air bleeding FIAT UNO 1983 Service Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 81 of 303

8

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dual-circuit hydraulic with servo unit and pressure regulating valve.

Discs front, drums rear. Handbrake mechanical to rear wheels.

Disc brakes

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Single cylinder, sliding caliper

Disc diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227.0 mm (8.94 in)

Disc thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.7 to 10.9 mm (0.42 to 0.43 in)

Minimum regrind thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 mm (0.35 in)

Minimum wear thickness of pad friction material . . . . . . . . . . . . . . . . . . 1.5 mm (0.06 in)

Caliper cylinder diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48.0 mm (1.89 in)

Drum brakes

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Single cylinder, with automatic adjusters

Drum internal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185.24 to 185.53 mm (7.30 to 7.31 in)

Maximum regrind diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187.0 mm (7.37 in)

Minimum shoe lining friction material thickness . . . . . . . . . . . . . . . . . . . 1.5 mm (0.06 in)

Cylinder diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.05 mm (0.75 in)

Master cylinder bore diameter . . . . . . . . . . . . . . . . . . . . . . . . 19.05 mm (0.75 in)

Vacuum servo diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158.5 mm (6.0 in)

Hydraulic fluid type/specification . . . . . . . . . . . . . . . . . . . . . Hydraulic fluid to DOT 3 or 4, or SAE J1703C

System capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.33 litre (0.58 pint)

Torque wrench settingsNm lbf ft

Caliper mounting bracket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 39

Rear wheel cylinder mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Pressure regulating valve mounting bolts . . . . . . . . . . . . . . . . . . . . . . . 20 15

Master cylinder mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Rear brake backplate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Chapter 8 Braking system

For modifications, and information applicable to later models, see Supplement at end of manual

Brake disc - inspection, renovation or renewal . . . . . . . . . . . . . . . . . 6

Brake drum - inspection, renovation or renewal . . . . . . . . . . . . . . . . 8

Brake pedal - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Caliper - removal, overhaul and refitting . . . . . . . . . . . . . . . . . . . . . . 5

Disc pads - inspection and renewal . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fault finding - braking system . . . . . . . . . . . . . . . . See end of Chapter

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Handbrake - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Handbrake cable - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Hydraulic hoses and pipes - inspection and renewal . . . . . . . . . . . . 11Hydraulic system - bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Master cylinder - removal, overhaul and refitting . . . . . . . . . . . . . . . 9

Pressure regulating valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rear brake shoes - inspection and removal . . . . . . . . . . . . . . . . . . . 4

Rear wheel cylinder - removal, overhaul and refitting . . . . . . . . . . . . 7

Stop lamp switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Vacuum servo unit - description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Vacuum servo unit - removal and refitting . . . . . . . . . . . . . . . . . . . . 15

Vacuum servo unit - servicing and testing . . . . . . . . . . . . . . . . . . . . 14

8•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 86 of 303

their originally fitted sequence and note in

which direction the seal lips are located.

11Inspect the surfaces of the piston and

cylinder bore. If scoring, corrosion or

metal-to-metal rubbing areas are evident,

renew the master cylinder complete.

12If the components are in good condition,

discard the oil seals and manipulate the new

ones into position, using the fingers only.

13Refit by reversing the removal operations;

apply pressure to the piston ends so that the

stop bolts can be fitted, then tighten the end

plug. Make sure that the grooves in the

pistons engage in the stop bolts.

14Before refitting the master cylinder to the

servo, measure the projection of the servo

piston pushrod. When the master cylinder is

fitted, there must be a clearance (see A in

Fig. 8.7) between the end of the pushrod and

the primary piston end face of between 0.825

and 1.025 mm (0.03 and 0.04 in). A depth

gauge will be required for these

measurements, the reference point being the

mating surfaces of the master cylinder and the

vacuum servo.

15Alter the adjusting screw on the servo as

necessary and lock it by applying locking fluid

to the threads on completion.16Bolt the master cylinder to the vacuum

servo or bulkhead, then reconnect the

pipelines and reservoir cap leads.

17Bleed the complete hydraulic system, as

described in Section 12.

10 Pressure regulating valve

3

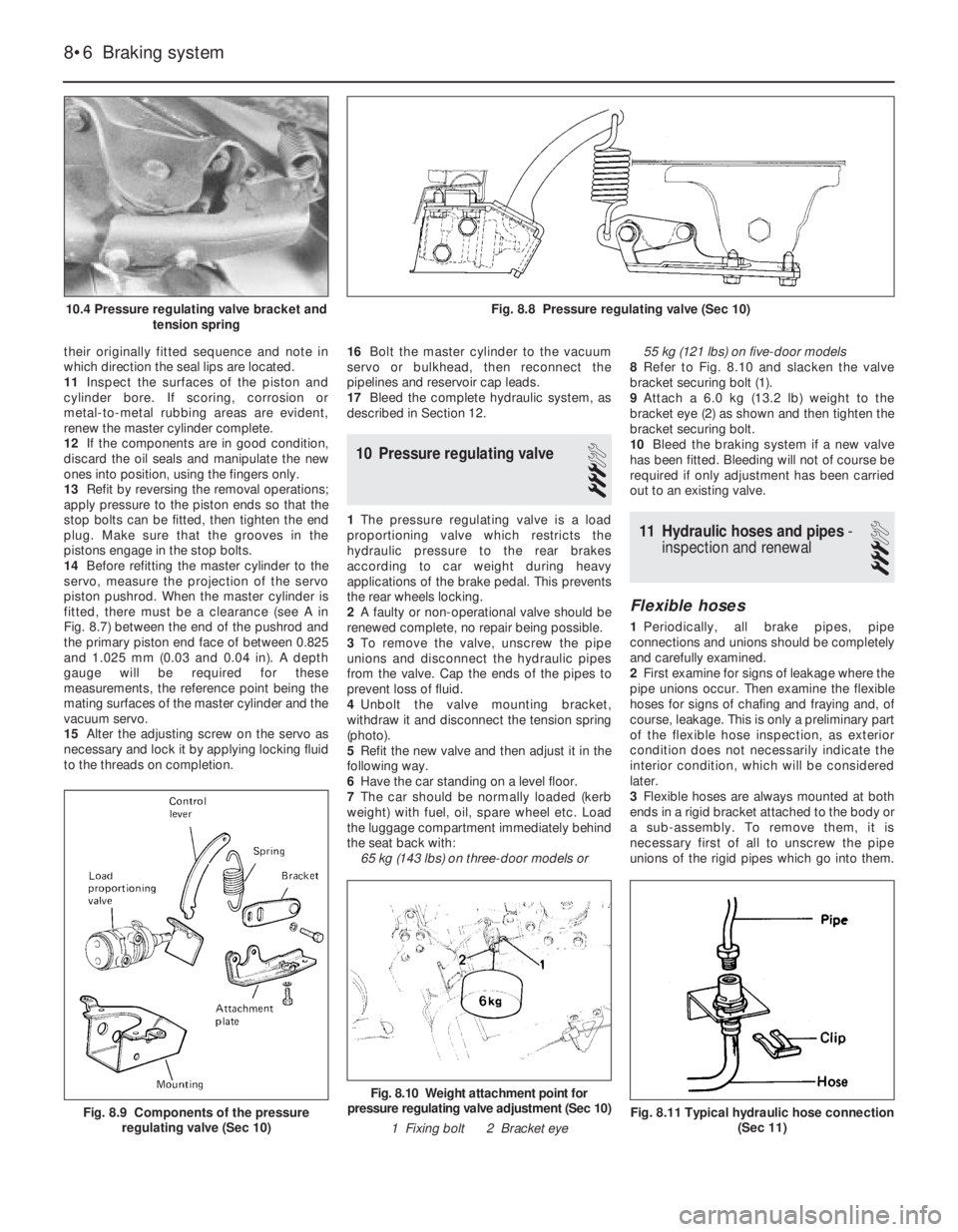

1The pressure regulating valve is a load

proportioning valve which restricts the

hydraulic pressure to the rear brakes

according to car weight during heavy

applications of the brake pedal. This prevents

the rear wheels locking.

2A faulty or non-operational valve should be

renewed complete, no repair being possible.

3To remove the valve, unscrew the pipe

unions and disconnect the hydraulic pipes

from the valve. Cap the ends of the pipes to

prevent loss of fluid.

4Unbolt the valve mounting bracket,

withdraw it and disconnect the tension spring

(photo).

5Refit the new valve and then adjust it in the

following way.

6Have the car standing on a level floor.

7The car should be normally loaded (kerb

weight) with fuel, oil, spare wheel etc. Load

the luggage compartment immediately behind

the seat back with:

65 kg (143 lbs) on three-door models or 55 kg (121 lbs) on five-door models

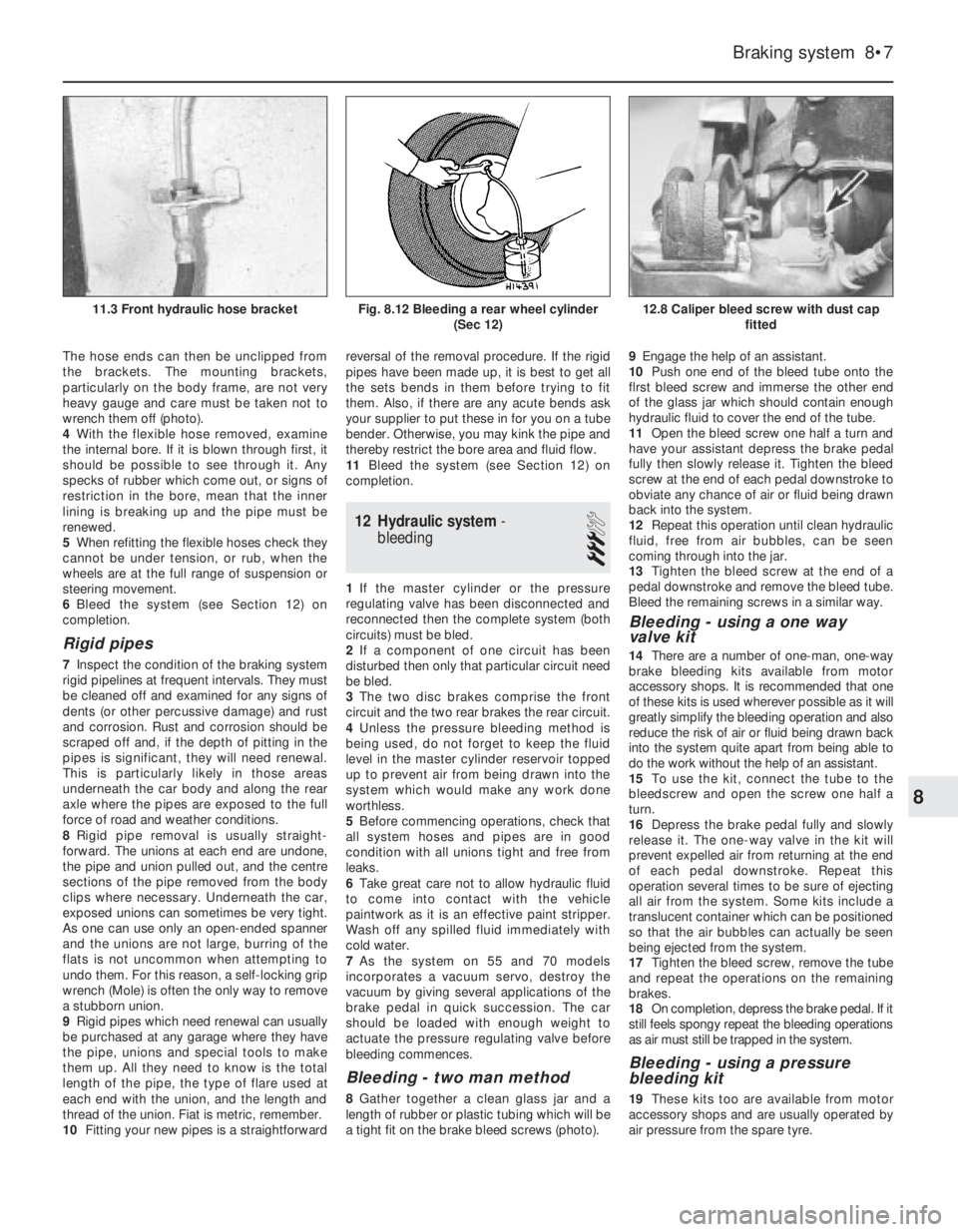

8Refer to Fig. 8.10 and slacken the valve

bracket securing bolt (1).

9Attach a 6.0 kg (13.2 lb) weight to the

bracket eye (2) as shown and then tighten the

bracket securing bolt.

10Bleed the braking system if a new valve

has been fitted. Bleeding will not of course be

required if only adjustment has been carried

out to an existing valve.11 Hydraulic hoses and pipes-

inspection and renewal

3

Flexible hoses

1Periodically, all brake pipes, pipe

connections and unions should be completely

and carefully examined.

2First examine for signs of leakage where the

pipe unions occur. Then examine the flexible

hoses for signs of chafing and fraying and, of

course, leakage. This is only a preliminary part

of the flexible hose inspection, as exterior

condition does not necessarily indicate the

interior condition, which will be considered

later.

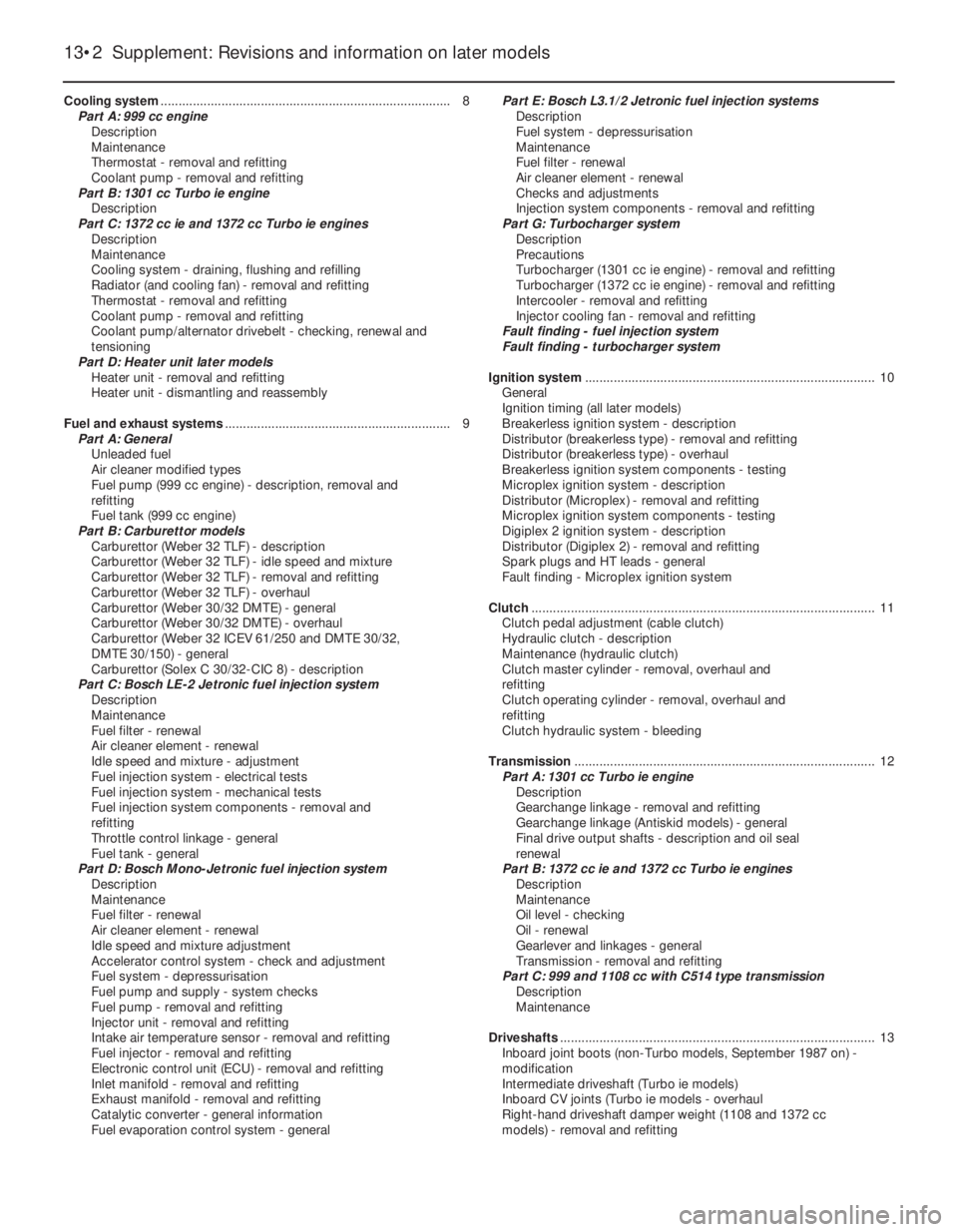

3Flexible hoses are always mounted at both

ends in a rigid bracket attached to the body or

a sub-assembly. To remove them, it is

necessary first of all to unscrew the pipe

unions of the rigid pipes which go into them.

8•6 Braking system

Fig. 8.11 Typical hydraulic hose connection

(Sec 11)

Fig. 8.10 Weight attachment point for

pressure regulating valve adjustment (Sec 10)

1 Fixing bolt 2 Bracket eye

Fig. 8.9 Components of the pressure

regulating valve (Sec 10)

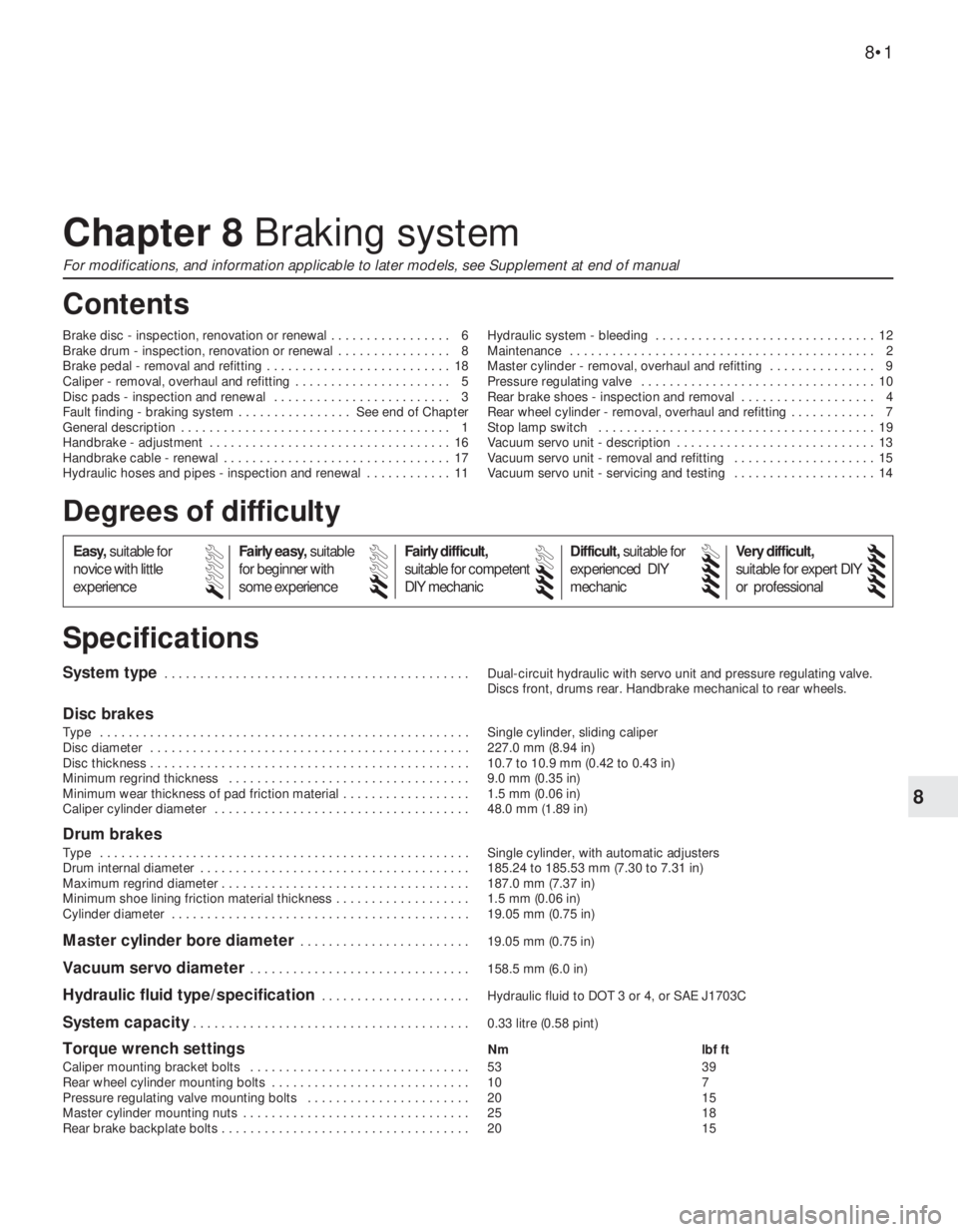

Fig. 8.8 Pressure regulating valve (Sec 10)10.4 Pressure regulating valve bracket and

tension spring

Page 87 of 303

The hose ends can then be unclipped from

the brackets. The mounting brackets,

particularly on the body frame, are not very

heavy gauge and care must be taken not to

wrench them off (photo).

4With the flexible hose removed, examine

the internal bore. If it is blown through first, it

should be possible to see through it. Any

specks of rubber which come out, or signs of

restriction in the bore, mean that the inner

lining is breaking up and the pipe must be

renewed.

5When refitting the flexible hoses check they

cannot be under tension, or rub, when the

wheels are at the full range of suspension or

steering movement.

6Bleed the system (see Section 12) on

completion.

Rigid pipes

7Inspect the condition of the braking system

rigid pipelines at frequent intervals. They must

be cleaned off and examined for any signs of

dents (or other percussive damage) and rust

and corrosion. Rust and corrosion should be

scraped off and, if the depth of pitting in the

pipes is significant, they will need renewal.

This is particularly likely in those areas

underneath the car body and along the rear

axle where the pipes are exposed to the full

force of road and weather conditions.

8Rigid pipe removal is usually straight-

forward. The unions at each end are undone,

the pipe and union pulled out, and the centre

sections of the pipe removed from the body

clips where necessary. Underneath the car,

exposed unions can sometimes be very tight.

As one can use only an open-ended spanner

and the unions are not large, burring of the

flats is not uncommon when attempting to

undo them. For this reason, a self-locking grip

wrench (Mole) is often the only way to remove

a stubborn union.

9Rigid pipes which need renewal can usually

be purchased at any garage where they have

the pipe, unions and special tools to make

them up. All they need to know is the total

length of the pipe, the type of flare used at

each end with the union, and the length and

thread of the union. Fiat is metric, remember.

10Fitting your new pipes is a straightforwardreversal of the removal procedure. If the rigid

pipes have been made up, it is best to get all

the sets bends in them before trying to fit

them. Also, if there are any acute bends ask

your supplier to put these in for you on a tube

bender. Otherwise, you may kink the pipe and

thereby restrict the bore area and fluid flow.

11Bleed the system (see Section 12) on

completion.

12 Hydraulic system-

bleeding

3

1If the master cylinder or the pressure

regulating valve has been disconnected and

reconnected then the complete system (both

circuits) must be bled.

2If a component of one circuit has been

disturbed then only that particular circuit need

be bled.

3The two disc brakes comprise the front

circuit and the two rear brakes the rear circuit.

4Unless the pressure bleeding method is

being used, do not forget to keep the fluid

level in the master cylinder reservoir topped

up to prevent air from being drawn into the

system which would make any work done

worthless.

5Before commencing operations, check that

all system hoses and pipes are in good

condition with all unions tight and free from

leaks.

6Take great care not to allow hydraulic fluid

to come into contact with the vehicle

paintwork as it is an effective paint stripper.

Wash off any spilled fluid immediately with

cold water.

7As the system on 55 and 70 models

incorporates a vacuum servo, destroy the

vacuum by giving several applications of the

brake pedal in quick succession. The car

should be loaded with enough weight to

actuate the pressure regulating valve before

bleeding commences.

Bleeding - two man method

8Gather together a clean glass jar and a

length of rubber or plastic tubing which will be

a tight fit on the brake bleed screws (photo).9Engage the help of an assistant.

10Push one end of the bleed tube onto the

flrst bleed screw and immerse the other end

of the glass jar which should contain enough

hydraulic fluid to cover the end of the tube.

11Open the bleed screw one half a turn and

have your assistant depress the brake pedal

fully then slowly release it. Tighten the bleed

screw at the end of each pedal downstroke to

obviate any chance of air or fluid being drawn

back into the system.

12Repeat this operation until clean hydraulic

fluid, free from air bubbles, can be seen

coming through into the jar.

13Tighten the bleed screw at the end of a

pedal downstroke and remove the bleed tube.

Bleed the remaining screws in a similar way.

Bleeding - using a one way

valve kit

14There are a number of one-man, one-way

brake bleeding kits available from motor

accessory shops. It is recommended that one

of these kits is used wherever possible as it will

greatly simplify the bleeding operation and also

reduce the risk of air or fluid being drawn back

into the system quite apart from being able to

do the work without the help of an assistant.

15To use the kit, connect the tube to the

bleedscrew and open the screw one half a

turn.

16Depress the brake pedal fully and slowly

release it. The one-way valve in the kit will

prevent expelled air from returning at the end

of each pedal downstroke. Repeat this

operation several times to be sure of ejecting

all air from the system. Some kits include a

translucent container which can be positioned

so that the air bubbles can actually be seen

being ejected from the system.

17Tighten the bleed screw, remove the tube

and repeat the operations on the remaining

brakes.

18On completion, depress the brake pedal. If it

still feels spongy repeat the bleeding operations

as air must still be trapped in the system.

Bleeding - using a pressure

bleeding kit

19These kits too are available from motor

accessory shops and are usually operated by

air pressure from the spare tyre.

Braking system 8•7

12.8 Caliper bleed screw with dust cap

fittedFig. 8.12 Bleeding a rear wheel cylinder

(Sec 12)11.3 Front hydraulic hose bracket

8

Page 88 of 303

20By connecting a pressurised container to

the master cylinder fluid reservoir, bleeding is

then carried out by simply opening each bleed

screw in turn and allowing the fluid to run out,

rather like turning on a tap, until no air is

visible in the expelled fluid.

21By using this method, the large reserve of

hydraulic fluid provides a safeguard against

air being drawn into the master cylinder

during bleeding which often occurs if the fluid

level in the reservoir is not maintained.

22Pressure bleeding is particularly effective

when bleeding “difficult” systems or when

bleeding the complete system at time of

routine fluid renewal.

All methods

23When bleeding is completed, check and

top up the fluid level in the master cylinder

reservoir.

24Check the feel of the brake pedal. If it

feels at all spongy, air must still be present in

the system and further bleeding is indicated.

Failure to bleed satisfactorily after a

reasonable period of the bleeding operation,

may be due to worn master cylinder seals.

25Discard brake fluid which has been

expelled. lt is almost certain to be

contaminated with moisture, air and dirt

making it unsuitable for further use. Clean

fluid should always be stored in an airtight

container as it absorbs moisture readily

(hygroscopic) which lowers its boiling point

and could affect braking performance under

severe conditions.

13 Vacuum servo unit-

description

A vacuum servo unit is fitted into the brake

hydraulic circuit on 55 and 70 models in series

with the master cylinder, to provide assistance

to the driver when the brake pedal is

depressed. This reduces the effort required by

the driver to operate the brakes under all

braking conditions.

The unit operates by vacuum obtained from

the induction manifold and comprises basically

a booster diaphragm and non-return valve. The

servo unit and hydraulic master cylinder are

connected together so that the servo unit

piston rod acts as the master cylinder pushrod.

The driver’s braking effort is transmitted

through another pushrod to the servo unit

piston and its built-in control system. The servo

unit piston does not fit tightly into the cylinder,

but has a strong diaphragm to keep its edges

in constant contact with the cylinder wall, so

assuring an air tight seal between the two

parts. The forward chamber is held under

vacuum conditions created in the inlet manifold

of the engine and, during periods when the

brake pedal is not in use, the controls open a

passage to the rear chamber so placing it

under vacuum conditions as well. When the

brake pedal is depressed, the vacuum passageto the rear chamber is cut off and the chamber

opened to atmospheric pressure. The

consequent rush of air pushes the servo piston

forward in the vacuum chamber and operates

the main pushrod to the master cylinder.

The controls are designed so that

assistance is given under all conditions and,

when the brakes are not required, vacuum in

the rear chamber is established when the

brake pedal is released. All air from the

atmosphere entering the rear chamber is

passed through a small air filter.

Under normal operating conditions, the

vacuum servo unit is very reliable and does

not require overhaul except at very high

mileages. In this case, it is far better to obtain

a service exchange unit, rather than repair the

original unit.

It is emphasised that the servo unit assists

in reducing the braking effort required at the

foot pedal and in the event of its failure, the

hydraulic braking system is in no way affected

except that the need for higher pressures will

be noticed.

14 Vacuum servo unit-

servicing and testing

1Regularly, check that the vacuum hose

which runs between the servo unit and the

inlet manifold is in good condition and is a

tight fit at both ends.

2If broken or badly clogged, renew the air

filter which is located around the brake pedal

push rod. Access to this is obtained by

disconnecting the pushrod from the

cross-shaft or pedal arm, withdrawing the

pushrod, dust excluding boot and end cap.

3If the new filter is cut diagonally from its

centre hole, future renewal can be carried out

without the need for disconnection of the

pushrod.

4If the efficiency of the servo unit is suspect,

it can be checked out in the following way.

5Run the engine, then switch off the ignition.

Depress the footbrake pedal; the distinctive

in-rush of air into the servo should be clearly

heard. It should be possible to repeat this

operation several times before the vacuum in

the system is exhausted.

6Start the engine and have an assistant

apply the footbrake pedal and hold it down.

Disconnect the vacuuum hose from the servo.

There should not be any in-rush of air into the

servo through the connecting stub. lf there is,

the servo diaphragm is probably faulty. During

this test, expect the engine to idle roughly,

unless the open end of the hose to the inlet

manifold is plugged. Reconnect the hose.

7With the engine off, depress the brake

pedal fully. Start the engine with the brake

pedal still depressed; the pedal should be felt

to go down fractionally.

8If the results of these tests are not

satisfactory, remove the unit and fit a new one

as described in the next Section.

15 Vacuum servo unit-

removal and refitting

3

1Syphon as much fluid as possible out of the

master cylinder reservolr.

2Disconnect electrical leads from the

terminals in the reservoir cap then uncouple

the rigid pipelines from the master cylinder

body. Be prepared to catch leaking fluid and

plug the open ends of the pipelines.

3The master cylinder can be unbolted now

from the servo unit, or detached later when

the complete assembly is withdrawn.

4Working inside the car, disconnect the

servo pushrod from the pedal then remove the

servo mounting nuts.

5Withdraw the servo assembly into the

engine compartment, then remove it to the

bench. lf the master cylinder is still attached,

cover the wings with protective sheeting, in

case brake fluid is spilled during removal.

6Refitting is a reversal of the removal

process, but adjust the pushrod clearance as

described in Section 9. On completion of

refitting, bleed the complete hydraulic system

as described in Section 12. Note: Where the

help of an assistant is available, the servo

pushrod need not be disconnected from the

pedal. The rod is a sliding fit in the servo and

the servo can be simply pulled off the rod.

Refitting without having disconnected the rod

from the pedal can be difficult unless the help

of an assistant is available.

16 Handbrake- adjustment

1

Adjustment is normally automatic, by the

movement of the rear brake shoes on their

automatic adjusters.

However, owing to cable stretch,

supplementary adjustment is occasionally

required at the control lever adjuster nut. The

need for this adjustment is usually indicated

by excessive movement of the control lever

when fully applied.

1The rear brakes should be fully applied

when the handbrake control lever has been

pulled over four or five notches.

2If adjustment is required, release the

8•8 Braking system

16.2 Handbrake adjuster nuts

Page 127 of 303

Cooling system................................................................................. 8

Part A: 999 cc engine

Description

Maintenance

Thermostat - removal and refitting

Coolant pump - removal and refitting

Part B: 1301 cc Turbo ie engine

Description

Part C: 1372 cc ie and 1372 cc Turbo ie engines

Description

Maintenance

Cooling system - draining, flushing and refilling

Radiator (and cooling fan) - removal and refitting

Thermostat - removal and refitting

Coolant pump - removal and refitting

Coolant pump/alternator drivebelt - checking, renewal and

tensioning

Part D: Heater unit later models

Heater unit - removal and refitting

Heater unit - dismantling and reassembly

Fuel and exhaust systems............................................................... 9

Part A: General

Unleaded fuel

Air cleaner modified types

Fuel pump (999 cc engine) - description, removal and

refitting

Fuel tank (999 cc engine)

Part B: Carburettor models

Carburettor (Weber 32 TLF) - description

Carburettor (Weber 32 TLF) - idle speed and mixture

Carburettor (Weber 32 TLF) - removal and refitting

Carburettor (Weber 32 TLF) - overhaul

Carburettor (Weber 30/32 DMTE) - general

Carburettor (Weber 30/32 DMTE) - overhaul

Carburettor (Weber 32 ICEV 61/250 and DMTE 30/32,

DMTE 30/150) - general

Carburettor (Solex C 30/32-CIC 8) - description

Part C: Bosch LE-2 Jetronic fuel injection system

Description

Maintenance

Fuel filter - renewal

Air cleaner element - renewal

Idle speed and mixture - adjustment

Fuel injection system - electrical tests

Fuel injection system - mechanical tests

Fuel injection system components - removal and

refitting

Throttle control linkage - general

Fuel tank - general

Part D: Bosch Mono-Jetronic fuel injection system

Description

Maintenance

Fuel filter - renewal

Air cleaner element - renewal

Idle speed and mixture adjustment

Accelerator control system - check and adjustment

Fuel system - depressurisation

Fuel pump and supply - system checks

Fuel pump - removal and refitting

Injector unit - removal and refitting

Intake air temperature sensor - removal and refitting

Fuel injector - removal and refitting

Electronic control unit (ECU) - removal and refitting

Inlet manifold - removal and refitting

Exhaust manifold - removal and refitting

Catalytic converter - general information

Fuel evaporation control system - generalPart E: Bosch L3.1/2 Jetronic fuel injection systems

Description

Fuel system - depressurisation

Maintenance

Fuel filter - renewal

Air cleaner element - renewal

Checks and adjustments

Injection system components - removal and refitting

Part G: Turbocharger system

Description

Precautions

Turbocharger (1301 cc ie engine) - removal and refitting

Turbocharger (1372 cc ie engine) - removal and refitting

Intercooler - removal and refitting

Injector cooling fan - removal and refitting

Fault finding - fuel injection system

Fault finding - turbocharger system

Ignition system................................................................................. 10

General

Ignition timing (all later models)

Breakerless ignition system - description

Distributor (breakerless type) - removal and refitting

Distributor (breakerless type) - overhaul

Breakerless ignition system components - testing

Microplex ignition system - description

Distributor (Microplex) - removal and refitting

Microplex ignition system components - testing

Digiplex 2 ignition system - description

Distributor (Digiplex 2) - removal and refitting

Spark plugs and HT leads - general

Fault finding - Microplex ignition system

Clutch................................................................................................ 11

Clutch pedal adjustment (cable clutch)

Hydraulic clutch - description

Maintenance (hydraulic clutch)

Clutch master cylinder - removal, overhaul and

refitting

Clutch operating cylinder - removal, overhaul and

refitting

Clutch hydraulic system - bleeding

Transmission.................................................................................... 12

Part A: 1301 cc Turbo ie engine

Description

Gearchange linkage - removal and refitting

Gearchange linkage (Antiskid models) - general

Final drive output shafts - description and oil seal

renewal

Part B: 1372 cc ie and 1372 cc Turbo ie engines

Description

Maintenance

Oil level - checking

Oil - renewal

Gearlever and linkages - general

Transmission - removal and refitting

Part C: 999 and 1108 cc with C514 type transmission

Description

Maintenance

Driveshafts........................................................................................ 13

Inboard joint boots (non-Turbo models, September 1987 on) -

modification

Intermediate driveshaft (Turbo ie models)

Inboard CV joints (Turbo ie models - overhaul

Right-hand driveshaft damper weight (1108 and 1372 cc

models) - removal and refitting

13•2 Supplement: Revisions and information on later models

Page 219 of 303

25Unscrew the union nut and detach the

hydraulic fluid line from the operating cylinder

(photo).

26Undo the cylinder/mounting bracket

retaining bolts and lift clear the cylinder

together with the bracket (photo). Release the

retaining clip and separate the cylinder from

the bracket.

27To dismantle the cylinder, prise free and

pull back the dust boot, withdrawing it

together with the operating rod.

28Invert the cylinder and shake free the

piston and seal assembly. If it is stuck inside

the cylinder, remove the bleed screw then

apply moderate air pressure (from a foot

pump) into the bleed port and catch the

cylinder in a clean cloth as it is ejected.

29Remove the seals noting their orientation.

Clean all components in methylated spirits or

new hydraulic fluid. If the cylinder is damaged,

scored or badly worn it must be renewed. The

seals must always be renewed once they are

removed.

30Assemble the new seals to the piston and

lubricate the cylinder, seals and piston

assembly with new hydraulic fluid (of the

specified type) before assembling them.

Ensure that the seals are fitted the correct

way round (as noted during removal).

31Renew the dust boot, fit and secure the

operating rod into position then refit the dust

boot over the cylinder. If removed, refit the

bleed screw.

32Reconnect the cylinder to the mounting

bracket and refit the combined assembly to

the vehicle in the reverse order of removal.

Ensure the hydraulic union is clean and take

care not to damage the threads as it is

reconnected.

33Remove the polythene seal from the

hydraulic reservoir filler neck, top up the fluid

level and bleed the system as described

below.

Clutch hydraulic system -

bleeding#

34The clutch hydraulic circuit is bled in

much the same manner to that described for a

brake circuit. Refer to Section 12 in Chapter 8

and proceed as described, but note that the

bleed screw for the clutch circuit is located inthe end of the operating cylinder (see

photo 11.25). The clutch hydraulic circuit

reservoir is mounted in the engine

compartment on the left-hand side near the

bulkhead and is separate from the master

cylinder. As the system is being bled, ensure

that the fluid level in the reservoir is

maintained between the MIN and MAX level

marks. Do not allow the fluid level to drop

below the MIN level mark otherwise air will

enter the system and greatly lengthen the

operation. Wipe clean any fluid spillage from

the paintwork or adjacent components as it

has a corrosive effect if left.

12 Transmission

PART A:

1301 CC TURBO IE ENGINE

Description

1The transmission is of five-speed type,

based on that used in the Fiat Strada 105 TC.

2For all practical purposes, the operations

described in Chapter 6 apply, but observe the

following differences.

Gearchange linkage -

removal and refitting Á

3This is of two-rod type.

4Remove the gaiter and disconnect the rodsat the gear lever end as described in Chap-

ter 6, Section 3.

5Disconnect the rods at the transmission

end by unscrewing the nuts and bolts which

connect the linkage rods to the selector rods

(photo).

6Extract the spring clip which retains the end

of the short link rod (photo).

Gearchange linkage

(Antiskid models) - general

7The gearchange linkage and internal

selector arrangement has been modified, as

shown in Fig. 13.89.

Final drive output shafts -

description and

oil seal renewal

#

8The output shafts on this transmission

incorporate a flange on the left-hand side, to

which a coupling flange on the driveshaft is

bolted. On the right-hand side, an

intermediate shaft (see Section 13) is splined

directly into the differential side gear.

9A leaking oil seal may be renewed on the

left-hand side of the final drive casing after

first disconnecting the driveshaft. Then using

two levers, prise out the flange/stub shaft

against the tension of its retaining circlip.

10Unbolt and remove the bearing cover.

When refitting the cover, make sure that the

O-ring is in good condition.

11To renew the oil seal on the right-hand

side, first remove the intermediate driveshaft,

and then prise the defective seal out of the

final drive housing using a suitable tool.

12Apply grease to the new seal lips before

refitting the intermediate shaft or the stub

shaft. Tighten all bolts to the specified torque.

PART B:

1372 CC IE AND 1372 CC

TURBO IE ENGINES

Description

1The transmission is of five-speed type,

based on that used in the FIAT Tipo. The

transmission is mounted in-line with the

engine and is located in the left-hand side of

the engine compartment. Drive from the

clutch is transferred through the input shaft

and the mainshaft to the integrally-located

13•94 Supplement: Revisions and information on later models

12A.6 Gearchange link rod spring clip

(arrowed) on the 1301 cc Turbo ie engine12A.5 Gearchange rod connections at

transmission (1301 cc Turbo ie engine)

11.26 Clutch operating lever (A) and

operating cylinder bracket-to-transmission

housing bolt (B)11.25 Clutch operating cylinder showing

hydraulic line connection and bleed nipple

(arrowed)

Page 284 of 303

MOT Test ChecksREF•1

This is a guide to getting your vehicle through the MOT test.

Obviously it will not be possible to examine the vehicle to the same

standard as the professional MOT tester. However, working through

the following checks will enable you to identify any problem areas

before submitting the vehicle for the test.

Where a testable component is in borderline condition, the tester

has discretion in deciding whether to pass or fail it. The basis of such

discretion is whether the tester would be happy for a close relative or

friend to use the vehicle with the component in that condition. If the

vehicle presented is clean and evidently well cared for, the tester may

be more inclined to pass a borderline component than if the vehicle is

scruffy and apparently neglected.

It has only been possible to summarise the test requirements here,

based on the regulations in force at the time of printing. Test standards

are becoming increasingly stringent, although there are some

exemptions for older vehicles. For full details obtain a copy of the Haynes

publication Pass the MOT! (available from stockists of Haynes manuals).

An assistant will be needed to help carry out some of these checks.

The checks have been sub-divided into four categories, as follows:

HandbrakeMTest the operation of the handbrake.

Excessive travel (too many clicks) indicates

incorrect brake or cable adjustment.

MCheck that the handbrake cannot be

released by tapping the lever sideways. Check

the security of the lever mountings.

Footbrake

MDepress the brake pedal and check that it

does not creep down to the floor, indicating a

master cylinder fault. Release the pedal, wait

a few seconds, then depress it again. If the

pedal travels nearly to the floor before firm

resistance is felt, brake adjustment or repair is

necessary. If the pedal feels spongy, there is

air in the hydraulic system which must be

removed by bleeding.MCheck that the brake pedal is secure and in

good condition. Check also for signs of fluid

leaks on the pedal, floor or carpets, which

would indicate failed seals in the brake master

cylinder.

MCheck the servo unit (when applicable) by

operating the brake pedal several times, then

keeping the pedal depressed and starting the

engine. As the engine starts, the pedal will

move down slightly. If not, the vacuum hose or

the servo itself may be faulty.

Steering wheel and column

MExamine the steering wheel for fractures or

looseness of the hub, spokes or rim.

MMove the steering wheel from side to side

and then up and down. Check that the

steering wheel is not loose on the column,

indicating wear or a loose retaining nut.

Continue moving the steering wheel as before,

but also turn it slightly from left to right.

MCheck that the steering wheel is not loose

on the column, and that there is no abnormalmovement of the steering wheel, indicating

wear in the column support bearings or

couplings.

Windscreen and mirrors

MThe windscreen must be free of cracks or

other significant damage within the driver’s

field of view. (Small stone chips are

acceptable.) Rear view mirrors must be

secure, intact, and capable of being adjusted.

1Checks carried out

FROM THE DRIVER’S SEAT

1Checks carried out

FROM THE DRIVER’S

SEAT2Checks carried out

WITH THE VEHICLE

ON THE GROUND3Checks carried out

WITH THE VEHICLE

RAISED AND THE

WHEELS FREE TO

TURN4Checks carried out on

YOUR VEHICLE’S

EXHAUST EMISSION

SYSTEM

REF

Page 288 of 303

Introduction

A selection of good tools is a fundamental

requirement for anyone contemplating the

maintenance and repair of a motor vehicle.

For the owner who does not possess any,

their purchase will prove a considerable

expense, offsetting some of the savings made

by doing-it-yourself. However, provided that

the tools purchased meet the relevant national

safety standards and are of good quality, they

will last for many years and prove an

extremely worthwhile investment.

To help the average owner to decide which

tools are needed to carry out the various tasks

detailed in this manual, we have compiled

three lists of tools under the following

headings: Maintenance and minor repair,

Repair and overhaul, and Special. Newcomers

to practical mechanics should start off with

the Maintenance and minor repairtool kit, and

confine themselves to the simpler jobs around

the vehicle. Then, as confidence and

experience grow, more difficult tasks can be

undertaken, with extra tools being purchased

as, and when, they are needed. In this way, a

Maintenance and minor repairtool kit can be

built up into a Repair and overhaultool kit over

a considerable period of time, without any

major cash outlays. The experienced do-it-

yourselfer will have a tool kit good enough for

most repair and overhaul procedures, and will

add tools from the Specialcategory when it is

felt that the expense is justified by the amount

of use to which these tools will be put.

Maintenance and minor repair

tool kit

The tools given in this list should be

considered as a minimum requirement if

routine maintenance, servicing and minor

repair operations are to be undertaken. We

recommend the purchase of combination

spanners (ring one end, open-ended the

other); although more expensive than open-

ended ones, they do give the advantages of

both types of spanner.

MCombination spanners: 8, 9, 10, 11, 12, 13,

14, 15, 16, 17, 19, 21, 22, 24 & 26 mm

MAdjustable spanner - 35 mm jaw (approx)

MSet of feeler gauges

MSpark plug spanner (with rubber insert)

MSpark plug gap adjustment tool

MBrake bleed nipple spannerMScrewdrivers: Flat blade and cross blade –

approx 100 mm long x 6 mm dia

MCombination pliers

MHacksaw (junior)

MTyre pump

MTyre pressure gauge

MOil can

MOil filter removal tool

MFine emery cloth

MWire brush (small)

MFunnel (medium size)

Repair and overhaul tool kit

These tools are virtually essential for

anyone undertaking any major repairs to a

motor vehicle, and are additional to those

given in the Maintenance and minor repairlist.

Included in this list is a comprehensive set of

sockets. Although these are expensive, they

will be found invaluable as they are so

versatile - particularly if various drives are

included in the set. We recommend the half-

inch square-drive type, as this can be used

with most proprietary torque wrenches. If you

cannot afford a socket set, even bought

piecemeal, then inexpensive tubular box

spanners are a useful alternative.

The tools in this list will occasionally need

to be supplemented by tools from the Special

list:

MSockets (or box spanners) to cover range in

previous list

MReversible ratchet drive (for use with

sockets) (see illustration)

MExtension piece, 250 mm (for use with

sockets)

MUniversal joint (for use with sockets)

MTorque wrench (for use with sockets)

MSelf-locking grips

MBall pein hammer

MSoft-faced mallet (plastic/aluminium or

rubber)

MScrewdrivers:

Flat blade - long & sturdy, short (chubby),

and narrow (electrician’s) types

Cross blade - Long & sturdy, and short

(chubby) types

MPliers:

Long-nosed

Side cutters (electrician’s)

Circlip (internal and external)

MCold chisel - 25 mm

MScriber

MScraperMCentre-punch

MPin punch

MHacksaw

MBrake hose clamp

MBrake bleeding kit

MSelection of twist drills

MSteel rule/straight-edge

MAllen keys

MSelection of files

MWire brush

MAxle stands

MJack (strong trolley or hydraulic type)

MLight with extension lead

Special tools

The tools in this list are those which are not

used regularly, are expensive to buy, or which

need to be used in accordance with their

manufacturers’ instructions. Unless relatively

difficult mechanical jobs are undertaken

frequently, it will not be economic to buy

many of these tools. Where this is the case,

you could consider clubbing together with

friends (or joining a motorists’ club) to make a

joint purchase, or borrowing the tools against

a deposit from a local garage or tool hire

specialist. It is worth noting that many of the

larger DIY superstores now carry a large

range of special tools for hire at modest rates.

The following list contains only those tools

and instruments freely available to the public,

and not those special tools produced by the

vehicle manufacturer specifically for its dealer

network. You will find occasional references

to these manufacturers’ special tools in the

text of this manual. Generally, an alternative

method of doing the job without the vehicle

manufacturers’ special tool is given. However,

sometimes there is no alternative to using

them. Where this is the case and the relevant

tool cannot be bought or borrowed, you will

have to entrust the work to a franchised

garage.

MValve spring compressor (see illustration)

MValve grinding tool

MPiston ring compressor (see illustration)

MPiston ring removal/installation tool (see

illustration)

MCylinder bore hone (see illustration)

MBalljoint separator

MCoil spring compressors (where applicable)

MTwo/three-legged hub and bearing puller

(see illustration)

Tools and Working FacilitiesREF•5

REF

Page 296 of 303

Glossary of Technical TermsREF•13

REF

A

ABS (Anti-lock brake system)A system,

usually electronically controlled, that senses

incipient wheel lockup during braking and

relieves hydraulic pressure at wheels that are

about to skid.

Air bag An inflatable bag hidden in the

steering wheel (driver’s side) or the dash or

glovebox (passenger side). In a head-on

collision, the bags inflate, preventing the

driver and front passenger from being thrown

forward into the steering wheel or windscreen.

Air cleanerA metal or plastic housing,

containing a filter element, which removes

dust and dirt from the air being drawn into the

engine.

Air filter elementThe actual filter in an air

cleaner system, usually manufactured from

pleated paper and requiring renewal at regular

intervals.

Allen keyA hexagonal wrench which fits into

a recessed hexagonal hole.

Alligator clipA long-nosed spring-loaded

metal clip with meshing teeth. Used to make

temporary electrical connections.

AlternatorA component in the electrical

system which converts mechanical energy

from a drivebelt into electrical energy to

charge the battery and to operate the starting

system, ignition system and electrical

accessories.

Ampere (amp)A unit of measurement for the

flow of electric current. One amp is the

amount of current produced by one volt

acting through a resistance of one ohm.

Anaerobic sealerA substance used to

prevent bolts and screws from loosening.

Anaerobic means that it does not require

oxygen for activation. The Loctite brand is

widely used.

AntifreezeA substance (usually ethylene

glycol) mixed with water, and added to a

vehicle’s cooling system, to prevent freezing

of the coolant in winter. Antifreeze also

contains chemicals to inhibit corrosion and

the formation of rust and other deposits that

would tend to clog the radiator and coolant

passages and reduce cooling efficiency.

Anti-seize compoundA coating that

reduces the risk of seizing on fasteners that

are subjected to high temperatures, such as

exhaust manifold bolts and nuts.

AsbestosA natural fibrous mineral with great

heat resistance, commonly used in the

composition of brake friction materials.Asbestos is a health hazard and the dust

created by brake systems should never be

inhaled or ingested.

AxleA shaft on which a wheel revolves, or

which revolves with a wheel. Also, a solid

beam that connects the two wheels at one

end of the vehicle. An axle which also

transmits power to the wheels is known as a

live axle.

AxleshaftA single rotating shaft, on either

side of the differential, which delivers power

from the final drive assembly to the drive

wheels. Also called a driveshaft or a halfshaft.

BBall bearingAn anti-friction bearing

consisting of a hardened inner and outer race

with hardened steel balls between two races.

BearingThe curved surface on a shaft or in a

bore, or the part assembled into either, that

permits relative motion between them with

minimum wear and friction.

Big-end bearingThe bearing in the end of

the connecting rod that’s attached to the

crankshaft.

Bleed nippleA valve on a brake wheel

cylinder, caliper or other hydraulic component

that is opened to purge the hydraulic system

of air. Also called a bleed screw.

Brake bleedingProcedure for removing air

from lines of a hydraulic brake system.

Brake discThe component of a disc brake

that rotates with the wheels.Brake drumThe component of a drum brake

that rotates with the wheels.

Brake liningsThe friction material which

contacts the brake disc or drum to retard the

vehicle’s speed. The linings are bonded or

riveted to the brake pads or shoes.

Brake padsThe replaceable friction pads

that pinch the brake disc when the brakes are

applied. Brake pads consist of a friction

material bonded or riveted to a rigid backing

plate.

Brake shoeThe crescent-shaped carrier to

which the brake linings are mounted and

which forces the lining against the rotating

drum during braking.

Braking systemsFor more information on

braking systems, consult the Haynes

Automotive Brake Manual.

Breaker barA long socket wrench handle

providing greater leverage.

BulkheadThe insulated partition between

the engine and the passenger compartment.

CCaliperThe non-rotating part of a disc-brake

assembly that straddles the disc and carries

the brake pads. The caliper also contains the

hydraulic components that cause the pads to

pinch the disc when the brakes are applied. A

caliper is also a measuring tool that can be set

to measure inside or outside dimensions of an

object.

CamshaftA rotating shaft on which a series

of cam lobes operate the valve mechanisms.

The camshaft may be driven by gears, by

sprockets and chain or by sprockets and a

belt.

CanisterA container in an evaporative

emission control system; contains activated

charcoal granules to trap vapours from the

fuel system.

CarburettorA device which mixes fuel with

air in the proper proportions to provide a

desired power output from a spark ignition

internal combustion engine.

CastellatedResembling the parapets along

the top of a castle wall. For example, a

castellated balljoint stud nut.

CastorIn wheel alignment, the backward or

forward tilt of the steering axis. Castor is

positive when the steering axis is inclined

rearward at the top.

Canister

Brake bleeding

Bearing

Air filter

Page 300 of 303

A

Accelerator cable - 3•12, 13•80

Accelerator control system - 13•75

Accelerator pump -3•7, 3•8, 3•11, 13•66

Acknowledgements - 0•4

Aerial -9•10

Air bags - 0•5

Air cleaner -3•4, 13•60, 13•69, 13•67,

13•75, 13•79

Air pressure switch - 13•70

Air temperature sensor - 13•76

Airflow meter - 13•67, 13•69, 13•80

Alternator -9•3, 13•58, 13•103, 13•104

Alternator fault -9•14

Anti-flooding device -3•8, 3•9, 3•10, 3•11,

13•64

Anti-knock sensor - 13•86, 13•90

Anti-roll bar - 13•111

Antifreeze - 0•6, 0•13, 2•1, 2•2

Antiskid system - 13•103

Armrest - 13•112

Asbestos - 0•5

Auxiliary shaft -1•29, 1•30, 13•51, 13•53

B

Battery -0•5, 9•2

Battery fault -9•14

Bleeding brakes -8•7

Bleeding clutch - 13•94

Bodywork- 12•1et seq, 13•111, REF•4

Bonnet - 12•3, 12•4

Boots -7•2, 10•2, 13•98

Brake fluid -0•13, 8•1, 13•110, 13•111

Braking system-8•1et seq, 13•100,

REF•1, REF•2, REF•3

Braking system fault finding -8•9

Breakerless ignition system - 13•85, 13•86

Bumpers - 12•4, 12•11, 13•113

Burning -0•5

C

Cables -3•12, 5•1, 8•9, 9•8, 13•80

Calipers -8•3, 13•101, 13•102Camshaft -1•19, 1•21, 1•24, 1•29, 1•32,

13•21, 13•30, 13•34, 13•41, 13•42

Capacities -0•6, 13•17

Carburettors -3•6 to 3•11, 13•62 to 13•66

Carpets - 12•2

Cassette player-9•10

Catalytic converter - 13•77

Central door locking -9•11, 13•109

Centre console - 12•9

Check control (warning module) system -

9•12, 9•13, 13•110, 13•111

Choke -3•11, 3•12

Cigar lighter -9•13, 13•109

Clock -9•13, 13•108

Clutch-5•1et seq, 13•83, 13•92, 13•94

Clutch fault finding -5•3

Clutch fluid -0•13

CO emissions (mixture) - REF•4

Coil -4•6, 13•86, 13•90, 13•91

Coil spring - 11•3, 11•4

Condenser -4•5

Connecting rods -1•12, 1•18, 1•22, 1•26,

1•30, 13•25, 13•26, 13•30, 13•35,

13•47, 13•48, 13•53

Console - 12•9

Constant velocity joint -0•13, 7•3, 13•98,

13•99

Contact breaker points -4•2, 4•3

Contents -0•2

Control panel - 13•108

Conversion factors -0•14

Coolant -0•6, 0•13, 2•1, 2•2, 13•69, 13•70,

13•110, 13•111

Coolant pump -2•4, 13•55, 13•58

Cooling and heating systems-2•1et seq,

13•54, 13•55

Cooling and heating systems fault finding -

2•8

Courtesy lamp -9•5, 9•8

Crankcase -1•17

Crankcase ventilation system -1•8

Crankshaft -1•18, 1•20, 1•30, 1•31, 13•44,

13•45, 13•52

Crossmember - 11•4

Crushing -0•5

CV joints -0•13, 7•3, 13•98, 13•99

Cylinder block -1•17Cylinder head -1•10, 1•16, 1•19, 1•22,

1•25, 1•28, 1•32, 13•19, 13•22, 13•30,

13•34, 13•43, 13•44, 13•53

D

Dents in bodywork - 12•2

Depressurisation (fuel system) - 13•75

Digiplex 2 ignition system - 13•90

Dim-dip system - 13•106

Dimensions -0•6, 13•17

Direction indicators -9•7

Discs -8•4, 13•101, 13•102

Distributor -4•3, 4•5, 13•86, 13•89, 13•90,

13•92

Doors -9•11, 12•5, 12•6, 12•7, 13•111,

13•112, 13•114, REF•2

Drivebelts -2•3, 13•58

Driveshaft

Driveshafts and hubs fault finding -7•6

Driveshafts,hubs,roadwheels and tyres-

0•13, 7•1et seq, 10•4, 11•3, 11•6,

13•98, 13•99, REF•3, REF•4

Drums -8•4

Dwell angle -4•4

E

Economy gauge (Econometer) -3•11, 9•12

Electric shock -0•5

Electric windows -9•11, 13•109

Electrical control circuit (ECU) - 13•67,

13•71, 13•81, 13•86, 13•90

Electrical system-9•1et seq,13•103,

REF•2

Electrical system fault finding -9•14,

REF•9

Electronic ignition -4•3, 4•6, 4•7

Engine-1•1et seq, 13•19, 13•33, 13•37

Engine fault finding -1•35, 1•36, 2•8, 3•13,

4•9, 13•92, REF•10, REF•11

Engine oil -0•6, 0•13, 1•3, 1•4, 1•8

Engine speed sensor -4•7, 13•89, 13•91

Environmental considerations - REF•8

Exhaust emission checks - REF•4

Exhaust manifold - 13•77

Exhaust system -3•12, REF•3

IndexREF•17

REF

Note: References throughout this index relate to Chapter•page number