headlight FIAT TIPO 5DOORS STATION WAGON 2017 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: TIPO 5DOORS STATION WAGON, Model: FIAT TIPO 5DOORS STATION WAGON 2017 1.GPages: 264, PDF Size: 4.53 MB

Page 67 of 264

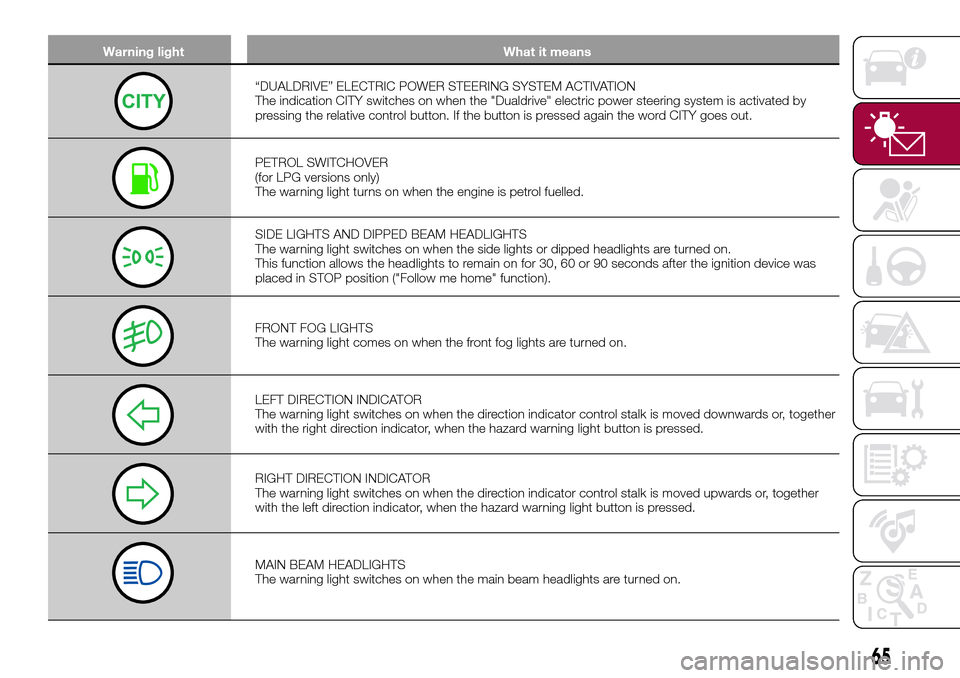

Warning light What it means

“DUALDRIVE” ELECTRIC POWER STEERING SYSTEM ACTIVATION

The indication CITY switches on when the "Dualdrive" electric power steering system is activated by

pressing the relative control button. If the button is pressed again the word CITY goes out.

PETROL SWITCHOVER

(for LPG versions only)

The warning light turns on when the engine is petrol fuelled.

SIDE LIGHTS AND DIPPED BEAM HEADLIGHTS

The warning light switches on when the side lights or dipped headlights are turned on.

This function allows the headlights to remain on for 30, 60 or 90 seconds after the ignition device was

placed in STOP position ("Follow me home" function).

FRONT FOG LIGHTS

The warning light comes on when the front fog lights are turned on.

LEFT DIRECTION INDICATOR

The warning light switches on when the direction indicator control stalk is moved downwards or, together

with the right direction indicator, when the hazard warning light button is pressed.

RIGHT DIRECTION INDICATOR

The warning light switches on when the direction indicator control stalk is moved upwards or, together

with the left direction indicator, when the hazard warning light button is pressed.

MAIN BEAM HEADLIGHTS

The warning light switches on when the main beam headlights are turned on.

65

Page 72 of 264

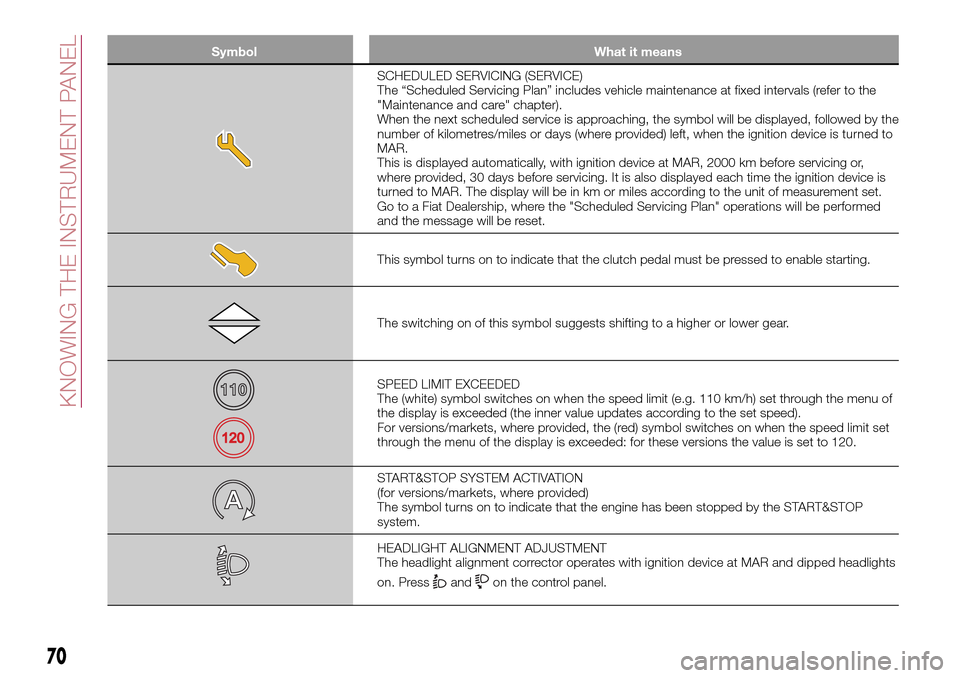

Symbol What it means

SCHEDULED SERVICING (SERVICE)

The “Scheduled Servicing Plan” includes vehicle maintenance at fixed intervals (refer to the

"Maintenance and care" chapter).

When the next scheduled service is approaching, the symbol will be displayed, followed by the

number of kilometres/miles or days (where provided) left, when the ignition device is turned to

MAR.

This is displayed automatically, with ignition device at MAR, 2000 km before servicing or,

where provided, 30 days before servicing. It is also displayed each time the ignition device is

turned to MAR. The display will be in km or miles according to the unit of measurement set.

Go to a Fiat Dealership, where the "Scheduled Servicing Plan" operations will be performed

and the message will be reset.

This symbol turns on to indicate that the clutch pedal must be pressed to enable starting.

The switching on of this symbol suggests shifting to a higher or lower gear.

SPEED LIMIT EXCEEDED

The (white) symbol switches on when the speed limit (e.g. 110 km/h) set through the menu of

the display is exceeded (the inner value updates according to the set speed).

For versions/markets, where provided, the (red) symbol switches on when the speed limit set

through the menu of the display is exceeded: for these versions the value is set to 120.

START&STOP SYSTEM ACTIVATION

(for versions/markets, where provided)

The symbol turns on to indicate that the engine has been stopped by the START&STOP

system.

HEADLIGHT ALIGNMENT ADJUSTMENT

The headlight alignment corrector operates with ignition device at MAR and dipped headlights

on. Press

andon the control panel.

70

KNOWING THE INSTRUMENT PANEL

Page 84 of 264

62)If the driver depresses the brake pedal

fully or carries out a fast steering during

system operation, the automatic braking

function may stop (e.g. to allow a possible

manoeuvre to avoid the obstacle).

63)The system intervenes on vehicles

travelling in the same lane. People, animals

and things (e.g. pushchairs) are not taken

into consideration.

64)If the car must be placed on a roller

bench for maintenance interventions or if it

is washed in an automatic roller washing

tunnel with an obstacle in the front part

(e.g. another car, a wall or another

obstacle), the system may detect its

presence and activate. In this case the

system must be deactivated through the

settings of theUconnect™5"or7" HD

system.

65)If the iTMPS system signals a pressure

decrease on the tyres, it is recommended

to check the pressure on all four tyres.

66)The iTPMS does not relieve the driver

from the obligation to check the tyre

pressure every month; it is not even to be

considered a replacing system for

maintenance or a safety system.

67)Tyre pressure must be checked with

tyres cold. Should it become necessary for

whatever reason to check pressure with

warm tyres, do not reduce pressure even

though it is higher than the prescribed

value, but repeat the check when tyres are

cold

68)The iTPMS cannot indicate sudden tyre

pressure drops (e.g. if a tyre bursts). In this

case, stop the vehicle, braking with caution

and avoiding abrupt steering.

69)The system only warns that the tyre

pressure is low: it is not able to inflate

them.70)Insufficient tyre inflation increases fuel

consumption, reduces the tread duration

and may affect the capacity to drive safely.

IMPORTANT

27)The system may have limited or absent

operation due to weather conditions such

as: heavy rain, hail, thick fog, heavy snow.

28)The section of the bumper before the

sensor must not be covered with

adhesives, auxiliary headlights or any other

object.

29)System intervention might be

unexpected or delayed when other vehicles

transport loads projecting from the side,

above or from the rear, with respect to the

normal size of the vehicle.

30)Operation can be adversely affected by

any structural change made to the vehicle,

such as a modification to the front

geometry, tyre change, or a heavier load

than the standard load of the vehicle.

31)Incorrect repairs made on the front part

of the vehicle (e.g. bumper, chassis) may

alter the position of the radar sensor, and

adversely affect its operation. Go to a Fiat

Dealership for any operation of this type.

32)Do not tamper nor operate on the radar

sensor. In the event of a sensor failure,

contact a Fiat Dealership.

33)When towing a trailer (with modules

installed after purchasing the vehicle), a

vehicle or during loading manoeuvres on a

vehicle transporter (or in vehicle for

transport), the system must be deactivated

via theUconnect™5"or7" HDsystem.34)Do not wash with high-pressure jets in

the bumper lower area: in particular do not

operate on the system's electrical

connector.

35)Be careful in the case of repairs and

new paintings in the area around the

sensor (panel covering the sensor on the

left side of the bumper). In the event of a

frontal impact the sensor may automatically

deactivate and display a warning to indicate

that the sensor needs to be repaired. Even

without a malfunction warning, deactivate

the system operation if you think that the

position of the radar sensor has changed

(e.g. due to low-speed frontal impact as

during parking manoeuvres). In these

cases, go to a Fiat Dealership to have the

radar sensor realigned or replaced.

82

SAFETY

Page 125 of 264

44)The section of the bumper before the

sensor must not be covered with

adhesives, auxiliary headlights or any other

object.

45)Operation can be adversely affected by

any structural change made to the vehicle,

such as a modification to the front

geometry, tyre change, or a heavier load

than the standard load of the vehicle.

46)Incorrect repairs made on the front part

of the vehicle (e.g. bumper, chassis) may

alter the position of the radar sensor, and

adversely affect its operation. Go to a Fiat

Dealership for any operation of this type.

47)Do not tamper nor operate on the radar

sensor. In the event of a sensor failure,

contact a Fiat Dealership.

48)Do not wash with high-pressure jets in

the bumper lower area: in particular do not

operate on the system's electrical

connector.

49)Be careful in the case of repairs and

new paintings in the area around the

sensor (panel covering the sensor on the

left side of the bumper). In the event of a

frontal impact the sensor may automatically

deactivate and display a warning to indicate

that the sensor needs to be repaired. Even

without a malfunction warning, deactivate

the system operation if you think that the

position of the radar sensor has changed

(e.g. due to low-speed frontal impact as

during parking manoeuvres). In these

cases, go to a Fiat Dealership to have the

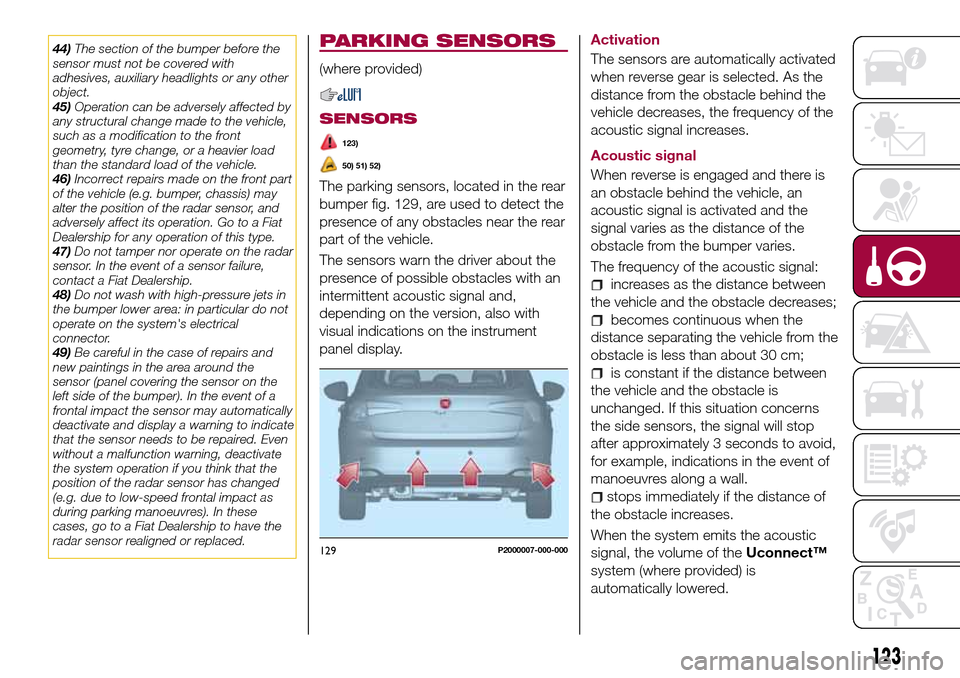

radar sensor realigned or replaced.PARKING SENSORS

(where provided)

SENSORS

123)

50) 51) 52)

The parking sensors, located in the rear

bumper fig. 129, are used to detect the

presence of any obstacles near the rear

part of the vehicle.

The sensors warn the driver about the

presence of possible obstacles with an

intermittent acoustic signal and,

depending on the version, also with

visual indications on the instrument

panel display.Activation

The sensors are automatically activated

when reverse gear is selected. As the

distance from the obstacle behind the

vehicle decreases, the frequency of the

acoustic signal increases.

Acoustic signal

When reverse is engaged and there is

an obstacle behind the vehicle, an

acoustic signal is activated and the

signal varies as the distance of the

obstacle from the bumper varies.

The frequency of the acoustic signal:

increases as the distance between

the vehicle and the obstacle decreases;

becomes continuous when the

distance separating the vehicle from the

obstacle is less than about 30 cm;

is constant if the distance between

the vehicle and the obstacle is

unchanged. If this situation concerns

the side sensors, the signal will stop

after approximately 3 seconds to avoid,

for example, indications in the event of

manoeuvres along a wall.

stops immediately if the distance of

the obstacle increases.

When the system emits the acoustic

signal, the volume of theUconnect™

system (where provided) is

automatically lowered.

129P2000007-000-000

123

Page 134 of 264

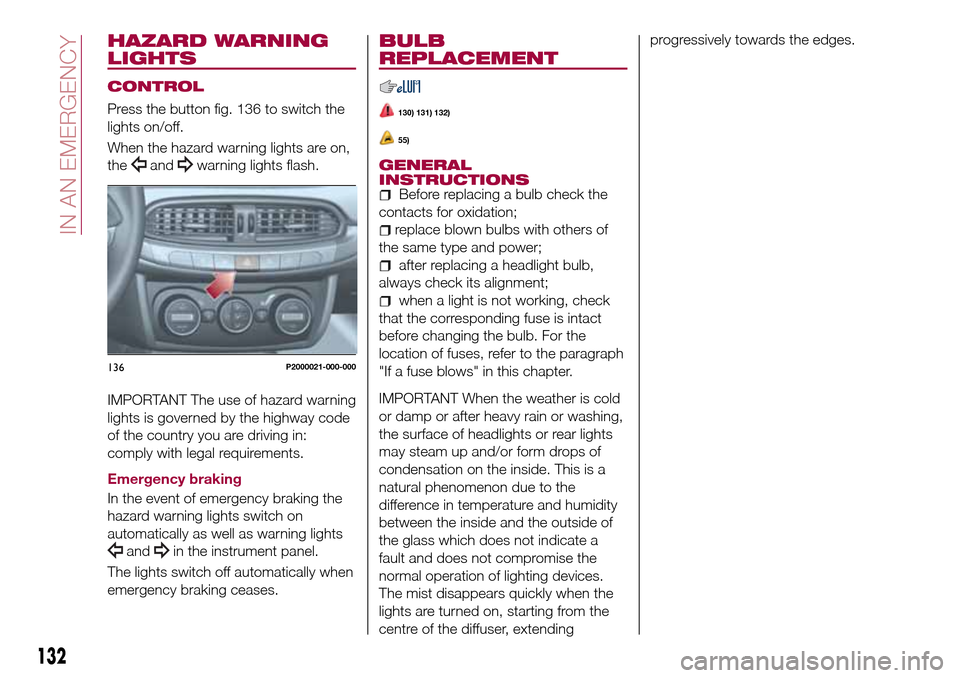

HAZARD WARNING

LIGHTS

CONTROL

Press the button fig. 136 to switch the

lights on/off.

When the hazard warning lights are on,

the

andwarning lights flash.

IMPORTANT The use of hazard warning

lights is governed by the highway code

of the country you are driving in:

comply with legal requirements.

Emergency braking

In the event of emergency braking the

hazard warning lights switch on

automatically as well as warning lights

andin the instrument panel.

The lights switch off automatically when

emergency braking ceases.

BULB

REPLACEMENT

130) 131) 132)

55)

GENERAL

INSTRUCTIONS

Before replacing a bulb check the

contacts for oxidation;

replace blown bulbs with others of

the same type and power;

after replacing a headlight bulb,

always check its alignment;

when a light is not working, check

that the corresponding fuse is intact

before changing the bulb. For the

location of fuses, refer to the paragraph

"If a fuse blows" in this chapter.

IMPORTANT When the weather is cold

or damp or after heavy rain or washing,

the surface of headlights or rear lights

may steam up and/or form drops of

condensation on the inside. This is a

natural phenomenon due to the

difference in temperature and humidity

between the inside and the outside of

the glass which does not indicate a

fault and does not compromise the

normal operation of lighting devices.

The mist disappears quickly when the

lights are turned on, starting from the

centre of the diffuser, extendingprogressively towards the edges.

136P2000021-000-000

132

IN AN EMERGENCY

Page 136 of 264

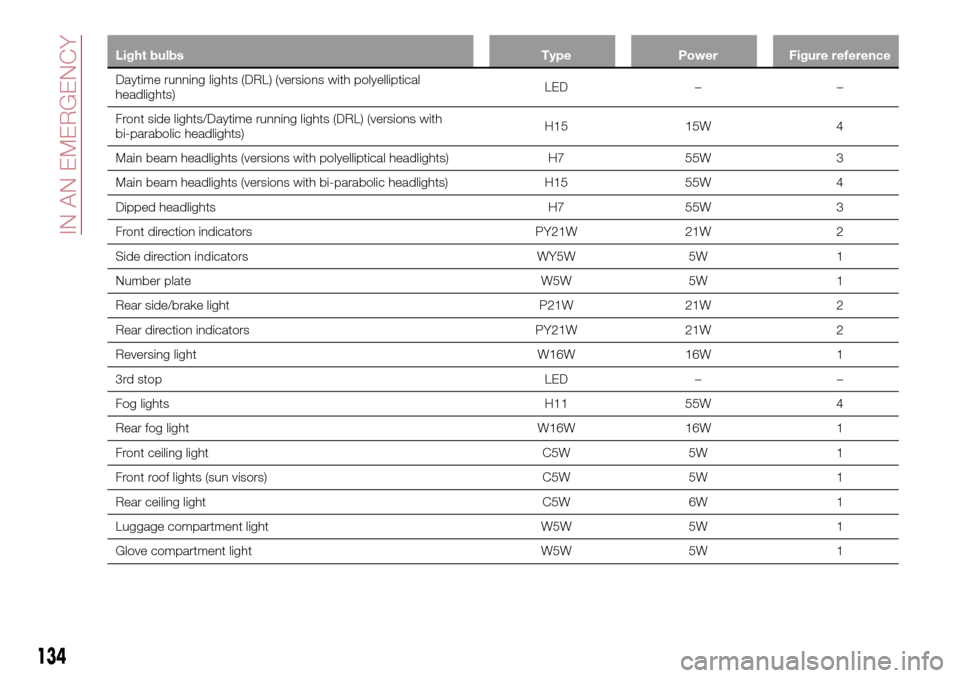

Light bulbs Type Power Figure reference

Daytime running lights (DRL) (versions with polyelliptical

headlights)LED – –

Front side lights/Daytime running lights (DRL) (versions with

bi-parabolic headlights)H15 15W 4

Main beam headlights (versions with polyelliptical headlights) H7 55W 3

Main beam headlights (versions with bi-parabolic headlights) H15 55W 4

Dipped headlights H7 55W 3

Front direction indicators PY21W 21W 2

Side direction indicators WY5W 5W 1

Number plate W5W 5W 1

Rear side/brake light P21W 21W 2

Rear direction indicators PY21W 21W 2

Reversing light W16W 16W 1

3rd stop LED – –

Fog lights H11 55W 4

Rear fog light W16W 16W 1

Front ceiling light C5W 5W 1

Front roof lights (sun visors) C5W 5W 1

Rear ceiling light C5W 6W 1

Luggage compartment light W5W 5W 1

Glove compartment light W5W 5W 1

134

IN AN EMERGENCY

Page 137 of 264

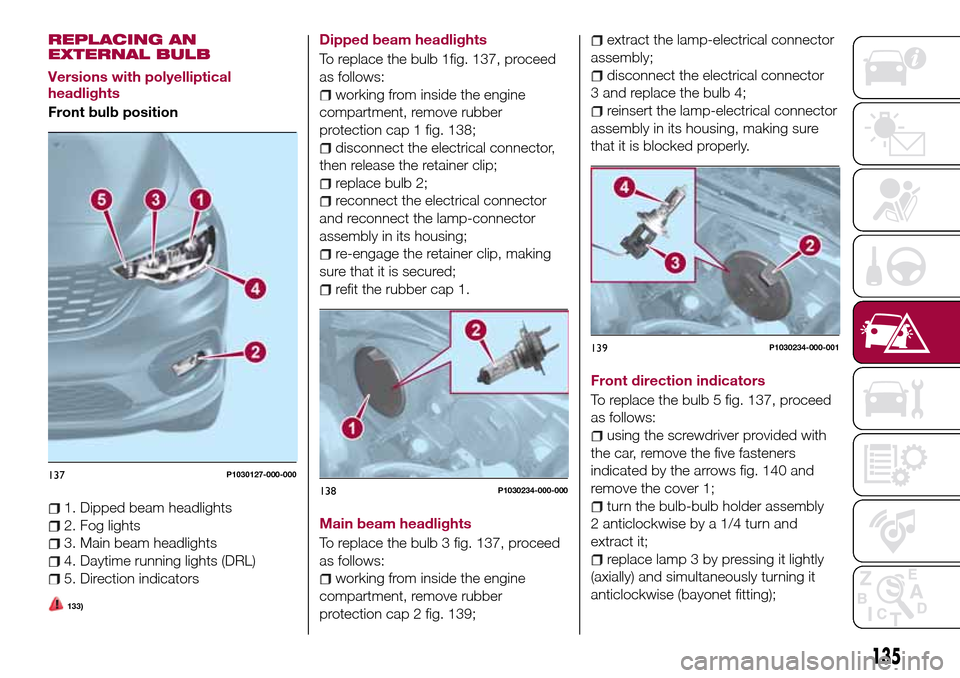

REPLACING AN

EXTERNAL BULB

Versions with polyelliptical

headlights

Front bulb position

1. Dipped beam headlights

2. Fog lights

3. Main beam headlights

4. Daytime running lights (DRL)

5. Direction indicators

133)

Dipped beam headlights

To replace the bulb 1fig. 137, proceed

as follows:

working from inside the engine

compartment, remove rubber

protection cap 1 fig. 138;

disconnect the electrical connector,

then release the retainer clip;

replace bulb 2;

reconnect the electrical connector

and reconnect the lamp-connector

assembly in its housing;

re-engage the retainer clip, making

sure that it is secured;

refit the rubber cap 1.

Main beam headlights

To replace the bulb 3 fig. 137, proceed

as follows:

working from inside the engine

compartment, remove rubber

protection cap 2 fig. 139;

extract the lamp-electrical connector

assembly;

disconnect the electrical connector

3 and replace the bulb 4;

reinsert the lamp-electrical connector

assembly in its housing, making sure

that it is blocked properly.

Front direction indicators

To replace the bulb 5 fig. 137, proceed

as follows:

using the screwdriver provided with

the car, remove the five fasteners

indicated by the arrows fig. 140 and

remove the cover 1;

turn the bulb-bulb holder assembly

2 anticlockwise by a 1/4 turn and

extract it;

replace lamp 3 by pressing it lightly

(axially) and simultaneously turning it

anticlockwise (bayonet fitting);

137P1030127-000-000

138P1030234-000-000

139P1030234-000-001

135

Page 139 of 264

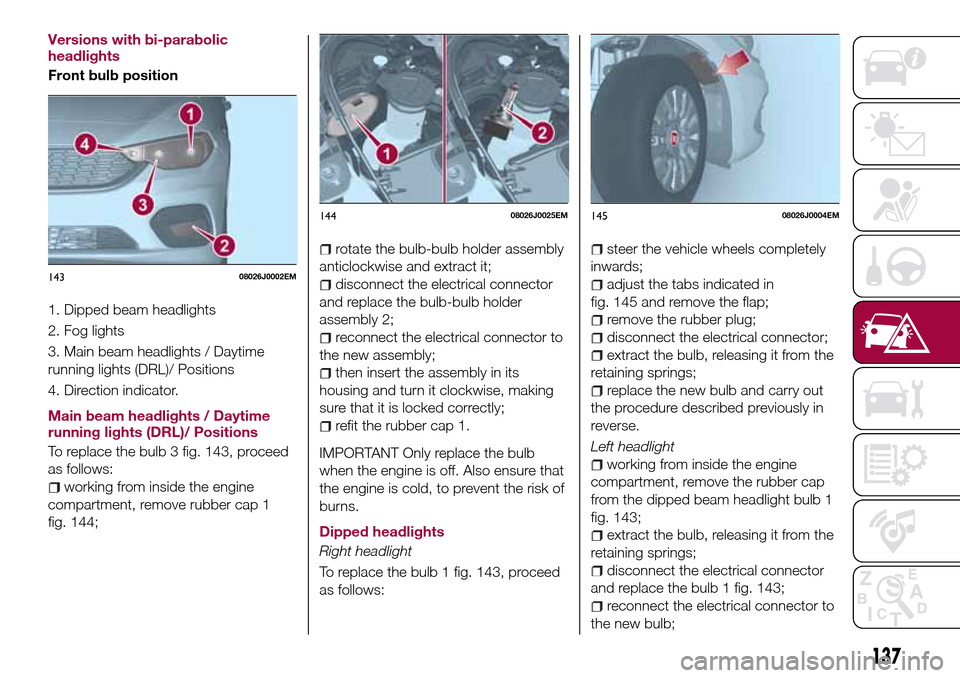

Versions with bi-parabolic

headlights

Front bulb position

1. Dipped beam headlights

2. Fog lights

3. Main beam headlights / Daytime

running lights (DRL)/ Positions

4. Direction indicator.

Main beam headlights / Daytime

running lights (DRL)/ Positions

To replace the bulb 3 fig. 143, proceed

as follows:

working from inside the engine

compartment, remove rubber cap 1

fig. 144;

rotate the bulb-bulb holder assembly

anticlockwise and extract it;

disconnect the electrical connector

and replace the bulb-bulb holder

assembly 2;

reconnect the electrical connector to

the new assembly;

then insert the assembly in its

housing and turn it clockwise, making

sure that it is locked correctly;

refit the rubber cap 1.

IMPORTANT Only replace the bulb

when the engine is off. Also ensure that

the engine is cold, to prevent the risk of

burns.

Dipped headlights

Right headlight

To replace the bulb 1 fig. 143, proceed

as follows:

steer the vehicle wheels completely

inwards;

adjust the tabs indicated in

fig. 145 and remove the flap;

remove the rubber plug;

disconnect the electrical connector;

extract the bulb, releasing it from the

retaining springs;

replace the new bulb and carry out

the procedure described previously in

reverse.

Left headlight

working from inside the engine

compartment, remove the rubber cap

from the dipped beam headlight bulb 1

fig. 143;

extract the bulb, releasing it from the

retaining springs;

disconnect the electrical connector

and replace the bulb 1 fig. 143;

reconnect the electrical connector to

the new bulb;

14308026J0002EM

14408026J0025EM14508026J0004EM

137

Page 164 of 264

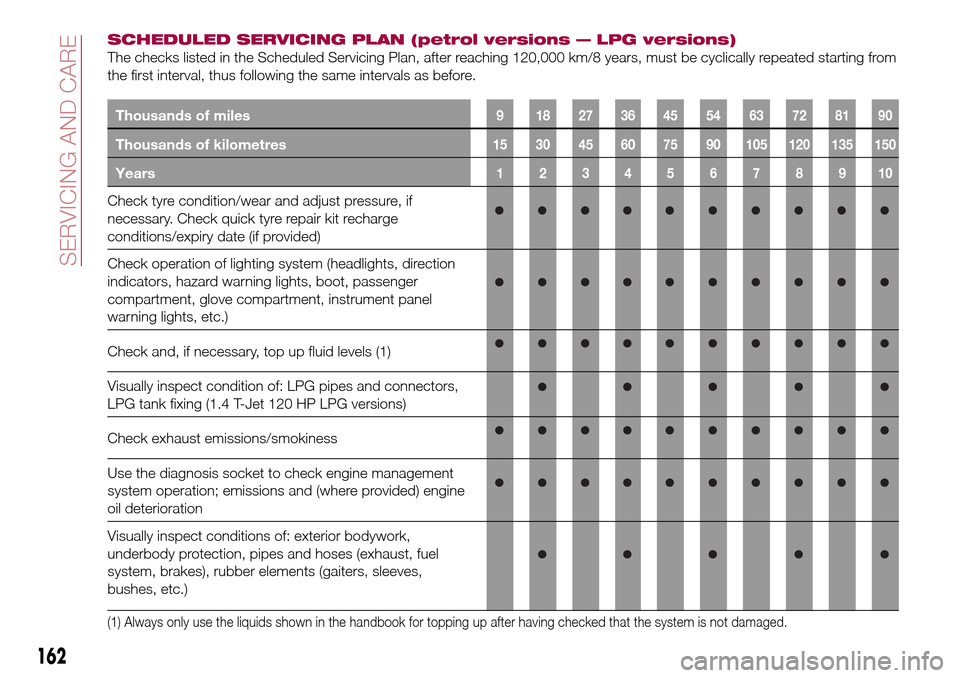

SCHEDULED SERVICING PLAN (petrol versions — LPG versions)

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/8 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of miles9 182736455463728190

Thousands of kilometres15 30 45 60 75 90 105 120 135 150

Years12345678910

Check tyre condition/wear and adjust pressure, if

necessary. Check quick tyre repair kit recharge

conditions/expiry date (if provided)

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, boot, passenger

compartment, glove compartment, instrument panel

warning lights, etc.)

Check and, if necessary, top up fluid levels (1)

Visually inspect condition of: LPG pipes and connectors,

LPG tank fixing (1.4 T-Jet 120 HP LPG versions)

Check exhaust emissions/smokiness

Use the diagnosis socket to check engine management

system operation; emissions and (where provided) engine

oil deterioration

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

162

SERVICING AND CARE

Page 168 of 264

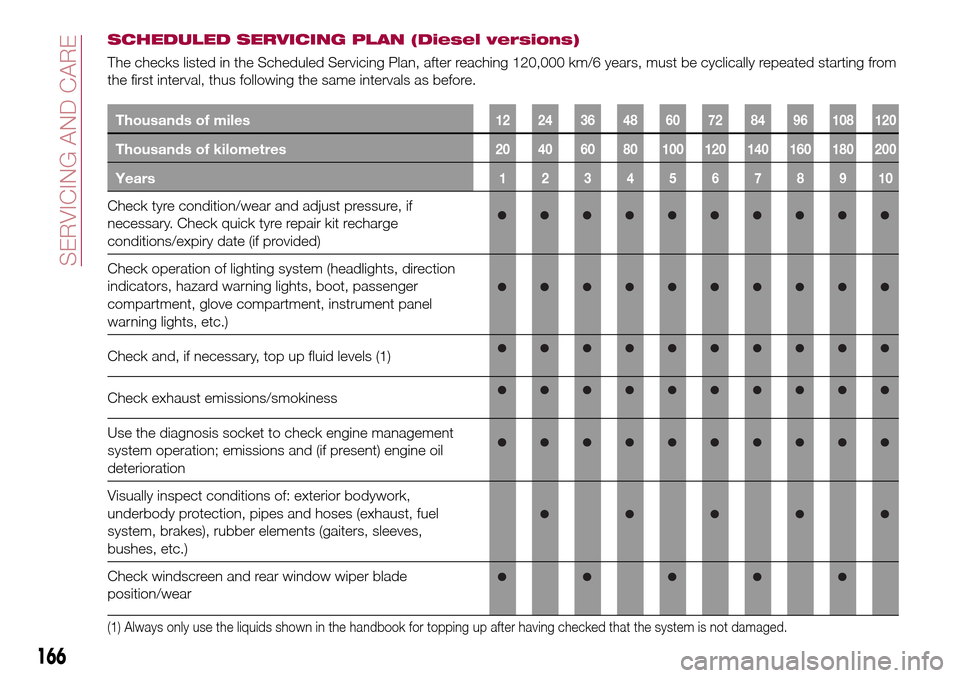

SCHEDULED SERVICING PLAN (Diesel versions)

The checks listed in the Scheduled Servicing Plan, after reaching 120,000 km/6 years, must be cyclically repeated starting from

the first interval, thus following the same intervals as before.

Thousands of miles12 24 36 48 60 72 84 96 108 120

Thousands of kilometres20 40 60 80 100 120 140 160 180 200

Years12345678910

Check tyre condition/wear and adjust pressure, if

necessary. Check quick tyre repair kit recharge

conditions/expiry date (if provided)

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, boot, passenger

compartment, glove compartment, instrument panel

warning lights, etc.)

Check and, if necessary, top up fluid levels (1)

Check exhaust emissions/smokiness

Use the diagnosis socket to check engine management

system operation; emissions and (if present) engine oil

deterioration

Visually inspect conditions of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)

Check windscreen and rear window wiper blade

position/wear

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

166

SERVICING AND CARE