engine coolant FIAT UNO 1983 Service Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 183 of 303

35Clean the mating faces of the thermostat

cover and cylinder head, and use a new

gasket when refitting the cover.

36Refill the cooling system as described

earlier in this Section.

Coolant pump -

removal and refittingÁ

Note: A new coolant pump gasket must be

used on refitting. If the pump is found to be

worn it must be renewed as a complete unit as

dismantling and repair is not possible.

37Disconnect the battery negative lead.

38Drain the cooling system as described

earlier in this Section.

39Remove the coolant/alternator drivebelt

as described in the next sub-Section.

40Unscrew the four coolant pump securing

bolts, noting that two of the bolts also secure

the alternator adjuster bracket, and withdraw

the pump from the housing (photo). Recover

the gasket.

41Refitting is a reversal of removal, bearing

in mind the following points.

42Use a new gasket between the pump and

the housing.

43Refit and tension the coolant

pump/alternator drivebelt as described in the

next sub-Section.

44On completion, refill the cooling system

as described earlier in this Section.

Coolant pump/alternator

drivebelt - checking,

renewal and tensioning

Á

45At the intervals specified in Section 3 or

“Routine maintenance” at the beginning of

this manual (as applicable), the drivebelt

should be checked and if necessary

re-tensioned.

46Access to the drivebelt is made from the

underside of the car on the right-hand side.

Loosen off the front right-hand roadwheel

retaining bolts, then raise and support the car

on axle stands at the front. Remove the front

roadwheel on the right-hand side.

47Remove the underwing shield from the

right-hand wheel arch by drifting the

compression pins out from the retaining

clips. Prise free the clips and remove the

shield.

48Additional, though somewhat restricted,

access can be obtained from above by

removing the air cleaner unit on the non-Turbo

ie-engine (photo).

49Check the full length of the drivebelt for

cracks and deterioration. It will be necessary

to turn the engine in order to check the

portions of the drivebelt in contact with the

pulleys. If a drivebelt is unserviceable, renew it

as follows (photo).

50Loosen the alternator mounting and

adjuster nuts and bolts and pivot the

alternator towards the cylinder block.51Slip the drivebelt from the alternator,

coolant pump and crankshaft pulleys.

52Fit the new drivebelt around the pulleys,

then lever the alternator away from the

cylinder block until the specified belt tension

is achieved. Lever the alternator using a

wooden or plastic lever at the pulley end to

prevent damage. It is helpful to partially

tighten the adjuster nut before tensioning the

drivebelt (photo).

53When the specified tension has been

achieved, tighten the mounting and adjuster

nuts and bolts (photo).

PART D: HEATER UNIT- LATER

MODELS

Heater unit -

removal and refitting

Á

1The heater unit is removed complete with

the facia/control panel. Commence by

draining the cooling system as described

previously in this Section.

2Disconnect the battery negative lead.

3Refer to Section 15 of this Chapter for

details and remove the ashtray/cigar lighter

and the auxiliary control panel.

4Undo the upper screw retaining the heater

unit to the facia (see Fig. 13.31).

5Remove the radio from the central facia.

6Undo the retaining screw on each side at

the front of the gear lever console. Prise free

13•58 Supplement: Revisions and information on later models

Fig. 13.31 Removing the heater unit-to-

facia upper retaining screw (Sec 8D)8C.53 Tightening the alternator adjuster

nut8C.52 Fitting a new coolant

pump/alternator drivebelt around the

pulleys

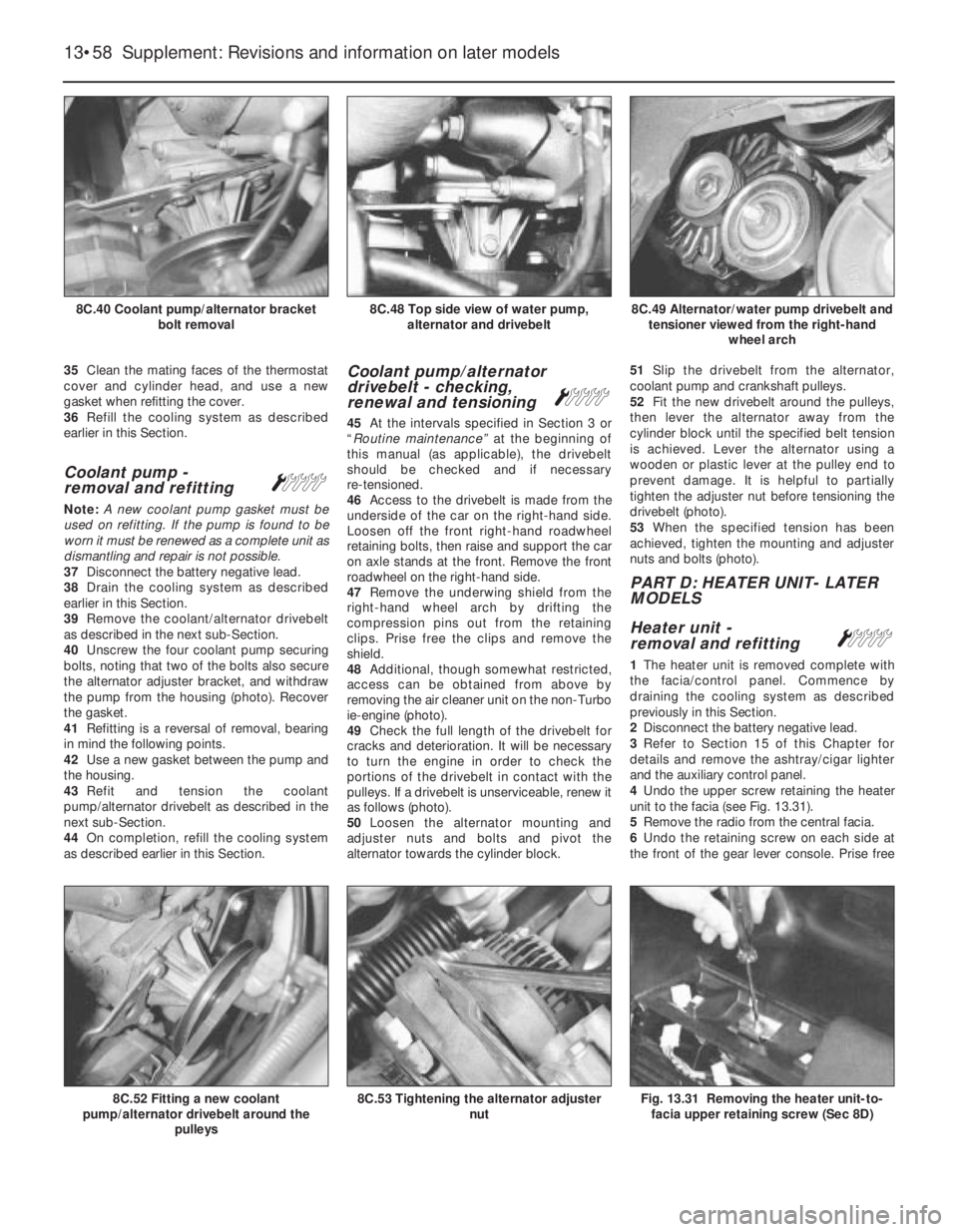

8C.49 Alternator/water pump drivebelt and

tensioner viewed from the right-hand

wheel arch8C.48 Top side view of water pump,

alternator and drivebelt8C.40 Coolant pump/alternator bracket

bolt removal

Page 187 of 303

PART B:

CARBURETTOR MODELS

Carburettor (Weber 32 TLF) -

description

Warning: Refer to the beginning

of this Section before starting

any work.

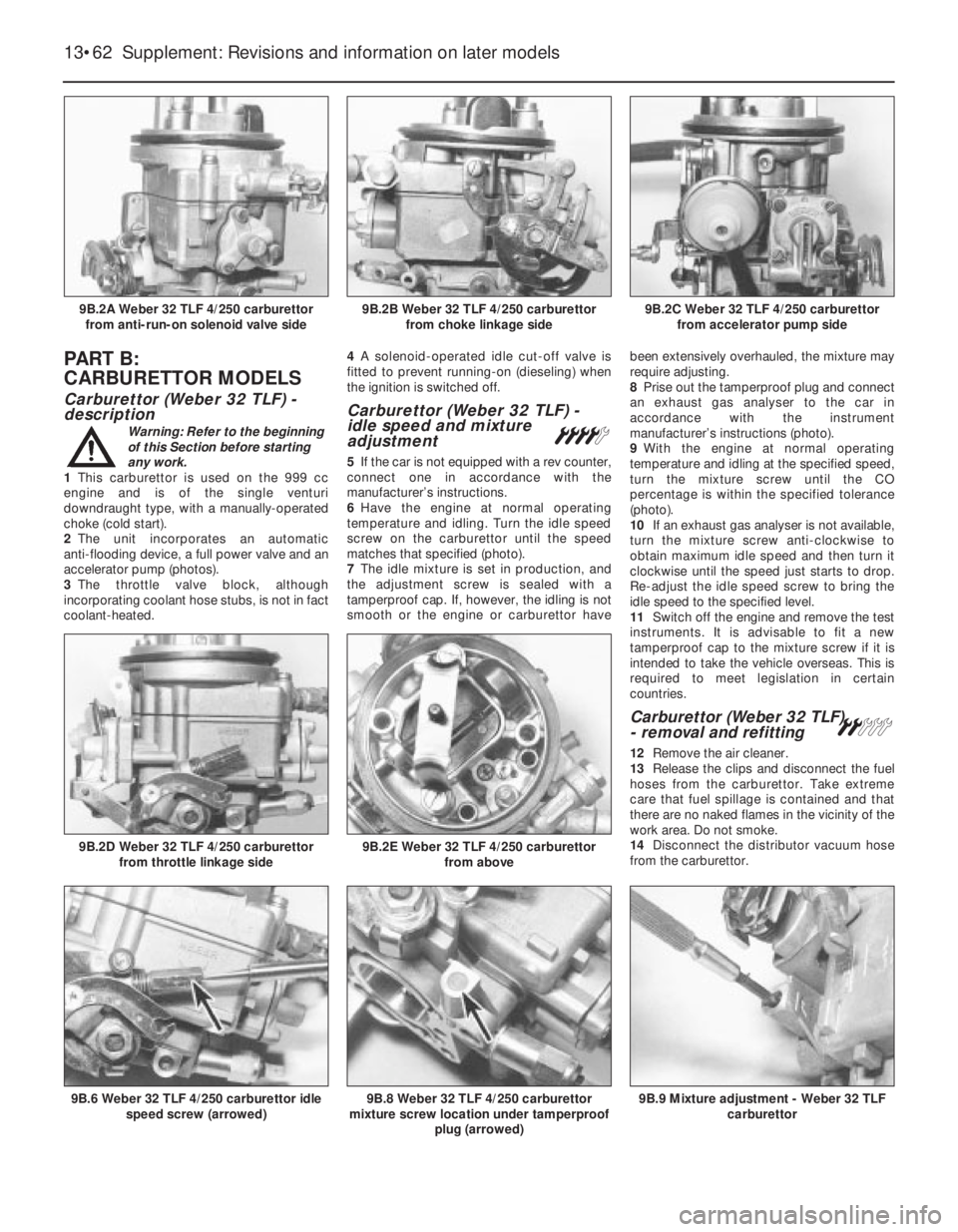

1This carburettor is used on the 999 cc

engine and is of the single venturi

downdraught type, with a manually-operated

choke (cold start).

2The unit incorporates an automatic

anti-flooding device, a full power valve and an

accelerator pump (photos).

3The throttle valve block, although

incorporating coolant hose stubs, is not in fact

coolant-heated.4A solenoid-operated idle cut-off valve is

fitted to prevent running-on (dieseling) when

the ignition is switched off.

Carburettor (Weber 32 TLF) -

idle speed and mixture

adjustment

¢

5If the car is not equipped with a rev counter,

connect one in accordance with the

manufacturer’s instructions.

6Have the engine at normal operating

temperature and idling. Turn the idle speed

screw on the carburettor until the speed

matches that specified (photo).

7The idle mixture is set in production, and

the adjustment screw is sealed with a

tamperproof cap. If, however, the idling is not

smooth or the engine or carburettor havebeen extensively overhauled, the mixture may

require adjusting.

8Prise out the tamperproof plug and connect

an exhaust gas analyser to the car in

accordance with the instrument

manufacturer’s instructions (photo).

9With the engine at normal operating

temperature and idling at the specified speed,

turn the mixture screw until the CO

percentage is within the specified tolerance

(photo).

10If an exhaust gas analyser is not available,

turn the mixture screw anti-clockwise to

obtain maximum idle speed and then turn it

clockwise until the speed just starts to drop.

Re-adjust the idle speed screw to bring the

idle speed to the specified level.

11Switch off the engine and remove the test

instruments. It is advisable to fit a new

tamperproof cap to the mixture screw if it is

intended to take the vehicle overseas. This is

required to meet legislation in certain

countries.

Carburettor (Weber 32 TLF)

- removal and refitting ª

12Remove the air cleaner.

13Release the clips and disconnect the fuel

hoses from the carburettor. Take extreme

care that fuel spillage is contained and that

there are no naked flames in the vicinity of the

work area. Do not smoke.

14Disconnect the distributor vacuum hose

from the carburettor.

13•62 Supplement: Revisions and information on later models

9B.9 Mixture adjustment - Weber 32 TLF

carburettor9B.8 Weber 32 TLF 4/250 carburettor

mixture screw location under tamperproof

plug (arrowed)9B.6 Weber 32 TLF 4/250 carburettor idle

speed screw (arrowed)

9B.2E Weber 32 TLF 4/250 carburettor

from above9B.2D Weber 32 TLF 4/250 carburettor

from throttle linkage side

9B.2C Weber 32 TLF 4/250 carburettor

from accelerator pump side9B.2B Weber 32 TLF 4/250 carburettor

from choke linkage side9B.2A Weber 32 TLF 4/250 carburettor

from anti-run-on solenoid valve side

Page 191 of 303

adjustments described in this sub-Section,

however, will require removal of the

carburettor.

39Disconnect the short, curved diaphragm

hose from the top cover.

40Extract the top cover screws, lift the cover

from the carburettor body, and rotate it in

order to release the cranked choke control

rod from its key hole (photo). Mop out the fuel

and clean the jets.

41Check the jet sizes and other components

against those listed in the Specifications, in

case a previous owner has substituted

incorrect components (photo).

42Overhaul procedures are generally as

given in Chapter 3, Section 14 for the Weber

30/32 DMTR, but use the Specifications listed

in this Chapter. Additional overhaul

procedures are given here.

Fuel inlet needle valve

43If a high float level causing flooding of the

carburettor has been evident, first check that

the inlet valve housing is tight, and its washer

is sealing satisfactorily. A leak here will cause

fuel to bypass the inlet valve.

44If the needle valve is to be renewed,

remove it in the following way.

45Access to the fuel inlet needle valve is

obtained by carefully tapping out the float arm

pivot pin. Take care, the pivot pin pillars are

very brittle (photo).

46Unscrew the fuel inlet valve body and

remove the valve and washer.47When refitting the new valve, always use a

new sealing washer.

Float stroke (travel) - see Fig. 3.10

48The float stroke should be between 42.5

and 43.5 mm when measured from the top

cover gasket. Adjust if necessary by bending

the tab on the end of the arm.

Accelerator pump

49Adjustment of the accelerator pump is

very rarely required, but if performance is

suspect, carry out the following operations.

50Fill the carburettor float chamber and then

operate the throttle valve plate lever several

times to prime the pump.

51Position a test tube under the accelerator

pump jet and give ten full strokes of the

throttle lever, pausing between each stroke to

allow fuel to finish dripping.

52The total volume of fuel collected should

be as specified. Adjust the nut on the pump

control if necessary to increase or decrease

the volume of fuel ejected.

General

53When the stage is reached where the

valve plate spindle bushes have worn, then

the carburettor should be renewed complete.

54When reassembling the carburettor, use

new gaskets which can be obtained in a repair

pack.

Carburettor (Weber 32 ICEV

61/250 and DMTE 30/32,

DMTE 30/150) - general

55These carburettor types are fitted to later

models according to engine type. They are

similar in structure and operation to their

equivalents described in Chapter 3. Reference

can therefore be made to that Chapter for the

description and any operations concerning

them, but refer to Section 2 of this Chapter for

their specifications.

Carburettor (Solex

C 30/32-CIC 8) - description

56This carburettor is fitted as an alternative

to the Weber unit on 1116 cc models

produced for certain markets. The removal,

refitting and overhaul procedures are

essentially the same as described earlier for

the Weber carburettors.

PART C:

BOSCH LE2-JETRONIC

FUEL INJECTION SYSTEM

Description

Warning: Refer to the beginning

of this Section before starting

any work.

1The Bosch LE2-Jetronic fuel injection

system, fitted to the 1301 cc Turbo ie model,

is an electronically controlled multi-point

injection (MPi) system.

2The fuel injectors are fed at constant

pressure in relation to inlet manifold vacuum

pressure.

3The system electronic control unit (ECU)

actuates the injectors for variable duration,

and so supplies the precise volume of fuel

required for any given engine speed and load

condition.

4The ECU also monitors the air induction, air

temperature, coolant temperature and throttle

opening as additional parameters to compute

the required opening of the fuel injectors,

giving maximum power with fuel economy.

Fuel supply system

5The fuel supply system consists of an

electric pump and primary filter, located

adjacent to the fuel tank. A fuel pressure peak

damper is located next to the pump (photo).

6Fuel is then pumped through a filter to the

fuel rail and injectors. The injectors are of the

13•66 Supplement: Revisions and information on later models

9C.5 Electric fuel pump/filter/pressure

damper assembly location on a 1301 cc

Turbo ie model

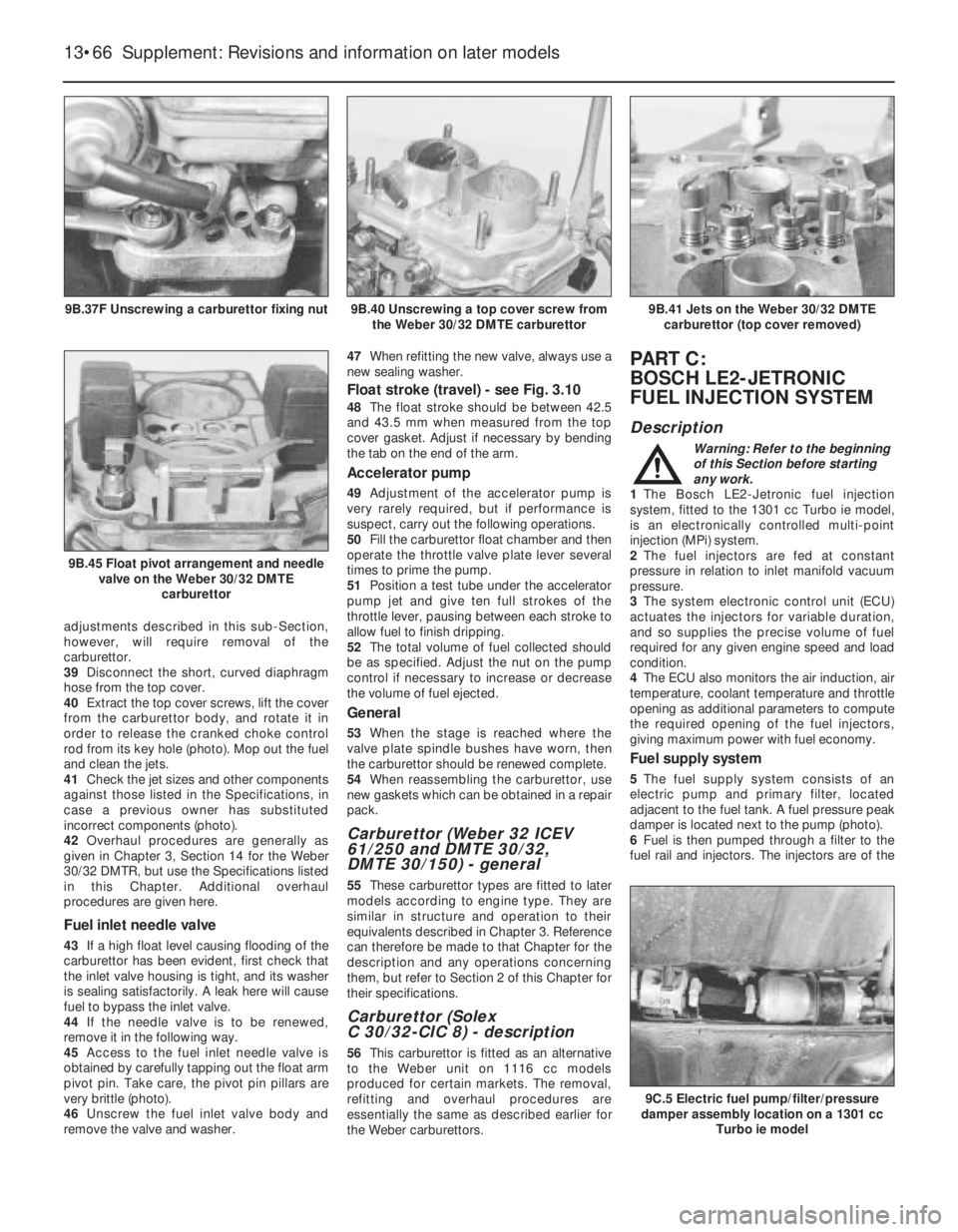

9B.41 Jets on the Weber 30/32 DMTE

carburettor (top cover removed)

9B.45 Float pivot arrangement and needle

valve on the Weber 30/32 DMTE

carburettor

9B.40 Unscrewing a top cover screw from

the Weber 30/32 DMTE carburettor9B.37F Unscrewing a carburettor fixing nut

Page 192 of 303

solenoid-operated type, actuated from the

ECU.

7Fuel pressure is regulated according to inlet

manifold vacuum pressure by a fuel pressure

regulator. Excess unpressurised fuel is

returned to the fuel tank.

Airflow meter

8This component measures the quantity of

air drawn into the engine, and converts this

into an electric signal which is transmitted to

the ECU.

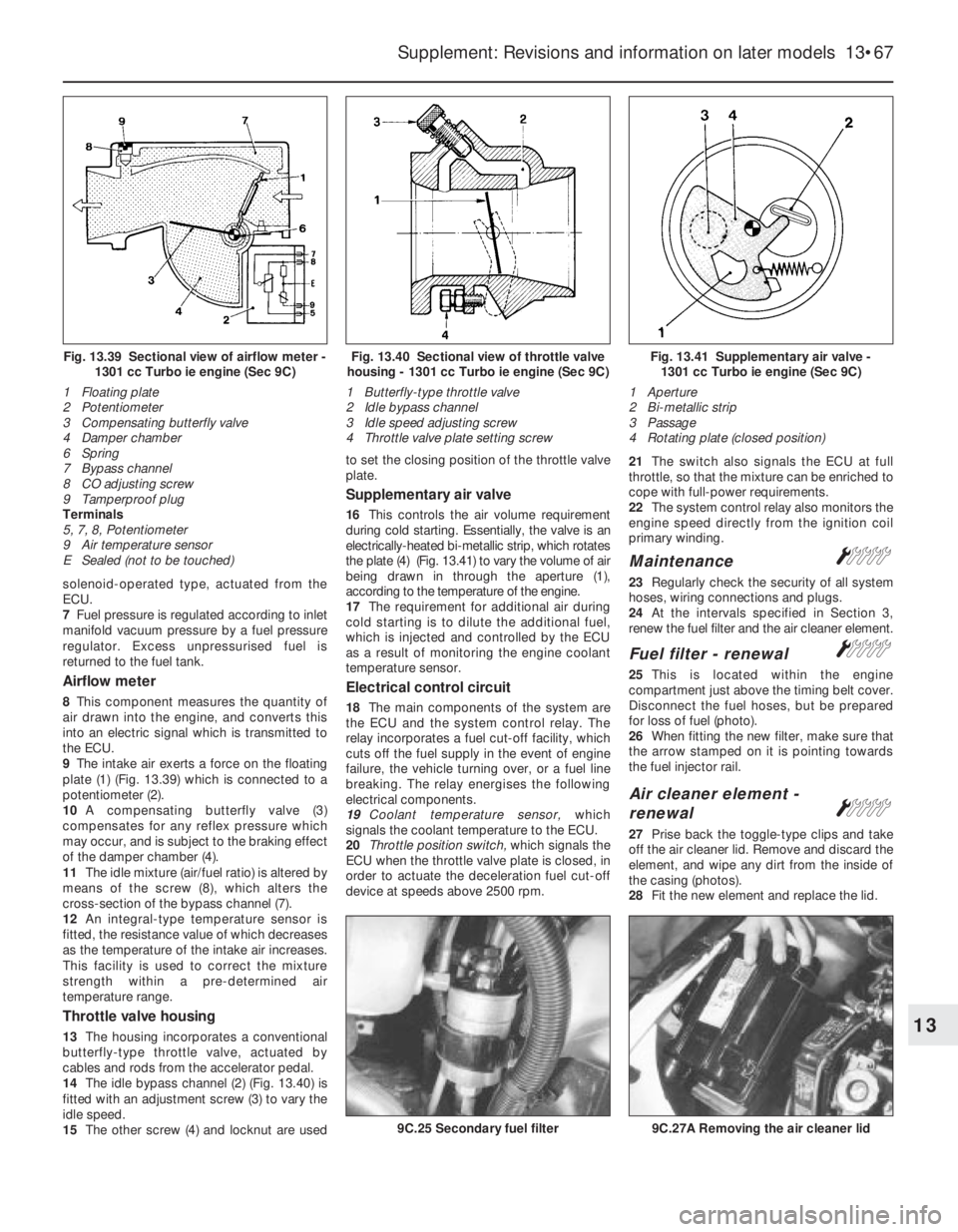

9The intake air exerts a force on the floating

plate (1) (Fig. 13.39) which is connected to a

potentiometer (2).

10A compensating butterfly valve (3)

compensates for any reflex pressure which

may occur, and is subject to the braking effect

of the damper chamber (4).

11The idle mixture (air/fuel ratio) is altered by

means of the screw (8), which alters the

cross-section of the bypass channel (7).

12An integral-type temperature sensor is

fitted, the resistance value of which decreases

as the temperature of the intake air increases.

This facility is used to correct the mixture

strength within a pre-determined air

temperature range.

Throttle valve housing

13The housing incorporates a conventional

butterfly-type throttle valve, actuated by

cables and rods from the accelerator pedal.

14The idle bypass channel (2) (Fig. 13.40) is

fitted with an adjustment screw (3) to vary the

idle speed.

15The other screw (4) and locknut are usedto set the closing position of the throttle valve

plate.

Supplementary air valve

16This controls the air volume requirement

during cold starting. Essentially, the valve is an

electrically-heated bi-metallic strip, which rotates

the plate (4) (Fig. 13.41) to vary the volume of air

being drawn in through the aperture (1),

according to the temperature of the engine.

17The requirement for additional air during

cold starting is to dilute the additional fuel,

which is injected and controlled by the ECU

as a result of monitoring the engine coolant

temperature sensor.

Electrical control circuit

18The main components of the system are

the ECU and the system control relay. The

relay incorporates a fuel cut-off facility, which

cuts off the fuel supply in the event of engine

failure, the vehicle turning over, or a fuel line

breaking. The relay energises the following

electrical components.

19Coolant temperature sensor, which

signals the coolant temperature to the ECU.

20Throttle position switch, which signals the

ECU when the throttle valve plate is closed, in

order to actuate the deceleration fuel cut-off

device at speeds above 2500 rpm.21The switch also signals the ECU at full

throttle, so that the mixture can be enriched to

cope with full-power requirements.

22The system control relay also monitors the

engine speed directly from the ignition coil

primary winding.

MaintenanceÁ

23Regularly check the security of all system

hoses, wiring connections and plugs.

24At the intervals specified in Section 3,

renew the fuel filter and the air cleaner element.

Fuel filter - renewalÁ

25This is located within the engine

compartment just above the timing belt cover.

Disconnect the fuel hoses, but be prepared

for loss of fuel (photo).

26When fitting the new filter, make sure that

the arrow stamped on it is pointing towards

the fuel injector rail.

Air cleaner element -

renewal

Á

27Prise back the toggle-type clips and take

off the air cleaner lid. Remove and discard the

element, and wipe any dirt from the inside of

the casing (photos).

28Fit the new element and replace the lid.

Supplement: Revisions and information on later models 13•67

Fig. 13.41 Supplementary air valve -

1301 cc Turbo ie engine (Sec 9C)

1 Aperture

2 Bi-metallic strip

3 Passage

4 Rotating plate (closed position)Fig. 13.40 Sectional view of throttle valve

housing - 1301 cc Turbo ie engine (Sec 9C)

1 Butterfly-type throttle valve

2 Idle bypass channel

3 Idle speed adjusting screw

4 Throttle valve plate setting screwFig. 13.39 Sectional view of airflow meter -

1301 cc Turbo ie engine (Sec 9C)

1 Floating plate

2 Potentiometer

3 Compensating butterfly valve

4 Damper chamber

6 Spring

7 Bypass channel

8 CO adjusting screw

9 Tamperproof plug

Terminals

5, 7, 8, Potentiometer

9 Air temperature sensor

E Sealed (not to be touched)

9C.27A Removing the air cleaner lid9C.25 Secondary fuel filter

13

Page 193 of 303

Idle speed and mixture

adjustment¢

29Before carrying out any adjustments, the

engine must be at operating temperature, the

fan having cut in at second speed and then

switched off.

30Release the locknut and turn the main idle

speed screw in the throttle valve housing until

the engine idles at the specified speed. This

should be all that is necessary to obtain the

correct idle speed, as the throttle valve plate

base setting is set during production.

However, if wear has taken place, or incorrect

adjustment has been carried out previously,

proceed in the following way.

31Disconnect the intake duct from the

throttle valve housing. Release the locknut on

the base (small) adjusting screw, and turn thescrew until there is a clearance between the

lower edge of the throttle valve plate and the

throat wall of between 0.05 and 0.1 mm

(photos).

32With the engine still at operating

temperature, start the engine, and having

released the locknut, turn the main (large) idle

speed screw fully clockwise to close the

bypass passage.

33Now turn the base (small) screw until the

engine idles at between 700 and 800 rpm.

Tighten the locknut.

34Finally, turn the main (large) adjusting

screw to give an idle speed of between 800

and 900 rpm.

35It is unlikely that the mixture will require

alteration, but if it does, connect an exhaust

gas analyser to the car in accordance with the

equipment manufacturer’s instructions.

36With the engine at operating temperature,

prise out the tamperproof cap, and turn the

mixture screw, which is located in the airflow

meter, until the CO level is as given in the

Specifications. Turning the screw clockwise

richens the mixture, turning it anti-clockwise

weakens the mixture. Use a close-fitting Allen

key for the adjustment (photo).

Fuel injection system -

electrical testsª

37When carrying out checks to trace a fault

in the system, an ohmmeter should be used

for the following tests.

38Disconnect the multipin connector from

the ECU, and also the one from the system

control relay, and apply the probes of the

ohmmeter in accordance with the following

sequence to check for continuity in thecables. The component wiring plug will of

course be disconnected for the test.

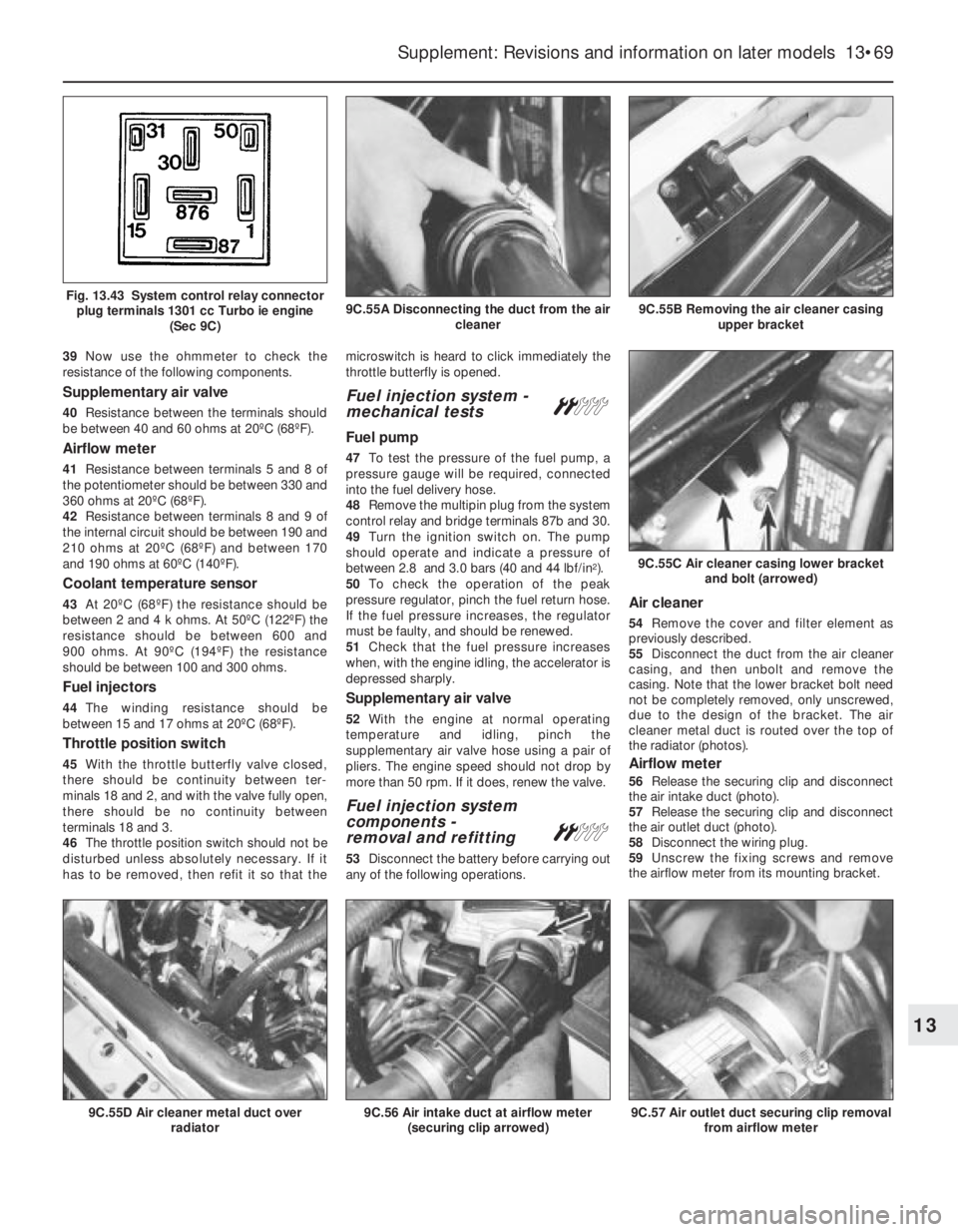

ECU connector Component connector

plug terminal plug terminal

1 1 of ignition coil

2 2 of throttle position

switch

3 3 of throttle position

switch

4 50 of ignition switch

5 Earth

5 5 of airflow meter

7 7 of airflow meter

8 8 of airflow meter

9 9 of airflow meter

9 9 of throttle position

switch

9 18 of supplementary air

valve

9 87 main relay socket

10 10 of coolant temperature

sensor

12 Injector terminals

13 Earth

System control Component connector

relay connector plug terminal

plug terminal

1 1 of ignition coil

15 15 of ignition switch

30 Battery positive

31 Earth

50 50 of ignition switch

87 Injector terminals

87 18 of throttle position

switch

87 9 of ECU multipin socket

87b Fuel pump (fused)

13•68 Supplement: Revisions and information on later models

Fig. 13.42 ECU and component connector plug terminals - 1301 cc Turbo ie engine (Sec 9C)

For colour code see main wiring diagrams

9C.31C Checking throttle valve plate

opening with a feeler blade

9C.36 Using an Allen key to adjust the

mixture (CO level)

9C.31B Idle speed base setting screw (1)

and main adjustment screw (2)9C.31A Disconnecting the throttle valve

housing intake duct9C.27B Removing the air cleaner element

Page 194 of 303

39Now use the ohmmeter to check the

resistance of the following components.

Supplementary air valve

40Resistance between the terminals should

be between 40 and 60 ohms at 20ºC (68ºF).

Airflow meter

41Resistance between terminals 5 and 8 of

the potentiometer should be between 330 and

360 ohms at 20ºC (68ºF).

42Resistance between terminals 8 and 9 of

the internal circuit should be between 190 and

210 ohms at 20ºC (68ºF) and between 170

and 190 ohms at 60ºC (140ºF).

Coolant temperature sensor

43At 20ºC (68ºF) the resistance should be

between 2 and 4 k ohms. At 50ºC (122ºF) the

resistance should be between 600 and

900 ohms. At 90ºC (194ºF) the resistance

should be between 100 and 300 ohms.

Fuel injectors

44The winding resistance should be

between 15 and 17 ohms at 20ºC (68ºF).

Throttle position switch

45With the throttle butterfly valve closed,

there should be continuity between ter-

minals 18 and 2, and with the valve fully open,

there should be no continuity between

terminals 18 and 3.

46The throttle position switch should not be

disturbed unless absolutely necessary. If it

has to be removed, then refit it so that themicroswitch is heard to click immediately the

throttle butterfly is opened.

Fuel injection system -

mechanical tests ª

Fuel pump

47To test the pressure of the fuel pump, a

pressure gauge will be required, connected

into the fuel delivery hose.

48Remove the multipin plug from the system

control relay and bridge terminals 87b and 30.

49Turn the ignition switch on. The pump

should operate and indicate a pressure of

between 2.8 and 3.0 bars (40 and 44 lbf/in

2).

50To check the operation of the peak

pressure regulator, pinch the fuel return hose.

If the fuel pressure increases, the regulator

must be faulty, and should be renewed.

51Check that the fuel pressure increases

when, with the engine idling, the accelerator is

depressed sharply.

Supplementary air valve

52With the engine at normal operating

temperature and idling, pinch the

supplementary air valve hose using a pair of

pliers. The engine speed should not drop by

more than 50 rpm. If it does, renew the valve.

Fuel injection system

components -

removal and refitting

ª

53Disconnect the battery before carrying out

any of the following operations.

Air cleaner

54Remove the cover and filter element as

previously described.

55Disconnect the duct from the air cleaner

casing, and then unbolt and remove the

casing. Note that the lower bracket bolt need

not be completely removed, only unscrewed,

due to the design of the bracket. The air

cleaner metal duct is routed over the top of

the radiator (photos).

Airflow meter

56Release the securing clip and disconnect

the air intake duct (photo).

57Release the securing clip and disconnect

the air outlet duct (photo).

58Disconnect the wiring plug.

59Unscrew the fixing screws and remove

the airflow meter from its mounting bracket.

Supplement: Revisions and information on later models 13•69

9C.55B Removing the air cleaner casing

upper bracket9C.55A Disconnecting the duct from the air

cleanerFig. 13.43 System control relay connector

plug terminals 1301 cc Turbo ie engine

(Sec 9C)

9C.57 Air outlet duct securing clip removal

from airflow meter

9C.55C Air cleaner casing lower bracket

and bolt (arrowed)

9C.56 Air intake duct at airflow meter

(securing clip arrowed)9C.55D Air cleaner metal duct over

radiator

13

Page 197 of 303

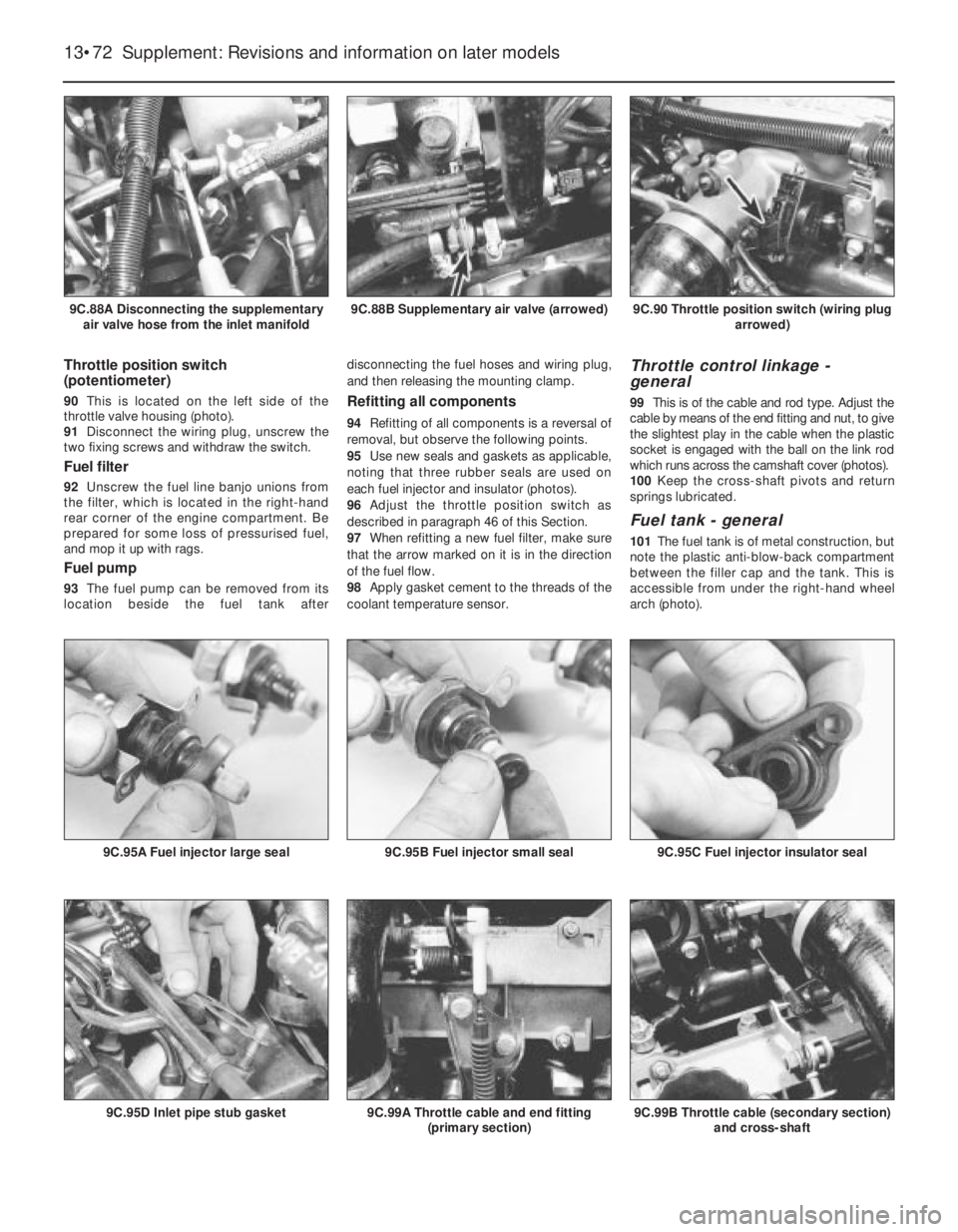

Throttle position switch

(potentiometer)

90This is located on the left side of the

throttle valve housing (photo).

91Disconnect the wiring plug, unscrew the

two fixing screws and withdraw the switch.

Fuel filter

92Unscrew the fuel line banjo unions from

the filter, which is located in the right-hand

rear corner of the engine compartment. Be

prepared for some loss of pressurised fuel,

and mop it up with rags.

Fuel pump

93The fuel pump can be removed from its

location beside the fuel tank afterdisconnecting the fuel hoses and wiring plug,

and then releasing the mounting clamp.

Refitting all components

94Refitting of all components is a reversal of

removal, but observe the following points.

95Use new seals and gaskets as applicable,

noting that three rubber seals are used on

each fuel injector and insulator (photos).

96Adjust the throttle position switch as

described in paragraph 46 of this Section.

97When refitting a new fuel filter, make sure

that the arrow marked on it is in the direction

of the fuel flow.

98Apply gasket cement to the threads of the

coolant temperature sensor.

Throttle control linkage -

general

99This is of the cable and rod type. Adjust the

cable by means of the end fitting and nut, to give

the slightest play in the cable when the plastic

socket is engaged with the ball on the link rod

which runs across the camshaft cover (photos).

100Keep the cross-shaft pivots and return

springs lubricated.

Fuel tank - general

101The fuel tank is of metal construction, but

note the plastic anti-blow-back compartment

between the filler cap and the tank. This is

accessible from under the right-hand wheel

arch (photo).

13•72 Supplement: Revisions and information on later models

9C.99B Throttle cable (secondary section)

and cross-shaft9C.99A Throttle cable and end fitting

(primary section)9C.95D Inlet pipe stub gasket

9C.95C Fuel injector insulator seal9C.95B Fuel injector small seal9C.95A Fuel injector large seal

9C.90 Throttle position switch (wiring plug

arrowed)9C.88B Supplementary air valve (arrowed)9C.88A Disconnecting the supplementary

air valve hose from the inlet manifold

Page 198 of 303

PART D:

BOSCH MONO-JETRONIC

FUEL INJECTION SYSTEM

Warning: Refer to the beginning

of this Section before starting

any work.

Description

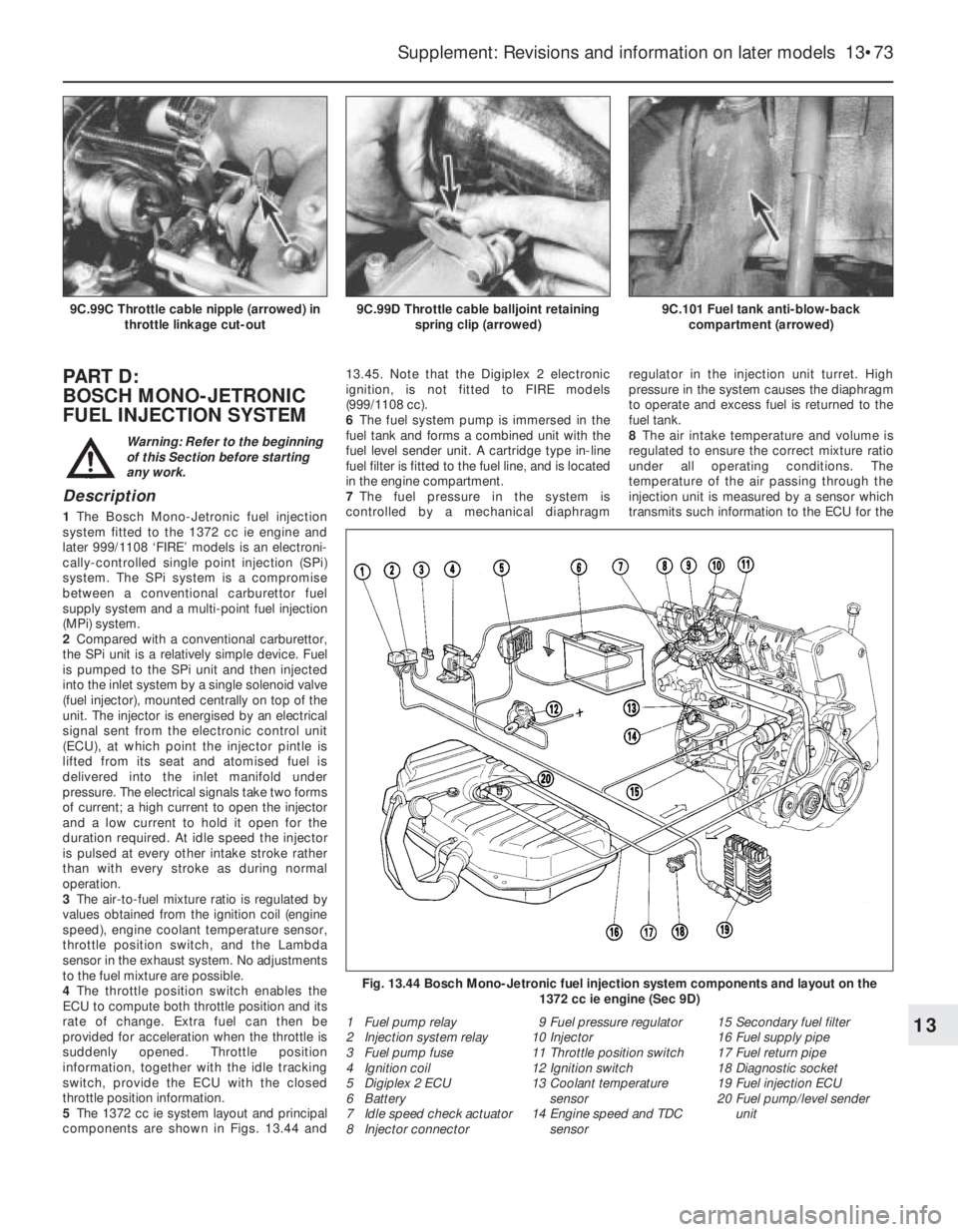

1The Bosch Mono-Jetronic fuel injection

system fitted to the 1372 cc ie engine and

later 999/1108 ‘FIRE’ models is an electroni-

cally-controlled single point injection (SPi)

system. The SPi system is a compromise

between a conventional carburettor fuel

supply system and a multi-point fuel injection

(MPi) system.

2Compared with a conventional carburettor,

the SPi unit is a relatively simple device. Fuel

is pumped to the SPi unit and then injected

into the inlet system by a single solenoid valve

(fuel injector), mounted centrally on top of the

unit. The injector is energised by an electrical

signal sent from the electronic control unit

(ECU), at which point the injector pintle is

lifted from its seat and atomised fuel is

delivered into the inlet manifold under

pressure. The electrical signals take two forms

of current; a high current to open the injector

and a low current to hold it open for the

duration required. At idle speed the injector

is pulsed at every other intake stroke rather

than with every stroke as during normal

operation.

3The air-to-fuel mixture ratio is regulated by

values obtained from the ignition coil (engine

speed), engine coolant temperature sensor,

throttle position switch, and the Lambda

sensor in the exhaust system. No adjustments

to the fuel mixture are possible.

4The throttle position switch enables the

ECU to compute both throttle position and its

rate of change. Extra fuel can then be

provided for acceleration when the throttle is

suddenly opened. Throttle position

information, together with the idle tracking

switch, provide the ECU with the closed

throttle position information.

5The 1372 cc ie system layout and principal

components are shown in Figs. 13.44 and13.45. Note that the Digiplex 2 electronic

ignition, is not fitted to FIRE models

(999/1108 cc).

6The fuel system pump is immersed in the

fuel tank and forms a combined unit with the

fuel level sender unit. A cartridge type in-line

fuel filter is fitted to the fuel line, and is located

in the engine compartment.

7The fuel pressure in the system is

controlled by a mechanical diaphragmregulator in the injection unit turret. High

pressure in the system causes the diaphragm

to operate and excess fuel is returned to the

fuel tank.

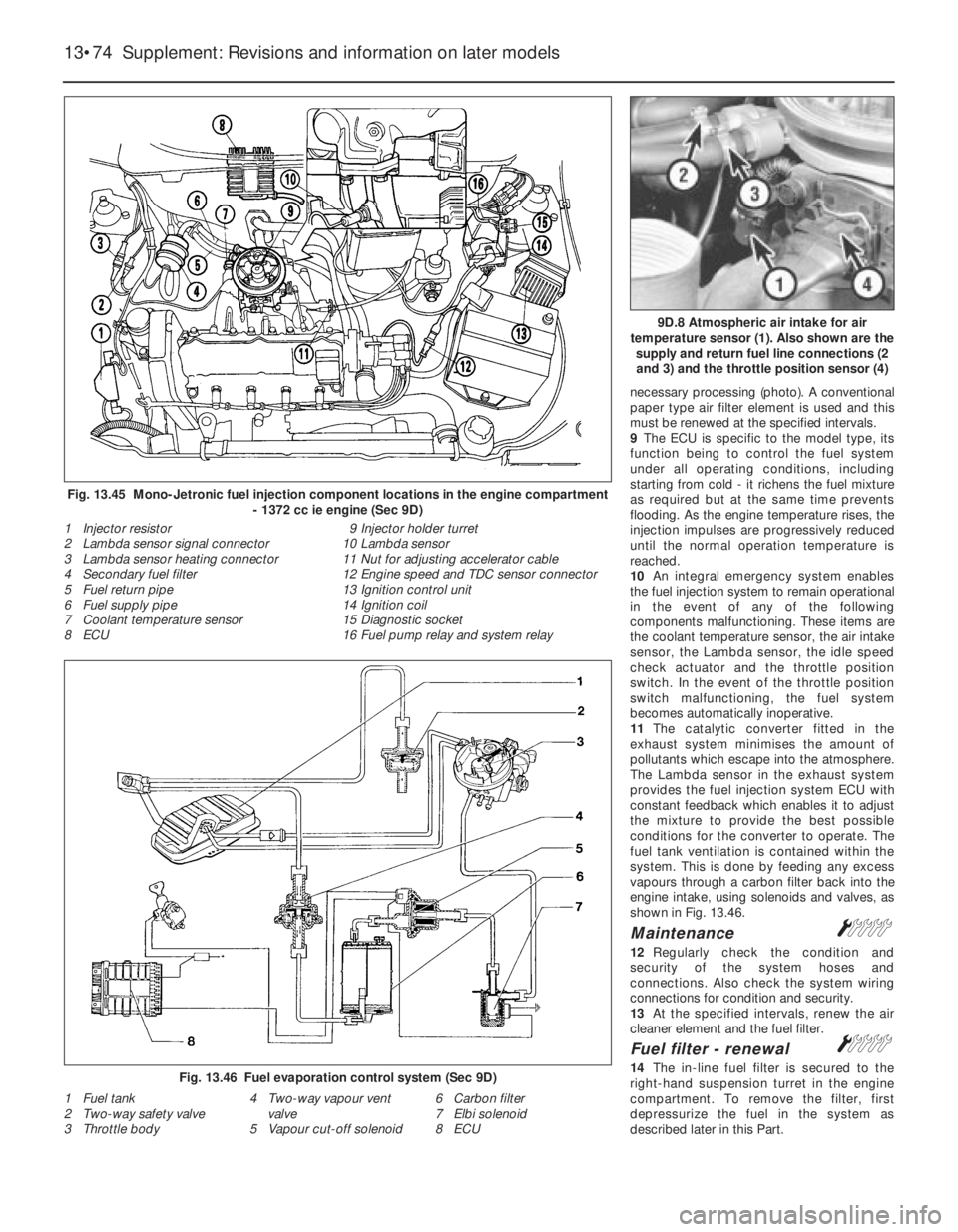

8The air intake temperature and volume is

regulated to ensure the correct mixture ratio

under all operating conditions. The

temperature of the air passing through the

injection unit is measured by a sensor which

transmits such information to the ECU for the

Supplement: Revisions and information on later models 13•73

9C.101 Fuel tank anti-blow-back

compartment (arrowed)9C.99D Throttle cable balljoint retaining

spring clip (arrowed)9C.99C Throttle cable nipple (arrowed) in

throttle linkage cut-out

Fig. 13.44 Bosch Mono-Jetronic fuel injection system components and layout on the

1372 cc ie engine (Sec 9D)

1 Fuel pump relay

2 Injection system relay

3 Fuel pump fuse

4 Ignition coil

5 Digiplex 2 ECU

6 Battery

7 Idle speed check actuator

8 Injector connector9 Fuel pressure regulator

10 Injector

11 Throttle position switch

12 Ignition switch

13 Coolant temperature

sensor

14 Engine speed and TDC

sensor15 Secondary fuel filter

16 Fuel supply pipe

17 Fuel return pipe

18 Diagnostic socket

19 Fuel injection ECU

20 Fuel pump/level sender

unit13

Page 199 of 303

necessary processing (photo). A conventional

paper type air filter element is used and this

must be renewed at the specified intervals.

9The ECU is specific to the model type, its

function being to control the fuel system

under all operating conditions, including

starting from cold - it richens the fuel mixture

as required but at the same time prevents

flooding. As the engine temperature rises, the

injection impulses are progressively reduced

until the normal operation temperature is

reached.

10An integral emergency system enables

the fuel injection system to remain operational

in the event of any of the following

components malfunctioning. These items are

the coolant temperature sensor, the air intake

sensor, the Lambda sensor, the idle speed

check actuator and the throttle position

switch. In the event of the throttle position

switch malfunctioning, the fuel system

becomes automatically inoperative.

11The catalytic converter fitted in the

exhaust system minimises the amount of

pollutants which escape into the atmosphere.

The Lambda sensor in the exhaust system

provides the fuel injection system ECU with

constant feedback which enables it to adjust

the mixture to provide the best possible

conditions for the converter to operate. The

fuel tank ventilation is contained within the

system. This is done by feeding any excess

vapours through a carbon filter back into the

engine intake, using solenoids and valves, as

shown in Fig. 13.46.

MaintenanceÁ

12Regularly check the condition and

security of the system hoses and

connections. Also check the system wiring

connections for condition and security.

13At the specified intervals, renew the air

cleaner element and the fuel filter.

Fuel filter - renewalÁ

14The in-line fuel filter is secured to the

right-hand suspension turret in the engine

compartment. To remove the filter, first

depressurize the fuel in the system as

described later in this Part.

13•74 Supplement: Revisions and information on later models

Fig. 13.46 Fuel evaporation control system (Sec 9D)

1 Fuel tank

2 Two-way safety valve

3 Throttle body4 Two-way vapour vent

valve

5 Vapour cut-off solenoid6 Carbon filter

7 Elbi solenoid

8 ECU

9D.8 Atmospheric air intake for air

temperature sensor (1). Also shown are the

supply and return fuel line connections (2

and 3) and the throttle position sensor (4)

Fig. 13.45 Mono-Jetronic fuel injection component locations in the engine compartment

- 1372 cc ie engine (Sec 9D)

1 Injector resistor

2 Lambda sensor signal connector

3 Lambda sensor heating connector

4 Secondary fuel filter

5 Fuel return pipe

6 Fuel supply pipe

7 Coolant temperature sensor

8 ECU9 Injector holder turret

10 Lambda sensor

11 Nut for adjusting accelerator cable

12 Engine speed and TDC sensor connector

13 Ignition control unit

14 Ignition coil

15 Diagnostic socket

16 Fuel pump relay and system relay

Page 202 of 303

air temperature sensor. Undo the retaining

screw and remove the sensor from the

injector unit (photo).

50Refit in the reverse order of removal.

Fuel injector -

removal and refittingÁ

51Depressurise the fuel system as

described previously, then disconnect the

battery negative lead.

52Remove the air cleaner unit.

53Release the injector feed wiring mutliplug

and detach it from the injector.

54Bend over the locking tabs retaining the

injector screws, then undo and remove the

screws. Withdraw the injector retaining collar,

then carefully withdraw the injector (noting its

orientation) followed by its seal.

55Refit in the reverse order of removal.

Always use new seals in the unit and the

retaining collar and lightly lubricate them with

clean engine oil prior to assembly. Take care

not to damage the seals when fitting and also

when the injector is fitted; check that it

engages correctly.

Fuel injection electronic

control unit (ECU) -

removal and refitting

Á

56The control unit is located under the facia

on the driver’s side of the vehicle. Commence

by disconnecting the battery negative lead.

57To gain access to the control unit, detach

and remove the trim panel from the underside

of the facia on the driver’s side of the car.

58Disconnect the wiring multiplug from the

control unit, then undo the retaining screw

and remove the unit from the car (photos).

59Refit in the reverse order of removal.

Inlet manifold -

removal and refittingÁ

60Remove the fuel injector unit as described

previously.

61Drain the cooling system as described in

Section 8 of this Chapter.

62Detach the coolant hose and coolant

temperature sensor from the inlet manifold.

63Unbolt and remove the accelerator

cable/throttle linkage support bracket from

the top of the inlet manifold. The cable can be

left attached to the bracket.64Detach the brake servo vacuum hose

from the connector on the manifold.

65Unscrew and remove the inlet manifold

securing bolts and nuts and remove the

manifold from the cylinder head. As they are

removed, note the location of the fastenings

and their spacers.

66Remove the gasket and clean the mating

faces of the manifold and the cylinder head.

The gasket must be renewed when refitting

the manifold.

67Refitting is a reversal of the removal

procedure. Ensure that the spacers are

correctly located (where applicable) and

tighten the retaining bolts and nuts to the

specified torque settings.

Exhaust manifold -

removal and refittingÁ

68Remove the inlet manifold as described

previously (1372 cc models only).

69Disconnect the Lambda sensor lead

(photo).

70Raise and support the car at the front end

on axle stands to allow sufficient clearance to

work underneath the car and disconnect the

exhaust downpipe from the manifold.

71Straighten the tab washers, then unscrew

and remove the exhaust downpipe-

to-manifold retaining nuts (photo). Detach the

downpipe from the manifold. Support the

downpipe so that the Lambda sensor will not

get knocked and/or damaged.72Undo the manifold-to-cylinder head

securing bolts/nuts and withdraw and remove

the manifold and heat shield.

73Remove the gasket and clean the mating

faces of the manifold, cylinder head and

downpipe flange. The gasket must be

renewed when refitting the manifold.

74Refitting is a reversal of the removal

procedure. Tighten the retaining bolts/nuts to

the specified torque setting.

Catalytic converter -

general information

75The catalytic converter is a reliable and

simple device which needs no maintenance in

itself, but there are some facts of which an

owner should be aware if the converter is to

function properly for its full service life.

a) DO NOT use leaded petrol in a car

equipped with a catalytic converter - the

lead will coat the precious metals,

reducing their converting efficiency and

will eventually destroy the converter.

b) Always keep the ignition and fuel systems

well-maintained in accordance with the

maintenance schedule - particularly, en-

sure that the air cleaner filter element the

fuel filter and the spark plugs are renewed

at the correct interval - if the intake air/fuel

mixture is allowed to become too rich due

to neglect, the unburned surplus will enter

and burn in the catalytic converter,

overheating the element and eventually

destroying the converter.

Supplement: Revisions and information on later models 13•77

9D.58B . . . for access to the ECU retaining

screw (arrowed)9D.58A Detach the multiplug (arrowed) . . .9D.49 Fuel injector unit sensor retaining

screw (1). Also shown is the intake air

temperature sensor (2)

9D.71 Exhaust downpipe to manifold

flange connection showing retaining nuts

and locktabs9D.69 Lambda sensor in exhaust

downpipe

13