engine FORD E SERIES 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1998, Model line: E SERIES, Model: FORD E SERIES 1998 4.GPages: 144, PDF Size: 2.14 MB

Page 74 of 144

Your vehicle's load capacity is designated by weight, not by volume, so

you cannot necessarily use all available space when loading a vehicle.

Distribute the load so that only 10 to 15% of the total is on the tongue.

Tie down the load so that it does not shift and change the weight on the

hitch.

Towing a trailer places an additional load on your vehicle's engine,

transmission, axle, brakes, tires and suspension. Inspect these

components carefully after any towing operation.

Do not exceed the GVWR or the GAWR specified on the Safety

Compliance Certification Label.

Towing trailers beyond the maximum recommended gross trailer

weight could result in engine damage, transmission/axle damage,

structural damage, loss of control, and personal injury.

Preparing to tow

Use the proper equipment for towing a trailer, and make sure it is

properly attached to your vehicle. See your dealer or a reliable trailer

dealer if you require assistance.

Hitches

Do not use or install hitches that clamp onto the bumper or to the axle.

Underbody hitches are acceptable if installed properly.

Safety chains

Always connect the trailer's safety chains to the vehicle. To connect the

trailer's safety chains, cross the chains under the trailer tongue and allow

slack for turning corners.

If you use a rental trailer, follow the instructions that the rental agency

gives to you.

Trailer brakes

Electric brakes and manual, automatic or surge-type brakes are safe if

installed properly and adjusted to the manufacturer's specifications. The

trailer brakes must meet local and Federal regulations.

Do not connect a trailer's hydraulic brake system directly to your

vehicle's brake system. Your vehicle may not have enough

braking power and your chances of having a collision greatly increase.

Driving

74

Page 75 of 144

The braking system of the tow vehicle is rated for operation at the

GVWR not GCWR.

Trailer lamps

Trailer lamps are required on most towed vehicles. Make sure your

trailer lamps conform to local and Federal regulations. See your dealer or

trailer rental agency for proper instructions and equipment for hooking

up trailer lamps.

Using a step bumper

The rear bumper is equipped with an integral hitch and requires only a

ball with a 25.4 mm (one inch) shank diameter. The bumper hasa2270

kg (5 000 lb.) trailer weight and 227 kg (500 lb.) tongue weight

capability.

If it is necessary to relocate the trailer hitch ball position, a

frame-mounted trailer hitch must be installed.

Driving while you tow

Do not drive faster than 88 km/h (55 mph) when towing a trailer. Do not

drive faster than 72 km/h (45 mph) with any weight on the trailer while

towing on a hot day or in hilly country.

Speed control may shut off if you are towing on long, steep grades.

When towing a trailer:

²Use D (Drive) or a lower gear when towing up or down steep hills.

This will eliminate excessive downshifting and upshifting for optimum

fuel economy and transmission cooling.

²Anticipate stops and brake gradually.

When descending long, steep downhill grades, always use a lower gear to

provide engine braking to save wear on brakes. Use Drive (Overdrive

OFF) on moderately steep hills, Second (2) on steep hills, and First (1)

on very steep hills.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to the Severe Duty Schedule in your

ªService Guideº for more information.

Driving

75

Page 76 of 144

Trailer towing tips

²Practice turning, stopping and backing up in an area before starting on

a trip to get the feel of the vehicle trailer combination. When turning,

make wider turns so the trailer wheels will clear curbs and other

obstacles.

²Allow more distance for stopping with a trailer attached.

²The trailer tongue weight should be 10±15% of the loaded trailer

weight.

²After you have traveled 80 km (50 miles), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

²When stopped in traffic for long periods of time in hot weather, place

the gearshift in P (Park) and increase idle speed. This aids engine

cooling and air conditioner efficiency.

²Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer's wheels.

Launching or retrieving a boat

When backing down a ramp during boat launching or retrieval,

²Do not allow the static water level to rise above the bottom edge of

the rear bumper and

²Do not allow waves to break higher than 15 cm (six inches) above the

bottom edge of the rear bumper.

Exceeding these limits may allow water to enter critical vehicle

components, adversely affecting driveability, emissions and reliability.

If the rear axle is submerged in water, the rear axle lubricant should be

changed. Axle lubricant quantities are not to be checked unless a leak is

suspected.

FUEL CONSUMPTION

Fuel economy can be improved by avoiding:

²lack of regular, scheduled maintenance.

²excessive speed.

²rapid acceleration.

²extended idle.

Driving

76

Page 77 of 144

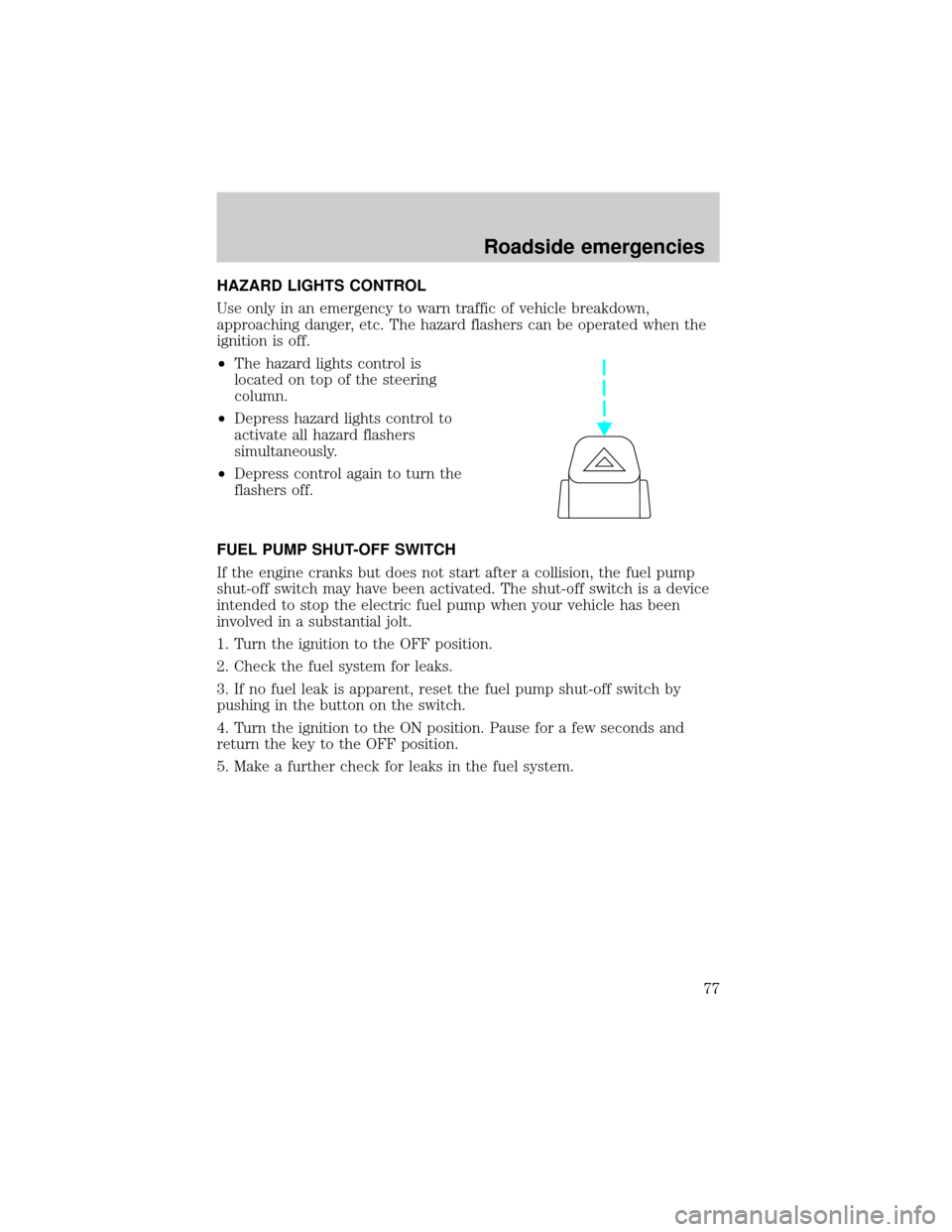

HAZARD LIGHTS CONTROL

Use only in an emergency to warn traffic of vehicle breakdown,

approaching danger, etc. The hazard flashers can be operated when the

ignition is off.

²The hazard lights control is

located on top of the steering

column.

²Depress hazard lights control to

activate all hazard flashers

simultaneously.

²Depress control again to turn the

flashers off.

FUEL PUMP SHUT-OFF SWITCH

If the engine cranks but does not start after a collision, the fuel pump

shut-off switch may have been activated. The shut-off switch is a device

intended to stop the electric fuel pump when your vehicle has been

involved in a substantial jolt.

1. Turn the ignition to the OFF position.

2. Check the fuel system for leaks.

3. If no fuel leak is apparent, reset the fuel pump shut-off switch by

pushing in the button on the switch.

4. Turn the ignition to the ON position. Pause for a few seconds and

return the key to the OFF position.

5. Make a further check for leaks in the fuel system.

Roadside emergencies

77

Page 82 of 144

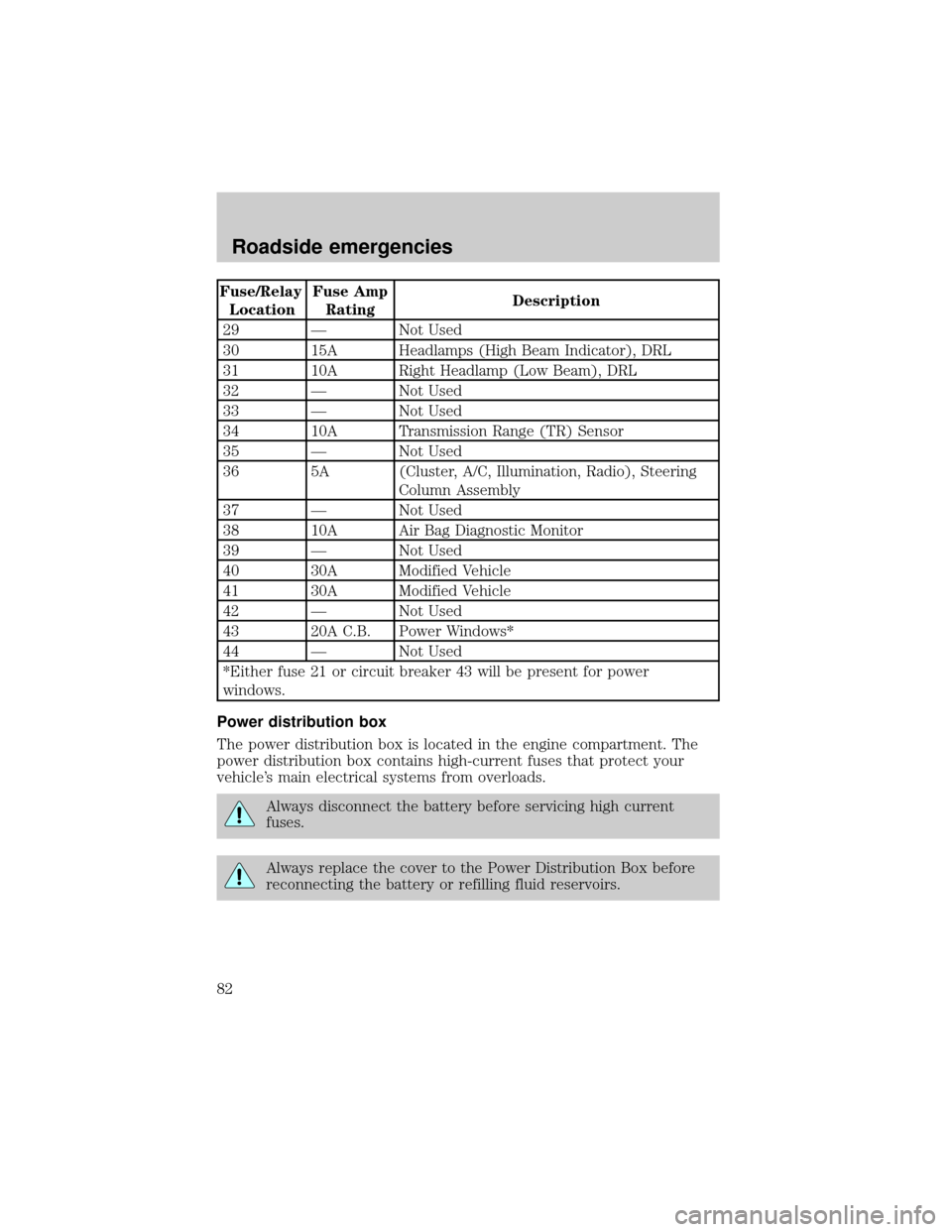

Fuse/Relay

LocationFuse Amp

RatingDescription

29 Ð Not Used

30 15A Headlamps (High Beam Indicator), DRL

31 10A Right Headlamp (Low Beam), DRL

32 Ð Not Used

33 Ð Not Used

34 10A Transmission Range (TR) Sensor

35 Ð Not Used

36 5A (Cluster, A/C, Illumination, Radio), Steering

Column Assembly

37 Ð Not Used

38 10A Air Bag Diagnostic Monitor

39 Ð Not Used

40 30A Modified Vehicle

41 30A Modified Vehicle

42 Ð Not Used

43 20A C.B. Power Windows*

44 Ð Not Used

*Either fuse 21 or circuit breaker 43 will be present for power

windows.

Power distribution box

The power distribution box is located in the engine compartment. The

power distribution box contains high-current fuses that protect your

vehicle's main electrical systems from overloads.

Always disconnect the battery before servicing high current

fuses.

Always replace the cover to the Power Distribution Box before

reconnecting the battery or refilling fluid reservoirs.

Roadside emergencies

82

Page 83 of 144

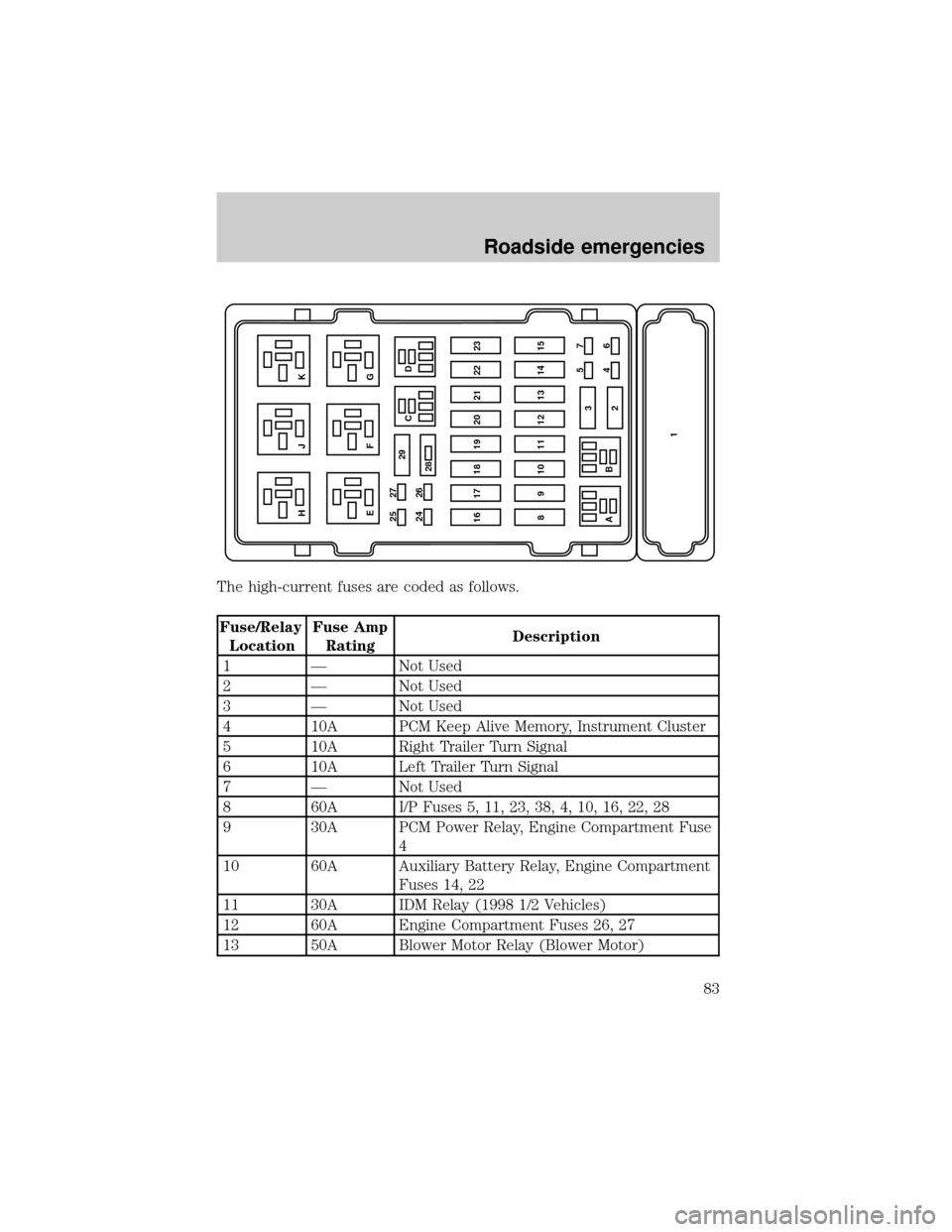

The high-current fuses are coded as follows.

Fuse/Relay

LocationFuse Amp

RatingDescription

1 Ð Not Used

2 Ð Not Used

3 Ð Not Used

4 10A PCM Keep Alive Memory, Instrument Cluster

5 10A Right Trailer Turn Signal

6 10A Left Trailer Turn Signal

7 Ð Not Used

8 60A I/P Fuses 5, 11, 23, 38, 4, 10, 16, 22, 28

9 30A PCM Power Relay, Engine Compartment Fuse

4

10 60A Auxiliary Battery Relay, Engine Compartment

Fuses 14, 22

11 30A IDM Relay (1998 1/2 Vehicles)

12 60A Engine Compartment Fuses 26, 27

13 50A Blower Motor Relay (Blower Motor)

AB3

2

146 5715 14 13 12 11 10 9 823 22 21 20 19 18 17 1624 26 25 27

29

CDG F EK J H

28

Roadside emergencies

83

Page 86 of 144

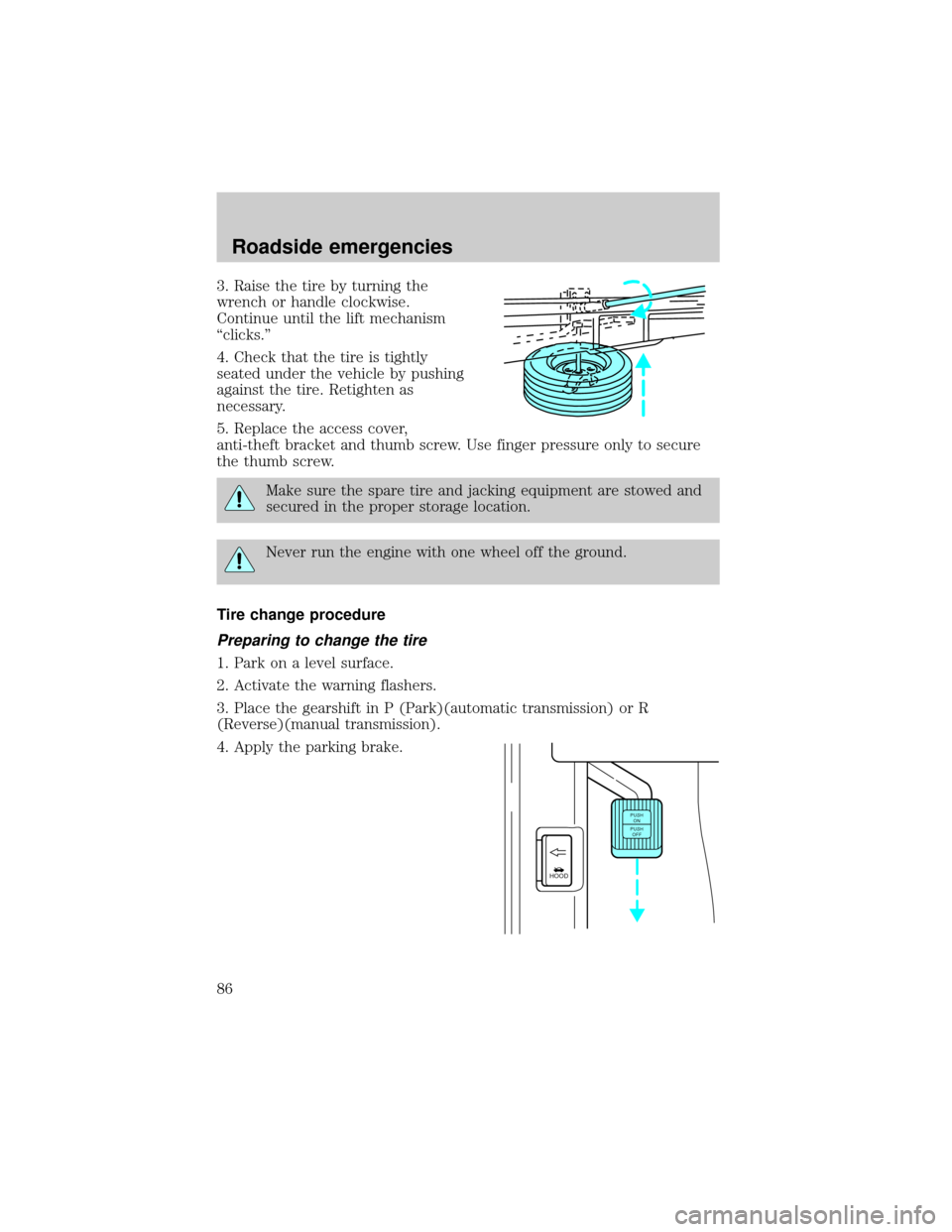

3. Raise the tire by turning the

wrench or handle clockwise.

Continue until the lift mechanism

ªclicks.º

4. Check that the tire is tightly

seated under the vehicle by pushing

against the tire. Retighten as

necessary.

5. Replace the access cover,

anti-theft bracket and thumb screw. Use finger pressure only to secure

the thumb screw.

Make sure the spare tire and jacking equipment are stowed and

secured in the proper storage location.

Never run the engine with one wheel off the ground.

Tire change procedure

Preparing to change the tire

1. Park on a level surface.

2. Activate the warning flashers.

3. Place the gearshift in P (Park)(automatic transmission) or R

(Reverse)(manual transmission).

4. Apply the parking brake.

HOOD

PUSH

ON

PUSH

OFF

Roadside emergencies

86

Page 88 of 144

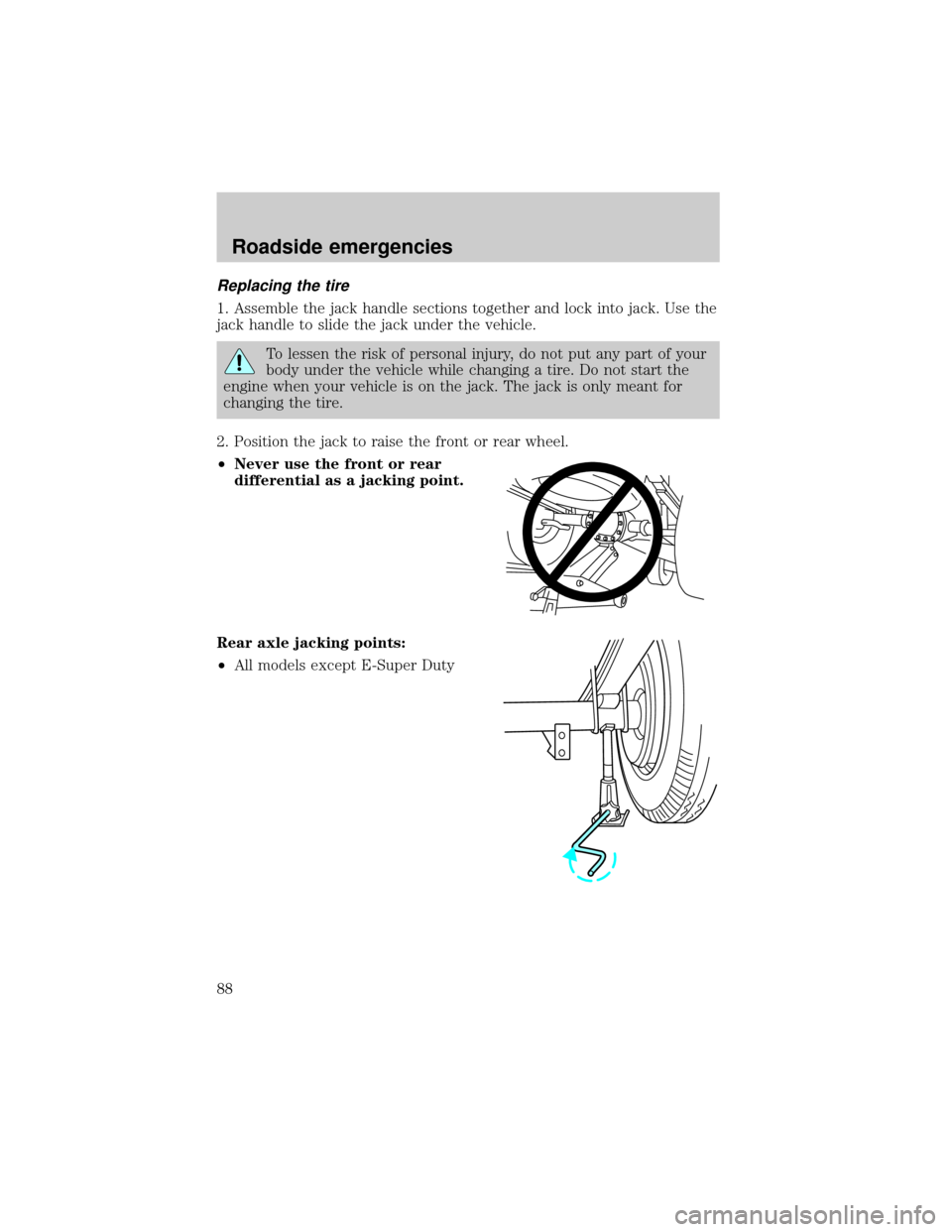

Replacing the tire

1. Assemble the jack handle sections together and lock into jack. Use the

jack handle to slide the jack under the vehicle.

To lessen the risk of personal injury, do not put any part of your

body under the vehicle while changing a tire. Do not start the

engine when your vehicle is on the jack. The jack is only meant for

changing the tire.

2. Position the jack to raise the front or rear wheel.

²Never use the front or rear

differential as a jacking point.

Rear axle jacking points:

²All models except E-Super Duty

Roadside emergencies

88

Page 91 of 144

Model Bolt Size Wheel Lug nut Torque*

N²M Ft-Lb

E-150 1/2-20 135 100

E-250, E-350 and

E-Super Duty9/16-18 190 140

* Torque specifications are for nut and bolt threads free of dirt and

rust. Do not use oil or grease on threads. Use only Ford recommended

replacement fasteners.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Do not push start your vehicle. You could damage the catalytic

converter.

Batteries contain sulfuric acid which burns skin, eyes, and

clothing.

Preparing your vehicle

Also see the label on the battery.

1. Use only a 12±volt supply to start your vehicle. If you connect your

battery to a 24±volt power supply you can damage your starter, ignition

system and other electrical components.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle's electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure theydo nottouch. Set the parking brake on both vehicles

and stay clear of the engine cooling fan and other moving parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

Roadside emergencies

91

Page 92 of 144

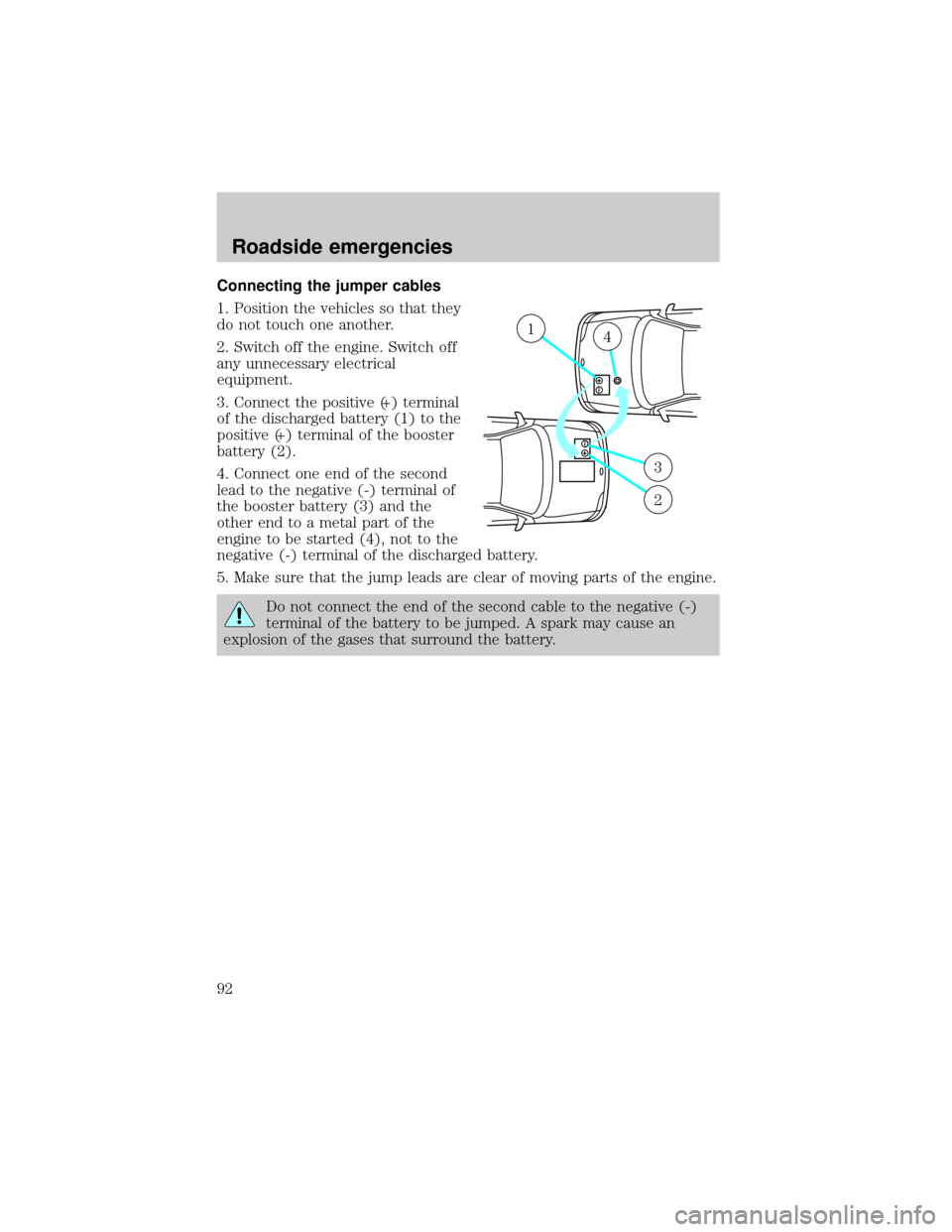

Connecting the jumper cables

1. Position the vehicles so that they

do not touch one another.

2. Switch off the engine. Switch off

any unnecessary electrical

equipment.

3. Connect the positive (+) terminal

of the discharged battery (1) to the

positive (+) terminal of the booster

battery (2).

4. Connect one end of the second

lead to the negative (-) terminal of

the booster battery (3) and the

other end to a metal part of the

engine to be started (4), not to the

negative (-) terminal of the discharged battery.

5. Make sure that the jump leads are clear of moving parts of the engine.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

+–

+–

14

3

2

Roadside emergencies

92