heater FIAT UNO 1983 Service Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 179 of 303

removal are in place under the

engine-to-gearbox bolts. Do not allow the

weight of the gearbox to hang on the input

shaft as it is engaged with the clutch friction

disc.

29Refit the starter motor, ensuring that the

wiring harness bracket is in position on the

top bolt.

30Locate the engine/transmission unit at the

front of the car and move it into position under

the engine compartment. Attach the lifting

sling and hoist as during removal.

31Enlist the aid of an assistant to help

steady the combined units as they are raised

into position and to locate the mountings in

the engine compartment.

32Once they are located, tighten the

mountings to the specified torque settings,

then disconnect the lifting hoist and sling.

33The remainder of the refitting and

reconnection procedures are a reversal of the

removal procedure described in Part C. For

further details on reconnecting the

suspension and driveshaft components,

refer to Chapter 7 and Section 13 of this

Chapter.

34Ensure that the exhaust downpipe-to-

manifold connection is clean and renew the

gasket when reconnecting this joint. Use a

smear of exhaust assembly paste on the jointfaces. Use new lockwashers and tighten the

flange nuts securely.

35Ensure that all fuel and coolant

connections are cleanly and securely made.

36Ensure that all wiring connections are

correct and securely made.

37Top up the engine and transmission oil

levels.

38Refill the cooling system.

39Check that all connections are securely

made, then reconnect the battery negative

lead.

Initial start-up after major

overhaul

40Refer to Chapter 1, Section 45.

8 Cooling system

PART A:

999 AND 1108 CC ENGINES

Description

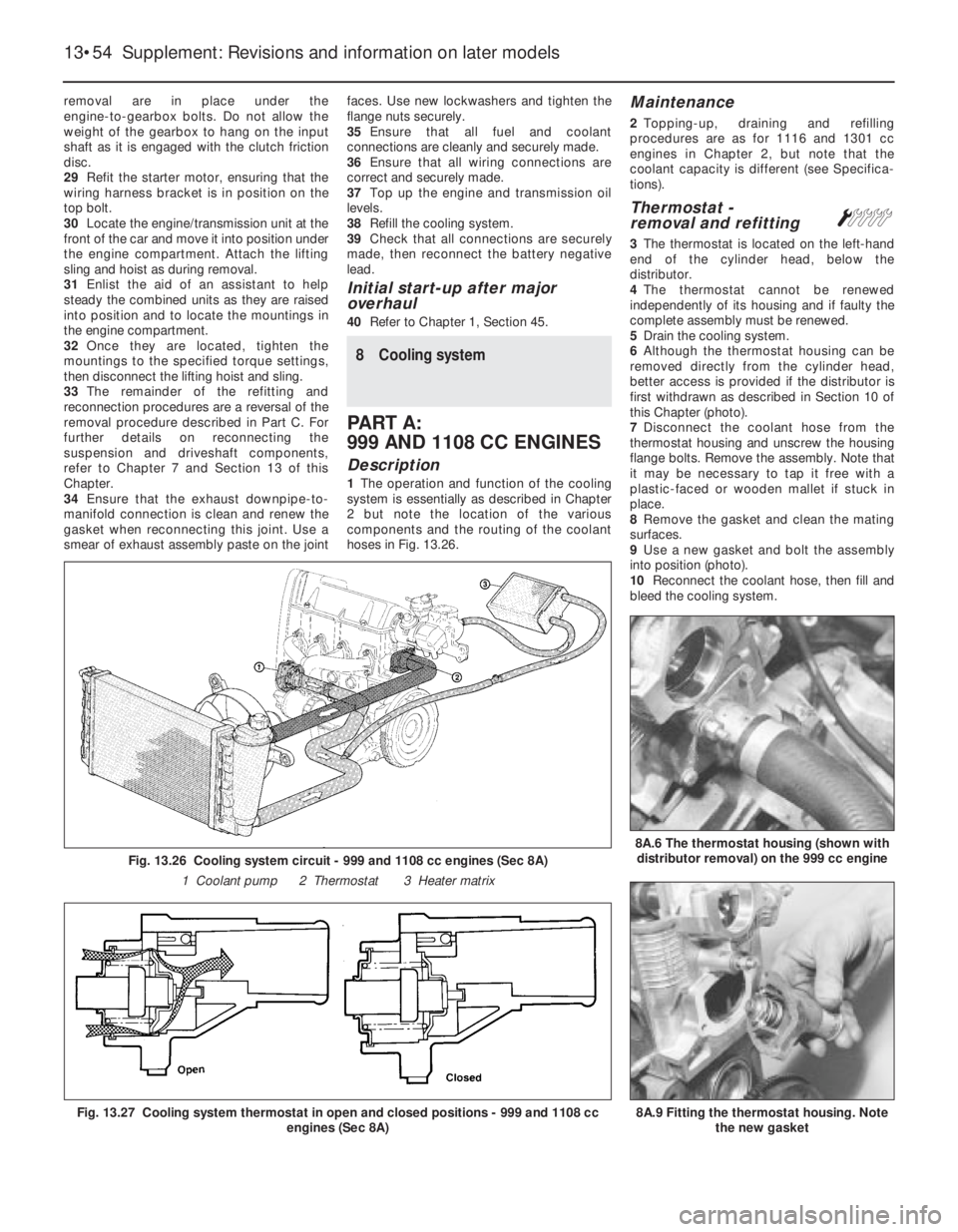

1The operation and function of the cooling

system is essentially as described in Chapter

2 but note the location of the various

components and the routing of the coolant

hoses in Fig. 13.26.

Maintenance

2Topping-up, draining and refilling

procedures are as for 1116 and 1301 cc

engines in Chapter 2, but note that the

coolant capacity is different (see Specifica-

tions).

Thermostat -

removal and refittingÁ

3The thermostat is located on the left-hand

end of the cylinder head, below the

distributor.

4The thermostat cannot be renewed

independently of its housing and if faulty the

complete assembly must be renewed.

5Drain the cooling system.

6Although the thermostat housing can be

removed directly from the cylinder head,

better access is provided if the distributor is

first withdrawn as described in Section 10 of

this Chapter (photo).

7Disconnect the coolant hose from the

thermostat housing and unscrew the housing

flange bolts. Remove the assembly. Note that

it may be necessary to tap it free with a

plastic-faced or wooden mallet if stuck in

place.

8Remove the gasket and clean the mating

surfaces.

9Use a new gasket and bolt the assembly

into position (photo).

10Reconnect the coolant hose, then fill and

bleed the cooling system.

13•54 Supplement: Revisions and information on later models

Fig. 13.26 Cooling system circuit - 999 and 1108 cc engines (Sec 8A)

1 Coolant pump 2 Thermostat 3 Heater matrix

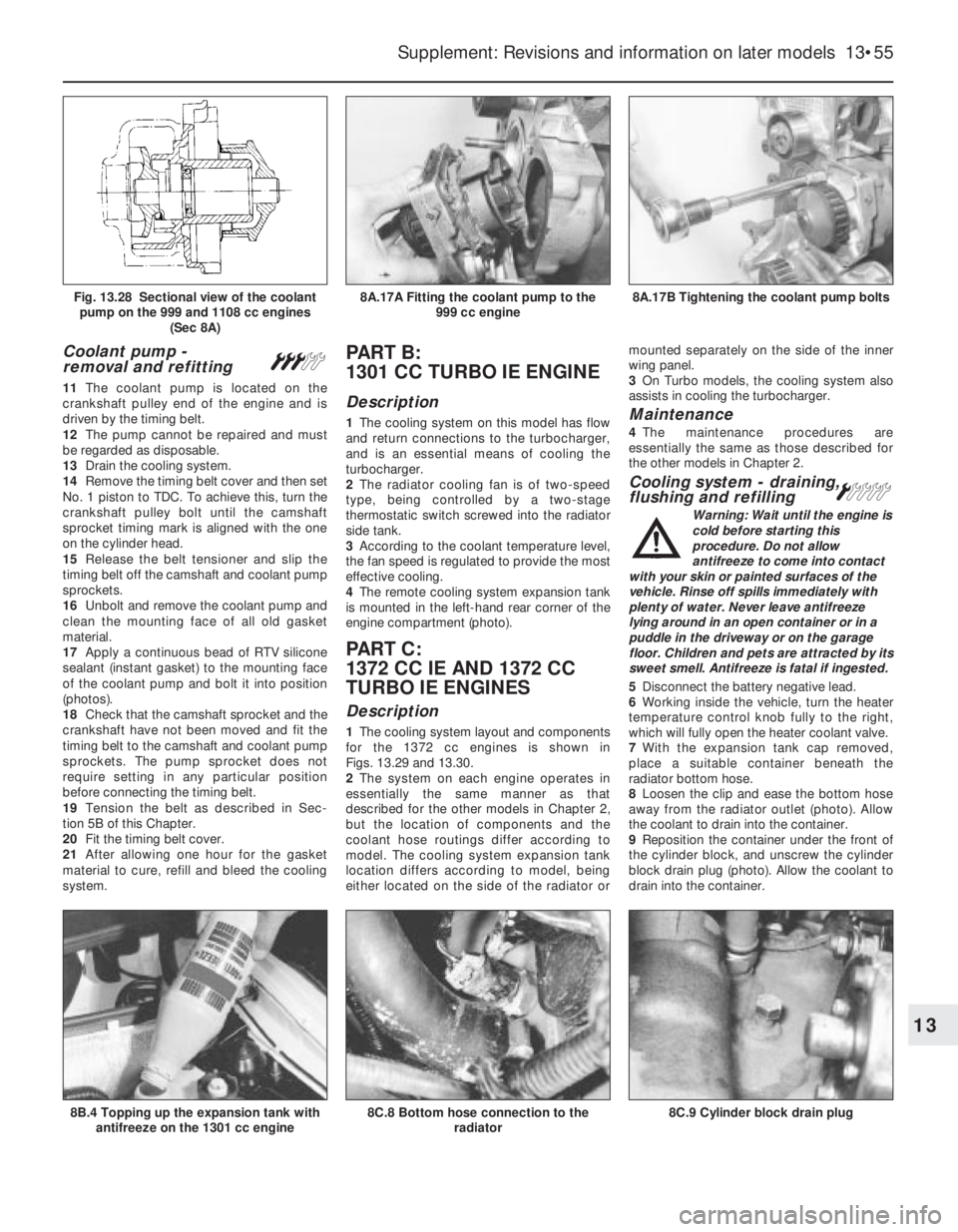

Fig. 13.27 Cooling system thermostat in open and closed positions - 999 and 1108 cc

engines (Sec 8A)8A.9 Fitting the thermostat housing. Note

the new gasket

8A.6 The thermostat housing (shown with

distributor removal) on the 999 cc engine

Page 180 of 303

Coolant pump -

removal and refitting#

11The coolant pump is located on the

crankshaft pulley end of the engine and is

driven by the timing belt.

12The pump cannot be repaired and must

be regarded as disposable.

13Drain the cooling system.

14Remove the timing belt cover and then set

No. 1 piston to TDC. To achieve this, turn the

crankshaft pulley bolt until the camshaft

sprocket timing mark is aligned with the one

on the cylinder head.

15Release the belt tensioner and slip the

timing belt off the camshaft and coolant pump

sprockets.

16Unbolt and remove the coolant pump and

clean the mounting face of all old gasket

material.

17Apply a continuous bead of RTV silicone

sealant (instant gasket) to the mounting face

of the coolant pump and bolt it into position

(photos).

18Check that the camshaft sprocket and the

crankshaft have not been moved and fit the

timing belt to the camshaft and coolant pump

sprockets. The pump sprocket does not

require setting in any particular position

before connecting the timing belt.

19Tension the belt as described in Sec-

tion 5B of this Chapter.

20Fit the timing belt cover.

21After allowing one hour for the gasket

material to cure, refill and bleed the cooling

system.

PART B:

1301 CC TURBO IE ENGINE

Description

1The cooling system on this model has flow

and return connections to the turbocharger,

and is an essential means of cooling the

turbocharger.

2The radiator cooling fan is of two-speed

type, being controlled by a two-stage

thermostatic switch screwed into the radiator

side tank.

3According to the coolant temperature level,

the fan speed is regulated to provide the most

effective cooling.

4The remote cooling system expansion tank

is mounted in the left-hand rear corner of the

engine compartment (photo).

PART C:

1372 CC IE AND 1372 CC

TURBO IE ENGINES

Description

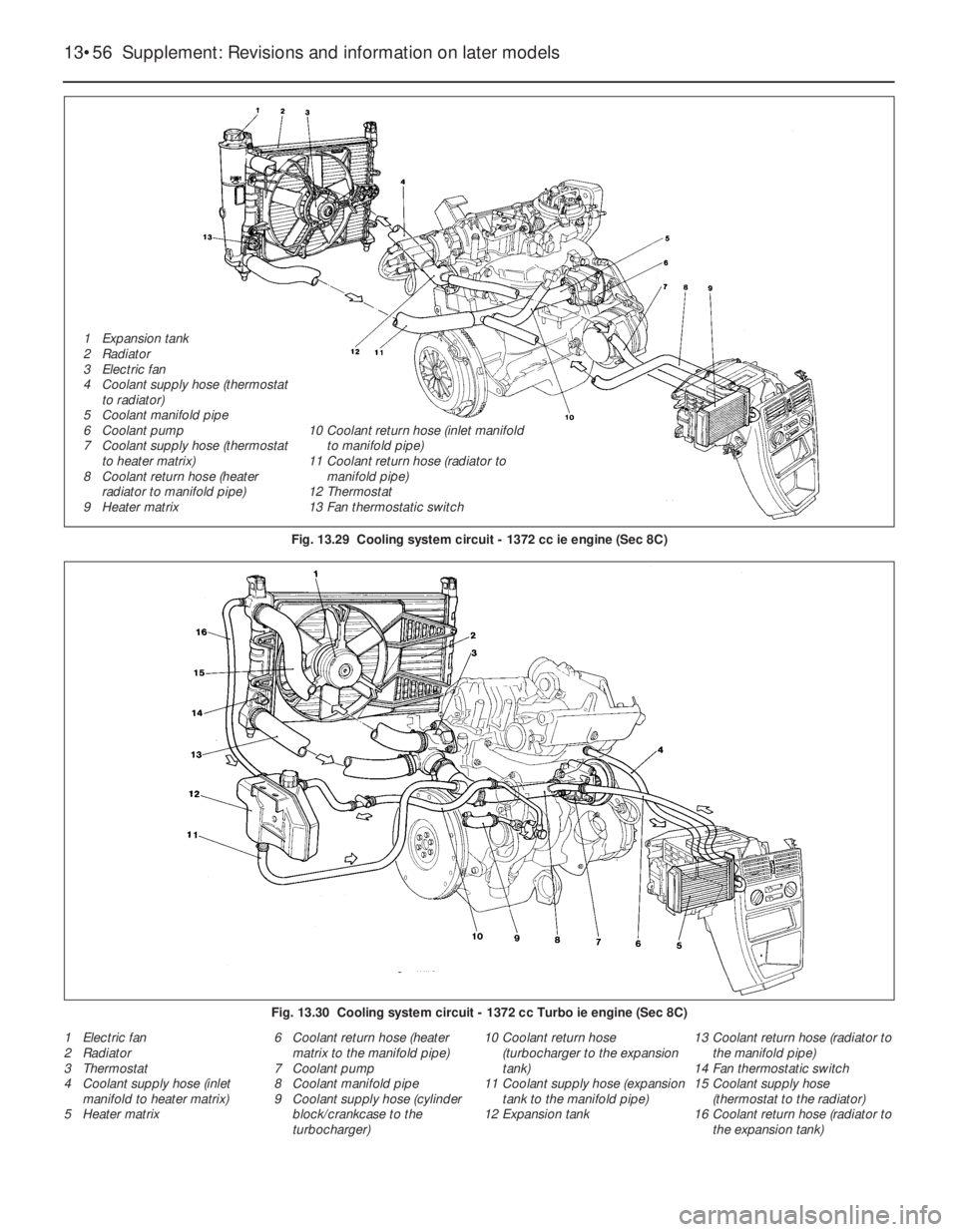

1The cooling system layout and components

for the 1372 cc engines is shown in

Figs. 13.29 and 13.30.

2The system on each engine operates in

essentially the same manner as that

described for the other models in Chapter 2,

but the location of components and the

coolant hose routings differ according to

model. The cooling system expansion tank

location differs according to model, being

either located on the side of the radiator ormounted separately on the side of the inner

wing panel.

3On Turbo models, the cooling system also

assists in cooling the turbocharger.

Maintenance

4The maintenance procedures are

essentially the same as those described for

the other models in Chapter 2.

Cooling system - draining,

flushing and refillingÁ

Warning: Wait until the engine is

cold before starting this

procedure. Do not allow

antifreeze to come into contact

with your skin or painted surfaces of the

vehicle. Rinse off spills immediately with

plenty of water. Never leave antifreeze

lying around in an open container or in a

puddle in the driveway or on the garage

floor. Children and pets are attracted by its

sweet smell. Antifreeze is fatal if ingested.

5Disconnect the battery negative lead.

6Working inside the vehicle, turn the heater

temperature control knob fully to the right,

which will fully open the heater coolant valve.

7With the expansion tank cap removed,

place a suitable container beneath the

radiator bottom hose.

8Loosen the clip and ease the bottom hose

away from the radiator outlet (photo). Allow

the coolant to drain into the container.

9Reposition the container under the front of

the cylinder block, and unscrew the cylinder

block drain plug (photo). Allow the coolant to

drain into the container.

Supplement: Revisions and information on later models 13•55

8A.17B Tightening the coolant pump bolts8A.17A Fitting the coolant pump to the

999 cc engineFig. 13.28 Sectional view of the coolant

pump on the 999 and 1108 cc engines

(Sec 8A)

8C.9 Cylinder block drain plug8C.8 Bottom hose connection to the

radiator8B.4 Topping up the expansion tank with

antifreeze on the 1301 cc engine

13

Page 181 of 303

1 Electric fan

2 Radiator

3 Thermostat

4 Coolant supply hose (inlet

manifold to heater matrix)

5 Heater matrix6 Coolant return hose (heater

matrix to the manifold pipe)

7 Coolant pump

8 Coolant manifold pipe

9 Coolant supply hose (cylinder

block/crankcase to the

turbocharger)10 Coolant return hose

(turbocharger to the expansion

tank)

11 Coolant supply hose (expansion

tank to the manifold pipe)

12 Expansion tank13 Coolant return hose (radiator to

the manifold pipe)

14 Fan thermostatic switch

15 Coolant supply hose

(thermostat to the radiator)

16 Coolant return hose (radiator to

the expansion tank)

13•56 Supplement: Revisions and information on later models

Fig. 13.29 Cooling system circuit - 1372 cc ie engine (Sec 8C)

Fig. 13.30 Cooling system circuit - 1372 cc Turbo ie engine (Sec 8C)

1 Expansion tank

2 Radiator

3 Electric fan

4 Coolant supply hose (thermostat

to radiator)

5 Coolant manifold pipe

6 Coolant pump

7 Coolant supply hose (thermostat

to heater matrix)

8 Coolant return hose (heater

radiator to manifold pipe)

9 Heater matrix10 Coolant return hose (inlet manifold

to manifold pipe)

11 Coolant return hose (radiator to

manifold pipe)

12 Thermostat

13 Fan thermostatic switch

Page 183 of 303

35Clean the mating faces of the thermostat

cover and cylinder head, and use a new

gasket when refitting the cover.

36Refill the cooling system as described

earlier in this Section.

Coolant pump -

removal and refittingÁ

Note: A new coolant pump gasket must be

used on refitting. If the pump is found to be

worn it must be renewed as a complete unit as

dismantling and repair is not possible.

37Disconnect the battery negative lead.

38Drain the cooling system as described

earlier in this Section.

39Remove the coolant/alternator drivebelt

as described in the next sub-Section.

40Unscrew the four coolant pump securing

bolts, noting that two of the bolts also secure

the alternator adjuster bracket, and withdraw

the pump from the housing (photo). Recover

the gasket.

41Refitting is a reversal of removal, bearing

in mind the following points.

42Use a new gasket between the pump and

the housing.

43Refit and tension the coolant

pump/alternator drivebelt as described in the

next sub-Section.

44On completion, refill the cooling system

as described earlier in this Section.

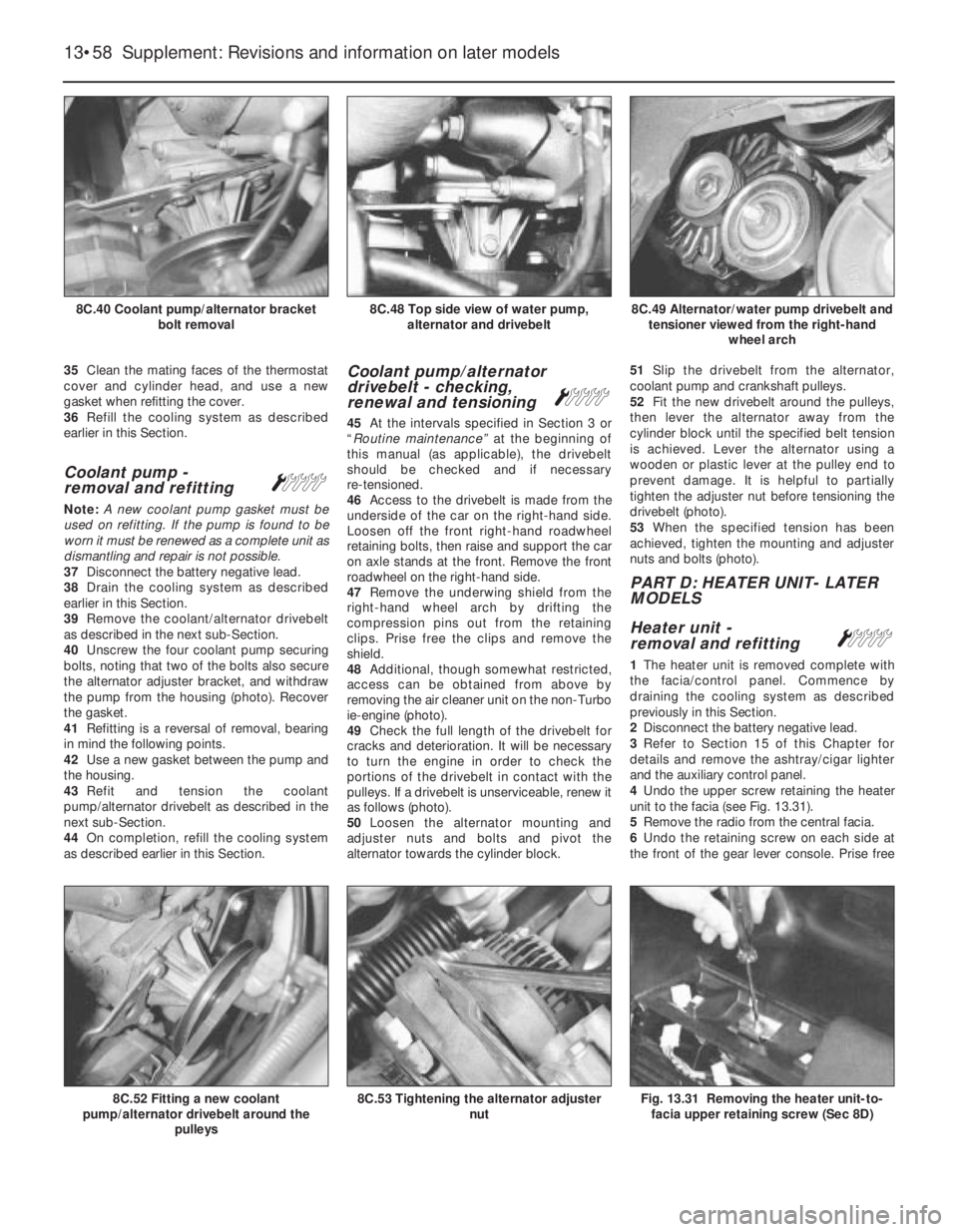

Coolant pump/alternator

drivebelt - checking,

renewal and tensioning

Á

45At the intervals specified in Section 3 or

“Routine maintenance” at the beginning of

this manual (as applicable), the drivebelt

should be checked and if necessary

re-tensioned.

46Access to the drivebelt is made from the

underside of the car on the right-hand side.

Loosen off the front right-hand roadwheel

retaining bolts, then raise and support the car

on axle stands at the front. Remove the front

roadwheel on the right-hand side.

47Remove the underwing shield from the

right-hand wheel arch by drifting the

compression pins out from the retaining

clips. Prise free the clips and remove the

shield.

48Additional, though somewhat restricted,

access can be obtained from above by

removing the air cleaner unit on the non-Turbo

ie-engine (photo).

49Check the full length of the drivebelt for

cracks and deterioration. It will be necessary

to turn the engine in order to check the

portions of the drivebelt in contact with the

pulleys. If a drivebelt is unserviceable, renew it

as follows (photo).

50Loosen the alternator mounting and

adjuster nuts and bolts and pivot the

alternator towards the cylinder block.51Slip the drivebelt from the alternator,

coolant pump and crankshaft pulleys.

52Fit the new drivebelt around the pulleys,

then lever the alternator away from the

cylinder block until the specified belt tension

is achieved. Lever the alternator using a

wooden or plastic lever at the pulley end to

prevent damage. It is helpful to partially

tighten the adjuster nut before tensioning the

drivebelt (photo).

53When the specified tension has been

achieved, tighten the mounting and adjuster

nuts and bolts (photo).

PART D: HEATER UNIT- LATER

MODELS

Heater unit -

removal and refitting

Á

1The heater unit is removed complete with

the facia/control panel. Commence by

draining the cooling system as described

previously in this Section.

2Disconnect the battery negative lead.

3Refer to Section 15 of this Chapter for

details and remove the ashtray/cigar lighter

and the auxiliary control panel.

4Undo the upper screw retaining the heater

unit to the facia (see Fig. 13.31).

5Remove the radio from the central facia.

6Undo the retaining screw on each side at

the front of the gear lever console. Prise free

13•58 Supplement: Revisions and information on later models

Fig. 13.31 Removing the heater unit-to-

facia upper retaining screw (Sec 8D)8C.53 Tightening the alternator adjuster

nut8C.52 Fitting a new coolant

pump/alternator drivebelt around the

pulleys

8C.49 Alternator/water pump drivebelt and

tensioner viewed from the right-hand

wheel arch8C.48 Top side view of water pump,

alternator and drivebelt8C.40 Coolant pump/alternator bracket

bolt removal

Page 184 of 303

the trim cover, undo the retaining screw at the

rear of the console. Prise free and release the

gear lever gaiter and lift clear the central

console.

7Undo the retaining screws and remove the

steering column upper and lower shroud.

8Detach and remove the lower facia trim on

the side of the central facia.

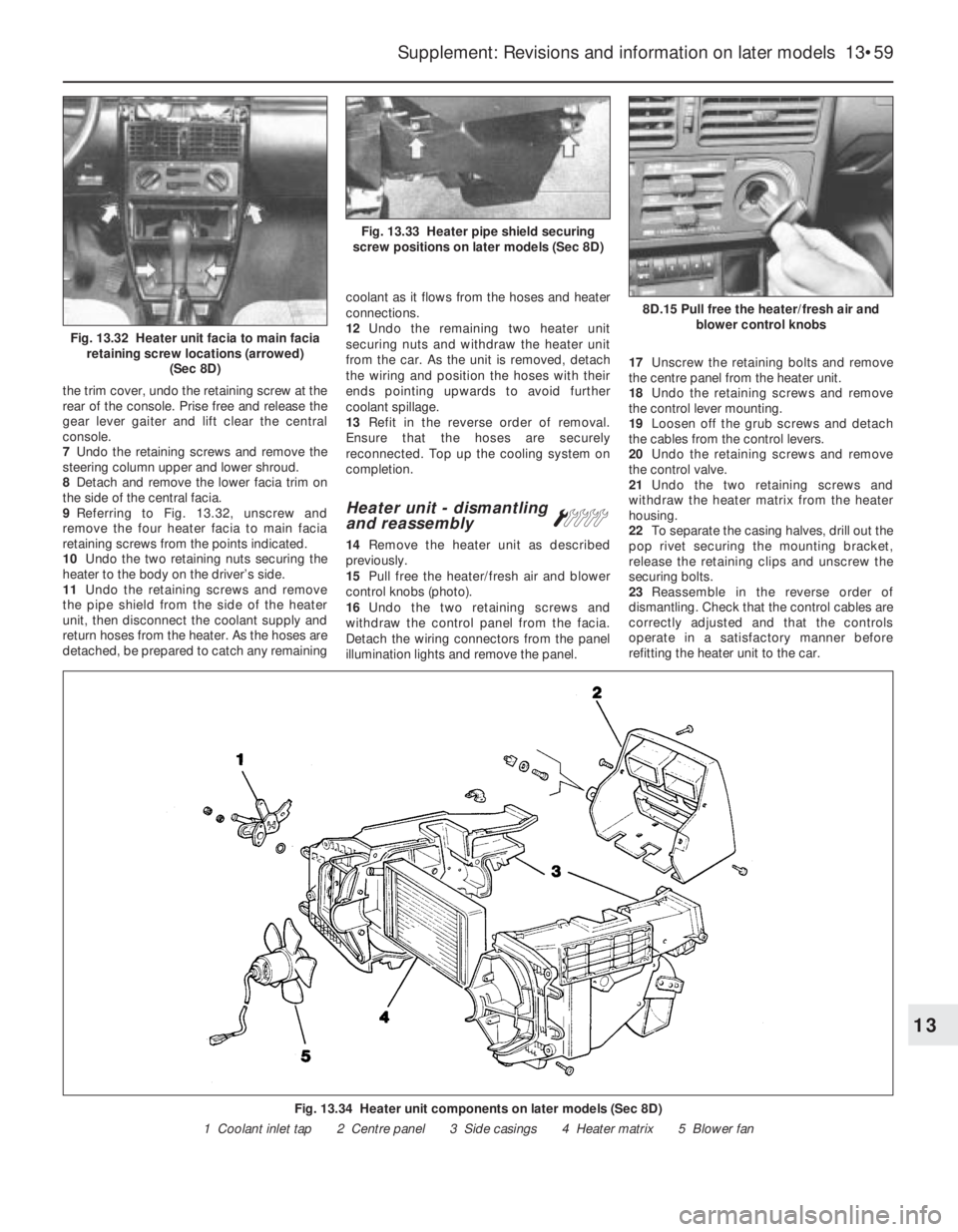

9Referring to Fig. 13.32, unscrew and

remove the four heater facia to main facia

retaining screws from the points indicated.

10Undo the two retaining nuts securing the

heater to the body on the driver’s side.

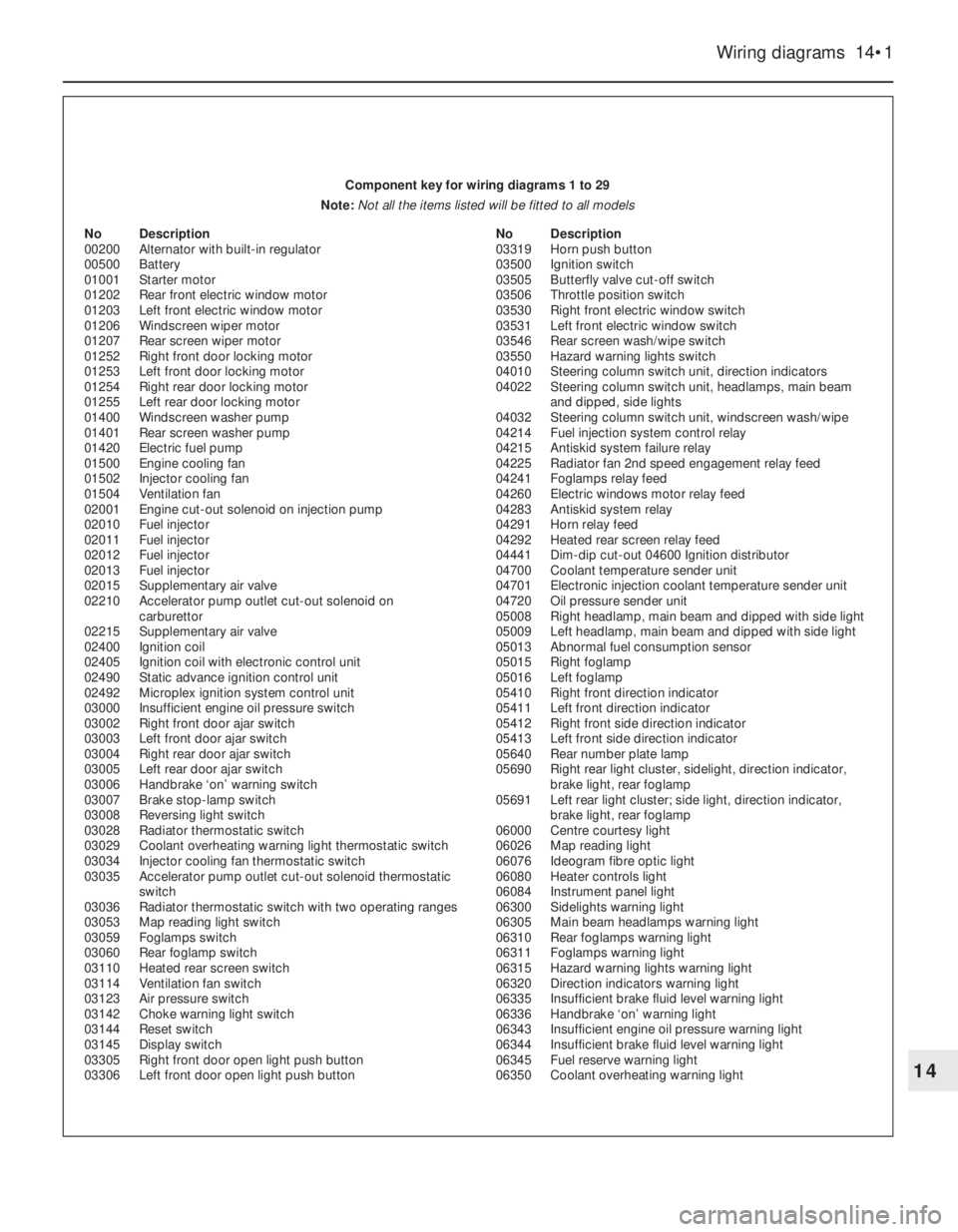

11Undo the retaining screws and remove

the pipe shield from the side of the heater

unit, then disconnect the coolant supply and

return hoses from the heater. As the hoses are

detached, be prepared to catch any remainingcoolant as it flows from the hoses and heater

connections.

12Undo the remaining two heater unit

securing nuts and withdraw the heater unit

from the car. As the unit is removed, detach

the wiring and position the hoses with their

ends pointing upwards to avoid further

coolant spillage.

13Refit in the reverse order of removal.

Ensure that the hoses are securely

reconnected. Top up the cooling system on

completion.

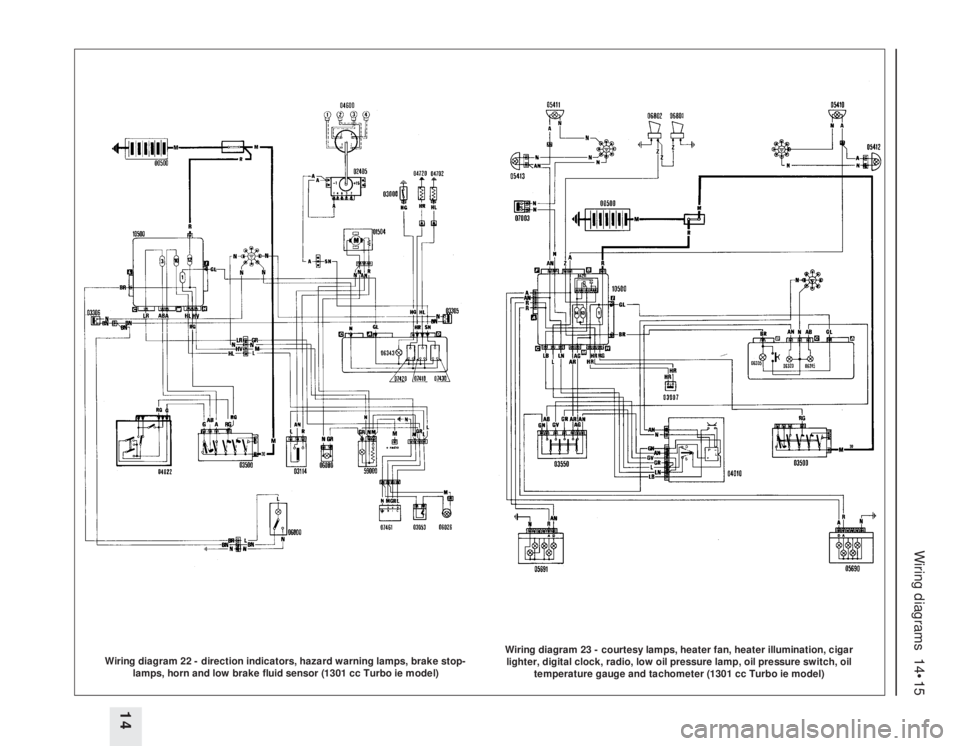

Heater unit - dismantling

and reassemblyÁ

14Remove the heater unit as described

previously.

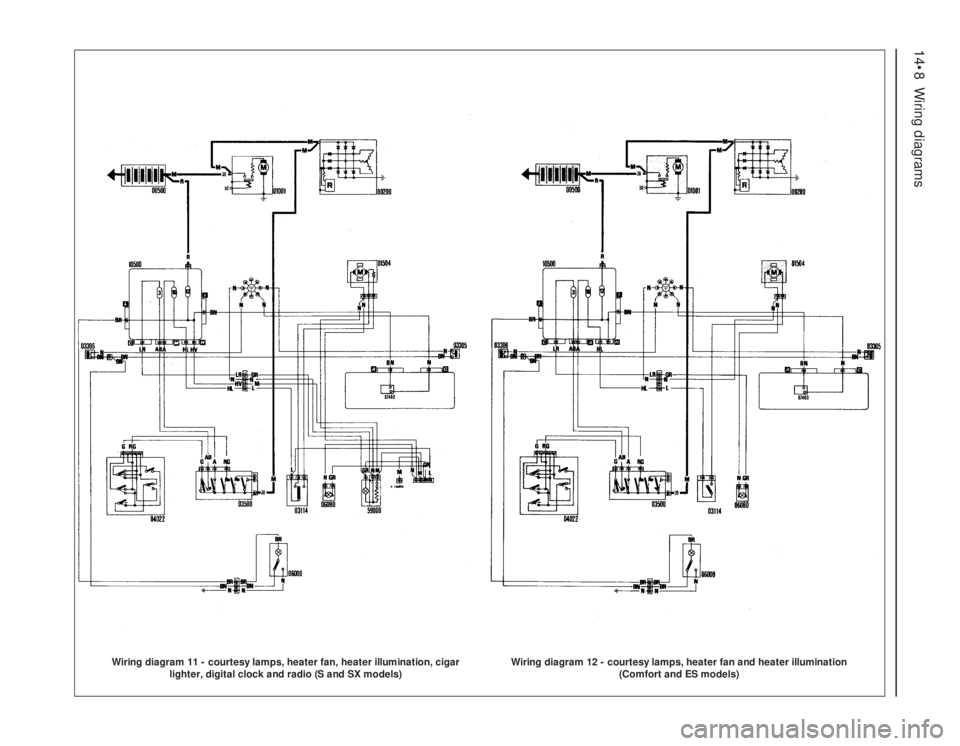

15Pull free the heater/fresh air and blower

control knobs (photo).

16Undo the two retaining screws and

withdraw the control panel from the facia.

Detach the wiring connectors from the panel

illumination lights and remove the panel.17Unscrew the retaining bolts and remove

the centre panel from the heater unit.

18Undo the retaining screws and remove

the control lever mounting.

19Loosen off the grub screws and detach

the cables from the control levers.

20Undo the retaining screws and remove

the control valve.

21Undo the two retaining screws and

withdraw the heater matrix from the heater

housing.

22To separate the casing halves, drill out the

pop rivet securing the mounting bracket,

release the retaining clips and unscrew the

securing bolts.

23Reassemble in the reverse order of

dismantling. Check that the control cables are

correctly adjusted and that the controls

operate in a satisfactory manner before

refitting the heater unit to the car.

Supplement: Revisions and information on later models 13•59

8D.15 Pull free the heater/fresh air and

blower control knobs

Fig. 13.33 Heater pipe shield securing

screw positions on later models (Sec 8D)

Fig. 13.32 Heater unit facia to main facia

retaining screw locations (arrowed)

(Sec 8D)

Fig. 13.34 Heater unit components on later models (Sec 8D)

1 Coolant inlet tap 2 Centre panel 3 Side casings 4 Heater matrix 5 Blower fan

13

Page 233 of 303

Auxiliary control panel

(later models) -

removal and refitting

Á

61Disconnect the battery negative lead.

62Insert the flat of a screwdriver under the

trim piece at the end of the auxiliary panel as

shown and prise it free. Repeat the procedure

and remove the trim piece at the other end of

the panel (photo).

63Undo the retaining screws, withdraw the

panel from the facia. Disconnect the wiring

connectors from the panel switches to

remove the panel completely (photo).

64A switch bulb can be renewed by

untwisting the holder and removing the holder

and bulb.

65A switch unit can be removed from the

panel by unscrewing the four retaining screws.66Refitting is a reversal of the removal

procedure. Ensure that the wiring connections

are securely made and check for satisfactory

operation of the switches on completion.

Heater control panel

(later models) -

removal and refitting

Á

67Disconnect the battery negative lead.

68Pull free the heater/fresh air and blower

control knobs (photo).

69Undo the two retaining screws and

withdraw the control panel from the facia

(photos). Detach the wiring connectors from the

panel illumination lights and remove the panel.

70Refitting is a reversal of the removal

procedure. Ensure that the wiring connections

are securely made and on completion check

that the operation of the controls is satisfactory.

Trip master Á

71This electronic instrument is fitted into the

check panel of 1100SL and 1300SL models

from 1986.

72The device provides information on fuel

consumption, range, speed and elapsed time.

73With the ignition key turned to MAR,

figures are displayed in respect of the last

journey - average fuel consumption, average

speed and elapsed time (up to switching off

the ignition).

74As soon as the engine is started, the

instrument processes the current values to

include fuel consumption, range and the

actual time. 75Fuel consumption is only displayed when

the road speed exceeds 8.0 km/h (5.0 mph).

76The fuel range is only displayed after a

road speed of between 25.0 and 70.0 km/h

(15.0 to 44.0 mph) has been maintained for at

least 90 seconds or at higher speeds for

22 seconds.

77A reset button is provided, also a display

change button (from instant to average or

total values). Should the instrument reading

exceed 99 hours, 59 minutes or 1000 km

(622 miles) depressing the display change

button will display all zeros. Depress button E

to resume normal function.

78Refer to the end of the manual for a wiring

diagram of the check panel, incorporating the

trip master.

Interior roof mounted spotlamp,

switch and/or clock -

removal and refitting

Á

79Disconnect the battery negative lead.

80Prise free the lamp unit from its aperture

in the roof panel using a thin-bladed

screwdriver. The lamp bulb can be inspected

by untwisting the holder and withdrawing it

from the rear of the unit (photos). Extract the

bulb from the holder if it requires renewal.

81To remove the lamp switch from the

panel, reach through the lamp aperture and

press it free from the roof panel (photo).

Detach the wiring connectors.

82To remove the clock, reach through the

lamp aperture and undo the retaining screws

(photo). Withdraw the clock and detach the

wiring connectors.

13•108 Supplement: Revisions and information on later models

15.69B . . . and withdraw the heater control

panel15.69A . . . undo the retaining screws

(arrowed)15.68 Remove the control knobs . . .

15.63 . . . and withdraw the auxiliary

control panel

15.62 Prise free the trim covers for access

to retaining screws . . .15.59B . . . and disconnect the

speedometer cable15.59A . . . withdraw the instrument

panel . . .

Page 240 of 303

Wiring diagrams 14•1

14

Component key for wiring diagrams 1 to 29

Note: Not all the items listed will be fitted to all models

No Description

00200 Alternator with built-in regulator

00500 Battery

01001 Starter motor

01202 Rear front electric window motor

01203 Left front electric window motor

01206 Windscreen wiper motor

01207 Rear screen wiper motor

01252 Right front door locking motor

01253 Left front door locking motor

01254 Right rear door locking motor

01255 Left rear door locking motor

01400 Windscreen washer pump

01401 Rear screen washer pump

01420 Electric fuel pump

01500 Engine cooling fan

01502 Injector cooling fan

01504 Ventilation fan

02001 Engine cut-out solenoid on injection pump

02010 Fuel injector

02011 Fuel injector

02012 Fuel injector

02013 Fuel injector

02015 Supplementary air valve

02210 Accelerator pump outlet cut-out solenoid on

carburettor

02215 Supplementary air valve

02400 Ignition coil

02405 Ignition coil with electronic control unit

02490 Static advance ignition control unit

02492 Microplex ignition system control unit

03000 Insufficient engine oil pressure switch

03002 Right front door ajar switch

03003 Left front door ajar switch

03004 Right rear door ajar switch

03005 Left rear door ajar switch

03006 Handbrake ‘on’ warning switch

03007 Brake stop-lamp switch

03008 Reversing light switch

03028 Radiator thermostatic switch

03029 Coolant overheating warning light thermostatic switch

03034 Injector cooling fan thermostatic switch

03035 Accelerator pump outlet cut-out solenoid thermostatic

switch

03036 Radiator thermostatic switch with two operating ranges

03053 Map reading light switch

03059 Foglamps switch

03060 Rear foglamp switch

03110 Heated rear screen switch

03114 Ventilation fan switch

03123 Air pressure switch

03142 Choke warning light switch

03144 Reset switch

03145 Display switch

03305 Right front door open light push button

03306 Left front door open light push button No Description

03319 Horn push button

03500 Ignition switch

03505 Butterfly valve cut-off switch

03506 Throttle position switch

03530 Right front electric window switch

03531 Left front electric window switch

03546 Rear screen wash/wipe switch

03550 Hazard warning lights switch

04010 Steering column switch unit, direction indicators

04022 Steering column switch unit, headlamps, main beam

and dipped, side lights

04032 Steering column switch unit, windscreen wash/wipe

04214 Fuel injection system control relay

04215 Antiskid system failure relay

04225 Radiator fan 2nd speed engagement relay feed

04241 Foglamps relay feed

04260 Electric windows motor relay feed

04283 Antiskid system relay

04291 Horn relay feed

04292 Heated rear screen relay feed

04441 Dim-dip cut-out 04600 Ignition distributor

04700 Coolant temperature sender unit

04701 Electronic injection coolant temperature sender unit

04720 Oil pressure sender unit

05008 Right headlamp, main beam and dipped with side light

05009 Left headlamp, main beam and dipped with side light

05013 Abnormal fuel consumption sensor

05015 Right foglamp

05016 Left foglamp

05410 Right front direction indicator

05411 Left front direction indicator

05412 Right front side direction indicator

05413 Left front side direction indicator

05640 Rear number plate lamp

05690 Right rear light cluster, sidelight, direction indicator,

brake light, rear foglamp

05691 Left rear light cluster; side light, direction indicator,

brake light, rear foglamp

06000 Centre courtesy light

06026 Map reading light

06076 Ideogram fibre optic light

06080 Heater controls light

06084 Instrument panel light

06300 Sidelights warning light

06305 Main beam headlamps warning light

06310 Rear foglamps warning light

06311 Foglamps warning light

06315 Hazard warning lights warning light

06320 Direction indicators warning light

06335 Insufficient brake fluid level warning light

06336 Handbrake ‘on’ warning light

06343 Insufficient engine oil pressure warning light

06344 Insufficient brake fluid level warning light

06345 Fuel reserve warning light

06350 Coolant overheating warning light

Page 247 of 303

14•8 Wiring diagrams

Wiring diagram 11 - courtesy lamps, heater fan, heater illumination, cigar

lighter, digital clock and radio (S and SX models)

Wiring diagram 12 - courtesy lamps, heater fan and heater illumination

(Comfort and ES models)

Page 254 of 303

Wiring diagrams 14•15

14

Wiring diagram 22 - direction indicators, hazard warning lamps, brake stop-

lamps, horn and low brake fluid sensor (1301 cc Turbo ie model)

Wiring diagram 23 - courtesy lamps, heater fan, heater illumination, cigar

lighter, digital clock, radio, low oil pressure lamp, oil pressure switch, oil

temperature gauge and tachometer (1301 cc Turbo ie model)

Page 259 of 303

14•20 Wiring diagrams

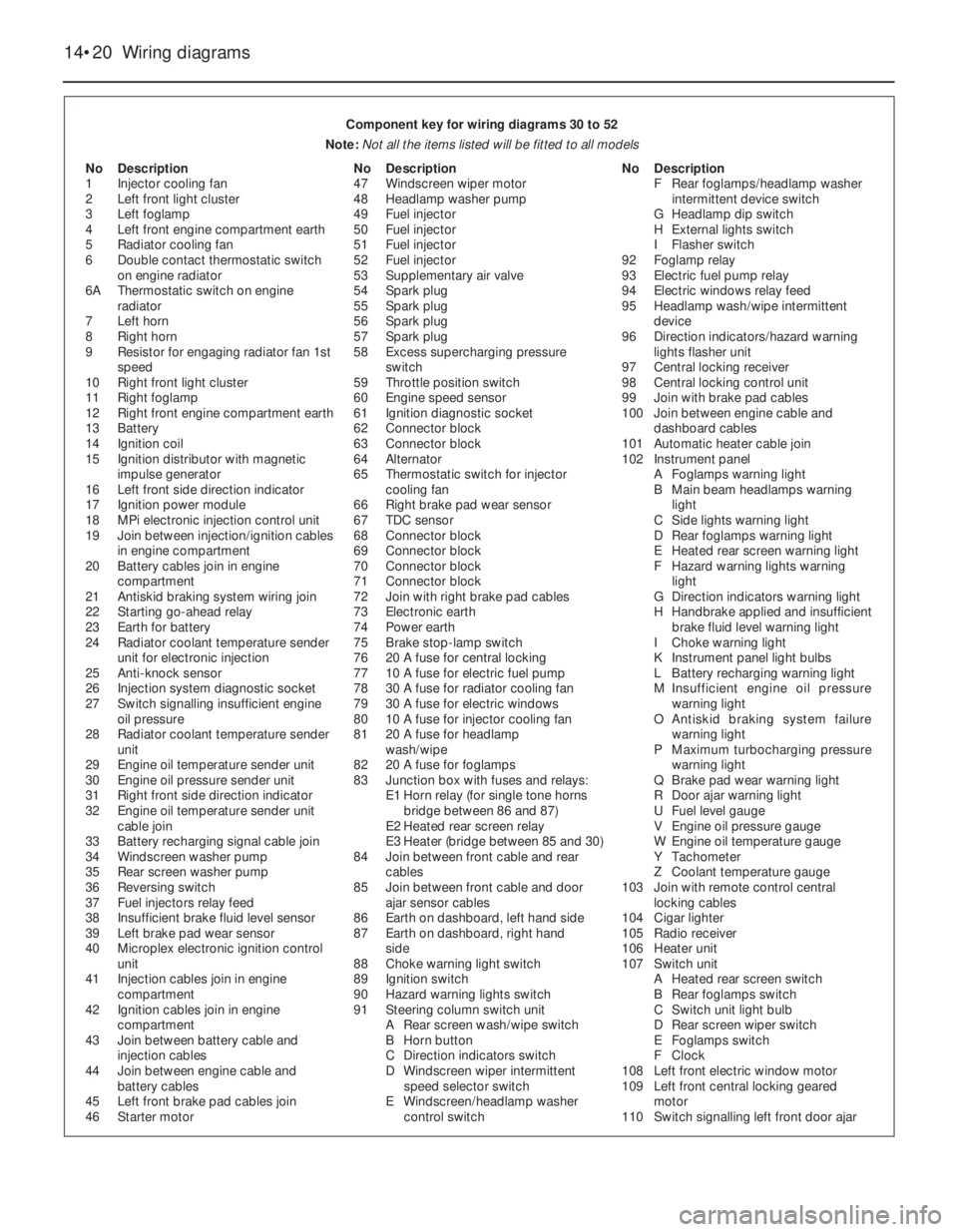

Component key for wiring diagrams 30 to 52

Note: Not all the items listed will be fitted to all models

No Description

1 Injector cooling fan

2 Left front light cluster

3 Left foglamp

4 Left front engine compartment earth

5 Radiator cooling fan

6 Double contact thermostatic switch

on engine radiator

6A Thermostatic switch on engine

radiator

7 Left horn

8 Right horn

9 Resistor for engaging radiator fan 1st

speed

10 Right front light cluster

11 Right foglamp

12 Right front engine compartment earth

13 Battery

14 Ignition coil

15 Ignition distributor with magnetic

impulse generator

16 Left front side direction indicator

17 Ignition power module

18 MPi electronic injection control unit

19 Join between injection/ignition cables

in engine compartment

20 Battery cables join in engine

compartment

21 Antiskid braking system wiring join

22 Starting go-ahead relay

23 Earth for battery

24 Radiator coolant temperature sender

unit for electronic injection

25 Anti-knock sensor

26 Injection system diagnostic socket

27 Switch signalling insufficient engine

oil pressure

28 Radiator coolant temperature sender

unit

29 Engine oil temperature sender unit

30 Engine oil pressure sender unit

31 Right front side direction indicator

32 Engine oil temperature sender unit

cable join

33 Battery recharging signal cable join

34 Windscreen washer pump

35 Rear screen washer pump

36 Reversing switch

37 Fuel injectors relay feed

38 Insufficient brake fluid level sensor

39 Left brake pad wear sensor

40 Microplex electronic ignition control

unit

41 Injection cables join in engine

compartment

42 Ignition cables join in engine

compartment

43 Join between battery cable and

injection cables

44 Join between engine cable and

battery cables

45 Left front brake pad cables join

46 Starter motorNo Description

47 Windscreen wiper motor

48 Headlamp washer pump

49 Fuel injector

50 Fuel injector

51 Fuel injector

52 Fuel injector

53 Supplementary air valve

54 Spark plug

55 Spark plug

56 Spark plug

57 Spark plug

58 Excess supercharging pressure

switch

59 Throttle position switch

60 Engine speed sensor

61 Ignition diagnostic socket

62 Connector block

63 Connector block

64 Alternator

65 Thermostatic switch for injector

cooling fan

66 Right brake pad wear sensor

67 TDC sensor

68 Connector block

69 Connector block

70 Connector block

71 Connector block

72 Join with right brake pad cables

73 Electronic earth

74 Power earth

75 Brake stop-lamp switch

76 20 A fuse for central locking

77 10 A fuse for electric fuel pump

78 30 A fuse for radiator cooling fan

79 30 A fuse for electric windows

80 10 A fuse for injector cooling fan

81 20 A fuse for headlamp

wash/wipe

82 20 A fuse for foglamps

83 Junction box with fuses and relays:

E1 Horn relay (for single tone horns

bridge between 86 and 87)

E2 Heated rear screen relay

E3 Heater (bridge between 85 and 30)

84 Join between front cable and rear

cables

85 Join between front cable and door

ajar sensor cables

86 Earth on dashboard, left hand side

87 Earth on dashboard, right hand

side

88 Choke warning light switch

89 Ignition switch

90 Hazard warning lights switch

91 Steering column switch unit

A Rear screen wash/wipe switch

B Horn button

C Direction indicators switch

D Windscreen wiper intermittent

speed selector switch

E Windscreen/headlamp washer

control switchNo Description

F Rear foglamps/headlamp washer

intermittent device switch

G Headlamp dip switch

H External lights switch

I Flasher switch

92 Foglamp relay

93 Electric fuel pump relay

94 Electric windows relay feed

95 Headlamp wash/wipe intermittent

device

96 Direction indicators/hazard warning

lights flasher unit

97 Central locking receiver

98 Central locking control unit

99 Join with brake pad cables

100 Join between engine cable and

dashboard cables

101 Automatic heater cable join

102 Instrument panel

A Foglamps warning light

B Main beam headlamps warning

light

C Side lights warning light

D Rear foglamps warning light

E Heated rear screen warning light

F Hazard warning lights warning

light

G Direction indicators warning light

H Handbrake applied and insufficient

brake fluid level warning light

I Choke warning light

K Instrument panel light bulbs

L Battery recharging warning light

M Insufficient engine oil pressure

warning light

O Antiskid braking system failure

warning light

P Maximum turbocharging pressure

warning light

Q Brake pad wear warning light

R Door ajar warning light

U Fuel level gauge

V Engine oil pressure gauge

W Engine oil temperature gauge

Y Tachometer

Z Coolant temperature gauge

103 Join with remote control central

locking cables

104 Cigar lighter

105 Radio receiver

106 Heater unit

107 Switch unit

A Heated rear screen switch

B Rear foglamps switch

C Switch unit light bulb

D Rear screen wiper switch

E Foglamps switch

F Clock

108 Left front electric window motor

109 Left front central locking geared

motor

110 Switch signalling left front door ajar