wheel FORD CAPRI 1974 Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 173 of 205

Chap te r 1 0 S uspension and steering

Wheel b,ll,lncing may bo carried out wllh the wheel Mher on or off the v eh icle. II b

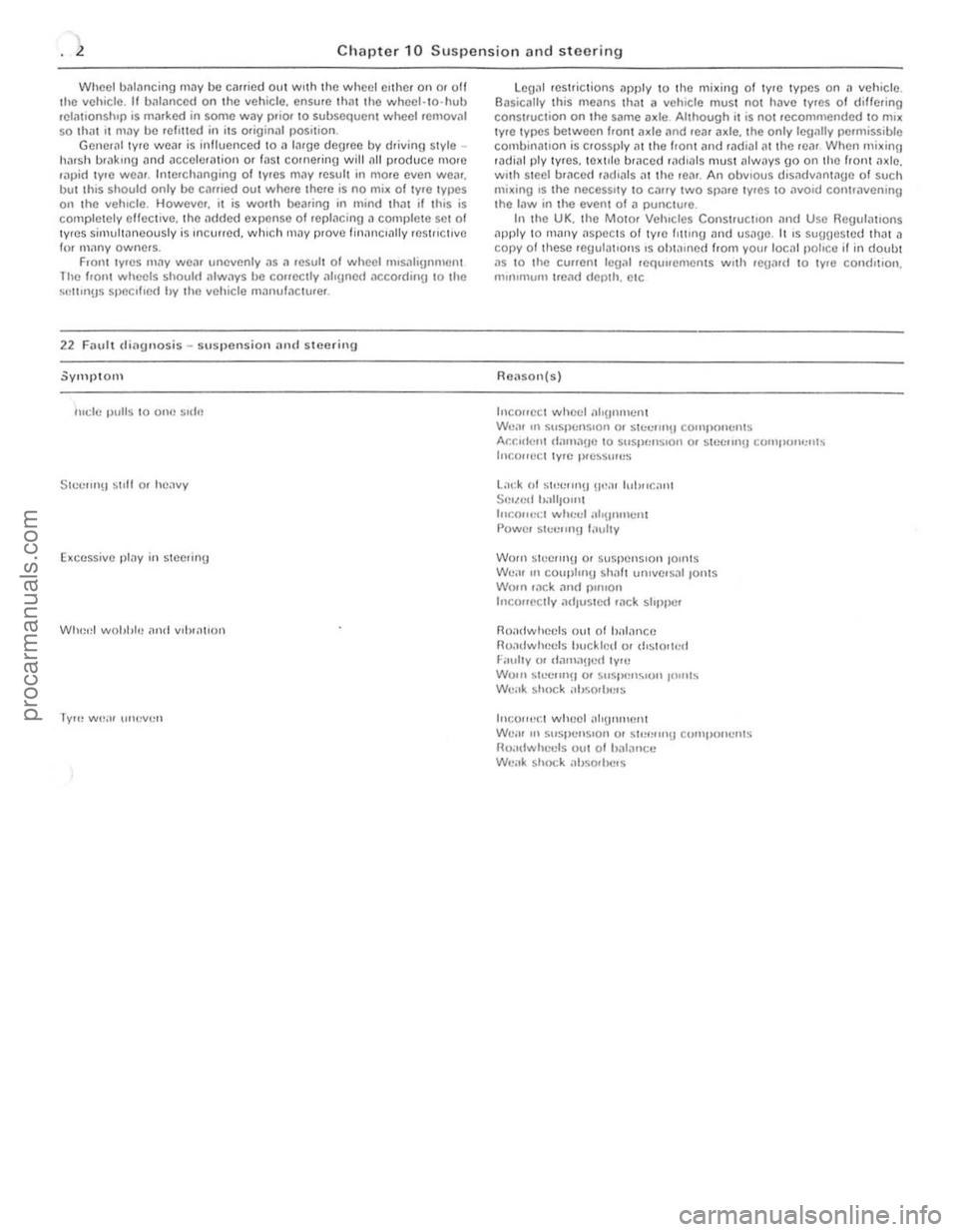

5ylllptOlll

III(; le pulls t o on!! ~Idll

Slecnl1!l ~trll or h eav y

Excessivc pt;Jy in s!Cerinu

W twd wohhtH ,11111 v,h,nIIOI1

Ty,,~ W(~;II 1lI11,VCn

leg,l ! restri ctions "pply \0 the mixing 0 1 tyre types on a vehicle . Bilsic;lfly this means Ihil a vehicle must nOt have Iy,es of dilleling conStruction on the same axle. Althoug h ;1 is nOI recommended t o mIx tyre type s belween Iront

InCOlfect whcel o1lrUlIlllent WC,II In SIISI)()IlS'On 01 SI(""""! I CO""llOnents Ar.r.uic"t .1""'''!lC 1 0 SUSllf,nSlon o r ~I.w" nu compUll"nts IIlr.Olllll:t lyre p.eSSUlt's

Lack 01 SieIJIIIl!J \J

W orn sleellng Or sus penSIOn 10UliS W en. III couplrnU shllft unlve,sal Joms Worn r,lc k ilnd 1)""On Incorfectly adJuSlcd rack Slrll llC'

RO:Hlwhe els oul 0 1 hnlance flU.ltlwhcels huck led or IhslO,Wd l:iHlhy ur dnmnHed IVII]

Wu,u s tL'f:II"!J Of SUSI""l~IOn JI1I1lI~ WlJnk Shoc k ;.hso'b"r~

'"collee.1 whee l ;' ''UIIIHlllll We: " III suspenSIon Ot st"""lIg C{)I11POIlCntS Ro,'llwhL'Cls out 0 1 halance WIJ;lk shoc k 'lhso.he'5

I

~. -----------------~

灲潣慲浡湵慬献捯m

Page 177 of 205

)76 Chapter 11 Bodywork and fitting

General description

The body is of all-s teel welded construction with impact ilbsorbing hont Dnd rear sections . Anli-burSllocks nrc lilted 10 the doors, ilnd the

t ailgDte is supponcd by \J

AI the in1erVills speCIfIed in the Routine M"IIl\cnilnCe section in the front 0 1 the nl

Check underbody protective coatiog 5 W,th the CM supponed on i1xle stilnds. check the cond,tlon 01 the un(lelbody protcctivc coating. i1nd wherc neceSSilry clean

M,,;ntcll

Wily to remove any aCCUIllUI,lted mud whIch WIll retillll mOlslu re

Mats and C

very line culling pils te. Finally, opply wax polish. WhNe the scrotch has penctrDt(ld right through to the metill of the bodywork. causing the mowl \0 rust. iI d ifferent repa ir lechnique is

required. Remove any loosc rus t fronl the bottom 01 the scra tch with a penknile. then apply rUSI inhibiting paint 10 prevent the lormation 01 rust in Ihe future. Using n rubber or nylon appliCiltor fill the scratch with bodystopper paste. II requ ired. this paste Ciln be mixed with cellulose thinners to provide a very thin paste which is ideal for filling narrow scratches. Before t he stopper·paSI(l in the scratch hardens. wrilp il piece 01 smooth COllon rJg i1round the lOp 01 J linger. Dip the finger in cellulose thinners and then quickly sweep it i1CIOSS the surlace of the 5topper-pJste in the scratCh: this will ensure tha t the surfilce 01 the stopper,pilste is slightly hollowed. The scratch can now be p

first wsk is to pull the dent out, untrl t he affected bodywork almost

procarmanuals.com

Page 201 of 205

" .... Index

------ --------------------------------------

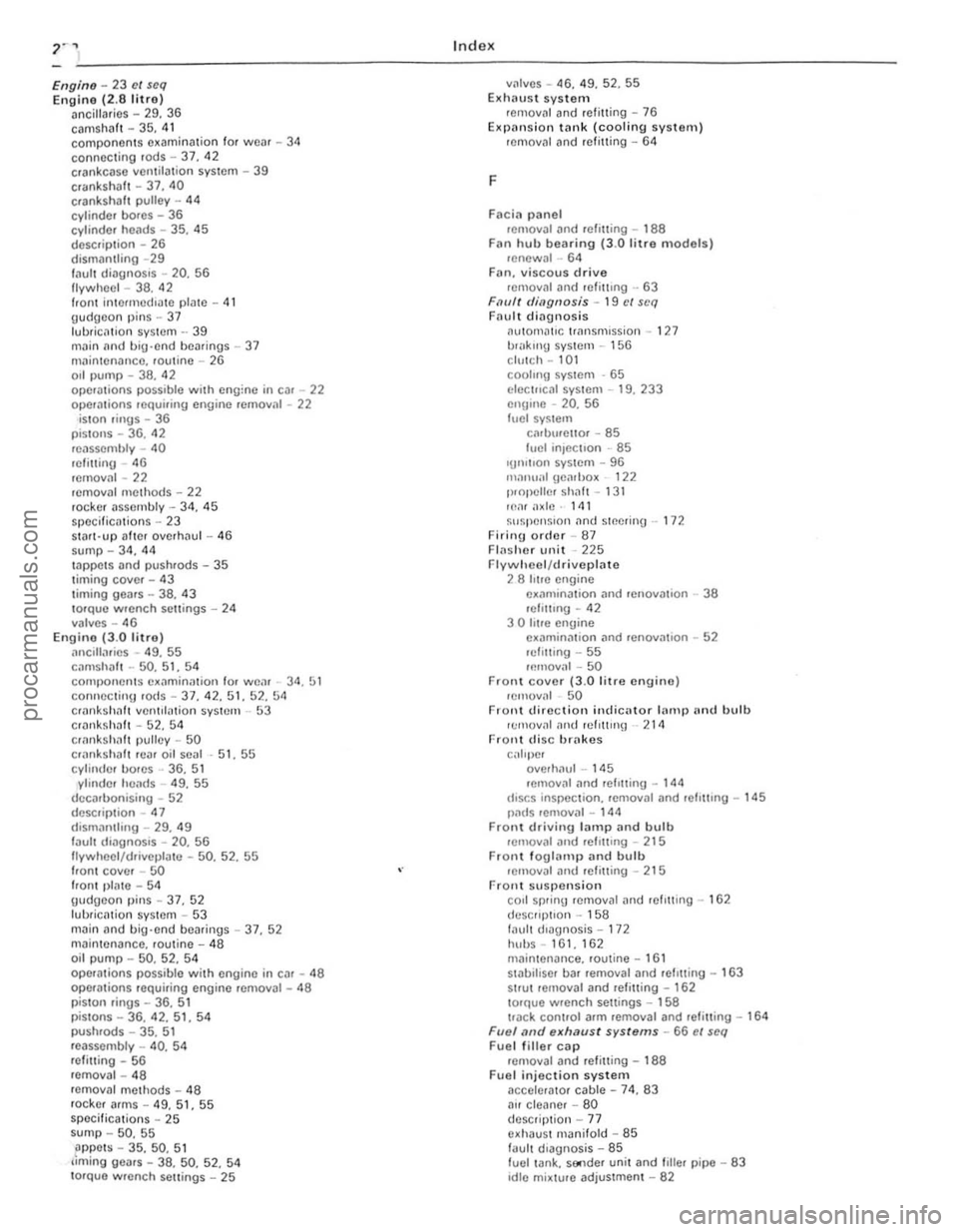

Engine -23 cl $cq Engine (2 .8 litro) lmcillllries -29. 36 camshaft -35, 41 components e~aminlltion for wear -34 connecting rods -37. 42 crankcase ventilation system -39 crankshllft -37, 40 crankshaft pulley -44 cylinder bores -36 cylinder heads -35. 45 description -26 dismantling -29 fault dingnOSlS -20. 56 flywheel -38. 42 front interm!.lt hate plme -41 gudgeon pins -37 lubriClllion system·-39 main Il!ld big·end bellrings -37 rll(lintenance, routine -26 OIl pump -38. 42 operations possible with eng :ne in car -22 op(!r;lIions rC'quiring engine remov,,' -22 iSlOn rings -36 pistons -36. 42 rC(lssembly -40 refining -46 removal -22 removal methods -22

rocker asscmbly -34. 45 spec ifications -23 start· up after overhau l-4 6 sump -34, 44 lappets ;:and pushrods -35 timing covcr -43 timing gears - 38. 43

l orque wrench senings -24 valvcs -46 Engino (3.0 litro) ilO)cill:lr ies • 49. 55 camshalt •. 50. 51. 54 componcnlS e~.-.minlllion lor WC:lr -34. 51 connecting rods -37. 42. 51. 52. 54 cr.-.nkshMt ventoilltion system --53 Crank~hllh -52. 54 Crtlnkshllh pulley -50

c .t1nkshaft rear oil seal -51. 55 cylillde. bores -36. 51 ylinde. hoad s -49. 55 decarbonising -52 descrif)1ion _ 47 dism.-.ntling -29. 49 faull dingnosis -20. 56 lIywhecl/d.ivepl(lte -50. 52 . 55 Iront covc. -50 hOn! plate -54 gudgeon pins -37. 52 IUbricntion system -53 main and big·end bcarings -37, 52 mainten(lnce. routine -48 oil pump -50. 52. 54 operations possible with engine in ca. -48 operations requiring engine .emov,)1 _ 48

piston rings -36. 51 pistons -36. 42. 51, 54 push.ods -35. 51 reassembly -40. 54

refining -56

removal _ 48

removn! methods -48

rocker arms - 49. 51. 55

specifications -25

sump -

50. 55 pppels -35. 50. 51 !lming gears -38. 50. 52. 54 torquo wrcnch sellings -25

.

villvcs -46. 49. 52. 55 Exhaus t syste m remova l and refining -76 EMpnfls ion tank ( coolin g sys tem) removal and refilling -64

F

Facia pilnel t(!mov,)1 and rcfining -188 Fan hub bearing (3.0 lit r e models) .encwal -64

Fan. viscous d rive remov,,1 and refinmg -63 Fnllli (Jingnosis -19 et seq Fault di,)gnosis

lIulOtl1allC lrnnsmrssion -127 tJ,nkmg system -156 Clutch -101 coolmg system -65 clectf1clll system -19. 233 cnlline -20. 56 fuel system cilrbure uor - 85 lucl inlCCho n -85 IHn,hon system -96 mllnu .. 1 !Je.l,hox 122 p.npeller shaft -131 1f!.1f

oved'lIul -

145 remov

rcmoval ilnd rcfilling -2 I 5 Front suspen sio n COIl sprinU removal and refIning -162 duscnp tlon -158 fault dIagnosis -172 h\,bs-161.162 milintenance. routine -161 stabiliscr bar removal and rcfming -163 Strut removal and refilling -162 lorque wrench sellings - 158 track control arm removal and .elilling -164 Fuel (/lid exhaust systems -66 el $eq Fuel filler cap .cmoval and refining -188 Fuo l injection syste m ')CCclcflltor cable -74. 83

air Cleilller -80 deSCri ption - 77 exhaust manifold - 85 fault diagnosis -85 fuel lank. s&nder unit and filler pipe -83 idle mixture ,)djustment -82

procarmanuals.com

Page 203 of 205

2"4 Index

",-----------------------------------------------------------------1 -

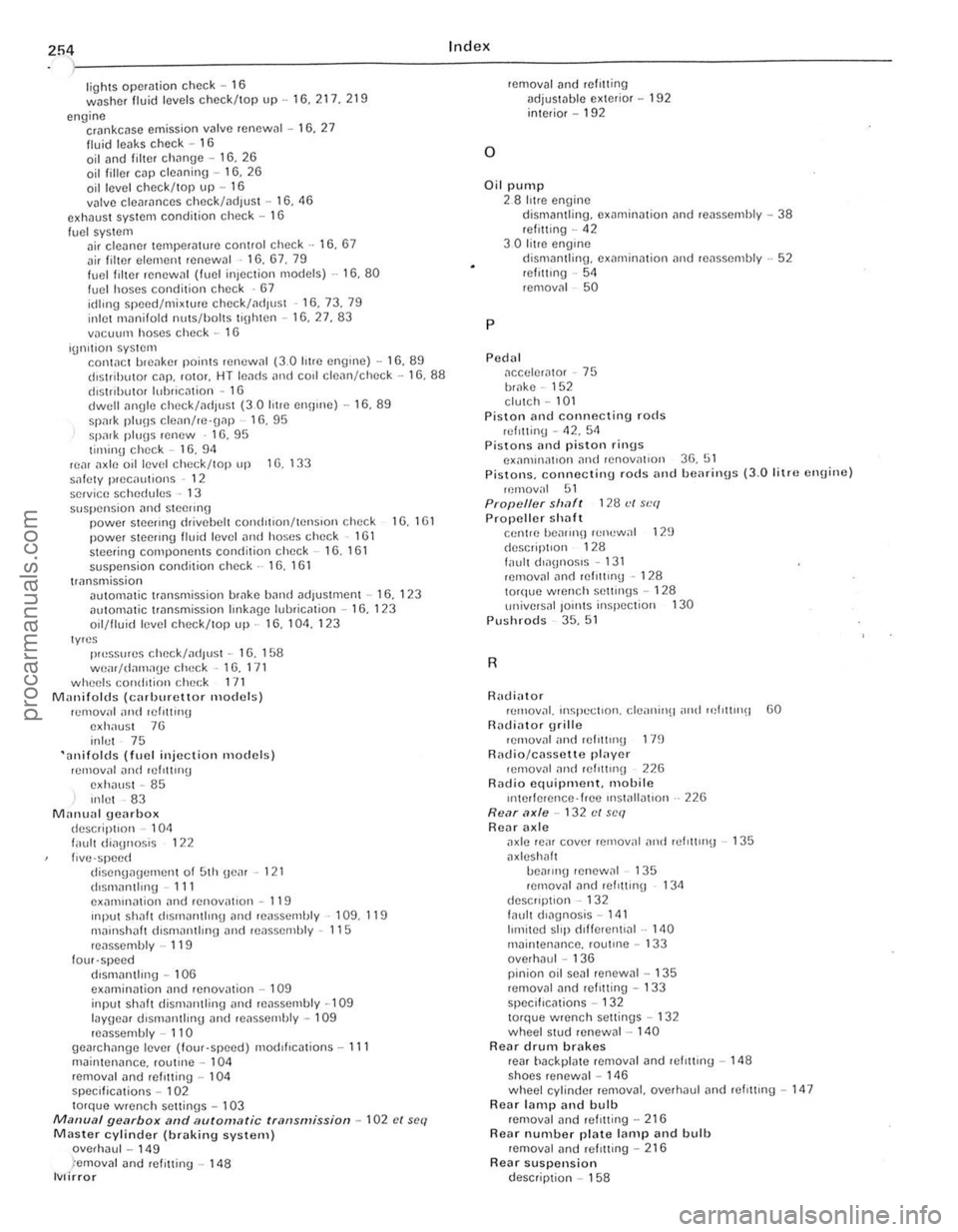

ligh\s operation check -16 w~she( fluid levels check/lop up - 16, 217, 219

engine

crankcase emission valve renewal -16, 27

fluid leaks check -16 oil i1nd filter change -16, 26 oil filler cap clClIning -16. 26 oil level check/lop up -16 1I;llvo clearances check/adjust -16. 46

exhaust system condition check -16

fuel sySlCm

removlll and relltting lldjustllble exter ior -192 interior -192

Oil pump

p

28 Iotre engine dismantling. examination and re~sselllhly -38 ref in in 9 -42 3 0 li tre englllc dismantling. eX~lllinmion ilnd reass embly .-52 [elit\lng -54 removill 50

Pedal ,1cceler,ltOr 75 bra k e · 152 clutch -101 Pisto n an d connec ting rods ref,nin\j -42. 51 Pistons and pisto n rin\js exanllna\lon ,1nd rcoova\lon 36,51 Pi sto ns. connecting rod s il11d bearin\js (3.0 litre cngine) [lmlov,11 51 Propeller shaft 128 d s, .'r/ Prop elle r shaft cenlre bcarln!J r()"l]w~1 12!J

descrip1l011 28 I"ul l (i iaunosis - 131 removat and rel,UlI1U -128 10rque wrench seHlIlgs -128 univers~1 10lllts inspection 130 Pushrods 35< 51

R

Rndi,lto r rel11ov~I, Inspcctoon, cie

Rear lamp and b ulb removal and refttling - 216 Rear number plilte lamp and bulb removal ilnd relilling -216 R ear su spension description - 158

procarmanuals.com

Page 204 of 205

fault diagnosis -172 leaf spling .emoval. bush renewal and refitting -165 maintllnance. louline -161 shock absorber remoyal and refitting -165 stabiliser bar removal and refitting -165 lorque wrenCh settings -158 R"ays -225 Rep.ir procedures, general - 9

Rocker e rms (3.0 litre engine) examinat ion and renovation -51 removal - 49 Rocker arms and coverl (3.0 litre engine) ref itting -55 Rocker assembly (2.8 litre engine) dismantling. examina tion and reassembly -34 Routine maintenance stt Maintenance. routine

5

Safety precautions - 12 Seat belts -191 Seats .emoval and refining -192 Sidelight bulb renewal -213 Spare parta buying -8

to carry in ca. - 19 Spark p lugs conditions (colour) -91 lemoval. servicing and .elilling -95 Speedometer cable renewal - 226 Stabiliur bar Iront -163 rear -165 Starter moto r

description -207

d ismant ling and reassembly -207

removal and refi tting -207 testing on engine -207 Steering column removal. overhaul and refitt ino -170 desc.iption -158 faull diagnosis -172 f,on t wheel alignmenl ~nd steering angles -171 gear (manual)

ove,haul and adjustment -166 removal and refittin g -166 maintenance. rouline -161 power steering bleeding -168 gear removal and refitting -168

pump femoval and refining - 168

specifications _ 157 torque wlench senings -158 track rod end balljoint renewal-167

whea' removal and refitt ing -168 Sump 2.8 litra engine

refining -44

removal and refining with engine in car -34 3.0 litre engine refitting -55 removal -50 Sunroof bracket and dr ive assembly lemoval and refitting -191 panel adjustments -189 removal and refining _ 190 Suspension lfnd steering _ 15 7 tl seq Suspension see Front suspension Imd Re ar suspension jtches removal and relining

Index

T

central facia - 225

door p illar - 224 handbrake warning light _ 225 hazard warning -223

ignition -224

instr um

ent cluster illum ination _ 224 light and windscreen wiper (Series II) -225 load sp':)ce lamp -225 steerin g column multi-Iunction -224

s top lamp - 152

Tailgate priv ate lock removal and relining -187 .emoval and refilling -187 striker plate removal and relin ing - 188 wnsher

nozzle removal and refitting -217

pump rllmov31 and refitting -217 window glass removal and relitting -180 wiper mOlOr and linkage remoyal and refitting -217 Tappets (3.0 litre engine) remoyal -50 Tappets and push rods el

care and maintenance -171 presswes -158 size -15 8

Underframe

maintenance -16. 176 Upholstery maintenance -176

v

Vacuum servo unit (braking system) description -156 lemov~! and refining -156 Valves clearances checking and adjustment -46 . 55 Valves (3.0 titre engine) removat -49 Valves and va lv e seats (3.0 litre engine) examination and renovation -52 Vehicle identification numbers - 8

255

procarmanuals.com

Page 205 of 205

")256

W

Water pump reliuinu -44. 61 removal -61 Weights. vehicle - 6 Wheels care Jod rll

Index

W indscree n washe r nozzle removal and refitting -219 pump removal and refitting -219 Windsc ree n wipers arms and blades removal and relitting -220 fault tracing -219 motor and lin kage removal and refi1ting -218 mOlor dismantling and roassembly -219 switch (Series II) -225 Wiring diagrams -235 to 249 Working facilit ies -11

."

procarmanuals.com