check engine light FORD CAPRI 1974 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 22 of 205

)

T

Fault diagnosis 21

Starter motor ((/rns cngino slowly Parti ali V disch~rilcd b

Engine ((/"'S normally but 1,1ils ( 0 SIMI Damp or dirlV HT !eads

Engine ClltS Ollt ;1nd wilinOI roslinl

fngine culS out suddenly -ignition I,wlt Loose or d'$Conncetcd l T wi.es WCI HT Icads o. d'S I"buiOI C;1P ("lIer tr;1VC'SOll!) w;1'er spl;1sh) Co,1 o . condenser lallulc (cheek 10' SI);lIk) Olhc. ignition laull (see Ch,'plfll 4)

Eflgine mistires belore CUlling oul IlIcll,wlt Fuel I,,"k Cillply Fllel pump dClfecl1vc o. 1,ltcl IIlo .; k(H! (dwck 1m dellvl"V) Fuel tank hllcr vcnl blut;kcd (StII; llon Will II" flV,{Io"'1 Oil lI~h"'~II'H C,11l) C;1llJulCIIor nccdlc v"lvc SIII;klll!J (WIU.'1I1 "ppI1c"hle) C,1lUwellor leiS blocked (ha:l COIII,lIl1ln,Hcll) Othcr lllcl sys!Cm l

BATTERY

lSin.MIN

POSITIVE

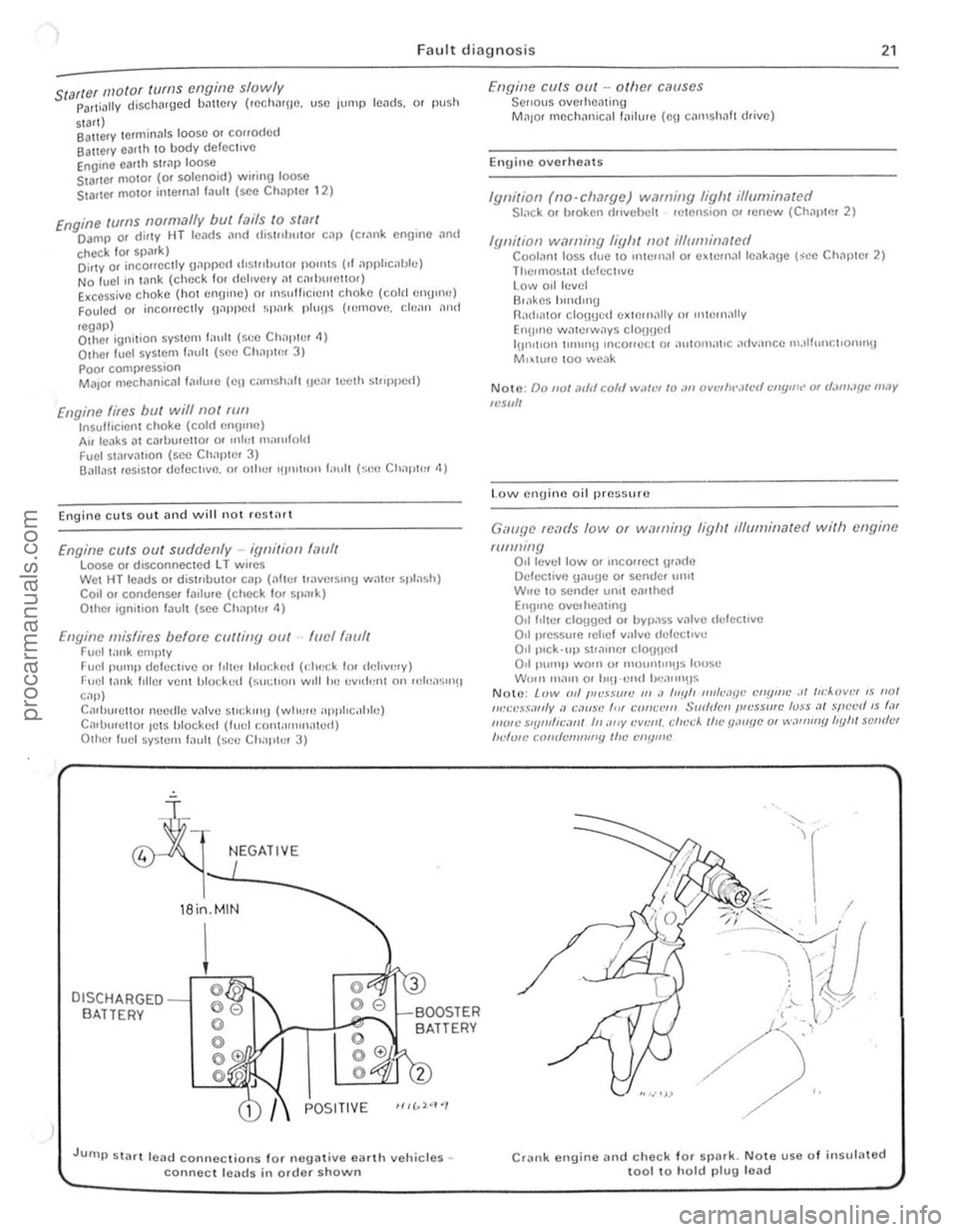

JUfl11) Slart lead conneClions f o r neg!Hive earth vchiclesconnect le;1ds in orde r shown

fllgine euls Ol1t -olhor eimses SCIiOliS ovcrhC~ling Mnior mcch

Ignitioll warning light /lot illuminBted Coollllll loss .Iuc 10 In!emnl 01 CXierr'JI ICJk

l.ow cnuinc oil JlfC!ssuro

G,wge reads low or warning lighl Illuminated wilh engillc

rWllling Olllcvcl low or mCOlfeel 0.,,<10 Deit.'Ctivc gllU!jC 01 sendCI 11111 Wife 10 sendCI UIII' C.1I.hC(1 Engonc ove.hC.1l ing O,lllllcr CIO!19c<1 01 byp,1SS v;1lvc delccllvc O,I ,llcssule lehef v'llve dc!ec tlve Oil pick-up strllll,e. ciomled 0,1 pUIllP WOIil or IllOlllllll1\l~ I\,osc Wo,n Ill,l'" 0' h'!J-cn(i hC.1I1I1!)s NOlO: Luw or! 1"t'HlifU III a IImh III"C"f1~" (.'IIYIIIC .J/ 11l;~()VI.'r I.~ 1101 1II.'I:<.'",.","/y,1 (.",lIlSV {o, CIIII{:"/U Suddel! fJf'~SS!lle {U$S ,11 SlIced IS {M "'/!IC SI{Jl!lflca"l (I! ,my cve/l/. .:In',·j. I/le .

procarmanuals.com

Page 36 of 205

o

Chapter 1 Engine 35

3 Examine the rocker shah ,md ,oc ker il,ms for we~r, II the rod", alill rl tha t conwcts the valve stem IS conSiderably worn. n,new the " ."'"nl I f it is worn shqhlly step-shnped it may be cleaned up wIth rOc e r ". . a fi ne oil stone. . , commencing Jalluary 1984. modolled ,oc ker shah sp"nOs have ~een fi n ed. Where wppet no,se IS evident 011 e~rlier models hl'lw",en e n g ine speeds of 1500 ,111d 2000 'p'll. the later type 01 SP,,,llIS nl.1Y he

I , n ed .

.

5 Od t he parts and reas~r)!llhle them on therr shahs III thO) n"lI,n;.1 or der With both rockel shafts f,tled the 001 holes must face downw.l,ds to th e cylindel heads Th.s po~"tlon IS lIl(hcated by a notch 011 Oil" "nd

lace of th e rocker shaft

13 Tappets and pushrod s - eXill11inalion 1It HI renova tion

I Examine the v

14 Can,shaft ilnd ciln ls h Hft b earings -cxmninatio n "" d

rCll ovntion

II there is excessIve WO),11 III lhe camsh;lft thp.y will h,lVl! t" lJ" lunc wed. As the 1'1lI1'11 ul '''"1'11 Iwarrll\lS w!(lI"es speel,lI [(",I, thl~ ~houtd be left 10 your 10c,, 1 FOI(! dealer. 2 The camshaft n1;IY show SI\II1S of wear Of) tlH! I)(:''''''!I 1""""'1s 00 C;In lobes. The main d(:elsloll to lake IS what de!)",,, "I I'll"," n ec e ssitaleS renewIng the camshaft. which IS e xpensIve S<:'H"'!IOI da",~ge to t he bearIng 10",()"ls cannO I he ren'OVNI hy ''''I,,,,,I'''!I. runew,)1 0 1 the camshnft IS the only so lutioll J The CJm lobes mny show SlUns of ridgIng or piltmg on Ill" I"U" poin ts . II ridging IS sllghl then It may be pOSSIble 10 rel\\OVC It woth "

lonc oil stone or emery clOlh. The cnm lobes. however. ;"" ~urf;It:e hau Jencd nnd once the h

,

15 Cylinde r heads -dismantling . renova tion and rCils sembly

Clenn the d "t nnd oil off the cylinder he

pl

.. ··'1:

. ,

•

,r· ' .

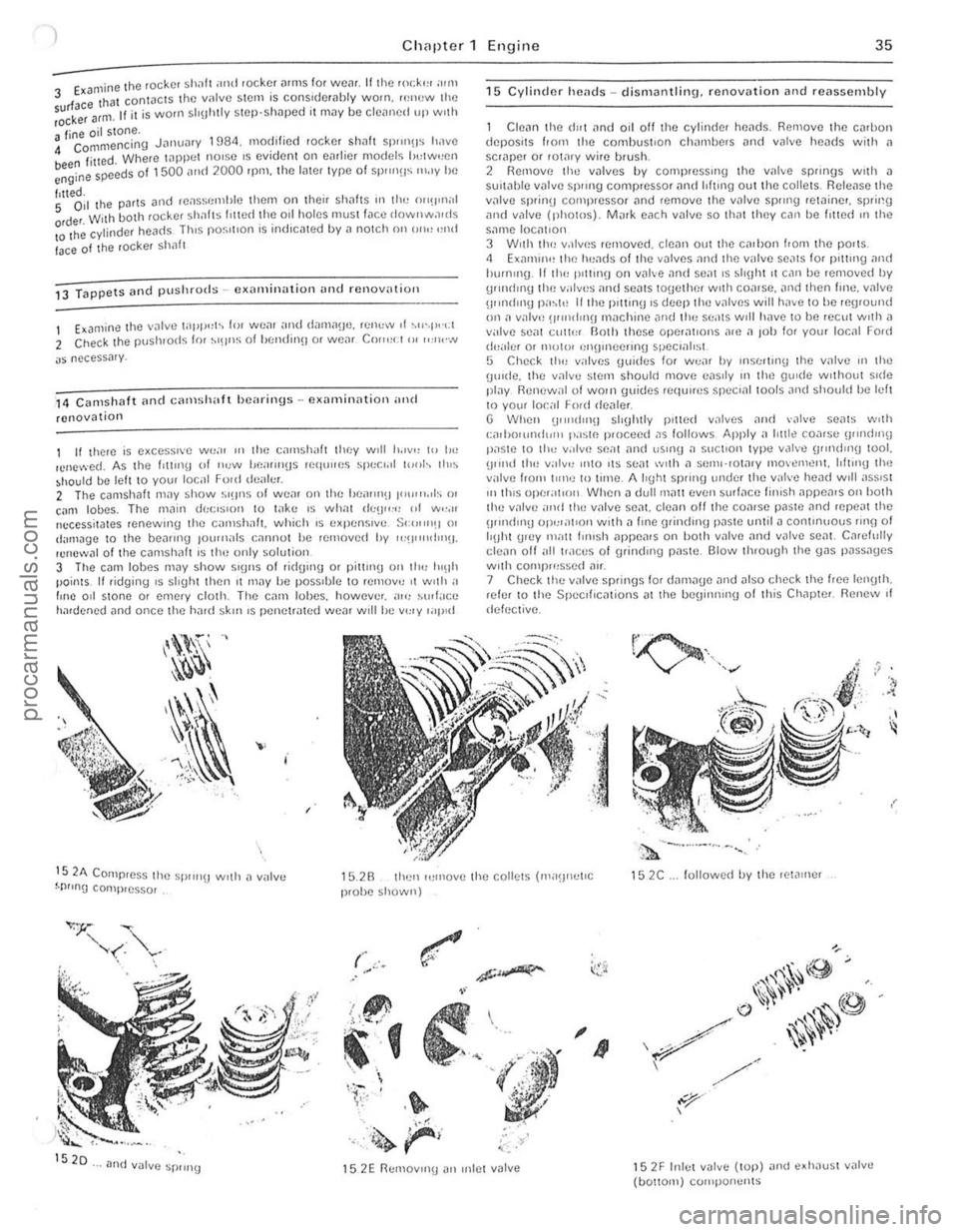

t5 2A Comp' ess the SP'Ii") woth II valvlJ

! ' Il "nU comp,esso, . 1

5 .2£1 thu" """ove the collets (n'il\l'lellC 15 2C. followe(1 by the ,elnmer

1520 ... an d valve SP"Il\!

p,ohe show,,)

t;. "" &' '

'('ii" " 18 ... ,,,

'" ' .

. '

15 2E RlInlov,nU nil 'nlel valve 15 2F Inltl valve (top) and cxhnust v<1lvU {bot 10m) COlllpo"ents

.. ----------------------------~, 灲潣慲浡湵慬献捯m

Page 48 of 205

Chapter 1 Engin e 47

--;; ble chec k ~II littings nnd elcct"cill connections. Ensu,e thnt the 2 .,",or is correctly lilted ilnd Ihil t Ihe IUnil,on tlmmg StJtlC Selllll\) 's distrlU

I CI , t II in doubt Ie el 10 1npler . eorr~~ ~10VO 1110 SPJlk plugs nnd the '- ' conneC lion from Ihe 1\)111110n 3 '1 Turn Ihe engine over on Ihe st~rler motor unlil Ihe 011 pres~!II{! co'· . light is e~til1gu,shed or unlIt 01' pres sure IS .ccorded on IIl{!

warnu"lg . d I This witt ensure Ihill Ihe engme ,s no l Slarve 0 0,1 dU"I1!11he g~~ge,. I,w minules running alte. IflIlJ.1t SI.:lrl·Up. The l uel syslulll W Ill ,,,toea . I· • be p!"iOled dunng IllS ope.atlon.

: SOReconne<:llhe '_ ' conneclion on the 'IIn'tlon co,1 and ,elll th e sp.:llk

lugs and loads .

Stilrl .Ihe ~ngme .. ~ AS soon as Ihe engme Ilfes and .uns. keel) ,t gOll1g ill il lilst \lckov(;.

nl (no las te,) and bring it up 10 nOlll1nl wo.kong ICmpernturc ~ ~s the engine WilflllS up there WIll lie (){I(I smelts nnd SOfll~ "mol Il

hom pariS getting hOI and uUI.l1Ing olf all (leposIl5. The Signs IU luok

10' arc l eilks 01 w

exact gos liUht position unlil lhe w:1I1l11h ;oml vlh!al'On hiwU ;I(;t,," on Ihem, and il is almos t CllrWU1 th.11 th(ly WIlt ncrHI I'Hhw1l1l1H hllth". Tills should be done. of course. wllh Ihe C"( ,,nc slopped 7 When nOrmal running lefllJ}Coallll e hilS hecn .cnch",

I' !.tilled as a new engine and run IIl.1t.1 .cducc(1 spcud tor Ih~ IUS I 1000 miles (1600 km).

PART B: 3.0 LITRE ENG INE

39 Gener;!1 description

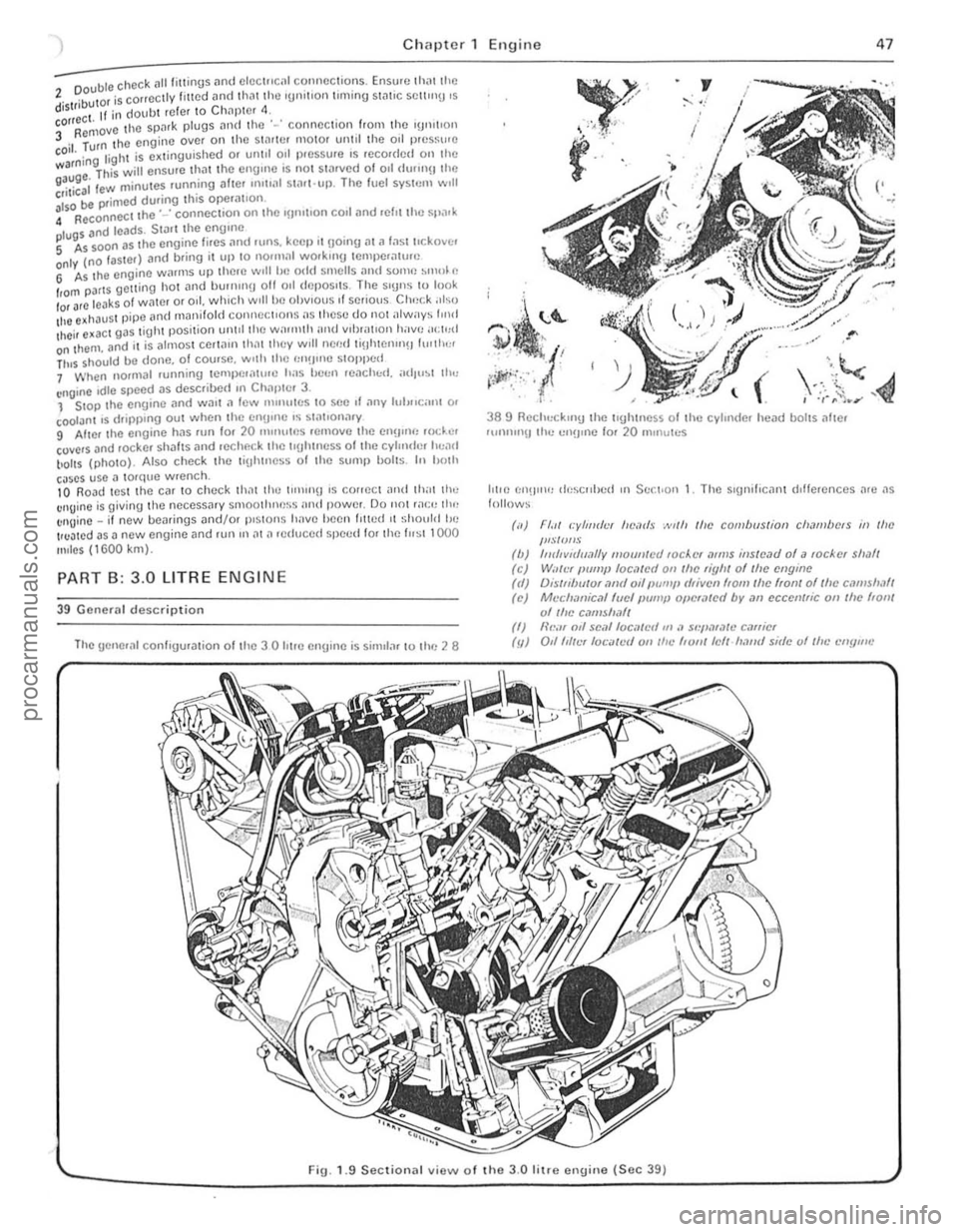

ThC !lcne'il' conl,uu'illion 0 1 the 3 0 hue enuine is sil11l'nr 10 the 2 8

( \:\.~ ,..d r •• -~~ .. ; ~

389 Recloeck,,'u Ihe Iluhlness 0 1 Ihe cyhnder head bolts afte. ,,,,,.loIlU lhe enu")e fOf 20 'I1In ul('"5

hire nllu""1 d(:~c"hed III Sec(,on 1. Thc Slunillcan t dltferences iI.e .1S follows

(i') FI,'I •. yllll(/vr ht',1(/$ ",'III the combustion cl.,1mba,s itl lila I".~I()IIS (b) Imhvr(/",llly IIIOUlIlCd rOC~t'f ,Jrms illstead of a lockct sitaft (c) W"lvr pump 10C,11cd 011 Ihe ,i!llu of the allgine ((f) DiSlfllmto' ,WI/ orf ,,"1/11' (I,ivell f,om thc front of thc c,lrmllllft (e) ML'ch,mic.1llllcl,Jl/flfP ollcfMed by ,1f1 ccccntric on tllC frolll vllhc c,lmshMt (f) /rr.';" (Ill sC;llloCMCII '" ,1 S':l'olfall: c,ltric, (y) OJ! trltvr IOt';llvl/ on tlw "I}fI1 lef(-h,mrf sidc (If tlw clI{Jlln'

Fig. 1.9 Sectional view o f tho 3.0 litre engine ( Sec 39)

i

"

'j

~ .... ------------------------------.. ~; 灲潣慲浡湵慬献捯m

Page 56 of 205

7

Chapter 1 Engine

Fig . 1.1 8 R ear oil sen I ilnd ildaptcr pliltc (Sec 84)

84 Renr oil se;1i ,,,,(I lIywheel - rc fitti"u

1 I'll the ()n!J"I(~ .r,," ,,(1"1'10' pla1<:1 and s(:clIre ,I wllh 'I S IIv(: holls. 2 Smenr en\J1ne (ld OlltO the CI,mkshah '''". Smear 0,1 on the lip 01 the sea l tlnd pos(( lon tlon ';".11 on th e cran hha ll. 3 Align the seil l c;""er holos wllh Ihose 011 the cylrnd(:, hlock . Insell the loul bolts and 11!lhlCll Ihem 10 the SpeCifIed 10lqUfl 4 F it the flywher.:l . or dllveplalc on au lOlllallC lwnsrnis sion Illodels.

InSerll h e six holl S ;",d u\llole rllhem 10 Ihe 10 lque w rench sell"'U Uiven in lhe Speclllcm'olls

8 5 Sump -rciiuill!)

En~",,, lh;ol Ill" ru,rI "'!) ',u.l,u :e s 01 hoth IllI.! Slimp a"d t h e c(,1nkcilsc ,lie cl ea" ,mol IIi,1I n", '.""I",!) SlIrJ ,u;e 01 the Sli mp IS not d'S lo lte d. 2 Apply IO" ,I,,,!! c"'''pollnd 1 0 the pOUltS wllel(~ Ihe l"llllll) cover ablilS lhu ,;yir r"lr" 1,Io ck .lIId where Ihe rea' 001 $u,,1 carr.(:r "dIOIllS II 3 Pln ce tloo \J,,~k"l '" fJo~.t.on, lIt tlo" SlIm l} ,'Ild IIlS(). 1 lhe r0Io1111il1l)

bolts ImUO I tl!lhl 4 PrO!lres~lvely 1I!llIt,," llw sump holt s 011 opposIte I'ilr ts lIllt,1 all 0 1

t

hem ,H" il l tl", ~ 1"":lllI"d IOlllUU , 5 FII ,1 now w;,~h", 10 Ihe ~Ul1lp II"'UI pili!) , IIlscrl lhe dl,lIll pllll) and

t ,uhlen ,t

8 6 Cylinder h e"ds re;rssernbly

L~y the cylrnd" r h",.\! on .IS s Ide. luhrrcnt e cvcry valve Uu ide with eng;l1(! oil. ,lilt! ,"~,,"t the valves 11110 the \Ju, dc Irom whIch lh ey wele remov(:d 2 To ,WOld d

lhero.s dilnlJC' oltl1<.: ~I""IU rcW""C' dillllil\)IIlU tllC villve SHlm 011 sen l

G Ahcr "lsert")!J tit" ~pllt collets. r eleilSo the spllny compressor (111(1

rcmove II 7 C hcc k th"t lh..: ~pl'l cull":IS hilve seilled properly and t

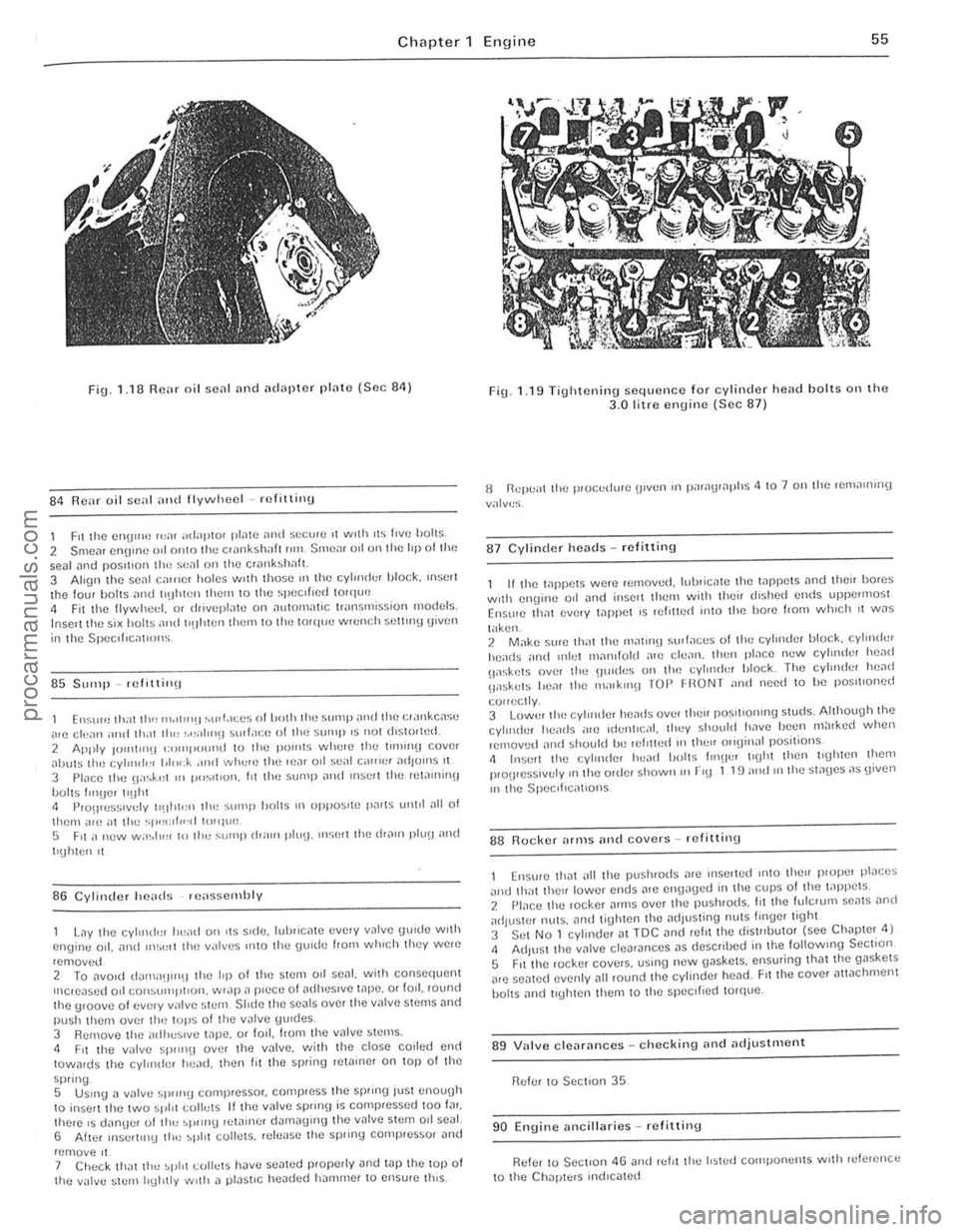

Fi g. 1.1 9 Tightening sequenc e for cylinde r head bolts on the 3.0 litre enuine (Sec 8 7)

a Repe"l liln pruccdwn orven III p;ua!Jrnphs 1 to 7 o n the (CmJlnlllU

v,llv"s

87 Cylinder heads - re fitt;nu

11 the tappels w ere rcmoved. luiJricnle lhe lilppets nnd I heu hores wnh enoine orl nnd insor t thOlll wilh lhc;, d Ished cnds uppermost Ensule lha l every tappet ,s rclltlcd Into lhe hore hom whIch II wns

t nkcl1

2 Mak e sure tha t Ihe rna t"'!1 surlaccs o f lhe cylinder block. cyl lndor henrJs ;Uld 1111,,1 Ill,lIlIlold ;lIe de;"l. then plnce new cyhndcr head \Ja~kets ove, the Wildes un thn cylrmh" block. Tho cyirnder head \I,,~k ~IS beilr thO malkln\! TOP f:nON T ilnd nced to h e pOSII,oned

cOII(:ct ly .

3 Low ul Ille cyl ""lcr he,1ds ov"r the" posl tlonrngst u(!s, Although t he cyhlld\~r headS ,"0 Id entlc;,I, they should h,lVe been Illtlrke d when remuved ilnd should be lehllUd III thcrr ()IIUinal positions t1 Inse rt the cyirndcf 11I)"d boilS f"'!I(:r t.!Jh l then tIghten lhelll prUglC SSlv(: ty OIl the olde, shown III r,U I l!J and III llle stnucs",s U iven

m the SpcelirC;lt'OnS

88 Rocker arms and cover

s -refiUing

Ensure Ihm "II Ihe puslllOlls ,lie ,nselwd I!ltO the" p'llpor placos ;II1

)olt S nntl lighten them t o the spec ,f led torque.

89 Valve clearnnees -checking nnd adjustment

R eier

to SeC!lon 3 5

90 Engine ancillaries -refitting

R eier 10 Sec tIon 46 and ref, t lhe I. ste d componenlS w,th refercnce

to th e Chaptels ind,cilte(f

procarmanuals.com

Page 72 of 205

) Chapter 3 Fuel and exhaust systems

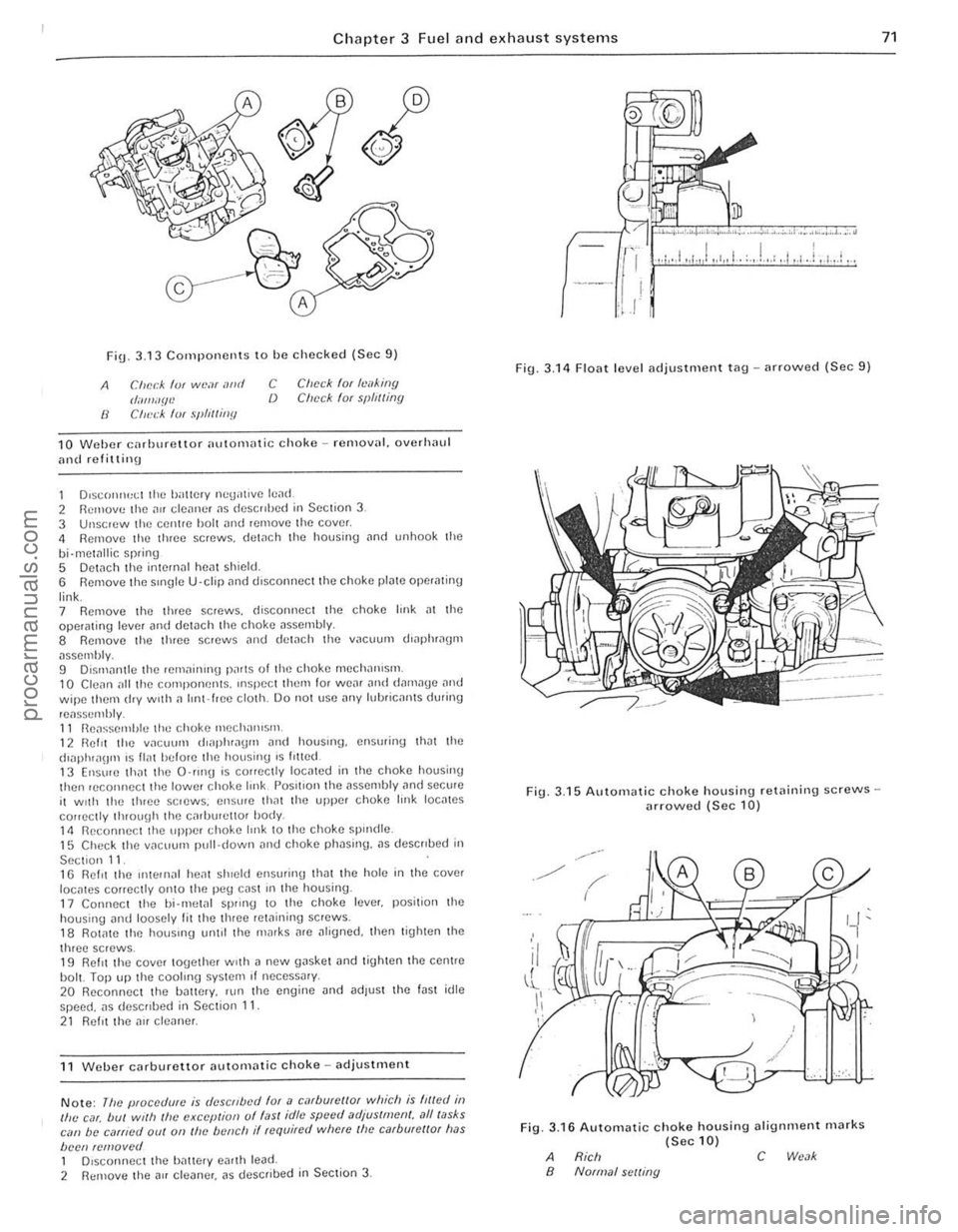

FiU _ 3.13 Components to he checked (Sec 9)

A

8

C/u':(:A fur wP.olf alJd (/illlli'f/I.l Clwck '(If .~/I"lIitJfJ

C CI)(xk for hd,ill{J {) Check (Of spfrlling

10 Weller cnrhurettor ""tom,lIie choke - rcmov,]L overhaul

and refitlinu

1 DlsconlH!~1 Ihe i)illicry nC\j

le"sselllhly. 11 Ik"ssemhle the choke meCh'1I11SI11. 12 Relit ll1e v"CUUIll til"phl1'lI)lIl alld hOUSII1,). enslllinu th"t lhe (hilphl,l()fIl IS lIolt before lile housing IS fllted. 13 Ensure thm the O-IIllg is correctly locmed in the choke housinU then reCOllnect the lower choke I",k Position the assembly and secure il WIth the thr ee sClews . ensure thnt the upper choke link loc"tes

cOlrectly tluouUh the c"rlJlJretlOf body 111 RecOllllec t the upper choke Imk to the choke Sp"l(tie. 15 Check the V"CUUIll pull· down

Note: lile pfOccc/

.l.I. .... , •• ,. ••. • .. .• . ,,~ ......... , •• , •• .;..,.: .•• ' •.•••• 1 . ;."

.,.', .,1,,/. 1,,' .. 1 . .. . , 1.,.: .. 1,.1.1,.1 .•. : ...

J

Fig. 3.1 4 F loat level adjustment t

.------

./ /' (

Fig.

/

3 .16 Automatic c hoke h ousing alignment (Sec 10)

A Rich c B Normal scl/lllg

marks

71

procarmanuals.com

Page 80 of 205

)

Chapte r 3 Fu el an d exhau st systems 79

Ii

0) G

\E )

' .. ~ ee)

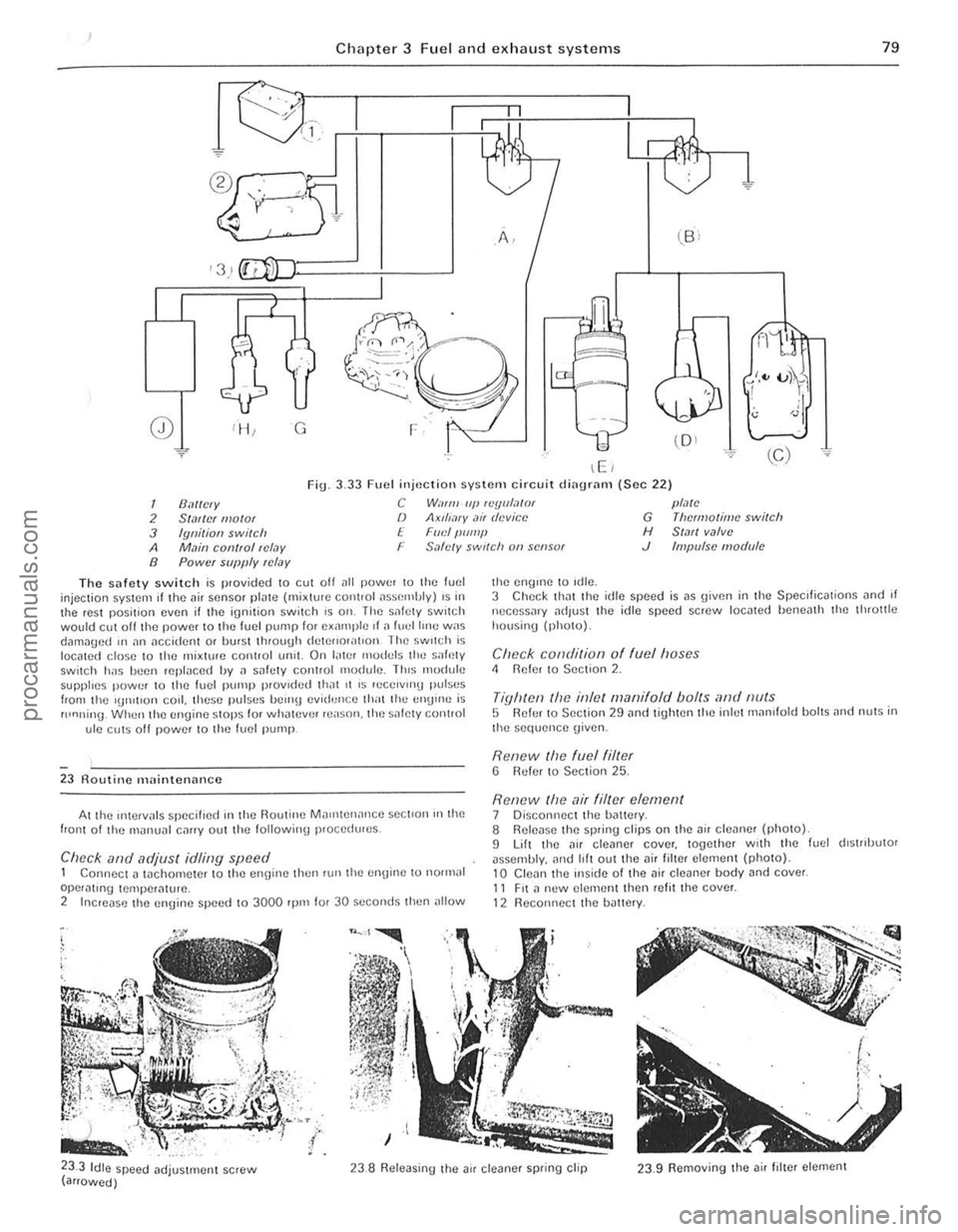

Fig. 3.33 Fuel injuctiOIl system circuit di

2 Sialicr I/Iolor /) Axll/,-"y ,1i, device G Theo1lO/lmc switch

3 fgnitioll switch E FIII;I/Iump H St,lfl valve

A M,lin con(Iol r(;/,)y F S

8 Power supply rcl.1Y

Tho safety switch is provided to cut olf illl power !O the fuel injection sySl(!m if the air sensor plJIC (mixt\HC COlllrol assemhly) IS il the rest position even if the ignition switch IS all. The s[lfcly switch would ell! off the power to the fuel pump for oillllpic ,I il fllOJllmu W

AI the IntelV

,. ,

< '(:,,~ , • . . ;::~t,·· . , ,

.' ) . ;~ ~~;:;: ~iJ" .. ,

n fr.X l

the engllle 10 'die.

3 Check Ihill I he idle speed is lIS given in the Specificmions ilnd il nccnssary "dlust the idle speed screw 10cllted heneillh Ihe Ihrottle housinv {photo).

Check conditiorl o f fuel hoses " Reier to SeClion 2.

Tighte/l the inlel manifold boilS and /luis 5 Refur 10 Section 29 and lighten the inlel rll

Renew the air filter element 7 Disconnect the h

-

I',

I t, ' .

;

!

" , ' .• I

! 1 I'

: 1'1 1 . ,

I

I '

I

procarmanuals.com

Page 95 of 205

94 Chapter 4 Ignition system

i ' .

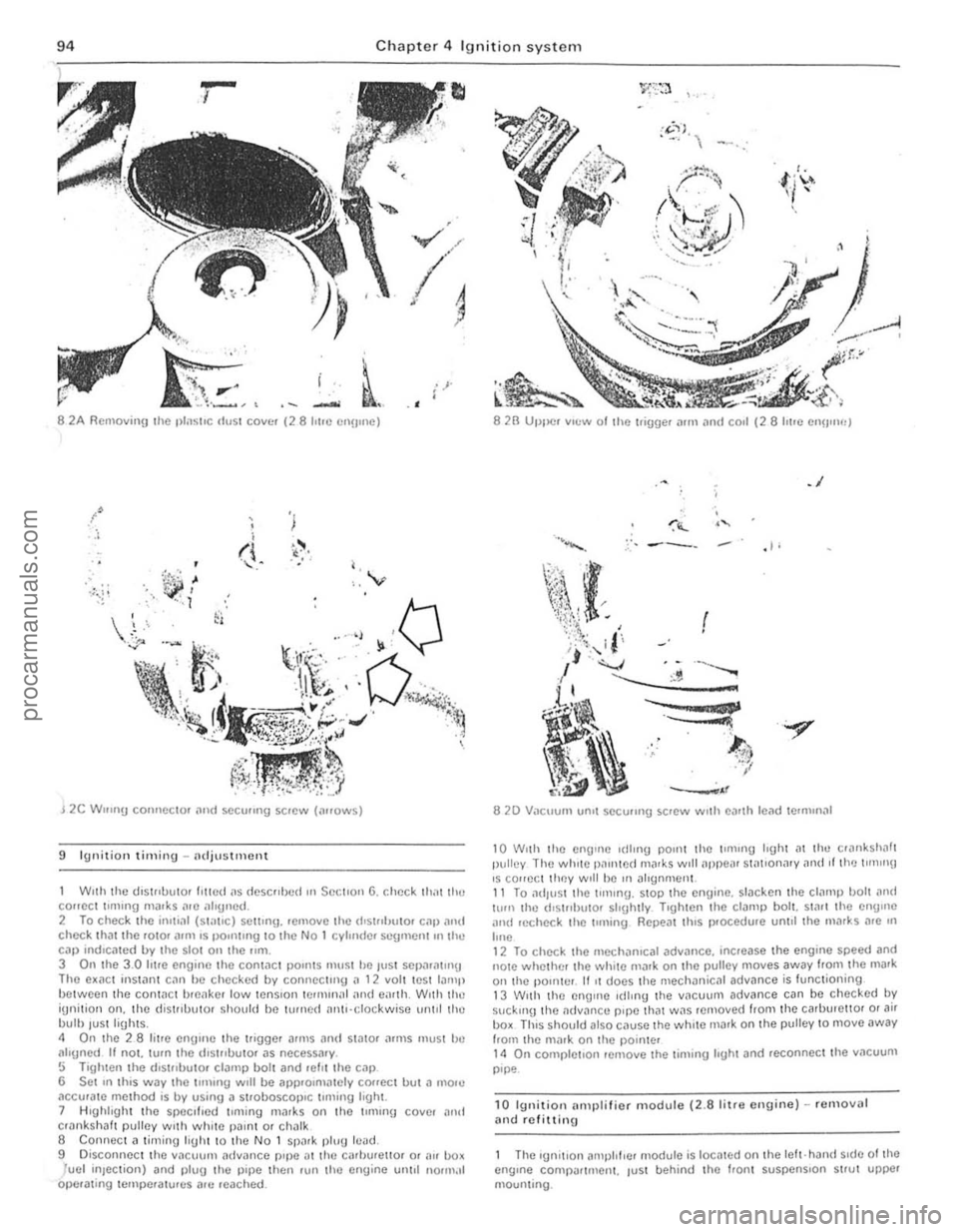

. --8 2A Removill{J the IllnSlre dust COve, (28 hl'c Cllume)

./ :,

, , ,

(\. I ,

" 'v

J 2C W'''I1!j connector i'Uld seCUJlIlg screw (lHOwS)

9 Ignitio n timing -adjustment

Wnh the (.lIs\"OuIO' III!Cd ilS dcscllbed OIl SectIon 6, check Ihilt 1Ill! COHCCt llllllng m;l!ks "'0 ;1119110d. 2 To check the ;1111,,11 (5 t;1I,e) setting, .emovc the (I'51"lIu I0' c;lll [11l\( check IhJllhc rOl0' ;lIm IS PO"1I1119 to the No 1 cylmdc. scgmon!.n the Cill) rndlcmed by the sial on the 11m. 3 On the 3.0 lUre engIne the cont,le l poullS ll\u~1 he ,ust SCI)ilril\U'!J Tho e~ilCt Instant C,1" he checked by connect"'u il 12 vol1 lest lamp between the contilC, brcilke r low tenSIon Iemur),,1 iUl(t O,"lh, W,th the iUnilion Oil, tho d is trlbuto. ShOllld be turn ed nrl\,·clockwisc unlol lho bulb luSlligh(s. " On (he 28 li(re enuule the ("gger arms and stator ;HIllS must bc aligned It not. (um I he (hst"bulOr as necessary . !:i Tighten the (hSI"buto. clamp boll and .ehl the cap 6 Set In thIS way the lUlling WIll be alll)'Olmalely co

8 2B UtJlle. vIew 01 the l.imJer Mrn .lrld Call (28 lIt Ie enU"Wj

.1

,I,

.. .."

8 20 Vacuum un.1 sC(:u"ng screw WIth e')Hh lead termmal

10 W,lh Ihe enij1l1e I(lIrng pornt thc \fmlng hgh( at the cr",lksholl1 pulley The wh,le 1),1mte

12 To check the mechanrcat adv.1nce. Increase the engIne speed and note whelher the wh,te malk on the pulley moves away Irom the mark on th e pOInter . 11 It docs the mechanical advance is lunctioning 13 W,th the enOlile Idlmu the vnCU\ Jm advance can be checked by suc kIng the oldv~ncu pIpe that W.1S removed from the carburellOI o r air box ThIS should also c.Juse the while rnark on the pulley to move away horn the mar k on the pointer 14 On completIon remove Ihe timlllU hght and rC(:onnec lthe v.1CUUIll pIpe

10 Ignition illlllllifier module (2.8 l i tre enuine) -removal and rClittinu

Thc Iunitlon illl\J}l lflcr module is locmed on Ihe left· hand SIde of the engIne COnlpar tment. tUSI behind Ihe hOnt suspenSIon strut upper mounting.

procarmanuals.com

Page 107 of 205

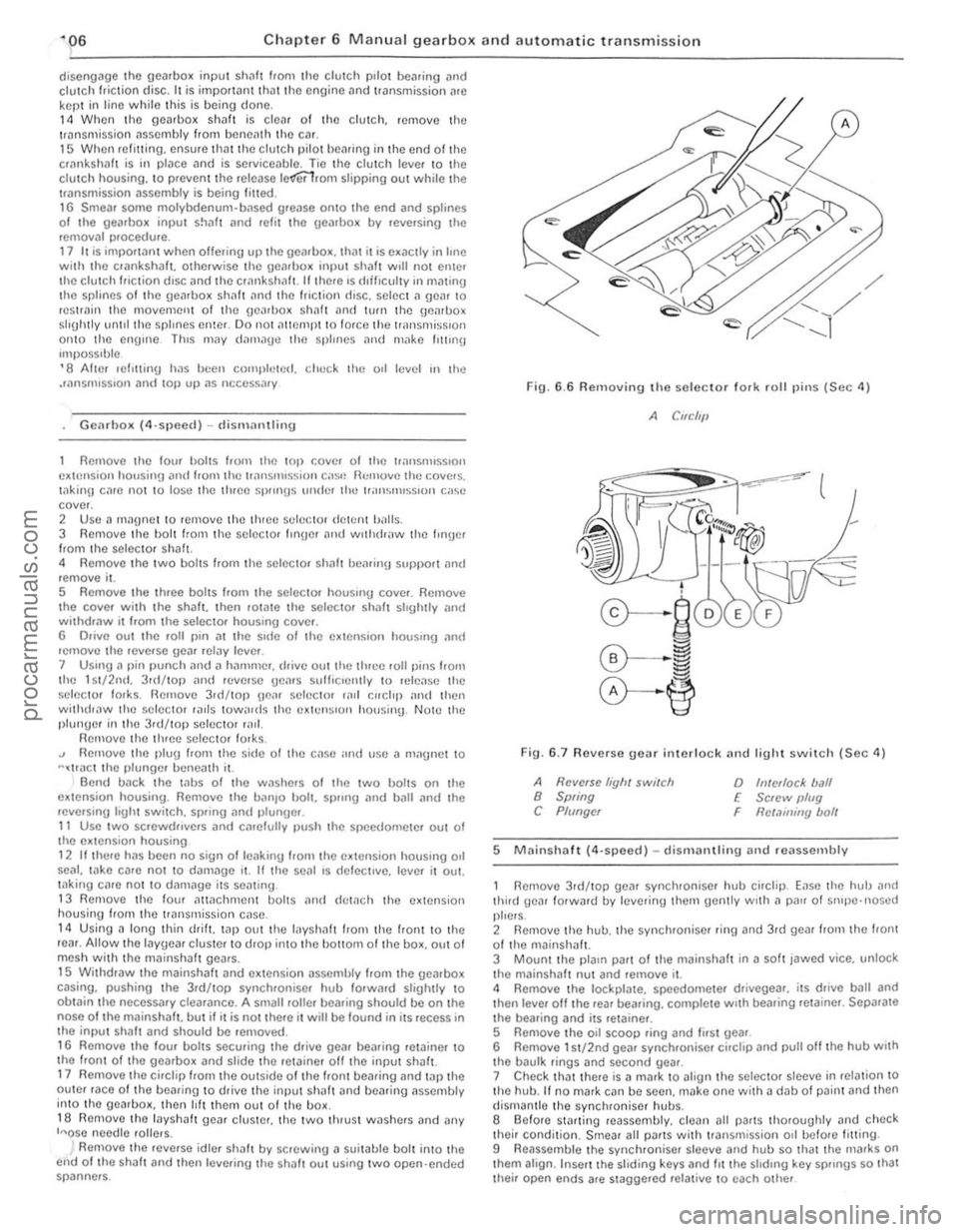

·06 Chapter 6 Manual gearbox and automatic transmiss io n

disengilge the gearbox inpu t Shill! hom ,ho clutch p,Iot bearing ,111(1 clu tc h friction disc. I, is imporlanllhal,hc engine and transmi ssion <'lre kept in lino while this is being done. 14 When the gearbox shaft is cleDr of the clutch, remove th e

tran smissio n assembly from bCn(!illh the car.

15 When refiuing, ensure 1il1 the clut ch pilot h earing in the end althe tfilnksha h is ill plilce Jncl is scrviceDble. Tic the clutch lever 10 the clutch housing, 1 0 pr(!venllhe release le.rertrolll slipping out while the ,Wnsmission assembly is being lined. 16 Smear some molybdenum-based grease OntO the end and splines 0' the gearbox input s!mh lind refit the gearbox by reversing the fcmovili p.ocedure. 17 II is impO.IMll when offering up the {jOMOO)(. th,lt il is e~

slightly until the splines enter Do not iluempltO lo.ce the tfilllsmisslOn

ontO thO enlJlnO ThiS Illay (i

'8 Ahe •• el,uinn has been completed. chuck the 011 level Ifl t he .r

Romoye the lou. bolts hom the 1011 cove. 01 the t.ansm.sslon c~t()"sion housin!J ilnd f.om the lri"'snHs~ir)Ol eo'S<' Ilcmovflthc \:oye. s.

t.1king c

R emoYo the .eyerse idle , shah by sc.ewing a suitable bolt into Ihe end of Iho shah and then leye.ing the Sh;'lit Out uSing Iw o open ·ended spanne.s. Fi\)

.

6.6 Removing the seleclor 10lk rolillins (Sec 4)

A CIfC/'11

Fin. 6 .7 Revorso gear interlock nnd light swil c h (Sec 11)

A Ravelse liyh, switch 8 Swing C Plf/ngcr

o h!/ellocl< ball E Sc,ew IJlug

Rct.1ininy bolt F

5 M

thud gear lotwald lly lel/erinu the,n gently wrth a p

their condition. Smear all Pi/ItS wilh tr3nsmission 011 befo.e fitting .

9 Reassemble the synchroniser sleeve and hub so that the nlafks on thorn align . Inse.t the sliding keys and 1IIIhe shdrn\) key sp"ngs so Ihat Ihei. open ends afe stagge.ed re lat ive 10 each other

procarmanuals.com

Page 128 of 205

Chapter 6 Manual gearbox and automatic transmissio n 127

2 Select position O' th en pri$e off the selector level escutcheon nnd. Irom under th e cnr. re move the plug in the side 01 the selector housing. 3 Adjust the inhibito r cnble locknut X to giv e a dimension of 0.1 to 0.2 mm (0.004 to 0 .008 in) (Fig. 6 .36). 4 Refit the plug nnd escutcheon. S With the trnn smission shih lever and the mnnunl selector lever in '0'. ndJust th e selector rod link until it cnll be reconnected without strain .

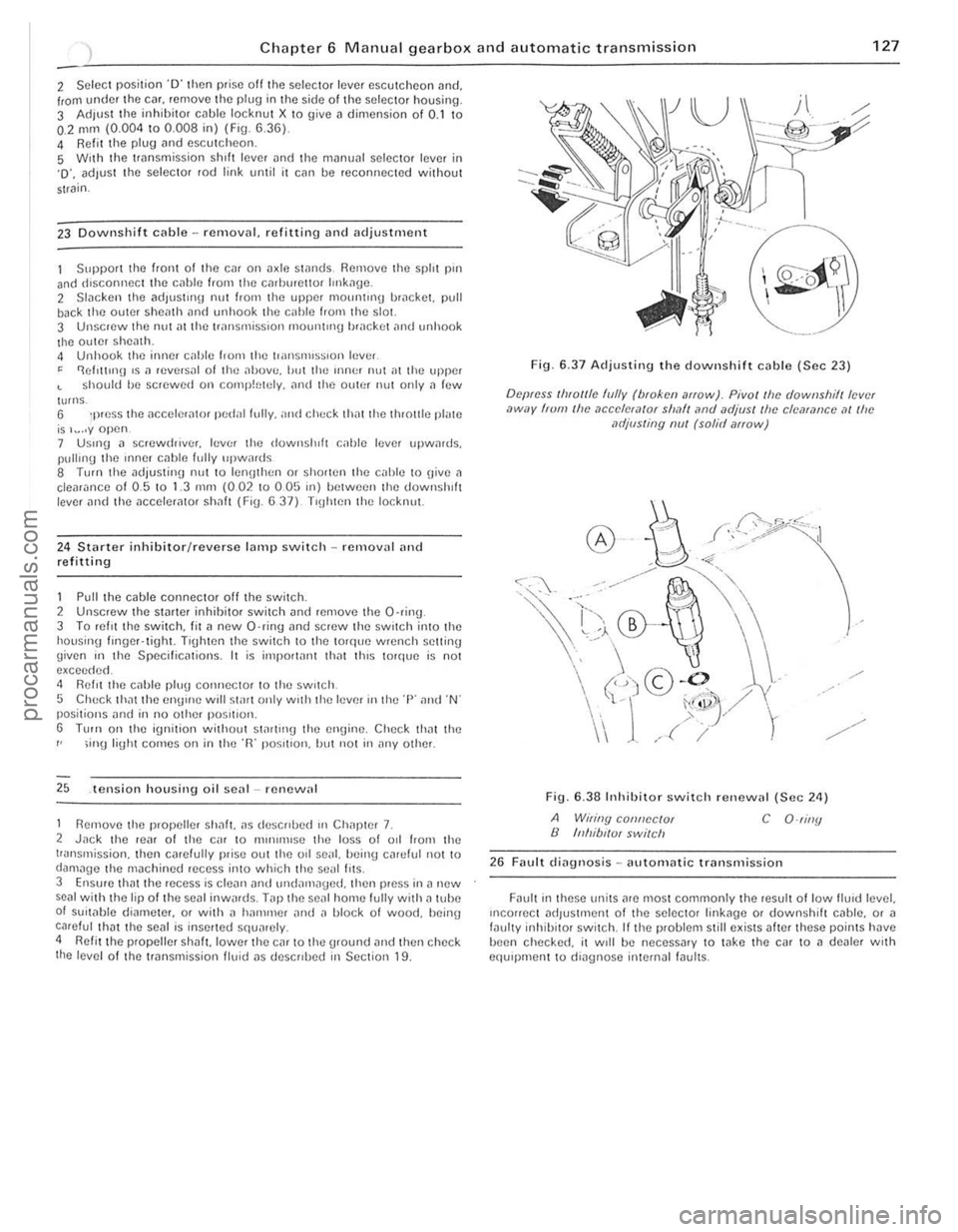

23 Downshift cable -removal. refitting and adjustment

Support till! front o f th e cm on Jxle Sl

24

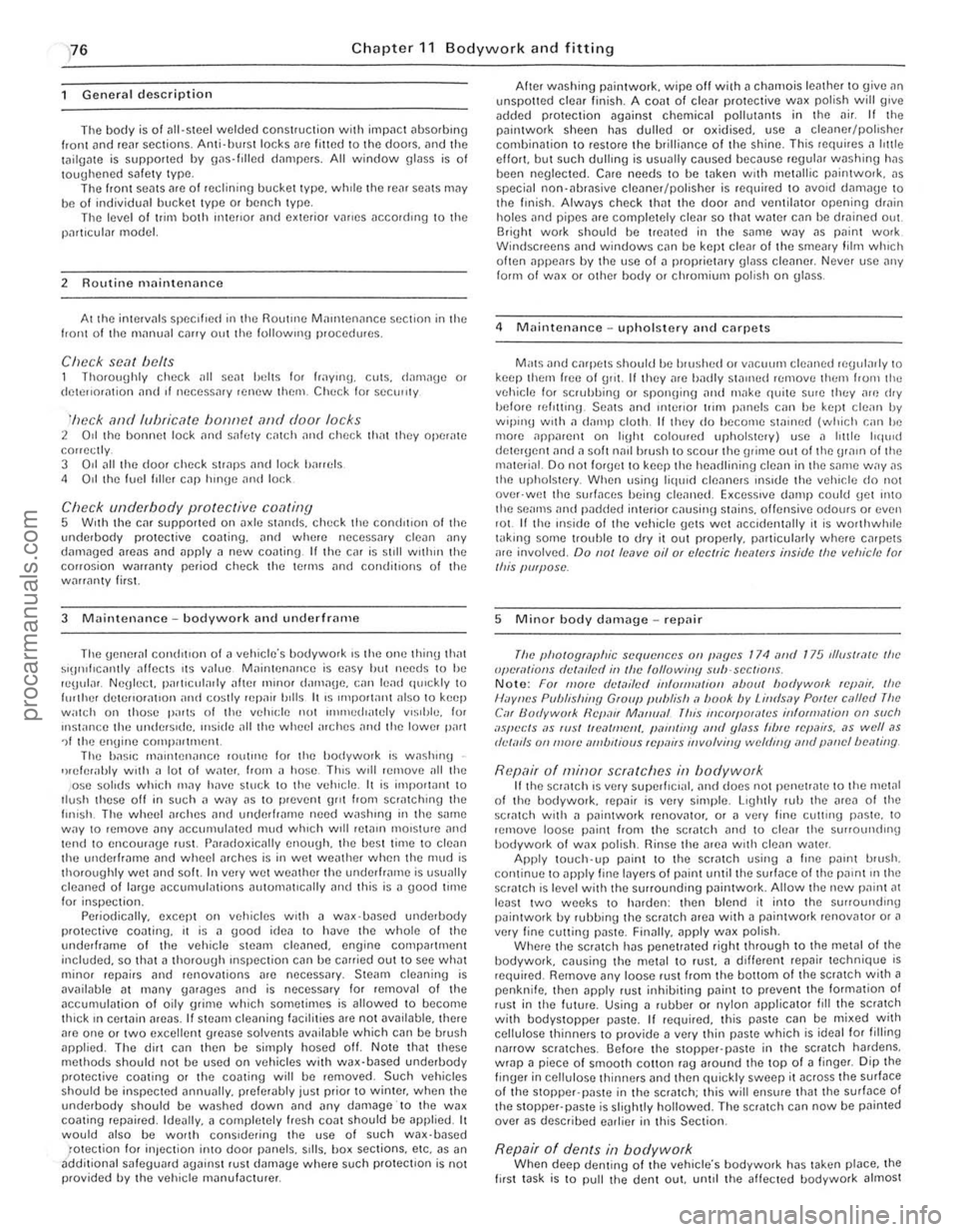

S lnrter inhibitor/reverse Inml) switch -removal and re fitting

1 Pull the cable connector off the switch" 2 Unscrew the slnrter inhihitor swilch and remove the a"int[ 3 To rel'llhe swilCh. fil a new a·ring nnd screw the switch into lhe housing longer. tight. T'gh ten Ihe switch 10 the lorque wrench settin g

given ,n the Specilicntions. I t is imporlnl11 ,hn t thiS torque is not excee dud, 4 Ro::I't the cnhle plug conn ector to the sw,tch,

5 Chuc k th,ll th e en!J"'c will st",t only w,th the lever '" the '1" and "N' posilions and in no other POSlt'on. S TlIIn 0 " the ignition without startll1g th e engine, Check IhM the

r ' ;inU light comes 0 11 in th e "R" po~rtlon, but not in any other.

25 .tension housing o il senl-renew,,1

1 Remove the propeller shnl!. ns do::scrrhed III Chi,pter 7.

2 Jnck t he r enr of Ihe c,u to [1Hn",HSe the loss of 011 from the

transmission . then carefully pr ise out the od seill. being cJrtJIut not to (JamJ,Je the machined recess into which the sc,rI I,ts, 3 E'lslIfe that the recess is cle

6.37 Adjusting the downshift cable (Sec 23)

Depress Ihlollle hJlly (bloken arIOw). Pivol/he downshilllev,·( ,)wuy frum Ihe ,1ccelef,1{Qr sllMI lind UdjllS! Ih e clcarance at Ihe MljllSling nul (solid arrow)

~r:;0/,/5.;~··ll ~

Fig. 6,38 Inhibito r switc h renewal (Sec 24)

A Wiling connector B Inhibl/Ul swilch C O-riny

26 Fault dingl10sis -nutornatic Ir

"."

" , .

, ,

J

,

procarmanuals.com

Page 177 of 205

)76 Chapter 11 Bodywork and fitting

General description

The body is of all-s teel welded construction with impact ilbsorbing hont Dnd rear sections . Anli-burSllocks nrc lilted 10 the doors, ilnd the

t ailgDte is supponcd by \J

AI the in1erVills speCIfIed in the Routine M"IIl\cnilnCe section in the front 0 1 the nl

Check underbody protective coatiog 5 W,th the CM supponed on i1xle stilnds. check the cond,tlon 01 the un(lelbody protcctivc coating. i1nd wherc neceSSilry clean

M,,;ntcll

Wily to remove any aCCUIllUI,lted mud whIch WIll retillll mOlslu re

Mats and C

very line culling pils te. Finally, opply wax polish. WhNe the scrotch has penctrDt(ld right through to the metill of the bodywork. causing the mowl \0 rust. iI d ifferent repa ir lechnique is

required. Remove any loosc rus t fronl the bottom 01 the scra tch with a penknile. then apply rUSI inhibiting paint 10 prevent the lormation 01 rust in Ihe future. Using n rubber or nylon appliCiltor fill the scratch with bodystopper paste. II requ ired. this paste Ciln be mixed with cellulose thinners to provide a very thin paste which is ideal for filling narrow scratches. Before t he stopper·paSI(l in the scratch hardens. wrilp il piece 01 smooth COllon rJg i1round the lOp 01 J linger. Dip the finger in cellulose thinners and then quickly sweep it i1CIOSS the surlace of the 5topper-pJste in the scratCh: this will ensure tha t the surfilce 01 the stopper,pilste is slightly hollowed. The scratch can now be p

first wsk is to pull the dent out, untrl t he affected bodywork almost

procarmanuals.com