belt FORD CAPRI 1974 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 9 of 205

Buying spare parts and

vehicle identification numbers

Bllyillg spare parts Sp;'1rc p"rlS ;lre ilwul.1!Jlc from momy sources. Jo. exam ple FOHI uar"gcs. oliler gil':lgCS ,-mtl ncccssu.y shOIIS. im(i mOlor ';.elms 0", a

I lOSII.ve idenlil leallol1, Bumcml)C. ,h;'1 .,,;,ny p;rrlS illt) ;'Yirrl;.hle on a InelOry exclHlnge schelllC illly PililS .elurne(1 should nlw,1ys he clennl II obviously makes oood snnse 10 go S\""Uhl \0 Ihn SIICel.1hsts on you. CM lor this Iype 01 PMI as Ihey n.e besl equipped Il) supply you O/hef yM,'yes Im.1 m:cesSOlr shops These a.e ollen ye'Y goot! plnces 10 buy Illate".lls al1

ileccssoflcs, uSlIillly l \.lye conyenlent opcnUlU hours, Ch.11Ue I, prices and can often be lound nOI la. hom home MOlor 1,7C(0IS ~ Good lacto.s will stock illl Ihe mOle Illlp,,, comllOnen lS which wea. oul .elilhycly qUI ckly ((..'9 Clutch COIllI,cm. PISIOI1S. villyes. e~hilusl systems. IJr;lku cyhnlie

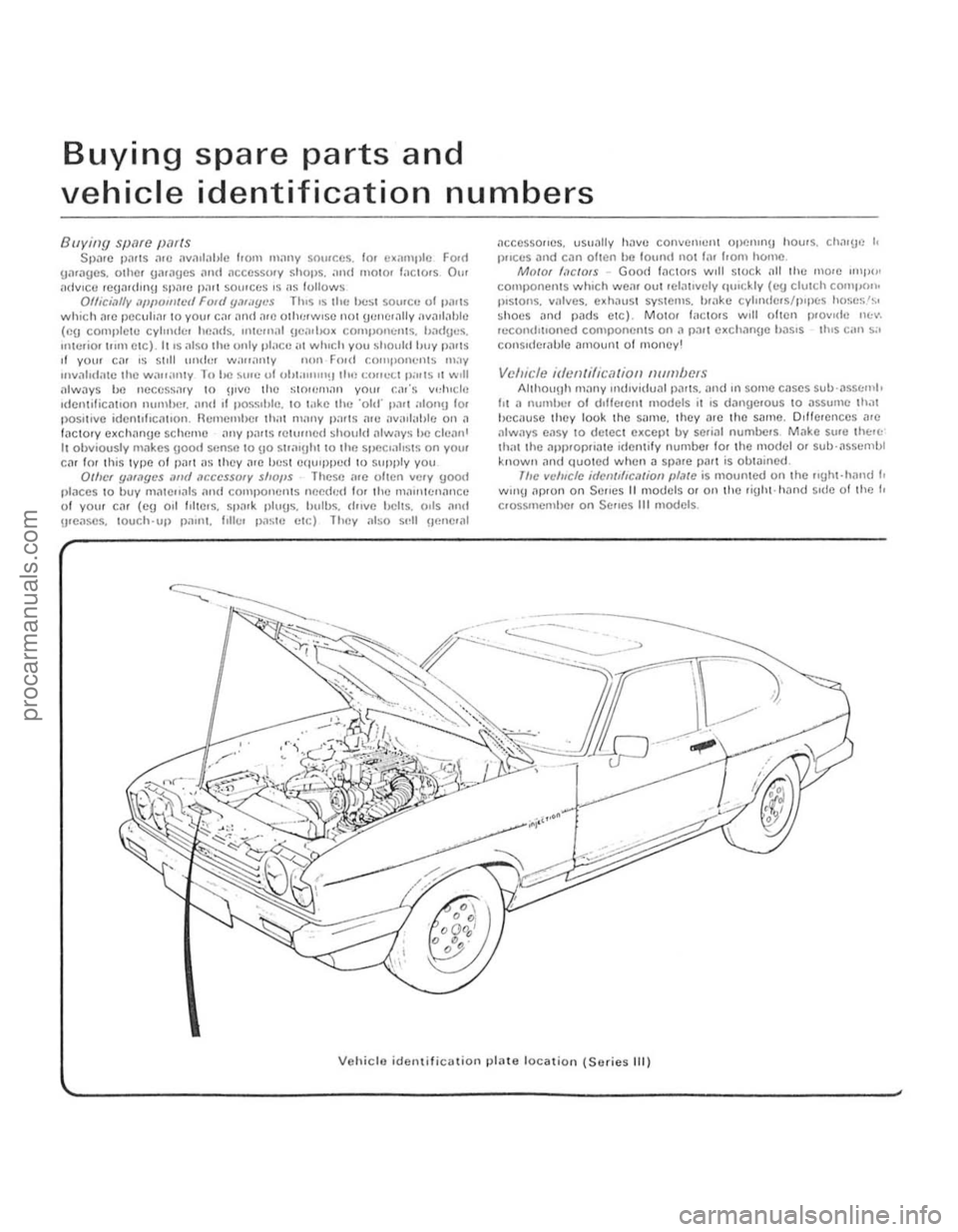

Vehicle itlenlificc1l;OIl numbers Altholl!lh milny uuhviduill pa.ls. 1md ill some cases sub-ass/:mlo III a lIU1nlJm 01 dlflerent models II IS dallge,ou$ 10 a ssUllle tll;1 \JCCilU5e they look the 5,lIn e, Ihey a.e the same. Dillelences n.e nlwilys e.1sy 10 detect excepl l.Iy serial numtJCrs Make su.e the.e th;otille ilPI),op"ale identify number for the mode! or suh-asseml.lt known .1n(l Quoled when a spare PMt is obtained. '"c v(!/m;fc irlCl!lrfrc.lfioll "IMe is mounted on the rIght-hand tr Will\! ilpron on SCries II models or on the righl·hand Side of Ihe f, Cfossmemher on Selles III models.

Vehiclo ident ifictltion philO location (Series III)

procarmanuals.com

Page 17 of 205

" ,

'6 Routine maintenance

)

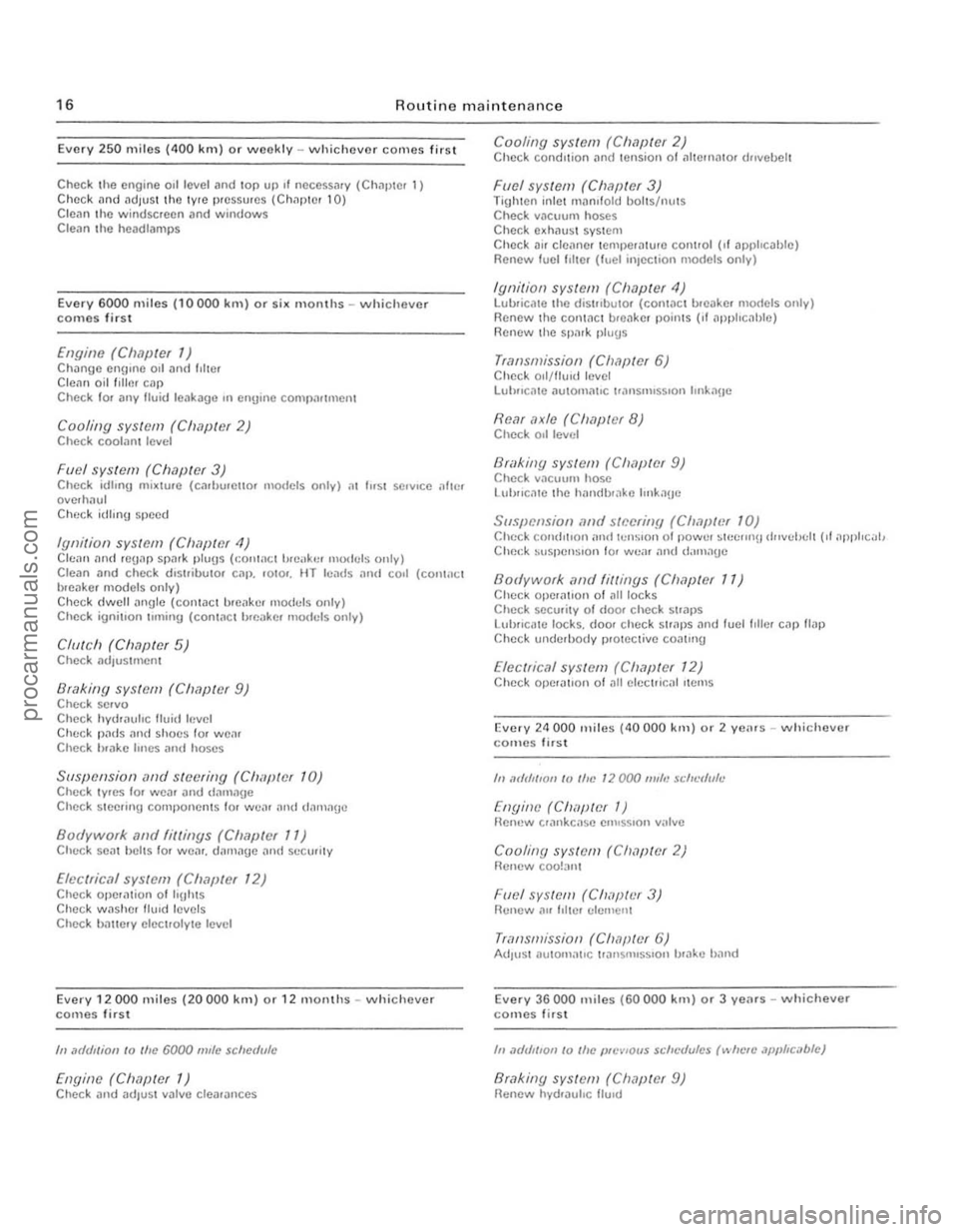

Every 250 miles (400 lUll) or weekly -whichever comes first

Check the engine 011 level and lOp up " OCCCSSJry (Chapler 1) Check and adlus t lhe IYIC pressures (Chilplcr 10) Clean the windscreen and windows C lean the hcadlamps

Every 6000 miles (10000 km) o r six Illonlhs - whichever comes fir s t

£II[1ille (Clwpter 1) Change engllle 011 and IIher

Cleiln oil flilm c"p Chcck 10 1 ,IllY fluid leaka!)e ,n enUme CO'llp:lnUlCIl1

Cooling syslem (Clwptet 2) Check cool:'lnt level

Fuel syslem (Clmpler 3) Check idh"U mi~lUle (cmiJUiello1 IllUdels onlv) al I"SI se.v,ce ollIe, overhaul C heck idllllg sj)ee d

Ignition sys/Cm (C/I,Wler 4) Clean ,1nd re!)"p Sl)".k plu!)s (.:on!nC ' breilkCl Illudels olllv) Cle an and check d'Shibu\o. C"I). '010'. HT lealls mId co.1 (COllWct

bleaker modcls only) Check elwell angle (cOntact b.e"ke. mo

Bri/king sys/Cm (Ch,1pter 9) Check selva

Che ck hydraulic flu id h,vel

Ch(: ck p"ds :'Illd sho(:s lor wear Check h.ake hllcs and hoses

Suspension .wel stvi'ring (Chi/pICr 10) Check tyres 10' w ear and dam:lge Check steering COmp{lIlCnlS l o r w e:l l "lid d.1nlilue

Bodywork. .111d fittings (Clwptef 11) C lu .. >ek se"t belts fa. we .... damage :lnd secwity

Elvc(ric.11 systcm (Ch,7jJ(ef 12 ) Check Ope.iltoon 01 "Uhts Check wilsher flUId levels Check b.1ltery eleclrolvle lev el

Every 12000 miles (20000 kill) or 12 mOll1hs - whichever comes first

III .1(/(lIlioll 10 Ihe 6000 m/le sciler/Ille

Engine (Ch.1f)ter 1) Check and adlUSI valve clearanc es

r"' .......... ~.~-.... ._ •• -.... __ .... . 3lii1&l •

Cooling system (Chapter 2) Check condition "net tension of 1111011)<1101 dflvehelt

Fllel sys tem (Chapter 3) Tighlcn inlel IIHlnl lold boits/nuts Check vacuum hoses Check e~hiluSI syst em Check ll1r ctonne. temperature cOllllol (,I applicable) Renew fuclllllC ' (fuel injec tion models only)

Ignilion system (Chapler 4) lubricate th e dis'flbulOf (conUlel br eake r models only) Renew the coninCt hu,akcr points (II nppllcJblc) Renew the spMk plugs

Transmission (Chapter 6) Check ool/th"d level Lulmc;ue automatIC 1.,'Insmlss,on IInk:'lue

Rcar axle (C/MplCt 8) Check 011 level

Bli/king system (Chaplet 9) Check v,lcuun' hose

llliJllc:'l1C Ihe handhlake Imk,loe

Suspensioll {//j(J swelill!J (C".1plt~( 10) Check condItIon and hlllSlon o f POWI.II ~I!'tllllli dllvthtl1 (II .1l1pllcal,

Check MlspenSlon 101 we;" ;111(1 d;1Il1.1!)e

Bodywork ,1I)d fillings (Clwpler 11) Check opera lion of all locks Check secu.ity 01 dOOf check sl.aps

LlIl)fIcalC locks. door c heck S\','P5 :'Ind fuel fdler cap flap

Check underbody pr olCctive coalm!)

Electrical system (Chapter 12) Check Opcra1l0n of all eleC111!:al IIcm5

Evcry 2<1 000 llIiles (40000 kill) or 2 yc;u s -\Nhichever comes firsl

III ,1(/111/'011 10 the 12000 111"'1 $d'~'f/u/e

[nyino (CIWpICf 1) f!ell'!W crankC:l $e e""5510l1 v;llve

Cooling syslofll (Clwptor 2) Renew COO!:1II1

Fllel SYS(CIII (Ch, '/pliJr 3) Renew"" II Ih!r elemenl

TrallsmissiOIl (ClwjJWr 6) AdjUSI aulom;1\IC trall5nll5SIOll h,ake b;'IIld

Every 36000 miles (60000 kill) o r 3 yenrs - whichever comes first

III .1(/{/I('01l 10 Illc JJIl'VlOUS schc(/ulcs (",lIc" JJJIJ"ci,bfc)

Brakillg system (Clwpter 9) Renew hyd,auhc flUId

procarmanuals.com

Page 51 of 205

\.

50 C hapter 1 Engine

51 T llp pcts -removat

Remove the 1

5 2 Crnnksh

4 Wilhdraw Ih~ Wood'uH key hom the end of th(! CllInk5hah and pl,lC,(! " w'lh Ihe pulley. til(! holl alld its washer 5 The C'.1nk~h;)h p"lIey m;oy he ICliloved wilh Ihe eno,,,e III Ihe C:\I. hilt ,I 'S IIIsl tU!Ccss;o,y 10 ,emove Ihe ',ld'illO' :lI1d thc rh'vehelts

53 Flyw heel -remov[ll

P,even llhe flywhcel hum 101m",!) by FHlHllln\J Ihe lin!) !lcal ;ollain~1 ;In imp.ovised SIOI). 2 On nlodels willi nl;lnu:ol 1I;o"$""S5'01i. Icmove Ihe Clulch plessure 1)1;lle and disc :os described in Ch:op!Cr 5. 3 Rele.lse Ihe s,~ bolts secu.in!1 Ihe flywheel 10 Ihe CllInksh;oll .lnd lefl\OVC I,ve of Ihenl.

4 Whilc supporling Ihe tJywheel III pl;ll':e .• emove Ihc Sixlh hoi' ,'11d Iolt Ihe lIywheel otl c;o,elully. so 111:01 Ihe m;lllllg su.lilccs of flywheel [lild c.;onksh;oit ;o.e 1101 dllm,'ged

5 4 Sump -removal

W"h lhe '''1(1'''') oul fli the e,". CII~"'C Ihal Ihe sump has 1o('CIl d,amvd ;ond then lilln the engll1C ()VCI so tl1011 Ihe sump's U l)I)ClmOSI F" wOOr1CII bloc"s tn Slll)lmrl tim en!l'ne 'n Ih,s POSIIiOIl . 2 Remove 11m h()IIS seCUlln( J the oil Sump 10 Ihe CI.1nkColSe o1nd rClllOVO Ihe SUll1p_ 11 the sump IS stuck 10 the c r;ollkcasc . II should be reh;lIsctl hy 1"'SII1\1 olle SIde wllh 11 sClcw drover. 3 To !Cn,ovtl .Ile sump wllh Ihc CIIU"HJ Hl tloe eM. 11151 IcnlUVC Ihe

d'l)S llck :ond d'SCOIlII(!Ct Ihe hatlery 4 Remove Ihe luur holts ;ond lou. Ch,)S ;ond dCI.leh Ihe OIl splash

shIeld.

5 Pl;oce a Con'"lIlcr 01 at lellst 6lttre (106 JlIllI) cal,,-.elly heneath Ihe SUml). remove Ihe d,ain pl\l(l ;ond d,aln Iha sump. Reflilhe d.am plull and (11)hlen II 10 Ihe 10lqUO wrench seilIng gtven In the SIXlClflC;JIIons G Del:och the engme fubl)CI mounllngs, by lemovlng the" nuts an(1 w:oshe!s. 7 Romove the ciampinI) bolt hom the tal) ;oml bOIlOI11 endS 01 the Steellll!.) intellnediate sh(lil. rush Ihe lap end 0 1 Ihe shlilt upwollds unlll Ihe lowcr ell(1 Clin be dlsenga\led 8 PI

55 FrOllt cover -removlll

If Ihe engHle IS In the CM. II wllllnSI he necessaly 10 dlsc()nneC lthe l!allefY. drll'" 11m coolll1\) sys tem ;ond lel110lle Iho radiillor. 2 loosen the alternalol mounllrlg bOilS. SWlrlg the aitemalor downwilids .0w:Olds the cyltnder block and lemove Ihe drive belt

3 Remove the bolt Irom the cenlro of Ihe cooling Ian .. nd pull (

Ian and clutch assembly. 4 Remove Ihc boil an d wilsher from Ihe centre of the cran pulley .. nd I hen use ., claw puller 10 drilw Ihe I)ulley ofllhe sha nOI anempllO lelle, Ihe pulley ott. t)Ccause Ihis may .esull in dllm. t he Irani covcr.

5 Rcmove the si~ bolts secuung Ihe sump 1 0 Ihe honl cover an, t he cleven bolts securing Ihe I ront cover 10 the Cylllldcl block . G lIlt Ihe cover ott ;ond remove Ihe g;oskel.

5 6 Tillling gears -relllov;ol

1 Remove the honl cover 10 e xpose Ihe IImlnu ueo1/S 2 Removc Ihe bolt and washer sccu"I1IJ Ihe fat!Je gear I,

cn,nsIl1'll t. IhCIi pull.he geill ol! and Icmovc tho Woodllll! key. 3 Dlllw the ileal hOI11 Ihe cr;onk!;h:oh am! remove Ihe Wood'utl

57 Carllshaft -r erllov;ol

The camsh:olt nwy be rCUlovfld wllh the cll!JlIle 1<1 Ihe car •• lollowlng p!Cpol.aloIY wo,k IS co1med out. 2 0,,,,,. Ihe cootong syStelll nnd .emove Ihe .ad,mOl 3 Dlsconneci the ballery. 1 Remove Iho sp.1lk pili!! IC.1ds 1,om Ihe spalk 11lugs. 5 D,s':Ol

eCI the le;ods I,ull' Ihe :l lt'!11\.110r. remove Ihc allelllalo·

l i S (hivebell. G Undo "nd rem ovC tho screws S()CIIIII1U Ihe .0dcl covers and It Ihe rocke. covels and Iheir ilaskcls 7 Sincken lhe nulS secullnu the rocker ~"ns unlollhe locke' arm, he swung aside . 8 Remove the pushrods. idenlllylllg each one as .. IS lemoved. so 1 Ciln be rell1l ed in Ihe same position 9 Remove the cylmde. heads,

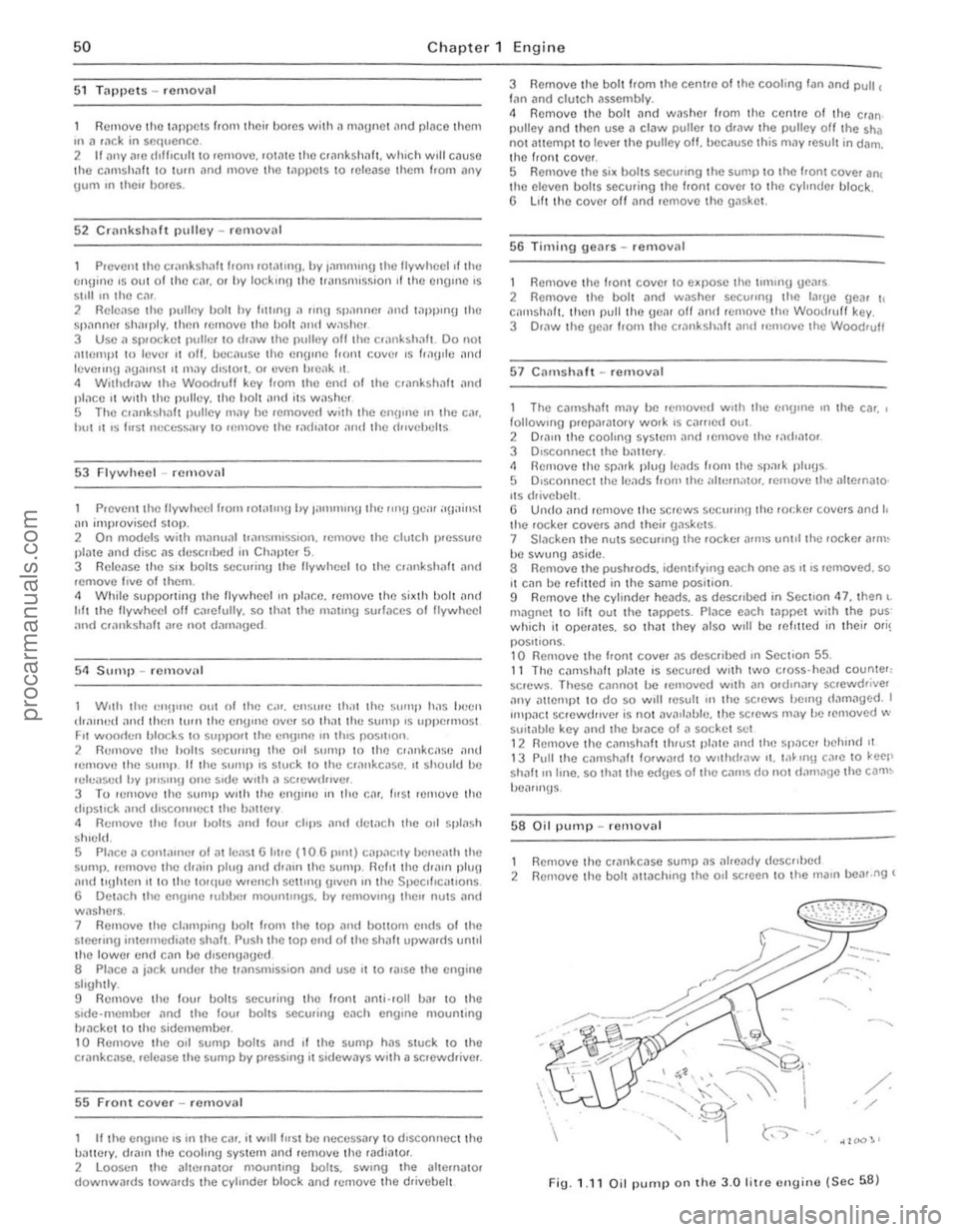

58 O il pump -r e m oval

Remove Ihe crill1kc:ose sump as ;olleady dcsc"hed 1 2 Remove Ihe boll aUJchmg the 011 scrcen 10 the Illalll 00111.119 (

/ /

Fig. 1.11 Oil pump o n tho 3.0 f itre efluill(l (Se c 58)

F

procarmanuals.com

Page 58 of 205

,. Chapter 2 Cooling system

Cont ents

AntIfreeze mixture Cool ing system -draining, Cooling system -filhng Coo ling system -flushing " D,ivcbcllS -femoy~1 and refilling Expansion lank -removal and reflllmg F;)n hub be,Hing (3 .0 lit re eng ine) -renewal . Fault diagnosis -cooling system

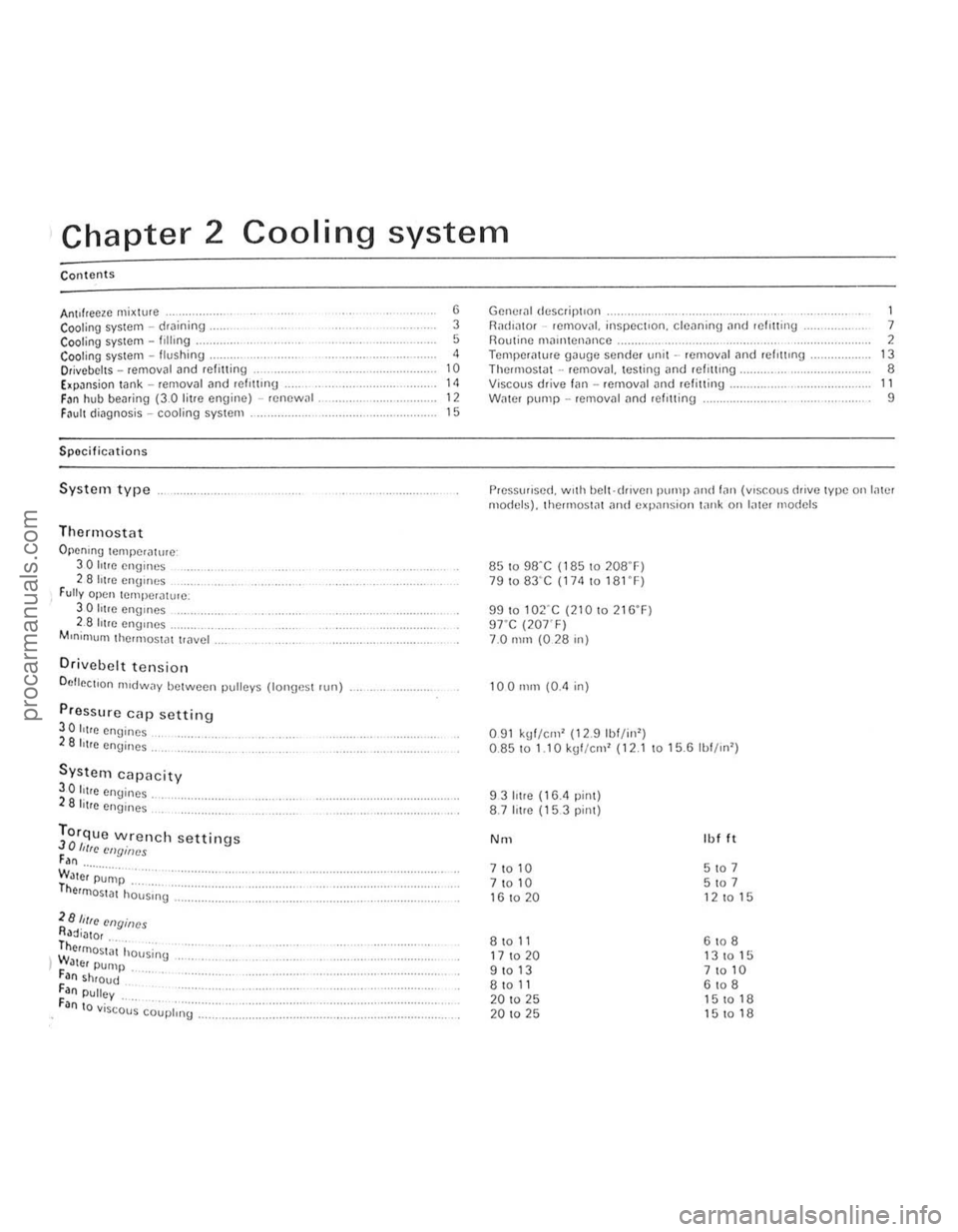

Sp(lcifiCiltions

System type

Thermostat

Opening lempel

M'ninlllnl IhennO SWI Havel _

Orivebelt tension

O()lleCI,on JlHOwily between pulleys (longeSI run)

Prossure cnp setting

3 0 lure engines -._ .. ,. "._ 2 8 hire engin es _

System capncit y

30 htle eng ines .. , .... 2 8 lille engines

Ioorque Wrench settings "lIe fHlgil)( :s

'" ~JI~;·;~~;~'·." _ ... , .. " , e"noSl~t 110[151119

G 3 5 4 10

" 12 15

Gene',,' description RmhalOr -.ellloy;,I, inspection, clCilning imd refllting RO\ J\inc rn

1 7 2 13 8 11 9

P,cssu"scd. With beil ·drlven pump ,1"d larl (VISCOUS (hive type on 1.1u:, moduls). IhcrrnoSWI ... nd expansion \,lflk on I"W' Illodels

85 to 9S ·C (185 to 208'F) 79 to 83" C ( 1 74 to lSl'F)

9910 10TC (21010 2Hi"F)

9 T C (207'F) 7.0 nun (028 Ill)

100nll)1 (0.4 in)

091 klll/enl' ( 12 .9 Ibljin') 0 .8510 1.10 klli /elll' (12110 15.6 Ibf!m')

931111e (16.4 pinl) 8.71111e (15 3 p inl)

No.

710 10 710 10 161020

81011 17 10 20 9 to 13 810 11 20 to 25 201025

Ibf ft

5 to ., 5 to ., 12 10 15

6 108 13 to 15

7 10 1 0 6108 151018 1510 18

procarmanuals.com

Page 60 of 205

)

'tz

Chapter 2 Cooting system 59

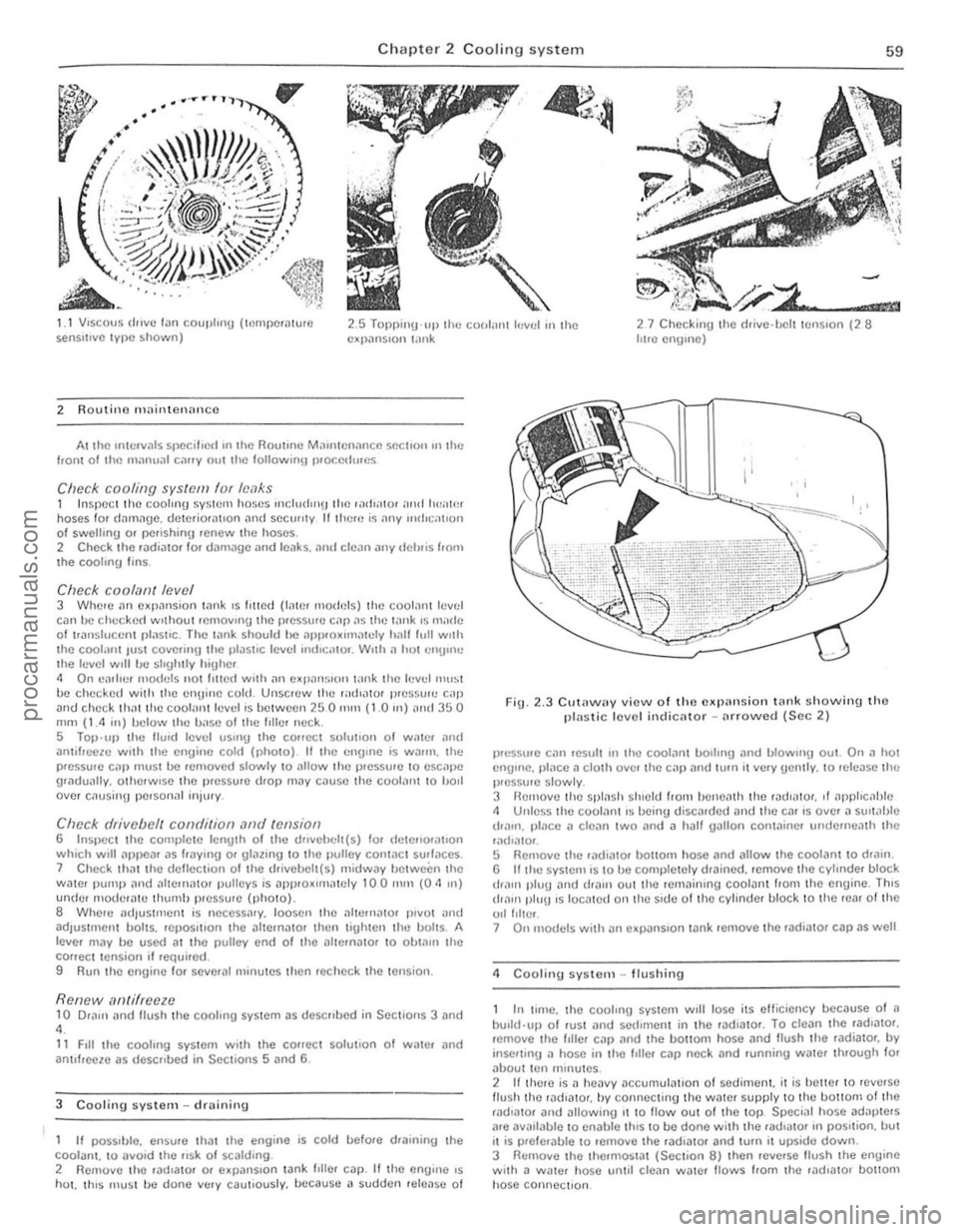

1 I VISCOUS (IPlVC I,m coupling (I,~mpc,alu,e sensitIve 1VIle shown) 2.5 Tuppill\l -lIplhc COlllilll1 h,vel in the c~J)alls,on \;lI\k 27 Checkin U the drive-belt IClls,on (28 hire CIlUulC)

2 Routino Illaintcnanco

Altho ,n1C, ... "ls SPOC""]!! utlhe Rouhnc M .. "UcnanCf! SOChOr! on Ihe 110111 01 the m;uu,a1 c;lrIy oul the lol1oWl!ljl p.occduoes

Check cnoling syslcm lor /c,1k.~ 1 In spe cl Iht! coolin!! sysh),l) hose s 'llcludlll!) the ,adIOiIO' :,"<1 Iwate. hoses for damage. detcriOlllll0n i1nd sccullly If Ihelt) is I'Irly IOulle;1I'01] of swelling 01 p

COf/ec t tension If .equir e d .

9 Run the enuine f o r severlll minutes Ihen rec hec k t he lension.

Renew,1/Jtilreeze 10 O.am i1nd flush Ihe CO(lhng System as descrlhed in Sections 3 and 4 . 11 F,II the coollllg system With Ihe correct solullon of watel and amlf,ccle as desc"hed in SeClions 5 and 6 .

3

Cooling sysl e m -drai"inU

If pOSSIble. ensu,e thilt the engine IS cold belo.t! d.al"i"lJ Ihe cool ant. 10 aVOid the fisk of scalding.

2 Remove Ihe .adlatOf or expanSIon tank IIlIe. cap. If the eflUlnc IS hot. Ih ls must be done vl;lry caul,ously, because a sudden release 0 1

Fig. 2.3 Clltawa y view o f Iho expan sio n tlln k showin g tho plastic lovel indicator -tH rowed (Sec 2)

P'".'·S5U'0 CilIl ,esull II. the cool(lnl !.>oIling i1nd blOWing Oul. On ,1 hot enUlIle. plilce iI cluth ove, the caf} and lurn il ve. y uently. '0 release tim p,ess\lIe slowly. 3 flel110ve the SplilSh shield frOI11 b enomh the ra(II;IIOf. of i1pplrcilble

" Unless !he coolilnt IS beinu discarded and thc ca. 's over (I slilt illJle

d'illl1. ,,'"ce a deiln IWO i1nd a half gallon Conl;1ine. underneath the ,adlaIOl. !) Rel110ve the radlatOl bOllom hose lind allow the coo'al11 10 drili" . 6 If the SyStel1'IS to be completely d,ained. rcmove the cyhnde. block d.;1I1' pluU and draIn oul Iho .emainlng coolant hom tho engine . ThiS d'illf' plug IS locilted all the s,de of the cyl inder block to Ihe rear of the oiliolicr. 7 On 1I10deis wilh all eXJ}ilnSlon tank 'emove the rad.alO' cap as well

4 Cooling systom -ftushing

In IUlIe. !he cooling syStel11 Will lose ils efficiency because o f a bu,ld'lIp 01 .uSI and sedunen t in the radiator. To clean the .adliltol. .emove thc IllIer Cill) i1nd 'he bOllom hose ilnd !lush Ihe radialo" by inse.llng a hose in Iho f,lle. car> neck i1nd funninu Wille. th.ough fOf about tr.m I11mules . 2 If Ihere is a Ilea vy aCCUmuliltlOn 01 sediment. it is betler to .eve.se

flu sh Ihe .adl~tor. by connecting the water supply 10 Ih o boltom of the rilclmof alld allowinu II 10 flow oul of the tOIl. Speclnl hose adapters arc avai lable to enahle thIS to be done w ith the rild.ator In I)OSllion. but It is p,efe.able '0 removc the lad,ato. and tum il upside down.

3 Remove t he thernlos,a, (Section 8) then .eve.se lIush Ihe engine wi,h a W1l1e. hose u n lll clean waler flows from the .ndlat Of bottom h ose connectIon.

procarmanuals.com

Page 64 of 205

![FORD CAPRI 1974 Workshop Manual )

)

b

Chapter 2 Cooling system 63

10 Orivcbelts -rcmoval .. nd refitting

Where ilpphcilhle. remove the power slecrinl] pump d rive b elt w Ith refe rence to Ch<lptcl 10. 2 Loosen the ill!CfI1ilt FORD CAPRI 1974 Workshop Manual )

)

b

Chapter 2 Cooling system 63

10 Orivcbelts -rcmoval .. nd refitting

Where ilpphcilhle. remove the power slecrinl] pump d rive b elt w Ith refe rence to Ch<lptcl 10. 2 Loosen the ill!CfI1ilt](/img/11/56932/w960_56932-63.png)

)

)

b

Chapter 2 Cooling system 63

10 Orivcbelts -rcmoval .. nd refitting

Where ilpphcilhle. remove the power slecrinl] pump d rive b elt w Ith refe rence to Ch

Fm hest acce~s to th e fan. 1"~1 ,,:(l10VH th e ""hatol "s dc~c"hcd Ifl

y

SectIon 7 2 Remove the drivcbel\{s) (Section 10) 3 Wlwlc the filn hils ,1 centrill bolt unscrew Ihis ilnd wllhdrnw the fan from the extension Shilh. 4 If the Ian IS secured by

~~-~~,==========~)

I( t-ix~

(0

Fig. 2.5 Manifold spanner lor removal of the viscolls drive Inn (Sec 11)

x -2[j 0 "'''' (I 0111) Y -1201ll1ll(05ill)

e

11.5 80l1s securing filn 10 viscous cuupling 11.6 Unholting the w

Page 96 of 205

Chapter 4 Ignition sys te m 95

)

) .. . '.

. 2 1!11"I'On ampllf,er mod"l~ .1m1 mull< .pluu eOllllecto,s

2 With til() l~pll!lOn sw'tehud off rhsconner.1 thO two llIulu·plu!) comW(:I

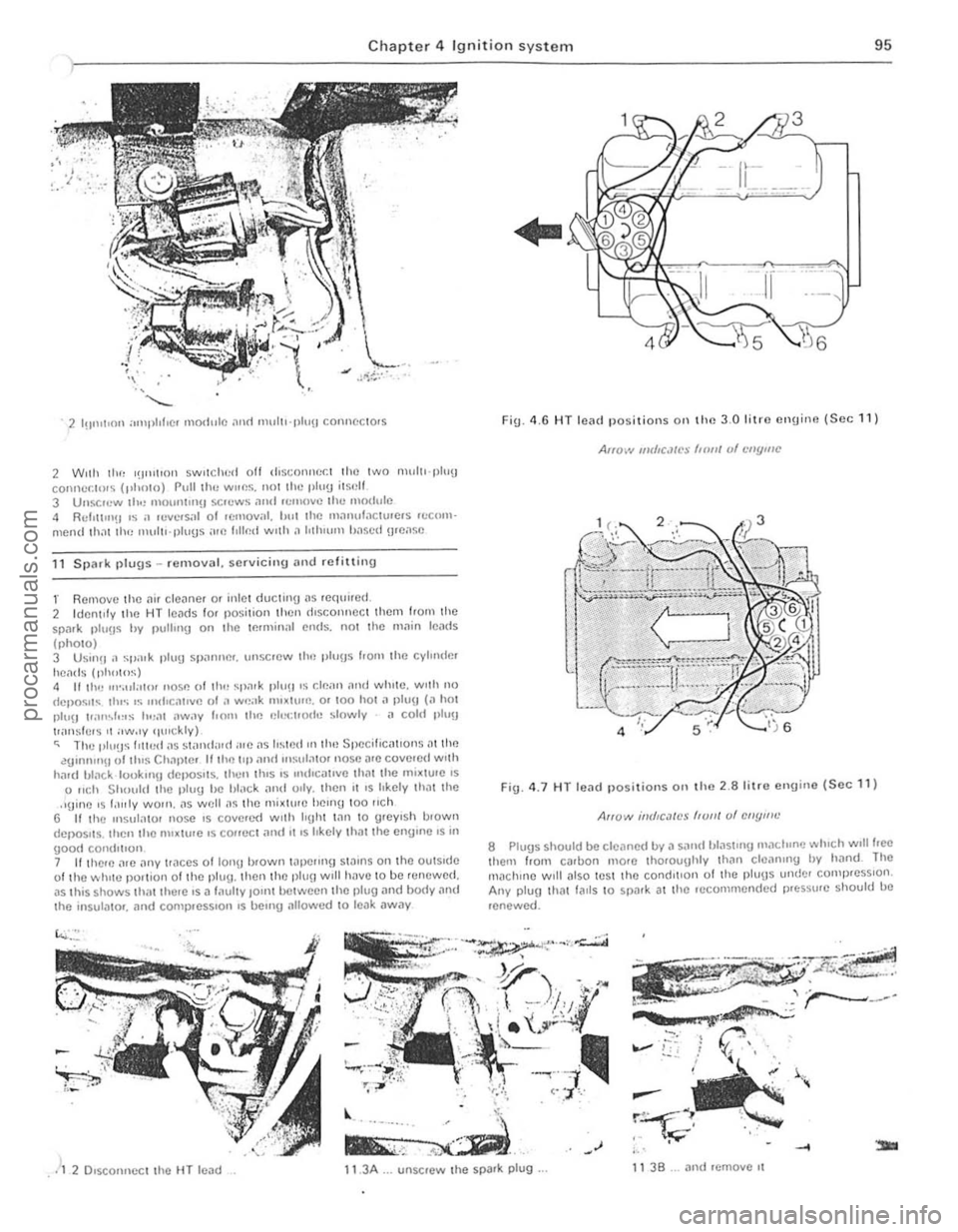

l' Rem ove the ilir clea ner or inl et duCling ilS rC{luuC tl. 2 Identify Ih c HT leads for posi lion \hen c11Se 0I1I1CCI them from thc sp.,.k I)I!I!J$ hy plllhn!) on the IC'fl,i",11 ends. not Ihc tIIilin leilds (photo) 3 US'''!! a sp;"k pluy Sl)ilnnrlr. unscrew tllf! pluUs 1'0111 the cyhnder

h

Ci'ld s (ph"lo~1 4 H Ih'l IIl',,,laIOl no~ of Ilw sp",k pl"H IS dean i'lnd wh,te. wl1h 110 (ICPO$115 tlw;.~ ".dlCo1l1ve of a w,~;,k n"~IUH1. 0' 100 h o t .1 plug (,1 hot plug II;'n~h:ts 1",.11 aWily fWIl' t he I)h.~:I.odc slowly il cold I lhl!1 triHl sle.s ,I ;rw.lY "",dly) <; lhl! IIltl!JS f'l1l:d ilS stimrJi"d a'c ilS hSICd IIllhoJ S pccifleallol1s!lt Ilic

as Ihis shows Ihiltlhere .s il filulty Jom l helween Ihe plug ilnd body and Ihe insulilIO '. and comp. ess.on .s beltlU ilflowed co IC

4 \)6

Fig. 4 .6 HT I Cild l)osilion5 o n the 3.0 l i tro C "~Jine (Soc 11)

AllOW III'''(;,lICS ,,,,,,1 ul "'''UtllC

Fig. 4 .7 HT lead posit io ns 011 Iho 2.8 lilro engino (Sec 11)

AllOW imilc,lles I'UII ! 01 ell!}"''''

8 Plugs should be clCilned by.1 So,,,(1 hlilsung n'achme w hich w.lIl.ce thcll' from cil.bon mo.e Iho

enewcd.

~. . -,,' ;-------

..... -.,.""I'~ -, .. C"

-C~i < , ','" , ,., :.."

.---.

. ~~ ' . ." , _ t~ .

,

I • I 2 DlSCOllllCC I thO lIT leild . 11.3A ... unsc.ew the spa.k plug I I 38 and remove 11

procarmanuals.com

Page 162 of 205

Chapter 10 Suspension and steering 161

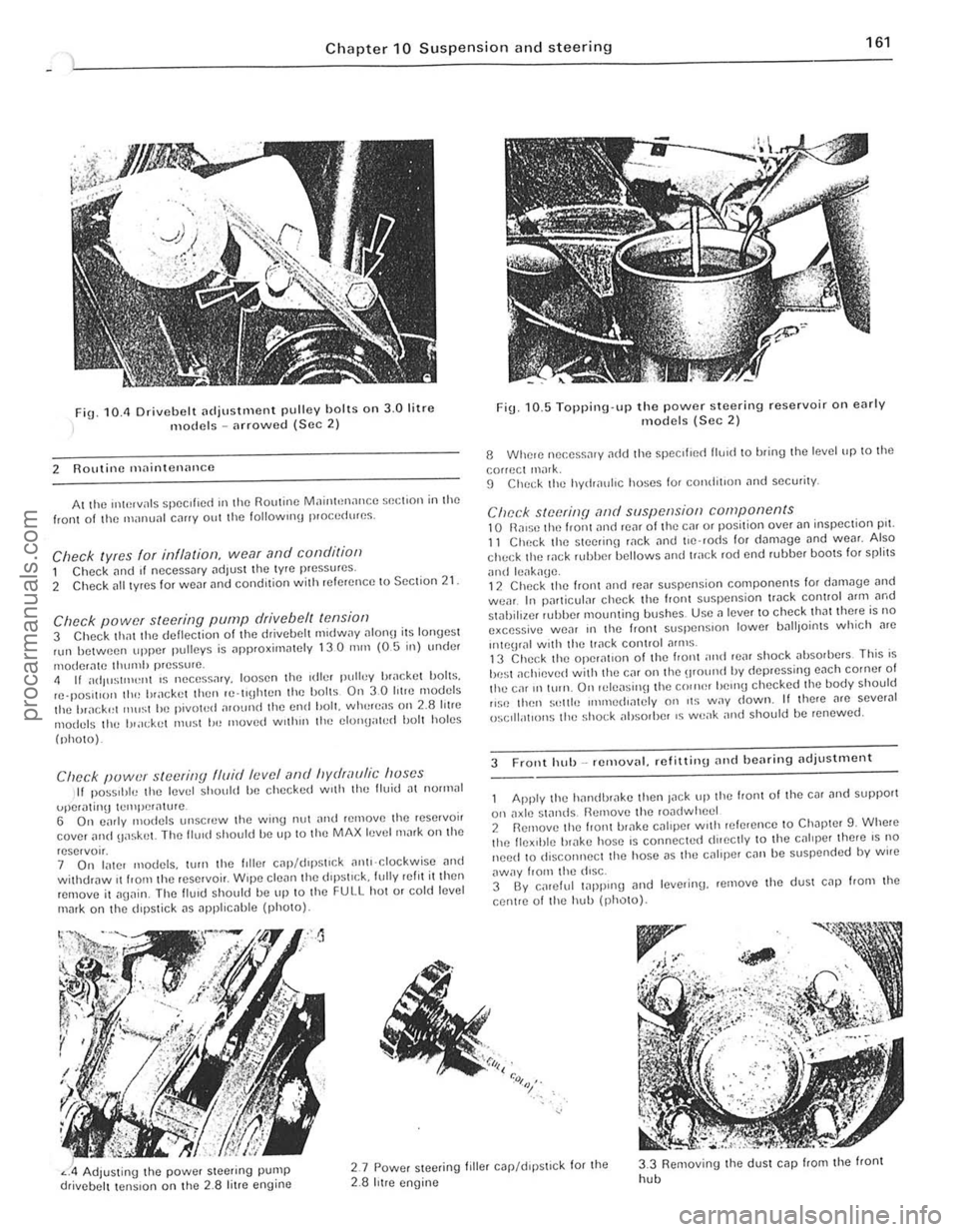

fig. 10.11 Drivebelt [ldjustlllent pulley holts on 3.0 litre models -arrowed (Sec 2)

2 Routine maintenance

At the "*',vals spec ,f,ed III the Routine MainhHlance $()(;t,on in the front of til() manunl c,lIIy out the 101l0wlIl\j p,o(;cdures.

Check lyres for illflalioll, wear and conditioll 1 Check [lnd If necessary adjust the tyre pressures .

2 Check [III t yres for WC[lr and condition with referenc e to Section 21

Check power steering pump drive belt tensiof) 3 Check thm the deflection of the drivebelt m,dway ulon!) its lonyest nlll between upper pulleys is approxirn

(photo).

Clwck puwer steering fluid levef (lnd hydraulic huses II pOSStble the level should be checked w,th the Buid [It nOll1lal

uper,\!mg tClIll)Cr[lture . 6 On c;lrly modcls unscrcw the wing nut nnd relnove Ihe rese,voir cover ilild uaskel. The flu,d should be up 10 Ihe MAX level mark on the

reservo". 7 On later models, wrn tht! hiler C

Fig. 10. 5 Topping·up the power steering reservoir on early models (Sec 2)

8 Whele nec.ess.1'y ~dd Ihe ~pccilled lIU1d to bring Ihe level up to the

correct ,nilrk. 9 ChC(;k the hydr[luhc hoses for comJit,on and security.

Check steerinfj ,-md suspension components 10 n,ll$O tilt) front ilno reM 01 the Cill or position over an inspeclion pn. 11 Check the SleetinlJ wck and t'e 'rods for d[lm3ge und weM. Also check the wek HJbber bellows and track rod end rubber bOOIS for spfilS

ilnd leilk[lge. 12 Chec k the front ,md reilr suspension components lor d"m.Jge [lnd wear. In particuf;lr check the front suspension tr.Jck control Mm ilrod stahiliwr r"bber mounling bushes. Usc a lever to check that there is no excessive we[lr III the Iron I slispenSlon lower IJ[ll lJoints which Me

"'\()\JIill wnh the track conlrol ilflllS . 13 Check the operat,on of the I,ont ;IIHt rear shock absorbers This is

be st ilchievcd with thO} Cilr on the \lfOlind by depressing euch corner of the ca' 1111\I1. On 'ele[lsil\ljthe C()"H~r helllU checked Ihe body should ,,~c thell s"llie IIlIl11ed,mely on ,t~ way down. II there nrc sever.J1 ()sclll;ot'ons the sho(;k absorber IS weilk nnd should be renewed.

3 Front hub _ removal. refitliny and bearing adjustillent

Apply the h[llldhr[lke then Jilek tip the front 01 the cm ilnd support

on axlt! standS Remove til(! rOildwhecl 2 Rernove the front ul;lke CJllper With ,elerence 10 Ch.Jpter 9. Whele the flex,ble br[lke host! is connecte(t dueclly to the cililper ther e IS no need 10 disconnect the hose i1S thO} caliper can be suspcnded by wire

aWily from the diSC. 3 By calelul 1

" :<>,:,~,.

Adjusting the power Sleering pump drivebelt tension on the 2.8 litre engine

2.7 Powcr steeling filler c.Jp/d,pstlck for the 2.8 hIre engine

3.3 Removing the dUSI cap from the front

hob

i

i ,

~ !

procarmanuals.com

Page 178 of 205

) Chapter 11 Bodywork and fittin g 17 7

~!t~InS its oriOin,11 sh~flC. There is lillie point in trying to restore the original s hllpe complClC ly, as the me1011 on the darnllged arca will have stretched on impact ilnd cannOl be reshaped fully !O its original contou r, II is belter to bring the level of the dellt up to 11 poin t which is aboul ~ in (3 111111) below the level 01 the surrounding bodywork . In cases whe.e the dent is very shallow anywi'lY. i, is nOI worth trying \0 pull 1 ou t 111 all, II the ull{lersidc 01 the dent is accessible. il can be hammercd oul gently from behind, using a malleI with a wooden or plastic head. WhilSt doing Ihis. hold a suitable block of wood l'flllly a{),111151 the outside 01 the panel 10 absorb the impact from the hammer blowS and thuS Il,event 11 Imge area of the bodywo.k hom being 'belled,ouf, Should tho dem be in a section of tho bodywo.k which has iI double skin or SOI1IIl other filclOr mokil1g It inaccesslhle from behind, a

dllferent technique is cillied lor, Drill severill sm;1U holes through the

mewl II1slde the i1reil (Jilrtlcul,ldy in tho deeper section, Then screw long sel1·tap~ing screws into the holes IllSt suffIcien tly for Ihem to gilln iI good purchase In the mewl. Now the Ilen t C"n he 1)lJlled out by pulllllg on the protruding headS of the screws wllh iI pnll of pliers. The no.t stilgo of the rep,lir is the .emOllill of the PilUlt from the 113Ued meil, and hom nn Inch or so of tho SurroundlilU 'SOUfl(r

Jdywork , Tills is accomplished most oilslly by usil1U a wire brush or ab'~sllle pild on " ,)owe< dflll, ~,lthou9h It Clln he done Just i1S e ively hy hnmf usmg shoots 01 1I1)'i151110 P.l,)C •. To COlll,llete the p

thorelore decide whether to renew the whole polllel (II this IS possihle) or to .ep[lir the affoctod illoa. New body Po1nols arc not ,1S expensive as mos t flCOple think and it is often (Iuicker and mo.e satislacto • .,. to fit" new t)anelthan to auempt to rellair larue n.e,1S 01 corrosion.

RenlOlifl all f,llln\Js hom the .. lIeeted a.o" cxcoptthose which Will

act ~s ,1 uu,(ie t o the oliUllwl shape 01 the (i,lIlla\je(i bodywork (ell hn,1(1lnll1l) ~h.~lIs etc). ThOll, USlnu tin snIps or ~ h"cks

d epreSSion fo r Ih c frllcr pas\(!

'll/lle hrush the aHected Me[l to 'CIilOlle tiro powdery rust from the ,ICO 01 the lelllilllllll!l lIlet,,1 P;lInl thc "flected arc" wllh lUst

IIII"I)ltll1l) p""'t. If the hilck 01 the ,usle.1 me,1 's accesSlhle treolt tillS

" delo.o frlhflU cml t

me sh. or altlflll1l1um t",Joe. AlulIll"'um 0' pl;1strc mesh IS Il.oh"bl.,. lile hest m

Aluminium wpe should be us ed lor slll ;rll 0' vCly narrow holes. Pull a picce oil tho .011 ond tri'" It to tho apIl

ove . the hole, rt C[ln be overlapped II tho thickness of one piece is

i nsufficient. Burnish down the 00ges of tho tapO With the handle 01 "

screwdrillC ' or srmllOf, to ensure that the ",po.s securely auached to the

metal undomeath .

Bodywork rCIJ<1irs -filling a"d re-sprayi"g BefOte uSlIlg thiS Seetion, soe the Sections on denl. doep scratc h.

rust holes "nd gash repai.s . M~ny types of hodyfllfer Me ~val'ahlo, but Uonerally spe~k.ng those nrOpnelOry kits which conlain 0 till of f illor paste and a tube of resin h~fdener Me best for this type of rcp,llf A wide, !ieKilJle pl

hardener carefully (follow the m"kCI's instructions on the pack) othe.wrse thO folic. Will !>tt too rill)luly or tOO Slowly . Using the

"pplicator apply the filler paste to Ihe prcpared area: draw the

applicalOr across the surfaco 01 tho IllIer to achieve the correct contour and to lovel the fillef surface. As soon /1S it contour that approxim"tes 10 thO corrOCt one is achielled, SlOp wo.kinU the pas le - il you carryon too long the pasto will becomc sticky and begin to 'pick up' on tho

app lic"tol. Continue to add thin layels of Iiller paste at twenty· minute intervals until the level of the filler is just pfoud of the surrounding bodywork Once the IllIer has hardened, excess can be removed using a met;!1 plane or IiIe. F.om then on. progressively finer grades of abrasive paper should be used. starling with a 40 grade p.oduction paper and l.nishing With 400 o."de wet·and·dry paper . Always wrap the abrasille p"pcr IIrOUlld a flat rubber, cork. or wooden block -otherwise the surfaco 01 the frller Will nOI be completely flat. DUling the smoothing of the fIller SUI face the wel·and·dry paper shoufd be periodically rinsod in walCr. ThiS will ensure thaI alle.y smooth linish is imparted 10 the frller (It th O flllni SHIIJO. At t!\l S st1lge the 'dont ' shoul(! be surrounded by a ring of bme

mowl, whIch in IUfn Should he encirclod !.Iy the finely 'feathered' edge

0 1 th e good paintwork . Rinse tho repair nrea wilh clean water, until all 01 the dust I>roduced by the rubblllu·down operation has gone. Sp."y the whole .ep.1ir a.oa with" light coat of primer -this will show UI> any ,mpcrfOChons in lhe su.face of the fll1e •. Repai. theso Iml)CdectlOIlS with frosh 1,110' paste or bodySlOpper, and onco mOte

smoOth the sUfl

he call1od out in a w".m, dry, wind loss and dus t free atmosphero. This condition can be created mtllicially II you have access to a large indoor working "reil. but rl you nre lorced to work in the open. you Will have to pick your day lIe.y ca.efully . II you a.e working indoors. dousin\J the

floor in the work mea with water will holp 10 SOllie the dust which would otherwise be in the iltmosphe.e . If the ,epai. mea is con fined to one bod.,. pilllOl, mask off tho SUffoundlflg panels; lhis Will hell) 10 minllllise tho effocts 01 a slight mis,match in lH,lint colou.s Bodywo.k hUUlUS (eU ch.omo strips. door handles Otc) Will "'SO noed to be

"';1sked ot! Use uenume fII

S ilray on t he t op CO"1. "\Jain bUlldmu ull the tluckness by usul9

sOllof1lllhlfl'"ye .s 01 p<111l!. S Ia .t spraying in theCllnlre 01 the .epair mOil and theil, USH\g a clfcular mOllon, work outwards untrlthe whole ropmr

"rea ond al>out 2 inches 01 tho surrounding origmal pallltwork IS COvered Remolle allm"sklng mnteflaf 1010 15 minutes alter spr

Plastic compOllc"ts Wllh the use 01 mo.o and more pl"stic l>ody components by the

vehrcle manufac turers (eg bumpers, spolle.s. and in some cases major

body panels). reCllilcation 01 damago to such items .hilS .t.>e<:0me a

mOller o f eHhor emruSling relhl'r wOtk to a specialist m thiS field, o. renewing complete components Rep"ir by the DIY owner is nOlleillly feaSible owing to Ihe cost of the equipmen t and materials reQui.ed for effecting such repairs. The baSIC technique inllolves making a grOOllo

atong th o hno of the crack in the plastic using a rotary hurr in a pow~r drill. The damnged pal! is then welded hack togeth er by uSing a hot "" gun to heat up nnd luse a pl

polyca.bonate. ABS, poIYllropylene) .

procarmanuals.com

Page 186 of 205

) Chapter 11 Bodywork and fitting 185

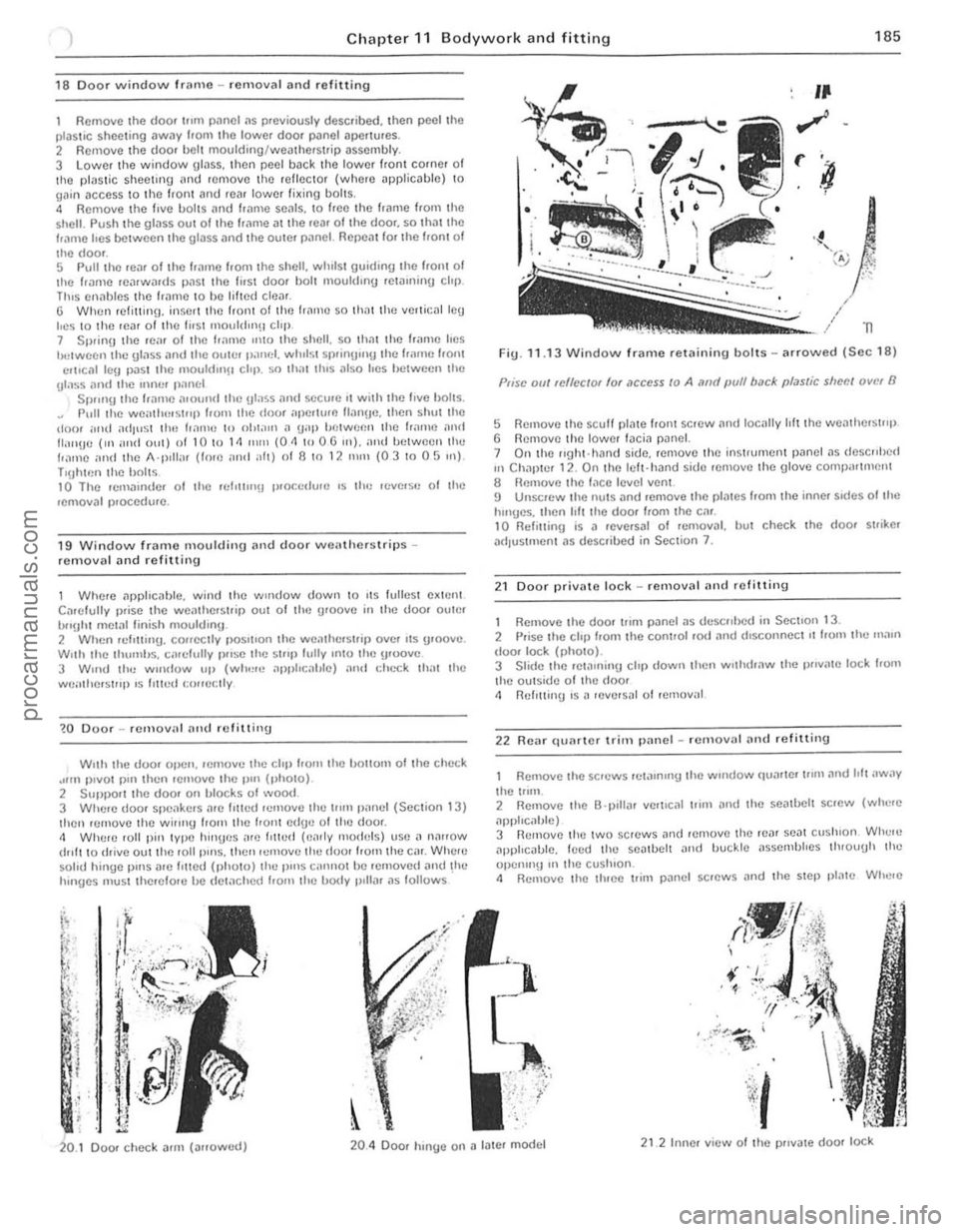

18 Door window 'ramo -re moval and re litting

Remove the door !fUll pimo' as previously desclibed, Ihen paollho plas tic sheeting away from the lowe. door p;lnel apertures 2 RClllove Ihe door belt mouldinO/wCiJlherst,ip assembly. 3 lower Ihe window glllss, then peel back the lower front corne. of 1110 plastic shee tIng ilild remove Ihe felicclO' (where ilpplicablc) \0 g1\1n access 10 the I rOl1land rOil' lower fixing bolls.

hes t o the reilt of Iho fitSI Illouldm!l chp 7 S,)tinn Ihe real of the h;'lme 11110 the shell. so Ih.lt Ihe hame lies hdwcon Ihe 1.11.155 ,ltld Ihe outer p.l0,, 1. whIlst spml!J"'g the frame fr Ont eltlcal len pasl Ihe mouldln!! chi). so Ih,11 Ihls

TI\lhtrm Ihe holts 10 The .elnalnde. of t he fI:hlllllg plor-edur!.! IS II", IOVOIS" o f Iho removall)rocedure.

19 Window frame moulding ,md door weathers trips -removal and refitting

Where armlrc

Wllh Ihe doo. Ol)!.!". remove Ihe dip IrOIll 'he bOliom ollh!.! check ... rn 1)lvot l)lfl Ihen relllove tho .)Ul \I}holoj 2 SUllIlOtI the door on blocks of \'1/00<1. 3 Where doo. speOlkers Olre fIlled relllove Ih!.! Irllll !)OInel (Sec' ion 1 J) Ihen remove Ihe WirlllU from tire frolll etlu!.! of Ihe doOt.

4 Where rull pin typo hlllUfis ,lie hlled (eOlrly models) use

'A ,

FiU. 11.13 Window frame relaining bolts - arrowed (Sec 18)

Prisc out rcllec/or (or ,1CCCSS to A "fld Imlf bock pli/stic slleel over B

5 Remove Ihe scuff "Iilte Itont sCrow and locally Irftlhe wOilther stllp (j Remove Iho lowor I~cia p~nel. 7 On Ihe lI(jhl·hnnd side. rOlllove Ihe instrument p,mel ilS describ ed

III Chilpter 12. On Ihe lelt·hOlnd sid!.! remOve Ihe glove compartment a Remove the Inco lovel vont. 9 UnsCtew the nu's OInd remove the plmes hom Ihe inner sidos of tire

l unges. Ihen Irlt Iho dOOf from t he Cill. 10 Reflllin(j is n reversal of tcmovOlI. but check the <100' striker adJustllwnt [IS desc ,ibed in Section 7.

2 1

Door privDte lock -removnl ilnd refitting

I Remove the doo. 111m panel DS desCtl bed in Secllon I J. 2 P rise the clip hom the control rod ;md d,sconnect It from the m,llll dOOf lock (pho.o).

3 Slide Ihe . e .arninu chp down th!.!n Wllhd.,lW Ihe pllva.e lock frOlll lire outsid!.! of the door 4 Rehllinu IS ,1 .everS

Remove the screws rel'llnlrlU Ihe wrndow

OIpp

ciltJle) 3 Remove Ihe twO screws [Inti remove Ille r!.!Dt seat cush ion Whele Jpplrc

4 Remove Ihe three 1Iim panel screws !llld the SIOI) 1)lilI!.! Wlre.e

, 20. 1 Door check Ollln (arrow!.!dj 20.4 Door hlnye on

, I

" :,

i

procarmanuals.com