FORD E SERIES 1998 4.G Manual Online

Manufacturer: FORD, Model Year: 1998, Model line: E SERIES, Model: FORD E SERIES 1998 4.GPages: 144, PDF Size: 2.14 MB

Page 81 of 144

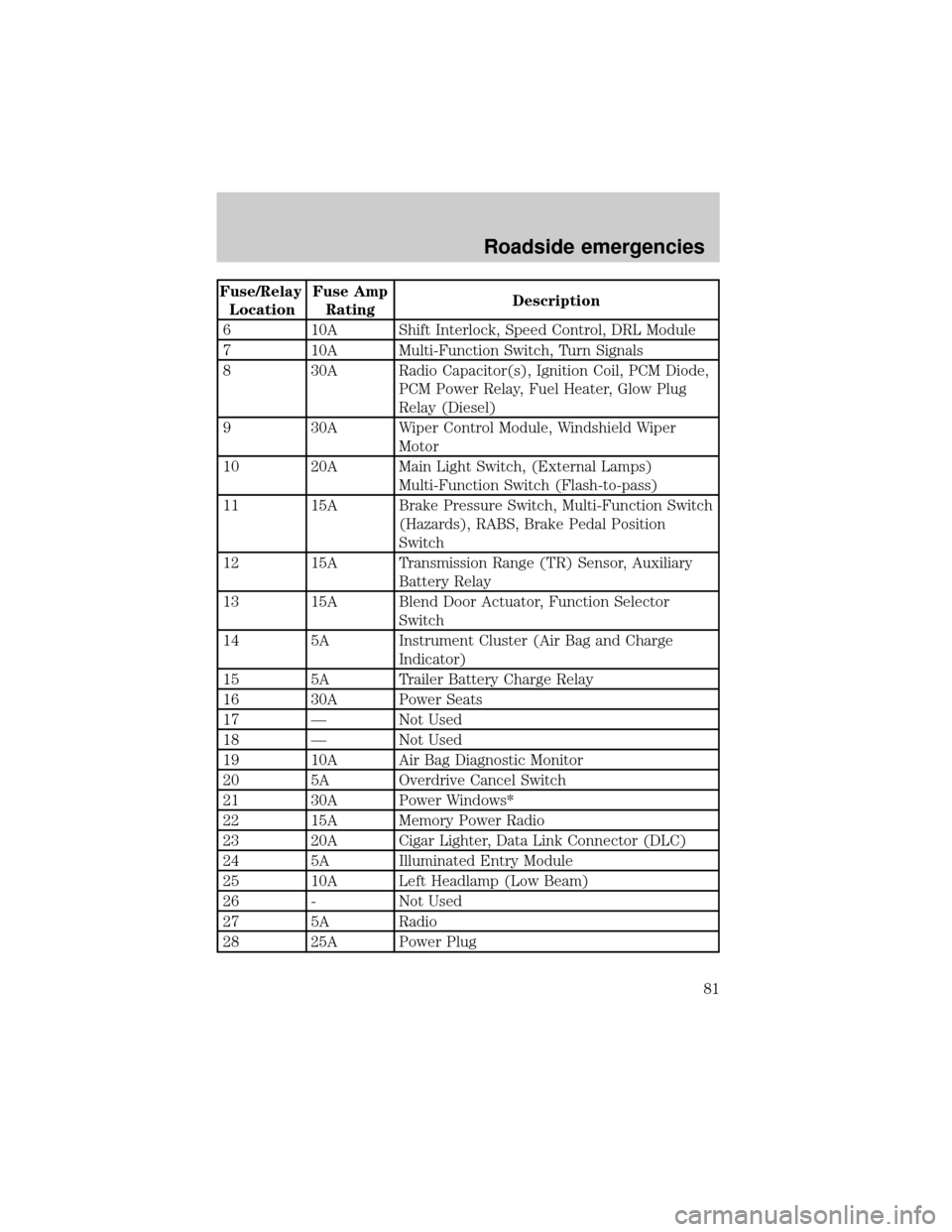

Fuse/Relay

LocationFuse Amp

RatingDescription

6 10A Shift Interlock, Speed Control, DRL Module

7 10A Multi-Function Switch, Turn Signals

8 30A Radio Capacitor(s), Ignition Coil, PCM Diode,

PCM Power Relay, Fuel Heater, Glow Plug

Relay (Diesel)

9 30A Wiper Control Module, Windshield Wiper

Motor

10 20A Main Light Switch, (External Lamps)

Multi-Function Switch (Flash-to-pass)

11 15A Brake Pressure Switch, Multi-Function Switch

(Hazards), RABS, Brake Pedal Position

Switch

12 15A Transmission Range (TR) Sensor, Auxiliary

Battery Relay

13 15A Blend Door Actuator, Function Selector

Switch

14 5A Instrument Cluster (Air Bag and Charge

Indicator)

15 5A Trailer Battery Charge Relay

16 30A Power Seats

17 Ð Not Used

18 Ð Not Used

19 10A Air Bag Diagnostic Monitor

20 5A Overdrive Cancel Switch

21 30A Power Windows*

22 15A Memory Power Radio

23 20A Cigar Lighter, Data Link Connector (DLC)

24 5A Illuminated Entry Module

25 10A Left Headlamp (Low Beam)

26 - Not Used

27 5A Radio

28 25A Power Plug

Roadside emergencies

81

Page 82 of 144

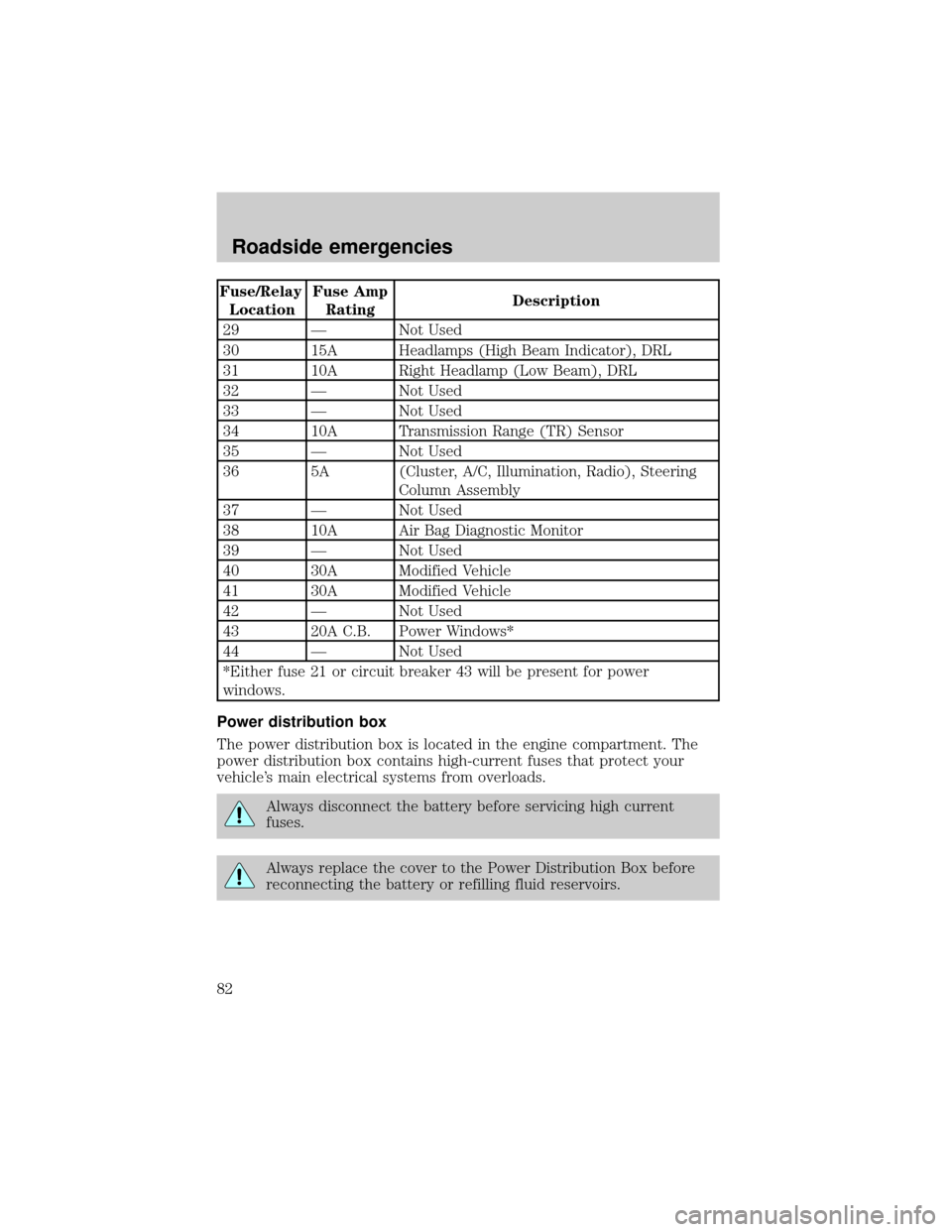

Fuse/Relay

LocationFuse Amp

RatingDescription

29 Ð Not Used

30 15A Headlamps (High Beam Indicator), DRL

31 10A Right Headlamp (Low Beam), DRL

32 Ð Not Used

33 Ð Not Used

34 10A Transmission Range (TR) Sensor

35 Ð Not Used

36 5A (Cluster, A/C, Illumination, Radio), Steering

Column Assembly

37 Ð Not Used

38 10A Air Bag Diagnostic Monitor

39 Ð Not Used

40 30A Modified Vehicle

41 30A Modified Vehicle

42 Ð Not Used

43 20A C.B. Power Windows*

44 Ð Not Used

*Either fuse 21 or circuit breaker 43 will be present for power

windows.

Power distribution box

The power distribution box is located in the engine compartment. The

power distribution box contains high-current fuses that protect your

vehicle's main electrical systems from overloads.

Always disconnect the battery before servicing high current

fuses.

Always replace the cover to the Power Distribution Box before

reconnecting the battery or refilling fluid reservoirs.

Roadside emergencies

82

Page 83 of 144

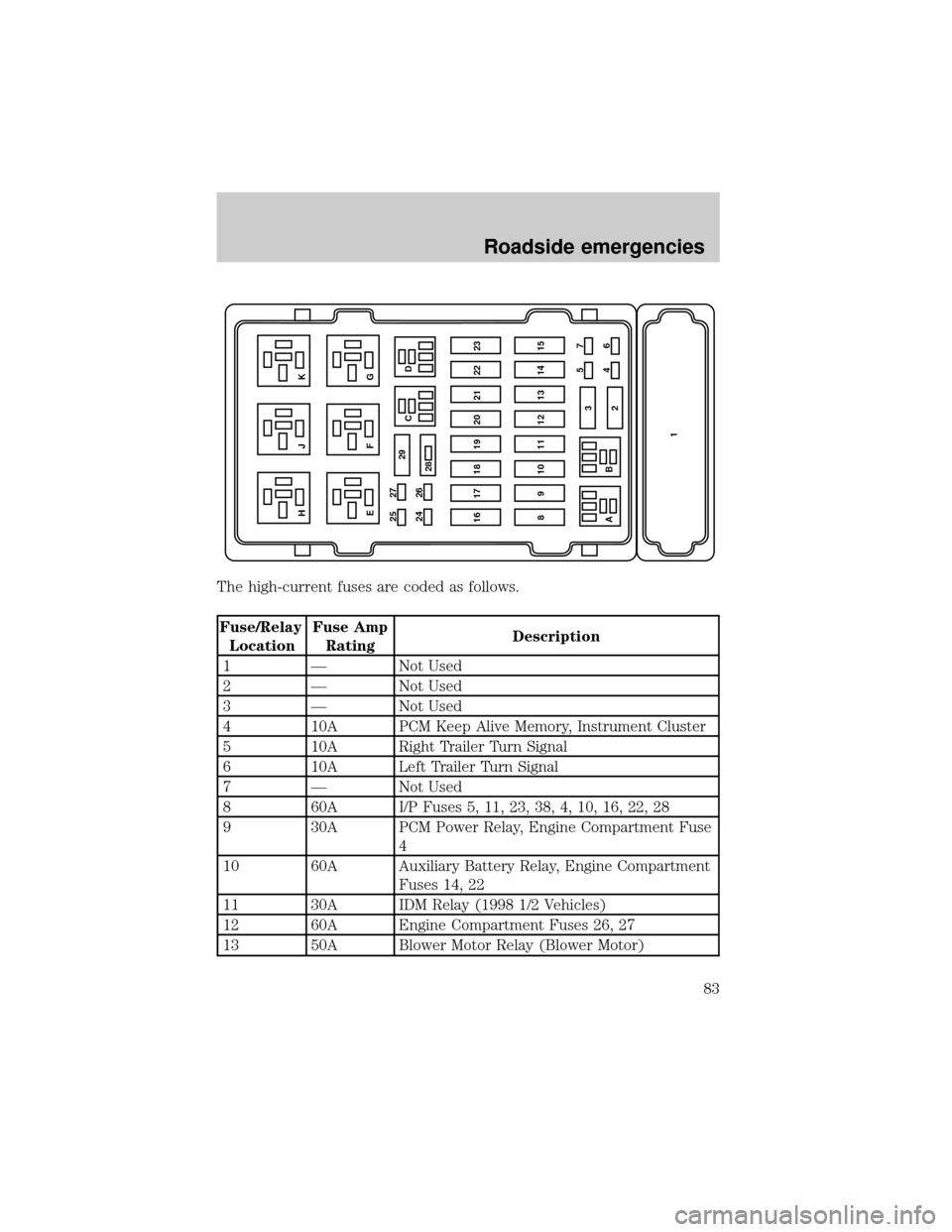

The high-current fuses are coded as follows.

Fuse/Relay

LocationFuse Amp

RatingDescription

1 Ð Not Used

2 Ð Not Used

3 Ð Not Used

4 10A PCM Keep Alive Memory, Instrument Cluster

5 10A Right Trailer Turn Signal

6 10A Left Trailer Turn Signal

7 Ð Not Used

8 60A I/P Fuses 5, 11, 23, 38, 4, 10, 16, 22, 28

9 30A PCM Power Relay, Engine Compartment Fuse

4

10 60A Auxiliary Battery Relay, Engine Compartment

Fuses 14, 22

11 30A IDM Relay (1998 1/2 Vehicles)

12 60A Engine Compartment Fuses 26, 27

13 50A Blower Motor Relay (Blower Motor)

AB3

2

146 5715 14 13 12 11 10 9 823 22 21 20 19 18 17 1624 26 25 27

29

CDG F EK J H

28

Roadside emergencies

83

Page 84 of 144

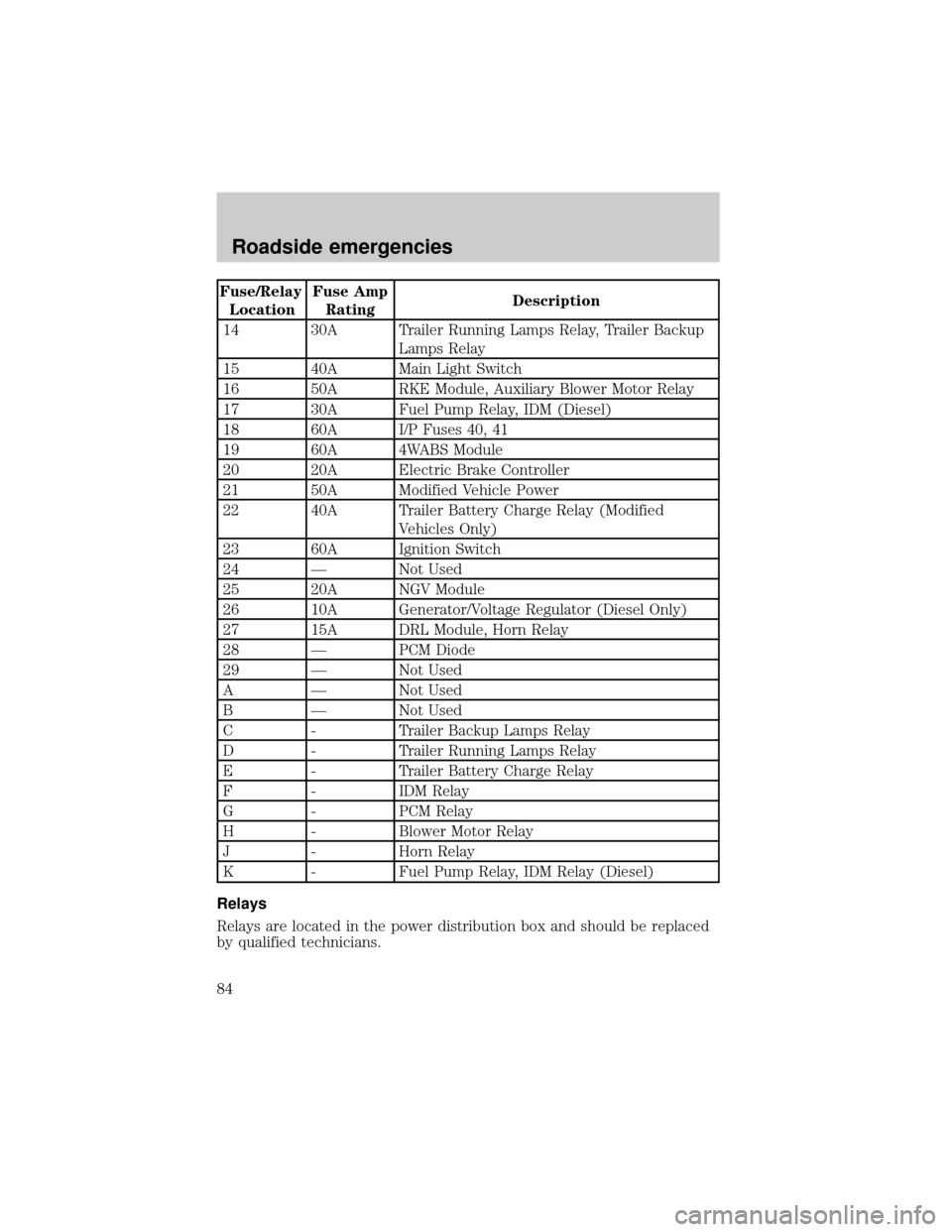

Fuse/Relay

LocationFuse Amp

RatingDescription

14 30A Trailer Running Lamps Relay, Trailer Backup

Lamps Relay

15 40A Main Light Switch

16 50A RKE Module, Auxiliary Blower Motor Relay

17 30A Fuel Pump Relay, IDM (Diesel)

18 60A I/P Fuses 40, 41

19 60A 4WABS Module

20 20A Electric Brake Controller

21 50A Modified Vehicle Power

22 40A Trailer Battery Charge Relay (Modified

Vehicles Only)

23 60A Ignition Switch

24 Ð Not Used

25 20A NGV Module

26 10A Generator/Voltage Regulator (Diesel Only)

27 15A DRL Module, Horn Relay

28 Ð PCM Diode

29 Ð Not Used

A Ð Not Used

B Ð Not Used

C - Trailer Backup Lamps Relay

D - Trailer Running Lamps Relay

E - Trailer Battery Charge Relay

F - IDM Relay

G - PCM Relay

H - Blower Motor Relay

J - Horn Relay

K - Fuel Pump Relay, IDM Relay (Diesel)

Relays

Relays are located in the power distribution box and should be replaced

by qualified technicians.

Roadside emergencies

84

Page 85 of 144

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

Spare tire information

The spare tire for your vehicle is stowed under the rear of your vehicle

(except cutaway and stripped chassis models).

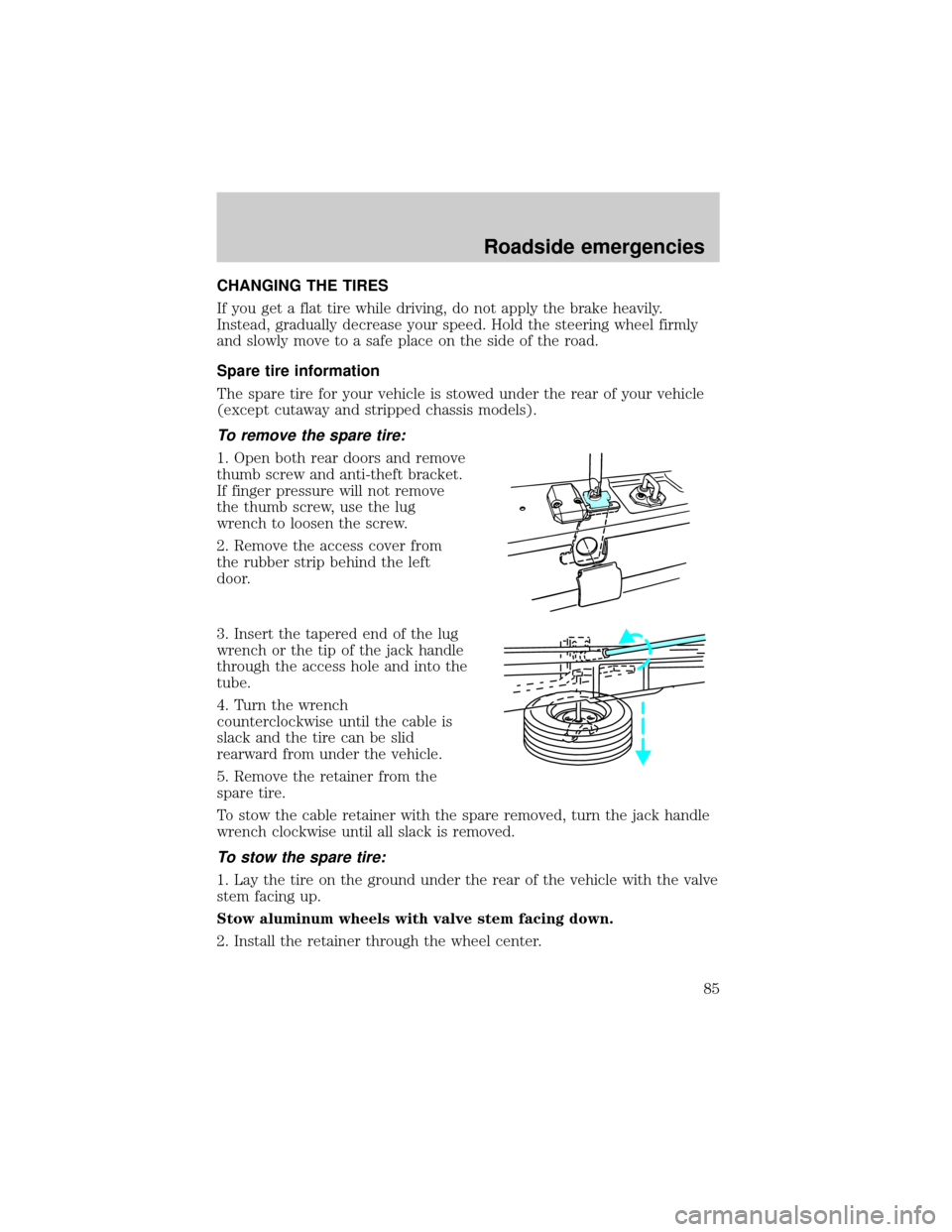

To remove the spare tire:

1. Open both rear doors and remove

thumb screw and anti-theft bracket.

If finger pressure will not remove

the thumb screw, use the lug

wrench to loosen the screw.

2. Remove the access cover from

the rubber strip behind the left

door.

3. Insert the tapered end of the lug

wrench or the tip of the jack handle

through the access hole and into the

tube.

4. Turn the wrench

counterclockwise until the cable is

slack and the tire can be slid

rearward from under the vehicle.

5. Remove the retainer from the

spare tire.

To stow the cable retainer with the spare removed, turn the jack handle

wrench clockwise until all slack is removed.

To stow the spare tire:

1. Lay the tire on the ground under the rear of the vehicle with the valve

stem facing up.

Stow aluminum wheels with valve stem facing down.

2. Install the retainer through the wheel center.

Roadside emergencies

85

Page 86 of 144

3. Raise the tire by turning the

wrench or handle clockwise.

Continue until the lift mechanism

ªclicks.º

4. Check that the tire is tightly

seated under the vehicle by pushing

against the tire. Retighten as

necessary.

5. Replace the access cover,

anti-theft bracket and thumb screw. Use finger pressure only to secure

the thumb screw.

Make sure the spare tire and jacking equipment are stowed and

secured in the proper storage location.

Never run the engine with one wheel off the ground.

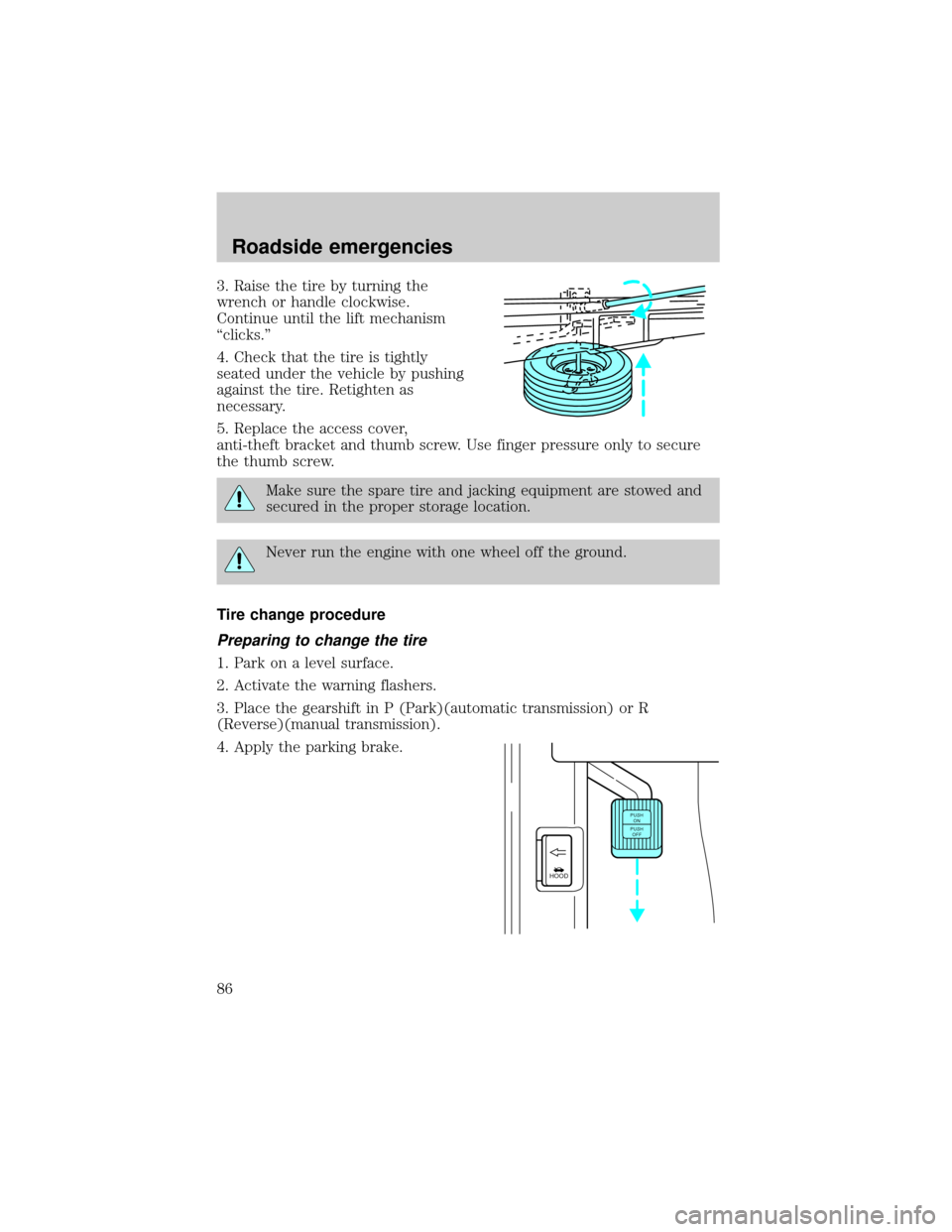

Tire change procedure

Preparing to change the tire

1. Park on a level surface.

2. Activate the warning flashers.

3. Place the gearshift in P (Park)(automatic transmission) or R

(Reverse)(manual transmission).

4. Apply the parking brake.

HOOD

PUSH

ON

PUSH

OFF

Roadside emergencies

86

Page 87 of 144

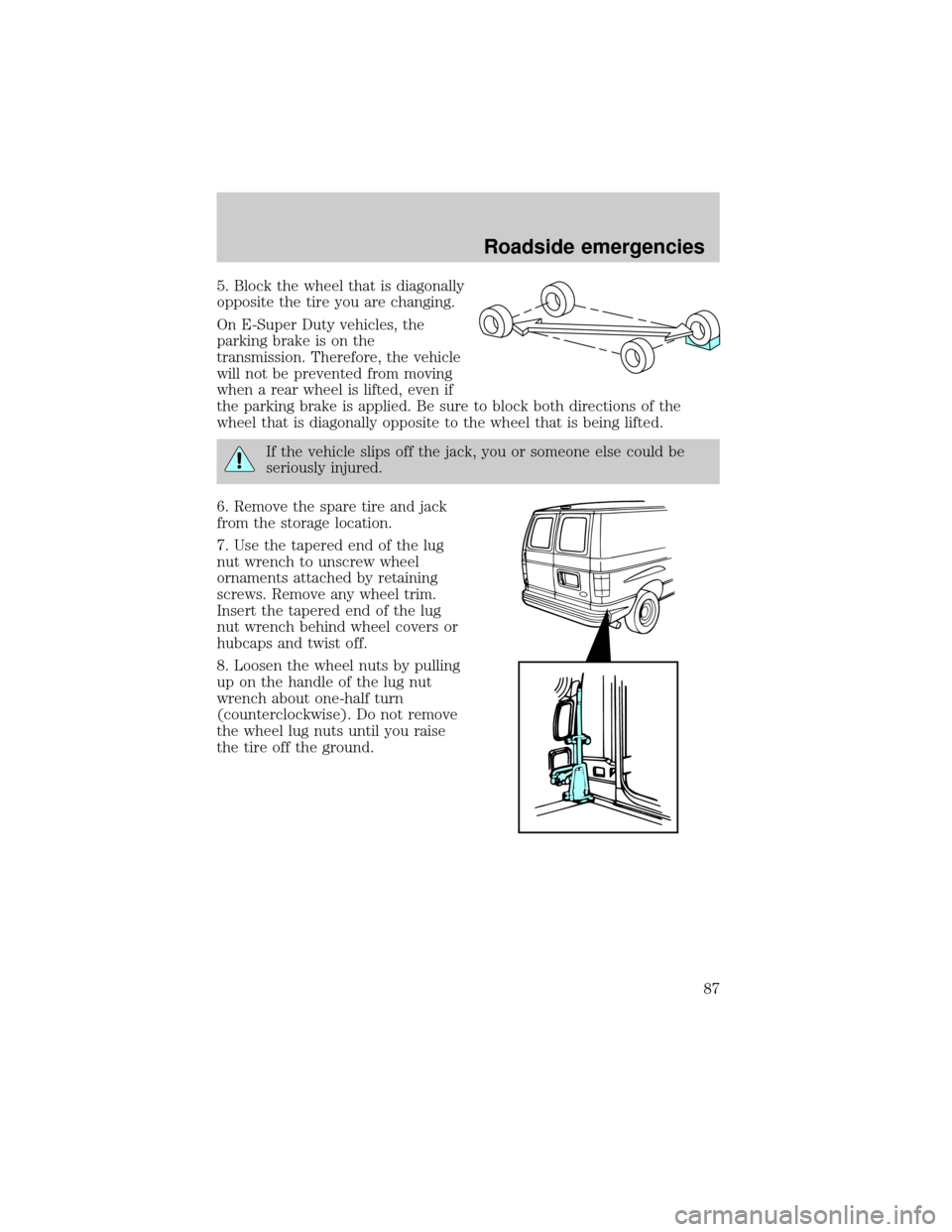

5. Block the wheel that is diagonally

opposite the tire you are changing.

On E-Super Duty vehicles, the

parking brake is on the

transmission. Therefore, the vehicle

will not be prevented from moving

when a rear wheel is lifted, even if

the parking brake is applied. Be sure to block both directions of the

wheel that is diagonally opposite to the wheel that is being lifted.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

6. Remove the spare tire and jack

from the storage location.

7. Use the tapered end of the lug

nut wrench to unscrew wheel

ornaments attached by retaining

screws. Remove any wheel trim.

Insert the tapered end of the lug

nut wrench behind wheel covers or

hubcaps and twist off.

8. Loosen the wheel nuts by pulling

up on the handle of the lug nut

wrench about one-half turn

(counterclockwise). Do not remove

the wheel lug nuts until you raise

the tire off the ground.

Roadside emergencies

87

Page 88 of 144

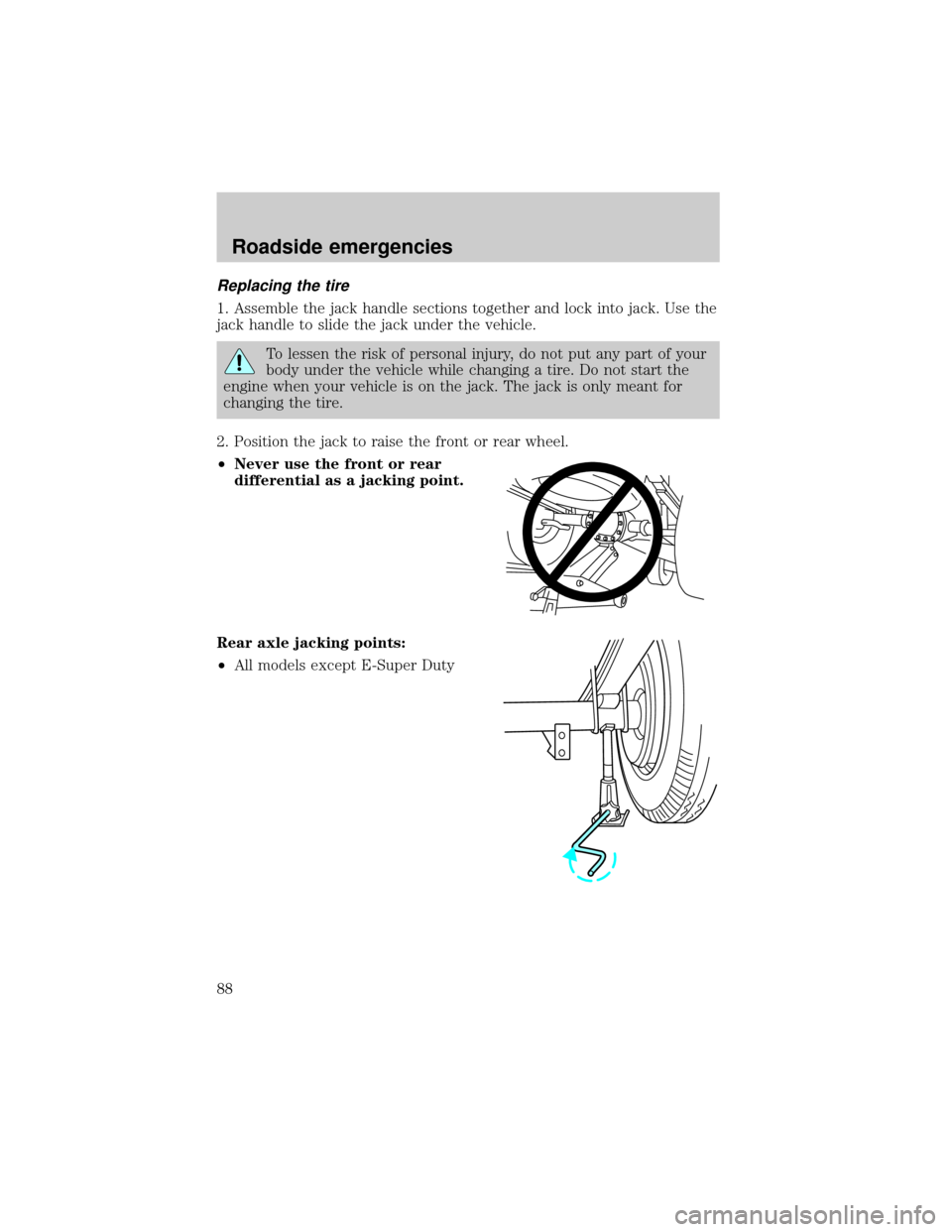

Replacing the tire

1. Assemble the jack handle sections together and lock into jack. Use the

jack handle to slide the jack under the vehicle.

To lessen the risk of personal injury, do not put any part of your

body under the vehicle while changing a tire. Do not start the

engine when your vehicle is on the jack. The jack is only meant for

changing the tire.

2. Position the jack to raise the front or rear wheel.

²Never use the front or rear

differential as a jacking point.

Rear axle jacking points:

²All models except E-Super Duty

Roadside emergencies

88

Page 89 of 144

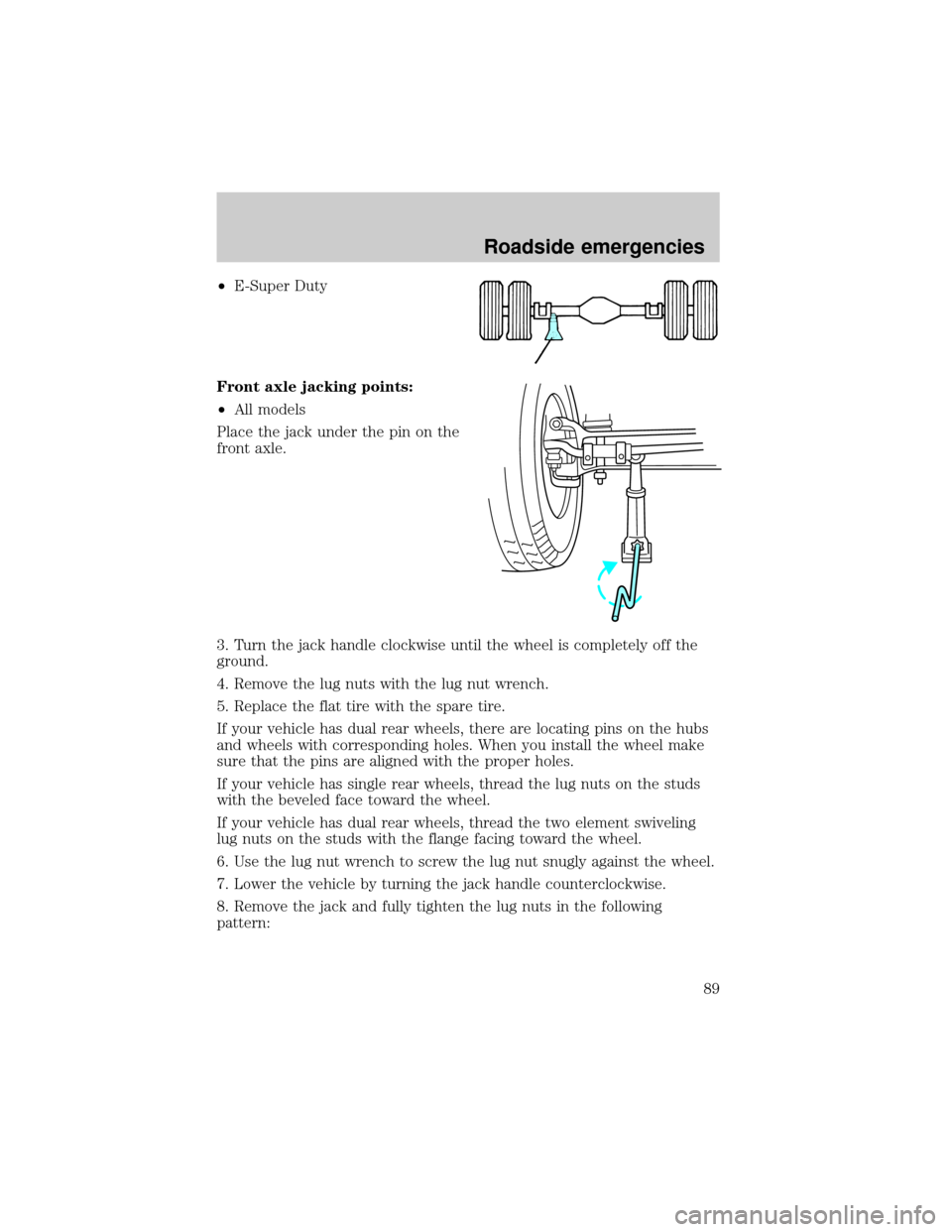

²E-Super Duty

Front axle jacking points:

²All models

Place the jack under the pin on the

front axle.

3. Turn the jack handle clockwise until the wheel is completely off the

ground.

4. Remove the lug nuts with the lug nut wrench.

5. Replace the flat tire with the spare tire.

If your vehicle has dual rear wheels, there are locating pins on the hubs

and wheels with corresponding holes. When you install the wheel make

sure that the pins are aligned with the proper holes.

If your vehicle has single rear wheels, thread the lug nuts on the studs

with the beveled face toward the wheel.

If your vehicle has dual rear wheels, thread the two element swiveling

lug nuts on the studs with the flange facing toward the wheel.

6. Use the lug nut wrench to screw the lug nut snugly against the wheel.

7. Lower the vehicle by turning the jack handle counterclockwise.

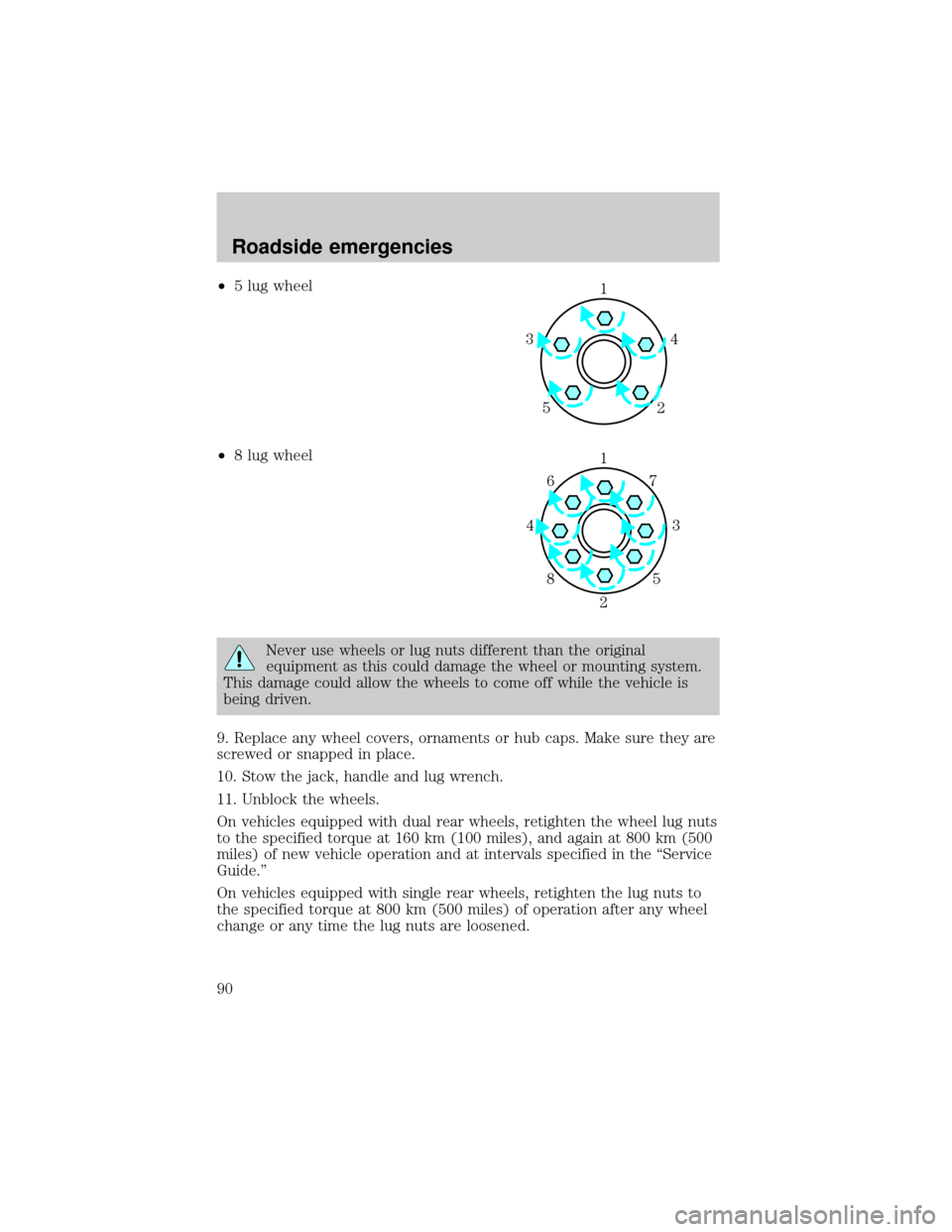

8. Remove the jack and fully tighten the lug nuts in the following

pattern:

Roadside emergencies

89

Page 90 of 144

²5 lug wheel

²8 lug wheel

Never use wheels or lug nuts different than the original

equipment as this could damage the wheel or mounting system.

This damage could allow the wheels to come off while the vehicle is

being driven.

9. Replace any wheel covers, ornaments or hub caps. Make sure they are

screwed or snapped in place.

10. Stow the jack, handle and lug wrench.

11. Unblock the wheels.

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts

to the specified torque at 160 km (100 miles), and again at 800 km (500

miles) of new vehicle operation and at intervals specified in the ªService

Guide.º

On vehicles equipped with single rear wheels, retighten the lug nuts to

the specified torque at 800 km (500 miles) of operation after any wheel

change or any time the lug nuts are loosened.

1

4 3

52

1

3 4

27 6

5 8

Roadside emergencies

90