boot FIAT TIPO 5DOORS STATION WAGON 2016 1.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: TIPO 5DOORS STATION WAGON, Model: FIAT TIPO 5DOORS STATION WAGON 2016 1.GPages: 240, PDF Size: 5.43 MB

Page 37 of 240

CLOSING

To close the tailgate, lower it onto the

lock until you hear it click.

IMPORTANT Before closing the tailgate

make sure that you have the keys,

since the tailgate is automatically

locked.

INITIALISATION

IMPORTANT If the battery is

disconnected or the protective fuse

blows, the tailgate opening/closing

mechanism must be reinitialised as

follows:

close all the doors and the tailgate;

press the"FIAT" button on the

remote control;

press thebutton on the remote

control.

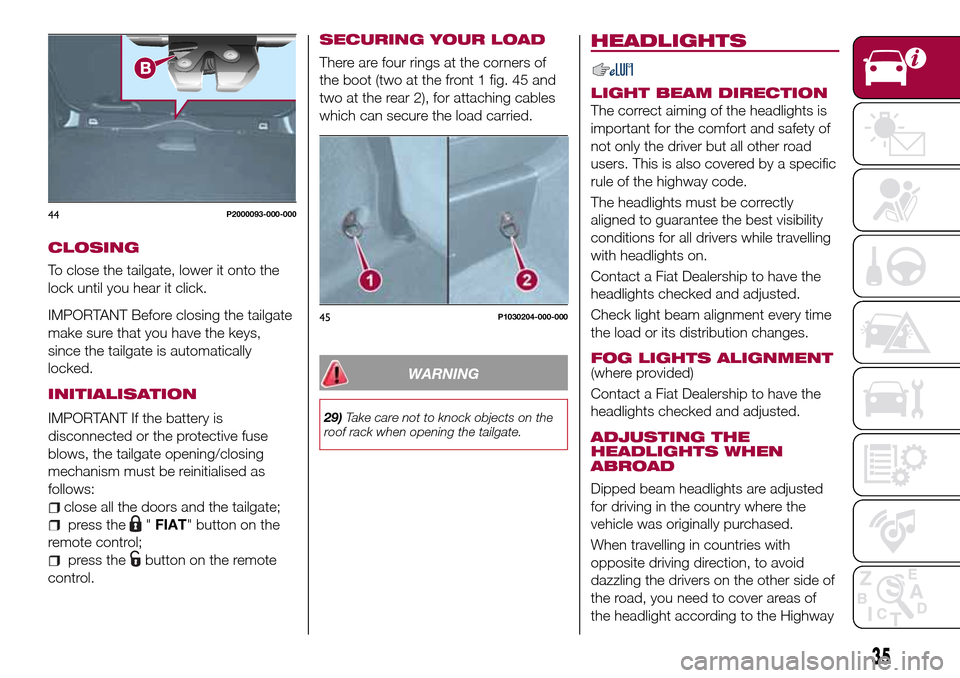

SECURING YOUR LOAD

There are four rings at the corners of

the boot (two at the front 1 fig. 45 and

two at the rear 2), for attaching cables

which can secure the load carried.

WARNING

29)Take care not to knock objects on the

roof rack when opening the tailgate.

HEADLIGHTS

LIGHT BEAM DIRECTION

The correct aiming of the headlights is

important for the comfort and safety of

not only the driver but all other road

users. This is also covered by a specific

rule of the highway code.

The headlights must be correctly

aligned to guarantee the best visibility

conditions for all drivers while travelling

with headlights on.

Contact a Fiat Dealership to have the

headlights checked and adjusted.

Check light beam alignment every time

the load or its distribution changes.

FOG LIGHTS ALIGNMENT(where provided)

Contact a Fiat Dealership to have the

headlights checked and adjusted.

ADJUSTING THE

HEADLIGHTS WHEN

ABROAD

Dipped beam headlights are adjusted

for driving in the country where the

vehicle was originally purchased.

When travelling in countries with

opposite driving direction, to avoid

dazzling the drivers on the other side of

the road, you need to cover areas of

the headlight according to the Highway

44P2000093-000-000

45P1030204-000-000

35

Page 116 of 240

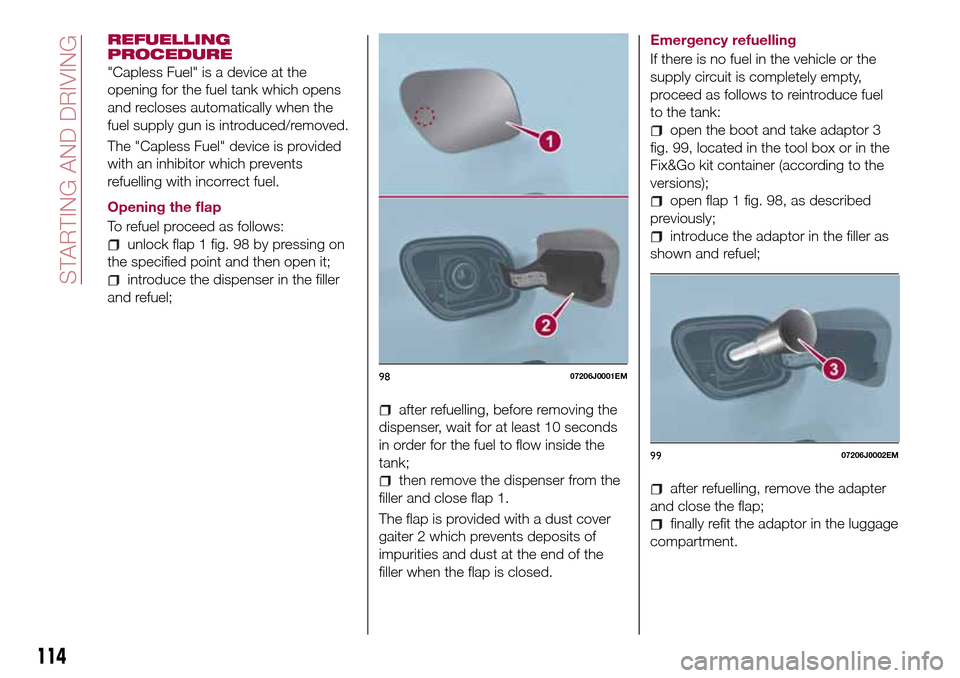

REFUELLING

PROCEDURE

"Capless Fuel" is a device at the

opening for the fuel tank which opens

and recloses automatically when the

fuel supply gun is introduced/removed.

The "Capless Fuel" device is provided

with an inhibitor which prevents

refuelling with incorrect fuel.

Opening the flap

To refuel proceed as follows:

unlock flap 1 fig. 98 by pressing on

the specified point and then open it;

introduce the dispenser in the filler

and refuel;

after refuelling, before removing the

dispenser, wait for at least 10 seconds

in order for the fuel to flow inside the

tank;

then remove the dispenser from the

filler and close flap 1.

The flap is provided with a dust cover

gaiter 2 which prevents deposits of

impurities and dust at the end of the

filler when the flap is closed.Emergency refuelling

If there is no fuel in the vehicle or the

supply circuit is completely empty,

proceed as follows to reintroduce fuel

to the tank:

open the boot and take adaptor 3

fig. 99, located in the tool box or in the

Fix&Go kit container (according to the

versions);

open flap 1 fig. 98, as described

previously;

introduce the adaptor in the filler as

shown and refuel;

after refuelling, remove the adapter

and close the flap;

finally refit the adaptor in the luggage

compartment.

9807206J0001EM

9907206J0002EM

114

STARTING AND DRIVING

Page 129 of 240

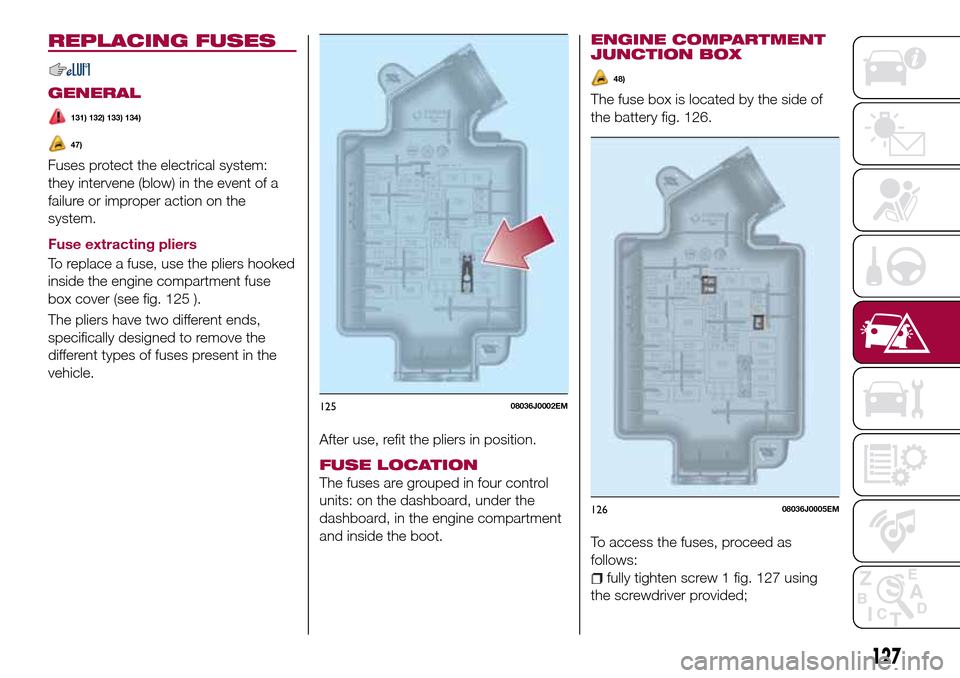

REPLACING FUSES

GENERAL

131) 132) 133) 134)

47)

Fuses protect the electrical system:

they intervene (blow) in the event of a

failure or improper action on the

system.

Fuse extracting pliers

To replace a fuse, use the pliers hooked

inside the engine compartment fuse

box cover (see fig. 125 ).

The pliers have two different ends,

specifically designed to remove the

different types of fuses present in the

vehicle.

After use, refit the pliers in position.

FUSE LOCATION

The fuses are grouped in four control

units: on the dashboard, under the

dashboard, in the engine compartment

and inside the boot.

ENGINE COMPARTMENT

JUNCTION BOX

48)

The fuse box is located by the side of

the battery fig. 126.

To access the fuses, proceed as

follows:

fully tighten screw 1 fig. 127 using

the screwdriver provided;

12508036J0002EM

12608036J0005EM

127

Page 135 of 240

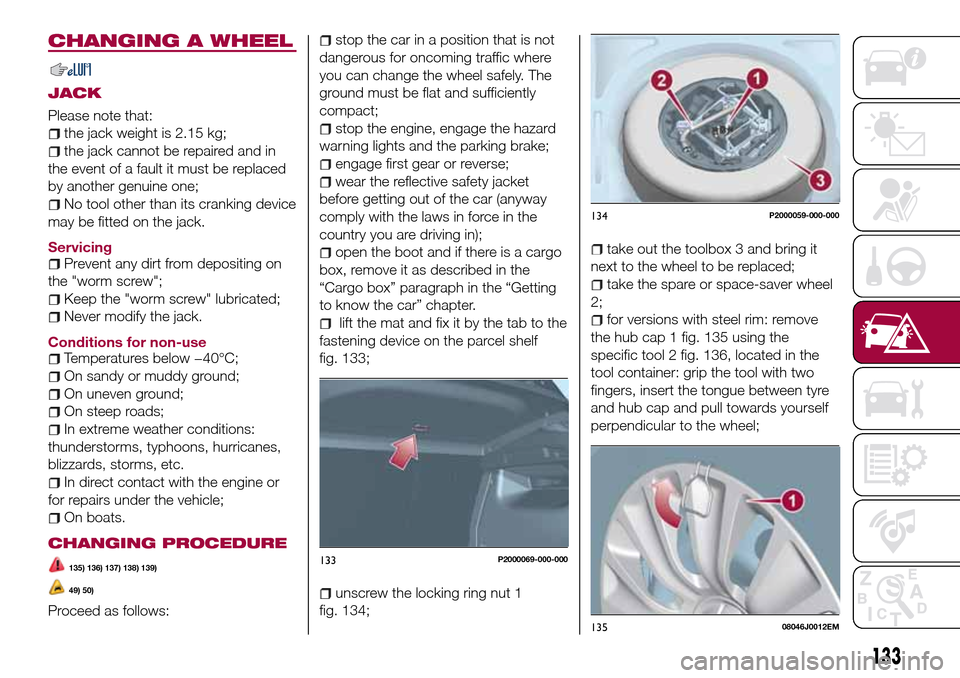

CHANGING A WHEEL

JACK

Please note that:

the jack weight is 2.15 kg;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another genuine one;

No tool other than its cranking device

may be fitted on the jack.

Servicing

Prevent any dirt from depositing on

the "worm screw";

Keep the "worm screw" lubricated;

Never modify the jack.

Conditions for non-use

Temperatures below −40°C;

On sandy or muddy ground;

On uneven ground;

On steep roads;

In extreme weather conditions:

thunderstorms, typhoons, hurricanes,

blizzards, storms, etc.

In direct contact with the engine or

for repairs under the vehicle;

On boats.

CHANGING PROCEDURE

135) 136) 137) 138) 139)

49) 50)

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can change the wheel safely. The

ground must be flat and sufficiently

compact;

stop the engine, engage the hazard

warning lights and the parking brake;

engage first gear or reverse;

wear the reflective safety jacket

before getting out of the car (anyway

comply with the laws in force in the

country you are driving in);

open the boot and if there is a cargo

box, remove it as described in the

“Cargo box” paragraph in the “Getting

to know the car” chapter.

lift the mat and fix it by the tab to the

fastening device on the parcel shelf

fig. 133;

unscrew the locking ring nut 1

fig. 134;

take out the toolbox 3 and bring it

next to the wheel to be replaced;

take the spare or space-saver wheel

2;

for versions with steel rim: remove

the hub cap 1 fig. 135 using the

specific tool 2 fig. 136, located in the

tool container: grip the tool with two

fingers, insert the tongue between tyre

and hub cap and pull towards yourself

perpendicular to the wheel;

133P2000069-000-000

134P2000059-000-000

13508046J0012EM

133

Page 137 of 240

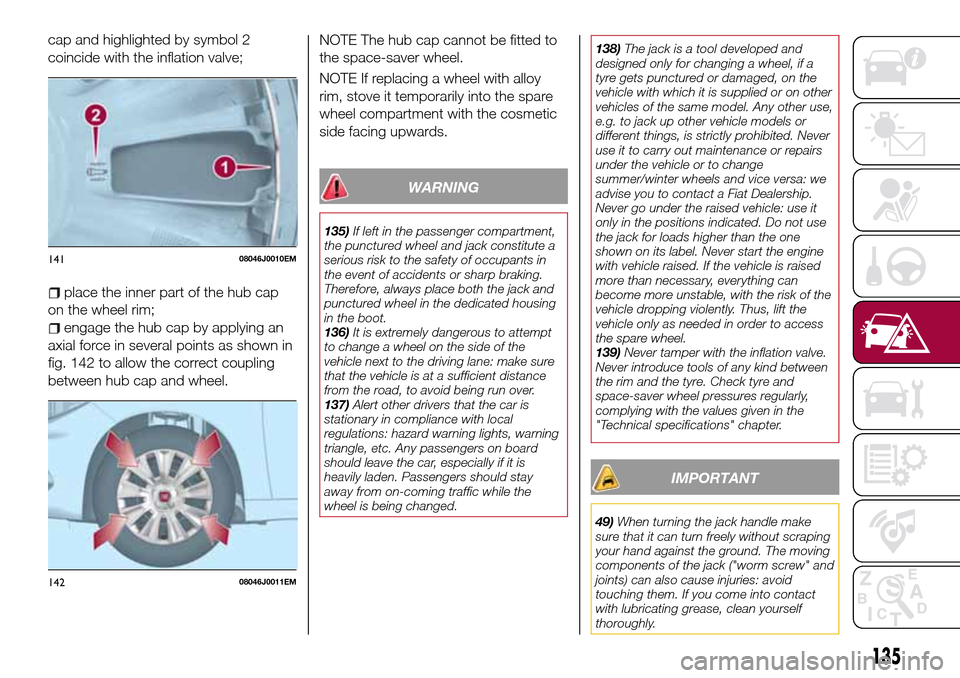

cap and highlighted by symbol 2

coincide with the inflation valve;

place the inner part of the hub cap

on the wheel rim;

engage the hub cap by applying an

axial force in several points as shown in

fig. 142 to allow the correct coupling

between hub cap and wheel.NOTE The hub cap cannot be fitted to

the space-saver wheel.

NOTE If replacing a wheel with alloy

rim, stove it temporarily into the spare

wheel compartment with the cosmetic

side facing upwards.

WARNING

135)If left in the passenger compartment,

the punctured wheel and jack constitute a

serious risk to the safety of occupants in

the event of accidents or sharp braking.

Therefore, always place both the jack and

punctured wheel in the dedicated housing

in the boot.

136)It is extremely dangerous to attempt

to change a wheel on the side of the

vehicle next to the driving lane: make sure

that the vehicle is at a sufficient distance

from the road, to avoid being run over.

137)Alert other drivers that the car is

stationary in compliance with local

regulations: hazard warning lights, warning

triangle, etc. Any passengers on board

should leave the car, especially if it is

heavily laden. Passengers should stay

away from on-coming traffic while the

wheel is being changed.138)The jack is a tool developed and

designed only for changing a wheel, if a

tyre gets punctured or damaged, on the

vehicle with which it is supplied or on other

vehicles of the same model. Any other use,

e.g. to jack up other vehicle models or

different things, is strictly prohibited. Never

use it to carry out maintenance or repairs

under the vehicle or to change

summer/winter wheels and vice versa: we

advise you to contact a Fiat Dealership.

Never go under the raised vehicle: use it

only in the positions indicated. Do not use

the jack for loads higher than the one

shown on its label. Never start the engine

with vehicle raised. If the vehicle is raised

more than necessary, everything can

become more unstable, with the risk of the

vehicle dropping violently. Thus, lift the

vehicle only as needed in order to access

the spare wheel.

139)Never tamper with the inflation valve.

Never introduce tools of any kind between

the rim and the tyre. Check tyre and

space-saver wheel pressures regularly,

complying with the values given in the

"Technical specifications" chapter.

IMPORTANT

49)When turning the jack handle make

sure that it can turn freely without scraping

your hand against the ground. The moving

components of the jack ("worm screw" and

joints) can also cause injuries: avoid

touching them. If you come into contact

with lubricating grease, clean yourself

thoroughly.

14108046J0010EM

14208046J0011EM

135

Page 147 of 240

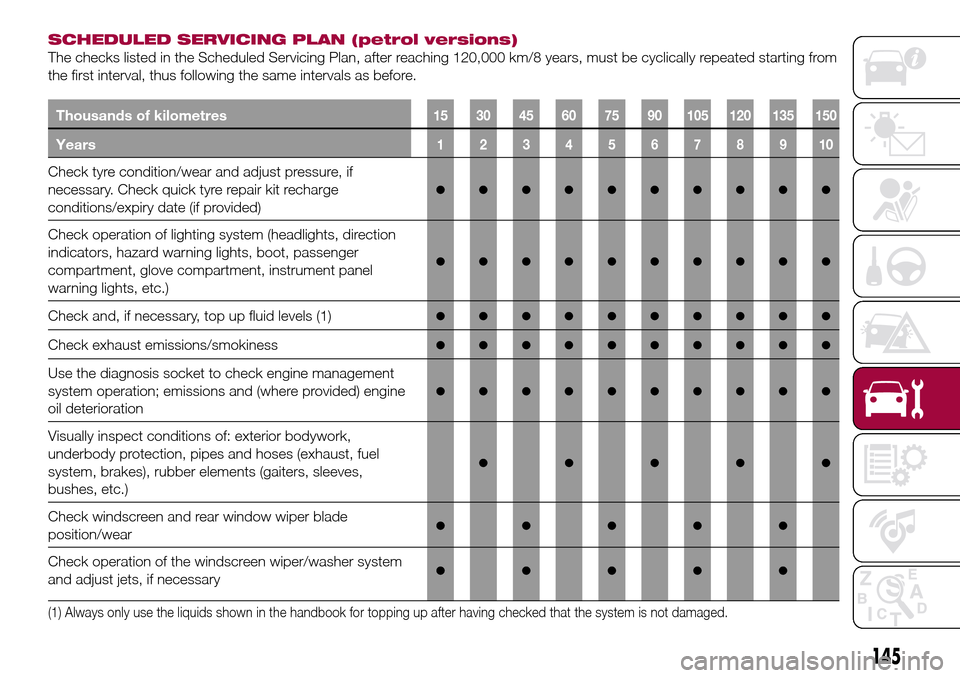

SCHEDULED SERVICING PLAN (petrol versions)

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/8 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of kilometres15 30 45 60 75 90 105 120 135 150

Years12345678910

Check tyre condition/wear and adjust pressure, if

necessary. Check quick tyre repair kit recharge

conditions/expiry date (if provided)

●●●●●●●●●●

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, boot, passenger

compartment, glove compartment, instrument panel

warning lights, etc.)

●●●●●●●●●●

Check and, if necessary, top up fluid levels (1)●●●●●●●●●●

Check exhaust emissions/smokiness●●●●●●●●●●

Use the diagnosis socket to check engine management

system operation; emissions and (where provided) engine

oil deterioration

●●●●●●●●●●

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)

●●●●●

Check windscreen and rear window wiper blade

position/wear●●●●●

Check operation of the windscreen wiper/washer system

and adjust jets, if necessary●●●●●

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

145

Page 150 of 240

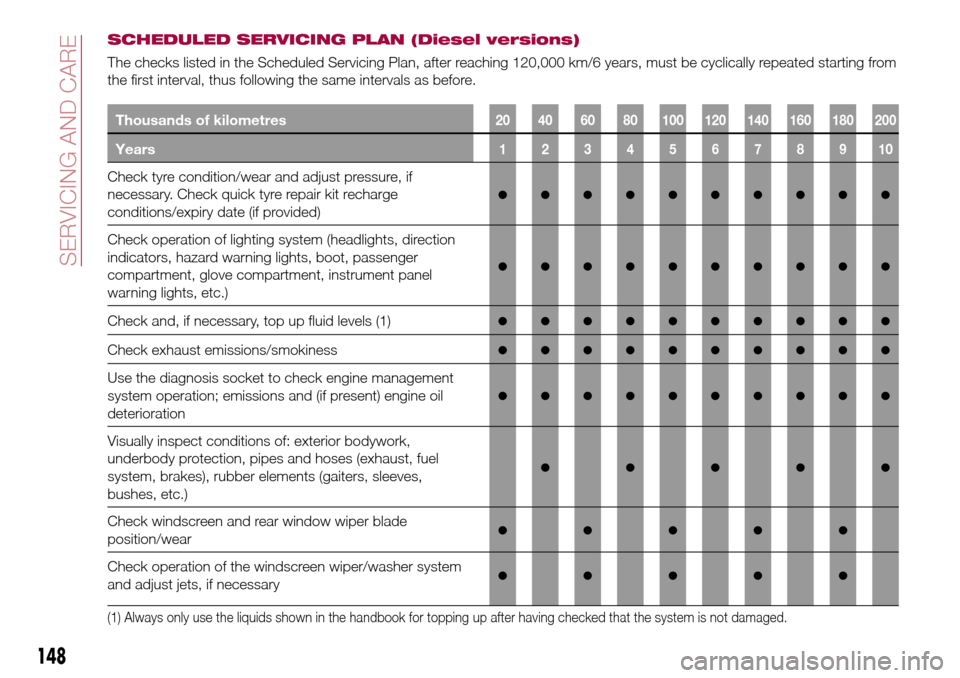

SCHEDULED SERVICING PLAN (Diesel versions)

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/6 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of kilometres20 40 60 80 100 120 140 160 180 200

Years12345678910

Check tyre condition/wear and adjust pressure, if

necessary. Check quick tyre repair kit recharge

conditions/expiry date (if provided)

●●●●●●●●●●

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, boot, passenger

compartment, glove compartment, instrument panel

warning lights, etc.)

●●●●●●●●●●

Check and, if necessary, top up fluid levels (1)●●●●●●●●●●

Check exhaust emissions/smokiness●●●●●●●●●●

Use the diagnosis socket to check engine management

system operation; emissions and (if present) engine oil

deterioration

●●●●●●●●●●

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)

●●●●●

Check windscreen and rear window wiper blade

position/wear●●●●●

Check operation of the windscreen wiper/washer system

and adjust jets, if necessary●●●●●

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

148

SERVICING AND CARE