steering FIAT UNO 1983 Service User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 87 of 303

The hose ends can then be unclipped from

the brackets. The mounting brackets,

particularly on the body frame, are not very

heavy gauge and care must be taken not to

wrench them off (photo).

4With the flexible hose removed, examine

the internal bore. If it is blown through first, it

should be possible to see through it. Any

specks of rubber which come out, or signs of

restriction in the bore, mean that the inner

lining is breaking up and the pipe must be

renewed.

5When refitting the flexible hoses check they

cannot be under tension, or rub, when the

wheels are at the full range of suspension or

steering movement.

6Bleed the system (see Section 12) on

completion.

Rigid pipes

7Inspect the condition of the braking system

rigid pipelines at frequent intervals. They must

be cleaned off and examined for any signs of

dents (or other percussive damage) and rust

and corrosion. Rust and corrosion should be

scraped off and, if the depth of pitting in the

pipes is significant, they will need renewal.

This is particularly likely in those areas

underneath the car body and along the rear

axle where the pipes are exposed to the full

force of road and weather conditions.

8Rigid pipe removal is usually straight-

forward. The unions at each end are undone,

the pipe and union pulled out, and the centre

sections of the pipe removed from the body

clips where necessary. Underneath the car,

exposed unions can sometimes be very tight.

As one can use only an open-ended spanner

and the unions are not large, burring of the

flats is not uncommon when attempting to

undo them. For this reason, a self-locking grip

wrench (Mole) is often the only way to remove

a stubborn union.

9Rigid pipes which need renewal can usually

be purchased at any garage where they have

the pipe, unions and special tools to make

them up. All they need to know is the total

length of the pipe, the type of flare used at

each end with the union, and the length and

thread of the union. Fiat is metric, remember.

10Fitting your new pipes is a straightforwardreversal of the removal procedure. If the rigid

pipes have been made up, it is best to get all

the sets bends in them before trying to fit

them. Also, if there are any acute bends ask

your supplier to put these in for you on a tube

bender. Otherwise, you may kink the pipe and

thereby restrict the bore area and fluid flow.

11Bleed the system (see Section 12) on

completion.

12 Hydraulic system-

bleeding

3

1If the master cylinder or the pressure

regulating valve has been disconnected and

reconnected then the complete system (both

circuits) must be bled.

2If a component of one circuit has been

disturbed then only that particular circuit need

be bled.

3The two disc brakes comprise the front

circuit and the two rear brakes the rear circuit.

4Unless the pressure bleeding method is

being used, do not forget to keep the fluid

level in the master cylinder reservoir topped

up to prevent air from being drawn into the

system which would make any work done

worthless.

5Before commencing operations, check that

all system hoses and pipes are in good

condition with all unions tight and free from

leaks.

6Take great care not to allow hydraulic fluid

to come into contact with the vehicle

paintwork as it is an effective paint stripper.

Wash off any spilled fluid immediately with

cold water.

7As the system on 55 and 70 models

incorporates a vacuum servo, destroy the

vacuum by giving several applications of the

brake pedal in quick succession. The car

should be loaded with enough weight to

actuate the pressure regulating valve before

bleeding commences.

Bleeding - two man method

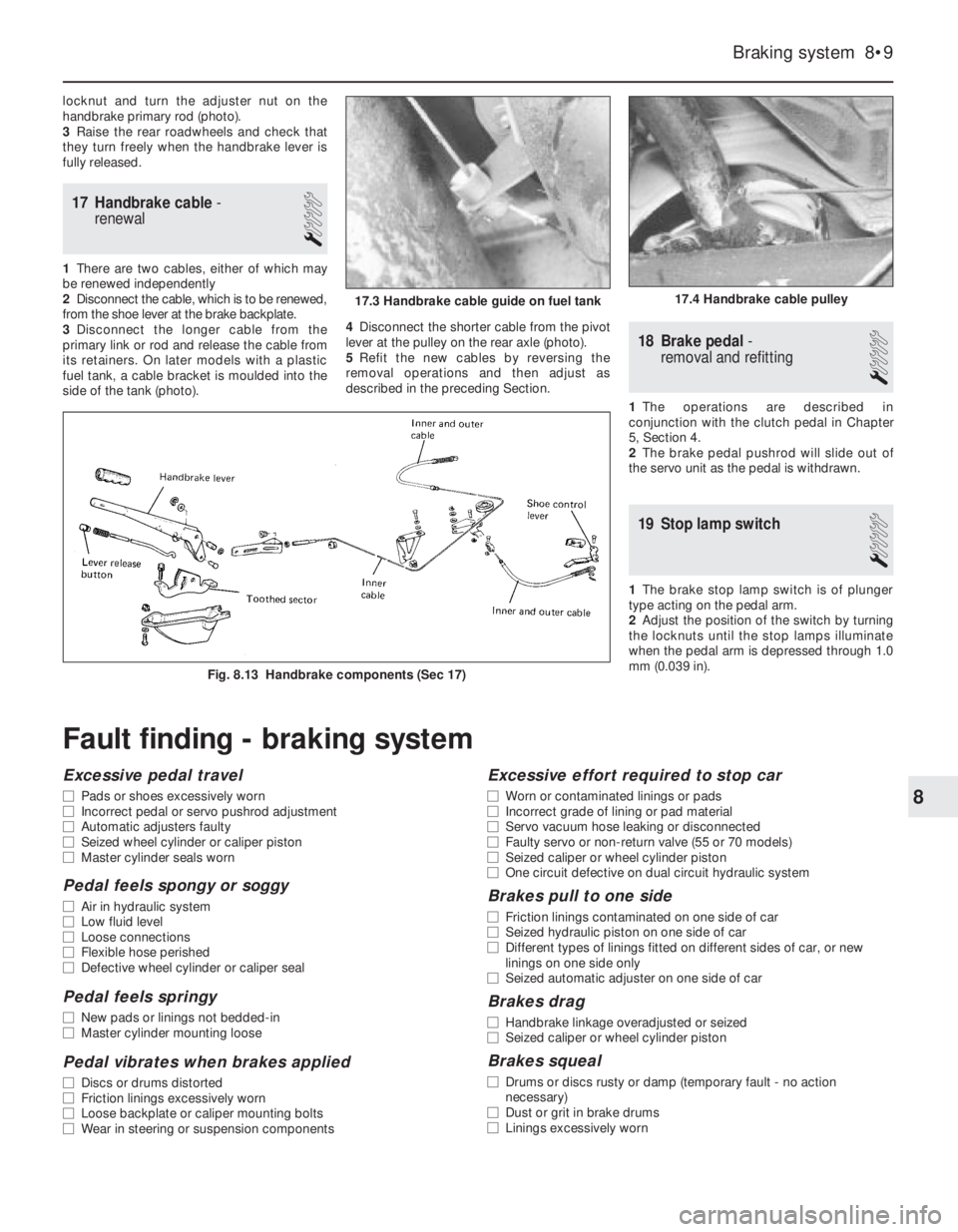

8Gather together a clean glass jar and a

length of rubber or plastic tubing which will be

a tight fit on the brake bleed screws (photo).9Engage the help of an assistant.

10Push one end of the bleed tube onto the

flrst bleed screw and immerse the other end

of the glass jar which should contain enough

hydraulic fluid to cover the end of the tube.

11Open the bleed screw one half a turn and

have your assistant depress the brake pedal

fully then slowly release it. Tighten the bleed

screw at the end of each pedal downstroke to

obviate any chance of air or fluid being drawn

back into the system.

12Repeat this operation until clean hydraulic

fluid, free from air bubbles, can be seen

coming through into the jar.

13Tighten the bleed screw at the end of a

pedal downstroke and remove the bleed tube.

Bleed the remaining screws in a similar way.

Bleeding - using a one way

valve kit

14There are a number of one-man, one-way

brake bleeding kits available from motor

accessory shops. It is recommended that one

of these kits is used wherever possible as it will

greatly simplify the bleeding operation and also

reduce the risk of air or fluid being drawn back

into the system quite apart from being able to

do the work without the help of an assistant.

15To use the kit, connect the tube to the

bleedscrew and open the screw one half a

turn.

16Depress the brake pedal fully and slowly

release it. The one-way valve in the kit will

prevent expelled air from returning at the end

of each pedal downstroke. Repeat this

operation several times to be sure of ejecting

all air from the system. Some kits include a

translucent container which can be positioned

so that the air bubbles can actually be seen

being ejected from the system.

17Tighten the bleed screw, remove the tube

and repeat the operations on the remaining

brakes.

18On completion, depress the brake pedal. If it

still feels spongy repeat the bleeding operations

as air must still be trapped in the system.

Bleeding - using a pressure

bleeding kit

19These kits too are available from motor

accessory shops and are usually operated by

air pressure from the spare tyre.

Braking system 8•7

12.8 Caliper bleed screw with dust cap

fittedFig. 8.12 Bleeding a rear wheel cylinder

(Sec 12)11.3 Front hydraulic hose bracket

8

Page 89 of 303

locknut and turn the adjuster nut on the

handbrake primary rod (photo).

3Raise the rear roadwheels and check that

they turn freely when the handbrake lever is

fully released.

17 Handbrake cable-

renewal

1

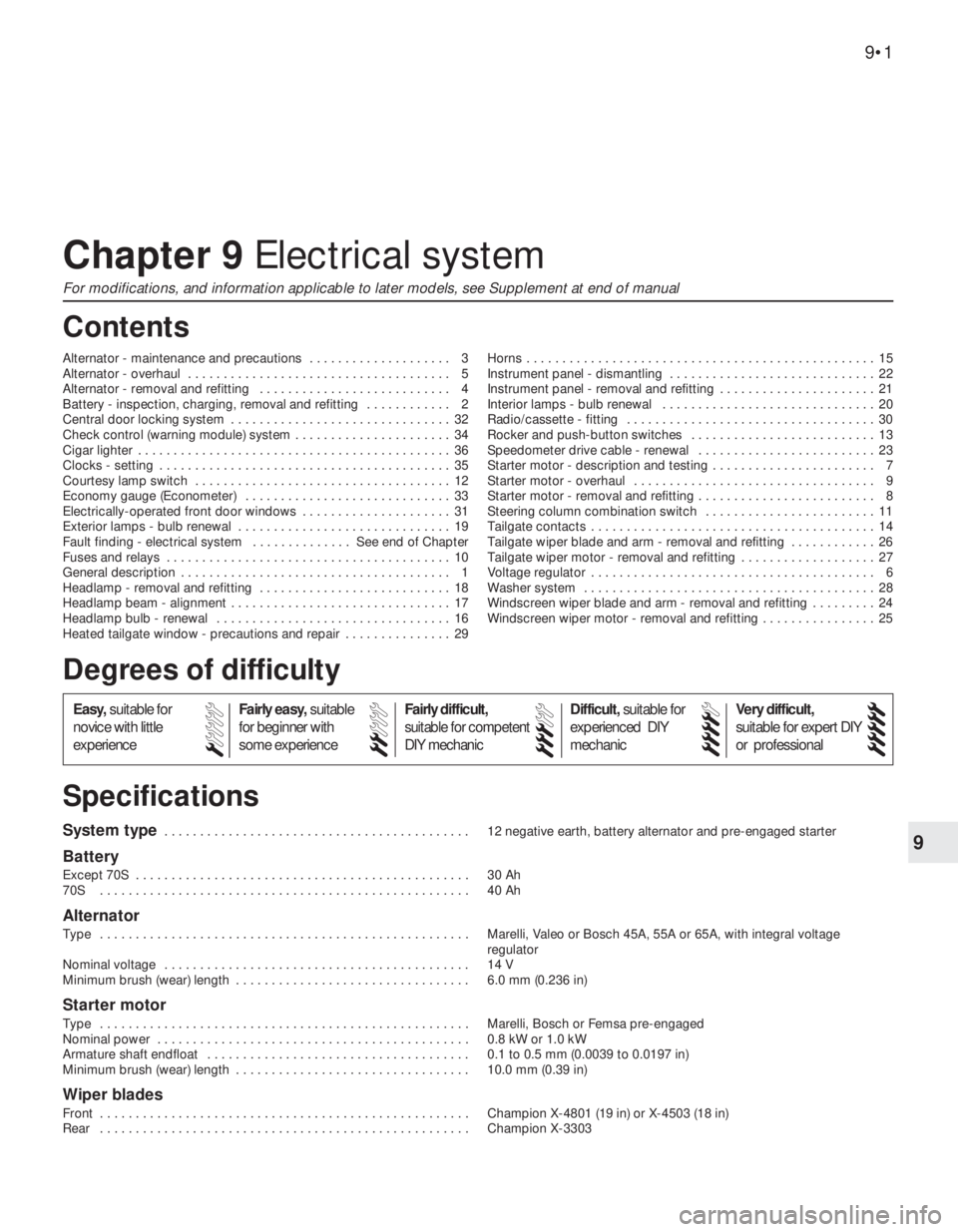

1There are two cables, either of which may

be renewed independently

2Disconnect the cable, which is to be renewed,

from the shoe lever at the brake backplate.

3Disconnect the longer cable from the

primary link or rod and release the cable from

its retainers. On later models with a plastic

fuel tank, a cable bracket is moulded into the

side of the tank (photo).4Disconnect the shorter cable from the pivot

lever at the pulley on the rear axle (photo).

5Refit the new cables by reversing the

removal operations and then adjust as

described in the preceding Section.

18 Brake pedal-

removal and refitting

1

1The operations are described in

conjunction with the clutch pedal in Chapter

5, Section 4.

2The brake pedal pushrod will slide out of

the servo unit as the pedal is withdrawn.

19 Stop lamp switch

1

1The brake stop lamp switch is of plunger

type acting on the pedal arm.

2Adjust the position of the switch by turning

the locknuts until the stop lamps illuminate

when the pedal arm is depressed through 1.0

mm (0.039 in).

Braking system 8•9

Fig. 8.13 Handbrake components (Sec 17)

17.4 Handbrake cable pulley17.3 Handbrake cable guide on fuel tank

8

Fault finding - braking system

Excessive pedal travel

m mPads or shoes excessively worn

m mIncorrect pedal or servo pushrod adjustment

m mAutomatic adjusters faulty

m mSeized wheel cylinder or caliper piston

m mMaster cylinder seals worn

Pedal feels spongy or soggy

m

mAir in hydraulic system

m mLow fluid level

m mLoose connections

m mFlexible hose perished

m mDefective wheel cylinder or caliper seal

Pedal feels springy

m

mNew pads or linings not bedded-in

m mMaster cylinder mounting loose

Pedal vibrates when brakes applied

m

mDiscs or drums distorted

m mFriction linings excessively worn

m mLoose backplate or caliper mounting bolts

m mWear in steering or suspension components

Excessive effort required to stop car

m

mWorn or contaminated linings or pads

m mIncorrect grade of lining or pad material

m mServo vacuum hose leaking or disconnected

m mFaulty servo or non-return valve (55 or 70 models)

m mSeized caliper or wheel cylinder piston

m mOne circuit defective on dual circuit hydraulic system

Brakes pull to one side

m

mFriction linings contaminated on one side of car

m mSeized hydraulic piston on one side of car

m mDifferent types of linings fitted on different sides of car, or new

linings on one side only

m mSeized automatic adjuster on one side of car

Brakes drag

m

mHandbrake linkage overadjusted or seized

m mSeized caliper or wheel cylinder piston

Brakes squeal

m

mDrums or discs rusty or damp (temporary fault - no action

necessary)

m mDust or grit in brake drums

m mLinings excessively worn

Page 90 of 303

9System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 negative earth, battery alternator and pre-engaged starter

Battery

Except 70S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Ah

70S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 Ah

Alternator

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Marelli, Valeo or Bosch 45A, 55A or 65A, with integral voltage

regulator

Nominal voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 V

Minimum brush (wear) length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 mm (0.236 in)

Starter motor

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Marelli, Bosch or Femsa pre-engaged

Nominal power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 kW or 1.0 kW

Armature shaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1 to 0.5 mm (0.0039 to 0.0197 in)

Minimum brush (wear) length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.0 mm (0.39 in)

Wiper blades

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X-4801 (19 in) or X-4503 (18 in)

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X-3303

Chapter 9 Electrical system

For modifications, and information applicable to later models, see Supplement at end of manual

Alternator - maintenance and precautions . . . . . . . . . . . . . . . . . . . . 3

Alternator - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Alternator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery - inspection, charging, removal and refitting . . . . . . . . . . . . 2

Central door locking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Check control (warning module) system . . . . . . . . . . . . . . . . . . . . . . 34

Cigar lighter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Clocks - setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Courtesy lamp switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Economy gauge (Econometer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Electrically-operated front door windows . . . . . . . . . . . . . . . . . . . . . 31

Exterior lamps - bulb renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fault finding - electrical system . . . . . . . . . . . . . . See end of Chapter

Fuses and relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Headlamp - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Headlamp beam - alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Headlamp bulb - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Heated tailgate window - precautions and repair . . . . . . . . . . . . . . . 29Horns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Instrument panel - dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Instrument panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 21

Interior lamps - bulb renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Radio/cassette - fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rocker and push-button switches . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Speedometer drive cable - renewal . . . . . . . . . . . . . . . . . . . . . . . . . 23

Starter motor - description and testing . . . . . . . . . . . . . . . . . . . . . . . 7

Starter motor - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Starter motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 8

Steering column combination switch . . . . . . . . . . . . . . . . . . . . . . . . 11

Tailgate contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Tailgate wiper blade and arm - removal and refitting . . . . . . . . . . . . 26

Tailgate wiper motor - removal and refitting . . . . . . . . . . . . . . . . . . . 27

Voltage regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Washer system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Windscreen wiper blade and arm - removal and refitting . . . . . . . . . 24

Windscreen wiper motor - removal and refitting . . . . . . . . . . . . . . . . 25

9•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 94 of 303

8Withdraw the solenoid and yoke off the

armature and from the drive end bracket.

Note the steel and fibre washers and the

shims on the armature shaft (photo).

9Extract the split pin and tap out the

engagement lever pivot pin.

10Pull the rubber packing piece from the

drive end bracket.

11Withdraw the armature with solenoid

plunger, coil spring and engagement lever.

12Clean the commutator with a fuel soaked

rag or very fine glass paper. Do not undercut

the mica insulators on the commutator.

Drive

13To remove the drive assembly from the

armature shaft, use a piece of tubing to tap

the stop collar down the shaft to expose the

snap ring. Remove the snap ring and stop

collar and slide the drive assembly from the

shaft.

14Refitting is a reversal of removal, but use a

new snap ring to secure the drive to the

armature shaft.

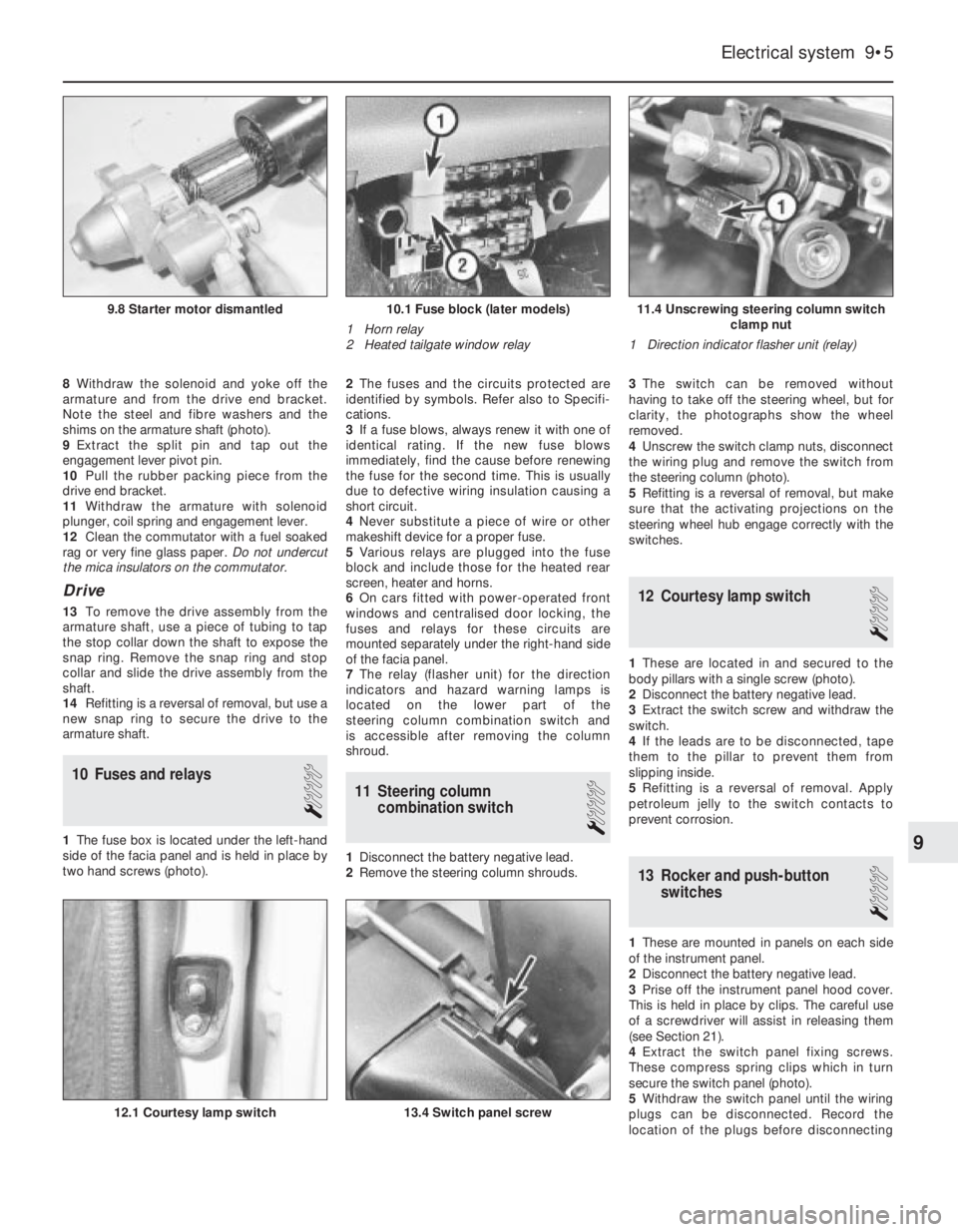

10 Fuses and relays

1

1The fuse box is located under the left-hand

side of the facia panel and is held in place by

two hand screws (photo).2The fuses and the circuits protected are

identified by symbols. Refer also to Specifi-

cations.

3If a fuse blows, always renew it with one of

identical rating. If the new fuse blows

immediately, find the cause before renewing

the fuse for the second time. This is usually

due to defective wiring insulation causing a

short circuit.

4Never substitute a piece of wire or other

makeshift device for a proper fuse.

5Various relays are plugged into the fuse

block and include those for the heated rear

screen, heater and horns.

6On cars fitted with power-operated front

windows and centralised door locking, the

fuses and relays for these circuits are

mounted separately under the right-hand side

of the facia panel.

7The relay (flasher unit) for the direction

indicators and hazard warning lamps is

located on the lower part of the

steering column combination switch and

is accessible after removing the column

shroud.

11 Steering column

combination switch

1

1Disconnect the battery negative lead.

2Remove the steering column shrouds. 3The switch can be removed without

having to take off the steering wheel, but for

clarity, the photographs show the wheel

removed.

4Unscrew the switch clamp nuts, disconnect

the wiring plug and remove the switch from

the steering column (photo).

5Refitting is a reversal of removal, but make

sure that the activating projections on the

steering wheel hub engage correctly with the

switches.

12 Courtesy lamp switch

1

1These are located in and secured to the

body pillars with a single screw (photo).

2Disconnect the battery negative lead.

3Extract the switch screw and withdraw the

switch.

4If the leads are to be disconnected, tape

them to the pillar to prevent them from

slipping inside.

5Refitting is a reversal of removal. Apply

petroleum jelly to the switch contacts to

prevent corrosion.

13 Rocker and push-button

switches

1

1These are mounted in panels on each side

of the instrument panel.

2Disconnect the battery negative lead.

3Prise off the instrument panel hood cover.

This is held in place by clips. The careful use

of a screwdriver will assist in releasing them

(see Section 21).

4Extract the switch panel fixing screws.

These compress spring clips which in turn

secure the switch panel (photo).

5Withdraw the switch panel until the wiring

plugs can be disconnected. Record the

location of the plugs before disconnecting

Electrical system 9•5

11.4 Unscrewing steering column switch

clamp nut

1 Direction indicator flasher unit (relay)10.1 Fuse block (later models)

1 Horn relay

2 Heated tailgate window relay9.8 Starter motor dismantled

13.4 Switch panel screw12.1 Courtesy lamp switch

9

Page 97 of 303

20 Interior lamps-

bulb renewal

1

Courtesy lamp

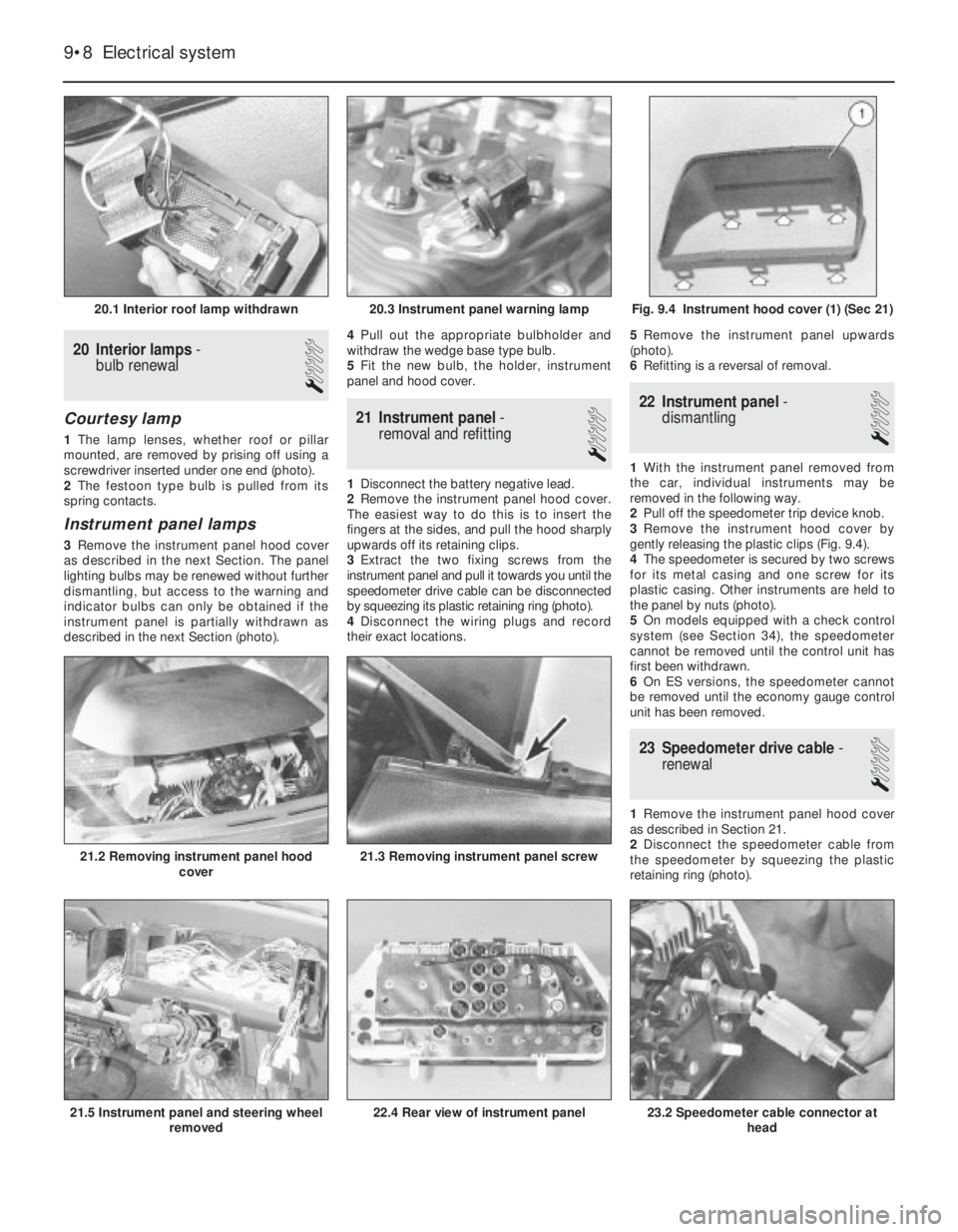

1The lamp lenses, whether roof or pillar

mounted, are removed by prising off using a

screwdriver inserted under one end (photo).

2The festoon type bulb is pulled from its

spring contacts.

Instrument panel lamps

3Remove the instrument panel hood cover

as described in the next Section. The panel

lighting bulbs may be renewed without further

dismantling, but access to the warning and

indicator bulbs can only be obtained if the

instrument panel is partially withdrawn as

described in the next Section (photo). 4Pull out the appropriate bulbholder and

withdraw the wedge base type bulb.

5Fit the new bulb, the holder, instrument

panel and hood cover.

21 Instrument panel-

removal and refitting

1

1Disconnect the battery negative lead.

2Remove the instrument panel hood cover.

The easiest way to do this is to insert the

fingers at the sides, and pull the hood sharply

upwards off its retaining clips.

3Extract the two fixing screws from the

instrument panel and pull it towards you until the

speedometer drive cable can be disconnected

by squeezing its plastic retaining ring (photo).

4Disconnect the wiring plugs and record

their exact locations. 5Remove the instrument panel upwards

(photo).

6Refitting is a reversal of removal.

22 Instrument panel-

dismantling

1

1With the instrument panel removed from

the car, individual instruments may be

removed in the following way.

2Pull off the speedometer trip device knob.

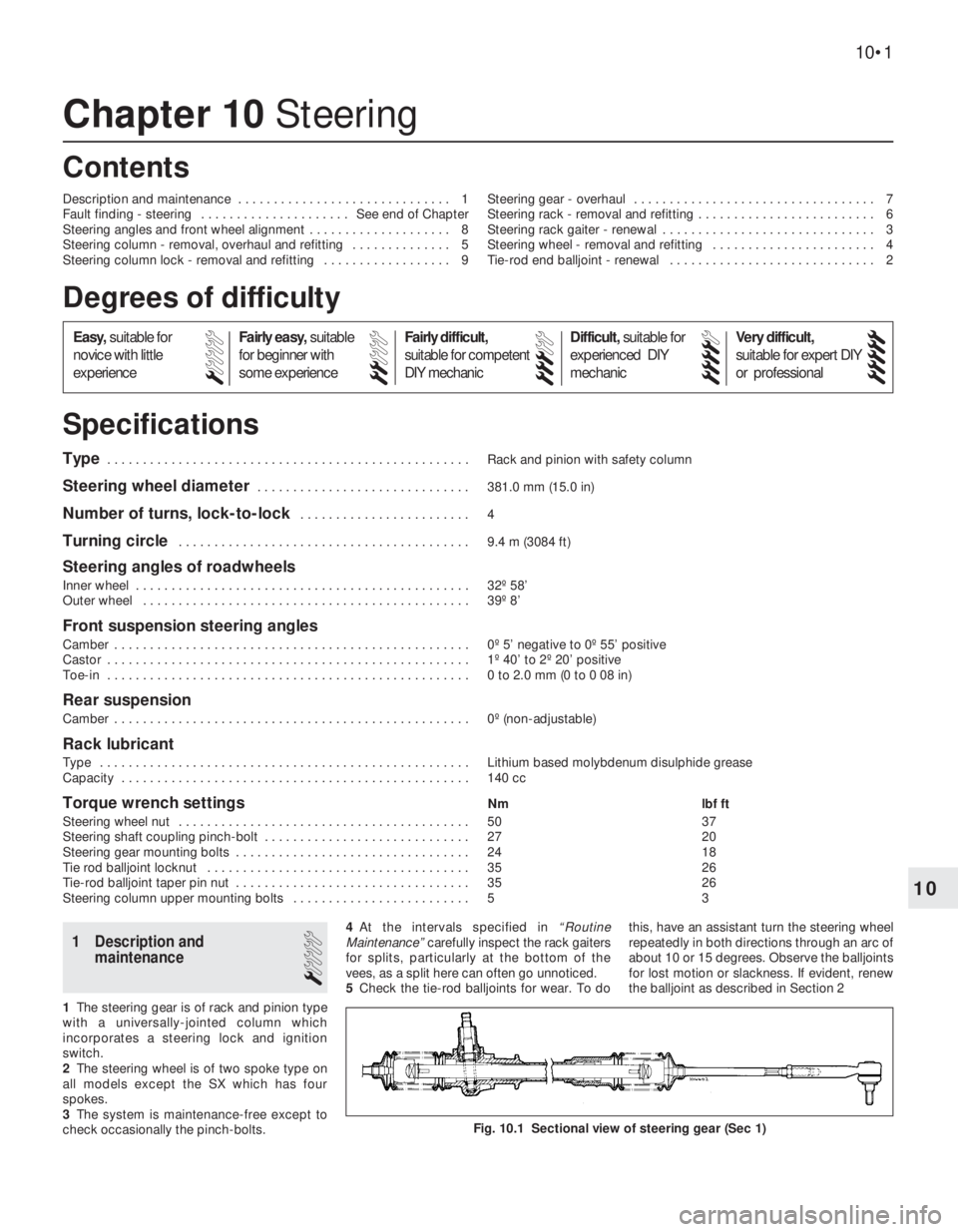

3Remove the instrument hood cover by

gently releasing the plastic clips (Fig. 9.4).

4The speedometer is secured by two screws

for its metal casing and one screw for its

plastic casing. Other instruments are held to

the panel by nuts (photo).

5On models equipped with a check control

system (see Section 34), the speedometer

cannot be removed until the control unit has

first been withdrawn.

6On ES versions, the speedometer cannot

be removed until the economy gauge control

unit has been removed.

23 Speedometer drive cable-

renewal

1

1Remove the instrument panel hood cover

as described in Section 21.

2Disconnect the speedometer cable from

the speedometer by squeezing the plastic

retaining ring (photo).

9•8 Electrical system

23.2 Speedometer cable connector at

head22.4 Rear view of instrument panel21.5 Instrument panel and steering wheel

removed

21.3 Removing instrument panel screw21.2 Removing instrument panel hood

cover

Fig. 9.4 Instrument hood cover (1) (Sec 21)20.3 Instrument panel warning lamp20.1 Interior roof lamp withdrawn

Page 104 of 303

10

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rack and pinion with safety column

Steering wheel diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381.0 mm (15.0 in)

Number of turns, lock-to-lock . . . . . . . . . . . . . . . . . . . . . . . . 4

Turning circle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.4 m (3084 ft)

Steering angles of roadwheels

Inner wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32º 58’

Outer wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39º 8’

Front suspension steering angles

Camber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0º 5’ negative to 0º 55’ positive

Castor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1º 40’ to 2º 20’ positive

Toe-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to 2.0 mm (0 to 0 08 in)

Rear suspension

Camber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0º (non-adjustable)

Rack lubricant

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Lithium based molybdenum disulphide grease

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140 cc

Torque wrench settingsNm lbf ft

Steering wheel nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 37

Steering shaft coupling pinch-bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 20

Steering gear mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 18

Tie rod balljoint locknut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 26

Tie-rod balljoint taper pin nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 26

Steering column upper mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . 5 3

Chapter 10 Steering

Description and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Fault finding - steering . . . . . . . . . . . . . . . . . . . . . See end of Chapter

Steering angles and front wheel alignment . . . . . . . . . . . . . . . . . . . . 8

Steering column - removal, overhaul and refitting . . . . . . . . . . . . . . 5

Steering column lock - removal and refitting . . . . . . . . . . . . . . . . . . 9Steering gear - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Steering rack - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 6

Steering rack gaiter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Steering wheel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 4

Tie-rod end balljoint - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

10•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 Description and

maintenance

1

1The steering gear is of rack and pinion type

with a universally-jointed column which

incorporates a steering lock and ignition

switch.

2The steering wheel is of two spoke type on

all models except the SX which has four

spokes.

3The system is maintenance-free except to

check occasionally the pinch-bolts.4At the intervals specified in“Routine

Maintenance”carefully inspect the rack gaiters

for splits, particularly at the bottom of the

vees, as a split here can often go unnoticed.

5Check the tie-rod balljoints for wear. To dothis, have an assistant turn the steering wheel

repeatedly in both directions through an arc of

about 10 or 15 degrees. Observe the balljoints

for lost motion or slackness. If evident, renew

the balljoint as described in Section 2

Fig. 10.1 Sectional view of steering gear (Sec 1)

Page 105 of 303

2 Tie-rod end balljoint-

renewal

4

1Jack up the front of the car and remove the

roadwheel from the side on which the balljoint

is to be renewed.

2Unscrew the tie-rod balljoint taper pin nut

and, using a suitable extractor, separate the

tie-rod balljoint from the eye of the steering

arm (photo).

3Release the locknut on the tie-rod,

unscrewing it only just enough to be able to

unscrew the tie-rod end from the tie-rod.

4With the tie-rod end removed, wire brush

the threads on the tie-rod without disturbing

the position of the locknut; apply grease to

the threads and screw on the new tie-rod end

until the locknut can be tightened by turning it

through the same amount of rotation it was

given when unscrewed.

5Reconnect the balljoint taper pin to the eye

of the steering arm and tighten the retaining nut

to the specified torque. Never grease the taper

pin or eye; the pin will otherwise turn when the

nut is tightened. If a taper pin is inclined to

rotate when a nut is being tightened, apply

pressure to the socket of the joint to force the

taper pin into closer contact with the tapered

hole in the eye. If a taper pin is pointing

downward, a strong lever can be used to apply

the extra pressure. Where the taper pin of a

balljoint points upward, a jack placed under the

joint socket will produce the desired result.

6Although the careful fitting of the new

tie-rod end will have approximatelymaintained the original front wheel alignment

of the car, manufacturing differences alone of

the new component make it essential to

check the setting, as described in Section 8

and to adjust if necessary.

3 Steering rack gaiter-

renewal

4

1If lubricant is found to be leaking from the

gaiters (at the ends of the housing), first check

that the gaiter clips are secure.

2If the lubricant is leaking from the gaiter

through a split, the gaiter can be removed in

the following way, without the necessity of

withdrawing the gear from the car.

3Remove the tie-rod end from the side

concerned, as described in the preceding

Section.

4Release the gaiter clips; draw the gaiter

from the rack housing and off the tie-rod.

5If the gaiter has only just split, road dirt is

unlikely to have entered and lubricant can be

wiped away. If it is severely grit contaminated,

the steering gear should be completely

removed, the original lubricant flushed out

and new lubricant pumped in.

6If the gear does not have to be removed

from the car, slide the new gaiter into position

and secure it with the inboard clip.

7The rack lubricant is molybdenum

disulphide type grease.

8When recharging the gaiter with this type of

lubricant, give full steering lock to the side

being replenished so that the extendedsection of the rack will take the grease into the

housing as it returns.

9Reconnect the tie-rod end to the tie-rod

and the eye of the steering arm. Provided the

locknut is tightened by only rotating it through

the same distance by which it was loosened,

the front wheel alignment (tracking) should not

have been unduly disturbed. Even so, check

the alignment as described in Section 8.

4 Steering wheel-

removal and refitting

1

1Disconnect the battery negative lead.

2Set the steering wheel and the front

roadwheels in the straight-ahead attitude.

Prise out the hub plate (photo).

3Unscrew and remove the steering wheel

securing nut, then pull the wheel from the

column shaft. If it is tight on its splines, tap it

upward at the wheel rim, using the palms of

the hands.

4Refitting is a reversal of the removal

process; make sure that the spokes of the

wheel are in the lower part of the wheel.

5Tighten the securing nut to the specified

torque.

5 Steering column- removal,

overhaul and refitting

3

1Remove the steering wheel as previously

described.

2Extract the screws from the underside of

the steering column upper shroud and then lift

off the upper and lower shroud sections

(photo). Where applicable, detach and remove

the trim panel from the underside of the facia

on the driver’s side.

3Disconnect the battery negative lead.

4Disconnect the wiring plug for the steering

column combination switch.

5Unscrew the clamp nuts and pull the

combination switch off the end of the steering

shaft.

6Unscrew the column upper mounting

bracket bolts and lower the shaft/column tube

to rest on the seat (photo).

7Remove the pinch-bolt from the lower

universal joint coupling and remove the

shaft/column tube from the car.

Overhaul

8Remove the pinch-bolt from the upper

universal joint and disconnect the lower shaft.

9Grip the tube mounting flange in the jaws of

a vice and relieve the staking at the base of

the tube.

10Using a plastic or copper-faced hammer,

tap the shaft down out of the tube.

11The lower bush will be ejected while the

upper one should be prised out of the tube.

12Reassemble the upper shaft into the tube

by tapping new bushes into position.

10•2 Steering

5.6 Steering column upper mounting5.2 Removing steering column shrouds

4.2 Removing steering wheel hub plate2.2 Disconnecting a tie-rod end balljoint

Page 106 of 303

13Stake the lower end of the tube to retain

the bush.

14Reassembly is a reversal of removal,

noting that the universal joint coupling

pinch-bolts should pass smoothly through the

grooves in the steering shaft.

15Fit the steering wheel when the

roadwheels are in the straight-ahead position.

16Tighten all nuts and bolts to the specified

torque. Reconnect the battery.

6 Steering rack-

removal and refitting

4

1Set the steering in the straight-ahead

mode.

2Working inside the car, disconnect thesteering shaft lower coupling by unscrewing

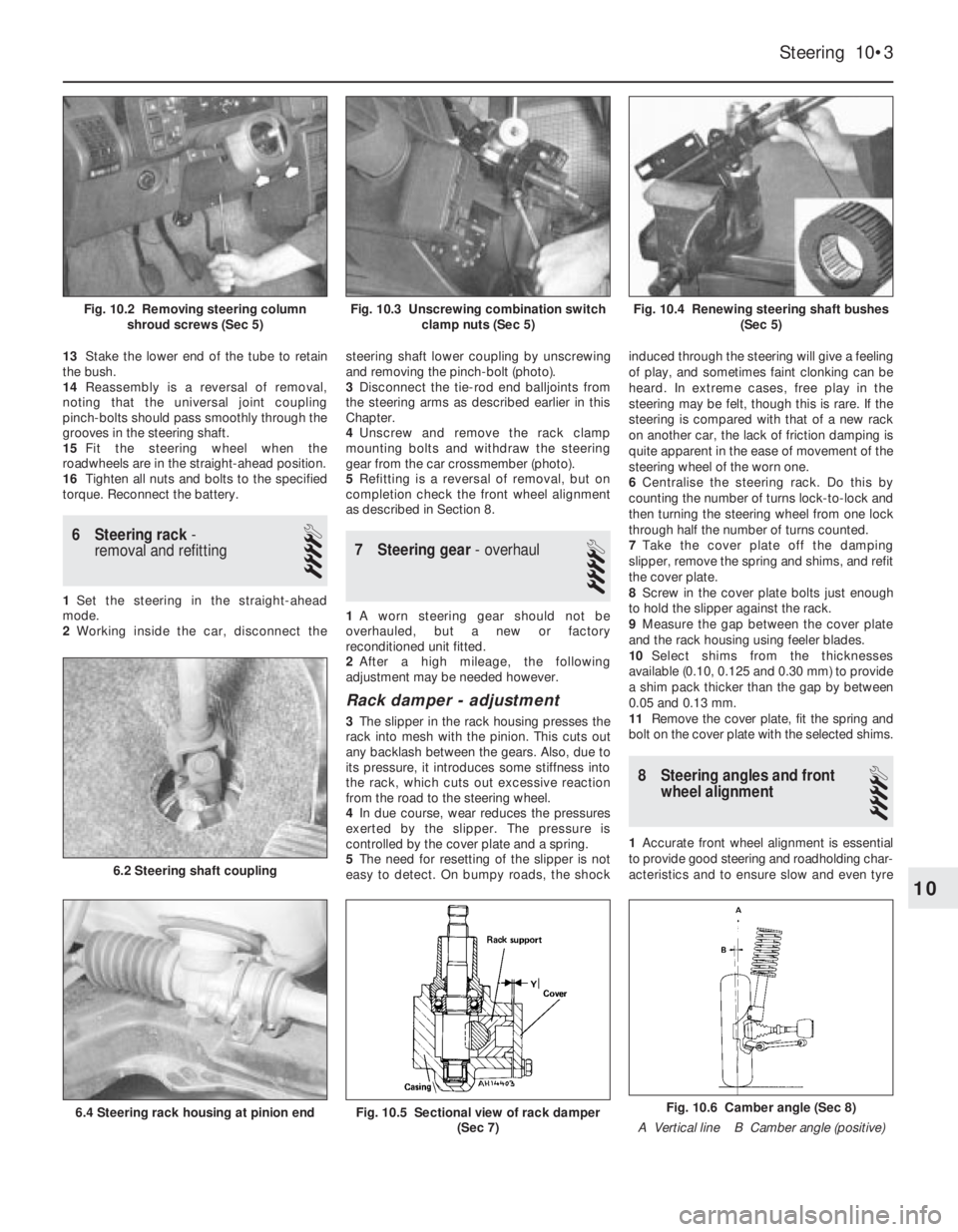

and removing the pinch-bolt (photo).

3Disconnect the tie-rod end balljoints from

the steering arms as described earlier in this

Chapter.

4Unscrew and remove the rack clamp

mounting bolts and withdraw the steering

gear from the car crossmember (photo).

5Refitting is a reversal of removal, but on

completion check the front wheel alignment

as described in Section 8.

7 Steering gear- overhaul

4

1A worn steering gear should not be

overhauled, but a new or factory

reconditioned unit fitted.

2After a high mileage, the following

adjustment may be needed however.

Rack damper - adjustment

3The slipper in the rack housing presses the

rack into mesh with the pinion. This cuts out

any backlash between the gears. Also, due to

its pressure, it introduces some stiffness into

the rack, which cuts out excessive reaction

from the road to the steering wheel.

4In due course, wear reduces the pressures

exerted by the slipper. The pressure is

controlled by the cover plate and a spring.

5The need for resetting of the slipper is not

easy to detect. On bumpy roads, the shockinduced through the steering will give a feeling

of play, and sometimes faint clonking can be

heard. In extreme cases, free play in the

steering may be felt, though this is rare. If the

steering is compared with that of a new rack

on another car, the lack of friction damping is

quite apparent in the ease of movement of the

steering wheel of the worn one.

6Centralise the steering rack. Do this by

counting the number of turns lock-to-lock and

then turning the steering wheel from one lock

through half the number of turns counted.

7Take the cover plate off the damping

slipper, remove the spring and shims, and refit

the cover plate.

8Screw in the cover plate bolts just enough

to hold the slipper against the rack.

9Measure the gap between the cover plate

and the rack housing using feeler blades.

10Select shims from the thicknesses

available (0.10, 0.125 and 0.30 mm) to provide

a shim pack thicker than the gap by between

0.05 and 0.13 mm.

11Remove the cover plate, fit the spring and

bolt on the cover plate with the selected shims.

8 Steering angles and front

wheel alignment

4

1Accurate front wheel alignment is essential

to provide good steering and roadholding char-

acteristics and to ensure slow and even tyre

Steering 10•3

Fig. 10.4 Renewing steering shaft bushes

(Sec 5)Fig. 10.3 Unscrewing combination switch

clamp nuts (Sec 5)Fig. 10.2 Removing steering column

shroud screws (Sec 5)

Fig. 10.6 Camber angle (Sec 8)

A Vertical line B Camber angle (positive)Fig. 10.5 Sectional view of rack damper

(Sec 7)6.4 Steering rack housing at pinion end

10

6.2 Steering shaft coupling

Page 107 of 303

Note: Before diagnosing steering faults, be

sure that trouble is not due to incorrect or

uneven tyre pressures, inappropriate tyre

combinations, or braking system or

suspension defects.

Car pulls to one side

m mIncorrect steering geometry

m mCollision damage

Vibration at steering wheel

m

mRoadwheels out of balance or loose

m mTyre damage

m mLoose driveshaft-to-hub nuts

Car wanders

m

mPlay in steering gear

m mWear in steering balljoints

Heavy or stiff steering

m

mLack of lubricant in steering gear or balljoints

m mIncorrect steering geometry

m mCollision damage

Play at steering wheel

m

mWear in steering rack or balljoints

m mLoose steering shaft coupling pinch-bolt or

worn splines

m mWorn steering column/shaft universal joints

Rattles from steering

m

mSteering damper defective or in need of

adjustment

m mLoose steering column mounting bolts

m mLoose steering column/shaft coupling

pinch-bolts

m mLoose steering rack housing mounting bolts

m mWorn steering shaft bushes

Excessive or uneven tyre wear

m

mIncorrect steering geometry

m mWorn steering components

m mCollision damage wear. Before considering the steering angles,

check that the tyres are correctly inflated, that

the front wheels are not buckled, the hub

bearings are not worn or incorrectly adjusted

and that the steering linkage is in good order,

without slackness or wear at the joints.

2Wheel alignment consists of four factors:

Camber, is the angle at which the road

wheels are set from the vertical when viewed

from the front or rear of the vehicle. Positive

camber is the angle (in degrees) that the wheels

are tilted outwards at the top from the vertical.

Castor, is the angle between the steering

axis and a vertical line when viewed from each

side of the vehicle. Positive castor is indicated

when the steering axis is inclined towards the

rear of the vehicle at its upper end.

Steering axis inclination, is the angle when

viewed from the front or rear of the vehicle

between vertical and an imaginary line drawn

between the upper and lower suspension

strut mountings.

Toe,is the amount by which the distance

between the front inside edges of the

roadwheel rims differs from that between the

rear inside edges.

3If the distance between the front edges is

less than that at the rear, the wheels are said

to toe-in. If the distance between the front

inside edges is greater than that at the rear,

the wheels toe-out.

4Camber and castor are set during

production of the car and are not adjustable.

Any deviation from specification will be due tocollision damage or to gross wear in the

components concerned.

5To check the front wheel alignment, first

make sure that the lengths of both tie-rods are

equal when the steering is in the straight-ahead

position. Measure between the locknut at the

balljoint and the ball cup at the end of the rack

housing by passing a thin rod under the rack of

the gaiter. If adjustment is required, release the

locknut and turn the tie-rod.

6Obtain a tracking gauge. These are

available in various forms from accessory

stores or one can be fabricated from a length

of steel tubing suitably cranked to clear the

sump and bellhousing and having a setscrew

and locknut at one end.

7With the gauge, measure the distance

between the two wheel inner rims (at hub

height) at the rear of the wheel. Push the

vehicle forward to rotate the wheel through

180º (half a turn) and measure the distance

between the wheel inner rims, again at hub

height, at the front of the wheel. This last

measurement should differ from (be less than)

the first by the appropriate toe-in according to

the Specification (see Specifications Section).

8Where the toe-in is found to be incorrect,

release the tie-rod balljoint locknuts and turn

the tie-rods equally. Only turn them a quarter

of a turn at a time before re-checking the

alignment. Viewed from the centre line of the

car, turning the tie-rod clockwise will

decrease the toe-in.

9Make sure that the gaiter outboard clip isreleased otherwise the gaiter will twist as the

tie-rod is rotated.

10Always turn both rods in the same

direction when viewed from the centre line of

the vehicle otherwise the rods will become

unequal in length. This would cause the

steering wheel spoke position to alter and

cause problems on turns with tyre scrubbing.

11On completion, tighten the tie-rod balljoint

locknuts without altering their setting. Check

that the balljoint is at the centre of its arc of

travel and then retighten the gaiter clip.

9 Steering column lock-

removal and refitting

1

1Remove the steering wheel and column

shrouds as described in Section 5, also the

steering column combination switch.

2Unscrew and remove the steering column

mounting bolts and lower the column to

expose the lock shear bolts.

3Drill out the bolts or extract them using an

extractor.

4Refer to Chapter 4 for details of separation

of the ignition switch from the lock section.

5When fitting the new lock, tighten the shear

bolts until their heads break off.

6Bolt up the column, fit the combination

switch, shrouds and steering wheel and

tighten all nuts and bolts to the specified

torque.

10•4 Steering

Fig. 10.9 Steering column lock shear bolts

(arrowed) (Sec 9)

Fig. 10.8 Front wheel alignment diagram

(Sec 8)

X Front dimension Y - X = Toe-in

Y Rear dimension

Fig. 10.7 Castor angle (Sec 8)

A Vertical line B Castor angle (positive)

Fault finding - steering

Page 111 of 303

balljoint from the hub carrier using a suitable

“splitter” tool. If such a tool is not available,

support the base of the brake disc and drive

the balljoint taper pin downwards, but screw

on the nut to protect the threads.

4Remove the hub carrier.

5Refitting is a reversal of removal, use a new

driveshaft nut and tighten all nuts and bolts to

the specified torque. Stake the driveshaft nut

after tightening.

6 Track control arm-

removal and refitting

3

1Raise the front of the car and support it

securely.

2Unless a special tool is available to press

the track control arm balljoint from the hub

carrier, the driveshaft will have to be

disconnected as described in Chapter 7,

Section 2, paragraphs 1 to 8 to provide more

space to enable the balljoint taper pin to be

driven from the hub carrier. This should now

be done as described in the preceding

Section (photo).

3Unbolt the inboard end of the track control

arm. This is retained by a pivot bolt and a

clamp (photo).

4As previously explained, a worn balljoint or

flexible pivot bushes will necessitate renewal

of the track control arm complete. Note that itmay, however, be possible to obtain a

replacement balljoint through a motor factor.

5Refitting is a reversal of removal. Tighten all

nuts and bolts to the specified torque. Use a

new driveshaft nut and stake it into the

driveshaft groove after tightening.

7 Front crossmember-

removal and refitting

3

1Raise the front of the car, support securely

with axle stands placed under the

side-members or sill jacking points.

2Remove the front roadwheels.

3Unscrew the nuts from the tie-rod end

balljoint taper pins and then using a balljoint

“splitter” tool disconnect the balljoints from

the steering arms on the hub carrier.

4Unscrew the bolts which hold the inboard

track control arms to the body members, and

also withdraw the pivot bolt from the body

bracket.

5Support the weight of the engine/

transmission using a hoist or support bar

across the top of the engine compartment as

described in Chapter 6.

6Disconnect the lower (central) engine/

transmission flexible mounting from the floor

pan.

7Unscrew the steering rack mounting boltsand remove them. Leave the steering rack

hanging loose.

8Remove the front crossmember mounting

bolts and manoeuvre it from the car.

9Refitting is a reversal of removal. Tighten all

nuts and bolts to the specified torque wrench

settings and on completion, check the front

wheel alignment as described in Chapter 10.

8 Rear shock absorber-

removal and refitting

3

1Open the tailgate and remove the cover

from the shock absorber top mounting which

is located within the luggage area (photo).

2Hold the flats on the spindle with an

open-ended spanner and then unscrew the

self-locking nut.

3Working under the car, disconnect the

shock absorber lower mounting.

4Withdraw the unit from under the wing.

5The shock absorber can be tested as

described in Section 2.

6Refitting is a reversal of removal. Tighten

mounting nuts and bolts to the specified

torque.

9 Rear coil spring-

removal and refitting

3

1Raise the rear of the car and support it

securely on axle stands placed under the

side-members or sill jacking points.

2Remove the roadwheel.

3Place a jack under the brake drum and

support the suspension trailing arm.

4Disconnect the shock absorber lower

mounting and then lower the trailing arm jack

until the coil spring can be withdrawn.

5Refitting is a reversal of removal. If the

spring is being changed, make sure that it is

of the same colour code as the original and

that its lower coil is correctly located up

against its stop in the spring pan.

6Tighten the shock absorber lower mounting

bolt to the specified torque.

11•4 Suspension

8.1 Rear shock absorber upper mounting

coverFig. 11.7 Front crossmember bolts (Sec 7)Fig. 11.6 Steering rack mounting bolts

(Sec 7)

6.3 Track control arm inboard fixing6.2 Separating track control arm balljoint

from hub carrier