lock FORD E SERIES 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1998, Model line: E SERIES, Model: FORD E SERIES 1998 4.GPages: 144, PDF Size: 2.14 MB

Page 61 of 144

Make sure the corresponding lights illuminate briefly. If a light fails to

illuminate, have the vehicle serviced.

²If the driver's safety belt is fastened, the light (

) will not illuminate.

STARTING THE ENGINE

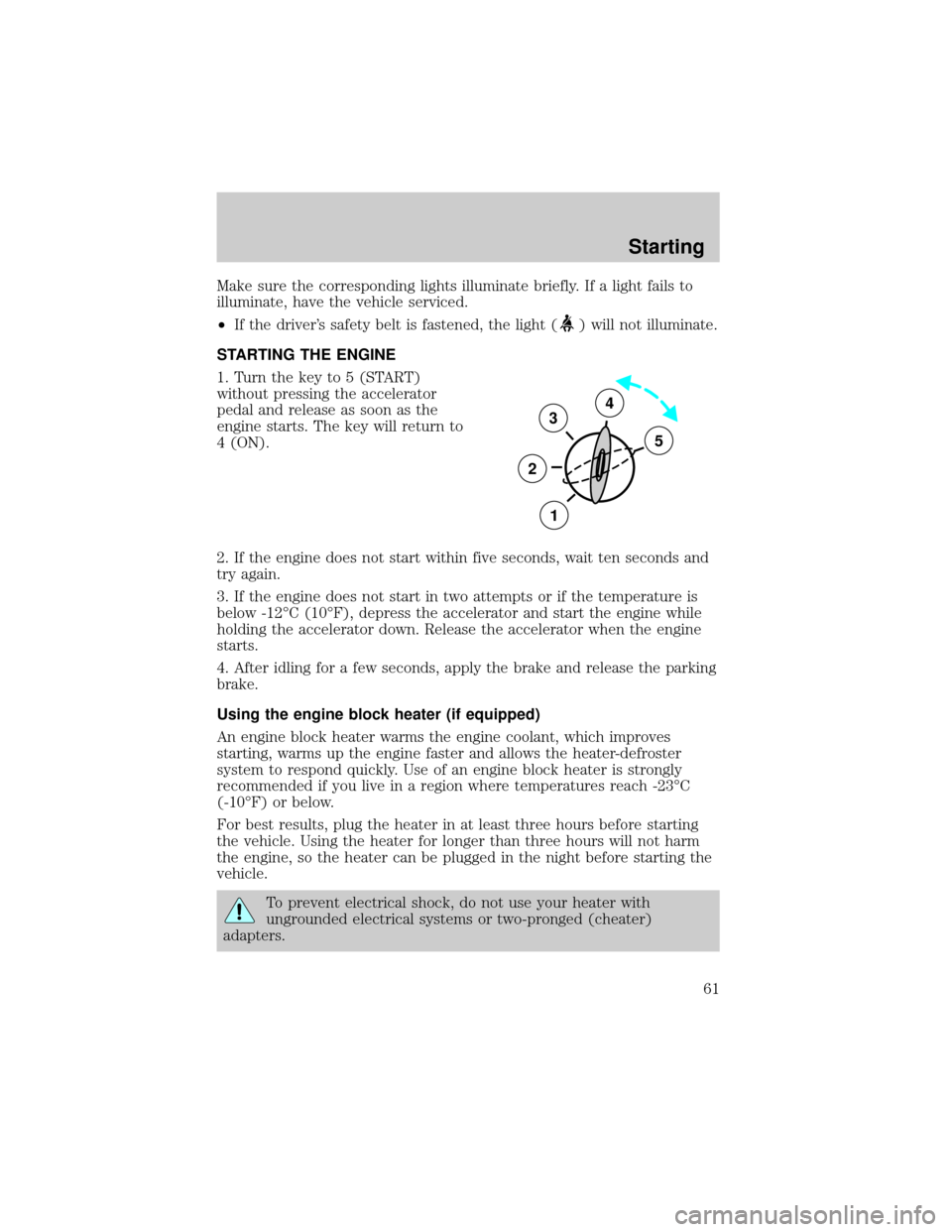

1. Turn the key to 5 (START)

without pressing the accelerator

pedal and release as soon as the

engine starts. The key will return to

4 (ON).

2. If the engine does not start within five seconds, wait ten seconds and

try again.

3. If the engine does not start in two attempts or if the temperature is

below -12ÉC (10ÉF), depress the accelerator and start the engine while

holding the accelerator down. Release the accelerator when the engine

starts.

4. After idling for a few seconds, apply the brake and release the parking

brake.

Using the engine block heater (if equipped)

An engine block heater warms the engine coolant, which improves

starting, warms up the engine faster and allows the heater-defroster

system to respond quickly. Use of an engine block heater is strongly

recommended if you live in a region where temperatures reach -23ÉC

(-10ÉF) or below.

For best results, plug the heater in at least three hours before starting

the vehicle. Using the heater for longer than three hours will not harm

the engine, so the heater can be plugged in the night before starting the

vehicle.

To prevent electrical shock, do not use your heater with

ungrounded electrical systems or two-pronged (cheater)

adapters.

3

2

1

5

4

Starting

61

Page 63 of 144

BRAKES

Your brakes are self-adjusting. Refer to the ªService Guideº for scheduled

maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Anti-lock brake system (ABS) (if equipped)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. If the vehicle has continuous vibration or shudder

while braking, felt mainly in the steering wheel, the vehicle most likely

needs service.

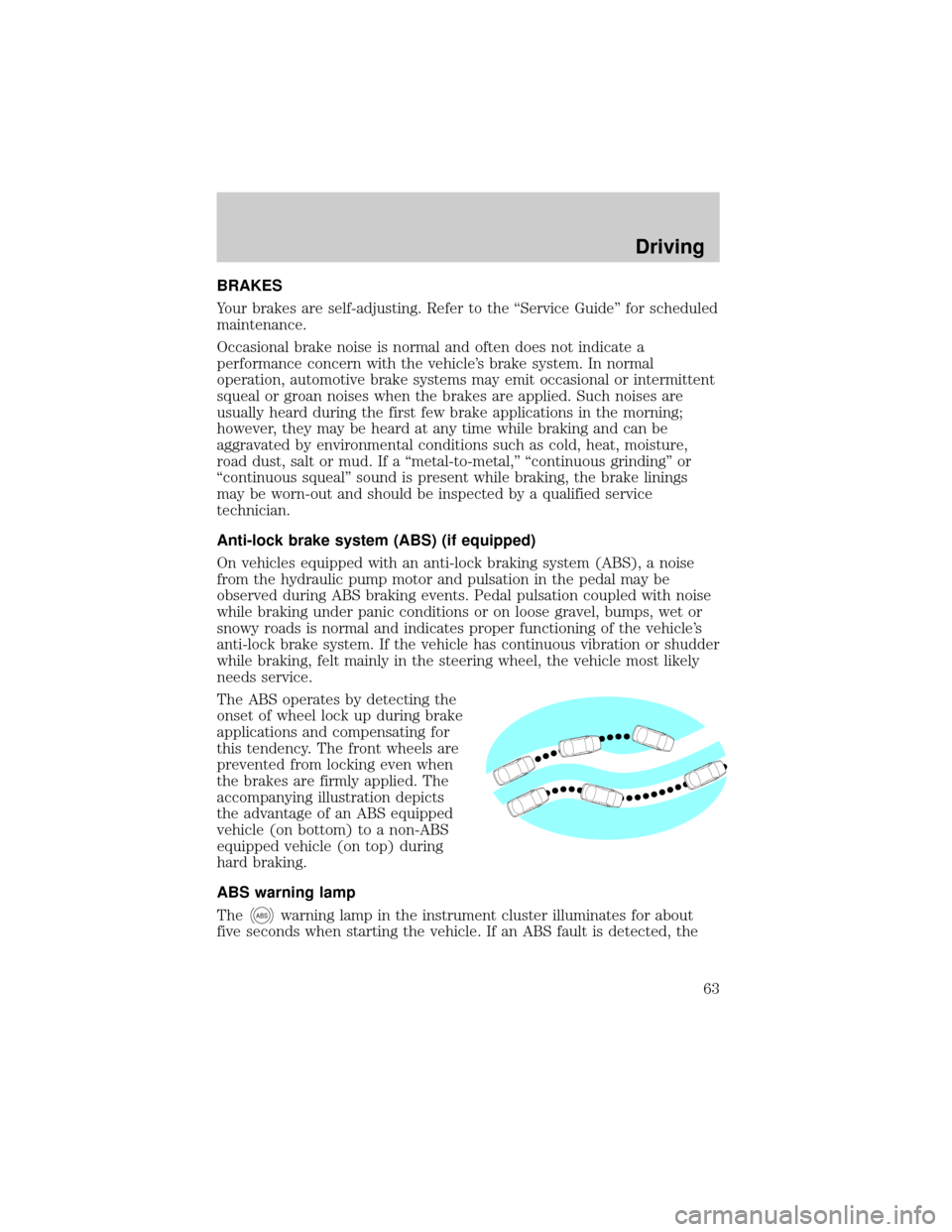

The ABS operates by detecting the

onset of wheel lock up during brake

applications and compensating for

this tendency. The front wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during

hard braking.

ABS warning lamp

The

ABSwarning lamp in the instrument cluster illuminates for about

five seconds when starting the vehicle. If an ABS fault is detected, the

Driving

63

Page 65 of 144

The parking brake is not designed to stop a moving vehicle. However, if

the normal brakes fail, the parking brake can be used to stop your

vehicle in an emergency. Since the parking brake applies only the rear

brakes, the vehicle's stopping distance will increase greatly and the

handling of your vehicle will be adversely affected.

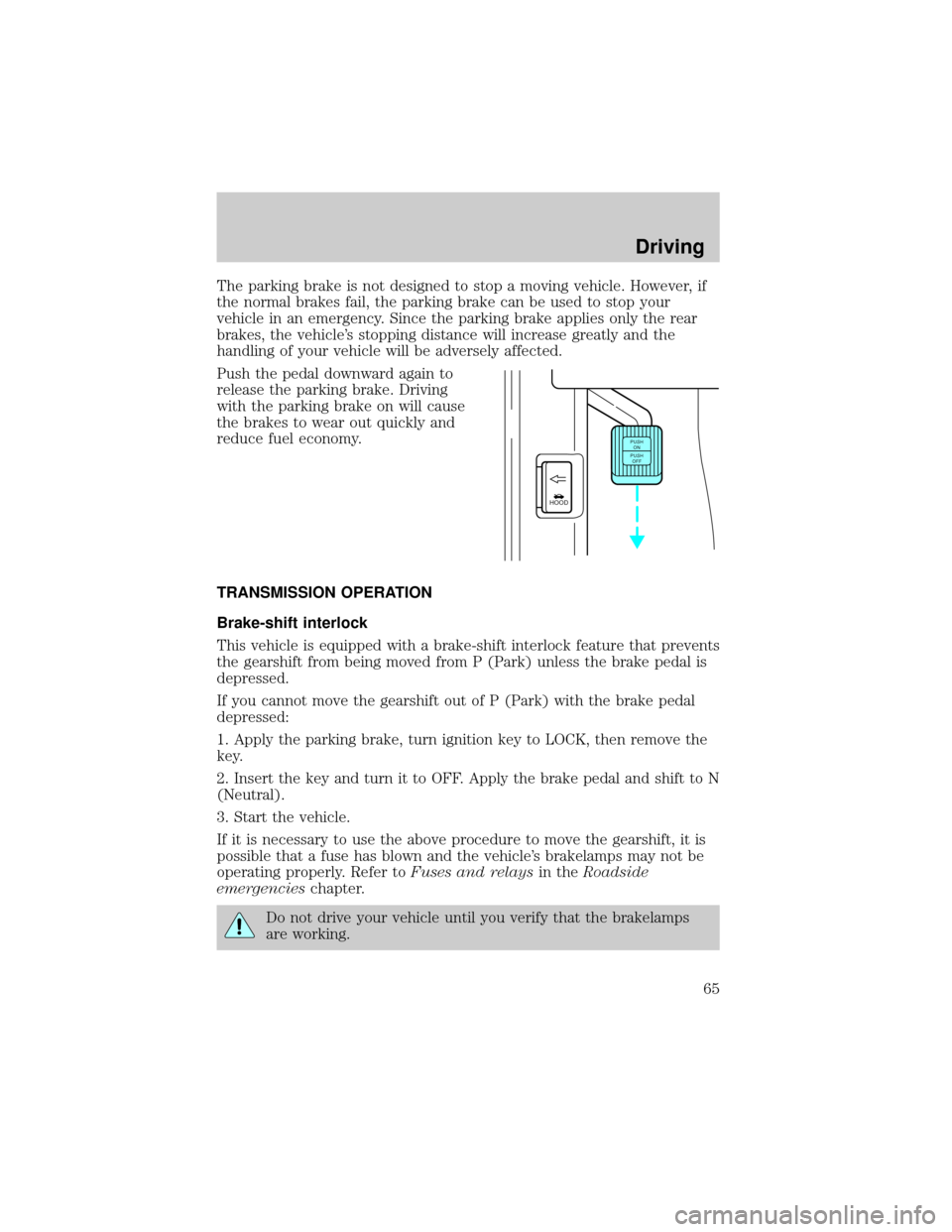

Push the pedal downward again to

release the parking brake. Driving

with the parking brake on will cause

the brakes to wear out quickly and

reduce fuel economy.

TRANSMISSION OPERATION

Brake-shift interlock

This vehicle is equipped with a brake-shift interlock feature that prevents

the gearshift from being moved from P (Park) unless the brake pedal is

depressed.

If you cannot move the gearshift out of P (Park) with the brake pedal

depressed:

1. Apply the parking brake, turn ignition key to LOCK, then remove the

key.

2. Insert the key and turn it to OFF. Apply the brake pedal and shift to N

(Neutral).

3. Start the vehicle.

If it is necessary to use the above procedure to move the gearshift, it is

possible that a fuse has blown and the vehicle's brakelamps may not be

operating properly. Refer toFuses and relaysin theRoadside

emergencieschapter.

Do not drive your vehicle until you verify that the brakelamps

are working.

HOOD

PUSH

ON

PUSH

OFF

Driving

65

Page 80 of 144

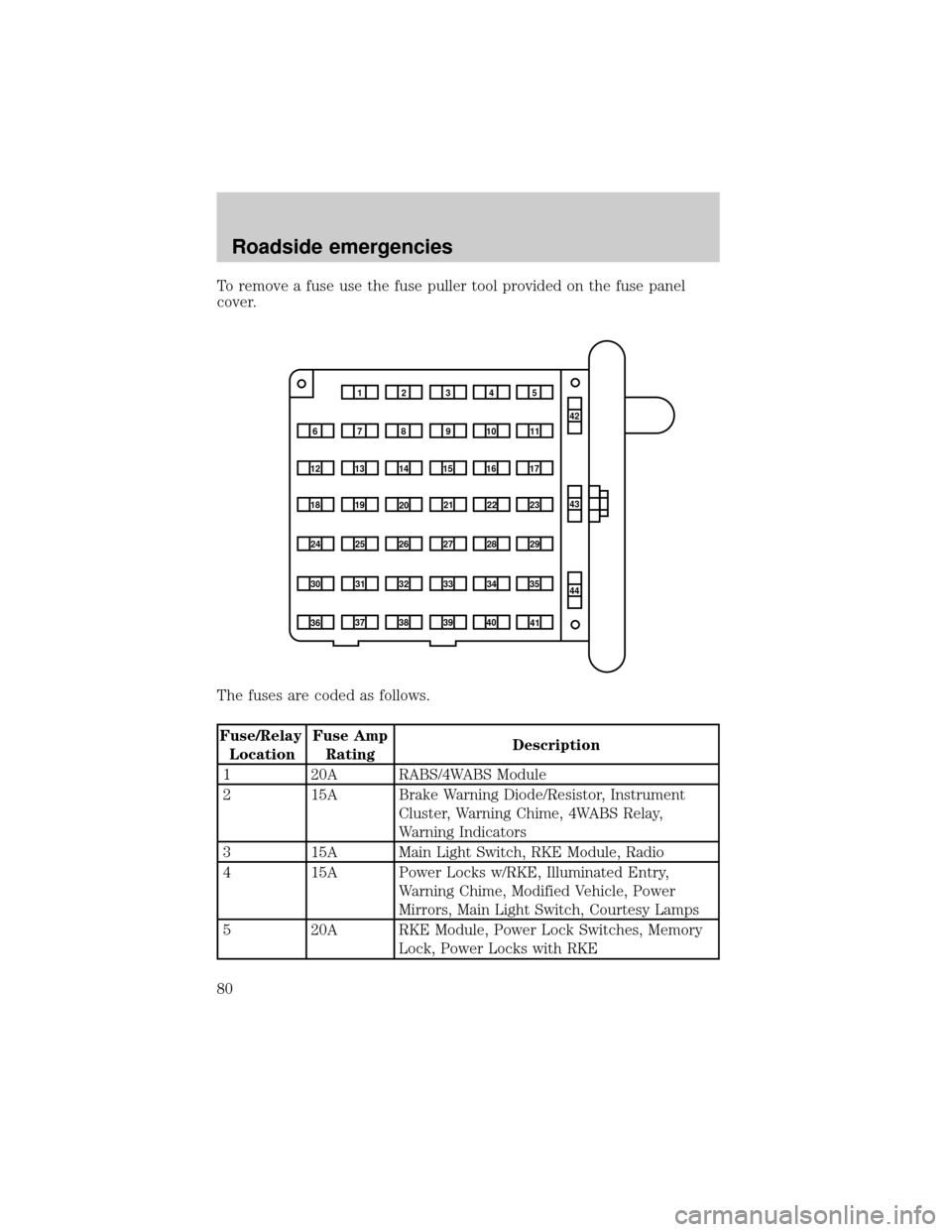

To remove a fuse use the fuse puller tool provided on the fuse panel

cover.

The fuses are coded as follows.

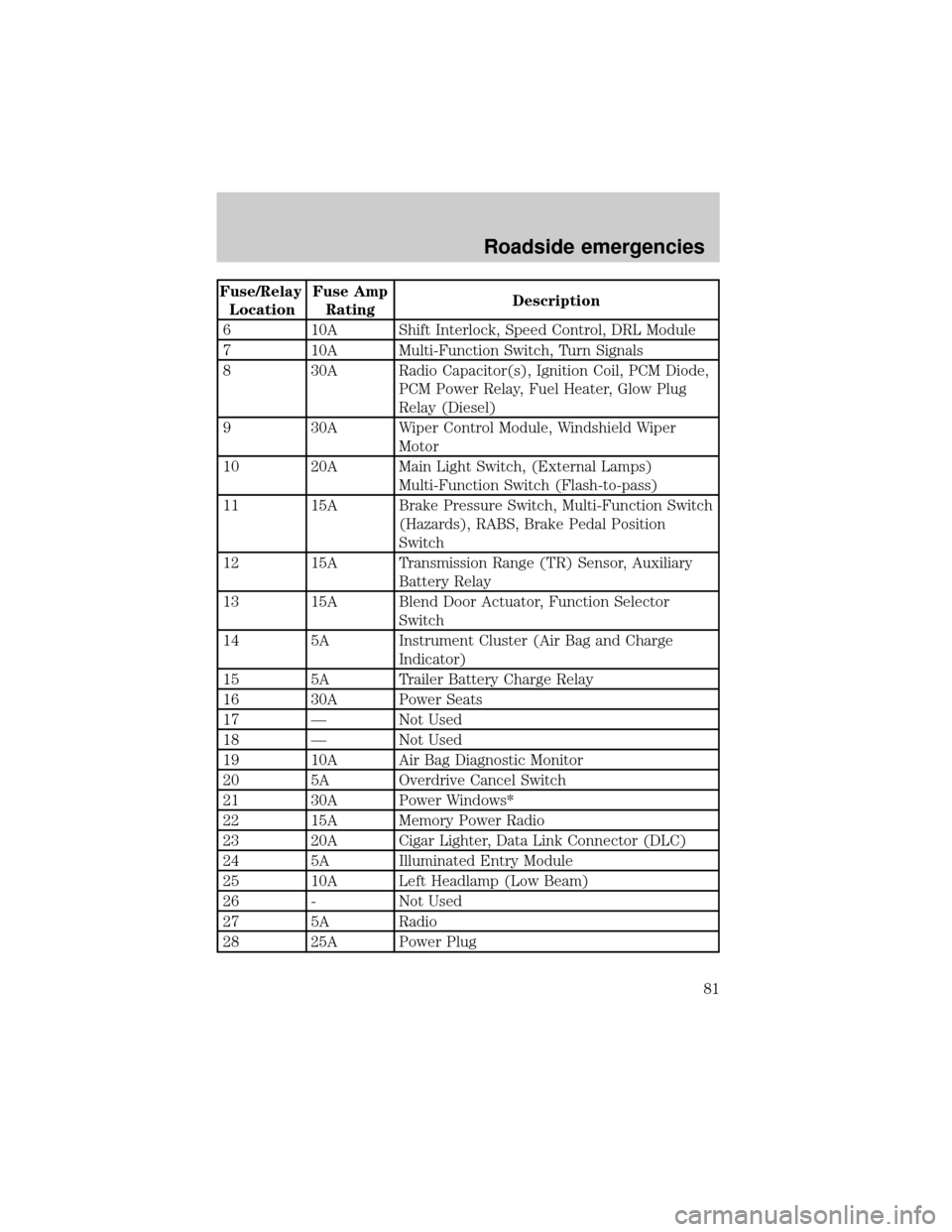

Fuse/Relay

LocationFuse Amp

RatingDescription

1 20A RABS/4WABS Module

2 15A Brake Warning Diode/Resistor, Instrument

Cluster, Warning Chime, 4WABS Relay,

Warning Indicators

3 15A Main Light Switch, RKE Module, Radio

4 15A Power Locks w/RKE, Illuminated Entry,

Warning Chime, Modified Vehicle, Power

Mirrors, Main Light Switch, Courtesy Lamps

5 20A RKE Module, Power Lock Switches, Memory

Lock, Power Locks with RKE

1234

5

7

689101142

43

44 13 12 14

15 16 17

19 18

2021 22 23

25 24

26 27 28 29

31 30 32 33 3435

37

3638 3940

41

Roadside emergencies

80

Page 81 of 144

Fuse/Relay

LocationFuse Amp

RatingDescription

6 10A Shift Interlock, Speed Control, DRL Module

7 10A Multi-Function Switch, Turn Signals

8 30A Radio Capacitor(s), Ignition Coil, PCM Diode,

PCM Power Relay, Fuel Heater, Glow Plug

Relay (Diesel)

9 30A Wiper Control Module, Windshield Wiper

Motor

10 20A Main Light Switch, (External Lamps)

Multi-Function Switch (Flash-to-pass)

11 15A Brake Pressure Switch, Multi-Function Switch

(Hazards), RABS, Brake Pedal Position

Switch

12 15A Transmission Range (TR) Sensor, Auxiliary

Battery Relay

13 15A Blend Door Actuator, Function Selector

Switch

14 5A Instrument Cluster (Air Bag and Charge

Indicator)

15 5A Trailer Battery Charge Relay

16 30A Power Seats

17 Ð Not Used

18 Ð Not Used

19 10A Air Bag Diagnostic Monitor

20 5A Overdrive Cancel Switch

21 30A Power Windows*

22 15A Memory Power Radio

23 20A Cigar Lighter, Data Link Connector (DLC)

24 5A Illuminated Entry Module

25 10A Left Headlamp (Low Beam)

26 - Not Used

27 5A Radio

28 25A Power Plug

Roadside emergencies

81

Page 85 of 144

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

Spare tire information

The spare tire for your vehicle is stowed under the rear of your vehicle

(except cutaway and stripped chassis models).

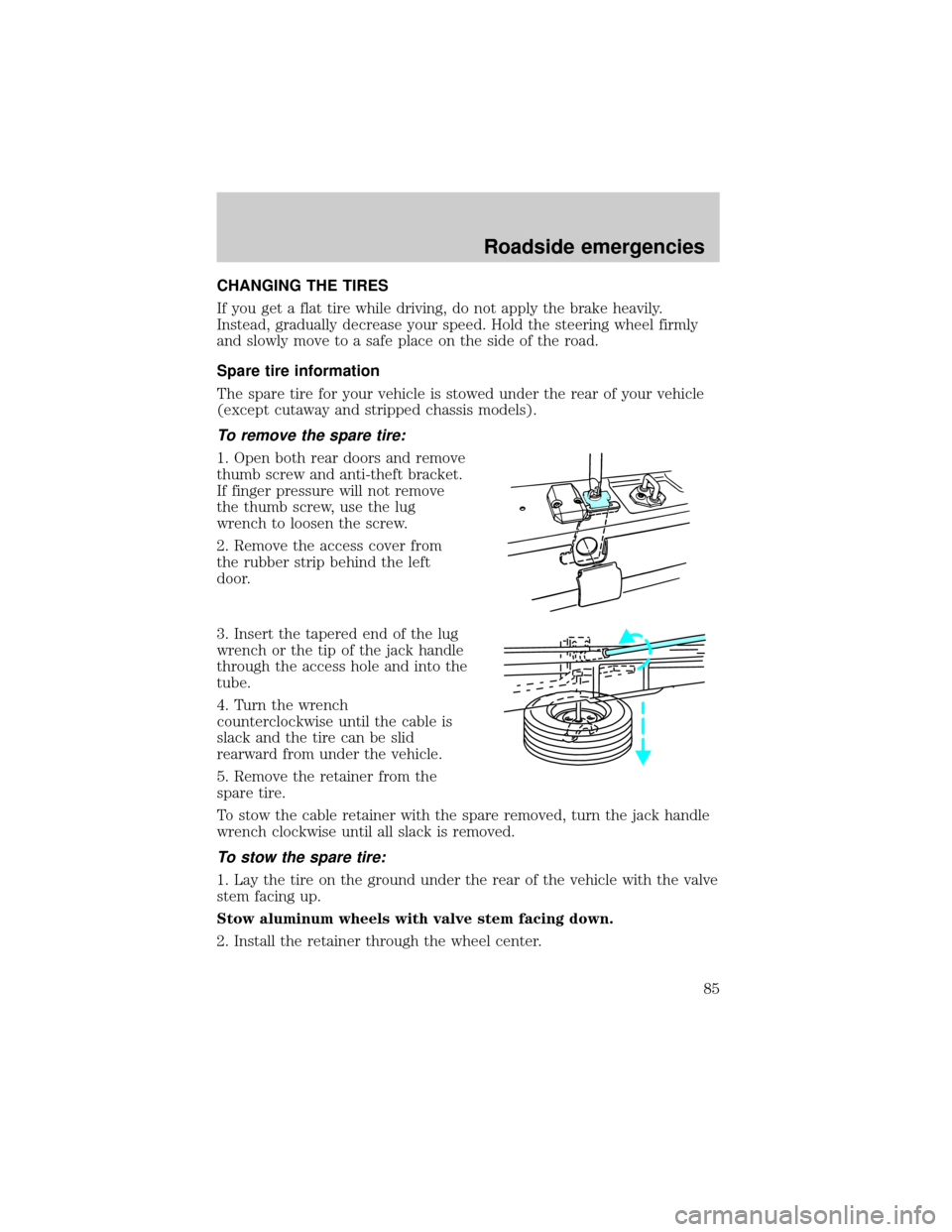

To remove the spare tire:

1. Open both rear doors and remove

thumb screw and anti-theft bracket.

If finger pressure will not remove

the thumb screw, use the lug

wrench to loosen the screw.

2. Remove the access cover from

the rubber strip behind the left

door.

3. Insert the tapered end of the lug

wrench or the tip of the jack handle

through the access hole and into the

tube.

4. Turn the wrench

counterclockwise until the cable is

slack and the tire can be slid

rearward from under the vehicle.

5. Remove the retainer from the

spare tire.

To stow the cable retainer with the spare removed, turn the jack handle

wrench clockwise until all slack is removed.

To stow the spare tire:

1. Lay the tire on the ground under the rear of the vehicle with the valve

stem facing up.

Stow aluminum wheels with valve stem facing down.

2. Install the retainer through the wheel center.

Roadside emergencies

85

Page 86 of 144

3. Raise the tire by turning the

wrench or handle clockwise.

Continue until the lift mechanism

ªclicks.º

4. Check that the tire is tightly

seated under the vehicle by pushing

against the tire. Retighten as

necessary.

5. Replace the access cover,

anti-theft bracket and thumb screw. Use finger pressure only to secure

the thumb screw.

Make sure the spare tire and jacking equipment are stowed and

secured in the proper storage location.

Never run the engine with one wheel off the ground.

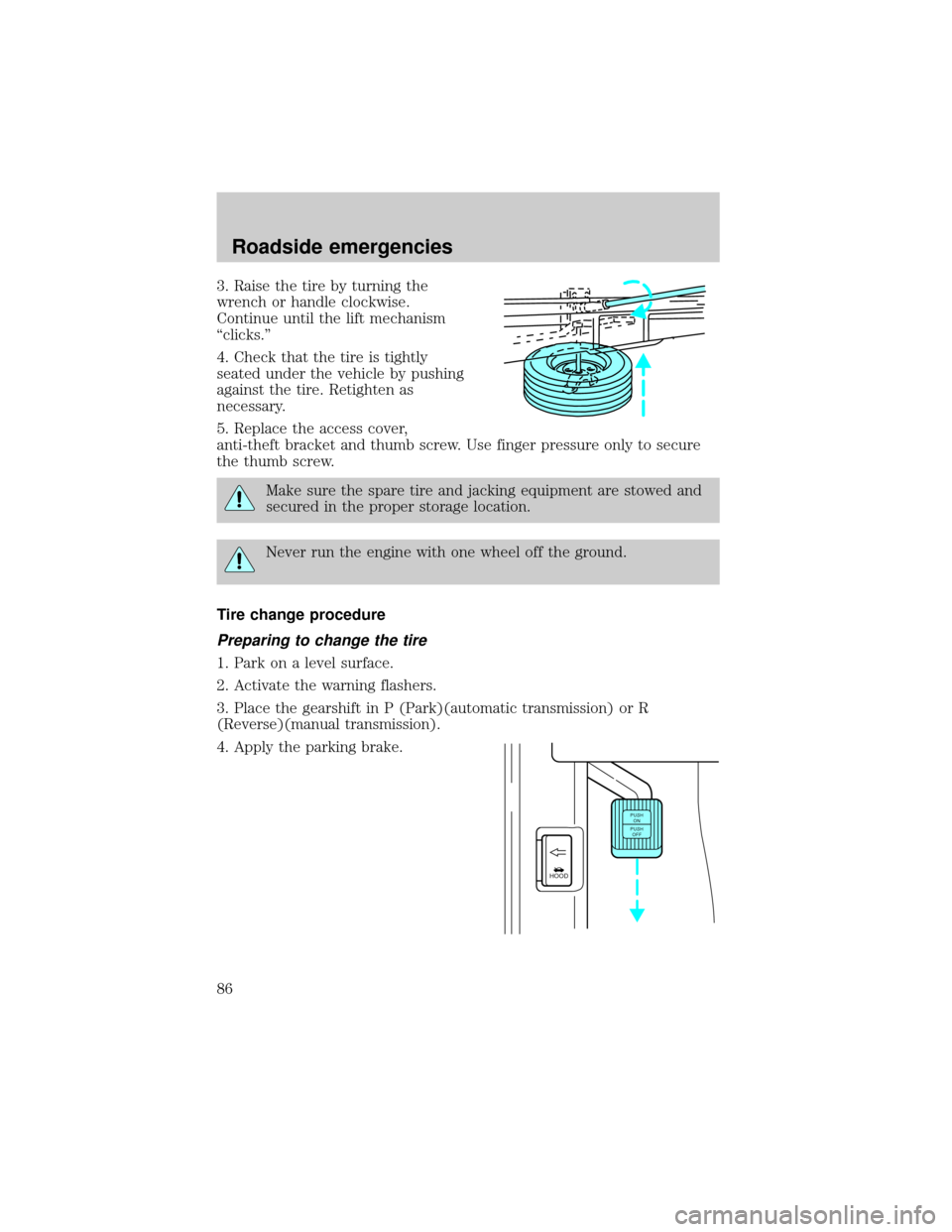

Tire change procedure

Preparing to change the tire

1. Park on a level surface.

2. Activate the warning flashers.

3. Place the gearshift in P (Park)(automatic transmission) or R

(Reverse)(manual transmission).

4. Apply the parking brake.

HOOD

PUSH

ON

PUSH

OFF

Roadside emergencies

86

Page 87 of 144

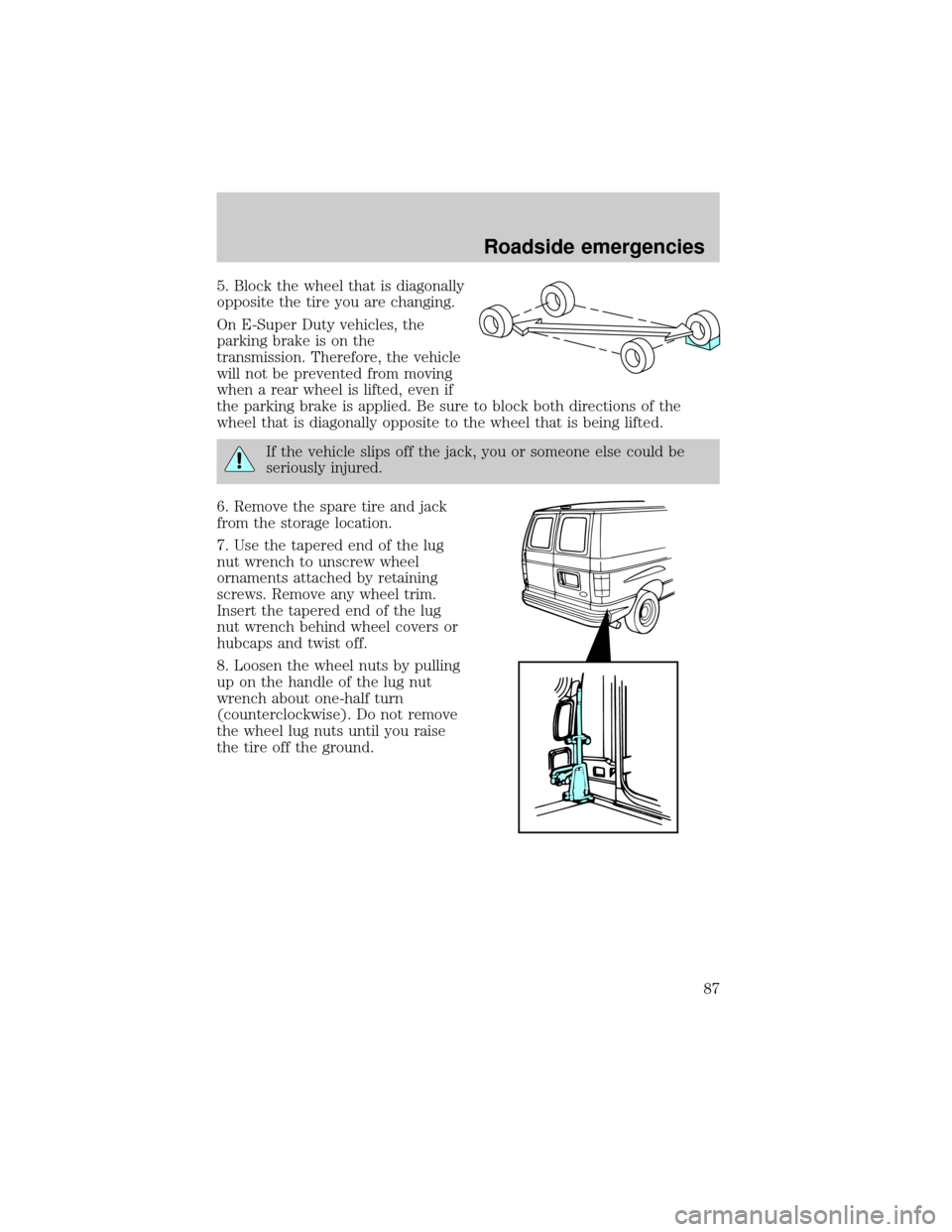

5. Block the wheel that is diagonally

opposite the tire you are changing.

On E-Super Duty vehicles, the

parking brake is on the

transmission. Therefore, the vehicle

will not be prevented from moving

when a rear wheel is lifted, even if

the parking brake is applied. Be sure to block both directions of the

wheel that is diagonally opposite to the wheel that is being lifted.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

6. Remove the spare tire and jack

from the storage location.

7. Use the tapered end of the lug

nut wrench to unscrew wheel

ornaments attached by retaining

screws. Remove any wheel trim.

Insert the tapered end of the lug

nut wrench behind wheel covers or

hubcaps and twist off.

8. Loosen the wheel nuts by pulling

up on the handle of the lug nut

wrench about one-half turn

(counterclockwise). Do not remove

the wheel lug nuts until you raise

the tire off the ground.

Roadside emergencies

87

Page 88 of 144

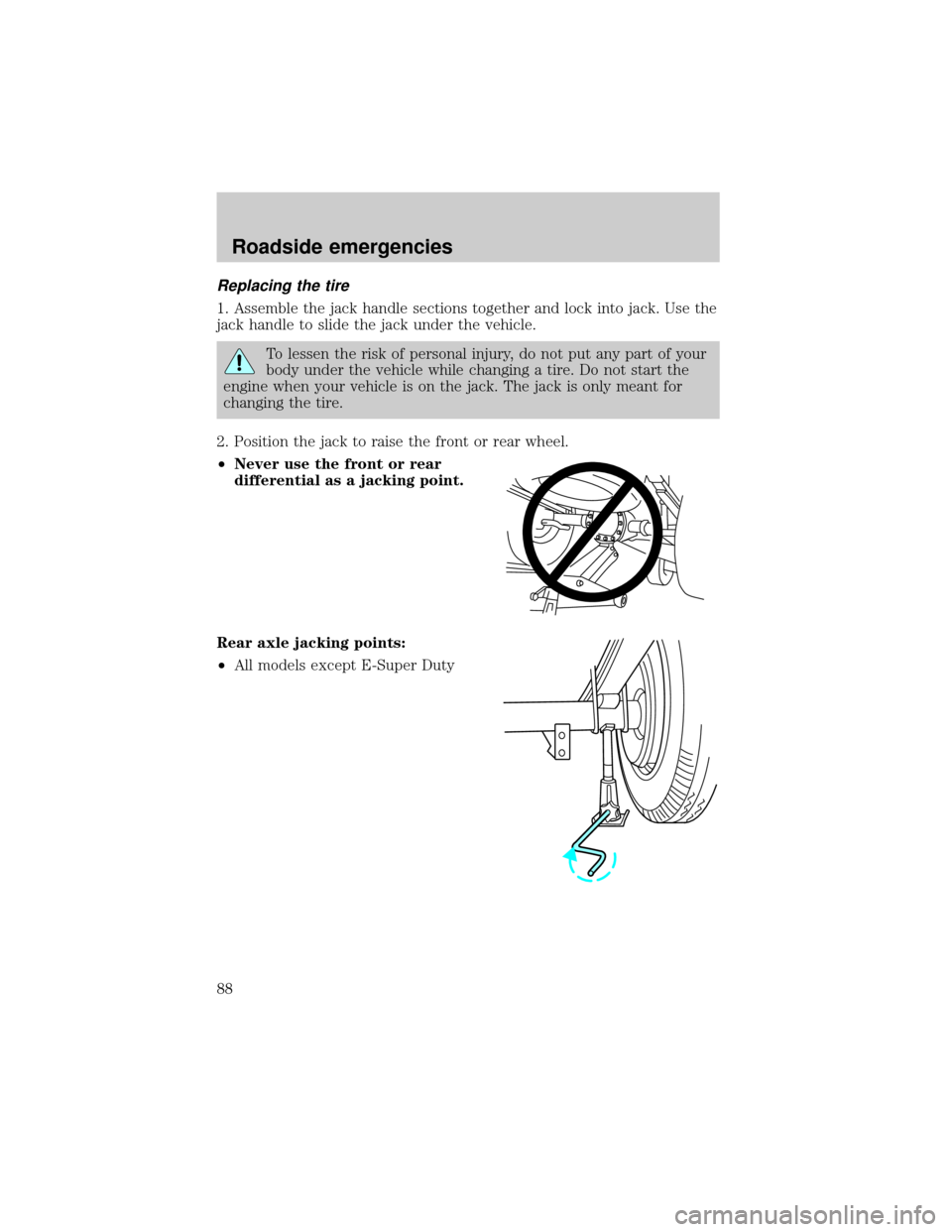

Replacing the tire

1. Assemble the jack handle sections together and lock into jack. Use the

jack handle to slide the jack under the vehicle.

To lessen the risk of personal injury, do not put any part of your

body under the vehicle while changing a tire. Do not start the

engine when your vehicle is on the jack. The jack is only meant for

changing the tire.

2. Position the jack to raise the front or rear wheel.

²Never use the front or rear

differential as a jacking point.

Rear axle jacking points:

²All models except E-Super Duty

Roadside emergencies

88

Page 89 of 144

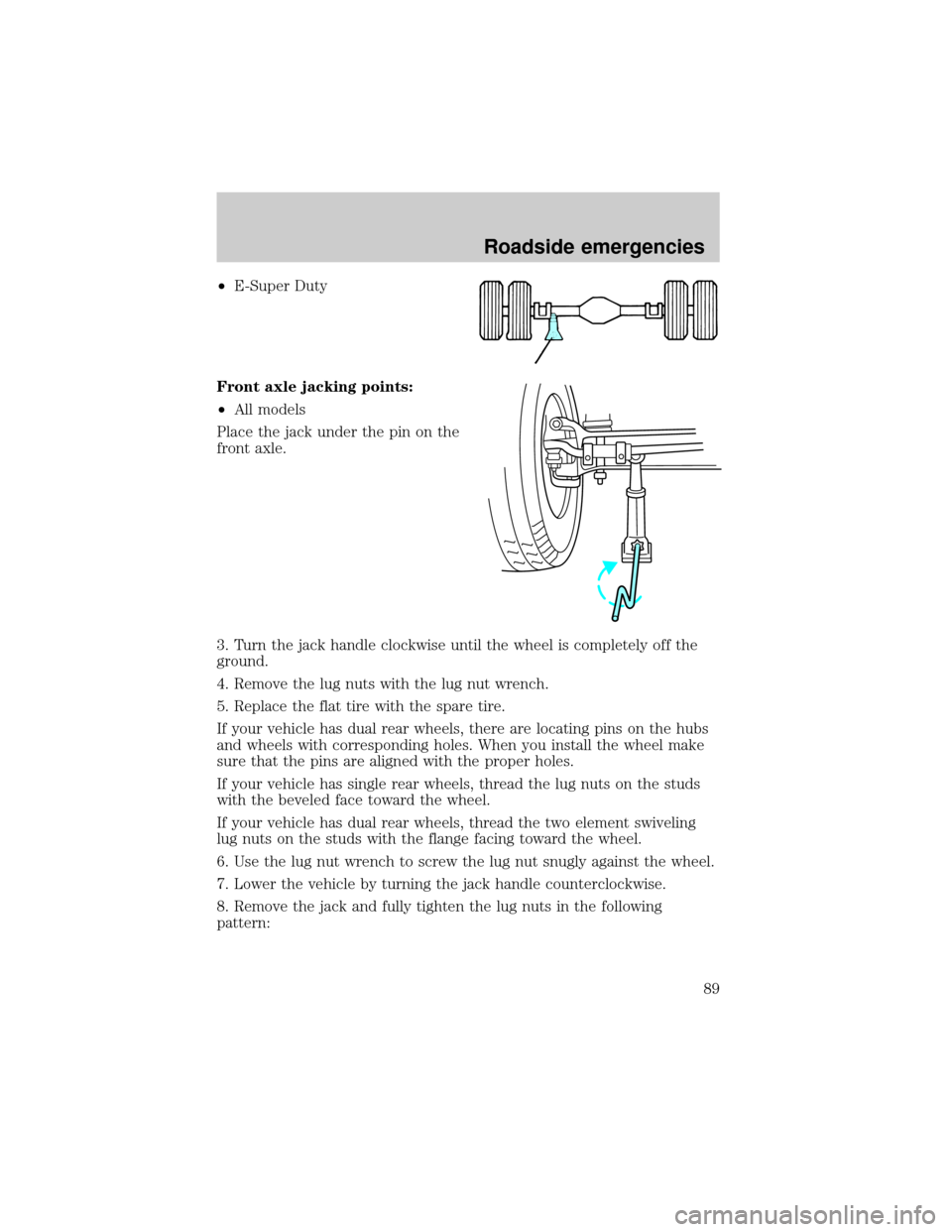

²E-Super Duty

Front axle jacking points:

²All models

Place the jack under the pin on the

front axle.

3. Turn the jack handle clockwise until the wheel is completely off the

ground.

4. Remove the lug nuts with the lug nut wrench.

5. Replace the flat tire with the spare tire.

If your vehicle has dual rear wheels, there are locating pins on the hubs

and wheels with corresponding holes. When you install the wheel make

sure that the pins are aligned with the proper holes.

If your vehicle has single rear wheels, thread the lug nuts on the studs

with the beveled face toward the wheel.

If your vehicle has dual rear wheels, thread the two element swiveling

lug nuts on the studs with the flange facing toward the wheel.

6. Use the lug nut wrench to screw the lug nut snugly against the wheel.

7. Lower the vehicle by turning the jack handle counterclockwise.

8. Remove the jack and fully tighten the lug nuts in the following

pattern:

Roadside emergencies

89