fuel FORD CAPRI 1974 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 79 of 205

,

. ,

I , ~. !

78 Chapter 3 FlIer and exhaust systems

TIlls system, when comp1lrcd with conventlon,lI c.Jrhwctlo, ~rrilngemen1s.

tI'(lllPS

A FI/ef Milk Fuef Plllllf! F/lel .?CCIIIIW/<1IOI Fuel filler F/lel ,IISltihular ,w(/ millime con/rol l11ralllc MIlllll/ce/Of "',1/1'115 AI( ch.ll11/"1(

B W

The fuel pump IS 0 1 eh,CIIICtllly operated. ,aile. cell Iyp" A .",SS (IIC rchd ..,:,1..,0 'S mco,p[)I;oh~(1 III the pwnp 10 preY",l! f:XCOSSlvn

p"'SSUIC la"ld III) '" tho event of ,1 ,,)Sl"Ctlon III th e pipelollf!s The fuel ,I(:c\llllula lor ha~ 'wo lunf.luItlS. (t) In 4'ill1I,)(:I1 llll! IIIII,,;,'U)!l 0 1 lhe luclllow. HHlu.:.iI ,ml hy Ihe I)\I"'P ;IIIf' (II) 10 11I;""t,"" Iud I"'"'~''''' ,,1";1 .h" .:o,!.m" h;os Iom,n sw"dn,,' "If TillS p.r.v"rlls .• v; 'po", IIH:1o; .lo.:vel"I'III!1 w,th t:'Hlf.O:'I""nt 100' ~t,'

6

9

The iI" sen~or 1)1"le is locilled in 'he main nIl Stlealll be.ween the iI'r clr:wller ,1nd the Ih'Ol\Io bullerfly. Du'ing idling. the ~irflow hits Ihe sensor plate which in tu.n '

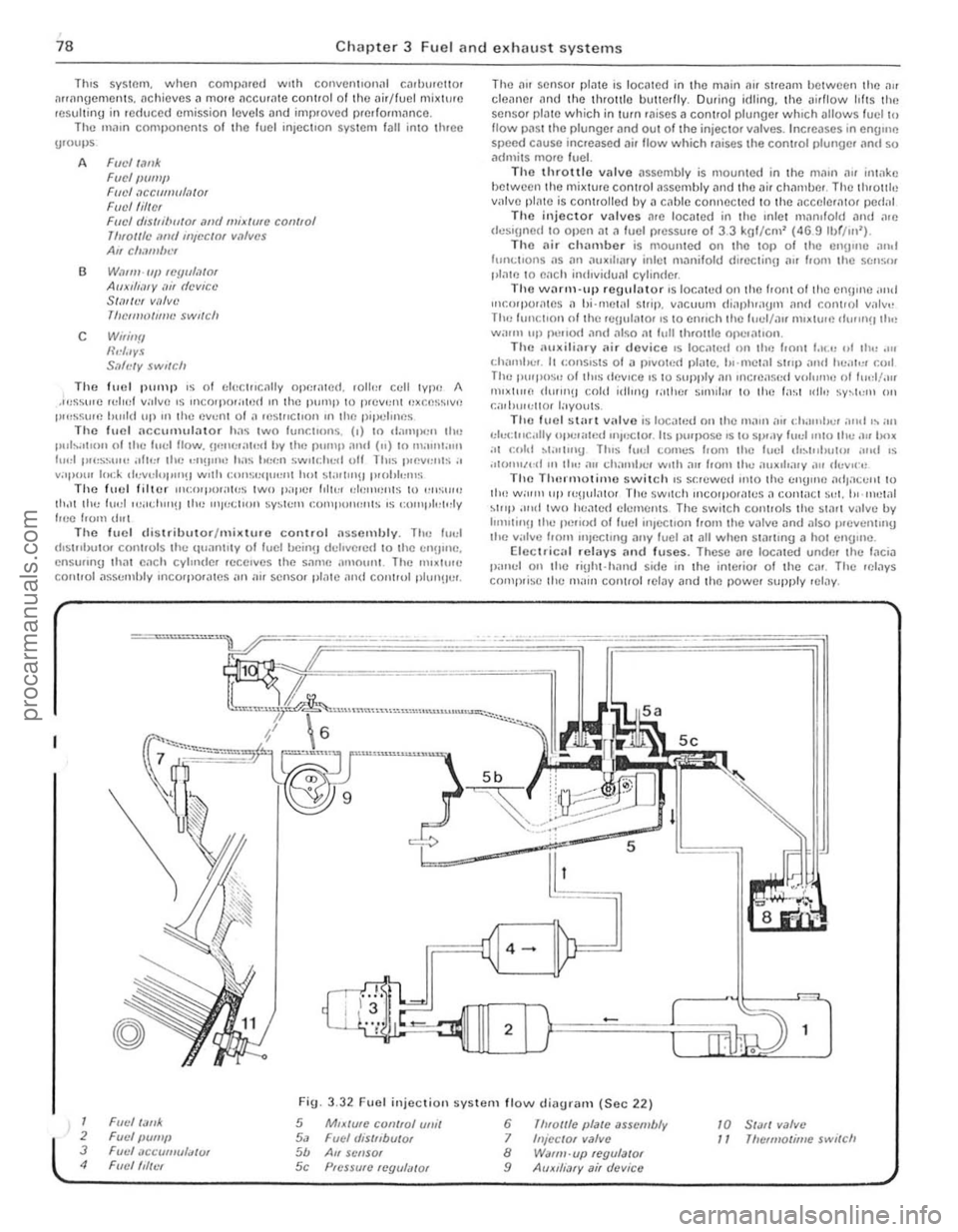

1 Flle/lall/(

"

Mu;/ulc CUIIIIOI ,mif 6 IIIIOlfic pla/c assembly 10 S/;II/ villve 2 Fuel PIIII/I' 5., Fucl (Iistllbutor 7 Inicc/or valvc /I 'hell1JOlimc sw,lch 3 Fuel i'CC/IIIIUI"tul 50 Alf SCIISOI 8 WiJllII·Up regula/or 4 Fuel '"10:1

"'

Plcssule regtllillQI 9 AU~IIt"aIY air device

·.i

<+

procarmanuals.com

Page 80 of 205

)

Chapte r 3 Fu el an d exhau st systems 79

Ii

0) G

\E )

' .. ~ ee)

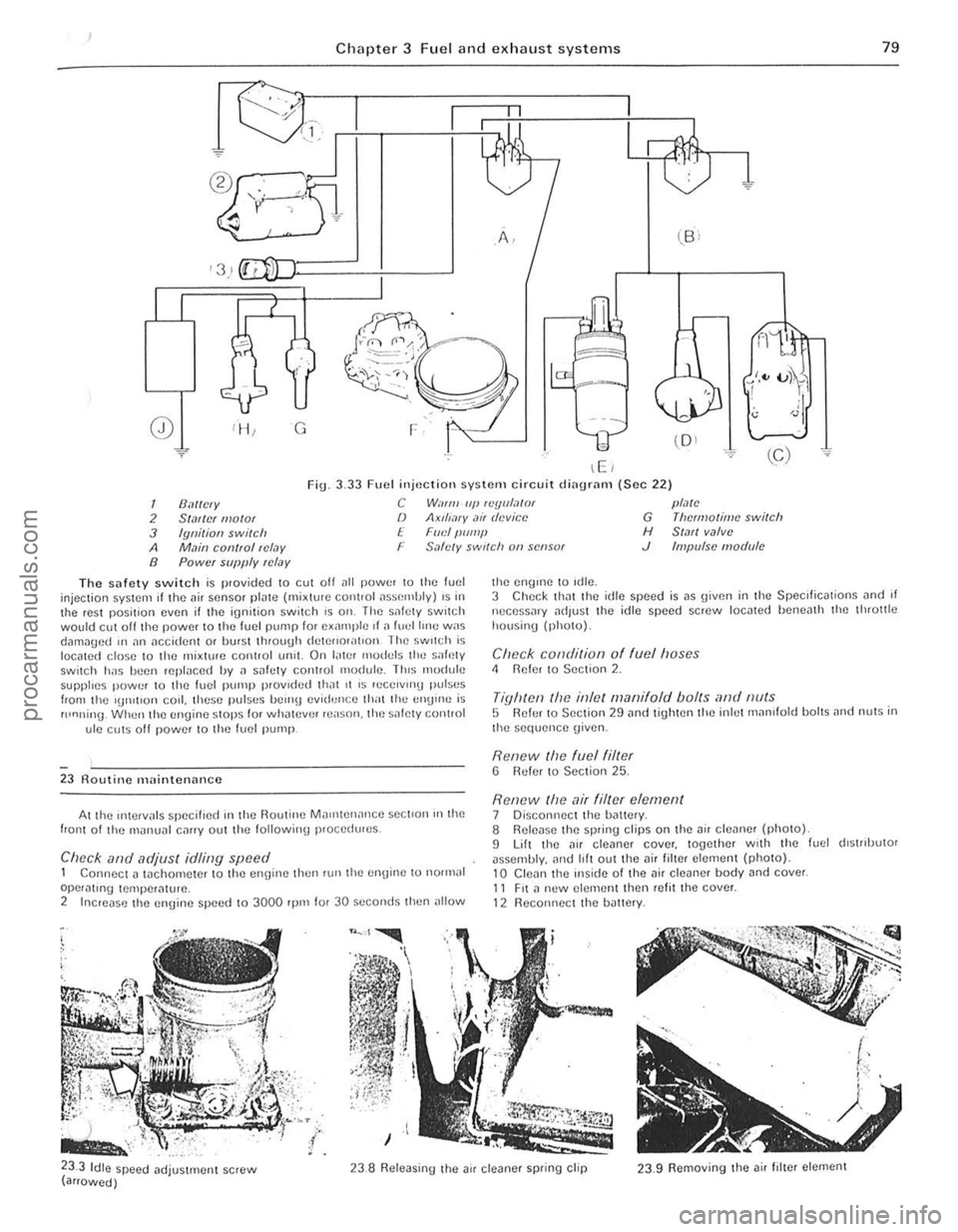

Fig. 3.33 Fuel injuctiOIl system circuit di

2 Sialicr I/Iolor /) Axll/,-"y ,1i, device G Theo1lO/lmc switch

3 fgnitioll switch E FIII;I/Iump H St,lfl valve

A M,lin con(Iol r(;/,)y F S

8 Power supply rcl.1Y

Tho safety switch is provided to cut olf illl power !O the fuel injection sySl(!m if the air sensor plJIC (mixt\HC COlllrol assemhly) IS il the rest position even if the ignition switch IS all. The s[lfcly switch would ell! off the power to the fuel pump for oillllpic ,I il fllOJllmu W

AI the IntelV

,. ,

< '(:,,~ , • . . ;::~t,·· . , ,

.' ) . ;~ ~~;:;: ~iJ" .. ,

n fr.X l

the engllle 10 'die.

3 Check Ihill I he idle speed is lIS given in the Specificmions ilnd il nccnssary "dlust the idle speed screw 10cllted heneillh Ihe Ihrottle housinv {photo).

Check conditiorl o f fuel hoses " Reier to SeClion 2.

Tighte/l the inlel manifold boilS and /luis 5 Refur 10 Section 29 and lighten the inlel rll

Renew the air filter element 7 Disconnect the h

-

I',

I t, ' .

;

!

" , ' .• I

! 1 I'

: 1'1 1 . ,

I

I '

I

procarmanuals.com

Page 81 of 205

80 Chapter 3 ~lIel and exhaust systems

24 Ai r cloanor -removal and re filling

1 Remove Iho elomerll as dllsc"hed III Sect,on 23. 2 Work,nn under Iht! left ·hand honl wheel arch. unboll the illr clenne, hOdy f,om Ih e s,de of the engmo compnl1lllen\. 3 Rohuil1g IS n rove rsal 01 tho lomova l I)rocodule wl lh relelence 10 $(1(;11011 23,

25 Main system compono n ts -rellloval "l1d rofitling

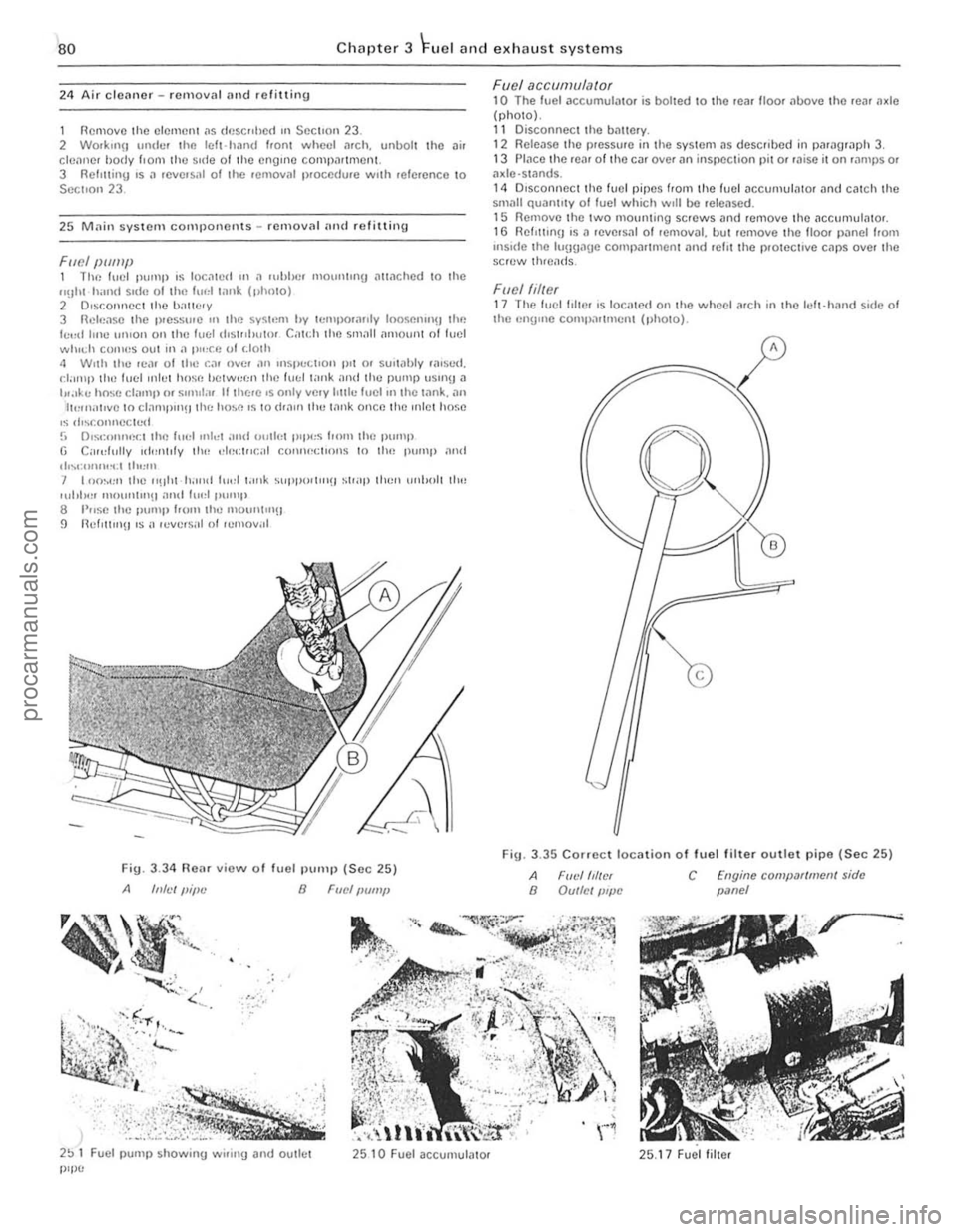

Fllel p /llllP 1 Thn hll)1 pump IS loc.lwd "' " lI,hlw.. 1ll011111111U .lUflchod 10 Ihe "!Ihl h"n{1 51th! 01 lhe 11I/,llal1k (phnIO) ') D,sC:OllllCCI Ihe h

'''~t:un'''~.1 11",," 7 I ,.,,.,~'''' the 1I!l11l hoilid Illd 1'lIlk SUPI)(Jl IIII(f Sl'ilP Illell unh(lll ll,,~ lul,I)". mOlllllll'H ami 111,,1 JlUlll!' 8 !'IISf) the pllmll "("n the "'OIull"'!! !) Ilcfllllll!j 's il IUliers,, 1 01 ,emOVi.1

FiU. 3 .34 R Oilr viow o f

A Ink'1 pi,ll}

fuel,HIIl'I) (Soc 25)

8 Fucl'WIII/'

..

) 2~ 1 Fllel pump showing Wlflflg ond oul'el pipe

~ .. . . ~ ~ ... ,

2510 Fuel accumulatO'

Fuel accumulator 10 The fuel accumulatO I is bolted to the Ical 11001 above Iho lear "Klc (phOIO). 11 Disconnect the bflltCly . 12 Releaso the preSSIJle in the system as descllbed in PfllfltJlilph 3, 13 I'lilCO the leal of th e car ovel ,1n inspection pit o. lilise il on ' ilmps O. fldo·stands. 1 4 D,sconnectlhe fucl pipes I,om the lu el accumul,110r and catch Ihe s

Fi U. 3.35 ConeCI 10Ciliion o f fuel filler oullel pipe (Sec 25)

A B Fuel "'ICf Ou/lelll'lle c Engine comporlmenl side p,wel

procarmanuals.com

Page 82 of 205

Chapter 3 Fuel and exhilust sys tems 81

1 8 Disco"nect the hllllmy 1 9 Relc,,~e tl", .. ,e5~II.e In t he system "s described in palaglaph 3 22 P lace some cluth hcnc,llh the luel flhel then disconnect the mlet ilnd outlet ", lions 2 1 Rcmollc tht) mOIlI1lIlI11 sc.cws ,1od withl1,,,w Lhe fuel f,ltc ,. Remove

the bl:lclwt II 'ltICIlS$:I'y 22 RchulI1U IS a .ellcls:l1 01 ,emoval. but m"ke sure tha t the 1,ltel is

pQs. t.onnd thll I:Olfe ct W,ly 10un(l. "n(1 Locate tile OUIICI plj'JC:I~ snown

io FiH. 33!)

Fucl tlisfllbu{(}r 23 The f""t d'~L"I"'lor .~ IOr.i'to(1 on top 0 1 the "" flltl'!'. 24 DISCOnl"" .t thu !o:m",y 25 n,;L""~,,, thO! L''''',~II''~ III (hI'! system:ls d"sl:"lmd in piull u,a"h :I"" t compL"L"ly 11,111"11" tho I,,,, d 111111 ",Hon 26 DI~r."'UII". t tl,,, """,11'1'1111 f,,(:II'"C$ 1,<)ul til(! llis t,d,utOI 27 UIIS'~":W ,I", nll"l1 """m'"'n sc",ws alld hit Ihe IIISIIIIJlIIOI away 28 RHhll""1 ".,' ",v':I~,,1 "I rr""OvilIIJlJ IIISC a IIIiW coppe, w"~.h,,, r:ach ~,de of Iht: '1',"'1" IIIIIW'~ ",,(I dO not OVf!rI'UII1I:rllhe llIliol Imils 9 Hall" Ih" :.y·.1t:1I1 I""",u'li t: heckr.d by yo"r dllatCr: 30 I\dl"~t th" "II" "I~:I"t :II\l IIIHXIIlIfl as ,leScII",,1I III SectIons 73 ,IIld 26.

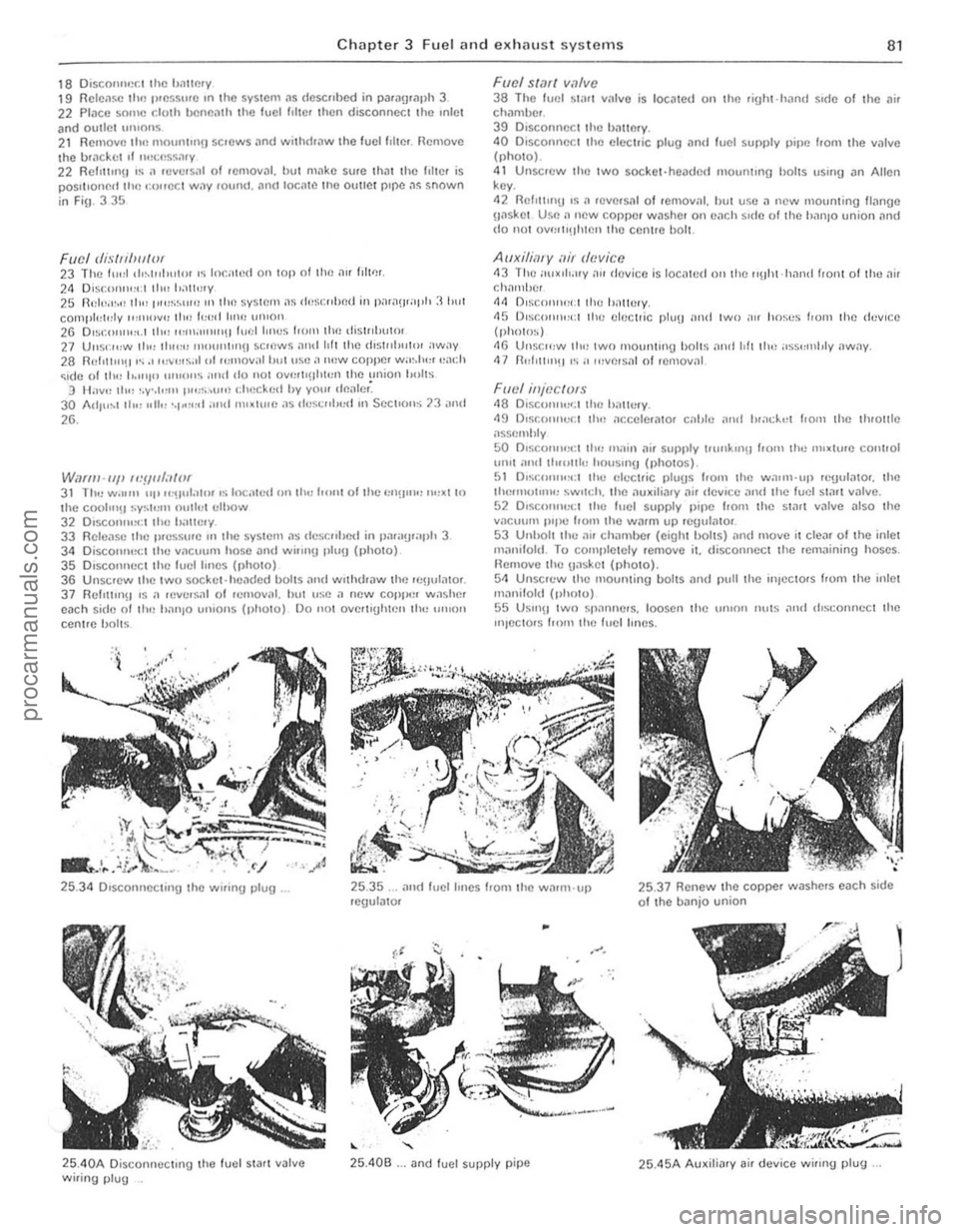

W"",,·/I/I/I.'ylll;/fOf 31 The w."'" "I' "'!I"I"tl1l 's loc ;llt,d on till! hunt of the ""!I"'" ""xtlO t he c(X,l"'H ~y~t"l11 nuth, t I:lhow 32 D,sco",,, • .: ! tl", lhlllCI" 33 Flcleasc Ihe prcssllfc In the sySlcm as desc"hed in parag'''I)h 3 34 Discount: GI Ihc lIacuum hose ilud wi"uy plllg (photo) 35 D'SCOI1"I:CI the fuel hiles (l)holO) 36 Unsc,ew the Iwo sockcl·he;lded uolts ;lnll wllhd';lw thll 'C!jUI;ltol . 37 Ref,(lln\1 IS ,1 ,cve.sa' o t ,emOIl"' . hut lise a new copp .. " wa~hcr eilch Si(lc 01 tim h,ll1l0 \llllons (phOIO) 00 nOl ove,l>ghtcil lh" I"'''on cenlre hol ts

Fuel S f"ff v:llvc 38 T hc luel stMI 1I:llve is located on thc ligl1l ·hand s,de of the lIir ch"mhel. 39 DIsconnect the bmlory . 40 Disconnect the elcctlic p lug and fuel supply pipc from th e lIalve (pholo) 41 Unscrew tho twO socke t·headed mount,ng bolts uSlllg an Allen

key .

42 Ref,,,,,,!) IS .1 'ellcrS:l1 of ,ernOllal. but u~e II ncw moullting flange !lasket Use" new copper w"shel all each SIde of the """10 union lind do nOI ovnlllllhien the Centrc holt.

A!lxih~1I"Y "i,. r/(!vicc 1\3 Thc i",x,h.n y "" rlcvice is 10C"II,1I On the IIU"t hal1d flOllI of thu lIir cha",!,,", 1\4 O lsc0I1"", .1 Ihe hallerI'. 1\5 D.scr"'''.,ct tl,(, eleCt,ic p l11\1 ;,ml IWO illf hoses IrOI11 the ""vice (phoIOS) 116 Unsc",w tl", two 'UO"nIl119 holts .11,,1 hit tl"l ;rss",,,t,ly i!Wlly. 1 7 Fl"f,It'''H .s ;1 HIIIC,s,,1 of 'elllolllli

Foel injocrurs 48 D, sclI"""'.t Ihe h;lll",y. 1\9 O, sr.

25 .4 0 A DisconnectIng Iho tuel slart valve

wiring plug

, "-

2 5 .4 06 ... and fuel supply pipe

•

25.4 5A Au xilia,y air dcvice w ifin g plug.

procarmanuals.com

Page 83 of 205

,

~ Chilpter 3 Fuel and exhaust systems

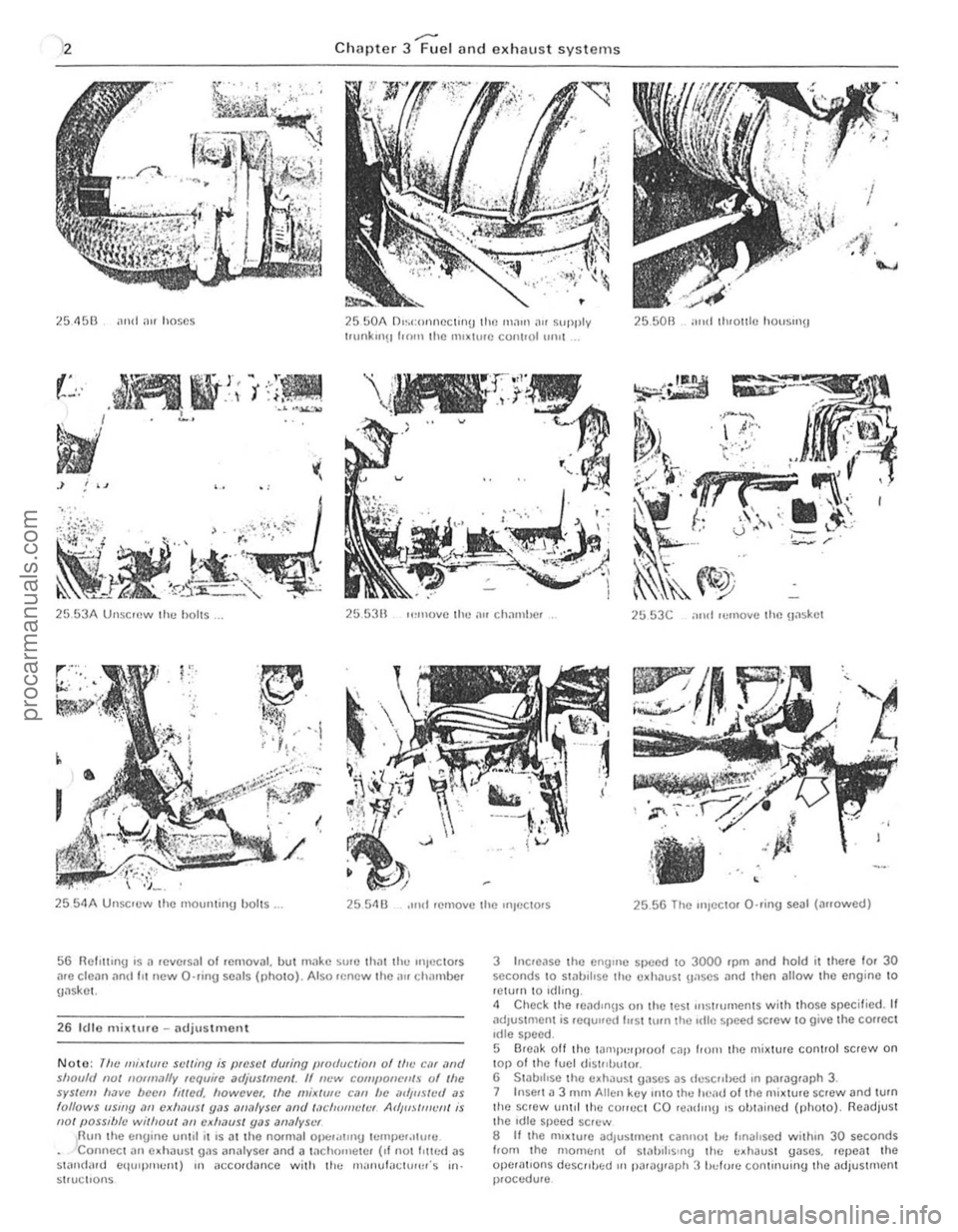

~5 4513 ,111<1 "'f hose s 2550A D",conneclinu the maUl "" supply t.unkul!! 1.011 the 1111~hue cont.ol 111111 25501l mid th'OI1I C houslIlU

"",'

25 53A UnsCII)w the holts. 255311 ,,,"U)IIC the ~'" chal11bcr ~5 53C ;11111 'cmoY(: the Haskct

,

25 5 4A UlIsc'ew the 11101l1lt;IIU bolts. 2554 U ,lIld remove the UIIL'CtOrs 2556 The "'Jecto, Q·rinU seal (a"owed)

56 Rcl,llll.g IS 11 reve rsal 01 rcmoval. hut mtlke SUiO Iha l til.., "l)OC Iors .IIC clea n and III new O'lIng seals (pholo). Also rencw the;IU chamber gtlskel.

26 I( H o mixture -adjustment

Noto: 11!e miJllllfe s"/liIl9 is preset during (!for/actiOIl of II", eM ,'nd shOll1ll 1101 "ofllwll~ require "djIISlment. If I!~'W r:QfIIl'O"Cllf.~ l)f 'he sys({)m ""VI! bccn flllCd. IlOwever. tile mix/IIII! (;,1/1 be mi,l/steil as lollows "Silly /II) cxlwlls/ y,l$

3 Incroase the enyulC speed 10 3000 'pm and hold it the,e 10' 30 seconds to Sl

5 Break oft the lalllpl:q)lOol cap 110111 the mj~ture conlrol screw on lap 01 Ihe fuel uistllbulOi. 6 S tabilise the cxhausl Ua ses as dcscllhc·d ,n paragraph 3. 7 In sert 11 3 r1\I AUcn key onto Ihe heau 01 the mixture SCfew and tum the SCfew urlld the COlfeCI CO re

procarmanuals.com

Page 84 of 205

·s

Chapter 3 Fuel and exhaust sys tems 83

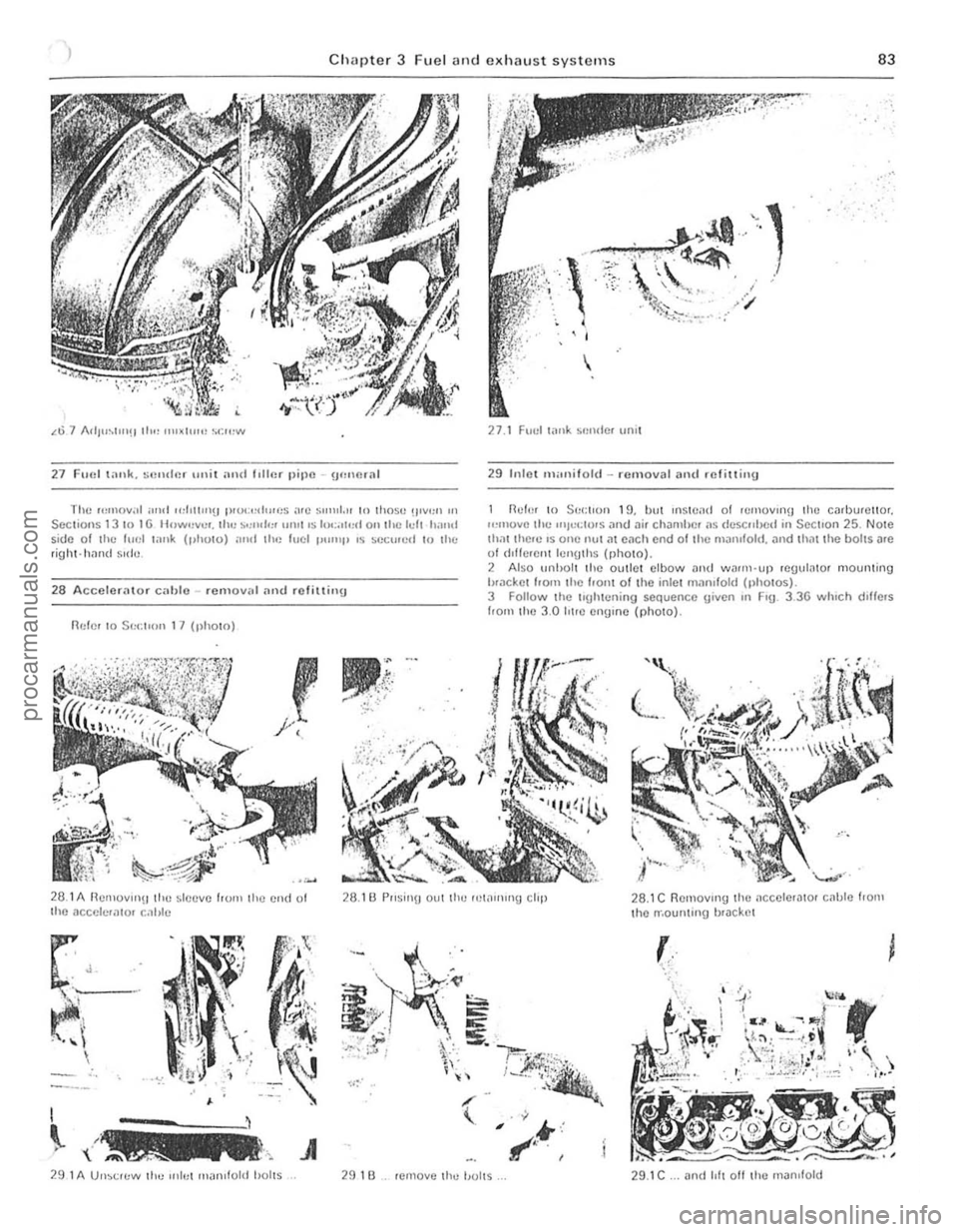

1.6 7 I\dJ"~IIII!J II", n"~h"" ~ t:"'w

27 F"HII;Hlk. $1)I"ll)r ,Uli( and Idll)r pipr. -Ufm() r(ll

The 1(,11101.',.1 ,11111 "dlu",U pH.II.",hJlf:S ;1Ii! SII"II,II III Ihose !I'V"'I III

Sec lions 13 10 16 Ilow'IV<:f. Ih., ~.:",h:r "nlt.s 1 ... :;.1.,,1 o n ti,e letl h"tHl side 01 lhe "ml tank (phOIO) "lid Ihl) luel I'UIIII' 'S ~l'C"" .. d 10 lh(: righl·h"ml $ 1110 .

28 ACGelerilto r c;thlO -removl.1 "nu relitling

27.1 F tHlll(1l1k ~'!tldef "nil

29 Inlel manifold -rcmoval and re li inU

Ilclm In S')(:tlon 19. bUI Irl sJ(w d 01 ,.,((\01.'11'(1 thc cilllnllc1l0f,

" ,movc Ihe "'I"I:IOIS (Inti iii. chilmhef as dc-sc"hed in SeC t.on 25. N Ole th,,1 the.c IS one nul ill eilch end of Ihe m(ln,Iol(l. ;md 111m the bOltS (lIe of d,ife.enl Icn(jlhs (phow). 2 Also unbolt Ihe oUlle t elbOW and will/n·U)) .e(jul"lo, 1ll0unlin(j hlilckct hOIll I he "onl of the inlet nI(lIl ,lold (phOl0S). 3 Follow the I'ghtening seQuence uiven III Fig. 3.36 w hich d,lIels IrOIll the 3 ,0 hIr e engine (photo)

28.1/ llel110vlll\l the sleeve hom Ihe end 0 1 the (lCceh:r.lI0r c"hle 28,1 B Plisinn O\'! til " 11,1,,11\I0 chp 2a.le Removmg tile ilccclcrmOI cntJle 110111 Ihe IT,oull ting bracko l

---,

I

~ =-~==) ,

~. ,

,

'1,'

29 1 A Un~(.:r1:w the Inh,t m,llulol( l ho lls

J

29 10 (emove tilt) IW!IS

r " ' , , '~;

29, I C ... 1If1(11,/t off the ma(\, Iold

I

procarmanuals.com

Page 86 of 205

Chapter 3 Fuel and exhaust systems

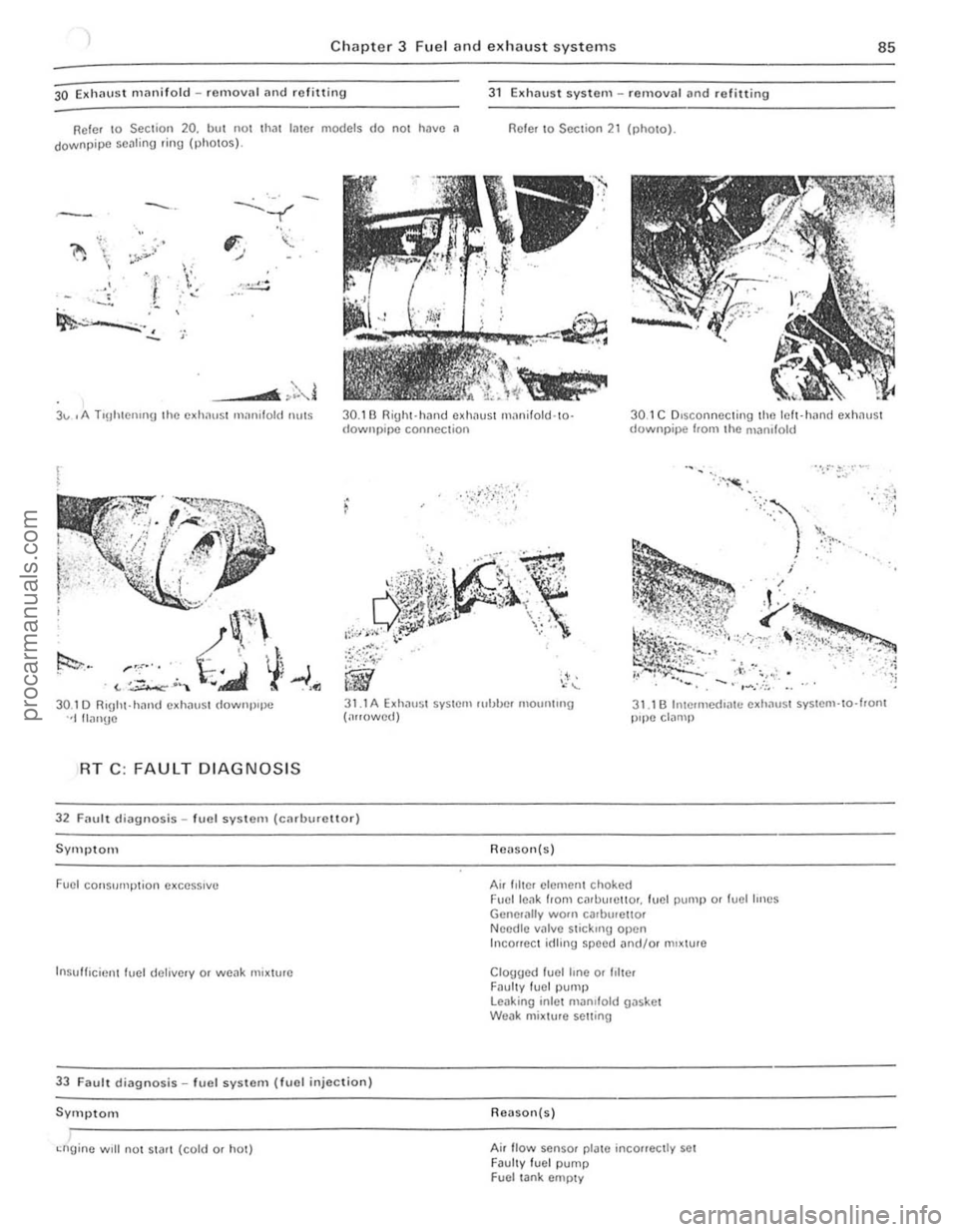

30 E~haust manifold -rOllloval nnd r e fitting

Rcle . \0 Section 20. but not that 1,11C' models do nOI have n downpipo scaling ring (photos)

~ ..

y

" ..:

';.

__ +.,,",l

31 E~haust system -removal and ro fitting

Reier to Section 21 (pholO).

85

3" ,A TI!Jhlenrrl!J Iho O~hilUSI mnnilold nuts 30.1 BRight hnnd e~hnust rn.1nilold ·todownpipc connection 30.1 C Dl sconnec tirrg the lell hnnd e~hnusl downp;,Je hom Ihe manIfOld

. ;/~}":"~"":'. ,

\"~'"

} ·':t-

i

31.1A hhnust system ,ubbe. mountIng (;,,,owed) 31.1 B Irnermed'ilttl oxhilu st system-to-honl pIpe clamp

RT C , FAULT D IAGNOSIS

32 Fault diagnosis -fuel sys tem (CMuurottor)

Symptom

Fuel COlls!ll11ption e~cesslve

Insu llicienl fuel detrvery or weak mi~lure

33 Fault diagnosis -fuel system (fuol injection)

Symptom

~ngine will no t starl (cold 0' hot)

Reason(s)

Ai . 1,ltel clement choked Fuel lenk flom cmbulellor. fuel pump Of luellrlles Gene.ally waUl ca,bu,ettor Needle vnlve StickIng open Incorrec t idling speed

o. hiler

F

llason(s)

Ai. !tow sensa. plale incorroctly sel FauilY fu el pump Fuel lank omply

'J

----------------------------......

procarmanuals.com

Page 87 of 205

Symptom

Engine will nOt Slnr1 (HOT)

Engine will not stal! (COLO )

Engine mIsfires on rond

Unsatisfacto,y ,oad p edomlilnce

Rough Idling (ilIWilYS)

Rough rdllng (during warm -up)

Excessive fuel consumptIon

nglne fUns on

I

C hapte r 3 Fuel and exha ust systems

Reason(s)

AuxiT inry air device not clOSing

Auxilimy ai, dev ice nOl opening SImI villve filulty Thermotime switch nOt closing

L oose fuel pump elec trical connections

System fuel presswe incoflec!

M,xture adjustment incorrect

AUKlhilr y ili, deVIce nOt OllC,ahng cOflec tly

Mixture M1ts utment incolleci leak in system fuel lines

Airtlow sensor plate or cont/otplunger not moving "eely Injector villves leakinU or then OJ)Cnlng pressure too low

procarmanuals.com

Page 92 of 205

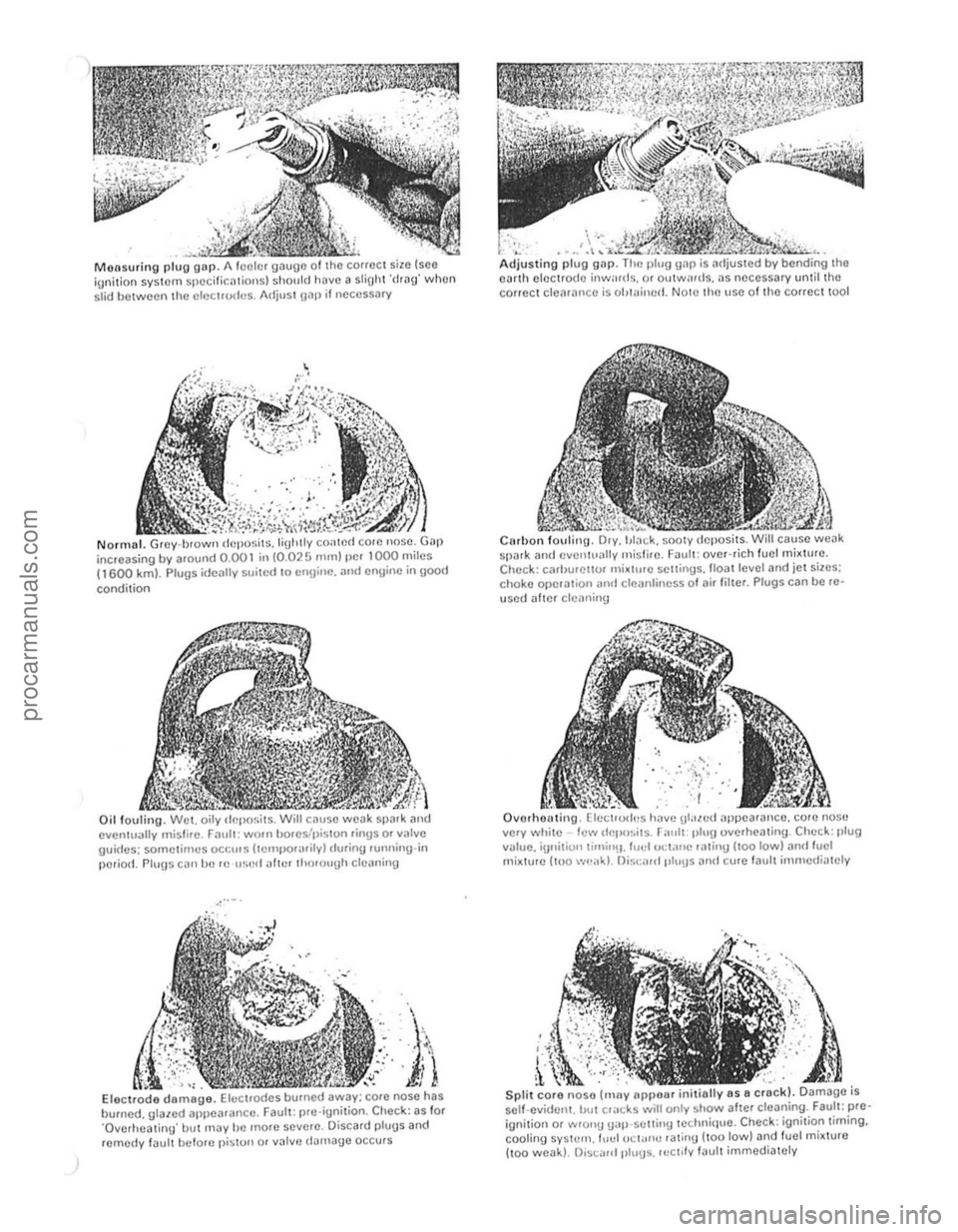

Monsurin g plug gnp . gaugo ;;:;;;-;;;"",,',,"," ignition sysICm spccilicalions) should have a sliUht 'drag' when slid between the olocuuch~s. Adjust {[liP if necessary

N orm al. r, dcpo~il~.liUlolly coaled corc nose. increasing by around 0.00 1 in (0.025 mm) pc, 1000 miles (1600 km). Plugs ideally suited to en\j ine. "nd engine in good

condition

Oil fouting. Wet. oily dr~pOl;its. cal,se eventually misfirc. Fllult : wmn bores/ilision 'ingSOf valve guidcs: sometimes OCC"'!! (temj.lO'Hrilyl d .. ring lunning-in

poriOd. Plug~ C()I1 IJ() H! u~ecl "ftc. thorouUh cleaning

-," ..

. \\'

in Electrode demoge. ;;;;,:;;;;;;;:;;;~;~;';::;;i ;;,,, ",,;; h;,

bumed, glazed appearance. Fa ult: pre')gnohon Check: as 101 'Overheating' bllt may be more sovero. Discard plugs ar1d rornedy fault belorc piston or v31vc d~",age occurs

.'

.. ", . ~,'''':c." ~~:~~~~~~::i, Adjusting plug gap. Tlu, plug gap is, 03rth electrode inwards, or oulwards, as I correct clearance is uillaim!d. NOlO II,,! use 01 tho COlfcct tool

spark ami I I' Chock: cMhulOllor , • sellings, 1I0al level ,lIld iot siles; c hoke (lJlOla lion .mel cltlanli n()ss 01 ai, fillel. Plugs can bo rcusod

vlJlue, iunitiun limill H. I"clu t;lillle I1Itillu (tOO lowl

i Split cor o noso (mny npllollI i 8 crBck). Damage is

sel f.evide nt, bUI cruc ks will only showalter cloaning. Faul t: preignition 01 wrOIl!) !)ap settin!) technique. Check : ignition liming,

cooling SYStCIl1. 1",,1 O C t;"" .. r alin!) (too low) and fuel mixlure lton woak) . Discilld "Iu!)s. ",Clllv laul t immediately

procarmanuals.com

Page 97 of 205

,6 Chapter 4 Ignition system

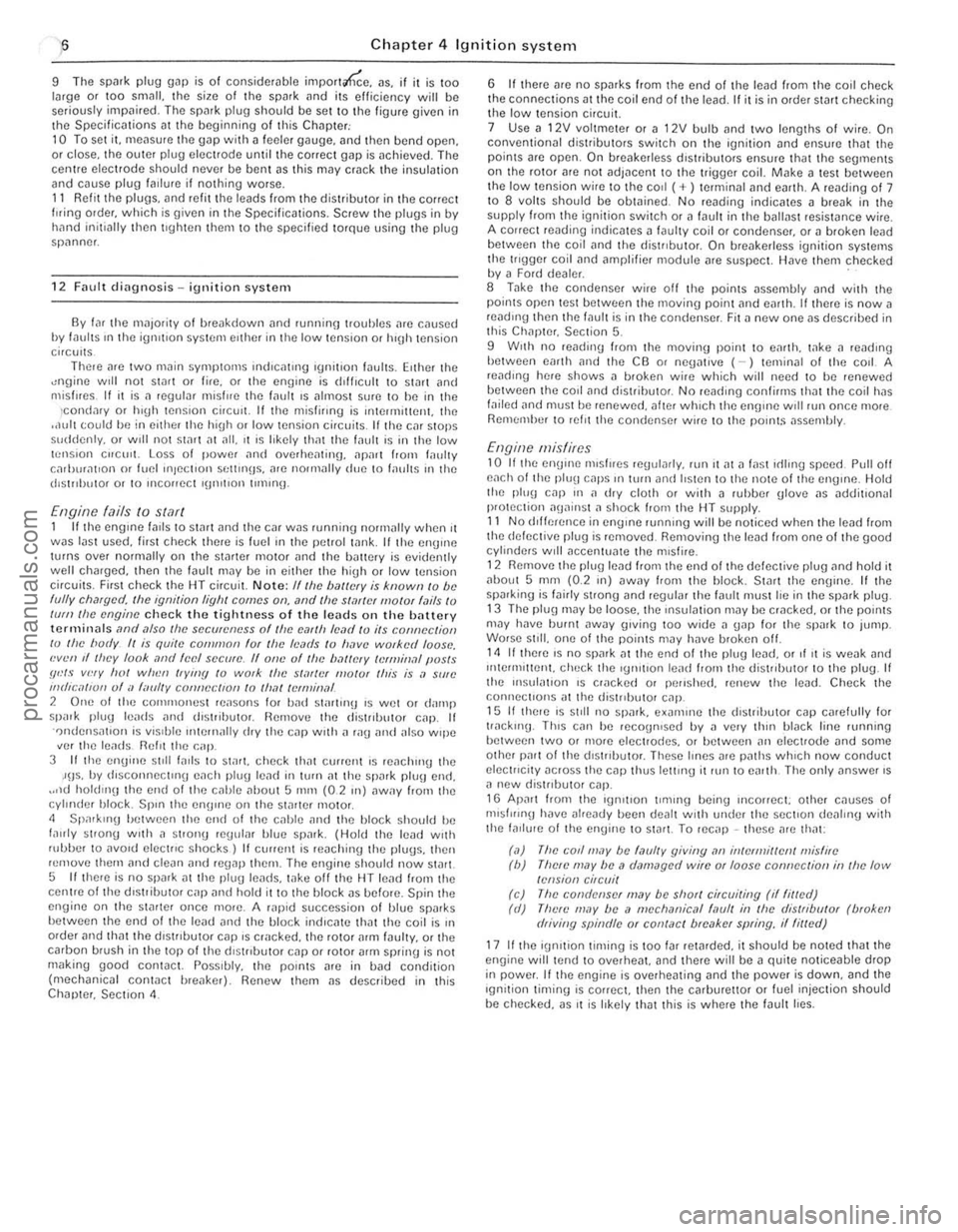

9 The spark plug gaf} is 01 conside rable impor1~e. as. if it is too lilrge or too small. the size of the spark ilnd its efficiency will be seriously impilired. The spilrk plug should be set to the ligure given in thl} Specifications ill the beginning of this Chapter; IOTa sel it, measure the gilp with a/cere, gauge. and then bend open. or close. the outer plug electrode untillhe correct gap is achieved. The centre electrode should never be benl as this may crack the insulation ilnd cause plug fAilure if nothing worse. 11 Relit the plugs, and re/ilthe leads from the distr ibu tor in the correct I"ing order. which is given in the Specifications. Screw the plugs in by hilnd initiilily then tighten them to the specified torque using the plug spilnnel.

12 Fault diagnosis -ignition system

By lar (he nlo1jori (y 01 brCJkdown and running troubles ilre caused by InUits In the igrlOlron system er(her in (he low (enSlon or high tens ion circuns There

Engine fails 10 staft 1 If the engine falls to StM( and t he cal was IIJnning norll1t1l1y when.t wns IJst used, first check ther e is fuel in the petrol wnk. If (he engille tums ovel normally on (he starter 1I10tor and the bilHery is evidently well chmged. then the lault mny be in either the high or low tension circuits. Firs( check Ihe HT circuit. Note: If lire hal/cry is known 10 hI! {(Illy ch,}lged, Ihe ignilion liglll cOllies on, ,1I)d Ihe s/arler 1II010r {,lils /() tum IIIe ongine check the tightness o f the le'lds on the biltlely terillinilis ,1I)d <1Iso (lte seCUIIHWSS oflhe e,l,th leold (0 irs cOllllec/ion 10 tire body It is qui(e common for tlie le,1(ls /0 Ii,}ve wOlked loose. l.'vc'1I If Ihey look ,1n(/ lecl seclI,e. /I one 01 the boll/my ((:{minM {Josts [11.'1.1' vC'IV liot wi".." (Iyiny (0 wOlk Ihe s/mler 1II0tOl (his is ;/ sUie IIId'C,7/IUI/ 0/ ;/ I;wlty COllllel;('On 1(1 1h.11Ie"lIillal. 2 One of tile commonest rOilsons lor bad stmtln!J IS wet or d;UllP sp,uk plug lead~ and dlstribu(or. Hemove (he distllblltor cap. H "JOdenSil(Ion is v iSIble IIlte!llillly dry the CJp With il rag and also wIpe ;lCf the leads nelu the cap_ 3 If (he enUiue sull fmls 1 0 St.l.t. check that cunent IS reachlllg (he JUS, by dlscounectln!1 ench plug le,l<1 in turn ilt the sp1Hk plllU end, .. ,ld holdlllg Ihe end olthe callie about 5 mm (0.2 Ill) aWilY from the cylillder block. Spin the enu'ne all the sta rter motor. 1 Spa,klllg between the end of the cable ilnd Ihe block should he fa"ly strong With J strong leuulm blue spark_ (Hold (he lead WI(h wbber to ilvold elec(IIc shocks) If Clluelll is reilching (he plugs. then rel110Ve them and clean and reg,lp them. Tho engine should now SWrt 5 If there is no spilrk ilt the plug leilds. wke of! the HT lead from the cenlre of the d'sltibutor C

Engine misfires 10 If the enOlnr. mlsfues re!Julariy. run It ilt a f~st irllrng speed. Pull off eilch 01 the plu(! C,lpS III hUll nnd hsten t o (he note 01 the engrne. Hold the phl(J cnp In il dry cloth or with a rubber g love

(,J) The cOllm.lV be {,lufly giving ,111 iniNmil/elll mislile (b) Thele limy he ,1 (/iJmiJged wile or loose cOrlflee/ioll in till! low (eflsion circuil (c) The condensel /II,lY I;e shOll circuiling (i{ filled) (d) There nwy be a meehanic,lllolUI! IiI Ihe dis/flbll/or (bfOken dliving spindle or eOlllac/bleaker spring. if filled)

17 If the ignition (iming is too far reto1lded, it should be noted thallhe engine will tend to overheat. and there will he a quite no(iceable drop in powel. If the engine is overheating and Ihe power is down, and Ihe ,oni(ion tim in!) is correct. then Ihe carburenor or fuel injection should be checked, i1S ,I is likely that this is where the Iilult lies.

procarmanuals.com