clock FIAT UNO 1983 Service User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 166 of 303

thumb and forefinger at the centre of the run

between the auxiliary shaft sprocket and the

camshaft sprocket. Using this method it

should just be possible to twist the belt

through 90º using moderate pressure.

55To adjust the tension, loosen off the

tensioner pulley nut then insert two rods (or

screwdrivers) into position in the pulley holes

and position a lever between them.

56Gently lever the tensioner pulley in the

required direction to set the tension as

described, then initially tighten the pulley nut

to lock the tensioner in the required position.

57Remove the tools from the tensioner,

recheck the tension and then tighten the

tensioner pulley nut securely.

58Rotate the crankshaft clockwise through

two complete turns using a socket or spanner

on the crankshaft pulley nut, then recheck the

belt tension. To avoid the possibility of

unscrewing the pulley nut, remove the spark

plugs to enable the engine to be turned over

easier.

59If further adjustment is required, repeat

the previously mentioned procedures. If in

doubt, err on the slightly tight side when

adjusting the tension. If the belt is set too

loose, it may jump off the sprockets resulting

in serious damage.

60Remove the crankshaft pulley retaining

nut, fit the timing belt cover, then refit and

tighten the pulley nut to the specified torque

setting.

61Refit the remaining components in the

reverse order of removal. Tighten the retaining

nuts/bolts to the specified torque settings

where given. Adjust the tension of the

alternator drivebelt as described in Section 8.

Adjustment using FIAT special

tools

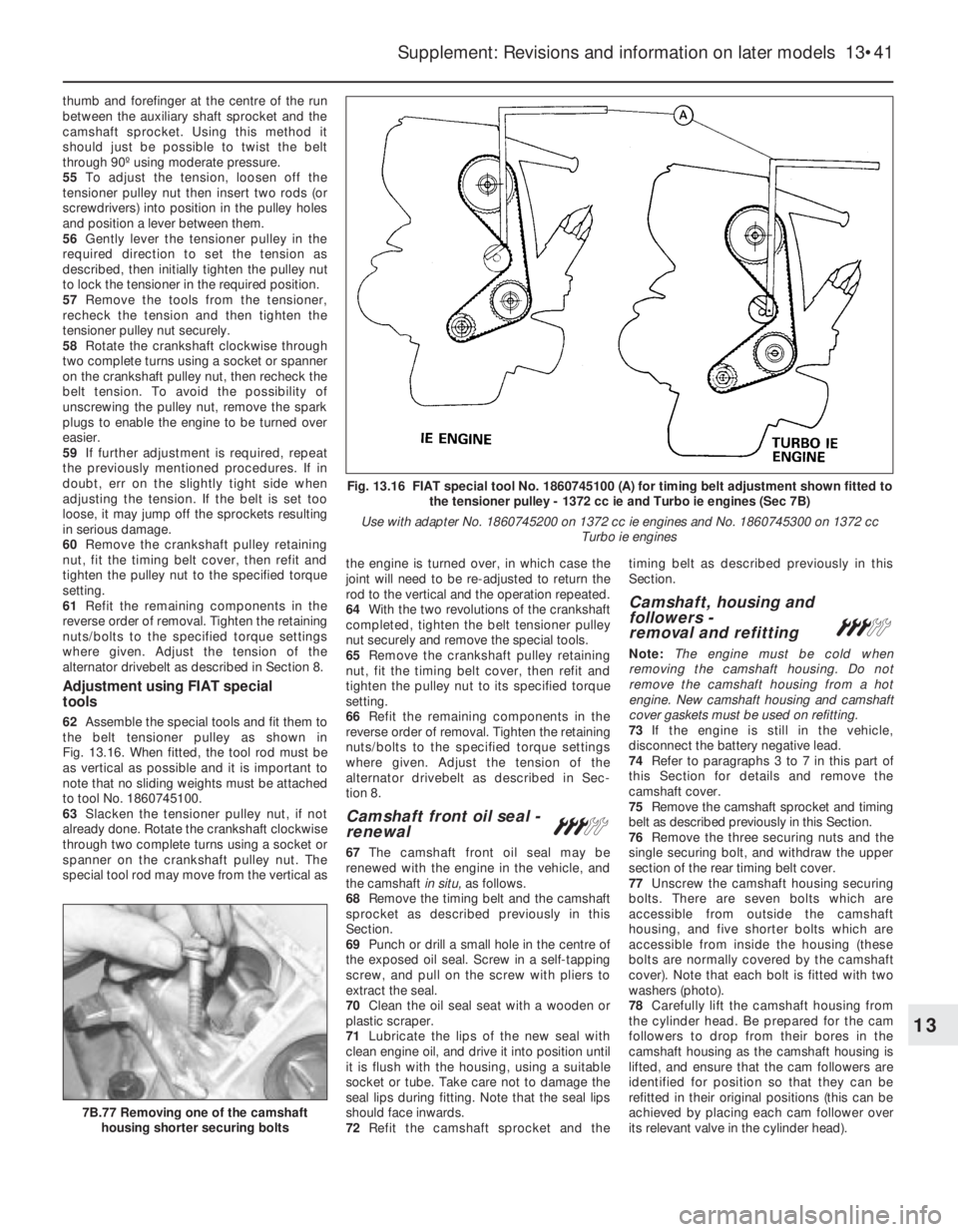

62Assemble the special tools and fit them to

the belt tensioner pulley as shown in

Fig. 13.16. When fitted, the tool rod must be

as vertical as possible and it is important to

note that no sliding weights must be attached

to tool No. 1860745100.

63Slacken the tensioner pulley nut, if not

already done. Rotate the crankshaft clockwise

through two complete turns using a socket or

spanner on the crankshaft pulley nut. The

special tool rod may move from the vertical asthe engine is turned over, in which case the

joint will need to be re-adjusted to return the

rod to the vertical and the operation repeated.

64With the two revolutions of the crankshaft

completed, tighten the belt tensioner pulley

nut securely and remove the special tools.

65Remove the crankshaft pulley retaining

nut, fit the timing belt cover, then refit and

tighten the pulley nut to its specified torque

setting.

66Refit the remaining components in the

reverse order of removal. Tighten the retaining

nuts/bolts to the specified torque settings

where given. Adjust the tension of the

alternator drivebelt as described in Sec-

tion 8.

Camshaft front oil seal -

renewal#

67The camshaft front oil seal may be

renewed with the engine in the vehicle, and

the camshaft in situ, as follows.

68Remove the timing belt and the camshaft

sprocket as described previously in this

Section.

69Punch or drill a small hole in the centre of

the exposed oil seal. Screw in a self-tapping

screw, and pull on the screw with pliers to

extract the seal.

70Clean the oil seal seat with a wooden or

plastic scraper.

71Lubricate the lips of the new seal with

clean engine oil, and drive it into position until

it is flush with the housing, using a suitable

socket or tube. Take care not to damage the

seal lips during fitting. Note that the seal lips

should face inwards.

72Refit the camshaft sprocket and thetiming belt as described previously in this

Section.

Camshaft, housing and

followers -

removal and refitting

#

Note: The engine must be cold when

removing the camshaft housing. Do not

remove the camshaft housing from a hot

engine. New camshaft housing and camshaft

cover gaskets must be used on refitting.

73If the engine is still in the vehicle,

disconnect the battery negative lead.

74Refer to paragraphs 3 to 7 in this part of

this Section for details and remove the

camshaft cover.

75Remove the camshaft sprocket and timing

belt as described previously in this Section.

76Remove the three securing nuts and the

single securing bolt, and withdraw the upper

section of the rear timing belt cover.

77Unscrew the camshaft housing securing

bolts. There are seven bolts which are

accessible from outside the camshaft

housing, and five shorter bolts which are

accessible from inside the housing (these

bolts are normally covered by the camshaft

cover). Note that each bolt is fitted with two

washers (photo).

78Carefully lift the camshaft housing from

the cylinder head. Be prepared for the cam

followers to drop from their bores in the

camshaft housing as the camshaft housing is

lifted, and ensure that the cam followers are

identified for position so that they can be

refitted in their original positions (this can be

achieved by placing each cam follower over

its relevant valve in the cylinder head).

Supplement: Revisions and information on later models 13•41

Fig. 13.16 FIAT special tool No. 1860745100 (A) for timing belt adjustment shown fitted to

the tensioner pulley - 1372 cc ie and Turbo ie engines (Sec 7B)

Use with adapter No. 1860745200 on 1372 cc ie engines and No. 1860745300 on 1372 cc

Turbo ie engines

7B.77 Removing one of the camshaft

housing shorter securing bolts

13

Page 187 of 303

PART B:

CARBURETTOR MODELS

Carburettor (Weber 32 TLF) -

description

Warning: Refer to the beginning

of this Section before starting

any work.

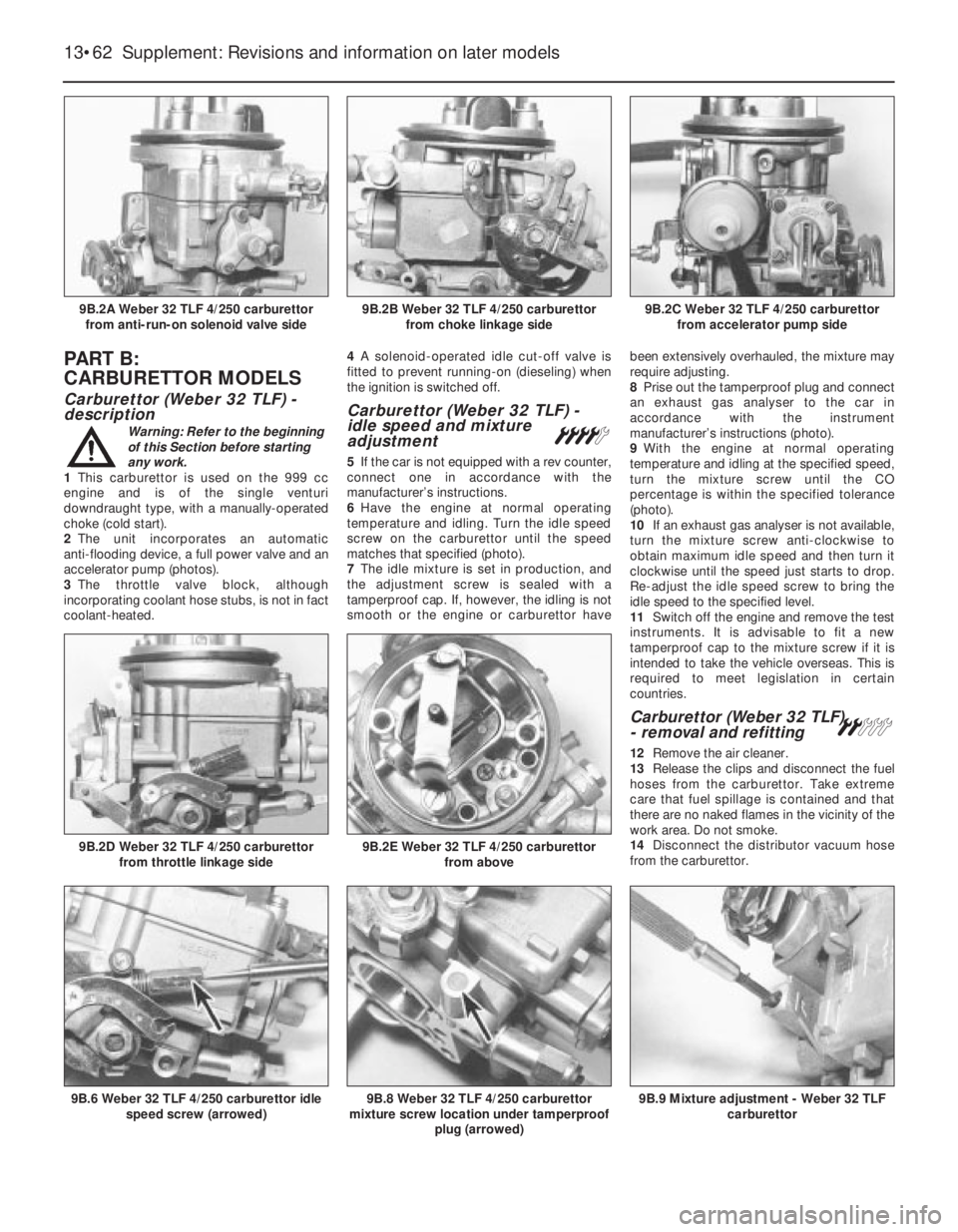

1This carburettor is used on the 999 cc

engine and is of the single venturi

downdraught type, with a manually-operated

choke (cold start).

2The unit incorporates an automatic

anti-flooding device, a full power valve and an

accelerator pump (photos).

3The throttle valve block, although

incorporating coolant hose stubs, is not in fact

coolant-heated.4A solenoid-operated idle cut-off valve is

fitted to prevent running-on (dieseling) when

the ignition is switched off.

Carburettor (Weber 32 TLF) -

idle speed and mixture

adjustment

¢

5If the car is not equipped with a rev counter,

connect one in accordance with the

manufacturer’s instructions.

6Have the engine at normal operating

temperature and idling. Turn the idle speed

screw on the carburettor until the speed

matches that specified (photo).

7The idle mixture is set in production, and

the adjustment screw is sealed with a

tamperproof cap. If, however, the idling is not

smooth or the engine or carburettor havebeen extensively overhauled, the mixture may

require adjusting.

8Prise out the tamperproof plug and connect

an exhaust gas analyser to the car in

accordance with the instrument

manufacturer’s instructions (photo).

9With the engine at normal operating

temperature and idling at the specified speed,

turn the mixture screw until the CO

percentage is within the specified tolerance

(photo).

10If an exhaust gas analyser is not available,

turn the mixture screw anti-clockwise to

obtain maximum idle speed and then turn it

clockwise until the speed just starts to drop.

Re-adjust the idle speed screw to bring the

idle speed to the specified level.

11Switch off the engine and remove the test

instruments. It is advisable to fit a new

tamperproof cap to the mixture screw if it is

intended to take the vehicle overseas. This is

required to meet legislation in certain

countries.

Carburettor (Weber 32 TLF)

- removal and refitting ª

12Remove the air cleaner.

13Release the clips and disconnect the fuel

hoses from the carburettor. Take extreme

care that fuel spillage is contained and that

there are no naked flames in the vicinity of the

work area. Do not smoke.

14Disconnect the distributor vacuum hose

from the carburettor.

13•62 Supplement: Revisions and information on later models

9B.9 Mixture adjustment - Weber 32 TLF

carburettor9B.8 Weber 32 TLF 4/250 carburettor

mixture screw location under tamperproof

plug (arrowed)9B.6 Weber 32 TLF 4/250 carburettor idle

speed screw (arrowed)

9B.2E Weber 32 TLF 4/250 carburettor

from above9B.2D Weber 32 TLF 4/250 carburettor

from throttle linkage side

9B.2C Weber 32 TLF 4/250 carburettor

from accelerator pump side9B.2B Weber 32 TLF 4/250 carburettor

from choke linkage side9B.2A Weber 32 TLF 4/250 carburettor

from anti-run-on solenoid valve side

Page 193 of 303

Idle speed and mixture

adjustment¢

29Before carrying out any adjustments, the

engine must be at operating temperature, the

fan having cut in at second speed and then

switched off.

30Release the locknut and turn the main idle

speed screw in the throttle valve housing until

the engine idles at the specified speed. This

should be all that is necessary to obtain the

correct idle speed, as the throttle valve plate

base setting is set during production.

However, if wear has taken place, or incorrect

adjustment has been carried out previously,

proceed in the following way.

31Disconnect the intake duct from the

throttle valve housing. Release the locknut on

the base (small) adjusting screw, and turn thescrew until there is a clearance between the

lower edge of the throttle valve plate and the

throat wall of between 0.05 and 0.1 mm

(photos).

32With the engine still at operating

temperature, start the engine, and having

released the locknut, turn the main (large) idle

speed screw fully clockwise to close the

bypass passage.

33Now turn the base (small) screw until the

engine idles at between 700 and 800 rpm.

Tighten the locknut.

34Finally, turn the main (large) adjusting

screw to give an idle speed of between 800

and 900 rpm.

35It is unlikely that the mixture will require

alteration, but if it does, connect an exhaust

gas analyser to the car in accordance with the

equipment manufacturer’s instructions.

36With the engine at operating temperature,

prise out the tamperproof cap, and turn the

mixture screw, which is located in the airflow

meter, until the CO level is as given in the

Specifications. Turning the screw clockwise

richens the mixture, turning it anti-clockwise

weakens the mixture. Use a close-fitting Allen

key for the adjustment (photo).

Fuel injection system -

electrical testsª

37When carrying out checks to trace a fault

in the system, an ohmmeter should be used

for the following tests.

38Disconnect the multipin connector from

the ECU, and also the one from the system

control relay, and apply the probes of the

ohmmeter in accordance with the following

sequence to check for continuity in thecables. The component wiring plug will of

course be disconnected for the test.

ECU connector Component connector

plug terminal plug terminal

1 1 of ignition coil

2 2 of throttle position

switch

3 3 of throttle position

switch

4 50 of ignition switch

5 Earth

5 5 of airflow meter

7 7 of airflow meter

8 8 of airflow meter

9 9 of airflow meter

9 9 of throttle position

switch

9 18 of supplementary air

valve

9 87 main relay socket

10 10 of coolant temperature

sensor

12 Injector terminals

13 Earth

System control Component connector

relay connector plug terminal

plug terminal

1 1 of ignition coil

15 15 of ignition switch

30 Battery positive

31 Earth

50 50 of ignition switch

87 Injector terminals

87 18 of throttle position

switch

87 9 of ECU multipin socket

87b Fuel pump (fused)

13•68 Supplement: Revisions and information on later models

Fig. 13.42 ECU and component connector plug terminals - 1301 cc Turbo ie engine (Sec 9C)

For colour code see main wiring diagrams

9C.31C Checking throttle valve plate

opening with a feeler blade

9C.36 Using an Allen key to adjust the

mixture (CO level)

9C.31B Idle speed base setting screw (1)

and main adjustment screw (2)9C.31A Disconnecting the throttle valve

housing intake duct9C.27B Removing the air cleaner element

Page 205 of 303

operation twice. Also prior to making

adjustments ensure that the supplementary

air valve pipe is in good condition, with no

leaks. Compress the air valve pipe using a

pair of grips to prevent incorrect adjustment

caused by a defective supplementary air

valve.

15The air cleaner must be connected when

checking and/or adjusting the engine idle

speed. To adjust, turn the adjuster screw in

the required direction to set the engine idle

speed to that specified.

16It is unlikely that the mixture will require

adjustment and unless this is proven by

measuring the exhaust gases using a CO

content analyser, its setting should not be

altered. As with idle speed adjustment, the

engine must be at its normal operating

temperature when making this check and

adjustment. It is also necessary to ensure that

the ignition idle advance is as specified.

Checking and adjustment must not be made

with the engine cooling fan, air conditioning

(where fitted) or other related items switched

on.

17If adjustment to the mixture is required,

prise free the tamperproof plug from the front

of the mixture adjustment screw in the control

unit, then turn the screw as required. Turn the

screw inwards (clockwise) to increase the CO

content or outwards (anti-clockwise) to

weaken it.

Throttle position switch adjustment

18This switch will not normally require

adjustment having been set during

production. The switch should not be

loosened off or reset unless absolutely

necessary.

19If a new switch is fitted it can be set by

loosely fitting the securing bolts, turning the

switch fully anti-clockwise, then clockwise

until one of the internal contacts is felt to click

into engagement. Hold the switch in this

position and tighten the retaining screws.

Reconnect the wiring multiplug to the switch.

Accelerator cable adjustment

20If the accelerator cable is removed or

detached from the support bracket at the

throttle control housing at any time, care must

be taken to adjust it correctly. When the inner

cable is connected to the throttle quadrant,

set the outer cable in the bracket so that the

inner cable has a minimal amount of free play,

yet does not prevent the throttle valve from

fully closing.

21When the engine is restarted, check that

the engine idle speed is as specified and that

the action of the accelerator is satisfactory.

Fuel pump and supply system checks

22Although the following basic checks can

be made to the fuel pump and fuel supply

system, specialised equipment is required to

undertake full and accurate tests of the fuel

supply system. Such checks must therefore

be entrusted to a FIAT dealer or a fuel

injection specialist.

23If the fuel pump is suspected of

malfunction, a basic check can be made by

turning the ignition on and listening around

the area of the pump unit to hear if it is

operating. The pump is located on the

underside of the car, just forward of the fuel

tank. If the pump fails to operate, check thatthe pump fuse is sound and that its

connection (and also that the relay) are clean

and secure.

24The pump can be further checked as

described previously for the LE2 fuel injection

system fuel pump in Part C of this Section.

Supplementary air valve check

25With the engine at its normal operating

temperature, allow it to idle, then pinch the

supplementary air valve hose using suitable

pliers as shown in Fig. 13.52 and check to see

if the engine speed drops by more than 50

rpm. If it does, the supplementary air valve is

defective and in need of renewal.

Injection system

components -

removal and refitting

Á

Warning: Refer to the beginning

of this Section before starting

any work.

26With the exception of the items mentioned

below, the various components of the fuel

injection system are removed in the same

manner as that described for the equivalent

items in Part C of this Chapter.

27Disconnect the battery negative lead

before carrying out any of the removal and

refitting operations. Where fuel lines are to be

disconnected it will first be necessary to

depressurise the injection system.

Airflow meter

28Release the retaining clips and detach the

air intake and outlet ducts from the airflow

meter.

29Ensure that the ignition is switched off,

then disconnect the multiplug from the ECU.

Unscrew the retaining bolts and remove the

airflow meter complete with the ECU.

30If required, the ECU can be separated

from the airflow meter by undoing the

securing bolts.

Throttle valve housing/inlet manifold

31Loosen off the retaining clip and detach

the air intake duct from the throttle housing,

the air cooling hoses for the injectors and the

supplementary air valve.

32Detach the accelerator cable from the

throttle linkage.

13•80 Supplement: Revisions and information on later models

Fig. 13.56 Disconnecting the injector air

cooling hoses and the supplementary air

valve hose on the 1372 cc Turbo ie engine

(Sec 9E)Fig. 13.55 Disconnecting the air intake

duct and accelerator cable from the

throttle housing on the 1372 cc Turbo ie

engine (Sec 9E)

Fig. 13.54 Accelerator cable adjustment

on the 1372 cc Turbo ie engine (Sec 9E)

1 Adjuster 3 Quadrant support

2 Inner cableFig. 13.53 Mixture adjustment screw

location on the 1372 cc Turbo ie engine

(Sec 9E)

Page 214 of 303

Ignition unit

36This comprises four elements (photo).

a) Power module - receives the ignition

advance command and controls the

conduction angle of the primary current

and energy stored in the coil.

b) Dissipater plate - eliminates the heat

which is generated by the high volume of

current.

c) Ignition coil with low primary resistance.

d) Distributor - a means of distributing high

tension to the spark plugs. The rotor is

driven in an anti-clockwise direction

(viewed from transmission) by a dog on

the end of the camshaft.

37The system incorporates a safety

pressure switch, which cuts out the ignition if

the turbocharging pressure exceeds a value

of between 0.84 and 0.93 bars (12.2 and

13.5 lbf/in

2) above atmospheric pressure.

Distributor (Microplex) -

removal and refitting#

38Remove the distributor cap and place it to

one side, complete with spark plug leads

(photo).

39Turn the crankshaft by means of the

pulley nut, or by raising and turning a front

wheel with top gear engaged, until No. 4

piston is on its firing stroke. This will be

indicated when the contact end of the rotorarm is aligned with the mark on the distributor

body rim, and the lug on the crankshaft pulley

is aligned with the timing pointer on the

engine. The right-hand underwing shield will

have to be removed in order to see the marks

(photo).

40Unscrew the distributor fixing nuts and

withdraw the distributor.

41When fitting the distributor, the offset

drive dog will automatically locate the

distributor rotor in its correct position, but the

distributor body may require rotating in order

to align the rim mark with the rotor. The

elongated slots for the fixing studs are to

permit initial alignment, not for subsequent

adjustment, as advance angle alterations are

carried out automatically by the system ECU

(photos).

42Tighten the nuts and refit the cap with

leads.

43Unless a stroboscope and a vacuum

pressure gauge are available, it will not be

possible to check the advance values with the

engine running. Where these instruments are

available, connect the vacuum gauge to the

inlet manifold, and the stroboscope in

accordance with the equipment manufac-

turer’s instructions. Refer to Fig. 13.79

according to the inlet manifold vacuum

pressure indicated.

Microplex ignition system

components - testing ª

44An ohmmeter and a voltmeter will be

required for these tests.

45Remove the multipin plug from the ECU.

Engine speed sensor

46Insert the probes of an ohmmeter

between terminals 3 and 16 of the multipin

connector; 618 to 748 ohms (1301 cc) or

578 to 782 ohms (1372 cc) should be

indicated.

47If necessary, carry out a check of the gap

between the sensor and flywheel teeth as

described in Chapter 4, Section 10.

Supplement: Revisions and information on later models 13•89

10.39 Crankshaft pulley timing marks

(arrowed)10.38 Removing the distributor cap10.36 Ignition coil (1) and power module (2)

on 1301 cc Turbo ie engine

Fig. 13.78 Rotor aligned with distributor

body rim mark - Microplex ignition system

(Sec 10)

10.41A Distributor body showing elongated

slots in the mounting lugs

Fig. 13.77 Crankshaft pulley timing mark

aligned with timing pointer - Microplex

ignition system (Sec 10)

1 TDC sensor10.41B Distributor drive dog

13

Page 226 of 303

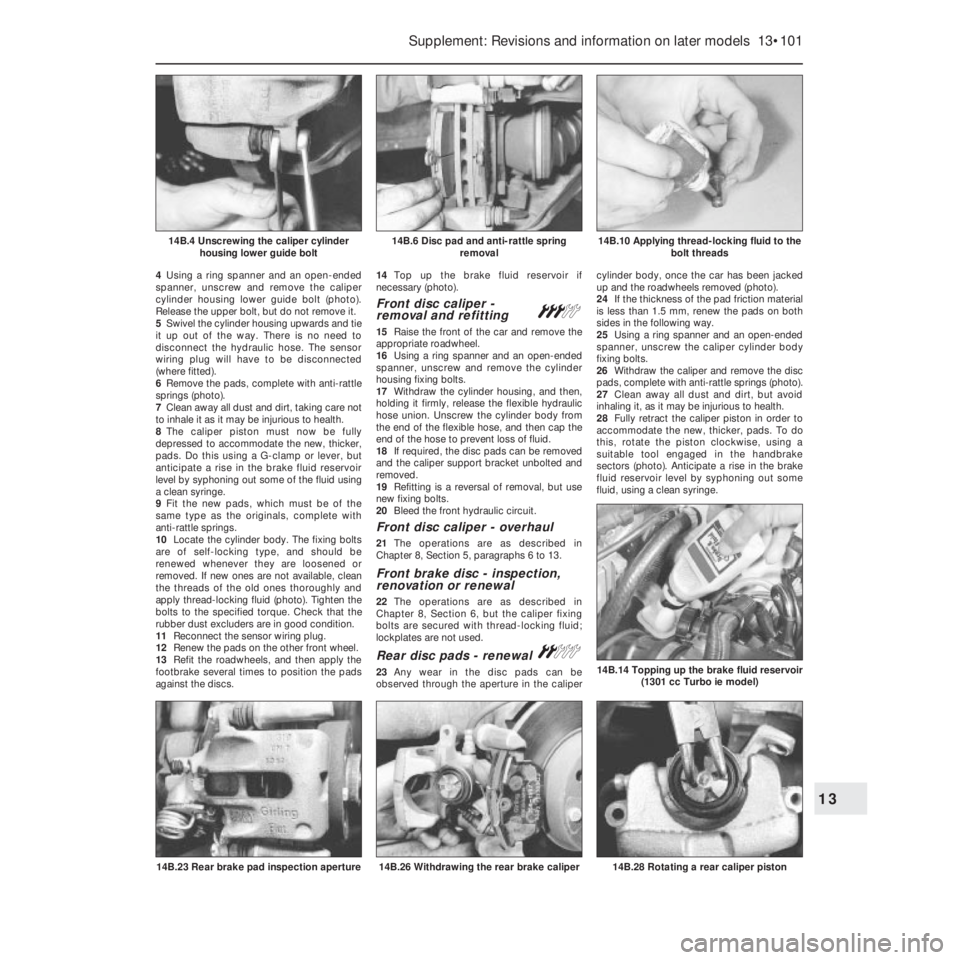

4Using a ring spanner and an open-ended

spanner, unscrew and remove the caliper

cylinder housing lower guide bolt (photo).

Release the upper bolt, but do not remove it.

5Swivel the cylinder housing upwards and tie

it up out of the way. There is no need to

disconnect the hydraulic hose. The sensor

wiring plug will have to be disconnected

(where fitted).

6Remove the pads, complete with anti-rattle

springs (photo).

7Clean away all dust and dirt, taking care not

to inhale it as it may be injurious to health.

8The caliper piston must now be fully

depressed to accommodate the new, thicker,

pads. Do this using a G-clamp or lever, but

anticipate a rise in the brake fluid reservoir

level by syphoning out some of the fluid using

a clean syringe.

9Fit the new pads, which must be of the

same type as the originals, complete with

anti-rattle springs.

10Locate the cylinder body. The fixing bolts

are of self-locking type, and should be

renewed whenever they are loosened or

removed. If new ones are not available, clean

the threads of the old ones thoroughly and

apply thread-locking fluid (photo). Tighten the

bolts to the specified torque. Check that the

rubber dust excluders are in good condition.

11Reconnect the sensor wiring plug.

12Renew the pads on the other front wheel.

13Refit the roadwheels, and then apply the

footbrake several times to position the pads

against the discs.14Top up the brake fluid reservoir if

necessary (photo).

Front disc caliper -

removal and refitting#

15Raise the front of the car and remove the

appropriate roadwheel.

16Using a ring spanner and an open-ended

spanner, unscrew and remove the cylinder

housing fixing bolts.

17Withdraw the cylinder housing, and then,

holding it firmly, release the flexible hydraulic

hose union. Unscrew the cylinder body from

the end of the flexible hose, and then cap the

end of the hose to prevent loss of fluid.

18If required, the disc pads can be removed

and the caliper support bracket unbolted and

removed.

19Refitting is a reversal of removal, but use

new fixing bolts.

20Bleed the front hydraulic circuit.

Front disc caliper - overhaul

21The operations are as described in

Chapter 8, Section 5, paragraphs 6 to 13.

Front brake disc - inspection,

renovation or renewal

22The operations are as described in

Chapter 8, Section 6, but the caliper fixing

bolts are secured with thread-locking fluid;

lockplates are not used.

Rear disc pads - renewal ª

23Any wear in the disc pads can be

observed through the aperture in the calipercylinder body, once the car has been jacked

up and the roadwheels removed (photo).

24If the thickness of the pad friction material

is less than 1.5 mm, renew the pads on both

sides in the following way.

25Using a ring spanner and an open-ended

spanner, unscrew the caliper cylinder body

fixing bolts.

26Withdraw the caliper and remove the disc

pads, complete with anti-rattle springs (photo).

27Clean away all dust and dirt, but avoid

inhaling it, as it may be injurious to health.

28Fully retract the caliper piston in order to

accommodate the new, thicker, pads. To do

this, rotate the piston clockwise, using a

suitable tool engaged in the handbrake

sectors (photo). Anticipate a rise in the brake

fluid reservoir level by syphoning out some

fluid, using a clean syringe.

Supplement: Revisions and information on later models 13•101

14B.10 Applying thread-locking fluid to the

bolt threads14B.6 Disc pad and anti-rattle spring

removal14B.4 Unscrewing the caliper cylinder

housing lower guide bolt

14B.28 Rotating a rear caliper piston14B.26 Withdrawing the rear brake caliper14B.23 Rear brake pad inspection aperture

14B.14 Topping up the brake fluid reservoir

(1301 cc Turbo ie model)

13

Page 227 of 303

14B.54 Master cylinder/vacuum servo

located next to the coolant expansion tank

(1301 cc Turbo ie model)

29Fit the new pads, complete with anti-rattle

springs (photo).

30Refit the caliper using new self-locking

bolts, or if not available, apply thread-locking

fluid to clean threads of the original bolts.

Tighten the bolts to the specified torque.

31Apply the brake pedal several times to

bring the disc pads up against the disc.

32Top up the brake fluid reservoir if

necessary.

33Check the adjustment of the handbrake.

34Refit the roadwheels and lower the car to

the ground.

Rear disc caliper -

removal, overhaul and

refitting

¢

35Carry out the operations described in

paragraphs 25 to 27.36Disconnect the handbrake cable from the

caliper. To do this, grip the cable nipple and

pull it until the cable can be slipped out of its

lever groove (photo). If necessary, slacken the

cable adjustment.

37Using a pair of pliers or similar tool, turn

the piston in an anti-clockwise direction until it

can be removed from the cylinder.

38Having obtained a repair kit, renew the

seal and dust excluder.

39Reassemble the piston to the cylinder,

turning it clockwise as far as it will go.

40Reconnect the handbrake cable.

41Carry out the operations described in

paragraphs 30 to 32.

Rear brake disc -

inspection, renovation

or renewal

ª

42The operations are as described in

Chapter 8, Section 6, but the caliper bracket

fixing bolts are of the socket-headed type and

thread-locking fluid is used, not lockplates

(photo).

Pressure regulating valve

43The valve renewal and adjustment

operations are described in Chapter 8,

Section 10, but the luggage compartment

should be loaded with 45 kg and the load

applied to the bracket eye should be 11 kg.

Brake pedal -

removal and refitting#

44The brake master cylinder and vacuum

servo are mounted on the left-hand side of theengine compartment rear bulkhead. In conse-

quence, the brake pedal on right-hand drive

cars operates through a cross-shaft, which is

located underneath the facia panel inside the

car.

45The cross-shaft is supported in two

brackets, whose mounting nuts can be

reached through cut-outs in the insulation on

the engine compartment rear bulkhead (photo).

46To remove the cross-shaft, working inside

the car, take off the cover from the left-hand

end of the shaft, and then disconnect the

servo pushrod from the crankarm on the

cross-shaft (photo).

47Disconnect the brake pedal from the

right-hand crankarm on the cross-shaft

(photo).

48Disconnect the accelerator pedal by

extracting the split pin which secures its pivot

spindle.

49The cross-shaft may now be removed

after extracting the cotter pin from the

left-hand end of the shaft.

50Push the shaft first to the right, and then

to the left, to release it from its brackets.

51Alternatively, the cross-shaft, complete

with brackets, may be removed as an

assembly if the bulkhead nuts are unscrewed.

52Removal of the brake and clutch pedals is

described in Chapter 5, Section 4, but note

that on hydraulic clutch models, the master

cylinder will also require removal as described

in Section 11 of this Chapter.

53Refitting is a reversal of the removal

procedure.

13•102 Supplement: Revisions and information on later models

14B.47 Right-hand end of brake pedal

cross-shaft14B.46 Left-hand end of brake pedal

cross-shaft

14B.45 Brake pedal cross-shaft fixed nut

(arrowed) on engine compartment rear

bulkhead

14B.42 Unscrewing a rear caliper bracket

bolt14B.36 Disconnecting the handbrake cable

from the caliper lever14B.29 Rear disc pad

Page 230 of 303

Starter motor brushes

(later models) - renewal#

25When renewing the starter motor brushes

on later models, the old brushes will need to

be crushed (in a vice or with a hammer) and

their leads then soldered to the new brushes.

Fuses - later models

26The fuse arrangement is slightly different

on later models, but the circuits protected are

still identified by a symbol. Refer to the

Specifications Section for full details. Note

also the terminal block with plastic cover,

which can be used to isolate the battery from

the electrical system by disconnecting the

leads from the terminals (photos).

Relays (Turbo ie models) -

general

27On Turbo ie models, the relays mounted

in the fuse block are as shown in Fig. 13.103.

Additional relays are located as follows:

Headlamp relay - on lead under main fuse

blockFuel injection system main control relay -

adjacent to airflow meter

Headlamps later models

28The headlamp units fitted on later models

differ according to model, but the bulb and

unit replacement details are generally the

same as described for previous models in

Chapter 9. Note that the rubber cover can

only be fitted with the tab to the top as shown

(photo).

Headlamp beam adjusters for

load compensation - later

models

29Some later models are fitted with

headlamp beam adjusters which allowtemporary resetting to be made (such as

when the car is fully loaded). Access to these

adjusters is made by lifting the bonnet (photo).

30Turn the adjusters anti-clockwise to lower

the beam to the normal level or clockwise to

raise the beam (when the car is unloaded).

Repeat the procedure on the opposite

headlamp unit an equal amount.

31Other later models have separate

horizontal and vertical beam adjusters,

positioned as shown (photos). A load

compensating lever is attached to the

adjusters to enable temporary resetting of the

headlamp beams, without changing the

normal adjustment. Turn the lever to the

appropriate side (right or left) to make the

adjustment as required. The normal setting

Supplement: Revisions and information on later models 13•105

15.26B Battery lead terminal block on the

1301 cc Turbo ie model15.23B Starter motor and wiring

connections on the 1372 cc ie engine

15.31B Headlamp vertical beam alignment

adjuster screw on a 1372 cc ie model. Note

the load compensator lever which is set in

the “O” (normal load) setting position15.31A Headlamp horizontal beam

alignment adjuster screw on a 1372 cc ie

model

15.29 Headlamp beam adjuster on the

999 cc Turbo ie model15.28 Headlamp unit fitted to the 1372 cc ie

model

15.26A Fuse block on the 1301 cc Turbo ie

model

13

Fig. 13.103 Auxiliary fuses and relays on

1301 cc Turbo ie models (Sec 15)

1 Horn relay

2 Heated rear screen relay

3 Foglamps relay

4 Radiator fan relay

5 Electric windows relay

6 Foglamps fuse

7 Radiator fan second speed fuse

8 Fuel injector fan fuse

9 Electric windows fuse

10 Electric fuel pump fuse

Page 233 of 303

Auxiliary control panel

(later models) -

removal and refitting

Á

61Disconnect the battery negative lead.

62Insert the flat of a screwdriver under the

trim piece at the end of the auxiliary panel as

shown and prise it free. Repeat the procedure

and remove the trim piece at the other end of

the panel (photo).

63Undo the retaining screws, withdraw the

panel from the facia. Disconnect the wiring

connectors from the panel switches to

remove the panel completely (photo).

64A switch bulb can be renewed by

untwisting the holder and removing the holder

and bulb.

65A switch unit can be removed from the

panel by unscrewing the four retaining screws.66Refitting is a reversal of the removal

procedure. Ensure that the wiring connections

are securely made and check for satisfactory

operation of the switches on completion.

Heater control panel

(later models) -

removal and refitting

Á

67Disconnect the battery negative lead.

68Pull free the heater/fresh air and blower

control knobs (photo).

69Undo the two retaining screws and

withdraw the control panel from the facia

(photos). Detach the wiring connectors from the

panel illumination lights and remove the panel.

70Refitting is a reversal of the removal

procedure. Ensure that the wiring connections

are securely made and on completion check

that the operation of the controls is satisfactory.

Trip master Á

71This electronic instrument is fitted into the

check panel of 1100SL and 1300SL models

from 1986.

72The device provides information on fuel

consumption, range, speed and elapsed time.

73With the ignition key turned to MAR,

figures are displayed in respect of the last

journey - average fuel consumption, average

speed and elapsed time (up to switching off

the ignition).

74As soon as the engine is started, the

instrument processes the current values to

include fuel consumption, range and the

actual time. 75Fuel consumption is only displayed when

the road speed exceeds 8.0 km/h (5.0 mph).

76The fuel range is only displayed after a

road speed of between 25.0 and 70.0 km/h

(15.0 to 44.0 mph) has been maintained for at

least 90 seconds or at higher speeds for

22 seconds.

77A reset button is provided, also a display

change button (from instant to average or

total values). Should the instrument reading

exceed 99 hours, 59 minutes or 1000 km

(622 miles) depressing the display change

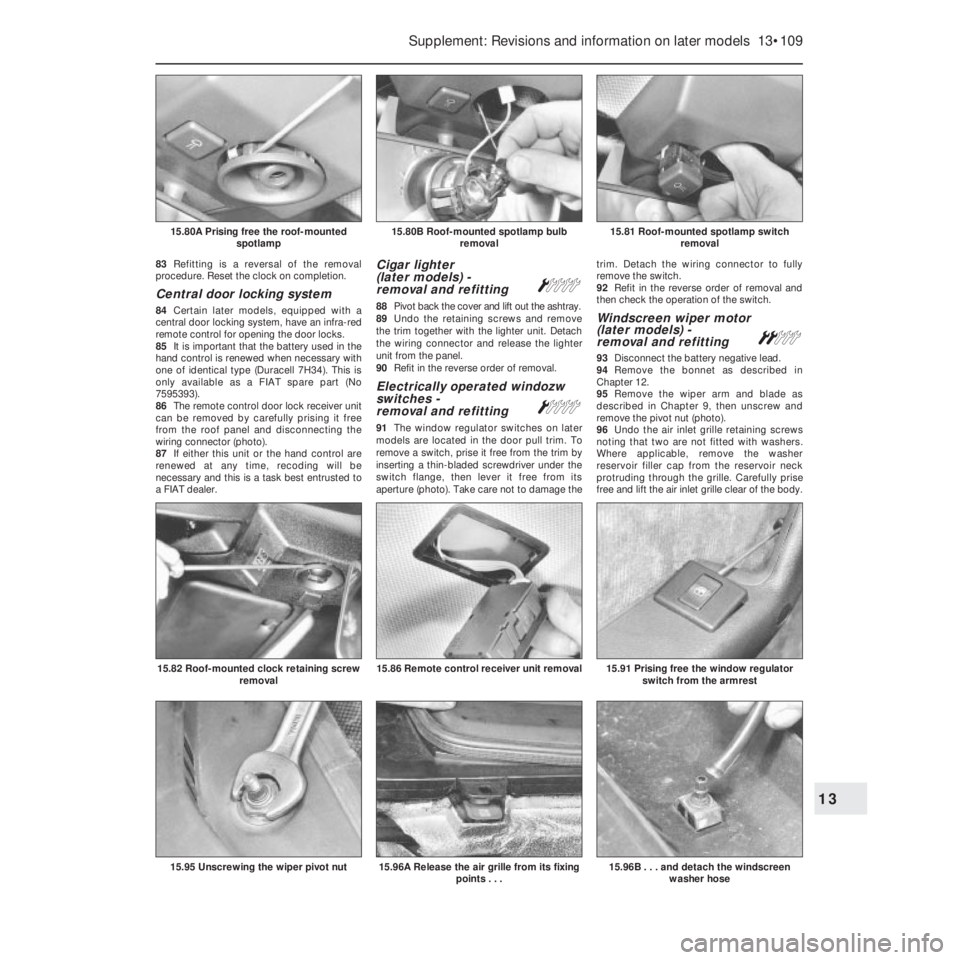

button will display all zeros. Depress button E

to resume normal function.

78Refer to the end of the manual for a wiring

diagram of the check panel, incorporating the

trip master.

Interior roof mounted spotlamp,

switch and/or clock -

removal and refitting

Á

79Disconnect the battery negative lead.

80Prise free the lamp unit from its aperture

in the roof panel using a thin-bladed

screwdriver. The lamp bulb can be inspected

by untwisting the holder and withdrawing it

from the rear of the unit (photos). Extract the

bulb from the holder if it requires renewal.

81To remove the lamp switch from the

panel, reach through the lamp aperture and

press it free from the roof panel (photo).

Detach the wiring connectors.

82To remove the clock, reach through the

lamp aperture and undo the retaining screws

(photo). Withdraw the clock and detach the

wiring connectors.

13•108 Supplement: Revisions and information on later models

15.69B . . . and withdraw the heater control

panel15.69A . . . undo the retaining screws

(arrowed)15.68 Remove the control knobs . . .

15.63 . . . and withdraw the auxiliary

control panel

15.62 Prise free the trim covers for access

to retaining screws . . .15.59B . . . and disconnect the

speedometer cable15.59A . . . withdraw the instrument

panel . . .

Page 234 of 303

83Refitting is a reversal of the removal

procedure. Reset the clock on completion.

Central door locking system

84Certain later models, equipped with a

central door locking system, have an infra-red

remote control for opening the door locks.

85It is important that the battery used in the

hand control is renewed when necessary with

one of identical type (Duracell 7H34). This is

only available as a FIAT spare part (No

7595393).

86The remote control door lock receiver unit

can be removed by carefully prising it free

from the roof panel and disconnecting the

wiring connector (photo).

87If either this unit or the hand control are

renewed at any time, recoding will be

necessary and this is a task best entrusted to

a FIAT dealer.

Cigar lighter

(later models) -

removal and refitting

Á

88Pivot back the cover and lift out the ashtray.

89Undo the retaining screws and remove

the trim together with the lighter unit. Detach

the wiring connector and release the lighter

unit from the panel.

90Refit in the reverse order of removal.

Electrically operated windozw

switches -

removal and refitting

Á

91The window regulator switches on later

models are located in the door pull trim. To

remove a switch, prise it free from the trim by

inserting a thin-bladed screwdriver under the

switch flange, then lever it free from its

aperture (photo). Take care not to damage thetrim. Detach the wiring connector to fully

remove the switch.

92Refit in the reverse order of removal and

then check the operation of the switch.

Windscreen wiper motor

(later models) -

removal and refitting

ª

93Disconnect the battery negative lead.

94Remove the bonnet as described in

Chapter 12.

95Remove the wiper arm and blade as

described in Chapter 9, then unscrew and

remove the pivot nut (photo).

96Undo the air inlet grille retaining screws

noting that two are not fitted with washers.

Where applicable, remove the washer

reservoir filler cap from the reservoir neck

protruding through the grille. Carefully prise

free and lift the air inlet grille clear of the body.

Supplement: Revisions and information on later models 13•109

15.81 Roof-mounted spotlamp switch

removal15.80B Roof-mounted spotlamp bulb

removal15.80A Prising free the roof-mounted

spotlamp

15.96B . . . and detach the windscreen

washer hose15.96A Release the air grille from its fixing

points . . .15.95 Unscrewing the wiper pivot nut

15.91 Prising free the window regulator

switch from the armrest15.86 Remote control receiver unit removal15.82 Roof-mounted clock retaining screw

removal

13