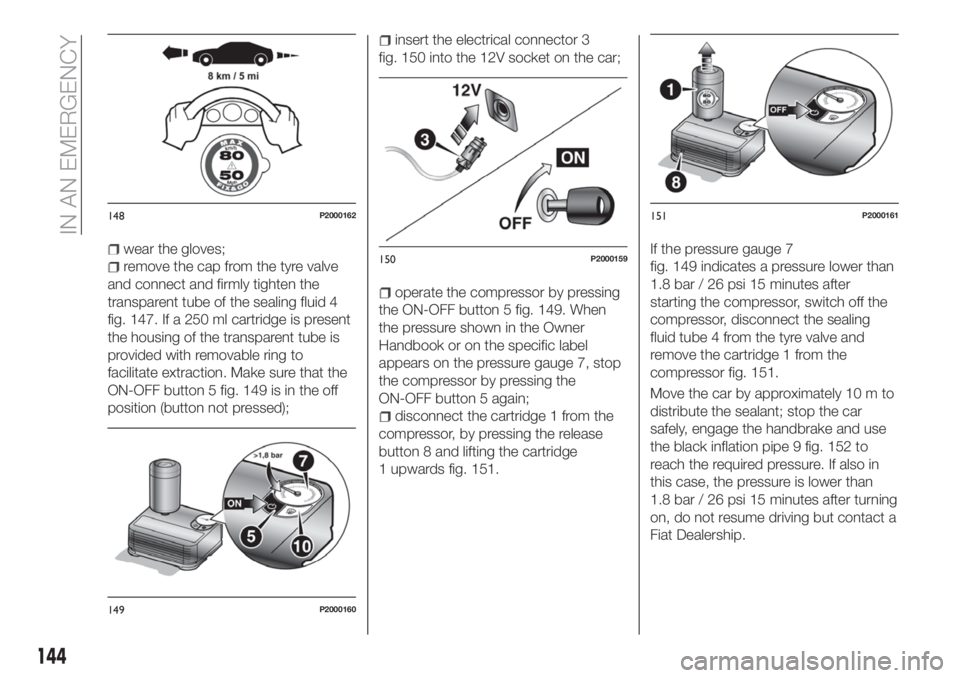

wear the gloves;

remove the cap from the tyre valve

and connect and firmly tighten the

transparent tube of the sealing fluid 4

fig. 147. If a 250 ml cartridge is present

the housing of the transparent tube is

provided with removable ring to

facilitate extraction. Make sure that the

ON-OFF button 5 fig. 149 is in the off

position (button not pressed);

insert the electrical connector 3

fig. 150 into the 12V socket on the car;

operate the compressor by pressing

the ON-OFF button 5 fig. 149. When

the pressure shown in the Owner

Handbook or on the specific label

appears on the pressure gauge 7, stop

the compressor by pressing the

ON-OFF button 5 again;

disconnect the cartridge 1 from the

compressor, by pressing the release

button 8 and lifting the cartridge

1 upwards fig. 151.If the pressure gauge 7

fig. 149 indicates a pressure lower than

1.8 bar / 26 psi 15 minutes after

starting the compressor, switch off the

compressor, disconnect the sealing

fluid tube 4 from the tyre valve and

remove the cartridge 1 from the

compressor fig. 151.

Move the car by approximately 10 m to

distribute the sealant; stop the car

safely, engage the handbrake and use

the black inflation pipe 9 fig. 152 to

reach the required pressure. If also in

this case, the pressure is lower than

1.8 bar / 26 psi 15 minutes after turning

on, do not resume driving but contact a

Fiat Dealership.

148P2000162

149P2000160

150P2000159

151P2000161

144

IN AN EMERGENCY

Page 147 of 252

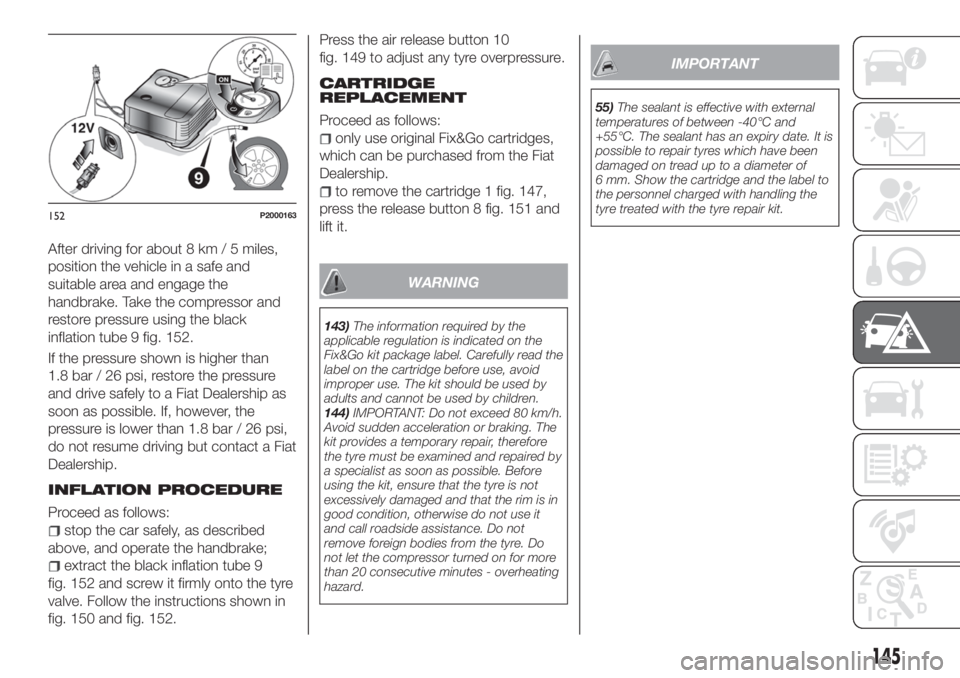

After driving for about 8 km / 5 miles,

position the vehicle in a safe and

suitable area and engage the

handbrake. Take the compressor and

restore pressure using the black

inflation tube 9 fig. 152.

If the pressure shown is higher than

1.8 bar / 26 psi, restore the pressure

and drive safely to a Fiat Dealership as

soon as possible. If, however, the

pressure is lower than 1.8 bar / 26 psi,

do not resume driving but contact a Fiat

Dealership.

INFLATION PROCEDURE

Proceed as follows:

stop the car safely, as described

above, and operate the handbrake;

extract the black inflation tube 9

fig. 152 and screw it firmly onto the tyre

valve. Follow the instructions shown in

fig. 150 and fig. 152.Press the air release button 10

fig. 149 to adjust any tyre overpressure.

CARTRIDGE

REPLACEMENT

Proceed as follows:

only use original Fix&Go cartridges,

which can be purchased from the Fiat

Dealership.

to remove the cartridge 1 fig. 147,

press the release button 8 fig. 151 and

lift it.

WARNING

143)The information required by the

applicable regulation is indicated on the

Fix&Go kit package label. Carefully read the

label on the cartridge before use, avoid

improper use. The kit should be used by

adults and cannot be used by children.

144)IMPORTANT: Do not exceed 80 km/h.

Avoid sudden acceleration or braking. The

kit provides a temporary repair, therefore

the tyre must be examined and repaired by

a specialist as soon as possible. Before

using the kit, ensure that the tyre is not

excessively damaged and that the rim is in

good condition, otherwise do not use it

and call roadside assistance. Do not

remove foreign bodies from the tyre. Do

not let the compressor turned on for more

than 20 consecutive minutes - overheating

hazard.

IMPORTANT

55)The sealant is effective with external

temperatures of between -40°C and

+55°C. The sealant has an expiry date. It is

possible to repair tyres which have been

damaged on tread up to a diameter of

6 mm. Show the cartridge and the label to

the personnel charged with handling the

tyre treated with the tyre repair kit.

152P2000163

145

Page 148 of 252

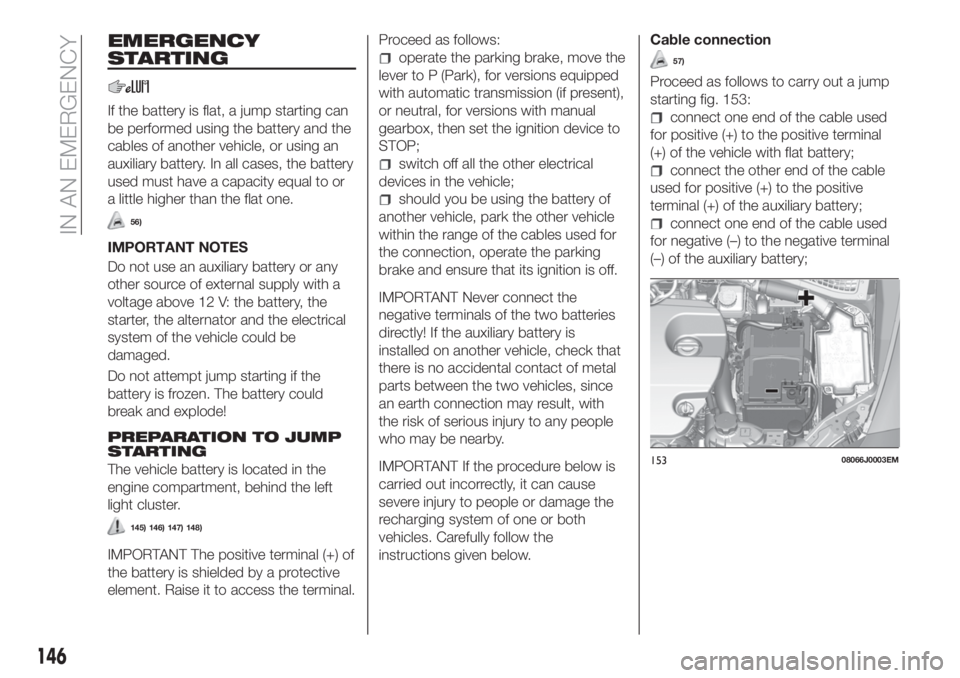

EMERGENCY

STARTING

If the battery is flat, a jump starting can

be performed using the battery and the

cables of another vehicle, or using an

auxiliary battery. In all cases, the battery

used must have a capacity equal to or

a little higher than the flat one.

56)

IMPORTANT NOTES

Do not use an auxiliary battery or any

other source of external supply with a

voltage above 12 V: the battery, the

starter, the alternator and the electrical

system of the vehicle could be

damaged.

Do not attempt jump starting if the

battery is frozen. The battery could

break and explode!

PREPARATION TO JUMP

STARTING

The vehicle battery is located in the

engine compartment, behind the left

light cluster.

145) 146) 147) 148)

IMPORTANT The positive terminal (+) of

the battery is shielded by a protective

element. Raise it to access the terminal.

Proceed as follows:

operate the parking brake, move the

lever to P (Park), for versions equipped

with automatic transmission (if present),

or neutral, for versions with manual

gearbox, then set the ignition device to

STOP;

switch off all the other electrical

devices in the vehicle;

should you be using the battery of

another vehicle, park the other vehicle

within the range of the cables used for

the connection, operate the parking

brake and ensure that its ignition is off.

IMPORTANT Never connect the

negative terminals of the two batteries

directly! If the auxiliary battery is

installed on another vehicle, check that

there is no accidental contact of metal

parts between the two vehicles, since

an earth connection may result, with

the risk of serious injury to any people

who may be nearby.

IMPORTANT If the procedure below is

carried out incorrectly, it can cause

severe injury to people or damage the

recharging system of one or both

vehicles. Carefully follow the

instructions given below.

Cable connection

57)

Proceed as follows to carry out a jump

starting fig. 153:

connect one end of the cable used

for positive (+) to the positive terminal

(+) of the vehicle with flat battery;

connect the other end of the cable

used for positive (+) to the positive

terminal (+) of the auxiliary battery;

connect one end of the cable used

for negative (–) to the negative terminal

(–) of the auxiliary battery;

15308066J0003EM

146

IN AN EMERGENCY

Page 149 of 252

connect the other end of the cable

used for negative (–) to an engine earth

(a visible metal part of the engine or

gearbox/transmission of the vehicle

with flat battery) away from the battery

and the fuel injection system;

start the vehicle engine with the

auxiliary battery, let it run for a few

minutes at idling. Start the engine of the

vehicle with flat battery.

Cable disconnection

Once the engine is started, remove the

leads, reversing the order above.

If after a few attempts the engine does

not start, do not persist but contact a

Fiat Dealership.

If it is often necessary to perform a

jump starting, have the vehicle battery

and the recharging system checked by

a Fiat Dealership.

WARNING

145)Before opening the bonnet, make

sure that the engine is off and that the

ignition key is in the STOP position. Follow

the indications on the plate underneath the

bonnet. We recommend that you remove

the key from the ignition if other people

remain in the vehicle. The vehicle should

always be left after the key has been

removed or turned to the STOP position.

During refuelling, make sure that the engine

is off (and that the ignition key is in the

STOP position).

146)Do not get too close to the radiator

cooling fan: the electric fan may start;

danger of injury. Scarves, ties and other

loose clothing might be pulled by moving

parts.

147)Remove any metal objects (e.g. rings,

watches, bracelets), that might cause an

accidental electrical contact and cause

serious injury.

148)The batteries contain acid that can

burn skin or eyes. Batteries produce

hydrogen, which is easily flammable and

explosive. Therefore, keep away flames or

devices which may cause sparks.

IMPORTANT

56)Never use a fast battery-charger to

start the engine as this could damage the

electronic systems of your vehicle,

particularly the ignition and engine fuel

supply control units.57)Do not connect the cable to the

negative terminal (–) of the flat battery. The

following spark could lead to battery

explosion and cause serious harm. Only

use the specific earth point; do not use any

other exposed metallic part.

147

Page 150 of 252

FUEL CUT-OFF

SYSTEM

DESCRIPTION

Diesel and petrol versions

This intervenes in the case of an impact

causing:

the interruption of the fuel supply

with the engine consequently switching

off;

the automatic unlocking of the

doors;

turning on of the lights inside the

vehicle;

deactivation of climate control

system ventilation;

switching on of the hazard warning

lights (to deactivate the lights press the

button on the dashboard).

On some versions, the intervention of

the system is indicated by a message

shown on the display. In the same way,

a dedicated message on the display

warns the driver if system operation is

compromised.

IMPORTANT Carefully check the vehicle

for fuel leaks, for instance in the engine

compartment, under the vehicle or near

the tank area. After a collision, bring the

ignition device to STOP to prevent the

battery from running down.

LPG versions

(where provided)

On LPG versions, in addition to the

above, the fuel cut-off system stops

petrol supply immediately, closes the

LPG safety solenoid valve and stops

injection, consequently shutting off the

engine.

148

IN AN EMERGENCY