lock FORD E SERIES 1997 4.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1997, Model line: E SERIES, Model: FORD E SERIES 1997 4.GPages: 192, PDF Size: 3.44 MB

Page 66 of 192

able to pull more belt out). If the

retractor is not locked, unbuckle

the belt and repeat steps two

through nine.

Check to make sure the child seat

is properly secured before each

use.

Installing a child safety seat at

the rear center seating position

with locking adjustable lap belt

1. Lengthen the lap belt. To

lengthen the belt, hold tongue so

that its bottom is perpendicular to

the direction of webbing while

sliding the tongue up the webbing.

2. Place the child safety seat in the

center seating position.

3. Route the tongue and webbing

through the child seat according to

the child seat manufacturer's

instructions.

4. Insert the belt tongue into the

proper buckle for the center

seating position until you hear a

snap and feel it latch. Make sure

the tongue is securely fastened to

the buckle by pulling on tongue.

5. Push down on the child seat

while pulling on the loose end of

the lap belt webbing to tighten the

belt.

6. Before placing the child into

child seat, forcibly tilt the child

seat from side-to-side and in

forward directions to ensure that

the seat is held securely in place.

If the child seat moves excessively,

eco_chils_seat_lap-belt

Seating and safety restraints

66

Page 77 of 192

Make sure the corresponding lights

illuminate briefly. If a light fails to

illuminate, have the vehicle

serviced.

²If the driver's safety belt is

fastened, the

light does not

illuminate.

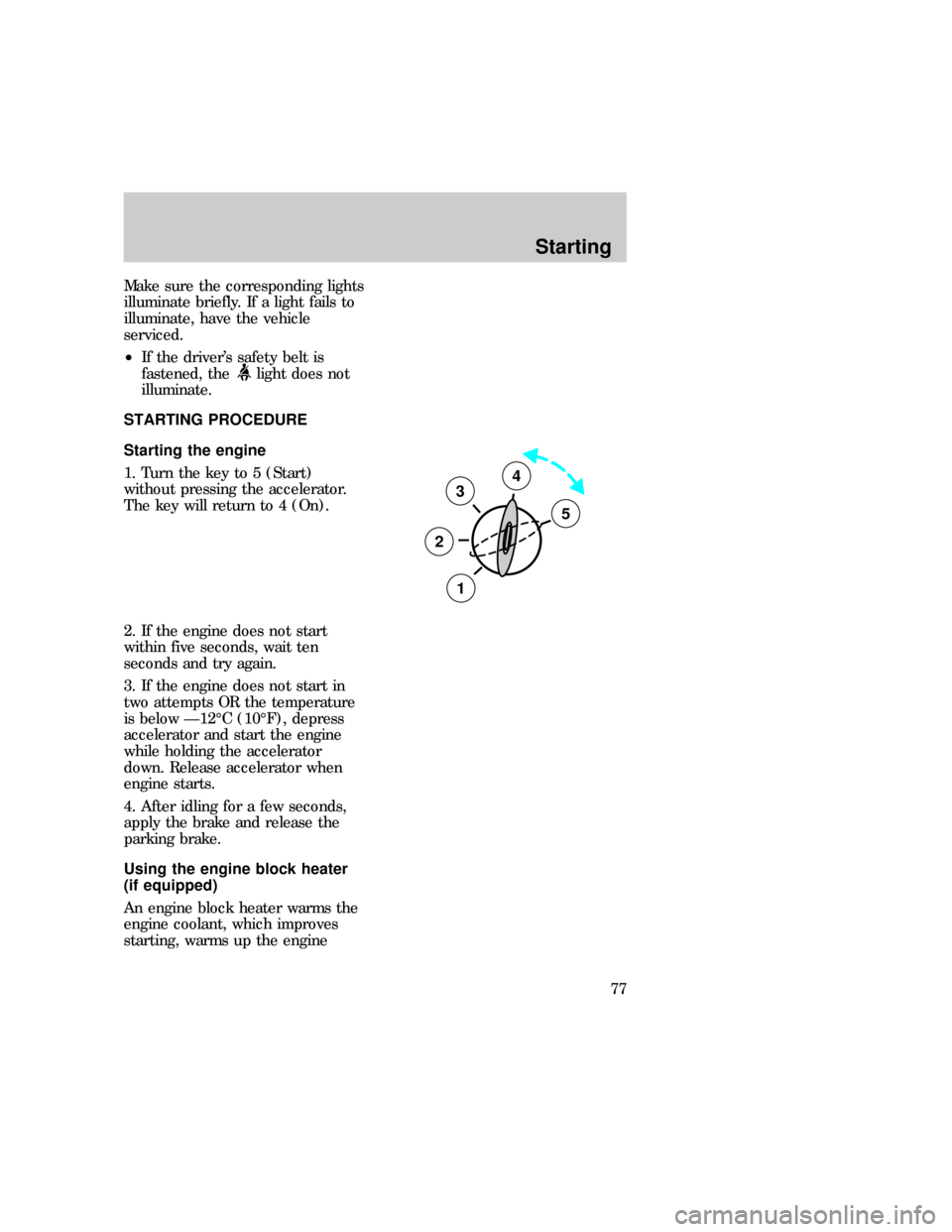

STARTING PROCEDURE

Starting the engine

1. Turn the key to 5 (Start)

without pressing the accelerator.

The key will return to 4 (On).

2. If the engine does not start

within five seconds, wait ten

seconds and try again.

3. If the engine does not start in

two attempts OR the temperature

is below Ð12ÉC (10ÉF), depress

accelerator and start the engine

while holding the accelerator

down. Release accelerator when

engine starts.

4. After idling for a few seconds,

apply the brake and release the

parking brake.

Using the engine block heater

(if equipped)

An engine block heater warms the

engine coolant, which improves

starting, warms up the engine

3

2

1

5

4

eco_start_title

com_starting_vehicle.01

com_engine_heater.01

Starting

77

Page 80 of 192

BRAKES

Your brakes are self-adjusting.

Refer to the ªService Guideº for

maintenance scheduling.

Anti-lock brake system (ABS) (if

equipped)

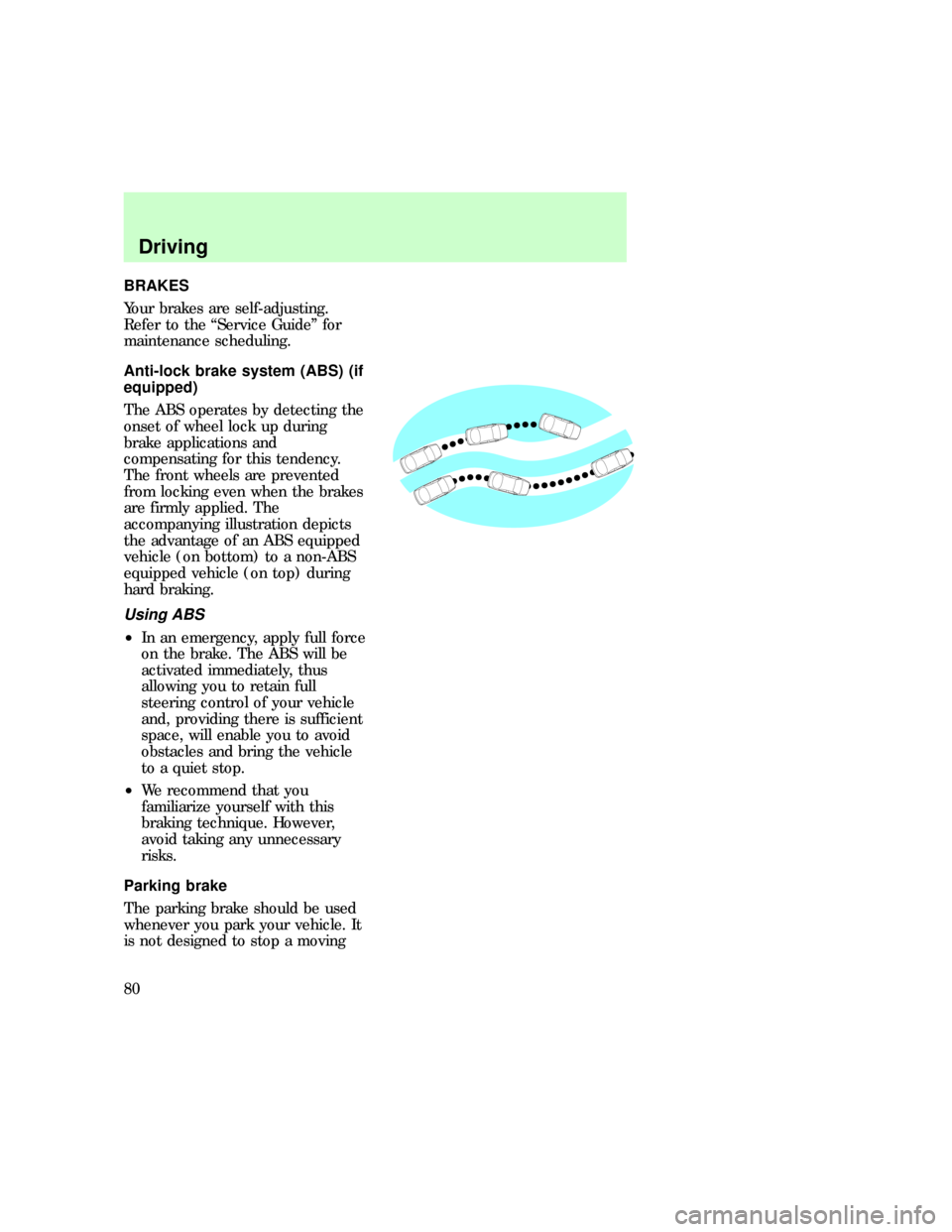

The ABS operates by detecting the

onset of wheel lock up during

brake applications and

compensating for this tendency.

The front wheels are prevented

from locking even when the brakes

are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during

hard braking.

Using ABS

²In an emergency, apply full force

on the brake. The ABS will be

activated immediately, thus

allowing you to retain full

steering control of your vehicle

and, providing there is sufficient

space, will enable you to avoid

obstacles and bring the vehicle

to a quiet stop.

²We recommend that you

familiarize yourself with this

braking technique. However,

avoid taking any unnecessary

risks.

Parking brake

The parking brake should be used

whenever you park your vehicle. It

is not designed to stop a moving

com_brakes.01

com_abs.01

com_using_abs.01

eco_parking_brake

Driving

80

Page 85 of 192

word ªOFFº) will no longer be

illuminated.

Each time the vehicle is started,

the transmission will automatically

return to normal overdrive mode

and you must press the TCS to

deactivate overdrive again if you

do not want overdrive operation.

2 (Second)Ð Use 2 (Second) to

start-up on slippery roads or to

provide additional engine braking

on downgrades. Transmission

operates in first and second gears.

1 (Low)Ð Use 1 (Low) to

provide maximum engine braking

on steep downgrades. Upshifts can

be made by shifting to 2 (Second)

or to

D(Overdrive). Selecting 1

(Low) at higher speeds causes a

shift to 2 (Second), and will shift

to 1 (Low) after vehicle

decelerates to the proper speed.

Brake-shift interlock

The brake-shift interlock feature

prevents you from shifting from P

(Park) unless the brake pedal is

depressed (with the ignition in the

ON position). If you cannot move

the gearshift out of P (Park) with

the brake pedal depressed:

1. Turn ignition key to Off.

2. Apply the parking brake.

3. Turn ignition key to Lock and

remove the key.

4. Re-insert the ignition key and

turn it to Off.

eco_brake_shift_inter-lock

Driving

85

Page 105 of 192

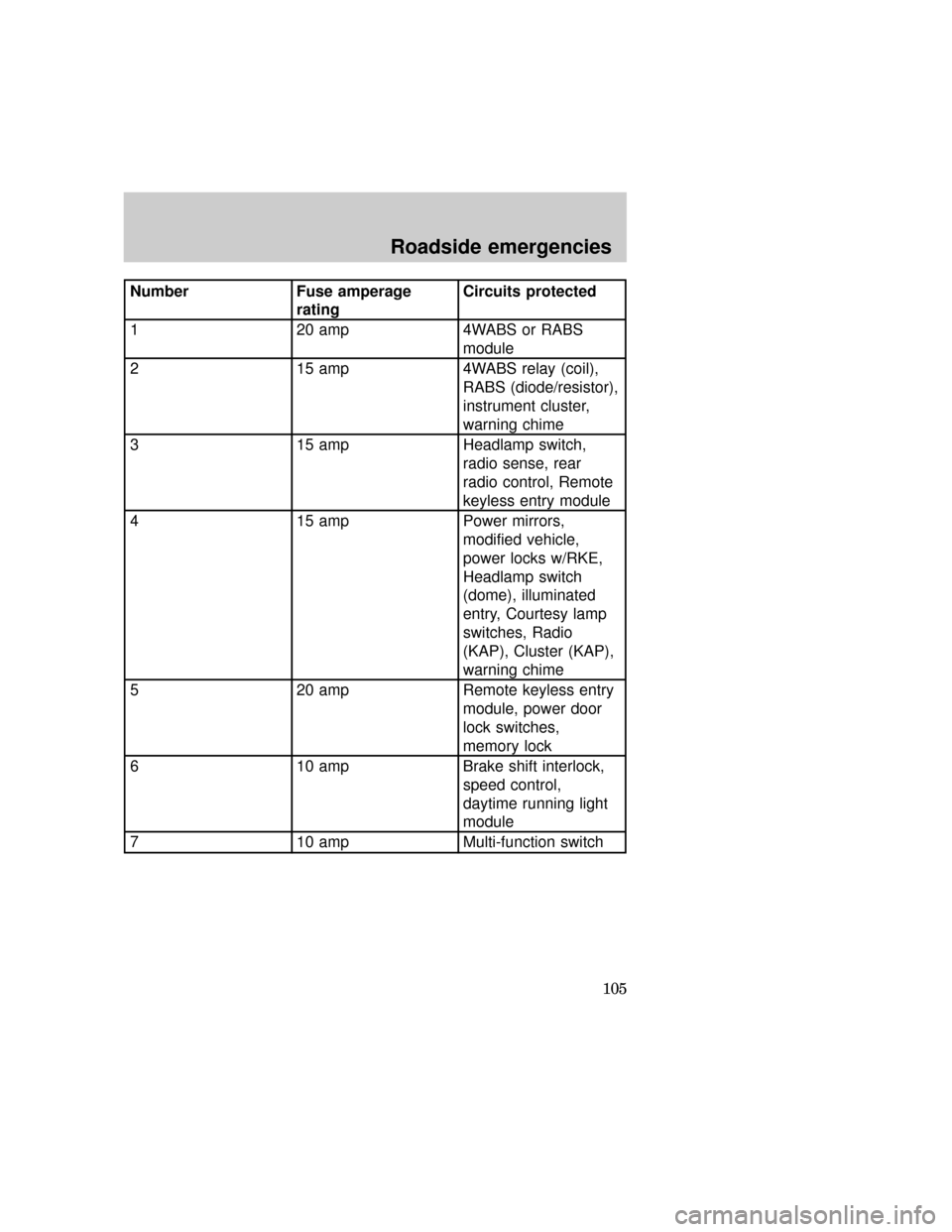

Number Fuse amperage

ratingCircuits protected

1 20 amp 4WABS or RABS

module

2 15 amp 4WABS relay (coil),

RABS (diode/resistor),

instrument cluster,

warning chime

3 15 amp Headlamp switch,

radio sense, rear

radio control, Remote

keyless entry module

4 15 amp Power mirrors,

modified vehicle,

power locks w/RKE,

Headlamp switch

(dome), illuminated

entry, Courtesy lamp

switches, Radio

(KAP), Cluster (KAP),

warning chime

5 20 amp Remote keyless entry

module, power door

lock switches,

memory lock

6 10 amp Brake shift interlock,

speed control,

daytime running light

module

7 10 amp Multi-function switch

Roadside emergencies

105

Page 109 of 192

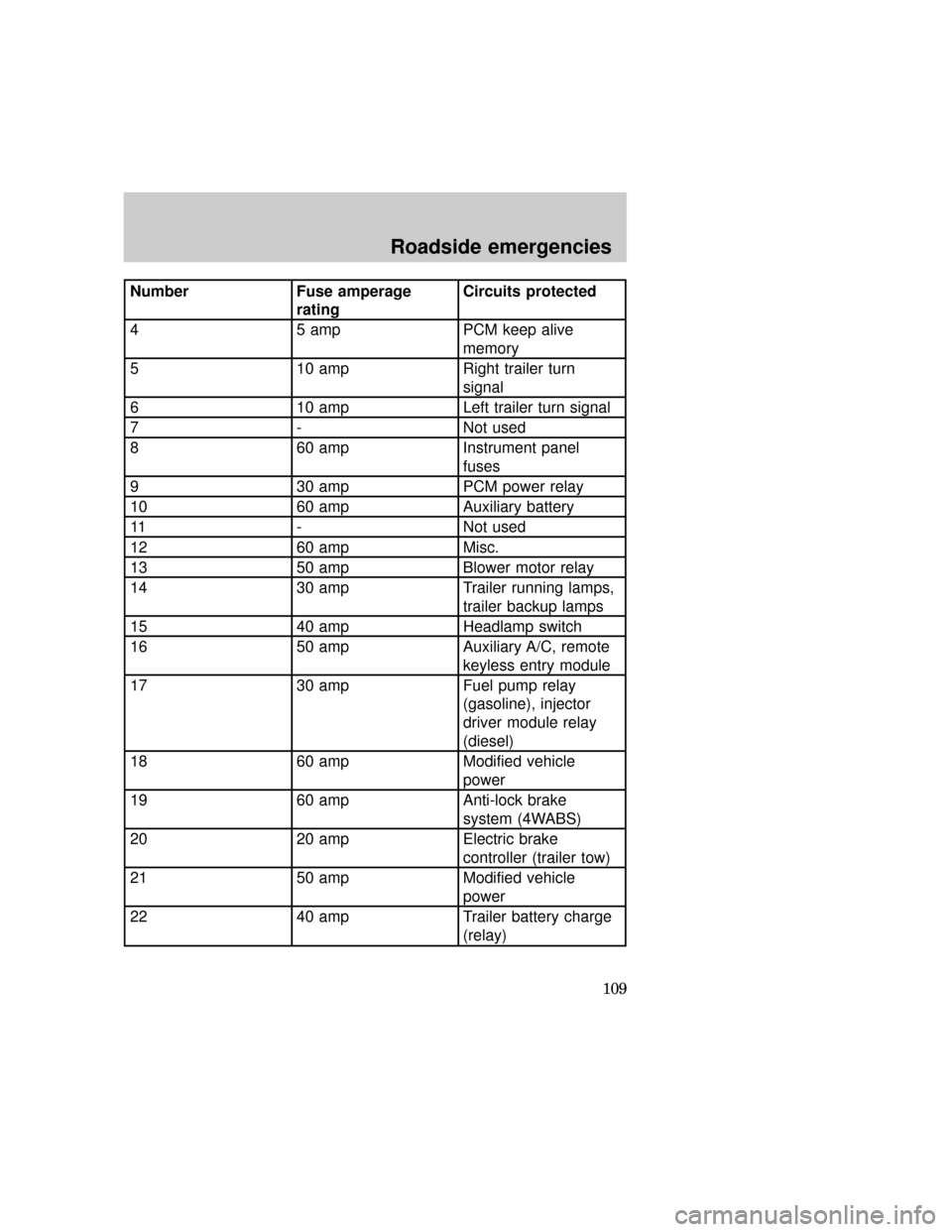

Number Fuse amperage

ratingCircuits protected

4 5 amp PCM keep alive

memory

5 10 amp Right trailer turn

signal

6 10 amp Left trailer turn signal

7 - Not used

8 60 amp Instrument panel

fuses

9 30 amp PCM power relay

10 60 amp Auxiliary battery

11 - Not used

12 60 amp Misc.

13 50 amp Blower motor relay

14 30 amp Trailer running lamps,

trailer backup lamps

15 40 amp Headlamp switch

16 50 amp Auxiliary A/C, remote

keyless entry module

17 30 amp Fuel pump relay

(gasoline), injector

driver module relay

(diesel)

18 60 amp Modified vehicle

power

19 60 amp Anti-lock brake

system (4WABS)

20 20 amp Electric brake

controller (trailer tow)

21 50 amp Modified vehicle

power

22 40 amp Trailer battery charge

(relay)

Roadside emergencies

109

Page 113 of 192

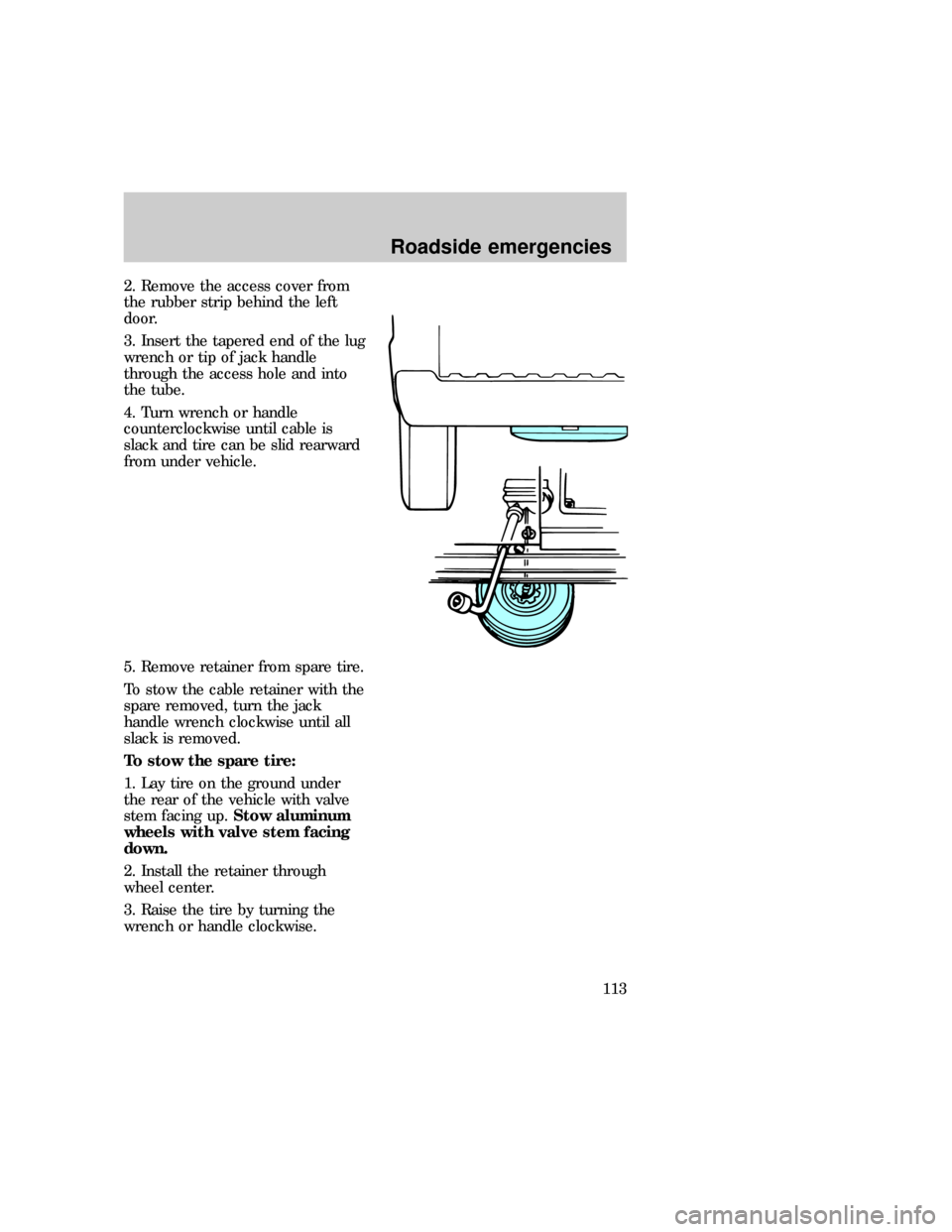

2. Remove the access cover from

the rubber strip behind the left

door.

3. Insert the tapered end of the lug

wrench or tip of jack handle

through the access hole and into

the tube.

4. Turn wrench or handle

counterclockwise until cable is

slack and tire can be slid rearward

from under vehicle.

5. Remove retainer from spare tire.

To stow the cable retainer with the

spare removed, turn the jack

handle wrench clockwise until all

slack is removed.

To stow the spare tire:

1. Lay tire on the ground under

the rear of the vehicle with valve

stem facing up.Stow aluminum

wheels with valve stem facing

down.

2. Install the retainer through

wheel center.

3. Raise the tire by turning the

wrench or handle clockwise.

Roadside emergencies

113

Page 115 of 192

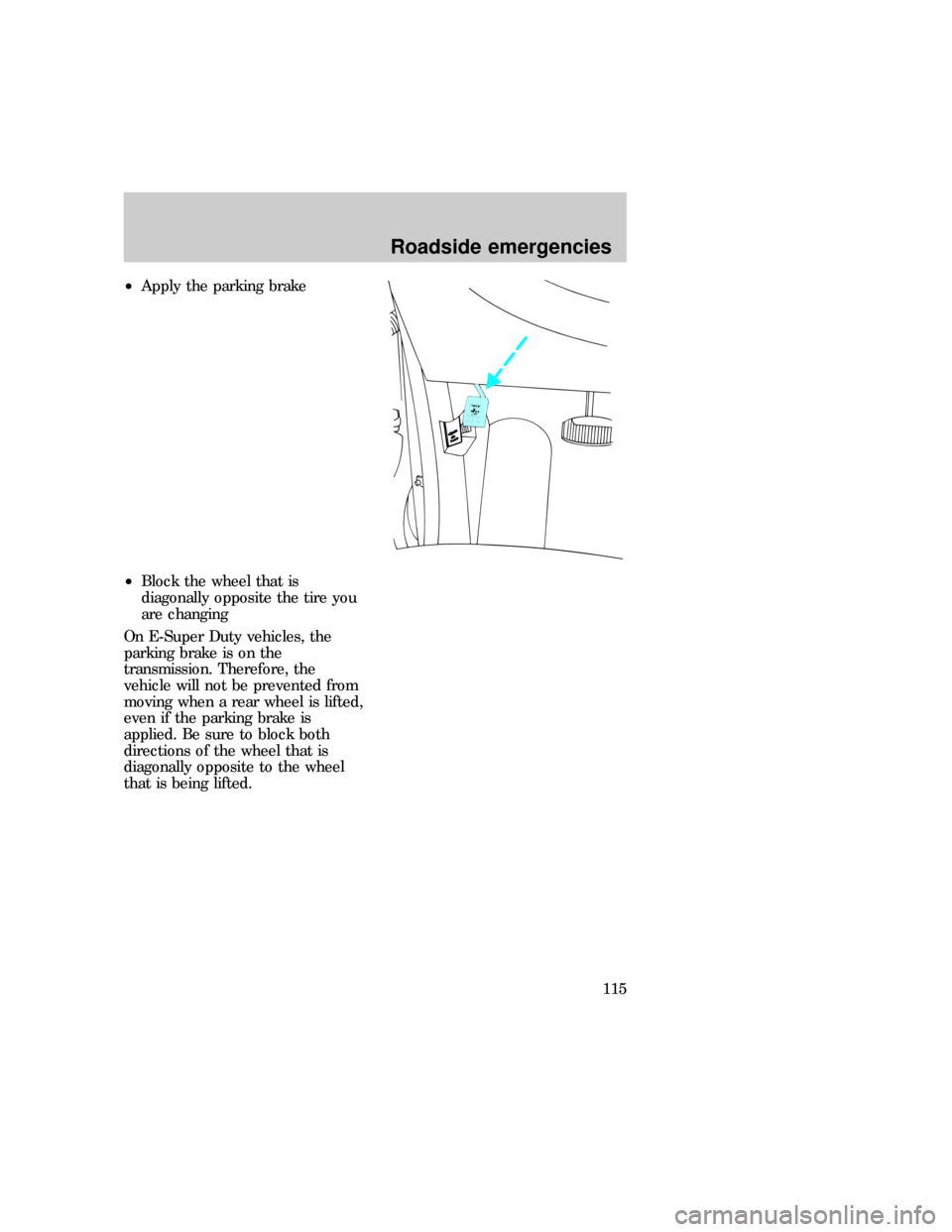

²Apply the parking brake

²Block the wheel that is

diagonally opposite the tire you

are changing

On E-Super Duty vehicles, the

parking brake is on the

transmission. Therefore, the

vehicle will not be prevented from

moving when a rear wheel is lifted,

even if the parking brake is

applied. Be sure to block both

directions of the wheel that is

diagonally opposite to the wheel

that is being lifted.

Roadside emergencies

115

Page 116 of 192

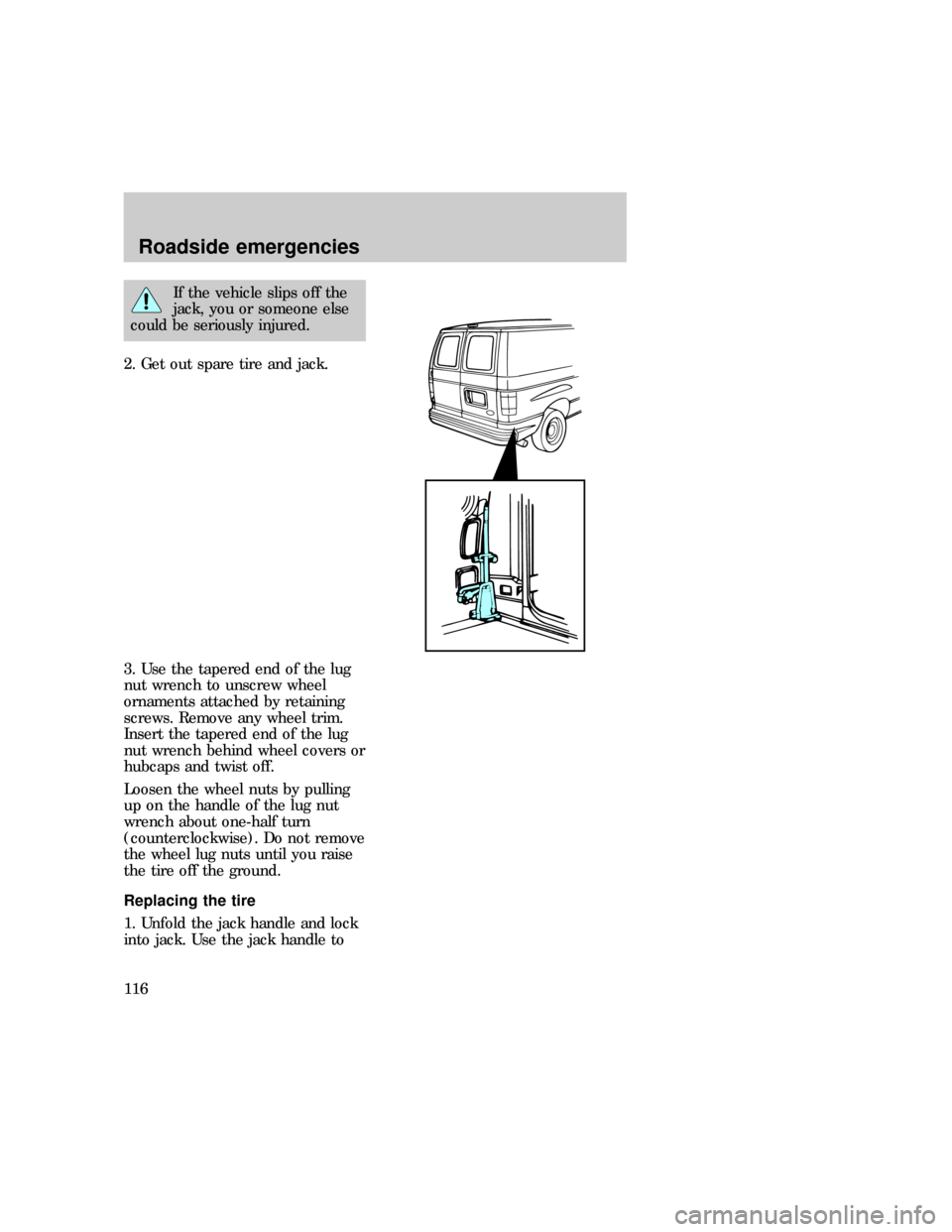

If the vehicle slips off the

jack, you or someone else

could be seriously injured.

2. Get out spare tire and jack.

3. Use the tapered end of the lug

nut wrench to unscrew wheel

ornaments attached by retaining

screws. Remove any wheel trim.

Insert the tapered end of the lug

nut wrench behind wheel covers or

hubcaps and twist off.

Loosen the wheel nuts by pulling

up on the handle of the lug nut

wrench about one-half turn

(counterclockwise). Do not remove

the wheel lug nuts until you raise

the tire off the ground.

Replacing the tire

1. Unfold the jack handle and lock

into jack. Use the jack handle to

eco_changing-tire

Roadside emergencies

116

Page 118 of 192

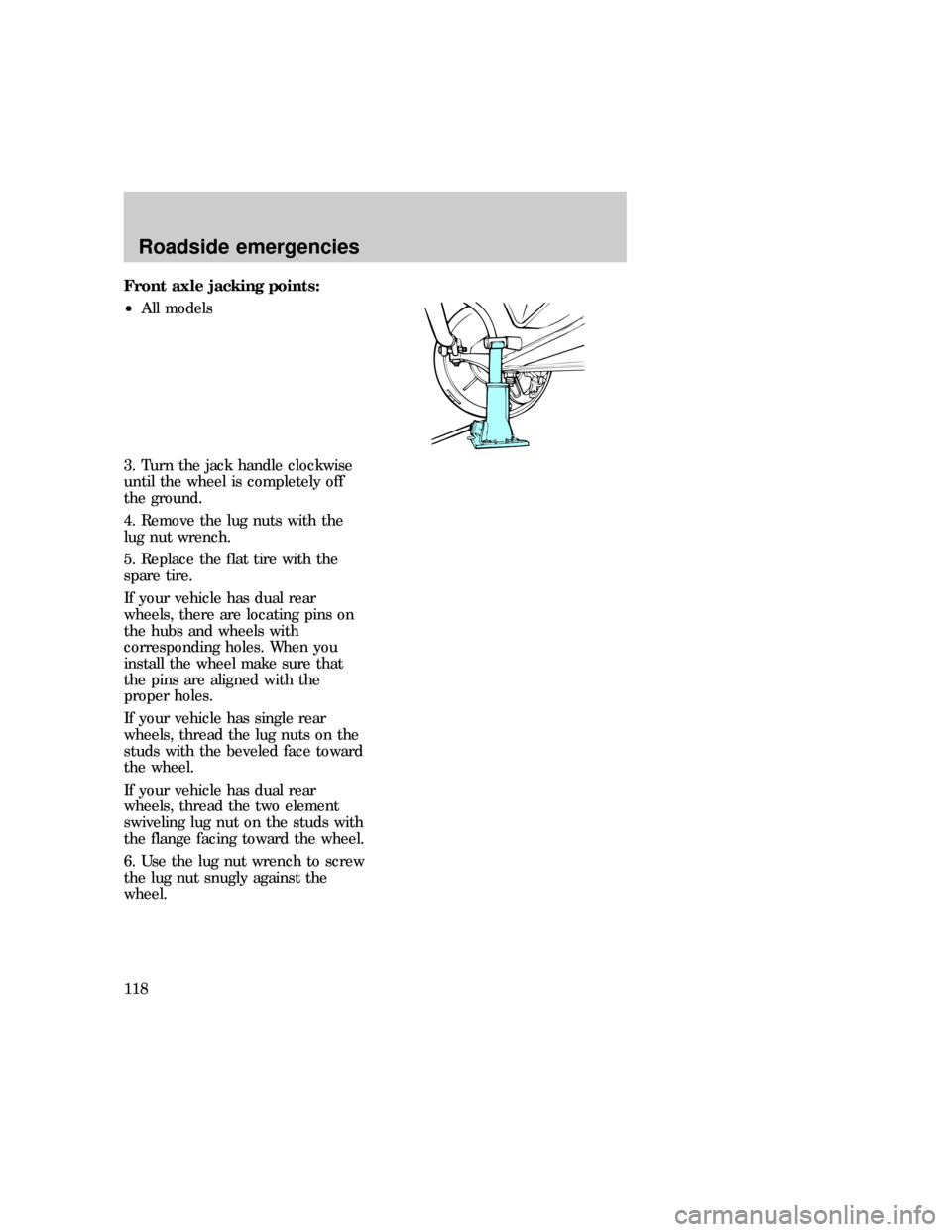

Front axle jacking points:

²All models

3. Turn the jack handle clockwise

until the wheel is completely off

the ground.

4. Remove the lug nuts with the

lug nut wrench.

5. Replace the flat tire with the

spare tire.

If your vehicle has dual rear

wheels, there are locating pins on

the hubs and wheels with

corresponding holes. When you

install the wheel make sure that

the pins are aligned with the

proper holes.

If your vehicle has single rear

wheels, thread the lug nuts on the

studs with the beveled face toward

the wheel.

If your vehicle has dual rear

wheels, thread the two element

swiveling lug nut on the studs with

the flange facing toward the wheel.

6. Use the lug nut wrench to screw

the lug nut snugly against the

wheel.

Roadside emergencies

118