door lock FORD CAPRI 1974 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 17 of 205

" ,

'6 Routine maintenance

)

Every 250 miles (400 lUll) or weekly -whichever comes first

Check the engine 011 level and lOp up " OCCCSSJry (Chapler 1) Check and adlus t lhe IYIC pressures (Chilplcr 10) Clean the windscreen and windows C lean the hcadlamps

Every 6000 miles (10000 km) o r six Illonlhs - whichever comes fir s t

£II[1ille (Clwpter 1) Change engllle 011 and IIher

Cleiln oil flilm c"p Chcck 10 1 ,IllY fluid leaka!)e ,n enUme CO'llp:lnUlCIl1

Cooling syslem (Clwptet 2) Check cool:'lnt level

Fuel syslem (Clmpler 3) Check idh"U mi~lUle (cmiJUiello1 IllUdels onlv) al I"SI se.v,ce ollIe, overhaul C heck idllllg sj)ee d

Ignition sys/Cm (C/I,Wler 4) Clean ,1nd re!)"p Sl)".k plu!)s (.:on!nC ' breilkCl Illudels olllv) Cle an and check d'Shibu\o. C"I). '010'. HT lealls mId co.1 (COllWct

bleaker modcls only) Check elwell angle (cOntact b.e"ke. mo

Bri/king sys/Cm (Ch,1pter 9) Check selva

Che ck hydraulic flu id h,vel

Ch(: ck p"ds :'Illd sho(:s lor wear Check h.ake hllcs and hoses

Suspension .wel stvi'ring (Chi/pICr 10) Check tyres 10' w ear and dam:lge Check steering COmp{lIlCnlS l o r w e:l l "lid d.1nlilue

Bodywork. .111d fittings (Clwptef 11) C lu .. >ek se"t belts fa. we .... damage :lnd secwity

Elvc(ric.11 systcm (Ch,7jJ(ef 12 ) Check Ope.iltoon 01 "Uhts Check wilsher flUId levels Check b.1ltery eleclrolvle lev el

Every 12000 miles (20000 kill) or 12 mOll1hs - whichever comes first

III .1(/(lIlioll 10 Ihe 6000 m/le sciler/Ille

Engine (Ch.1f)ter 1) Check and adlUSI valve clearanc es

r"' .......... ~.~-.... ._ •• -.... __ .... . 3lii1&l •

Cooling system (Chapter 2) Check condition "net tension of 1111011)<1101 dflvehelt

Fllel sys tem (Chapter 3) Tighlcn inlel IIHlnl lold boits/nuts Check vacuum hoses Check e~hiluSI syst em Check ll1r ctonne. temperature cOllllol (,I applicable) Renew fuclllllC ' (fuel injec tion models only)

Ignilion system (Chapler 4) lubricate th e dis'flbulOf (conUlel br eake r models only) Renew the coninCt hu,akcr points (II nppllcJblc) Renew the spMk plugs

Transmission (Chapter 6) Check ool/th"d level Lulmc;ue automatIC 1.,'Insmlss,on IInk:'lue

Rcar axle (C/MplCt 8) Check 011 level

Bli/king system (Chaplet 9) Check v,lcuun' hose

llliJllc:'l1C Ihe handhlake Imk,loe

Suspensioll {//j(J swelill!J (C".1plt~( 10) Check condItIon and hlllSlon o f POWI.II ~I!'tllllli dllvthtl1 (II .1l1pllcal,

Check MlspenSlon 101 we;" ;111(1 d;1Il1.1!)e

Bodywork ,1I)d fillings (Clwpler 11) Check opera lion of all locks Check secu.ity 01 dOOf check sl.aps

LlIl)fIcalC locks. door c heck S\','P5 :'Ind fuel fdler cap flap

Check underbody pr olCctive coalm!)

Electrical system (Chapter 12) Check Opcra1l0n of all eleC111!:al IIcm5

Evcry 2<1 000 llIiles (40000 kill) or 2 yc;u s -\Nhichever comes firsl

III ,1(/111/'011 10 the 12000 111"'1 $d'~'f/u/e

[nyino (CIWpICf 1) f!ell'!W crankC:l $e e""5510l1 v;llve

Cooling syslofll (Clwptor 2) Renew COO!:1II1

Fllel SYS(CIII (Ch, '/pliJr 3) Renew"" II Ih!r elemenl

TrallsmissiOIl (ClwjJWr 6) AdjUSI aulom;1\IC trall5nll5SIOll h,ake b;'IIld

Every 36000 miles (60000 kill) o r 3 yenrs - whichever comes first

III .1(/{/I('01l 10 Illc JJIl'VlOUS schc(/ulcs (",lIc" JJJIJ"ci,bfc)

Brakillg system (Clwpter 9) Renew hyd,auhc flUId

procarmanuals.com

Page 166 of 205

Chapter 10 Suspensio n and ste e ring 165

he IllJhlCned when Ihe em IS on Ihe '1IOUI1(1. \0 Ihe speclhe(1 100quO Lock Iho cnSlC\lnlCd I1UI wllh n new spill pin.

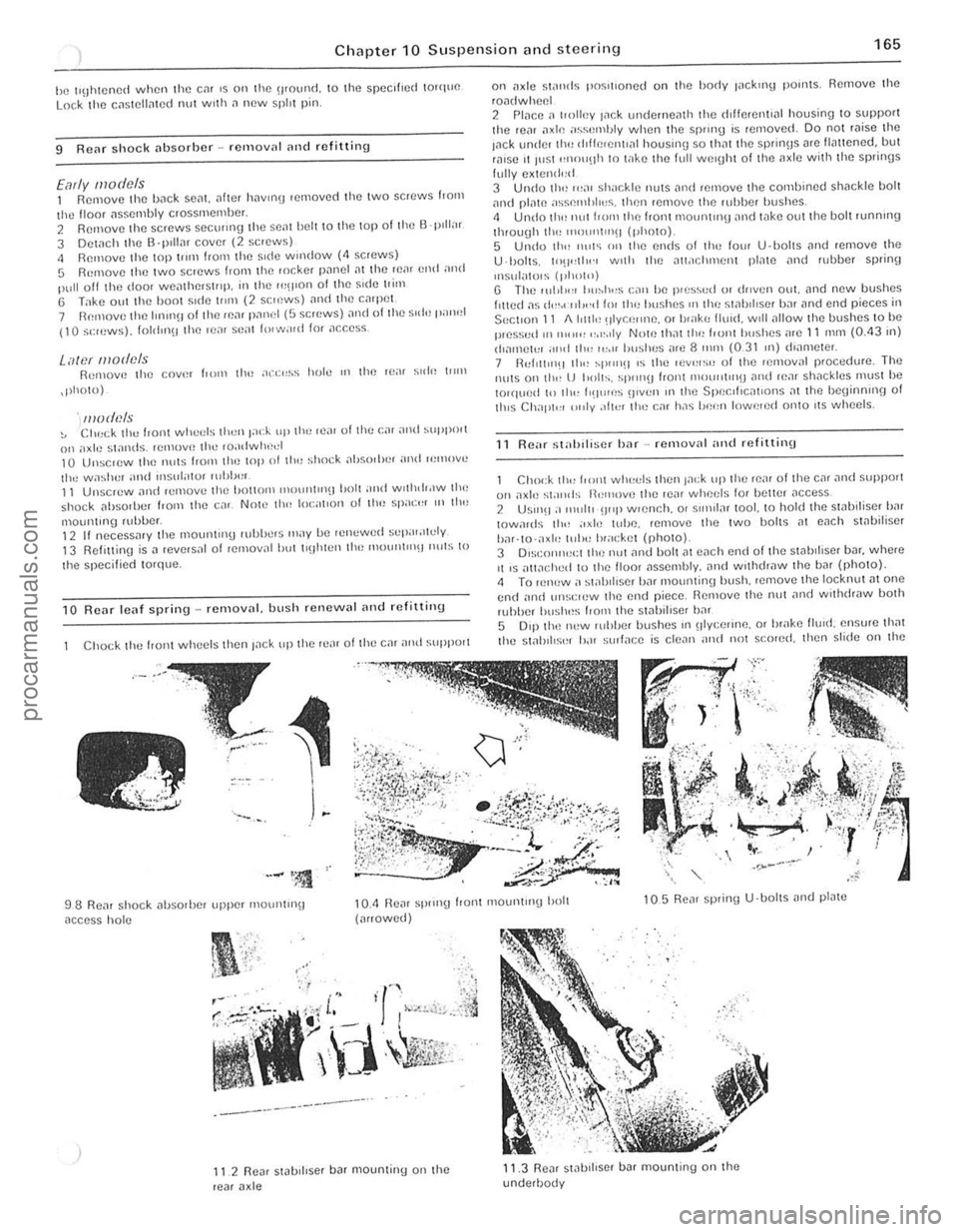

9 Renr shock nbsorbcr -rClllovnl nlld rofitting

Early models 1 Remove Ihe bnck sent.

.pholo)

. models ~, CIlr:ck the front wheds Ihun F":k up th,) rca r olthc (:;" and SUPI"lI l on "xle swnds. tCmovH Ihe ,o.ldwlwel 10 Unsc,ew Ihe nu(S Iron' tim lOp 01 III" ~hock ilhsnrhe, ilnd ,,:move the wa~her and ,nsul"l!)r rllhh,,,. 11 Unscrew nllll ,emove Ihe hollom IIH)l1ll1l"~1 holl and wllhd,.lW Ih(, shock nhsOliJer trom the cnr. Now tlw 100:"t,on of Ihe Sllacr:, '" II",

1110ul1lll1g lubber. 12 If nocessmy (he moun(lng lUhbers IIlay be relwwed sepal;l1cly 13 Relittinu is il reversal of refllov

C

hock I hl) hOI1l whl)l)ls then Inck up Ihe rl);11 of Ihe cm nntl SliPPOlt

98 Renr shock ilhSOlbel upper mOIJnlln\j

nccess hol e

"

-----------_.-

II 2 Re~, stabi llser b ar mountinu on Ihe rear a xle

on

U ·lJol ls. 10'1",1"., WIth Ihe all.lchment pl,110 ilnd fubber splinf)

Insulatols (1,1",11') U The I(lhll'" Ilu~h"s C;\l1 be p,es'>vd 01 dl1ven oul. lind new bushes fllted ns {I",.( ·"l,,·d 11)1 Ih" hushes OIl Ihl! s!ahd ,se r bnr lind end pieces in

SectIon 11 1I1r1l1t~ !lIY CI;"nc. or I,,"kr, flUId . WIll

R eM st"hiliscr har -rcmovnl ,,"d refitting

Chock tlr" from WIH't:I~ Ihen Jack up (h o ron, 01 the cal ~nd ~Hpport 011 nxle stands il"I1love Iho rear whet:ls fo, holtcr ilCCeS$ 2 USlnO :1 11111111 !J"P wlCnch. 0' sll1>llnr tool. to hold the swoiliser b,'r IOwa,ds 11r"

5 0'$1 Ih(~ new ruhber bushes III olycelll1e. 01 hrake lIuld. ensure that tho stabIlise, b.H ~(JIlnce is clc

procarmanuals.com

Page 174 of 205

Chapter 11 Bodywork and fittings

Contents

i'ldIUS\

Specifications

Torque w rench settings Se.llbel ls :

) pillar .\ lIoor .............. ............. .......... _ ._ ..... .. . Openlnu rcar qUilrter glass tougle 10 C pIllar.

Heal"r cOlllrols removill im(1 rchUrn!! lIemcr Willer villve (heilvy dull' he;II'~r) rcrnoval and rel,ttrng I"tc"or m ,,,or -remov,,1 and refrtllng . LOild spnce I"", pifflel -refl1ov~1 and refillmu M,l,nten;mcc bodywork ,1nd underfr;lflle M;r,nICnnnce • upholstery imd C;Hpets Millo r body dilm

NIH

2010 30 35 10 42 4.5

Ib l It

15 to 22 26 1 0 31 33

41

" 38

" 3 4 G 5 23 ,

22 2 3G 39

" 35

33

27 28

" 11

"nd 19 10

----------------------------

.. !i

procarmanuals.com

Page 177 of 205

)76 Chapter 11 Bodywork and fitting

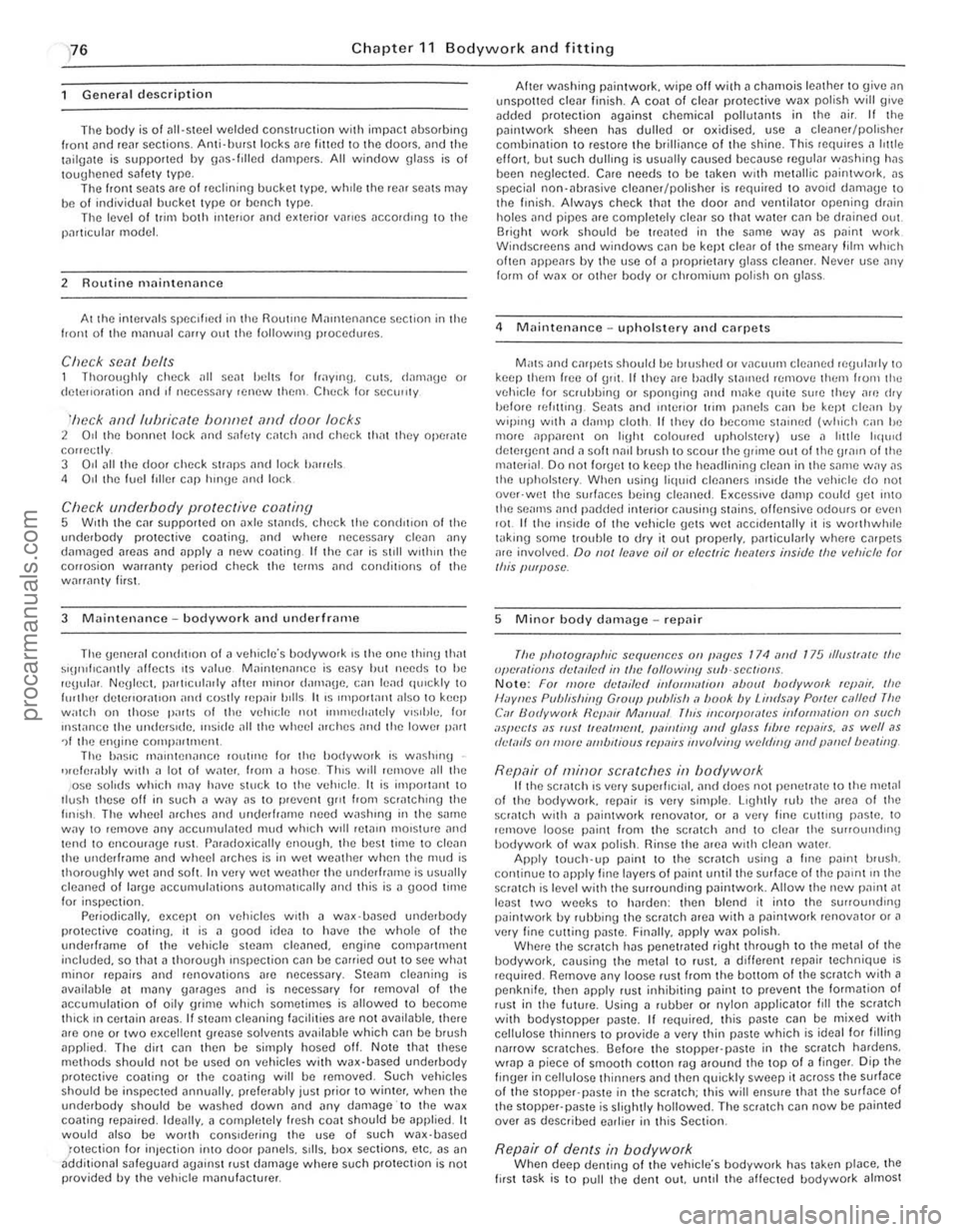

General description

The body is of all-s teel welded construction with impact ilbsorbing hont Dnd rear sections . Anli-burSllocks nrc lilted 10 the doors, ilnd the

t ailgDte is supponcd by \J

AI the in1erVills speCIfIed in the Routine M"IIl\cnilnCe section in the front 0 1 the nl

Check underbody protective coatiog 5 W,th the CM supponed on i1xle stilnds. check the cond,tlon 01 the un(lelbody protcctivc coating. i1nd wherc neceSSilry clean

M,,;ntcll

Wily to remove any aCCUIllUI,lted mud whIch WIll retillll mOlslu re

Mats and C

very line culling pils te. Finally, opply wax polish. WhNe the scrotch has penctrDt(ld right through to the metill of the bodywork. causing the mowl \0 rust. iI d ifferent repa ir lechnique is

required. Remove any loosc rus t fronl the bottom 01 the scra tch with a penknile. then apply rUSI inhibiting paint 10 prevent the lormation 01 rust in Ihe future. Using n rubber or nylon appliCiltor fill the scratch with bodystopper paste. II requ ired. this paste Ciln be mixed with cellulose thinners to provide a very thin paste which is ideal for filling narrow scratches. Before t he stopper·paSI(l in the scratch hardens. wrilp il piece 01 smooth COllon rJg i1round the lOp 01 J linger. Dip the finger in cellulose thinners and then quickly sweep it i1CIOSS the surlace of the 5topper-pJste in the scratCh: this will ensure tha t the surfilce 01 the stopper,pilste is slightly hollowed. The scratch can now be p

first wsk is to pull the dent out, untrl t he affected bodywork almost

procarmanuals.com

Page 178 of 205

) Chapter 11 Bodywork and fittin g 17 7

~!t~InS its oriOin,11 sh~flC. There is lillie point in trying to restore the original s hllpe complClC ly, as the me1011 on the darnllged arca will have stretched on impact ilnd cannOl be reshaped fully !O its original contou r, II is belter to bring the level of the dellt up to 11 poin t which is aboul ~ in (3 111111) below the level 01 the surrounding bodywork . In cases whe.e the dent is very shallow anywi'lY. i, is nOI worth trying \0 pull 1 ou t 111 all, II the ull{lersidc 01 the dent is accessible. il can be hammercd oul gently from behind, using a malleI with a wooden or plastic head. WhilSt doing Ihis. hold a suitable block of wood l'flllly a{),111151 the outside 01 the panel 10 absorb the impact from the hammer blowS and thuS Il,event 11 Imge area of the bodywo.k hom being 'belled,ouf, Should tho dem be in a section of tho bodywo.k which has iI double skin or SOI1IIl other filclOr mokil1g It inaccesslhle from behind, a

dllferent technique is cillied lor, Drill severill sm;1U holes through the

mewl II1slde the i1reil (Jilrtlcul,ldy in tho deeper section, Then screw long sel1·tap~ing screws into the holes IllSt suffIcien tly for Ihem to gilln iI good purchase In the mewl. Now the Ilen t C"n he 1)lJlled out by pulllllg on the protruding headS of the screws wllh iI pnll of pliers. The no.t stilgo of the rep,lir is the .emOllill of the PilUlt from the 113Ued meil, and hom nn Inch or so of tho SurroundlilU 'SOUfl(r

Jdywork , Tills is accomplished most oilslly by usil1U a wire brush or ab'~sllle pild on " ,)owe< dflll, ~,lthou9h It Clln he done Just i1S e ively hy hnmf usmg shoots 01 1I1)'i151110 P.l,)C •. To COlll,llete the p

thorelore decide whether to renew the whole polllel (II this IS possihle) or to .ep[lir the affoctod illoa. New body Po1nols arc not ,1S expensive as mos t flCOple think and it is often (Iuicker and mo.e satislacto • .,. to fit" new t)anelthan to auempt to rellair larue n.e,1S 01 corrosion.

RenlOlifl all f,llln\Js hom the .. lIeeted a.o" cxcoptthose which Will

act ~s ,1 uu,(ie t o the oliUllwl shape 01 the (i,lIlla\je(i bodywork (ell hn,1(1lnll1l) ~h.~lIs etc). ThOll, USlnu tin snIps or ~ h"cks

d epreSSion fo r Ih c frllcr pas\(!

'll/lle hrush the aHected Me[l to 'CIilOlle tiro powdery rust from the ,ICO 01 the lelllilllllll!l lIlet,,1 P;lInl thc "flected arc" wllh lUst

IIII"I)ltll1l) p""'t. If the hilck 01 the ,usle.1 me,1 's accesSlhle treolt tillS

" delo.o frlhflU cml t

me sh. or altlflll1l1um t",Joe. AlulIll"'um 0' pl;1strc mesh IS Il.oh"bl.,. lile hest m

Aluminium wpe should be us ed lor slll ;rll 0' vCly narrow holes. Pull a picce oil tho .011 ond tri'" It to tho apIl

ove . the hole, rt C[ln be overlapped II tho thickness of one piece is

i nsufficient. Burnish down the 00ges of tho tapO With the handle 01 "

screwdrillC ' or srmllOf, to ensure that the ",po.s securely auached to the

metal undomeath .

Bodywork rCIJ<1irs -filling a"d re-sprayi"g BefOte uSlIlg thiS Seetion, soe the Sections on denl. doep scratc h.

rust holes "nd gash repai.s . M~ny types of hodyfllfer Me ~val'ahlo, but Uonerally spe~k.ng those nrOpnelOry kits which conlain 0 till of f illor paste and a tube of resin h~fdener Me best for this type of rcp,llf A wide, !ieKilJle pl

hardener carefully (follow the m"kCI's instructions on the pack) othe.wrse thO folic. Will !>tt too rill)luly or tOO Slowly . Using the

"pplicator apply the filler paste to Ihe prcpared area: draw the

applicalOr across the surfaco 01 tho IllIer to achieve the correct contour and to lovel the fillef surface. As soon /1S it contour that approxim"tes 10 thO corrOCt one is achielled, SlOp wo.kinU the pas le - il you carryon too long the pasto will becomc sticky and begin to 'pick up' on tho

app lic"tol. Continue to add thin layels of Iiller paste at twenty· minute intervals until the level of the filler is just pfoud of the surrounding bodywork Once the IllIer has hardened, excess can be removed using a met;!1 plane or IiIe. F.om then on. progressively finer grades of abrasive paper should be used. starling with a 40 grade p.oduction paper and l.nishing With 400 o."de wet·and·dry paper . Always wrap the abrasille p"pcr IIrOUlld a flat rubber, cork. or wooden block -otherwise the surfaco 01 the frller Will nOI be completely flat. DUling the smoothing of the fIller SUI face the wel·and·dry paper shoufd be periodically rinsod in walCr. ThiS will ensure thaI alle.y smooth linish is imparted 10 the frller (It th O flllni SHIIJO. At t!\l S st1lge the 'dont ' shoul(! be surrounded by a ring of bme

mowl, whIch in IUfn Should he encirclod !.Iy the finely 'feathered' edge

0 1 th e good paintwork . Rinse tho repair nrea wilh clean water, until all 01 the dust I>roduced by the rubblllu·down operation has gone. Sp."y the whole .ep.1ir a.oa with" light coat of primer -this will show UI> any ,mpcrfOChons in lhe su.face of the fll1e •. Repai. theso Iml)CdectlOIlS with frosh 1,110' paste or bodySlOpper, and onco mOte

smoOth the sUfl

he call1od out in a w".m, dry, wind loss and dus t free atmosphero. This condition can be created mtllicially II you have access to a large indoor working "reil. but rl you nre lorced to work in the open. you Will have to pick your day lIe.y ca.efully . II you a.e working indoors. dousin\J the

floor in the work mea with water will holp 10 SOllie the dust which would otherwise be in the iltmosphe.e . If the ,epai. mea is con fined to one bod.,. pilllOl, mask off tho SUffoundlflg panels; lhis Will hell) 10 minllllise tho effocts 01 a slight mis,match in lH,lint colou.s Bodywo.k hUUlUS (eU ch.omo strips. door handles Otc) Will "'SO noed to be

"';1sked ot! Use uenume fII

S ilray on t he t op CO"1. "\Jain bUlldmu ull the tluckness by usul9

sOllof1lllhlfl'"ye .s 01 p<111l!. S Ia .t spraying in theCllnlre 01 the .epair mOil and theil, USH\g a clfcular mOllon, work outwards untrlthe whole ropmr

"rea ond al>out 2 inches 01 tho surrounding origmal pallltwork IS COvered Remolle allm"sklng mnteflaf 1010 15 minutes alter spr

Plastic compOllc"ts Wllh the use 01 mo.o and more pl"stic l>ody components by the

vehrcle manufac turers (eg bumpers, spolle.s. and in some cases major

body panels). reCllilcation 01 damago to such items .hilS .t.>e<:0me a

mOller o f eHhor emruSling relhl'r wOtk to a specialist m thiS field, o. renewing complete components Rep"ir by the DIY owner is nOlleillly feaSible owing to Ihe cost of the equipmen t and materials reQui.ed for effecting such repairs. The baSIC technique inllolves making a grOOllo

atong th o hno of the crack in the plastic using a rotary hurr in a pow~r drill. The damnged pal! is then welded hack togeth er by uSing a hot "" gun to heat up nnd luse a pl

polyca.bonate. ABS, poIYllropylene) .

procarmanuals.com

Page 179 of 205

17 8 Chapter 11 B odywork and fitting

If the owner is renewing ~ complete component himself. he will be left with the problem of IlIldmg a sUI1

Major u o d y damage - repair

Where serious danHlge has or.cur",d or la,ue aW

Ir

Loose door or window winde, ",,,,dft,!; (Ii) Loose 0' lIIiS.lliUned d(Jo, lock c(lillj/olJC!lJl~ (c) Loose or worn relllOle con/iol ""."/."";",i$III

2 It IS quite possrule 10' r,rllies 10 he the ",suit of" [O,,,lrrllirl,Orl 01 111<.1 atrove laullS. so a c;,r(:/ul <.1xanrrrr;riron should he rn",h, 10 ilCIl'UllU1e III<, exact CillrSf:! 3 If

)

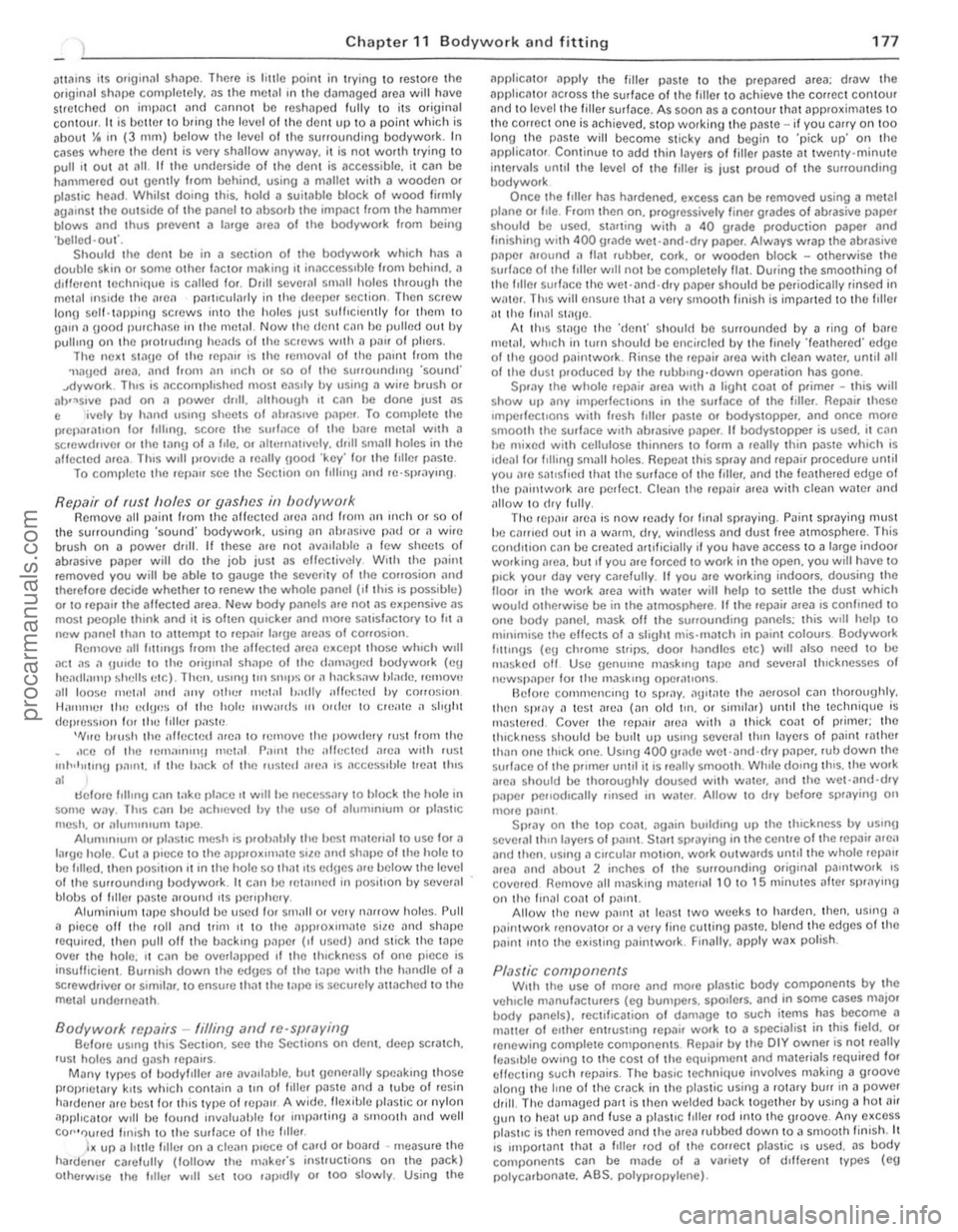

7 .3 Door striker plate

f ,i

j

I

j

I

\:

it

1

(.'----+"<, --'-1 ------<0

00>-----1\.. -~--.

F i!J.1l.1 A lignin!J the s triker 10 lock support plnte (Sec 7)

Edyes A and lJ shoold be 1'.1(.lllel

A

'0- - -- . ,

,'---I.::i.I I ,

--/

F ig 11.2 Lock claw·to·striker cleiHance (Sec 7)

A -70,11111 (028111)

5 Wrlh t he lock in the open positron. check the lock cl

8 Bumper s -removal nnd refitlin g

FrOIll bumpN 1 D,sconnect the u<.rttery earth lend. Also where necessary dis connect the IIldrC

Rear bUll/pel 5 Open the lJ.tgate. Ihen rernOve the mal ilnd the sub·floor. G Remove the Jack ilnd washer water reservOIr (where applrcable) . 7 Remove the two nuts. Sp",l(J wilsher and 11m wilshers.

Page 183 of 205

![FORD CAPRI 1974 Workshop Manual 82 Chapter 11 Bodywork and fitting

3 , n,~(lIOVlr'!J

13 Door trim

Ih" w in, low winder mson ( , ,lIC, models)

panel renoval ,,,,(1 refit" III!]

1 Carefully loll (photo) "p alU l "II" 2 FORD CAPRI 1974 Workshop Manual 82 Chapter 11 Bodywork and fitting

3 , n,~(lIOVlr'!J

13 Door trim

Ih" w in, low winder mson ( , ,lIC, models)

panel renoval ,,,,(1 refit" III!]

1 Carefully loll (photo) "p alU l "II" 2](/img/11/56932/w960_56932-182.png)

82 Chapter 11 Bodywork and fitting

3 , n,~(lIOVlr'!J

13 Door trim

Ih" w in, low winder mson ( ' , ,lIC, models)

panel re'noval ,,,,(1 refit" III!]

1 Carefully loll (photo) "p alU l "'II" 2 ' I"e {I", w Remove II", '''dow w"HI",

",,' ",,,,,,,,". ~"'d'" ',.",d'"'·" ,,,"",, .. """" 3 • Remov e Ih~\:hOIOS) u . ",wl\1 sc,ew ,,,,d pull

:0 ",,' po" mol ,,~.""'''''' ,,'''''''''' ,," "" h"",," C~{cfllil (. lOp II .",. ( , !J SCtcws. luon II Y !<""OVc Ill" J Ii lo toS) ,e ",m,est I t. ,,,.note cont , I HOUIJh 10 ilelclt 'Y shduUJ 11 10 . rWiuds ilnd

",'.

13 2A R ",nove 11 h -'" ~clew

lJl1sere I 5 W wile!,,,,,,,,,,, -, h"I() _') I . 01_ InltlO.1 I knob ( I • I P U:

d'SCOIlIlCC.l II c ,"m p.mel r til() p,mel UI 7 n I 'U spc~kc' lorn th o do I"""lwork ","""'"'' . w""'" (ph'" "' "."'"' W, """,, '" ,h,,, w,,..,, ,;, "'''"." ,,' ""'"',,' 7" "". "pp''''''''; pOSitIon . () wmduw IS (;1{1' ,u, I" the wm I sp

'"

,

13 3A R emove lile st,ews 133B lhen'turn l' remove 11 Ie m rmes! 90 ' 10

13 <1 B Door lock iJul10n 13" R :.:> emoving tl mmOi control kn~~ nul frOlll lhe t)xt eriOi

procarmanuals.com

Page 184 of 205

Chapter 11 Bodywork and fitting 183

.", .

13 6A Door Ir;I" rwool lewining chp 136(3 Oisconll(:CIIIlg spen kOl WiWl!J when ICIllOV;"U Ihe dool Ir"ll p;lnel 14.2 Removing Iho plastic sheel from tho inllcr (Ioor

•

:, .. '

•

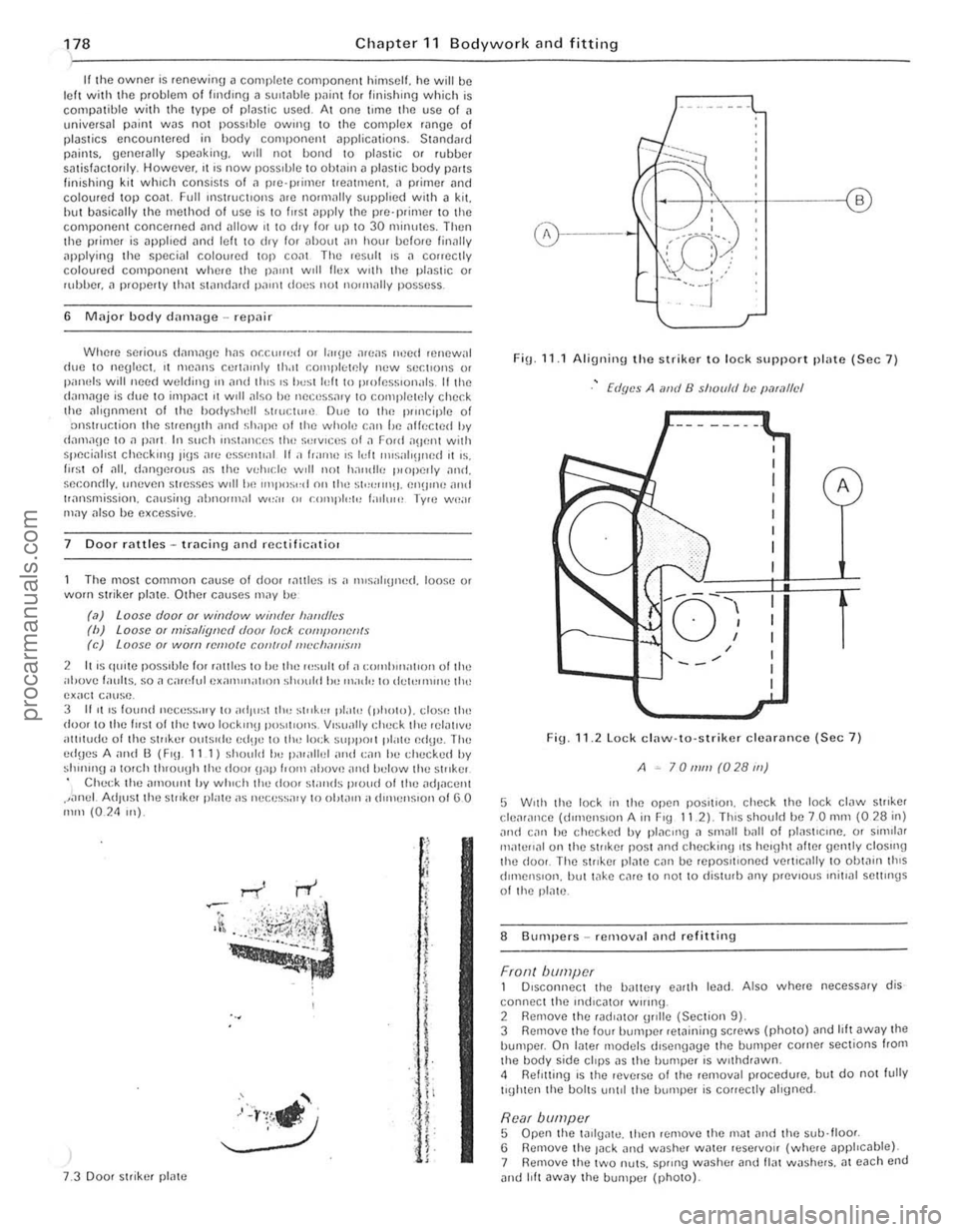

14.4A On l a tel models Ihe window IC9ullltor is I;ve ted 10 the doo.

14 Door window rcgul;otor (lsscf11b ly -r el1lov(l1 lmd refining

1 Remove Ihe dool II"n Ihlllei. liS dcscllb(~(1 III lhe preVIOUS Seclloll 2 Peel oH Ihe pl;1StiC shee t (phOto) 3 Teltll)Ol;111ly ICfl1 the wI"der h;1nd le and lowel the WII1(low 4 On emil' models lelllOve the screws SCC!ll"lU the reuul;rIOI ~<~ernbly to Ihe innel dool p;1l1el On l

Fig.l1. S Door window regulator assembly (Sec 14)

...r,

14.48 Window regulilto r relay b.acket

sc'ews

l e

nglh of '"lle. usc a wooden SUI>I>o.t ,,5 well 7 W,thdl

1 R eillove Ihe door 11;111 pam:l. ;15 plevlously deSCfibed . 2 Pull aw"y horn the pl"sII c sh ee . 'he cxtello, handle then dlsconncc. 'he .wo corlll&''''iJ hnks from 'he door lock \0 the extello, handlc .

Fig. 11.9 Ex te rior door hlllldle (Sec 15)

procarmanuals.com

Page 185 of 205

![FORD CAPRI 1974 Workshop Manual )84 Chapter 1 1 Bodywork and fitting

3 Remove Ihe lWO h,1ntllc mi.,,,,,,,\! 1I01.s illld Wllhd.llw Ih" hilOldle 4 Rclrlhng IS t he reve.s.: Ollhc ,cUloy;] 1 l"l)l:",h"c. hul ,In "01 lurgel 10 inst FORD CAPRI 1974 Workshop Manual )84 Chapter 1 1 Bodywork and fitting

3 Remove Ihe lWO h,1ntllc mi.,,,,,,,\! 1I01.s illld Wllhd.llw Ih" hilOldle 4 Rclrlhng IS t he reve.s.: Ollhc ,cUloy;] 1 l"l)l:",h"c. hul ,In "01 lurgel 10 inst](/img/11/56932/w960_56932-184.png)

)84 Chapter 1 1 Bodywork and fitting

3 Remove Ihe lWO h,1ntllc mi.,,,,,,,\! 1I01.s illld Wllhd.llw Ih" hilOldle 4 Rclrlhng IS t he reve.s.: Ollhc ,cUloy;] 1 l"l)l:",h"c. hul ,In "01 lurgel 10 install the hushoS 10' Ihfl link .ods A 1o.lIfll>cl,olcum ]dly on the .od ends 10",11 nSS,Sl w'lh the" "lsWIlIll'/)1l

16 Door lock tlsSClllhly rClllovnl illld refitting

Remove Ihe ct()or HUll p:mel as l"flVlou~IV ,h~5Cflhcd ,1nf! remove the pfilstic sh elHlng 2 Remove thl! Hl!l101(! conlrnl h;]llcth~ ,111(1 Iwn WII\(low ,.;1",e boilS 3 Using " St:rcw(hrv e., Pl15U tlw .;Io,'S tron, Ih" ".111"0' h;uufiu rort ,1,,<1 doweh the ,OIls '''1111 II", Iud il Remove Ill" \,to~s·I'u,1(1 ~,:r"ws ~i:(:"'"\H II,,, I""k .0 Ih" ~h,,11 ;lIld the plnslJc clips SU(;UIIlljl 11,,~ ")""01,, cOlll",1 ",

Ih e lock o n IIUl .Ino. ~1":lI. pu~hll'!llhe halllfl lowa.ds Ih.! oul,,, panfil. 10 ennllie Ill" I",:k 10 10" ,;orrm :lly po~'I,or",d 01, II", W;rr sh,,11 , Sucu,,, 11\11 h,, :k w,lh Ihe lto",e S<:"'w~ ,11\11 S()CU'C Ih" ""nOle conllol 'od 10 II", "'''''' parl!:l. w'lh 11m two pl.l~hC clops 8 Rein II", ",xh,um han.llI; ""h '" Ih(", ",~p •. ~:I'v() luck 10";'1'0115 1'0511,on Ih" 1,1.".k I,u~h A IIIId wl"l() Iru~h,,~ IJ .IS ~hnwil III r'!1 11 10.

., ,

,

16. 4 Door lock and reta'l1"IIi screws

Fig. 11 .11 Romoving I h o door bell moulding (Sec 17) 9

The ,emilUldcr 01 I

ho rChllll1!) procedure .s the levelse 01 lhe rcmov~1 prOCedure .

17 Door window glilSS -removal and refining

Remove the door trim pilOel. as previously described. Ihen peel the plas lic sh ee ling away 110m ' he dool panel apertures. 2 Remove Ihe doO! bel l mouldlnU/Wealhf]rsllip assembly (see Fig. 11.11 ). 3 Wind up Ihe w,ndow glass. Ihen lemove 'he pivot plate screws. Remove Ihe four rellulmor lIem plme securrog screws or rivels . Disengage Ihe stu(ls and rOllers of the regulntor mms hom the door glass channel an(1 cmefully hit oul the \jlnss Allow Ihe regulalor 10 fall ilwily. piVOI,ng on Ihe legulmor hnndle shilli.

" When refi llin\j. initially Insert a snlall hloc k 01 wood in Ihe hOllom 01 Ille door assembly. locate Ihl} \)1,155 on Ihl} door panel. so thm il is leSl ,nu on Ih e woodell blo ck 5 locale lh e sluds nnd rolle,s ollhc ICUUI,lIOI ann 11110 ttw door IIlilSS ch~,ulel. I hen ICmpornrlly inswlllhc w,ndow handle and turn ,110 alton

Ihe ueilf pl,lle w'lh Ihe panel flxin!JS . SecIHe Ihe fllal~ 10 Ihe ,nner pnrlel. 6 loosely assmnhle Ihl} p,vOI pia!!!. Ihen Wind up tim UI,lSS ,1m! al'lIn

, I ,n Ihe Irame T,uhlell Ihe p,vOI 111;r1l! SCICWS 7 The remain(l el 01 Ihe rellHmU procedure IS the rev ..... se 01 Ihe .emoval proc(.~lu,e

1

FiU. 11 .1 0 Tho hlack (A) lHld whi:e (0) door lock bushes (Sec16)

Fig . 11 .1 2 Removing Ihe door window g lass (Sec 17)

procarmanuals.com

Page 186 of 205

) Chapter 11 Bodywork and fitting 185

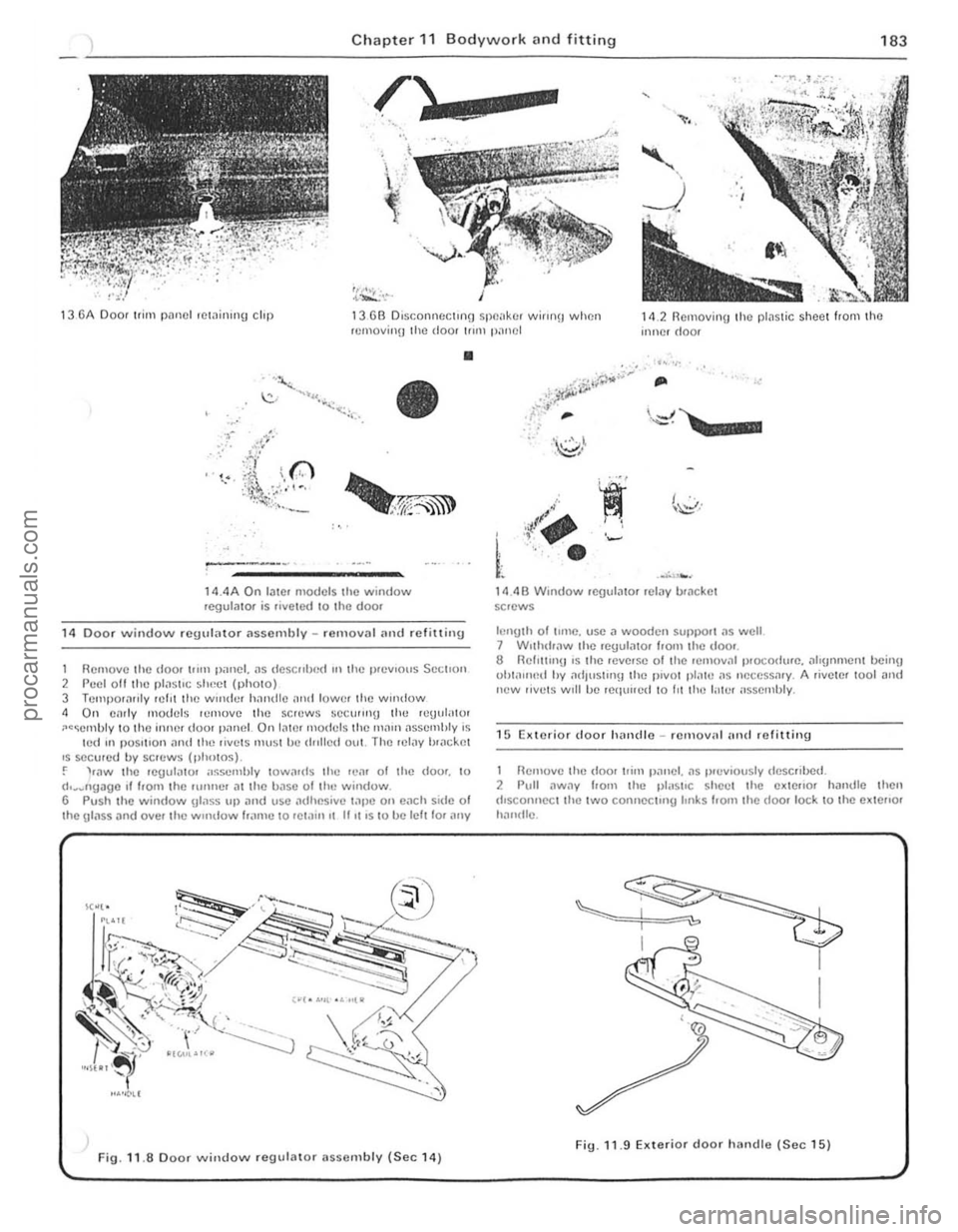

18 Door window 'ramo -re moval and re litting

Remove the door !fUll pimo' as previously desclibed, Ihen paollho plas tic sheeting away from the lowe. door p;lnel apertures 2 RClllove Ihe door belt mouldinO/wCiJlherst,ip assembly. 3 lower Ihe window glllss, then peel back the lower front corne. of 1110 plastic shee tIng ilild remove Ihe felicclO' (where ilpplicablc) \0 g1\1n access 10 the I rOl1land rOil' lower fixing bolls.

hes t o the reilt of Iho fitSI Illouldm!l chp 7 S,)tinn Ihe real of the h;'lme 11110 the shell. so Ih.lt Ihe hame lies hdwcon Ihe 1.11.155 ,ltld Ihe outer p.l0,, 1. whIlst spml!J"'g the frame fr Ont eltlcal len pasl Ihe mouldln!! chi). so Ih,11 Ihls

TI\lhtrm Ihe holts 10 The .elnalnde. of t he fI:hlllllg plor-edur!.! IS II", IOVOIS" o f Iho removall)rocedure.

19 Window frame moulding ,md door weathers trips -removal and refitting

Where armlrc

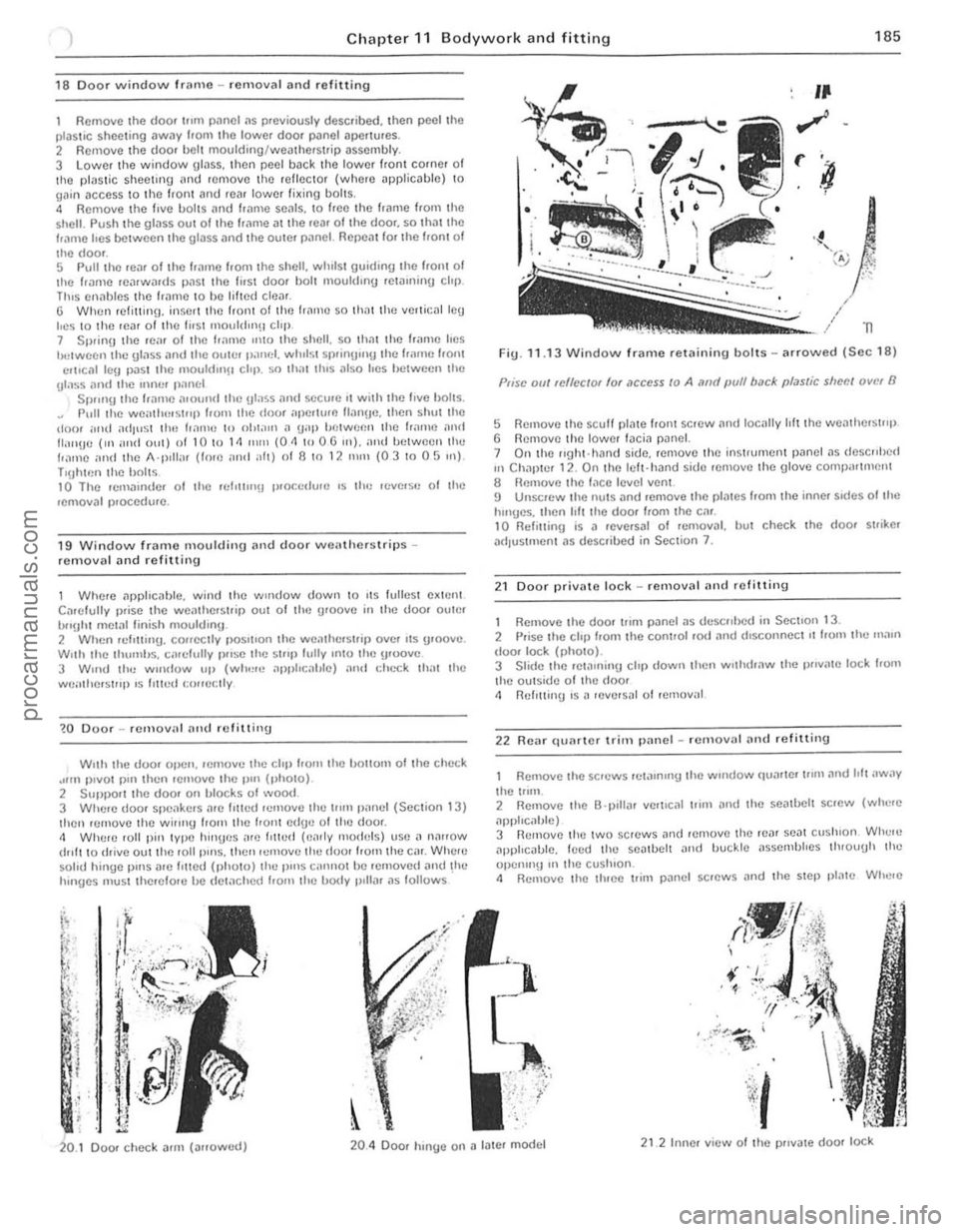

Wllh Ihe doo. Ol)!.!". remove Ihe dip IrOIll 'he bOliom ollh!.! check ... rn 1)lvot l)lfl Ihen relllove tho .)Ul \I}holoj 2 SUllIlOtI the door on blocks of \'1/00<1. 3 Where doo. speOlkers Olre fIlled relllove Ih!.! Irllll !)OInel (Sec' ion 1 J) Ihen remove Ihe WirlllU from tire frolll etlu!.! of Ihe doOt.

4 Where rull pin typo hlllUfis ,lie hlled (eOlrly models) use

'A ,

FiU. 11.13 Window frame relaining bolts - arrowed (Sec 18)

Prisc out rcllec/or (or ,1CCCSS to A "fld Imlf bock pli/stic slleel over B

5 Remove Ihe scuff "Iilte Itont sCrow and locally Irftlhe wOilther stllp (j Remove Iho lowor I~cia p~nel. 7 On Ihe lI(jhl·hnnd side. rOlllove Ihe instrument p,mel ilS describ ed

III Chilpter 12. On Ihe lelt·hOlnd sid!.! remOve Ihe glove compartment a Remove the Inco lovel vont. 9 UnsCtew the nu's OInd remove the plmes hom Ihe inner sidos of tire

l unges. Ihen Irlt Iho dOOf from t he Cill. 10 Reflllin(j is n reversal of tcmovOlI. but check the <100' striker adJustllwnt [IS desc ,ibed in Section 7.

2 1

Door privDte lock -removnl ilnd refitting

I Remove the doo. 111m panel DS desCtl bed in Secllon I J. 2 P rise the clip hom the control rod ;md d,sconnect It from the m,llll dOOf lock (pho.o).

3 Slide Ihe . e .arninu chp down th!.!n Wllhd.,lW Ihe pllva.e lock frOlll lire outsid!.! of the door 4 Rehllinu IS ,1 .everS

Remove the screws rel'llnlrlU Ihe wrndow

OIpp

ciltJle) 3 Remove Ihe twO screws [Inti remove Ille r!.!Dt seat cush ion Whele Jpplrc

4 Remove Ihe three 1Iim panel screws !llld the SIOI) 1)lilI!.! Wlre.e

, 20. 1 Door check Ollln (arrow!.!dj 20.4 Door hlnye on

, I

" :,

i

procarmanuals.com