fuel pump FORD CAPRI 1974 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 22 of 205

)

T

Fault diagnosis 21

Starter motor ((/rns cngino slowly Parti ali V disch~rilcd b

Engine ((/"'S normally but 1,1ils ( 0 SIMI Damp or dirlV HT !eads

Engine ClltS Ollt ;1nd wilinOI roslinl

fngine culS out suddenly -ignition I,wlt Loose or d'$Conncetcd l T wi.es WCI HT Icads o. d'S I"buiOI C;1P ("lIer tr;1VC'SOll!) w;1'er spl;1sh) Co,1 o . condenser lallulc (cheek 10' SI);lIk) Olhc. ignition laull (see Ch,'plfll 4)

Eflgine mistires belore CUlling oul IlIcll,wlt Fuel I,,"k Cillply Fllel pump dClfecl1vc o. 1,ltcl IIlo .; k(H! (dwck 1m dellvl"V) Fuel tank hllcr vcnl blut;kcd (StII; llon Will II" flV,{Io"'1 Oil lI~h"'~II'H C,11l) C;1llJulCIIor nccdlc v"lvc SIII;klll!J (WIU.'1I1 "ppI1c"hle) C,1lUwellor leiS blocked (ha:l COIII,lIl1ln,Hcll) Othcr lllcl sys!Cm l

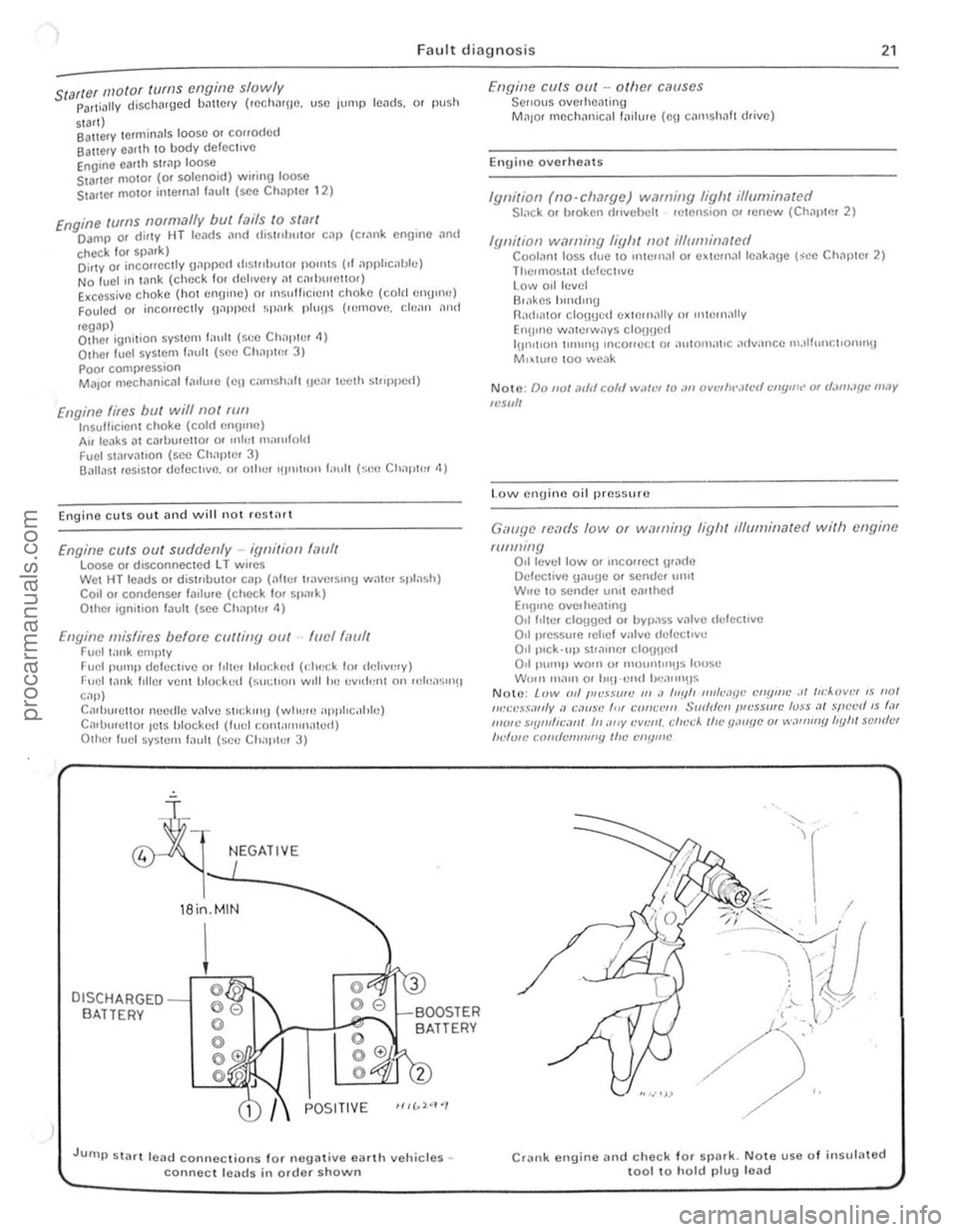

BATTERY

lSin.MIN

POSITIVE

JUfl11) Slart lead conneClions f o r neg!Hive earth vchiclesconnect le;1ds in orde r shown

fllgine euls Ol1t -olhor eimses SCIiOliS ovcrhC~ling Mnior mcch

Ignitioll warning light /lot illuminBted Coollllll loss .Iuc 10 In!emnl 01 CXierr'JI ICJk

l.ow cnuinc oil JlfC!ssuro

G,wge reads low or warning lighl Illuminated wilh engillc

rWllling Olllcvcl low or mCOlfeel 0.,,<10 Deit.'Ctivc gllU!jC 01 sendCI 11111 Wife 10 sendCI UIII' C.1I.hC(1 Engonc ove.hC.1l ing O,lllllcr CIO!19c<1 01 byp,1SS v;1lvc delccllvc O,I ,llcssule lehef v'llve dc!ec tlve Oil pick-up strllll,e. ciomled 0,1 pUIllP WOIil or IllOlllllll1\l~ I\,osc Wo,n Ill,l'" 0' h'!J-cn(i hC.1I1I1!)s NOlO: Luw or! 1"t'HlifU III a IImh III"C"f1~" (.'IIYIIIC .J/ 11l;~()VI.'r I.~ 1101 1II.'I:<.'",.","/y,1 (.",lIlSV {o, CIIII{:"/U Suddel! fJf'~SS!lle {U$S ,11 SlIced IS {M "'/!IC SI{Jl!lflca"l (I! ,my cve/l/. .:In',·j. I/le .

procarmanuals.com

Page 53 of 205

, ,

52 Chapter 1 Engin e

68 Connecting rods and gudgeon pins -Il~nmination a nd renovation

Refer 10 Sccuo n 18.

69 Cr,lIlkshnft -e~(lrl1in

70 Mail' and biu·end heafinUs -olwillinmion and H)!1ovation

Ilelo,r to Seo.:lIOIl 20

71 TilninU oellrs -e~i1miniltion find renOVlltio n

Re f

el to Sec t,on 21.

72 Flywhee l/ d riveplale -Okamitliltiotl lind ronovtttion

Inspf:CI lhu ffywhf)l)I 0 ' ([ttvl'pl,,": fOI (!;U";'\lC ilnd 1:I".1I:k Ih;'1 Ihe ""!I H".u docs uol have .IIlY \)Iok"n o. l);Idly wOtn teeth. :1 On ''''''''';11 I'''"''''US~IO'' mnd"b ,I IS pOSSII.Il) 10 'CHew the I"'!l \]C,II .'S Ilesl:

[xallutle Ihl} v,tlves 101 IlIls "lid !l,ooves lind the valve SIems to. e~c,'SslV') we,l' III d'~loIIIOII' 2 Ek,""l1ltJ Ihe v,oIVil hf)"d 10' SI!.!"S 01 hu",u,U of the vOllvo seillS lind ch .. !ck Ihe ht 01 Ihl) villves III Iho v,llve UUldes . 10 SCl) II Ihe villve uu,des il,e WO!ll

3 We"" valve U",dcs c;'" be r l),lIned O\It lind vlIlves w'th overs.~e Siems lilted II iI v

S To 1,1P the valves. In tt s u ction Iype gnmlonu 1001 to Ihe villvc hettd. smeil' a lu tle COil.se c;ubo.unllulll urmdmu pOIste on to I he sealing I~c e 01 Ihe vnlve ond inserllhe valve 11110 the cyJonder he"d. Rub Ihe stern of the v al ve gundlng 1001 hetween the palms 0 1 the hands. so Ihal Ihe valve,s ,otllle(l hHckwards 1I11d lo.wa.ds When II IS lelt lhOlI culling has

ceased. loft Ihe villvc. rotate It th.ough 90·, lowe. 1 and fepCill the u"n(llnu o.:.e.atlon . • e dlslllbulill9 the g"nd,ng pas!O on Ihe seal if necessilry. Conlinue Ihe process unlll a mllll gwy bOlnd IS pfoduced OIloun d the complete pe"phclY of hoth the vlllvc and t he valve seil l G RepoiJl Ihe opcrilllO" US" 'U fine o""d,nU I).Jsle. 10 ohtil'"

IInlsh. then clean lJoth Ihe valvcs and Ille v alve seals 10 ,emove IIU \llIces 01 u"ndlno pash:! 7 II 'I IS convenl,,1lI 10 liIke Ihe eyhndc. he

When Ihe cyllnde. heilds (li e removed. eilhe. in Ihe Course ovelhJul Of for inspection 01 bows 0. villve condllion when the e IS in Ihe CM . il IS nO'''1

Ihe eiliite. dilys 01 10nU stroke low .eVYlnO en!)lIles tJUllllodern enUil fuels ilnd Itrb"canlS C,1use less cOIIOOn deposils OInyway and any. b ehind lend merely 10 cause h O I .SpO IS.

75 Oil PU"',) -disnwntlino. eknmin"liOil ,,"d reOlssembly

The Oil pump mm"Itt;"S a I)ressure 0 1 ilbout 2 8 kgl/cm' (3 Ihf/in') lInd unless Ihere is ,1 sIo",IIcanl (hop In 001 P'(lSsuro willel ,)loved to he due 10 the Pllln,). rillhn. Ih;", 10 wo", heil'm!)s. 11 IS be .

t o le"ve Ihe 011 pump und'S hilhed. 2 To d'smanlle Ihe pump. fll:.1 ,emove II hOln the en!l'ne ns desc,,1 III SUClion 58 3 Remove Ihe IWO bolts seCulII1!J Ihe en d cover 10 the body 1 'emove the covel ilnd 1he .ehel v;" ve "sscmhly. Ihen Ihe Iwo P"

fOIOI assembly.

" Remove ,he IWO bolts lind ,,,ke Ihe p,ck·up w he lind SCIl' lIssembly oft Ihe pump housin!1 S Wilsh all lhe pilrlS In petlo'. usc iI hlllsh 10 cleol" Ihe Inside 01 1 pump ho usinu ilnd lhe p.cssu,.., .elle' vil've eh'!lnbel. ilnd milke 5' Ihilt ,111 p,tltlClcs 01 dill ilnd mewl n,e ,emoved Allow the pttrlS 10'~ n;IIUf,lllyor blow them d.y G Check Ihe Illslde ollho Puml) houSII'9. Ihe OilIer .;w:e ilnd Ihe 101 101 dilfllilUe and e~cesSIve weill 7 E~ll'''Ule the I111lling su.lace 01 lhe I)Ump cove. 101 we,lr It Ihe CO' IS sco,ed. o rooved. a. shows ilny s'g ns o f wea •. a new covef must I hlled 8 W,lh the ,otor assembly filted in the hOuSing. place a straighl·ed!. over Ihe end 0 1 the housing

Page 67 of 205

)

,

i

I II

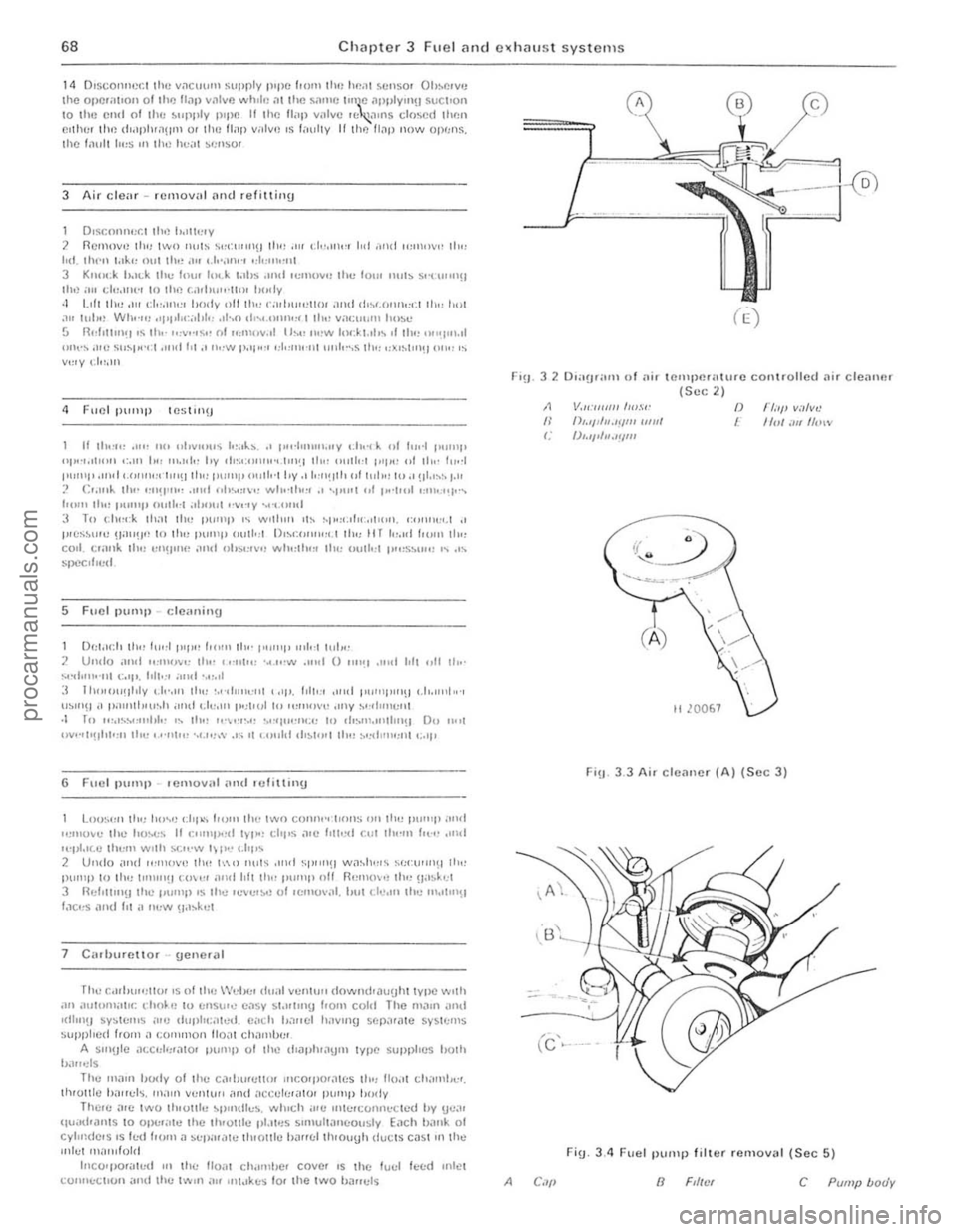

Chapter 3 Fuel and exhaust systems

Contents

Pari A: C,UbufCIIQr system AccchmllOf cable -removal .1n( rerilling , ........... , ...... . Accclm

PMf A: Cilfborettor system

Gctwrctl System 'Y lloC

Fuel pump delivery l)reSS\lrc .

Fuc l I,ln k c,lpnc,'Y .

Cilrhurcttor lytle Tluol1le baf!el dranwtcr

Vcnlull d"ll'ICICI

Mainjct: 1 !I71\/1975 1976 onwards Idlong speed: 1971\/1975 1976 .............. .. 1977onwilfd5 FilSI idle speed: 1976 1974/1975 ilnd HI77 onwilr(ls

Floal leveL: 6111SS lIoal

PlaStic float

Floill Iravel ...

CO %

111 idle: 197<1/1975 1976 1977 oowards ......... ........ , .................... . Maximum choke vacuum p ull down. 1974/1975 .......... ....... .. 1976 1977 onwards ............... . Choke phasing: 1974/1975 1976 .......... .. 1977 onwards,

17 18 3 7 8 20 21 5 6 4 14 13

16

15

1 19 ,

9 12

Weber calburellor

Exh,luSt system .. lemoval ,1nd rnf,ttin!1 Fuel l:lnk. sCIld el utUt and follel l"floC !!fmc.,,1 Gene.;,1 descflpt,on

Irlle nuxture • ,1d/l' Slmenl ..

Inle t man,fold .• emoval and 'ef,nn,!]

Ma,n systcm compo nents .emoval and rd,ll'n!) nouline m.1jnlcn,lnce .

P.1r( C: F.1l1ff di,1gnosis Fintlt d,n!]l1osis .. fuel syslem (cadJll,ello,) Faull d'agnosis -fuel system (fuel injeCI,on) ,

11

"

:12 33

Dual vcnlu.i downcfoa"llhl carh,",cl1or. m~IHI"'Ci,lIv Or.cHnlcd (hap'" .agm luel pump. tempcrilh rrc cOllI/oiled air clenne, on sallHl "'0111:15 02510 0.35 kgl/cm' (3.7 1 0 50 1I,l/ln') 580 Il1re (I2 7 1)011)

Weber (Iunl venturi wilh autorn;rt,c choke 3801111 27 nun

1450101 or 1<12 mill 142 mm

800 J. 25 rpm 825 1. 25 'pm 850 l 25 rpm

noo ,., 100 rpm 2000 ± 100 rpm

40.0 mm (1.575 in)

3 4 .3 mm (1.350 in) 12.5 1. 0 .49 mOl (0.492 L 0 .02 in)

2.8:l. 0 .2 1.75 10

5 .0 1 0 .25 nun (0.197 7.0 J . 0 .25 mm (0.276 5.5 :t 0 .25 mill (0.217

2.3 ± 0.25 mm (0091

, 0,01 , 001 , 0.01

± 0 .01

3 .0 :t. 0 .25 nun (0 118 ± 0.01 2 .8 :l: O .25mm{0.110 J. 0 .01

in)

in)

,n)

in)

in)

III)

procarmanuals.com

Page 69 of 205

I,

68 Chapter 3 Fuel and ClChau st systems

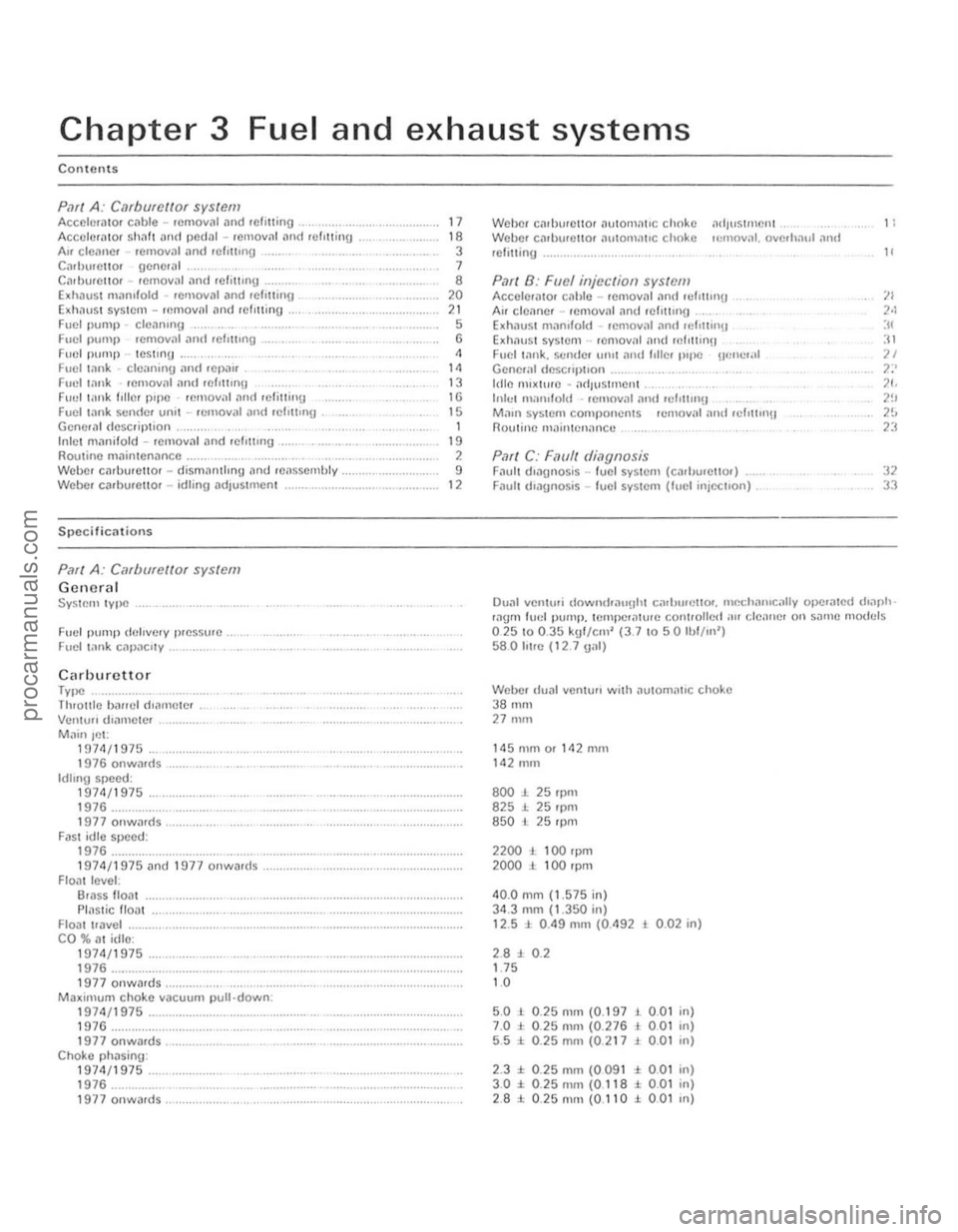

14 Dlsco""C(:t lhl) V;1CllUlll ~lIprly IUPC (10111 th,: h<:.11 ~Cllsor Oh~r.rv'J Ihe O,) CI; ,hOil Olillc U;1,) villvi) whll!) ,'Ilhe s,.,mc hn~c ;)PpIY"l!1 SUCtIo n 10 Illu cnd 01 lhc ~"ppIV plpn It Ihe 11;111 v,llve 'C~1"'S closed then CI!lu:r tlw (i .dplu;)!l11l or 1110 flap V"IV~l IS 1 ,I\Jlly If thl) I lilP now opf;n~. Ihe f;lUII 1":$ III Ih,~ hea l ~(:n ~o(

3 Air clear -rCllloval nml le fittinu

1 Q,seol1ll(;f:l lhe 1I,,1h !IY 2 Remove tli' l two n"l~ '<:t:lII,n!l 111".111 (,"'.III,,, lid "nt! ",m""" II,,, hd. til ... " I,ll" OUI 11", "" 1.1,',,,,.., 0;1,,11\,,111 3 Kuuc.k '>.ILk lh" I"", Iud. l"hs _mel 'CIIlU"" Ihe toUl Ilul:> so'' tuH1!! lh,);oll ch',IIlt" if) !he r.;Hhu"·lw, lu>

H Ih.·", .11" .. II ""Y'"'''' 1",,1..~ " 1",·I"",,,,,,y •. h d).. .. I 1111"1 I""" P "I~",'I"'" ':,111 I" , ",.,11" I,V ot"".""" .. ,.I"I~1 110" ",,11"1 1"11" "I II ... It ... 1 1"""1' .,,'U I '.(""","'I",!) II", 11111"1' OI,lh' l I,y., I''''!III, (,I 1"1,,, I"" ~II.,~" I." :' Cr.,,,1.. 111" ""!I"'" .",,' /,h~",\"" ..... 1"·. 1"" _, "'''''1 .. 1 p,'III,1 '''''''', .... I",,,, .h" '''''''I' .",,1"1 .,11111" I''''''''y .. , .. ... ,,,' :1 To c.h""k 111.11 II,,! I''''''P ,<; w.II"" 'h ~p""oI" .'IIUIl. ,,,,,,,,,,, ,1 .' p.e"~",,, !la,,!!,! 1 0 th,! IU""p outkl D'M·,"''' ... '. t III" II r ","", hom 11", co,l. c,;ulk th" ""!)"l{, ;11111 UhM"V" wh",h'" Ih" 1>\1,1,,1 1''''';''''111 " ." SllCCd'e d

5 Fucl purlll) dc,,,,illg

D"I,'I:II (h .) 1",,11111'" 10",,, II,,· 1"""1> ,,,I ... lui", 2 Umlo ,IIlIt """("'" lh,' ( •. ".", '~" ...... _ .. "t 0 ""'1 .""t t.!1 "tt lh,· .... ~III".· .. 1 "''1'. 1,lk' '''Ht ,.",,1 :l 1 t""oU~II,ly (.1""" 11", ·,,-ltll"':I'1 "tl'. 1,110;' ,11,,1 III''''t''''\) ,.1,.11,,1,,·, U~"'H a 1);ou'tl>l,,·,11 ,tlHI ( .11"", 1";h"II() '",n<) "" "ny ",·,111"(:1'1 ,I In ,,,,,,,,,,,,,,101,- " tt", "'''''','! ""qll"IlI;" !to ,h"m.IIIIIII'H Dn " .. 1 UVI""!tl'I"" II,,, '.""1", '.,.,.,,\' .• ,; '( (",,1<1 (h~t'''1 tlon ~.,(t llw,"1 ("'t>

6 Fuel P""'tl ,emovnl ,md .uliuiny

L()U~"II II", h""l! ,.ht ... Io<)l1l Ille IWO C(Jlln," (1011:; ')" It\!! P""' P ;,,,,1 ''''"0~C Ihl! ho~" If "'''"1)<,<1 IVp" d, .. ~ ,,,e I'lh .. '<:I cu, Ih,-m Iol'(' .",d H'lti.,e.C lh"m w'lh ).C'l'W lH'" • . ht> .. 2 Undo ,lnd "'!II(We (h" [<\0 nul~ ""d ~fI"'l!1 wn"h,,,~ senor'''!! II", jllllnp to (li e 1"11"'\1 rI"'" H!ull'(11Ih' I,uml' nil nCIll()'" II", !I"~~~I 3 n(:l.tinlH lhe 1""111' 'S the '(:YI:'~ 0' '(:11101';11 . hUl de,H' lhe ,,,.,,\11\1 ',lC",S ,lIld 1'1 " r"' ..... 'I,l~kc(

7 C;orbllrnU or · gCnc'ill

'Th" c,,,hu .. ,uu< IS nllh" \Vclx.r ci .. ,,1 "CIll,,1I (lownd';1uuhl lVI)C Willi ;111 .1II1UI\1;.U<: ('ho~ (~ 10 (:nsur" C;1Sy S.,\lIII1\1 100'" cold The m,un ;Ultl

IItim U sy~",,,,s ;IIe dup"t;~ I1 ... '(I. p;,ch b.1 .. cl h<1Y1I\9 S('j).lf<11e SVS1(:II1S supplied Irom 11 (;0"'111011 110<11 ch,lI1'u." A S'"(JtC ,'lcd':f<110' pump 01 Ih~ dJi)ph"lYIll lVt)C supphes hOlh b;lr!

3 2 O,; ,ur;om 0 1 nir tcmpcr;ohorc contro llC d ilir clcnn.] r (Suc 2) V.I<: IIII11! /",.1,·

f)""d".IfltJJ lllUl f),.II""_"''''

(A j

()

1 1"1:'1' V;,'~!! I/ul ;'" /I"IV

FiU . 3.3 Air c lcm'er (A) (Sec 3)

(c ' ..

Fig_ 3.4 Fuel pump filter rcmo",,1 (Scc 5)

8 c Pump body

procarmanuals.com

Page 71 of 205

70 Chapter 3 Fucl and exhaust systems

liS seatmu Note ,1nd reco.d the number of lurns, so th,11 the screws can be relltted 10 their orjuin~' settings . Unscrew cilch screw fully and remove it and its SPfing . 13 Che<:k the lIoat

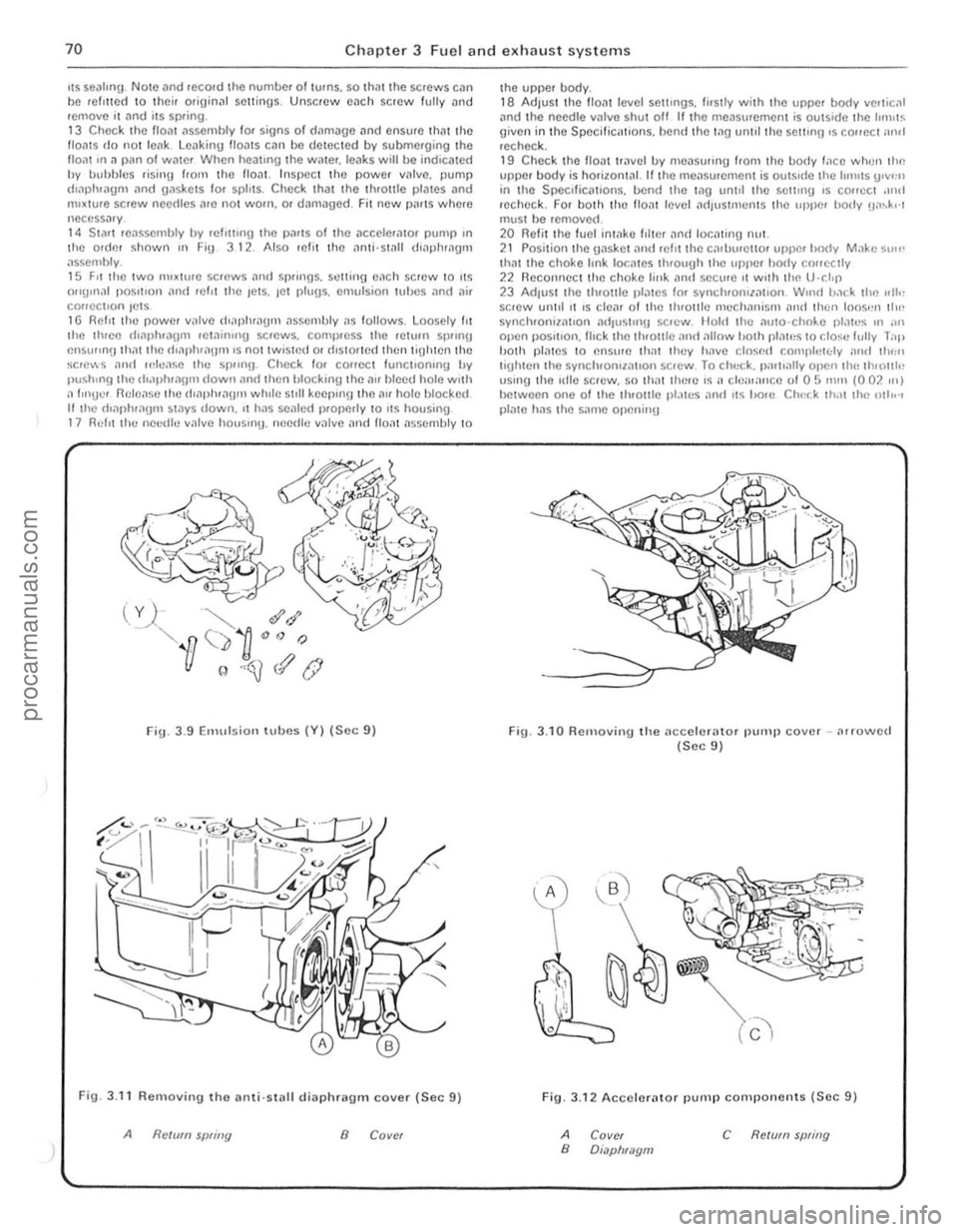

Fig. 3 .9 Emulsion t u bes (V) (Sec 9)

Fig, 3.11 Removin!J tho IIlIli'Slilll dillphragm cover (Soc 9)

Refum sWing 8 Cover

the upper body. 18 Adjuslthe flo." level settings, fi,slly w;l h the upper body verlical .md I he needle villve s hut off lithe meilsurerneot is outsIde Ihe IInlllS given in the SpecifiC

Fig. 3.10 Relllovingllie IIccelcrillor pump cover -(lrrowcd (Sec 9)

..

Fig. 3.12 Accelerator pump components (Sec 9)

A B Covcr Diapl/mom c RC/(lfll swing

procarmanuals.com

Page 79 of 205

,

. ,

I , ~. !

78 Chapter 3 FlIer and exhaust systems

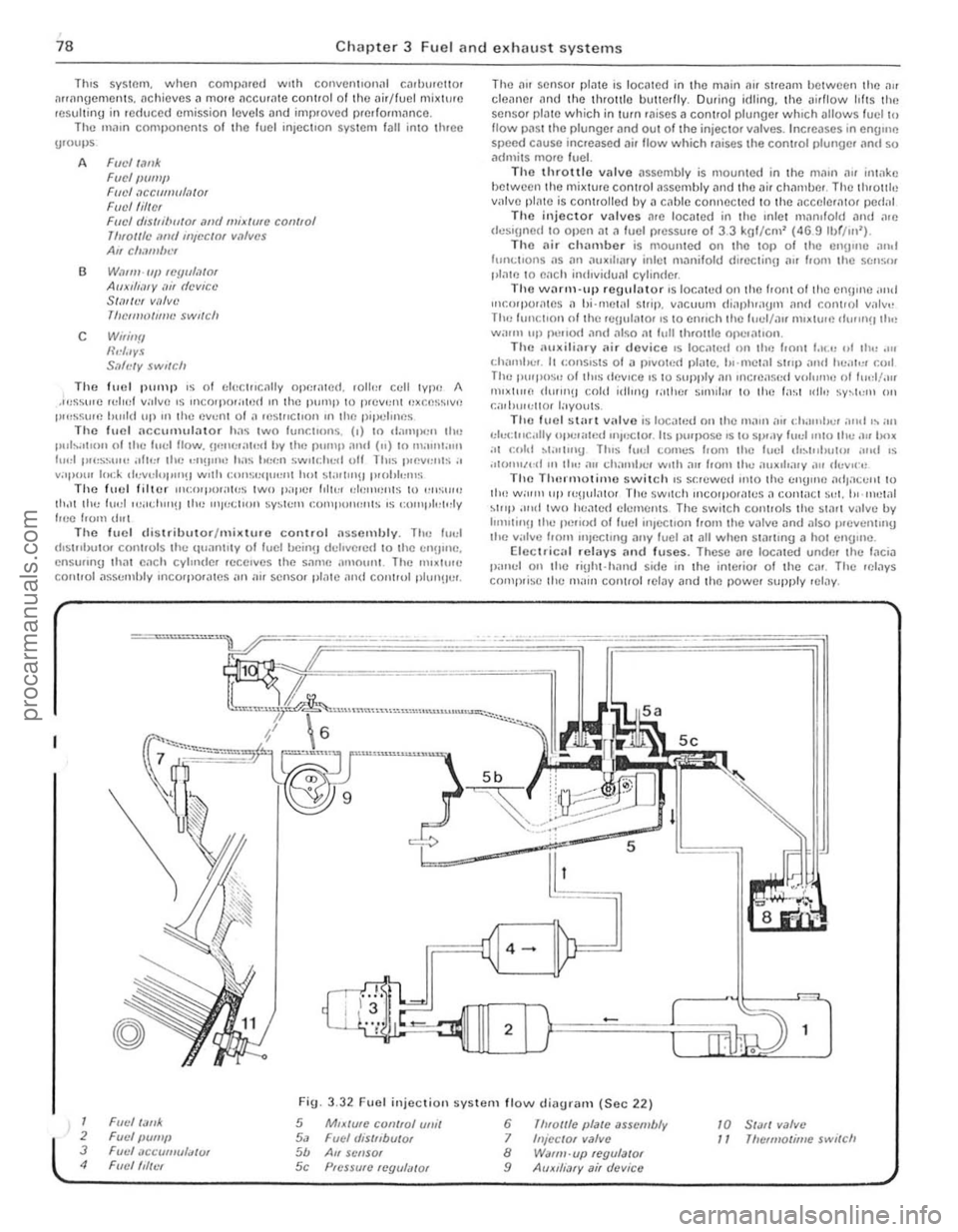

TIlls system, when comp1lrcd with conventlon,lI c.Jrhwctlo, ~rrilngemen1s.

tI'(lllPS

A FI/ef Milk Fuef Plllllf! F/lel .?CCIIIIW/<1IOI Fuel filler F/lel ,IISltihular ,w(/ millime con/rol l11ralllc MIlllll/ce/Of "',1/1'115 AI( ch.ll11/"1(

B W

The fuel pump IS 0 1 eh,CIIICtllly operated. ,aile. cell Iyp" A .",SS (IIC rchd ..,:,1..,0 'S mco,p[)I;oh~(1 III the pwnp 10 preY",l! f:XCOSSlvn

p"'SSUIC la"ld III) '" tho event of ,1 ,,)Sl"Ctlon III th e pipelollf!s The fuel ,I(:c\llllula lor ha~ 'wo lunf.luItlS. (t) In 4'ill1I,)(:I1 llll! IIIII,,;,'U)!l 0 1 lhe luclllow. HHlu.:.iI ,ml hy Ihe I)\I"'P ;IIIf' (II) 10 11I;""t,"" Iud I"'"'~''''' ,,1";1 .h" .:o,!.m" h;os Iom,n sw"dn,,' "If TillS p.r.v"rlls .• v; 'po", IIH:1o; .lo.:vel"I'III!1 w,th t:'Hlf.O:'I""nt 100' ~t,'

6

9

The iI" sen~or 1)1"le is locilled in 'he main nIl Stlealll be.ween the iI'r clr:wller ,1nd the Ih'Ol\Io bullerfly. Du'ing idling. the ~irflow hits Ihe sensor plate which in tu.n '

1 Flle/lall/(

"

Mu;/ulc CUIIIIOI ,mif 6 IIIIOlfic pla/c assembly 10 S/;II/ villve 2 Fuel PIIII/I' 5., Fucl (Iistllbutor 7 Inicc/or valvc /I 'hell1JOlimc sw,lch 3 Fuel i'CC/IIIIUI"tul 50 Alf SCIISOI 8 WiJllII·Up regula/or 4 Fuel '"10:1

"'

Plcssule regtllillQI 9 AU~IIt"aIY air device

·.i

<+

procarmanuals.com

Page 80 of 205

)

Chapte r 3 Fu el an d exhau st systems 79

Ii

0) G

\E )

' .. ~ ee)

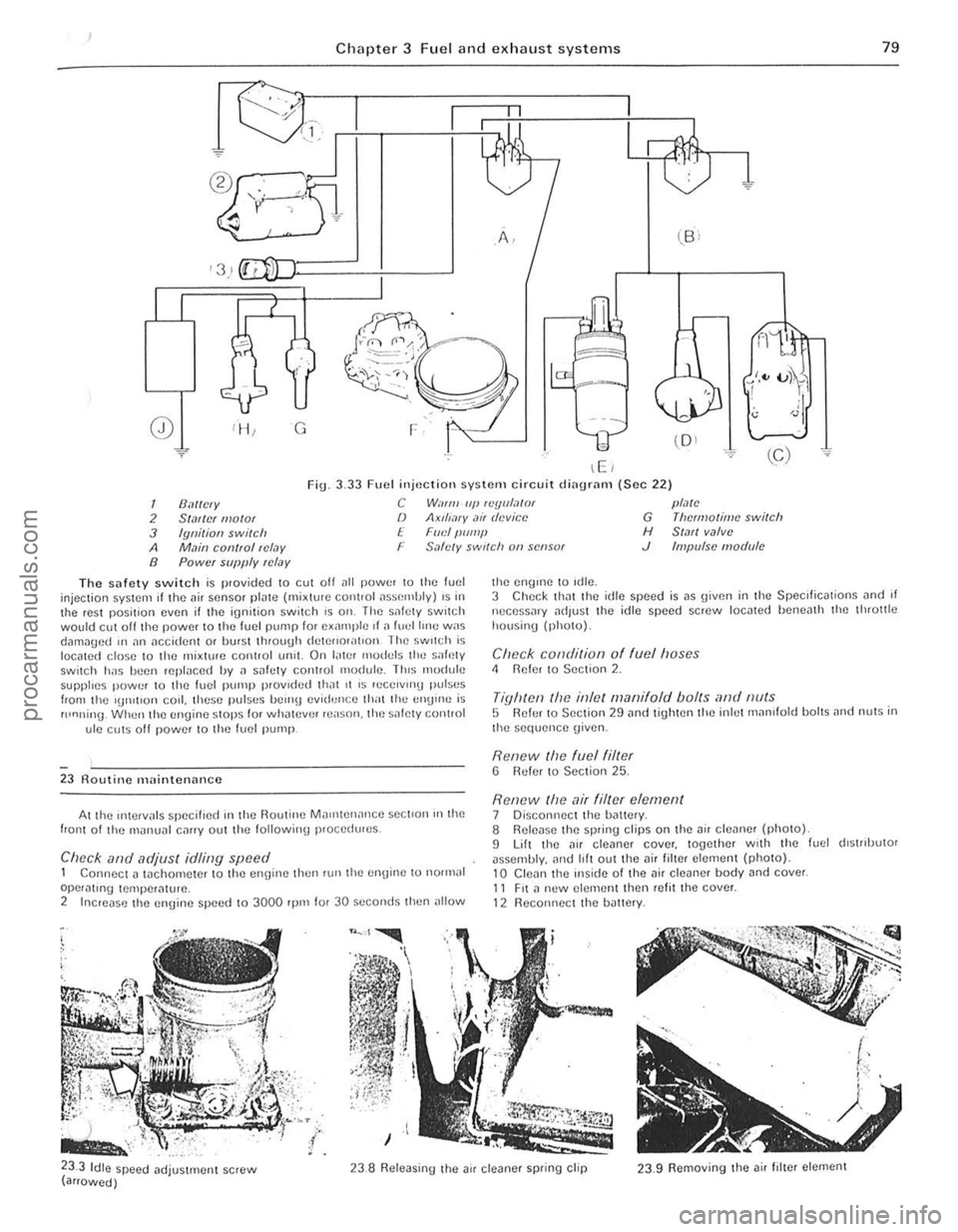

Fig. 3.33 Fuel injuctiOIl system circuit di

2 Sialicr I/Iolor /) Axll/,-"y ,1i, device G Theo1lO/lmc switch

3 fgnitioll switch E FIII;I/Iump H St,lfl valve

A M,lin con(Iol r(;/,)y F S

8 Power supply rcl.1Y

Tho safety switch is provided to cut olf illl power !O the fuel injection sySl(!m if the air sensor plJIC (mixt\HC COlllrol assemhly) IS il the rest position even if the ignition switch IS all. The s[lfcly switch would ell! off the power to the fuel pump for oillllpic ,I il fllOJllmu W

AI the IntelV

,. ,

< '(:,,~ , • . . ;::~t,·· . , ,

.' ) . ;~ ~~;:;: ~iJ" .. ,

n fr.X l

the engllle 10 'die.

3 Check Ihill I he idle speed is lIS given in the Specificmions ilnd il nccnssary "dlust the idle speed screw 10cllted heneillh Ihe Ihrottle housinv {photo).

Check conditiorl o f fuel hoses " Reier to SeClion 2.

Tighte/l the inlel manifold boilS and /luis 5 Refur 10 Section 29 and lighten the inlel rll

Renew the air filter element 7 Disconnect the h

-

I',

I t, ' .

;

!

" , ' .• I

! 1 I'

: 1'1 1 . ,

I

I '

I

procarmanuals.com

Page 81 of 205

80 Chapter 3 ~lIel and exhaust systems

24 Ai r cloanor -removal and re filling

1 Remove Iho elomerll as dllsc"hed III Sect,on 23. 2 Work,nn under Iht! left ·hand honl wheel arch. unboll the illr clenne, hOdy f,om Ih e s,de of the engmo compnl1lllen\. 3 Rohuil1g IS n rove rsal 01 tho lomova l I)rocodule wl lh relelence 10 $(1(;11011 23,

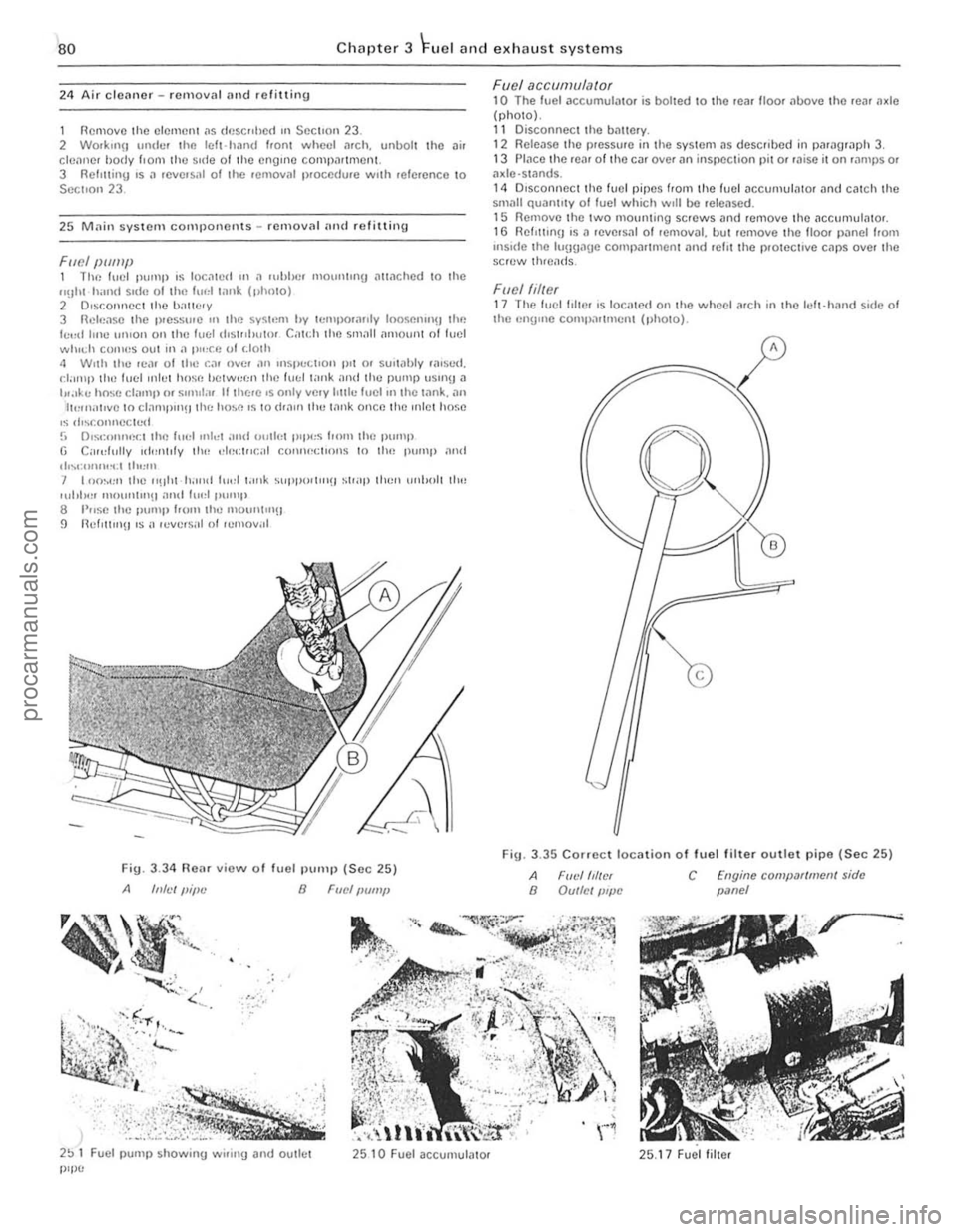

25 Main system compono n ts -rellloval "l1d rofitling

Fllel p /llllP 1 Thn hll)1 pump IS loc.lwd "' " lI,hlw.. 1ll011111111U .lUflchod 10 Ihe "!Ihl h"n{1 51th! 01 lhe 11I/,llal1k (phnIO) ') D,sC:OllllCCI Ihe h

'''~t:un'''~.1 11",," 7 I ,.,,.,~'''' the 1I!l11l hoilid Illd 1'lIlk SUPI)(Jl IIII(f Sl'ilP Illell unh(lll ll,,~ lul,I)". mOlllllll'H ami 111,,1 JlUlll!' 8 !'IISf) the pllmll "("n the "'OIull"'!! !) Ilcfllllll!j 's il IUliers,, 1 01 ,emOVi.1

FiU. 3 .34 R Oilr viow o f

A Ink'1 pi,ll}

fuel,HIIl'I) (Soc 25)

8 Fucl'WIII/'

..

) 2~ 1 Fllel pump showing Wlflflg ond oul'el pipe

~ .. . . ~ ~ ... ,

2510 Fuel accumulatO'

Fuel accumulator 10 The fuel accumulatO I is bolted to the Ical 11001 above Iho lear "Klc (phOIO). 11 Disconnect the bflltCly . 12 Releaso the preSSIJle in the system as descllbed in PfllfltJlilph 3, 13 I'lilCO the leal of th e car ovel ,1n inspection pit o. lilise il on ' ilmps O. fldo·stands. 1 4 D,sconnectlhe fucl pipes I,om the lu el accumul,110r and catch Ihe s

Fi U. 3.35 ConeCI 10Ciliion o f fuel filler oullel pipe (Sec 25)

A B Fuel "'ICf Ou/lelll'lle c Engine comporlmenl side p,wel

procarmanuals.com

Page 86 of 205

Chapter 3 Fuel and exhaust systems

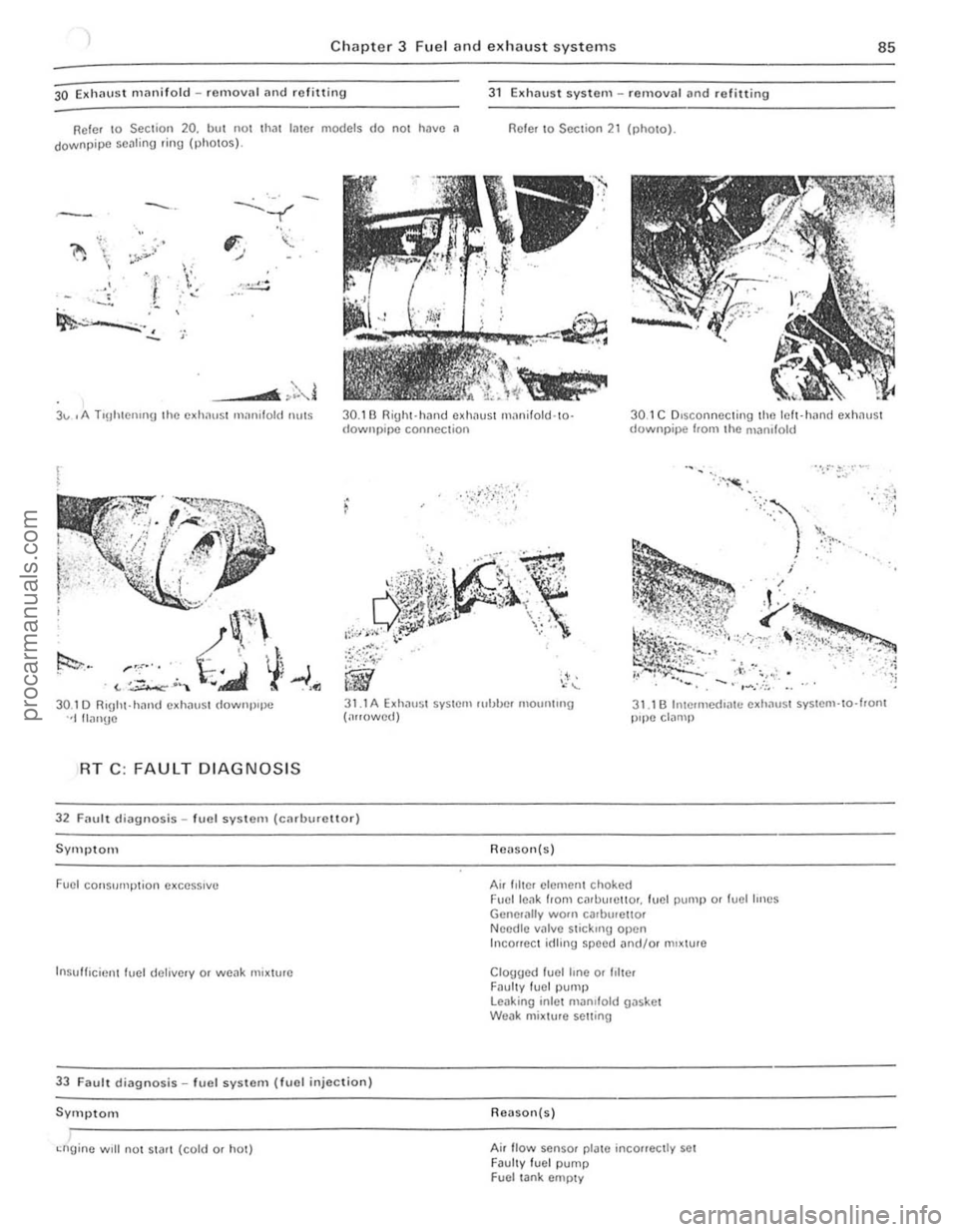

30 E~haust manifold -rOllloval nnd r e fitting

Rcle . \0 Section 20. but not that 1,11C' models do nOI have n downpipo scaling ring (photos)

~ ..

y

" ..:

';.

__ +.,,",l

31 E~haust system -removal and ro fitting

Reier to Section 21 (pholO).

85

3" ,A TI!Jhlenrrl!J Iho O~hilUSI mnnilold nuts 30.1 BRight hnnd e~hnust rn.1nilold ·todownpipc connection 30.1 C Dl sconnec tirrg the lell hnnd e~hnusl downp;,Je hom Ihe manIfOld

. ;/~}":"~"":'. ,

\"~'"

} ·':t-

i

31.1A hhnust system ,ubbe. mountIng (;,,,owed) 31.1 B Irnermed'ilttl oxhilu st system-to-honl pIpe clamp

RT C , FAULT D IAGNOSIS

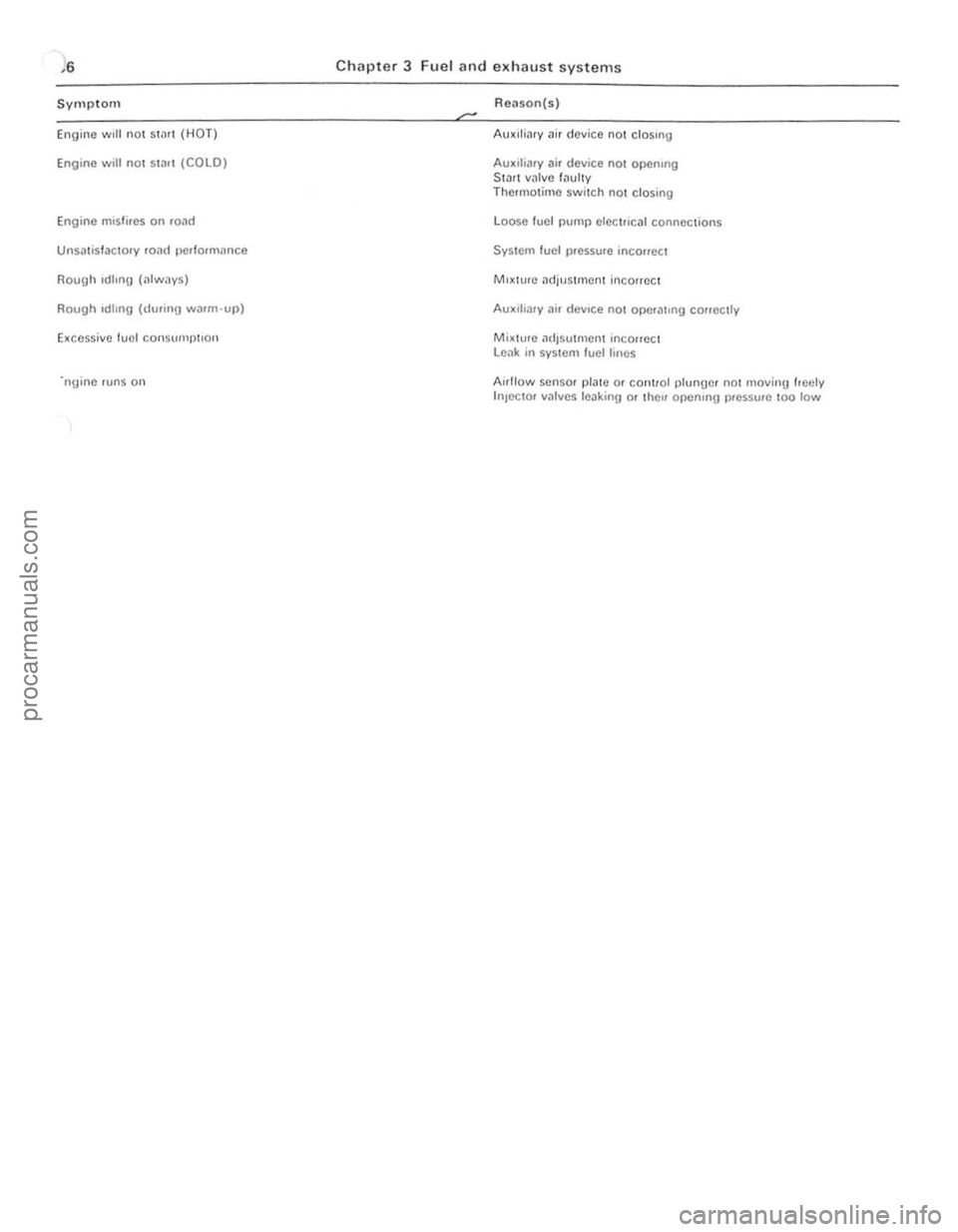

32 Fault diagnosis -fuel sys tem (CMuurottor)

Symptom

Fuel COlls!ll11ption e~cesslve

Insu llicienl fuel detrvery or weak mi~lure

33 Fault diagnosis -fuel system (fuol injection)

Symptom

~ngine will no t starl (cold 0' hot)

Reason(s)

Ai . 1,ltel clement choked Fuel lenk flom cmbulellor. fuel pump Of luellrlles Gene.ally waUl ca,bu,ettor Needle vnlve StickIng open Incorrec t idling speed

o. hiler

F

llason(s)

Ai. !tow sensa. plale incorroctly sel FauilY fu el pump Fuel lank omply

'J

----------------------------......

procarmanuals.com

Page 87 of 205

Symptom

Engine will nOt Slnr1 (HOT)

Engine will not stal! (COLO )

Engine mIsfires on rond

Unsatisfacto,y ,oad p edomlilnce

Rough Idling (ilIWilYS)

Rough rdllng (during warm -up)

Excessive fuel consumptIon

nglne fUns on

I

C hapte r 3 Fuel and exha ust systems

Reason(s)

AuxiT inry air device not clOSing

Auxilimy ai, dev ice nOl opening SImI villve filulty Thermotime switch nOt closing

L oose fuel pump elec trical connections

System fuel presswe incoflec!

M,xture adjustment incorrect

AUKlhilr y ili, deVIce nOt OllC,ahng cOflec tly

Mixture M1ts utment incolleci leak in system fuel lines

Airtlow sensor plate or cont/otplunger not moving "eely Injector villves leakinU or then OJ)Cnlng pressure too low

procarmanuals.com