engine FIAT TIPO 5DOORS STATION WAGON 2016 1.G Manual PDF

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: TIPO 5DOORS STATION WAGON, Model: FIAT TIPO 5DOORS STATION WAGON 2016 1.GPages: 240, PDF Size: 5.43 MB

Page 160 of 240

159)When performing any operation on

the battery or near it, always protect your

eyes with special goggles.

IMPORTANT

55)Be careful not to confuse the various

types of fluids while topping up: they are

not compatible with each other! Topping up

with an unsuitable fluid could severely

damage your vehicle.

56)The oil level must never exceed the

MAX. mark.

57)Always top up using engine oil of the

same specifications as that already in the

engine.

58)PARAFLU

UPanti-freeze is used in the

engine cooling system. Use fluid of the

same type as that contained in the cooling

system for any top-ups. PARAFLU

UP

cannot be mixed with any other type of

fluid. If this happens, do not start the

engine under any circumstances and

contact a Fiat Dealership.

59)Prevent brake fluid, which is highly

corrosive, from coming into contact with

painted parts. Should it happen,

immediately wash with water.

60)If the vehicle must remain unused for a

long time at a very low temperature,

remove the battery and take it to a warm

place, to avoid freezing.61)Incorrect installation of electric and

electronic devices may cause severe

damage to your car. After purchasing your

vehicle, if you wish to install any

accessories (e.g. anti-theft, radio phone,

etc.), go to a Fiat Dealership, which will

suggest the most suitable devices and

advise you whether a higher capacity

battery needs to be installed.

IMPORTANT

3)The used engine oil and the filter that has

been replaced contain substances that are

harmful to the environment. To change the

oil and filters, we advise you to contact a

Fiat Dealership.

4)Batteries contain substances which are

very dangerous for the environment. For

battery replacement, contact a Fiat

Dealership.

BATTERY

RECHARGING

IMPORTANT NOTES

IMPORTANT The battery recharging

procedure is given as information only.

To carry out this operation contact a

Fiat Dealership.

IMPORTANT After setting the ignition

device to STOP and having closed the

driver side door, wait at least one

minute before disconnecting the

electrical supply from the battery. When

reconnecting the electrical supply to the

battery, make sure that the ignition

device is in the STOP position and the

driver side door is closed.

IMPORTANT Charging should be slow

at a low ampere rating for

approximately 24 hours. Charging for a

longer time may damage the battery.

IMPORTANT The cables of the

electrical system must be correctly

reconnected to the battery, i.e. the

positive cable (+) to the positive

terminal and the negative cable (–) to

the negative terminal. The battery

terminals are marked with the positive

(+) and negative (–) symbols, and are

shown on the battery cover. The battery

terminals must also be corrosion-free

and firmly secured to the terminals. If a

158

SERVICING AND CARE

Page 161 of 240

"quick-type" battery charger is used

with the battery fitted on the vehicle,

before connecting it disconnect both

cables of the battery itself. Do not use a

"quick-type" battery charger to provide

the starting voltage.

VERSIONS WITHOUT

STOP/START SYSTEM

To recharge, proceed as follows:

disconnect the terminal from the

negative battery pole;

connect the charger cables to the

battery terminals, observing the polarity;

turn on the charger;

when it is recharged, turn the

charger off before disconnecting it from

the battery;

reconnect the terminal to the

negative battery pole.

VERSIONS WITH

STOP/START SYSTEM

(where provided)

To recharge, proceed as follows:

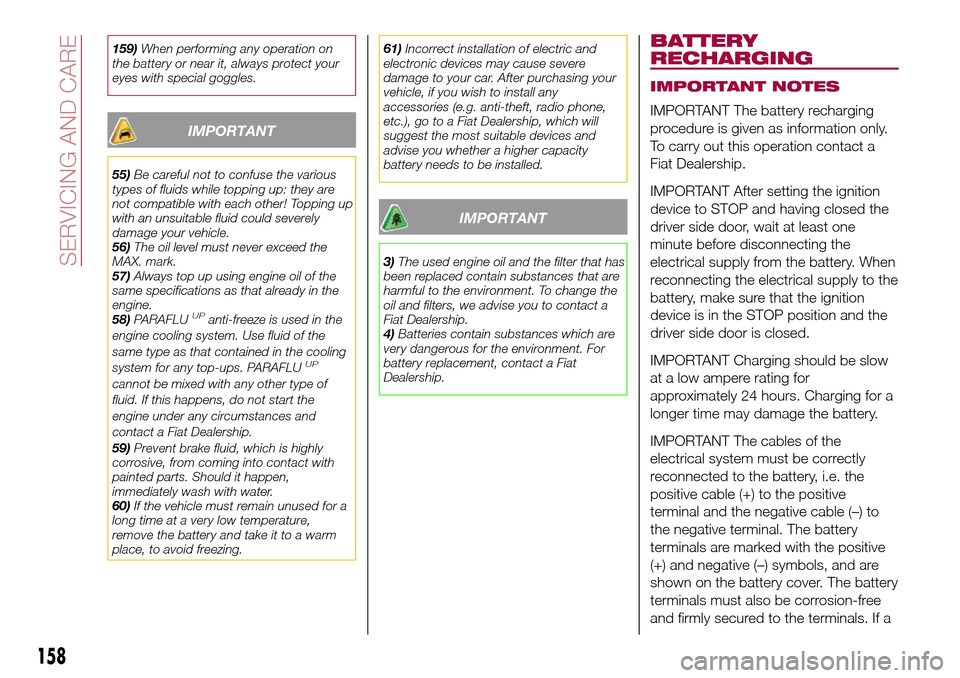

disconnect the connector 1

fig. 158 (pressing the button 2) from the

sensor 3 monitoring the battery

conditions, on the negative pole (–) 4 of

the battery;

connect the positive cable (+) of the

battery charger to the positive battery

terminal 5 and the negative cable (–) to

sensor terminal 4 as shown;

turn on the battery charger. At the

end of the charging process, switch the

battery charger off;

after having disconnected the

charging device, reconnect connector 1

to the sensor 3 as shown.

SERVICING

PROCEDURES

160) 162) 163)

The following pages contain the rules

on therequiredmaintenance

envisaged by the technical personnel

who designed the vehicle.

In addition to these specific

maintenance instructions specified for

routine scheduled servicing, there are

other components which may require

intervention or replacements over the

vehicle’s life cycle.

ENGINE OIL

Engine oil level check

65)

To ensure correct engine lubrication, the

oil must always be kept at the

prescribed level (see "Engine

compartment" in this chapter).

Check the oil level at regular intervals,

each time you refuel for example.

It must be checked about 5 minutes

after stopping the engine, once full

operating temperature is reached. The

vehicle must also be parked on as level

a surface as possible.

Ensure that the oil level is within the

15809036J0001EM

159

interval on the dipstick between the

minimum and maximum limits.

Page 162 of 240

Changing the engine oil

See the "Scheduled servicing plan" for

the correct servicing intervals.

Choice of engine oil type

To ensure optimal performance and

maximum protection in all operating

conditions, it is advisable to use solely

ACEA-certified engine oils (see

description in "Fluid and lubricants" in

the "Technical specifications" chapter).

Additives for engine oil

It is strongly recommended not to use

additives (other than leak detection

dyes) with the engine oil.

The engine oil is a product designed

specially for the vehicle and its

performance may be deteriorated

through the use of further additives.

Disposal of used engine oil and

filters

For the disposal of the engine oil and

filters, contact the appropriate body to

determine local regulations.

IMPORTANT Used engine oil disposed

of incorrectly may seriously harm the

environment.ENGINE OIL

Engine oil level check

66)

To ensure correct engine lubrication, the

oil must always be kept at the

prescribed level (see "Engine

compartment" in this chapter).

ENGINE OIL FILTER

Replacing the engine oil filter

The engine oil filter must be replaced

each time the engine oil is changed.

It is advisable to replace it with a

genuine spare part, specifically

designed for this vehicle.

AIR FILTER

160)

Replacing the air cleaner

See the "Scheduled servicing plan" for

the correct servicing intervals.

It is advisable to replace it with a

genuine spare part, specifically

designed for this vehicle.

AIR CONDITIONING

SYSTEM MAINTENANCE

66) 67)

To ensure the best possible

performance, the air conditioning

system must be checked and undergo

maintenance at a Fiat Dealership at the

beginning of the summer.

WINDSCREEN / REAR

WINDOW WIPERS

161)

Periodically clean the windscreen and

rear window and rubber profile of the

windscreen/rear window wiper blades,

using a sponge or a soft cloth and a

non-abrasive detergent. This eliminates

the salt or impurities accumulated when

driving.

Prolonged operation of the windscreen

window wipers with dry glass may

cause the deterioration of the blades, in

addition to abrasion of the surface of

the glass. To eliminate the impurities on

the dry glass, always operate the

windscreen/rear window washers.

In the case of very low outdoor

temperatures (below 0 °C), ensure that

the movement of the rubber part in

contact with the glass is not

obstructed, before activating the

windscreen/rear window wiper. Use a

suitable deicing product to release it if

required.

Do not use the windscreen wipers to

remove frost or ice.

Also avoid contact of the rubber profile

of the blades with petroleum derivatives

such as engine oil, petrol, etc.

IMPORTANT The envisaged life of the

windscreen and rear window wiper

160

SERVICING AND CARE

Page 164 of 240

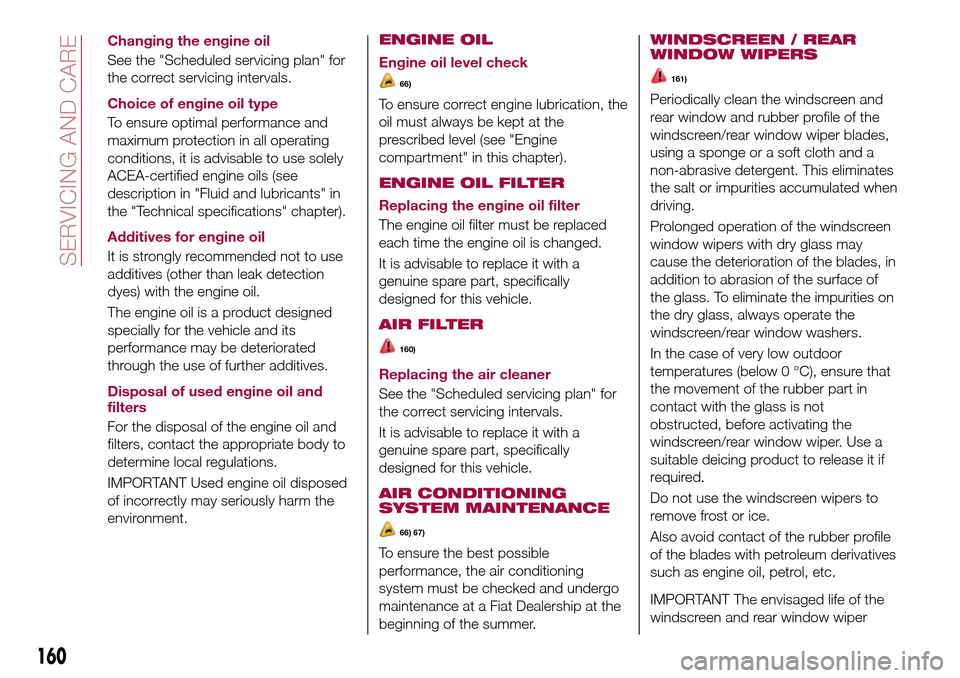

Replacing the rear window wiper

blade

Proceed as follows:

widen the two tabs as shown by the

arrows and rotate cover 1

fig. 161 outwards;

undo nut 2 and remove arm 3 from

the central pin;

correctly align the new arm;

fully tighten nut 2 and then reclose

cover 1.

Windscreen/rear window washer

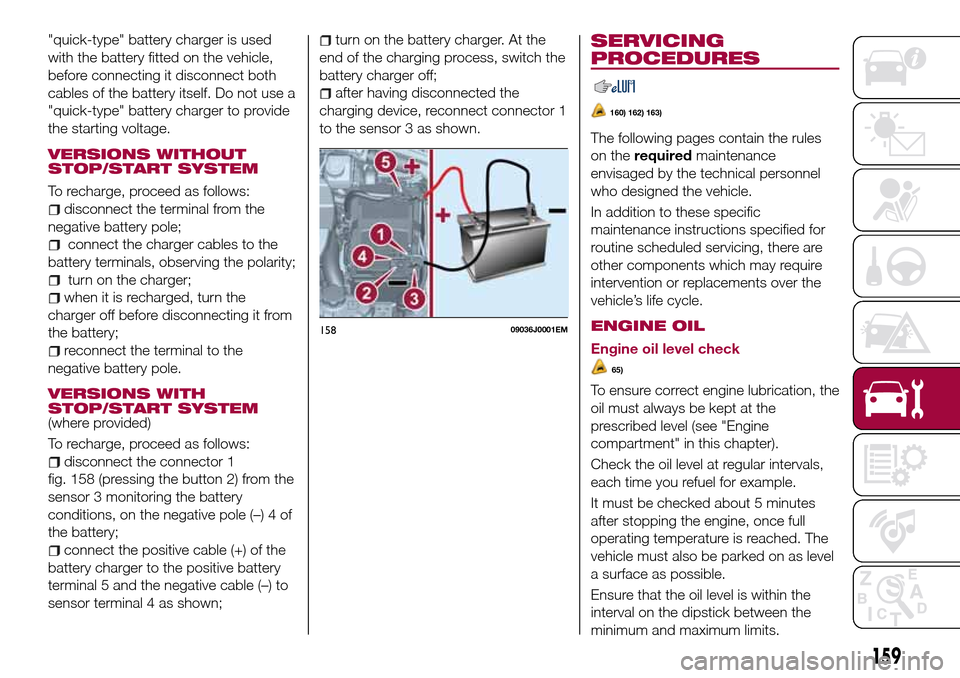

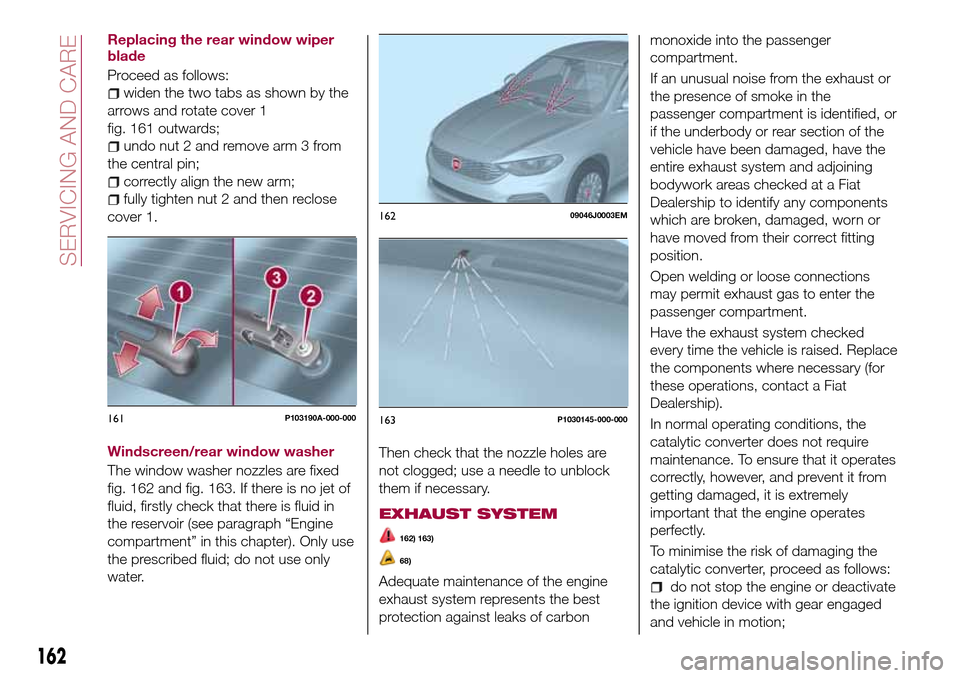

The window washer nozzles are fixed

fig. 162 and fig. 163. If there is no jet of

fluid, firstly check that there is fluid in

the reservoir (see paragraph “Engine

compartment” in this chapter). Only use

the prescribed fluid; do not use only

water.Then check that the nozzle holes are

not clogged; use a needle to unblock

them if necessary.

EXHAUST SYSTEM

162) 163)

68)

Adequate maintenance of the engine

exhaust system represents the best

protection against leaks of carbonmonoxide into the passenger

compartment.

If an unusual noise from the exhaust or

the presence of smoke in the

passenger compartment is identified, or

if the underbody or rear section of the

vehicle have been damaged, have the

entire exhaust system and adjoining

bodywork areas checked at a Fiat

Dealership to identify any components

which are broken, damaged, worn or

have moved from their correct fitting

position.

Open welding or loose connections

may permit exhaust gas to enter the

passenger compartment.

Have the exhaust system checked

every time the vehicle is raised. Replace

the components where necessary (for

these operations, contact a Fiat

Dealership).

In normal operating conditions, the

catalytic converter does not require

maintenance. To ensure that it operates

correctly, however, and prevent it from

getting damaged, it is extremely

important that the engine operates

perfectly.

To minimise the risk of damaging the

catalytic converter, proceed as follows:do not stop the engine or deactivate

the ignition device with gear engaged

and vehicle in motion;

161P103190A-000-000

16209046J0003EM

163P1030145-000-000

162

SERVICING AND CARE

Page 165 of 240

do not attempt to start the engine by

bump starting;

do not persist in using the vehicle if

idling is very irregular or the operating

conditions are very notably irregular.

EXHAUST SYSTEM

162) 163)

68)

Adequate maintenance of the engine

exhaust system represents the best

protection against leaks of carbon

monoxide into the passenger

compartment.

WARNING

160)The air intake system (air cleaner,

rubber hoses, etc.) can be a protection in

the case of blowbacks from the engine. DO

NOT REMOVE this system unless you

need to carry out repair or servicing

operations. Before starting the engine,

ensure that the system has not been

removed: failure to observe this precaution

may result in serious injury.

161)Driving with worn windscreen/rear

window wiper blades is a serious hazard,

because visibility is reduced in bad

weather.

162)Exhaust emissions are very

dangerous, and may be lethal. They

contain carbon monoxide, a colourless,

odourless gas which can cause fainting

and poisoning if inhaled.163)The exhaust system may reach high

temperatures and may cause a fire if the

vehicle is parked on flammable material.

Dry grass or leaves can also catch fire if

they come into contact with the exhaust

system. Do not park or use the vehicle in a

place in which the exhaust system might

come into contact with flammable material.

IMPORTANT

62)It is recommended to have the vehicle

serviced by a Fiat Dealership. When

carrying out normal periodic operations and

small servicing interventions personally on

the vehicle, it is recommended to use

suitable equipment, genuine spare parts

and the necessary fluids. Do not carry out

any interventions if you don't have the

necessary experience.

63)Incorrect servicing of the vehicle or

failure to carry out operations or repairs

(when necessary) may lead to more

expensive repairs, damage to other

components or have a negative impact on

the vehicle performance. Have any

malfunction inspected immediately by a Fiat

Dealership.

64)The vehicle is equipped with fluids

which are optimised or protecting its

performance and life and extending service

intervals. Do not use chemicals for washing

these components since they may damage

the engine, the gearbox or the climate

control system. This damage is not covered

by the vehicle’s warranty. If any component

needs to be washed due to malfunctioning,

use only the specific liquid for that

procedure.65)An excessive or insufficient amount of

oil inside the base is extremely damaging to

the engine. Make sure it is always at an

adequate level.

66)Always require the use of only

compressor coolants and lubricants

approved and suitable for the specific air

conditioning system fitted on the vehicle.

Some non-approved coolants are

flammable and may explode, with the risk

of injuries. The use of non-approved

coolants or lubricants may adversely affect

system efficiency, leading to expensive

repairs.

67)The air conditioner system contains

coolant under high pressure: to avoid

injuries to people or damage to the system,

any coolant addition or repair that requires

to disconnect the cables must be carried

out by a Fiat Dealership.

68)Vehicles equipped with catalytic

converter must be fuelled only with

unleaded petrol. Leaded petrol would

permanently damage the catalytic

converter and eliminate its ability to reduce

polluting emissions, seriously

compromising the engine performance,

which would be irreparably damaged. If the

engine does not work correctly, especially if

it starts irregularly or if there is a reduction

of its performance, immediately go to a Fiat

Dealership. Prolonged and faulty operation

of the engine may cause overheating of the

converter and, as a consequence, possible

damage to the converter and the vehicle.

163

Page 167 of 240

BODY

PRESERVING THE

BODYWORK

Paint

70)

5)

Touch up abrasions and scratches

immediately to prevent the formation of

rust.

Maintenance of paintwork consists of

washing the car: the frequency

depends on the conditions and

environment where the car is used. For

example, it is advisable to wash the

vehicle more often in areas with high

levels of atmospheric pollution or salted

roads.

Some parts of the vehicle may be

covered with a matt paint which, in

order to be maintained intact, requires

special care: see the instructions in the

warning at the end of this paragraph

71)

To correctly wash the vehicle, follow

these instructions:

if the vehicle is washed remove the

aerial from the roof;

if high pressure jets or cleaners are

used to wash the vehicle, keep a

distance of at least 40 cm from thebodywork to avoid damage or

alteration. Build up of water could

cause damage to the vehicle in the long

term;

wash the bodywork using a low

pressure jet of water if possible;

wipe a sponge with a slightly soapy

solution over the bodywork, frequently

rinsing the sponge;

rinse well with water and dry with a

jet of air or a chamois leather.

Dry the less visible parts (e.g. door

frames, bonnet, headlight frames, etc.)

with special care, as water may

stagnate more easily in these areas. Do

not wash the car after it has been left in

the sun or with the bonnet hot: this may

alter the shine of the paintwork.

Exterior plastic parts must be cleaned

in the same way as the rest of the

vehicle.

IMPORTANT NOTES

Avoid parking under trees; the resin

dropped by trees makes the paintwork

go opaque and increases the possibility

of corrosion.

Bird droppings must be washed off

immediately and thoroughly as the acid

they contain is particularly aggressive.Windows

Use specific detergents and clean

cloths to prevent scratching or altering

the transparency.

IMPORTANT Wipe the rear window

inside gently with a cloth following the

direction of the filaments to avoid

damaging the heating device.

Front headlights

Use a soft cloth soaked in water and

detergent for washing cars.

IMPORTANT Never use aromatic

substances (e.g. petrol) or ketones (e.g.

acetone) for cleaning the plastic lenses

of the headlights.

IMPORTANT When cleaning with a

pressure washer, keep the water jet at

least 20 cm away from the headlights.

Engine compartment

At the end of every winter, wash the

engine compartment thoroughly, taking

care not to aim the jet of water directly

at the electronic control units or at the

windscreen/rear window wiper motors.

Have this operation performed at a

specialised workshop.

IMPORTANT The washing should take

place with the engine cold and the

ignition device in the STOP position.

After the washing operation, make sure

165

Page 170 of 240

TECHNICAL DATA

Everything you may find useful for

understanding how your vehicle is

made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

vehicle.

IDENTIFICATION DATA.........169

ENGINE..................170

WHEELS.................172

DIMENSIONS..............175

WEIGHTS.................176

REFUELLING...............178

FLUIDS AND LUBRICANTS......180

PERFORMANCE............183

FUEL CONSUMPTION.........184

CO2 EMISSIONS............186

PRESCRIPTIONS FOR HANDLING

THE VEHICLE AT THE END OF ITS

LIFE....................187

168

TECHNICAL DATA

Page 171 of 240

IDENTIFICATION

DATA

VEHICLE IDENTIFICATION

NUMBER (VIN) PLATE

It is located on the driver's door pillar. It

can be read with the door open and

bears the following data fig. 165:

AName of manufacturer

BVehicle type-approval number

CVehicle identification number

DTechnically allowed max. weight with

full load

ETechnically allowed max. weight for

combined vehicle

FTechnically allowed max. weight on

axle 1

GTechnically allowed max. weight on

axle 2

HEngine identification

IType variant version

LPaintwork colour code

MSmoke absorption coefficient (Diesel

versions)

NFurther instructions.

VEHICLE IDENTIFICATION

NUMBER

The Vehicle Identification Number (VIN)

is stamped on the plate shown in

fig. 166, located on the front left corner

of the dashboard cover, which can be

seen from outside the vehicle, through

the windscreen.

This number is also stamped on the

passenger compartment floor, in front

of the front right seat.To access it, slide flap 1 fig. 167 in the

direction shown by the arrow.

The marking includes:

type of vehicle;

chassis serial number.

ENGINE MARKING

It is stamped on the cylinder block and

includes the type and the engine serial

number.165P2000048-000-000

16610016J0001EM

167P2000047-000-000

169

Page 172 of 240

ENGINE

172)

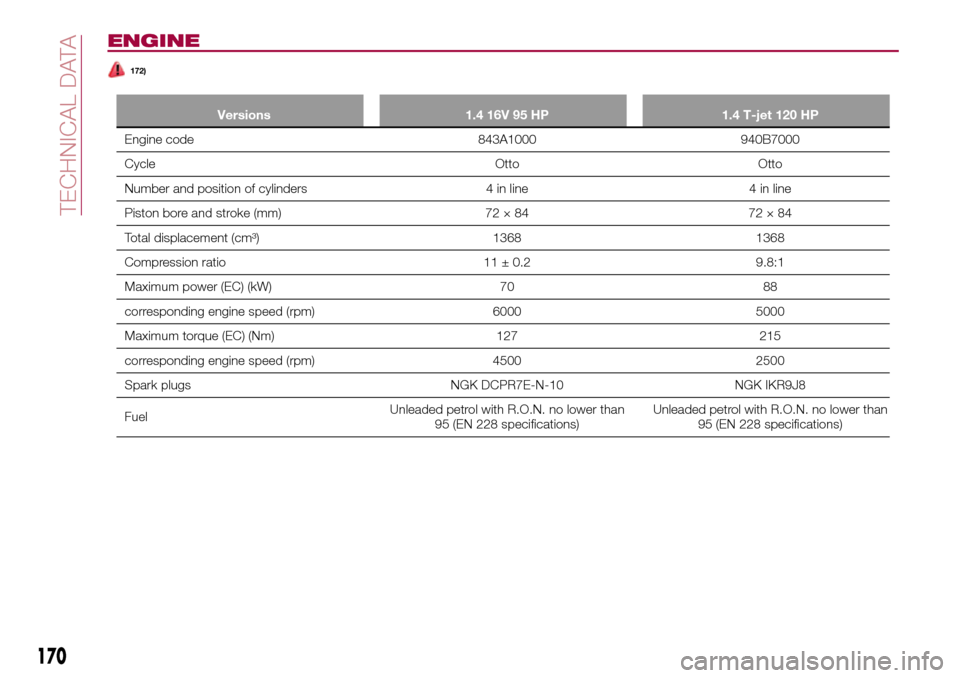

Versions 1.4 16V 95 HP 1.4 T-jet 120 HP

Engine code 843A1000 940B7000

Cycle Otto Otto

Number and position of cylinders 4 in line 4 in line

Piston bore and stroke (mm) 72 × 84 72 × 84

Total displacement (cm³) 1368 1368

Compression ratio 11 ± 0.2 9.8:1

Maximum power (EC) (kW) 70 88

corresponding engine speed (rpm) 6000 5000

Maximum torque (EC) (Nm) 127 215

corresponding engine speed (rpm) 4500 2500

Spark plugs NGK DCPR7E-N-10 NGK IKR9J8

FuelUnleaded petrol with R.O.N. no lower than

95 (EN 228 specifications)Unleaded petrol with R.O.N. no lower than

95 (EN 228 specifications)

170

TECHNICAL DATA

Page 173 of 240

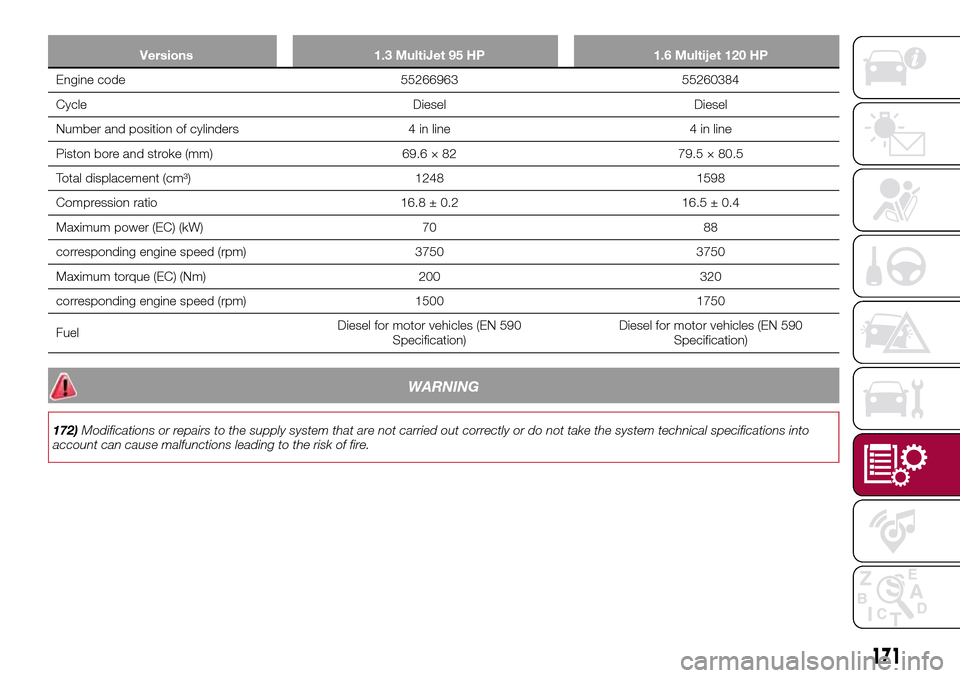

Versions 1.3 MultiJet 95 HP 1.6 Multijet 120 HP

Engine code 55266963 55260384

Cycle Diesel Diesel

Number and position of cylinders 4 in line 4 in line

Piston bore and stroke (mm) 69.6 × 82 79.5 × 80.5

Total displacement (cm³) 1248 1598

Compression ratio 16.8 ± 0.2 16.5 ± 0.4

Maximum power (EC) (kW) 70 88

corresponding engine speed (rpm) 3750 3750

Maximum torque (EC) (Nm) 200 320

corresponding engine speed (rpm) 1500 1750

FuelDiesel for motor vehicles (EN 590

Specification)Diesel for motor vehicles (EN 590

Specification)

WARNING

172)Modifications or repairs to the supply system that are not carried out correctly or do not take the system technical specifications into

account can cause malfunctions leading to the risk of fire.

171